Carbon Nanostructures for Actuators: An Overview of Recent Developments

Abstract

1. Introduction

2. Molecular Actuation

3. Nanostructured Carbon: Effective Tools for Carbon-Based Nanoactuators

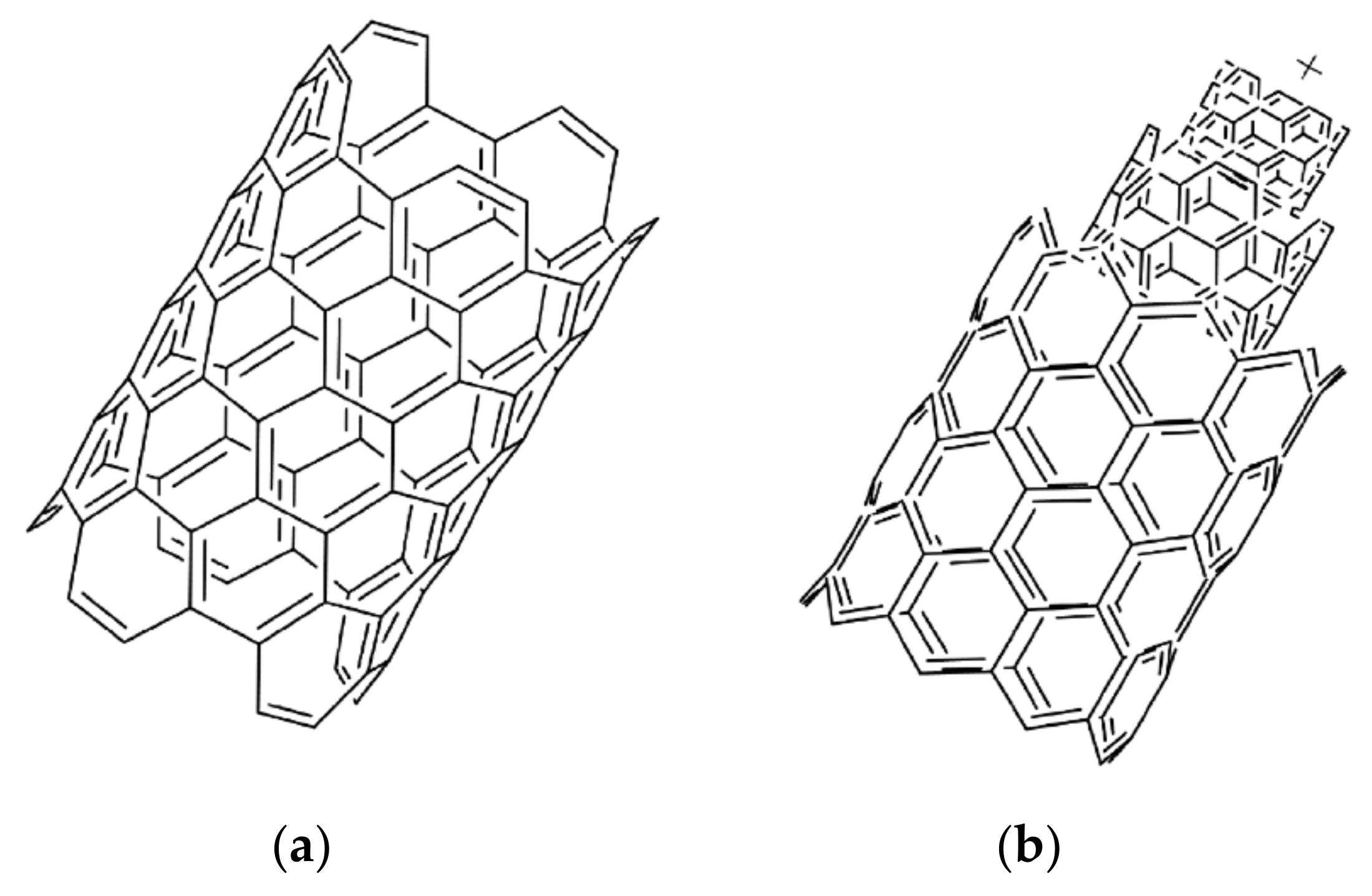

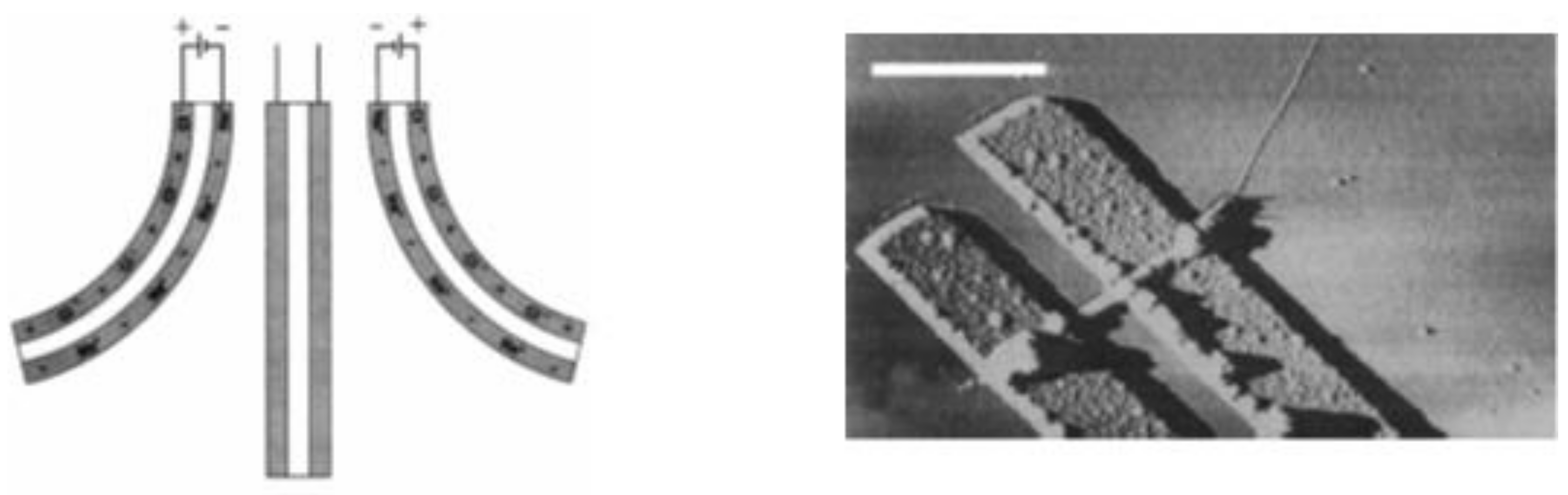

3.1. Carbon Nanotube-Based Actuators

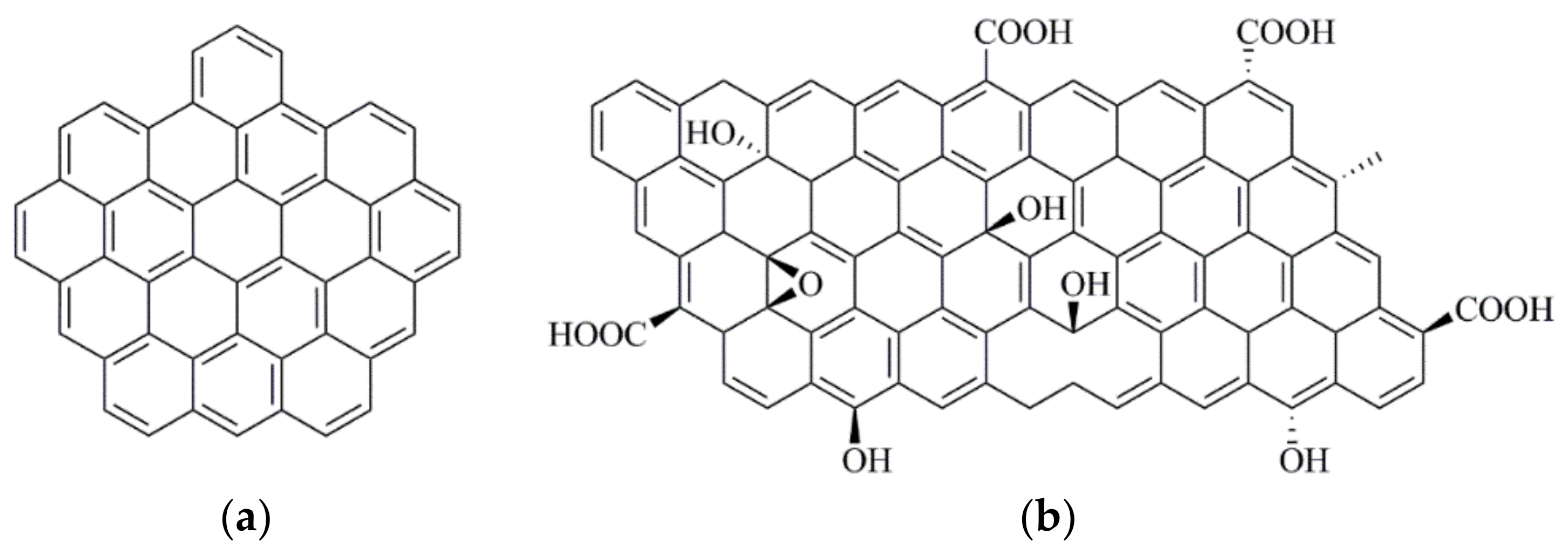

3.2. Graphene and Graphene Oxide

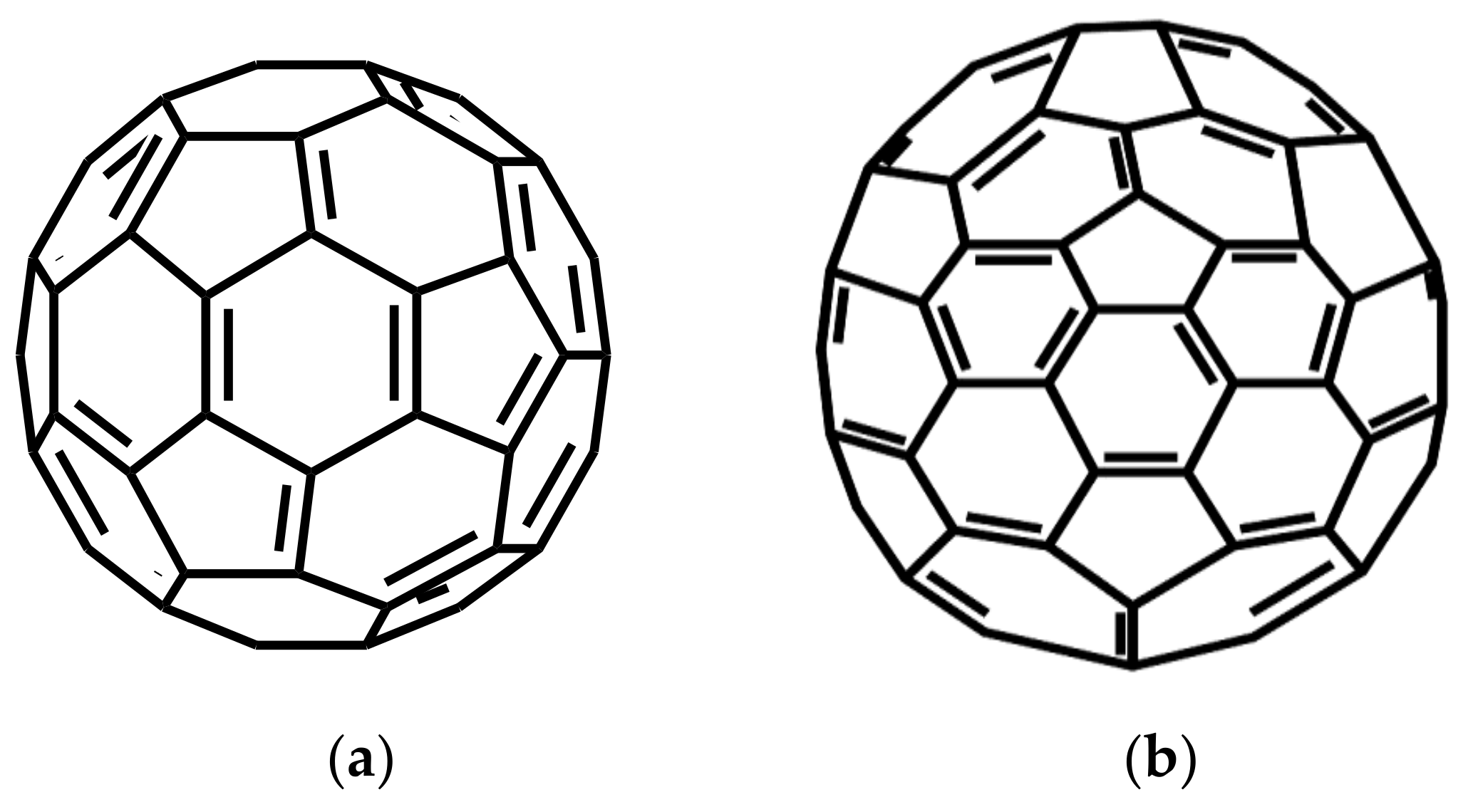

3.3. Fullerene-Based Actuators

4. Applications

4.1. Carbon Nanotube-Based Actuators

4.2. Graphene and Graphene Oxide Actuators

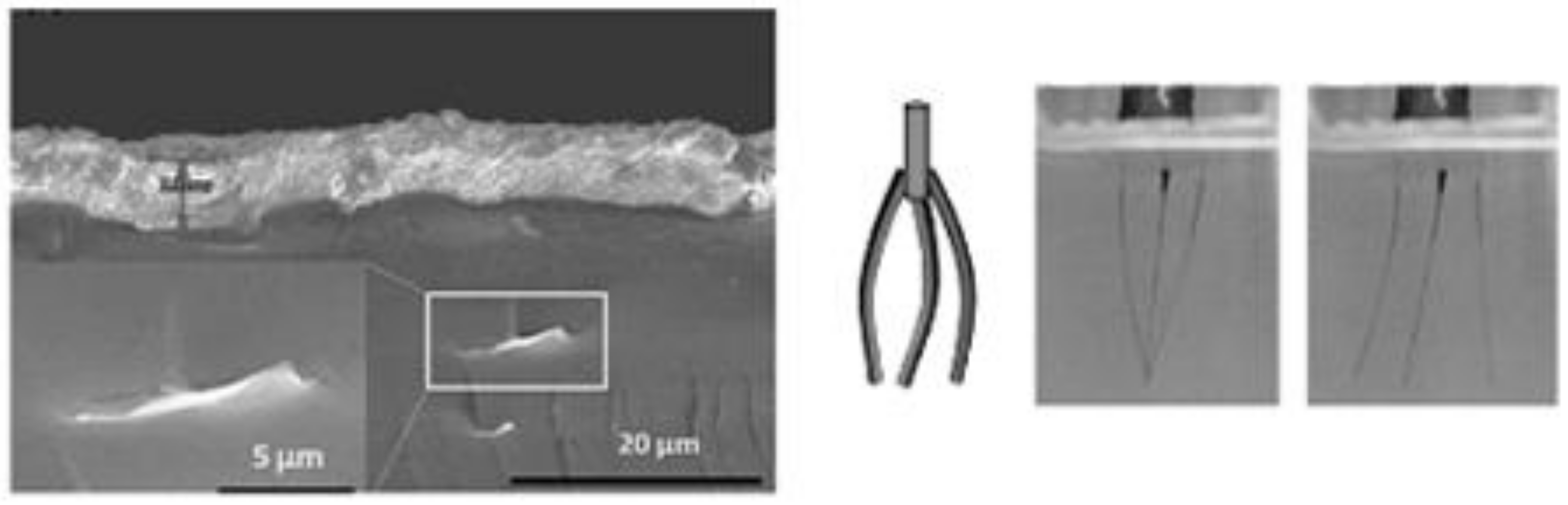

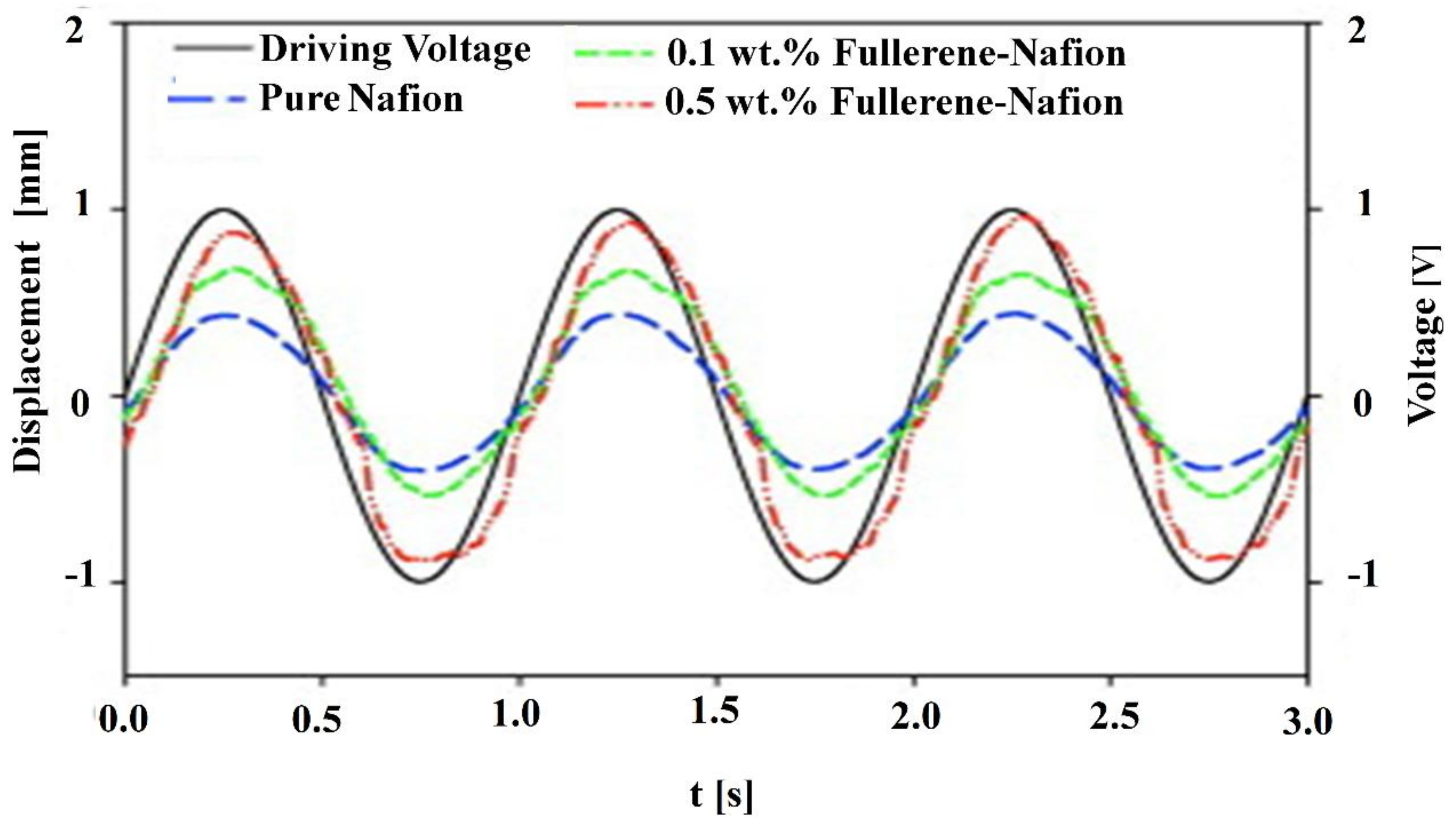

4.3. Fullerene-Based Actuators

5. Challenges and Prospective of Actuators Based on Carbon Nanostructures

6. Conclusions

Acknowledgements

Conflicts of Interest

References

- Vanderborght, B.; Albu-Schäffer, A.; Bicchi, A.; Burdet, E.; Caldwell, D.G.; Carloni, R.; Catalano, M.; Eiberger, O.; Friedl, W.; Ganesh, G. Variable impedance actuators: A review. Robot. Auton. Syst. 2013, 61, 1601–1614. [Google Scholar] [CrossRef]

- Jammes, F.; Smit, H. Service-oriented paradigms in industrial automation. IEEE Trans. Ind. Inform. 2005, 1, 62–70. [Google Scholar] [CrossRef]

- Kirkam, H. Optical current transducers for power systems: A review. IEEE Trans. Power Deliv. 1994, 9, 1778–1788. [Google Scholar]

- Kovacs, G.T. Micromachined Transducers Sourcebook; McGraw-Hill Science Engineering: New York, NY, USA, 1998. [Google Scholar]

- Terrones, M.; Hsu, W.K.; Kroto, H.W.; Walton, D.R. Nanotubes: A Revolution in Materials Science and Electronics. In Fullerenes and Related Structures; Springer: New York, NY, USA, 1999; pp. 189–234. [Google Scholar]

- Kroto, H. C60 Buckminsterfullerene, other fullerenes and the icospiral shell. Comput. Math. Appl. 1989, 17, 417–423. [Google Scholar] [CrossRef]

- Cataldo, F. The impact of a fullerene-like concept in carbon black science. Carbon 2002, 40, 157–162. [Google Scholar] [CrossRef]

- Wang, J. Carbon-nanotube based electrochemical biosensors: A review. Electroanal. Int. J. Devoted Fundam. Pract. Asp. Electroanal. 2005, 17, 7–14. [Google Scholar] [CrossRef]

- Malik, S. Structural and electronic properties of nano-carbon materials such as graphene, nanotubes and fullerenes. Nature 1985, 318, 162–163. [Google Scholar]

- Heerema, S.J.; Dekker, C. Graphene nanodevices for DNA sequencing. Nat. Nanotechnol. 2016, 11, 127–136. [Google Scholar] [CrossRef]

- Kamat, P.V.; Guldi, D.M.; D’Souza, F. Fullerenes and Nanotubes: The Building Blocks of Next Generation Nanodevices: Proceedings of the International Symposium on Fullerenes, Nanotubes, and Carbon Nanoclusters; The Electrochemical Society: Pennington, NJ, USA, 2003. [Google Scholar]

- Matsuo, Y.; Nakamura, E. Application of fullerenes to nanodevices. Chem. Nanocarbons 2010, 173–187. [Google Scholar] [CrossRef]

- Choi, J.; Pyo, S.; Baek, D.-H.; Lee, J.-I.; Kim, J. Thickness-, alignment- and defect-tunable growth of carbon nanotube arrays using designed mechanical loads. Carbon 2014, 66, 126–133. [Google Scholar] [CrossRef]

- Ghasemi, M.; Daud, W.R.W.; Hassan, S.H.; Oh, S.-E.; Ismail, M.; Rahimnejad, M.; Jahim, J.M. Nano-structured carbon as electrode material in microbial fuel cells: A comprehensive review. J. Alloys Compd. 2013, 580, 245–255. [Google Scholar] [CrossRef]

- Gooding, J.J. Nanostructuring electrodes with carbon nanotubes: A review on electrochemistry and applications for sensing. Electrochim. Acta 2005, 50, 3049–3060. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, H.; Wu, X.; Wang, L.; Zhang, A.; Xia, T.; Dong, H.; Li, X.; Zhang, L. Progress of electrochemical capacitor electrode materials: A review. Int. J. Hydrog. Energy 2009, 34, 4889–4899. [Google Scholar] [CrossRef]

- Li, C.; Thostenson, E.T.; Chou, T.-W. Sensors and actuators based on carbon nanotubes and their composites: A review. Compos. Sci. Technol. 2008, 68, 1227–1249. [Google Scholar] [CrossRef]

- Ma, P.-C.; Siddiqui, N.A.; Marom, G.; Kim, J.-K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Patil, A.; Schriver, G.; Carstensen, B.; Lundberg, R. Fullerene functionalized polymers. Polym. Bull. 1993, 30, 187–190. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and graphene oxide: Synthesis, properties, and applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef]

- Berg, H.C. How bacteria swim. Sci. Am. 1975, 233, 36–45. [Google Scholar] [CrossRef]

- Adelstein, R.S.; Conti, M.A.; Barylko, B. The role of myosin phosphorylation in regulating actin-myosin interaction in human blood platelets. Thromb. Haemost. 1978, 39, 241–244. [Google Scholar] [CrossRef]

- Krebs, E.G.; Kent, A.B.; Fischer, E.H. The muscle phosphorylase b kinase reaction. J. Biol. Chem. 1958, 231, 73–83. [Google Scholar]

- Wenz, G.; Han, B.-H.; Müller, A. Cyclodextrin rotaxanes and polyrotaxanes. Chem. Rev. 2006, 106, 782–817. [Google Scholar] [CrossRef]

- Schill, G. Catenanes, Rotaxanes, and Knots; Elsevier: Amsterdam, The Netherlands, 2017; Volume 22. [Google Scholar]

- Zhang, Y.; Ma, Y.; Sun, J. Reversible actuation of polyelectrolyte films: Expansion-induced mechanical force enables cis–trans isomerization of azobenzenes. Langmuir 2013, 29, 14919–14925. [Google Scholar] [CrossRef] [PubMed]

- Madden, J.D.; Kanigan, T.S.; Lafontaine, S.; Hunter, I.W. Conducting Polymer Actuator. U.S. Patent Application No. 6,249,076B1, 19 June 2001. [Google Scholar]

- Maitland, D.J.; Lee, A.P.; Schumann, D.L.; Matthews, D.L.; Decker, D.E.; Jungreis, C.A. Shape Memory Polymer Actuator and Catheter. U.S. Patent Application No. 6,740,094B2, 25 May 2004. [Google Scholar]

- Noh, T.-G.; Tak, Y.; Nam, J.-D.; Choi, H. Electrochemical characterization of polymer actuator with large interfacial area. Electrochim. Acta 2002, 47, 2341–2346. [Google Scholar] [CrossRef]

- Wang, X.; Li, Q.; Xie, J.; Jin, Z.; Wang, J.; Li, Y.; Jiang, K.; Fan, S. Fabrication of ultralong and electrically uniform single-walled carbon nanotubes on clean substrates. Nano Lett. 2009, 9, 3137–3141. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.; Dyer, M.J.; Skidmore, G.D.; Rohrs, H.W.; Lu, X.; Ausman, K.D.; Von Ehr, J.R.; Ruoff, R.S. Three-dimensional manipulation of carbon nanotubes under a scanning electron microscope. Nanotechnology 1999, 10, 244–252. [Google Scholar] [CrossRef]

- Majumdar, S.; Lin, J.; Link, T.; Millard, J.; Augat, P.; Ouyang, X.; Newitt, D.; Gould, R.; Kothari, M.; Genant, H. Fractal analysis of radiographs: Assessment of trabecular bone structure and prediction of elastic modulus and strength. Med. Phys. 1999, 26, 1330–1340. [Google Scholar] [CrossRef]

- Kasumov, A.Y.; Khodos, I.; Ajayan, P.; Colliex, C. Electrical resistance of a single carbon nanotube. EPL (Europhys. Lett.) 1996, 34, 429–434. [Google Scholar] [CrossRef]

- Krueger, A. Carbon Materials and Nanotechnology; John Wiley & Sons: New York, NY, USA, 2010. [Google Scholar]

- Hu, Y.; Chen, W.; Lu, L.; Liu, J.; Chang, C. Electromechanical actuation with controllable motion based on a single-walled carbon nanotube and natural biopolymer composite. ACS Nano 2010, 4, 3498–3502. [Google Scholar] [CrossRef]

- Narendar, S. Mathematical modelling of rotating single-walled carbon nanotubes used in nanoscale rotational actuators. Def. Sci. J. 2011, 61, 317–324. [Google Scholar] [CrossRef]

- Deng, J.; Li, J.; Chen, P.; Fang, X.; Sun, X.; Jiang, Y.; Weng, W.; Wang, B.; Peng, H. Tunable photothermal actuators based on a pre-programmed aligned nanostructure. J. Am. Chem. Soc. 2015, 138, 225–230. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. In Nanoscience and Technology: A Collection of Reviews from Nature Journals; World Scientific: Singapore, 2010; pp. 11–19. [Google Scholar]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.; Kohlhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-based composite materials. Nature 2006, 442, 282–286. [Google Scholar] [CrossRef] [PubMed]

- Charlier, J.C.; Issi, J.P. Electrical conductivity of novel forms of carbon. J. Phys. Chem. Solids 1996, 57, 957–965. [Google Scholar] [CrossRef]

- Stoller, M.D.; Park, S.; Zhu, Y.; An, J.; Ruoff, R.S. Graphene-based ultracapacitors. Nano Lett. 2008, 8, 3498–3502. [Google Scholar] [CrossRef] [PubMed]

- Smith, A.T.; LaChance, A.M.; Zeng, S.; Liu, B.; Sun, L. Synthesis, properties, and applications of graphene oxide/reduced graphene oxide and their nanocomposites. Nano Mater. Sci. 2019, 1, 31–47. [Google Scholar] [CrossRef]

- Xu, Z. Chapter 4—Fundamental properties of graphene. In Graphene; Zhu, H., Xu, Z., Xie, D., Fang, Y., Eds.; Academic Press: New York, NY, USA, 2018; pp. 73–102. [Google Scholar]

- Dresselhaus, M.S.; Dresselhaus, G.; Eklund, P.C. Science of Fullerenes and Carbon Nanotubes: Their Properties and Applications; Elsevier: Amsterdam, The Netherlands, 1996. [Google Scholar]

- Guldi, D.; Martin, N. Functionalized fullerenes: Synthesis and functions. Compr. Nanosci. Nanotechnol. 2019, 187–191. [Google Scholar]

- Kroto, H.W.; Heath, J.R.; O’Brien, S.C.; Curl, R.F.; Smalley, R.E. C60: Buckminsterfullerene. Nature 1985, 318, 162–163. [Google Scholar] [CrossRef]

- Krätschmer, W.; Lamb, L.D.; Fostiropoulos, K.; Huffman, D.R. Solid C60: A new form of carbon. Nature 1990, 347, 354–358. [Google Scholar] [CrossRef]

- Biagiotti, G.; Cicchi, S.; De Sarlo, F.; Machetti, F. Reactivity of [60] fullerene with primary nitro compounds: Addition or catalysed condensation to isoxazolo [60] fullerenes. Eur. J. Org. Chem. 2014, 2014, 7906–7915. [Google Scholar] [CrossRef]

- Chen, J.; Wu, F. Review of hydrogen storage in inorganic fullerene-like nanotubes. Appl. Phys. A 2004, 78, 989–994. [Google Scholar] [CrossRef]

- Echegoyen, L.; Echegoyen, L.E. Electrochemistry of fullerenes and their derivatives. Acc. Chem. Res. 1998, 31, 593–601. [Google Scholar] [CrossRef]

- Yadav, B.C.; Kumar, R. Structure, properties and applications of fullerenes. Int. J. Nanotechnol. Appl. 2008, 2, 15–24. [Google Scholar]

- Lekawa-Raus, A.; Patmore, J.; Kurzepa, L.; Bulmer, J.; Koziol, K. Electrical properties of carbon nanotube based fibers and their future use in electrical wiring. Adv. Funct. Mater. 2014, 24, 3661–3682. [Google Scholar] [CrossRef]

- Sun, H.-B.; Ge, G.; Zhu, J.; Hailong, Y.; Lu, Y.; Wu, Y.; Wan, J.; Han, M.; Luo, Y. High electrical conductivity of graphene-based transparent conductive films with silver nanocomposites. RSC Adv. 2015, 5, 108044–108049. [Google Scholar] [CrossRef]

- Baughman, R.H.; Cui, C.; Zakhidov, A.A.; Iqbal, Z.; Barisci, J.N.; Spinks, G.M.; Wallace, G.G.; Mazzoldi, A.; De Rossi, D.; Rinzler, A.G. Carbon nanotube actuators. Science 1999, 284, 1340–1344. [Google Scholar] [CrossRef] [PubMed]

- Roth, S.; Baughman, R.H. Actuators of individual carbon nanotubes. Curr. Appl. Phys. 2002, 2, 311–314. [Google Scholar] [CrossRef]

- Baughman, R.H.; Zakhidov, A.A.; De Heer, W.A. Carbon nanotubes—The route toward applications. Science 2002, 297, 787–792. [Google Scholar] [CrossRef]

- Fakhrabadi, M.M.S.; Rastgoo, A.; Ahmadian, M.T. Size-dependent instability of carbon nanotubes under electrostatic actuation using nonlocal elasticity. Int. J. Mech. Sci. 2014, 80, 144–152. [Google Scholar] [CrossRef]

- Fakhrabadi, M.M.S.; Rastgoo, A.; Ahmadian, M.T. Non-linear behaviors of carbon nanotubes under electrostatic actuation based on strain gradient theory. Int. J. Non Linear Mech. 2014, 67, 236–244. [Google Scholar] [CrossRef]

- Suppiger, D.; Busato, S.; Ermanni, P. Characterization of single-walled carbon nanotube mats and their performance as electromechanical actuators. Carbon 2008, 46, 1085–1090. [Google Scholar] [CrossRef]

- Geier, S.M.; Mahrholz, T.; Wierach, P.; Sinapius, M. Morphology- and ion size-induced actuation of carbon nanotube architectures. Int. J. Smart Mater. 2018, 9, 111–134. [Google Scholar] [CrossRef]

- Senga, R.; Hirahara, K.; Yamaguchi, Y.; Nakayama, Y. Carbon nanotube torsional actuator based on transition between flattened and tubular states. J. Non-Cryst. Solids 2012, 358, 2541–2544. [Google Scholar] [CrossRef]

- Giménez, P.; Mukai, K.; Asaka, K.; Hata, K.; Oike, H.; Otero, T.F. Capacitive and faradic charge components in high-speed carbon nanotube actuator. Electrochim. Acta 2012, 60, 177–183. [Google Scholar] [CrossRef]

- Hung, N.T.; Nugraha, A.R.T.; Saito, R. Three-dimensional carbon Archimedean lattices for high-performance electromechanical actuators. Carbon 2017, 125, 472–479. [Google Scholar] [CrossRef]

- Hung, N.T.; Nugraha, A.R.T.; Saito, R. Charge-induced electrochemical actuation of armchair carbon nanotube bundles. Carbon 2017, 118, 278–284. [Google Scholar] [CrossRef]

- Ouakad, H.M.; Sedighi, H.M. Rippling effect on the structural response of electrostatically actuated single-walled carbon nanotube based NEMS actuators. Int. J. Non-Linear Mech. 2016, 87, 97–108. [Google Scholar] [CrossRef]

- Frolov, A.I.; Kirchner, K.; Kirchner, T.; Fedorov, M.V. Molecular-scale insights into the mechanisms of ionic liquids interactions with carbon nanotubes. Faraday Discuss. 2012, 154, 235–247. [Google Scholar] [CrossRef] [PubMed]

- Fukushima, T.; Aida, T. Ionic liquids for soft functional materials with carbon nanotubes. Chem. A Eur. J. 2007, 13, 5048–5058. [Google Scholar] [CrossRef]

- Sugino, T.; Shibata, Y.; Kiyohara, K.; Asaka, K. Actuation mechanism of dry-type polymer actuators composed by carbon nanotubes and ionic liquids. Sens. Actuators B Chem. 2018, 273, 955–965. [Google Scholar] [CrossRef]

- Sugino, T.; Kiyohara, K.; Takeuchi, I.; Mukai, K.; Asaka, K. Actuator properties of the complexes composed by carbon nanotube and ionic liquid: The effects of additives. Sens. Actuators B Chem. 2009, 141, 179–186. [Google Scholar] [CrossRef]

- Terasawa, N.; Hayashi, Y.; Koga, T.; Higashi, N.; Asaka, K. High-performance polymer actuators based on poly(ethylene oxide) and single-walled carbon nanotube–ionic liquid-based gels. Sens. Actuators B Chem. 2014, 202, 382–387. [Google Scholar] [CrossRef]

- Pelrine, R.; Kornbluh, R.; Joseph, J.; Heydt, R.; Pei, Q.; Chiba, S. High-field deformation of elastomeric dielectrics for actuators. Mater. Sci. Eng. C 2000, 11, 89–100. [Google Scholar] [CrossRef]

- Fang, X.; Li, A.; Yildiz, O.; Shao, H.; Bradford, P.D.; Ghosh, T.K. Enhanced anisotropic response of dielectric elastomer actuators with microcombed and etched carbon nanotube sheet electrodes. Carbon 2017, 120, 366–373. [Google Scholar] [CrossRef]

- Cakmak, E.; Fang, X.; Yildiz, O.; Bradford, P.D.; Ghosh, T.K. Carbon nanotube sheet electrodes for anisotropic actuation of dielectric elastomers. Carbon 2015, 89, 113–120. [Google Scholar] [CrossRef]

- Yeo, S.C.; Eisenberg, A. Physical properties and supermolecular structure of perfluorinated ion-containing (Nafion) polymers. J. Appl. Polym. Sci. 1977, 21, 875–898. [Google Scholar] [CrossRef]

- Lian, H.; Qian, W.; Estevez, L.; Liu, H.; Liu, Y.; Jiang, T.; Wang, K.; Guo, W.; Giannelis, E.P. Enhanced actuation in functionalized carbon nanotube–Nafion composites. Sens. Actuators B Chem. 2011, 156, 187–193. [Google Scholar] [CrossRef]

- Lu, H.; Yin, J.; Xu, B.; Gou, J.; Hui, D.; Fu, Y. Synergistic effects of carboxylic acid-functionalized carbon nanotube and Nafion/silica nanofiber on electrical actuation efficiency of shape memory polymer nanocomposite. Compos. Part B Eng. 2016, 100, 146–151. [Google Scholar] [CrossRef]

- Mukai, K.; Yamato, K.; Asaka, K.; Hata, K.; Oike, H. Actuator of double layer film composed of carbon nanotubes and polypyrroles. Sens. Actuators B Chem. 2012, 161, 1010–1017. [Google Scholar] [CrossRef]

- Sachyani, E.; Layani, M.; Tibi, G.; Avidan, T.; Degani, A.; Magdassi, S. Enhanced movement of CNT-based actuators by a three-layered structure with controlled resistivity. Sens. Actuators B Chem. 2017, 252, 1071–1077. [Google Scholar] [CrossRef]

- Zhang, W.; Weng, M.; Zhou, P.; Chen, L.; Huang, Z.; Zhang, L.; Liu, C.; Fan, S. Transparency-switchable actuator based on aligned carbon nanotube and paraffin-polydimethylsiloxane composite. Carbon 2017, 116, 625–632. [Google Scholar] [CrossRef]

- Ning, W.; Wang, Z.; Liu, P.; Zhou, D.; Yang, S.; Wang, J.; Li, Q.; Fan, S.; Jiang, K. Multifunctional super-aligned carbon nanotube/polyimide composite film heaters and actuators. Carbon 2018, 139, 1136–1143. [Google Scholar] [CrossRef]

- Zhou, Z.-W.; Yan, Q.-H.; Liu, C.-H.; Fan, S.-S. An arm-like electrothermal actuator based on superaligned carbon nanotube/polymer composites. New Carbon Mater. 2017, 32, 411–418. [Google Scholar] [CrossRef]

- Palmre, V.; Torop, J.; Arulepp, M.; Sugino, T.; Asaka, K.; Jänes, A.; Lust, E.; Aabloo, A. Impact of carbon nanotube additives on carbide-derived carbon-based electroactive polymer actuators. Carbon 2012, 50, 4351–4358. [Google Scholar] [CrossRef]

- Gendron, D.; Bubak, G.; Ceseracciu, L.; Ricciardella, F.; Ansaldo, A.; Ricci, D. Significant strain and force improvements of single-walled carbon nanotube actuator: A metal chalcogenides approach. Sens. Actuators B Chem. 2016, 230, 673–683. [Google Scholar] [CrossRef]

- Torop, J.; Arulepp, M.; Leis, J.; Punning, A.; Johanson, U.; Palmre, V.; Aabloo, A. Nanoporous carbide-derived carbon material-based linear actuators. Materials 2010, 3, 9–25. [Google Scholar] [CrossRef]

- Capeluto, M.G.; Salvador, R.F.; Eceiza, A.; Goyanes, S.; Ledesma, S.A. Azopolymer film as an actuator for organizing multiwall carbon nanotubes. Opt. Mater. 2017, 66, 247–252. [Google Scholar] [CrossRef]

- Ji, X.; El Haitami, A.; Sorba, F.; Rosset, S.; Nguyen, G.T.M.; Plesse, C.; Vidal, F.; Shea, H.R.; Cantin, S. Stretchable composite monolayer electrodes for low voltage dielectric elastomer actuators. Sens. Actuators B Chem. 2018, 261, 135–143. [Google Scholar] [CrossRef]

- Rasouli, H.; Naji, L.; Hosseini, M.G. The effect of MWCNT content on electropolymerization of PPy film and electromechanical behavior of PPy electrode-based soft actuators. J. Electroanal. Chem. 2017, 806, 136–149. [Google Scholar] [CrossRef]

- Shirasu, K.; Yamamoto, G.; Inoue, Y.; Ogasawara, T.; Shimamura, Y.; Hashida, T. Development of large-movements and high-force electrothermal bimorph actuators based on aligned carbon nanotube reinforced epoxy composites. Sens. Actuators A Phys. 2017, 267, 455–463. [Google Scholar] [CrossRef]

- Galantini, F.; Bianchi, S.; Castelvetro, V.; Gallone, G. Functionalized carbon nanotubes as a filler for dielectric elastomer composites with improved actuation performance. Smart Mater. Struct. 2013, 22, 055025. [Google Scholar] [CrossRef]

- Terasawa, N.; Ono, N.; Mukai, K.; Koga, T.; Higashi, N.; Asaka, K. High performance polymer actuators based on multi-walled carbon nanotubes that surpass the performance of those containing single-walled carbon nanotubes: Effects of ionic liquid and composition. Sens. Actuators B Chem. 2012, 163, 20–28. [Google Scholar] [CrossRef]

- Chen, I.W.P.; Cottinet, P.-J.; Tsai, S.-Y.; Foster, B.; Liang, R.; Wang, B.; Zhang, C. Improved performance of carbon nanotube buckypaper and ionic-liquid-in-Nafion actuators for rapid response and high durability in the open air. Sens. Actuators B Chem. 2012, 171–172, 515–521. [Google Scholar] [CrossRef]

- Chen, I.W.P.; Liang, Z.; Wang, B.; Zhang, C. Charge-induced asymmetrical displacement of an aligned carbon nanotube buckypaper actuator. Carbon 2010, 48, 1064–1069. [Google Scholar] [CrossRef]

- Saane, S.S.R.; Onck, P.R. Atomistic modeling of the stiffness, strength and charge-induced actuation of graphene nanofoams. Extrem. Mech. Lett. 2015, 5, 54–61. [Google Scholar] [CrossRef]

- Tungkavet, T.; Seetapan, N.; Pattavarakorn, D.; Sirivat, A. Graphene/gelatin hydrogel composites with high storage modulus sensitivity for using as electroactive actuator: Effects of surface area and electric field strength. Polymer 2015, 70, 242–251. [Google Scholar] [CrossRef]

- Jung, J.-H.; Jeon, J.-H.; Sridhar, V.; Oh, I.-K. Electro-active grapheme—Nafion actuators. Carbon 2011, 49, 1279–1289. [Google Scholar] [CrossRef]

- Wang, Y.; Bian, K.; Hu, C.; Zhang, Z.; Chen, N.; Zhang, H.; Qu, L. Flexible and wearable graphene/polypyrrole fibers towards multifunctional actuator applications. Electrochem. Commun. 2013, 35, 49–52. [Google Scholar] [CrossRef]

- Sen, I.; Seki, Y.; Sarikanat, M.; Cetin, L.; Gurses, B.O.; Ozdemir, O.; Yilmaz, O.C.; Sever, K.; Akar, E.; Mermer, O. Electroactive behavior of graphene nanoplatelets loaded cellulose composite actuators. Compos. Part B Eng. 2015, 69, 369–377. [Google Scholar] [CrossRef]

- Chen, T.; Qiu, J.; Zhu, K.; Li, J. Electro-mechanical performance of polyurethane dielectric elastomer flexible micro-actuator composite modified with titanium dioxide-graphene hybrid fillers. Mater. Des. 2016, 90, 1069–1076. [Google Scholar] [CrossRef]

- Liu, H.; Niu, D.; Jiang, W.; Zhao, T.; Lei, B.; Yin, L.; Shi, Y.; Chen, B.; Lu, B. Illumination-oriented and thickness-dependent photomechanical bilayer actuators realized by graphene-nanoplatelets. Sens. Actuators A Phys. 2016, 239, 45–53. [Google Scholar] [CrossRef]

- Jiang, D.; Zhu, H.; Yang, W.; Cui, L.; Liu, J. One-side non-covalent modification of CVD graphene sheet using pyrene-terminated PNIPAAm generated via RAFT polymerization for the fabrication of thermo-responsive actuators. Sens. Actuators B Chem. 2017, 239, 193–202. [Google Scholar] [CrossRef]

- Brodie, B.C., XIII. On the atomic weight of graphite. Philos. Trans. R. Soc. Lond. 1859, 149, 249–259. [Google Scholar]

- Hummers, W.S.J.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Dreyer, D.R.; Park, S.; Bielawski, C.W.; Ruoff, R.S. The chemistry of graphene oxide. Chem. Soc. Rev. 2010, 39, 228–240. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.; Hao, Y.-W.; Yang, P.; Li, P.-L.; Sun, N.; Feng, X.-W.; Zhao, J.; Chen, C.-A.; Song, J.-F. Fast fabrication of graphene oxide/reduced graphene oxide hybrid hydrogels for thermosensitive smart actuator utilizing laser irradiation. Mater. Lett. 2019, 237, 245–248. [Google Scholar] [CrossRef]

- Chen, Z.; Cao, R.; Ye, S.; Ge, Y.; Tu, Y.; Yang, X. Graphene oxide/poly (N-isopropylacrylamide) hybrid film-based near-infrared light-driven bilayer actuators with shape memory effect. Sens. Actuators B Chem. 2018, 255, 2971–2978. [Google Scholar] [CrossRef]

- Surana, K.; Singh, P.K.; Bhattacharya, B.; Verma, C.S.; Mehra, R.M. Synthesis of graphene oxide coated Nafion membrane for actuator application. Ceram. Int. 2015, 41, 5093–5099. [Google Scholar] [CrossRef]

- Lee, J.-W.; Kwon, T.; Kang, Y.; Han, T.H.; Cho, C.G.; Hong, S.M.; Hwang, S.-W.; Koo, C.M. Styrenic block copolymer/sulfonated graphene oxide composite membranes for highly bendable ionic polymer actuators with large ion concentration gradient. Compos. Sci. Technol. 2018, 163, 63–70. [Google Scholar] [CrossRef]

- Liu, A.; Yuan, W.; Shi, G. Electrochemical actuator based on polypyrrole/sulfonated graphene/graphene tri-layer film. Thin Solid Films 2012, 520, 6307–6312. [Google Scholar] [CrossRef]

- Vural, M.; Lei, Y.; Pena-Francesch, A.; Jung, H.; Allen, B.; Terrones, M.; Demirel, M.C. Programmable molecular composites of tandem proteins with graphene oxide for efficient bimorph actuators. Carbon 2017, 118, 404–412. [Google Scholar] [CrossRef]

- Terasawa, N.; Asaka, K. High-performance graphene oxide/vapor-grown carbon fiber composite polymer actuator. Sens. Actuators B Chem. 2018, 255, 2829–2837. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, Y.-L.; Han, B.; Ma, J.-N.; Wang, J.-N.; Han, D.-D.; Ma, Z.-C.; Sun, H.-B. A complementary strategy for producing moisture and alkane dual-responsive actuators based on graphene oxide and PDMS bimorph. Sens. Actuators B Chem. 2019, 290, 133–139. [Google Scholar] [CrossRef]

- Selvakumar, D.; Alsalme, A.; Alghamdi, A.; Jayavel, R. Reduced graphene oxide paper as bimorphic electrical actuators. Mater. Lett. 2017, 191, 182–185. [Google Scholar] [CrossRef]

- Wang, W.; Liu, D.; Liu, Y.; Leng, J.; Bhattacharyya, D. Electrical actuation properties of reduced graphene oxide paper/epoxy-based shape memory composites. Compos. Sci. Technol. 2015, 106, 20–24. [Google Scholar] [CrossRef]

- Muralidharan, M.N.; Shinu, K.P.; Seema, A. Optically triggered actuation in chitosan/reduced graphene oxide nanocomposites. Carbohydr. Polym. 2016, 144, 115–121. [Google Scholar] [CrossRef]

- Kaur, R.P.; Engles, D. Transport in a fullerene terminated aromatic molecular device. J. Sci. Adv. Mater. Devices 2018, 3, 206–212. [Google Scholar] [CrossRef]

- Huang, T.; Zhao, J.; Feng, M.; Popov, A.A.; Yang, S.; Dunsch, L.; Petek, H. A multi-state single-molecule switch actuated by rotation of an encapsulated cluster within a fullerene cage. Chem. Phys. Lett. 2012, 552, 1–12. [Google Scholar] [CrossRef]

- Jung, J.-H.; Vadahanambi, S.; Oh, I.-K. Electro-active nano-composite actuator based on fullerene-reinforced Nafion. Compos. Sci. Technol. 2010, 70, 584–592. [Google Scholar] [CrossRef]

- Panwar, V.; Ko, S.Y.; Park, J.-O.; Park, S. Enhanced and fast actuation of fullerenol/PVDF/PVP/PSSA based ionic polymer metal composite actuators. Sens. Actuators B Chem. 2013, 183, 504–517. [Google Scholar] [CrossRef]

- Jagdale, P.; Ziegler, D.; Rovere, M.; Tulliani, J.M.; Tagliaferro, A. Waste coffee ground biochar: A material for humidity sensors. Sensors 2019, 19, 801. [Google Scholar] [CrossRef]

- Pourhashem, G.; Hung, S.Y.; Medlock, K.B.; Masiello, C.A. Policy support for biochar: Review and recommendations. GCB Bioenergy 2019, 11, 364–380. [Google Scholar] [CrossRef]

- Wang, Y.; Fang, L.; Xiang, L.; Wu, G.; Zeng, Y.; Chen, Q.; Wei, X. On-chip thermionic electron emitter arrays based on horizontally aligned single-walled carbon nanotubes. IEEE Trans. Electron Devices 2019, 66, 1069–1074. [Google Scholar] [CrossRef]

- Qiu, S.; Wu, K.; Gao, B.; Li, L.; Jin, H.; Li, Q. Solution-processing of high-purity semiconducting single-walled carbon nanotubes for electronics devices. Adv. Mater. 2019, 31, 1800750. [Google Scholar] [CrossRef] [PubMed]

- Materón, E.M.; Lima, R.S.; Joshi, N.; Shimizu, F.M.; Oliveira, O.N.J. Graphene-containing microfluidic and chip-based sensor devices for biomolecules. In Graphene-Based Electrochemical Sensors for Biomolecules; Elsevier: Amsterdam, The Netherlands, 2019; pp. 321–336. [Google Scholar]

- Tseng, L.-T.; Kazazis, D.; Wang, X.; Popescu, C.M.; Robinson, A.P.; Ekinci, Y. Sub-20 nm Si fins with high aspect ratio via pattern transfer using fullerene-based spin-on-carbon hard masks. Microelectron. Eng. 2019, 210, 8–13. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giorcelli, M.; Bartoli, M. Carbon Nanostructures for Actuators: An Overview of Recent Developments. Actuators 2019, 8, 46. https://doi.org/10.3390/act8020046

Giorcelli M, Bartoli M. Carbon Nanostructures for Actuators: An Overview of Recent Developments. Actuators. 2019; 8(2):46. https://doi.org/10.3390/act8020046

Chicago/Turabian StyleGiorcelli, Mauro, and Mattia Bartoli. 2019. "Carbon Nanostructures for Actuators: An Overview of Recent Developments" Actuators 8, no. 2: 46. https://doi.org/10.3390/act8020046

APA StyleGiorcelli, M., & Bartoli, M. (2019). Carbon Nanostructures for Actuators: An Overview of Recent Developments. Actuators, 8(2), 46. https://doi.org/10.3390/act8020046