5.1. Tensile Testing of the Hinge Materials

Application of the theory requires knowing the mechanical properties of the hinge material. This section presents the tensile tests performed and the acquired mechanical properties.

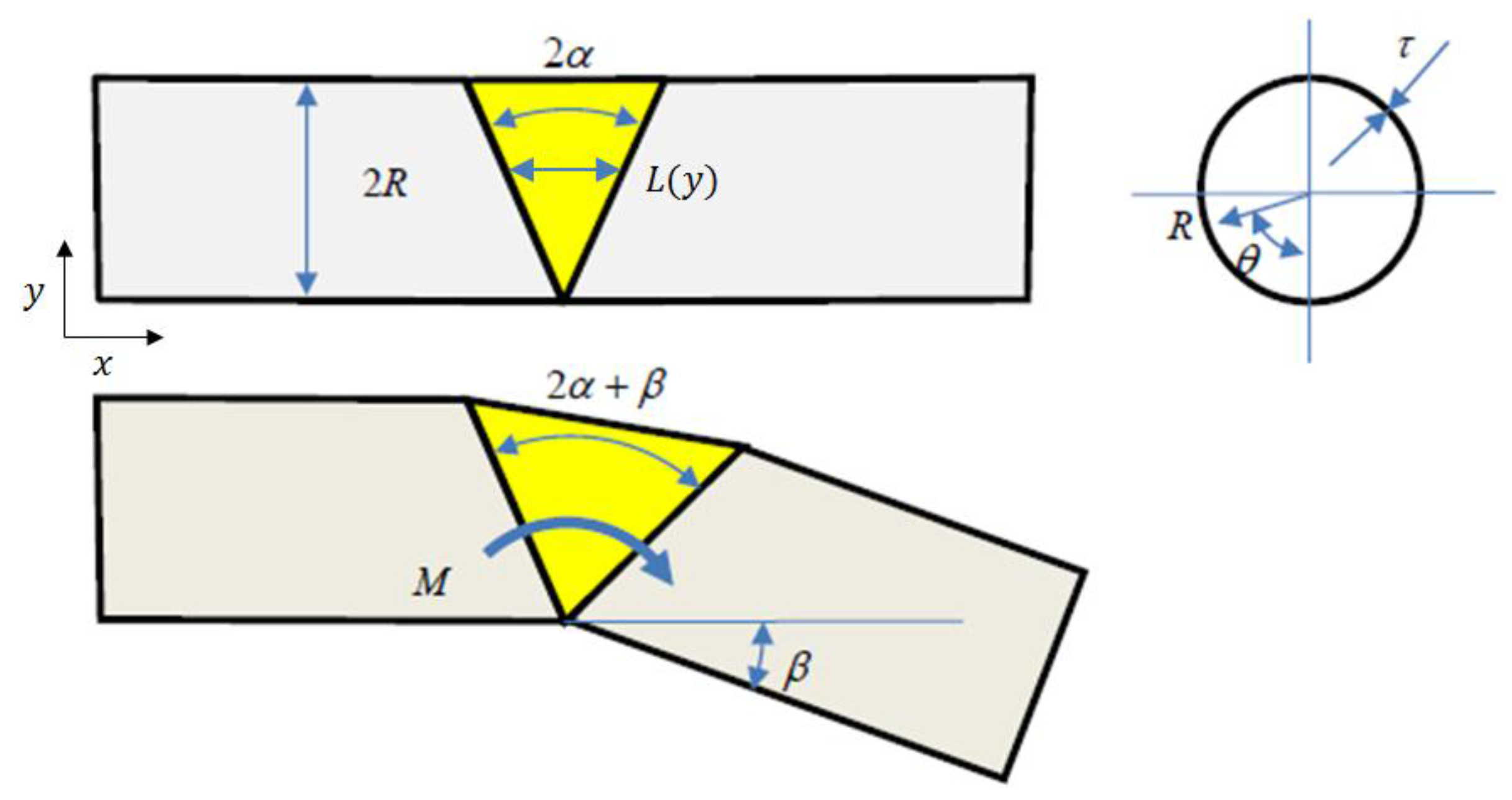

By reducing the circumferential expansion of the hinge membrane using the Kevlar wires, plane strain is assumed. The effective elastic modulus for the longitudinal elongation is therefore:

In the tensile tests, the specimen is free to contract perpendicular to the direction of tension so is at a state of plane stress, the stress to strain ratio provides the modulus of elasticity, while Poisson’s ratio ν is obtained by recording the width and thickness of the specimen at each load step.

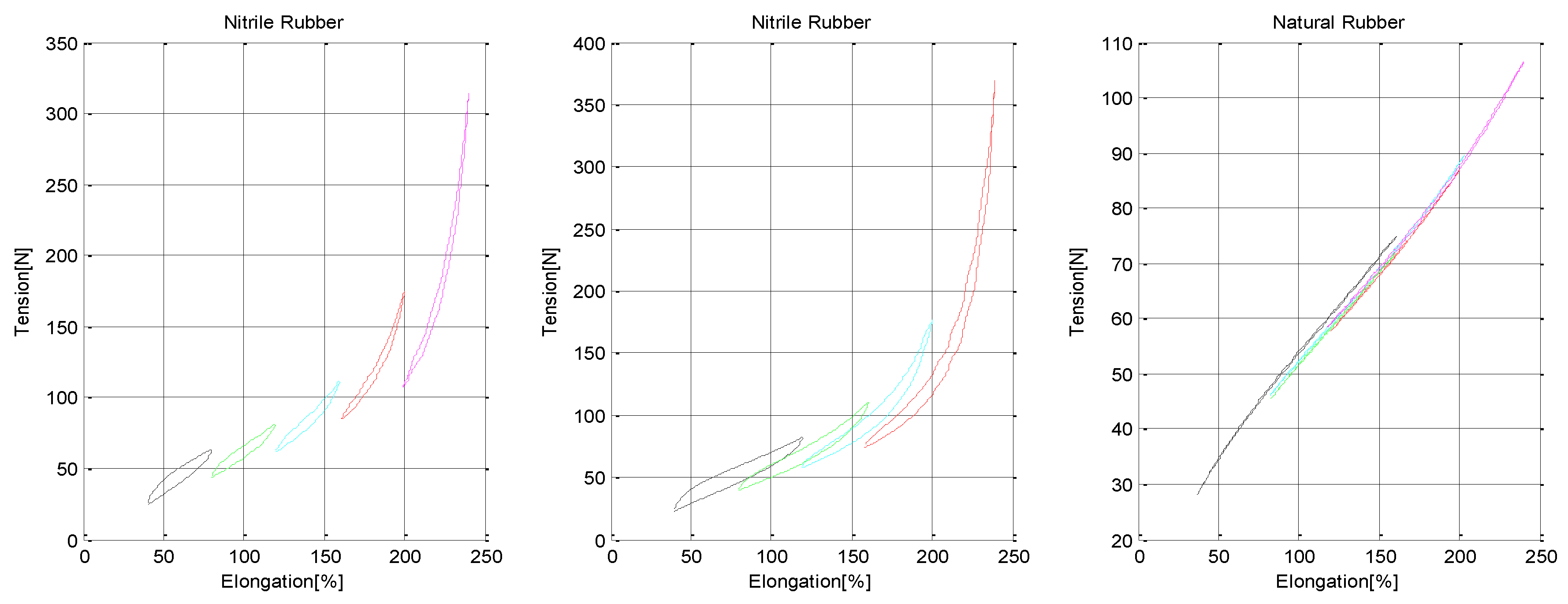

Tensile tests were also performed for a full loading cycle in order to determine energy loss through hysteresis. The material was pre-stretched and went through a few load cycles before recording stress and strain during loading and relaxation. A few load cycles were conducted in a series of strain ranges. This is necessary since the relaxation curve and resulting energy losses depend on the strain range exhibited by the material.

Figure 3 presents a few load-release curves for nitrile rubber and for natural rubber.

Figure 3.

Experimental load cycle curves for natural rubber (right) and nitrile rubber. Leftmost is a 40% elongation range and center is for 80%.

Figure 3.

Experimental load cycle curves for natural rubber (right) and nitrile rubber. Leftmost is a 40% elongation range and center is for 80%.

For a given load cycle, the average value of energy loss per unit volume can be obtained by the area inside the hysteresis loop.

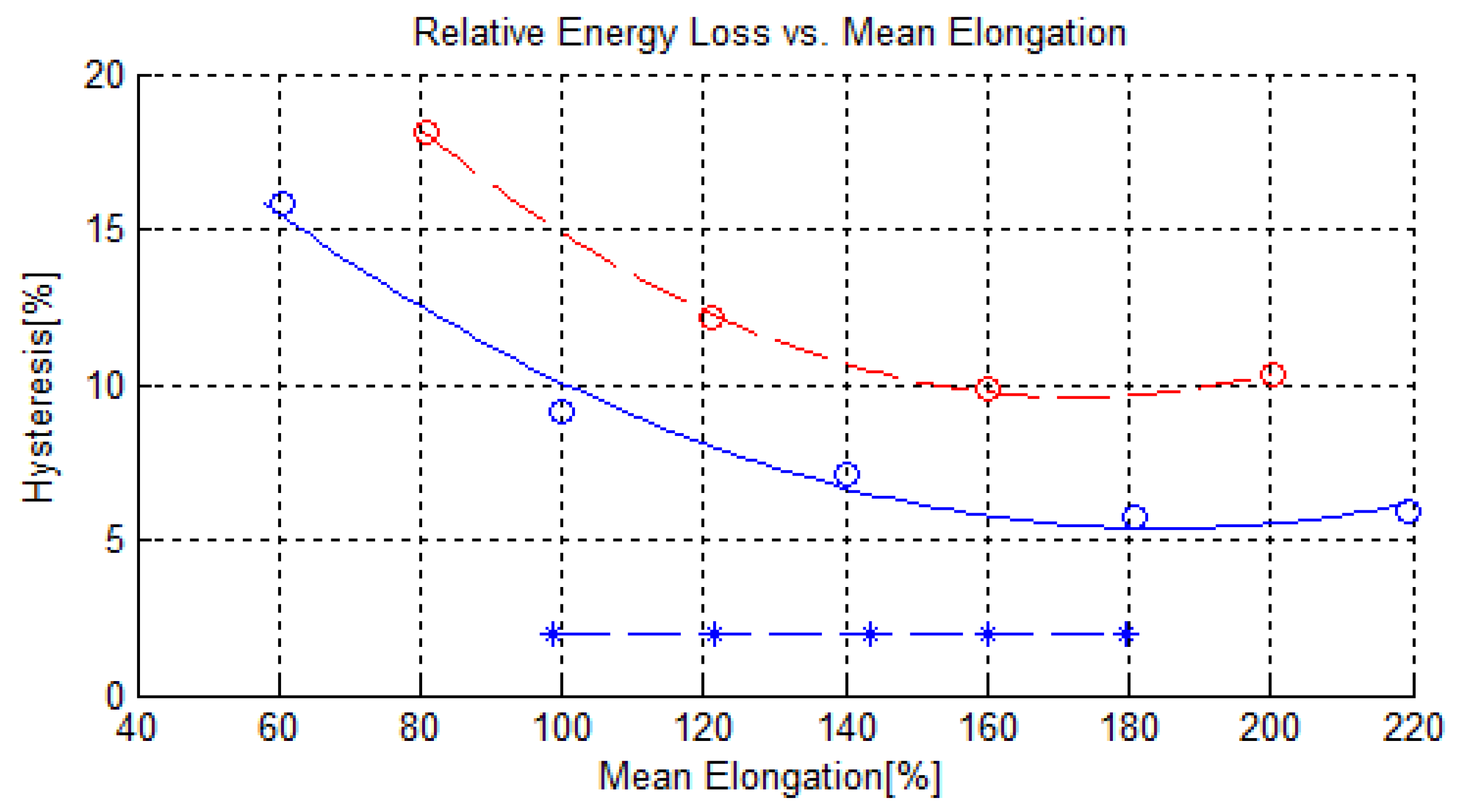

Figure 4 compares relative energy loss

versus starting elongation for the curves in

Figure 3. Averaging all the measured load cycles (including those not presented in

Figure 3) the nitrile rubber exhibited 23.8% relative energy loss, while the natural rubber exhibited about 1.9% relative energy loss.

The parabolic fits are 0.0000ΔL2 + 0.001L + 1.99 for natural rubber, 0.0007ΔL2 − 0.2409ΔL + 27.5939 for nitrile rubber at 40% elongation range and 0.0010ΔL2 − 0.3469ΔL + 39.5437 for nitrile rubber at 80% elongation range.

Figure 4.

Relative hysteresis versus mean elongation exhibited in a load cycle. Asterisks mark natural rubber load cycles. Red circles present nitrile rubber at elongation range 80%. Blue circles present nitrile rubber at elongation range 40%. Lines are parabolic fits.

Figure 4.

Relative hysteresis versus mean elongation exhibited in a load cycle. Asterisks mark natural rubber load cycles. Red circles present nitrile rubber at elongation range 80%. Blue circles present nitrile rubber at elongation range 40%. Lines are parabolic fits.

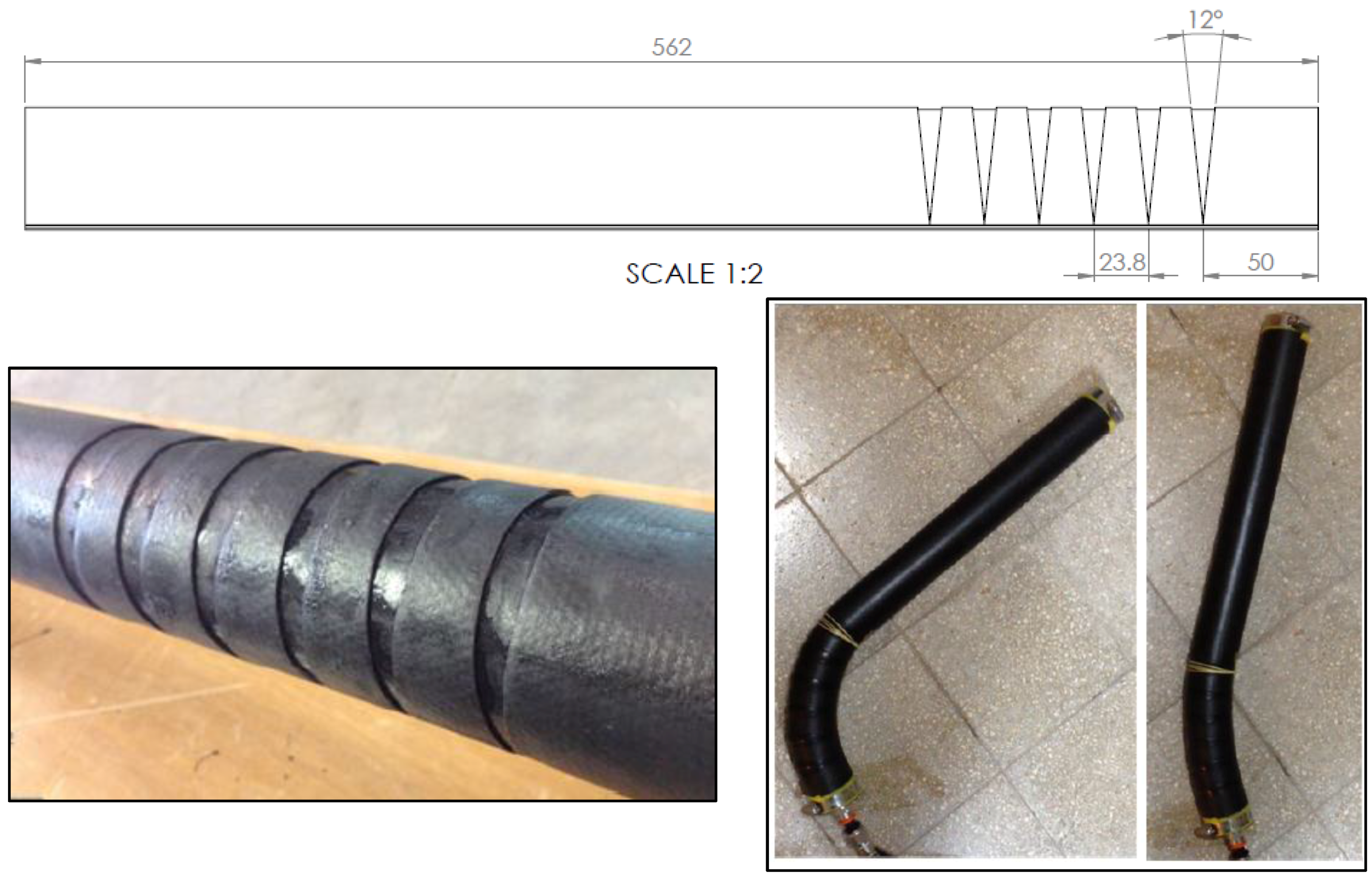

5.2. Parameters and Response of HELM Prototype 1

The first prototype has ten hinges of head angles 2α = 8°, 10°, 12°,…26°. The tube radius is R = 35 mm, and the thickness of the hinge membrane is τ = 1 mm. The hinge is made of EPDM while HYPOLON is used for the inflexible tube.

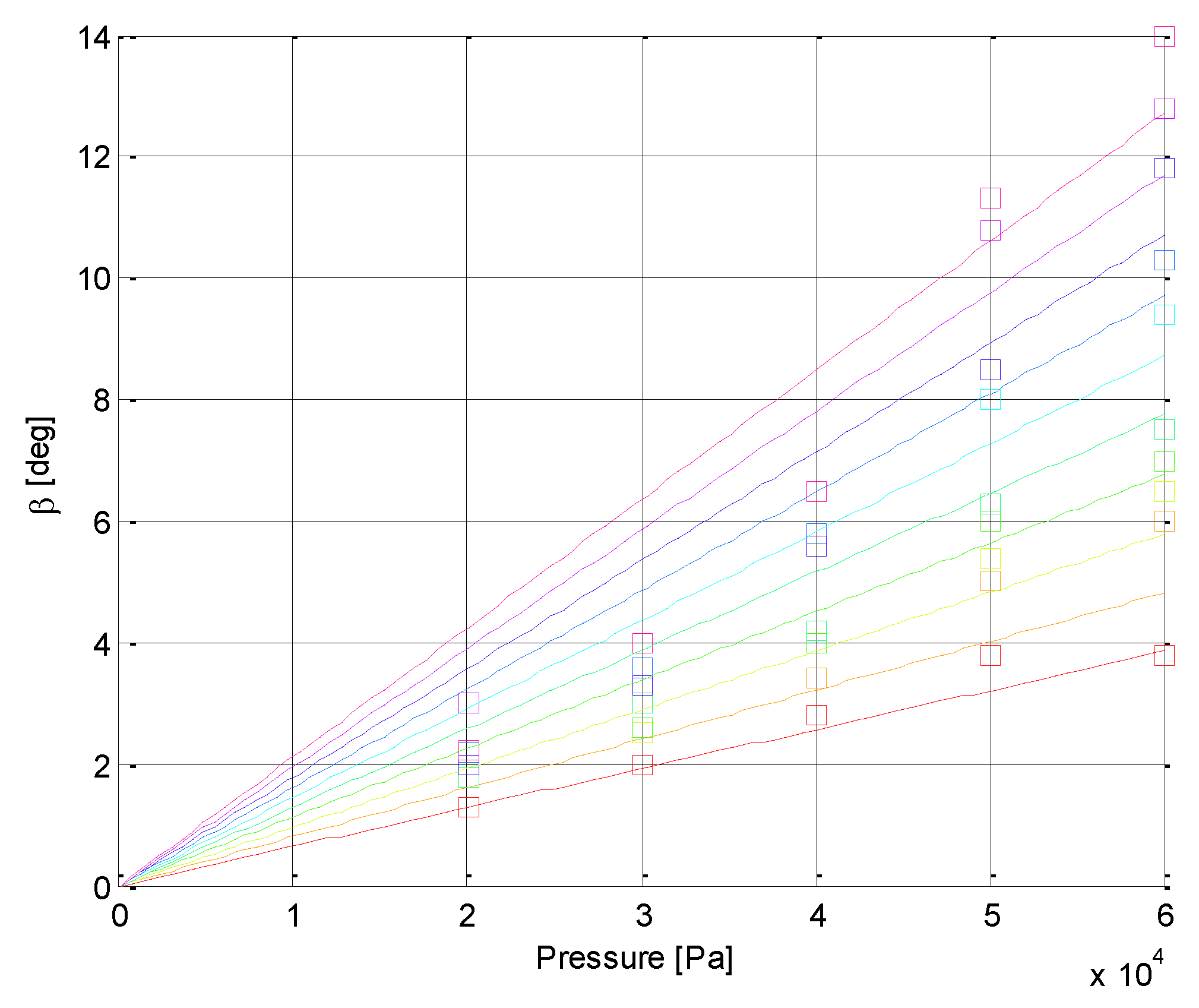

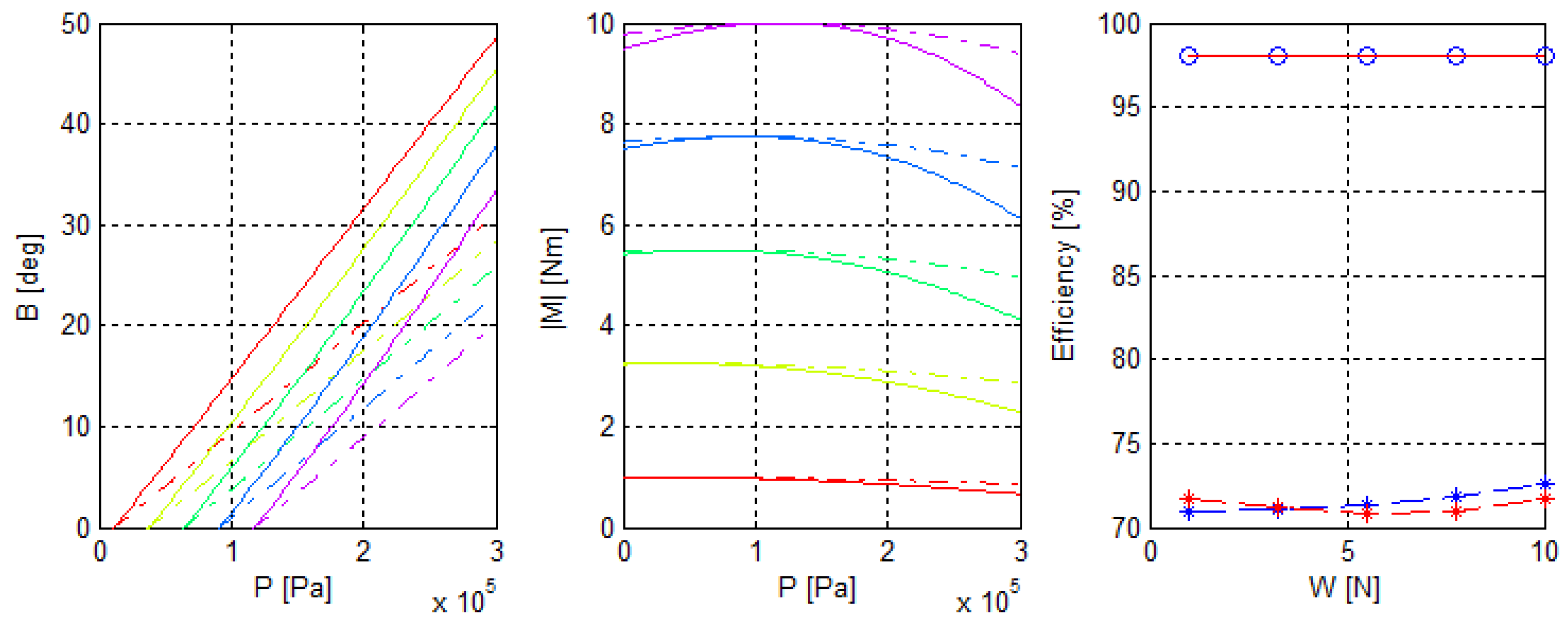

Pressure was slowly applied to the HELM, and the rotation angle

β was measured at each hinge. These measurements were compared with theory, Equation (7), assuming an effective elastic modulus of

E = 2.279 MPa based on the tensile tests of the EPDM.

Figure 5 presents the static pressure response of the prototype 1.

From

Figure 5, the linear analysis is applicable for HYPOLON hinges with relatively small head angles at low pressures. This is most likely due to the small angle nature of our formulation, as well as material nonlinearity and effects of deformations occurring outside of the hinge (which we have neglected in our formulation).

Figure 5.

Static pressure response of prototype 1. Each color corresponds to each hinge (of a specified head angle). Squares mark the experiment, while lines represent the theoretical linear response.

Figure 5.

Static pressure response of prototype 1. Each color corresponds to each hinge (of a specified head angle). Squares mark the experiment, while lines represent the theoretical linear response.

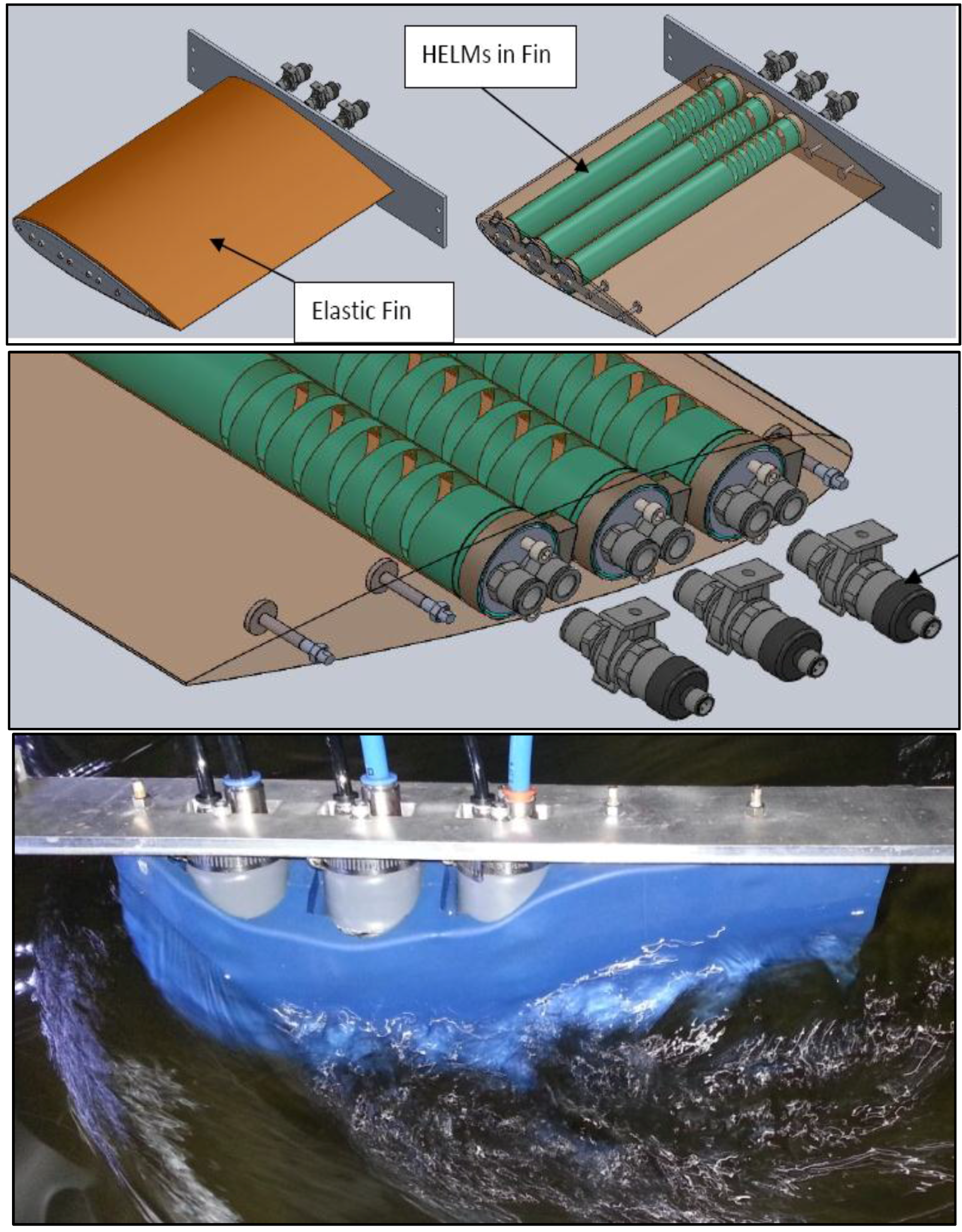

5.4. Parameters and Response of HELM Prototype 3

The third prototype has six hinges made of nitrile rubber with 2α = 12°, τ = 3.5 mm and R = 25 mm. In order to test our theoretical formulation for external loading; a test was conducted where the HELM was loaded by an external force at its tip, while simultaneously increasing internal pressure.

Let us define the relative angle of each joint to the x-axis as:

The angle at the tip of the HELM

B6 (accumulated by the six equal hinges) was recorded along with the external load

F, its angle of application

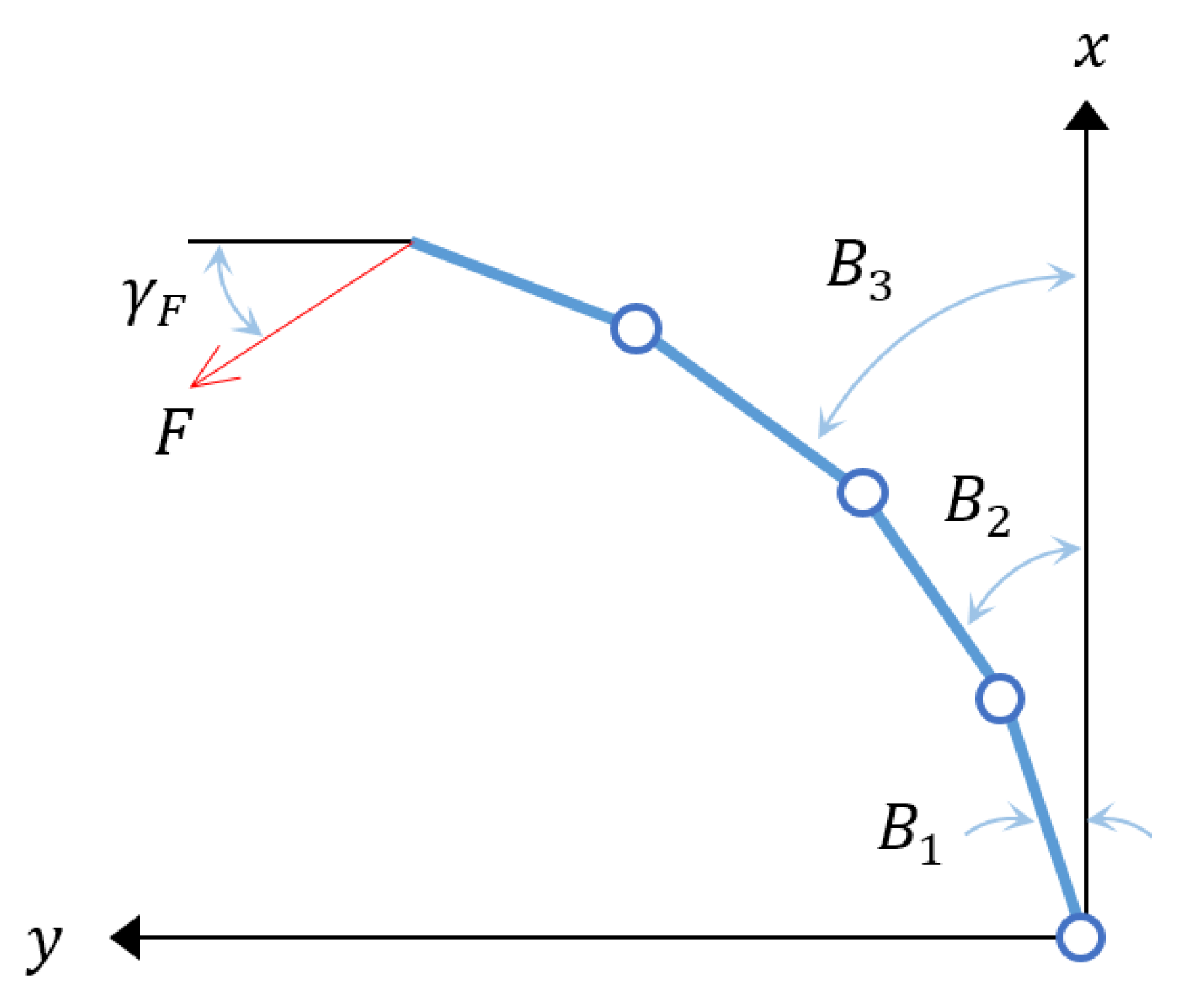

γF and internal pressure (See

Figure 7 for a schematic representation).

Figure 7.

Schematic representation of the kinematics of the external loading experiment.

Figure 7.

Schematic representation of the kinematics of the external loading experiment.

Applying a pressure and moment, we can express the total stress in each hinge (which is uniform in the whole membrane of the hinge), from Equations (5), (7), and (10):

Then, we can find the strain by the experimental stress-strain curve, and, from Equation (5), obtain the angle of bending of each hinge along the HELM.

In order to retroactively compute the moment applied about each hinge by the external load, we must furnish the location of each joint relative to the tip. Let

ln denote the distance between adjacent joints. Assuming the HELM is rigid between hinges, the location (x, y) of each hinge is:

Experimental angles were compared with nonlinear theory, using the experimental stress-strain curve of the hinge material. Knowing the external moment about each joint, the stress applied to the hinge membrane can be found using the tension–moment relation in Equation (10) and pressure stress at Equation (7). The corresponding strain was interpolated from the experimental stress-stain curve (

Figure 3) and finally the rotation angle was calculated by Equation (5).

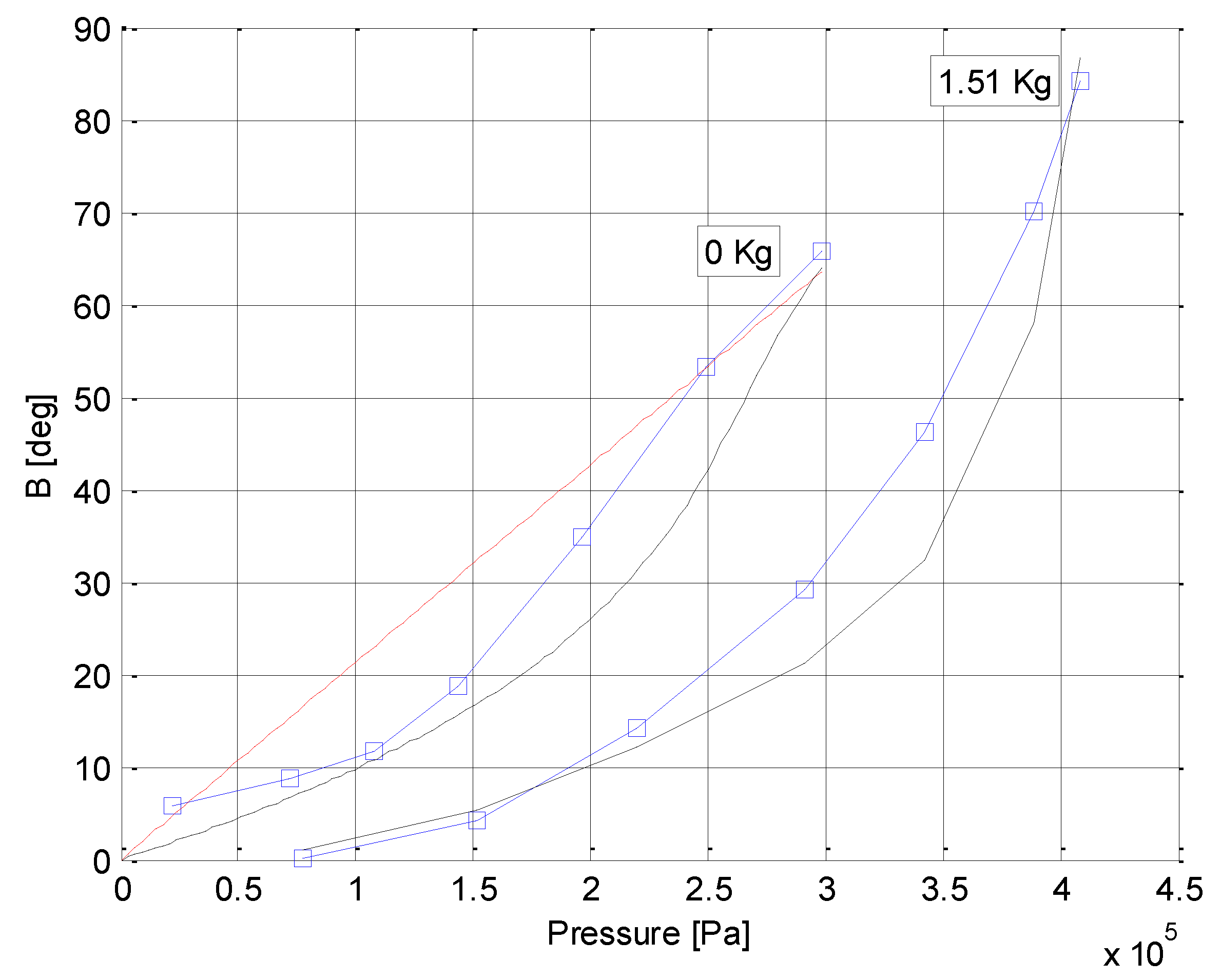

Figure 8 presents the static response for HELM prototype 3, with and without external load. For the case with no external load, comparison with linear theory by Equation (11) is also presented.

Figure 8.

Static response for HELM prototype 3, with and without external loading. The red line presents linear theory with E = 1.709 MPa. The black curve presents nonlinear analysis, while blue squares mark the experiment.

Figure 8.

Static response for HELM prototype 3, with and without external loading. The red line presents linear theory with E = 1.709 MPa. The black curve presents nonlinear analysis, while blue squares mark the experiment.

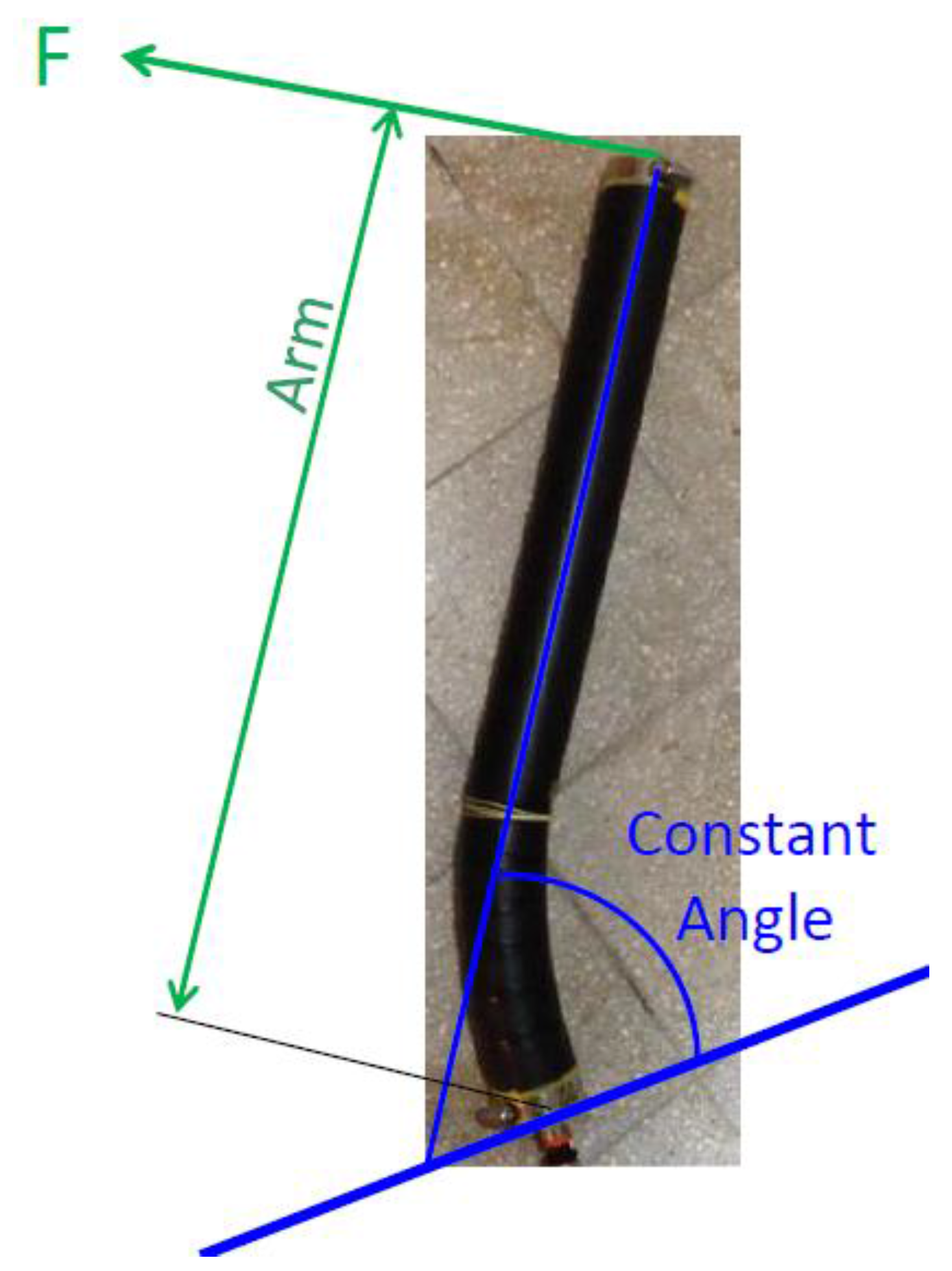

For more complete characterization of this prototype, a series of blocked moment experiments were conducted. In each experiment, the angle of the HELM was held constant using a cable with a force gage connected to the tip of the actuator. The cable was perpendicular to the last long section of the HELM. For each constant angle, the pressure was applied in steps and the force and arm where measured to yield the moment about the root of the HELM (see

Figure 9). This process was repeated for a few angles.

Figure 9.

Blocked moment Experiment.

Figure 9.

Blocked moment Experiment.

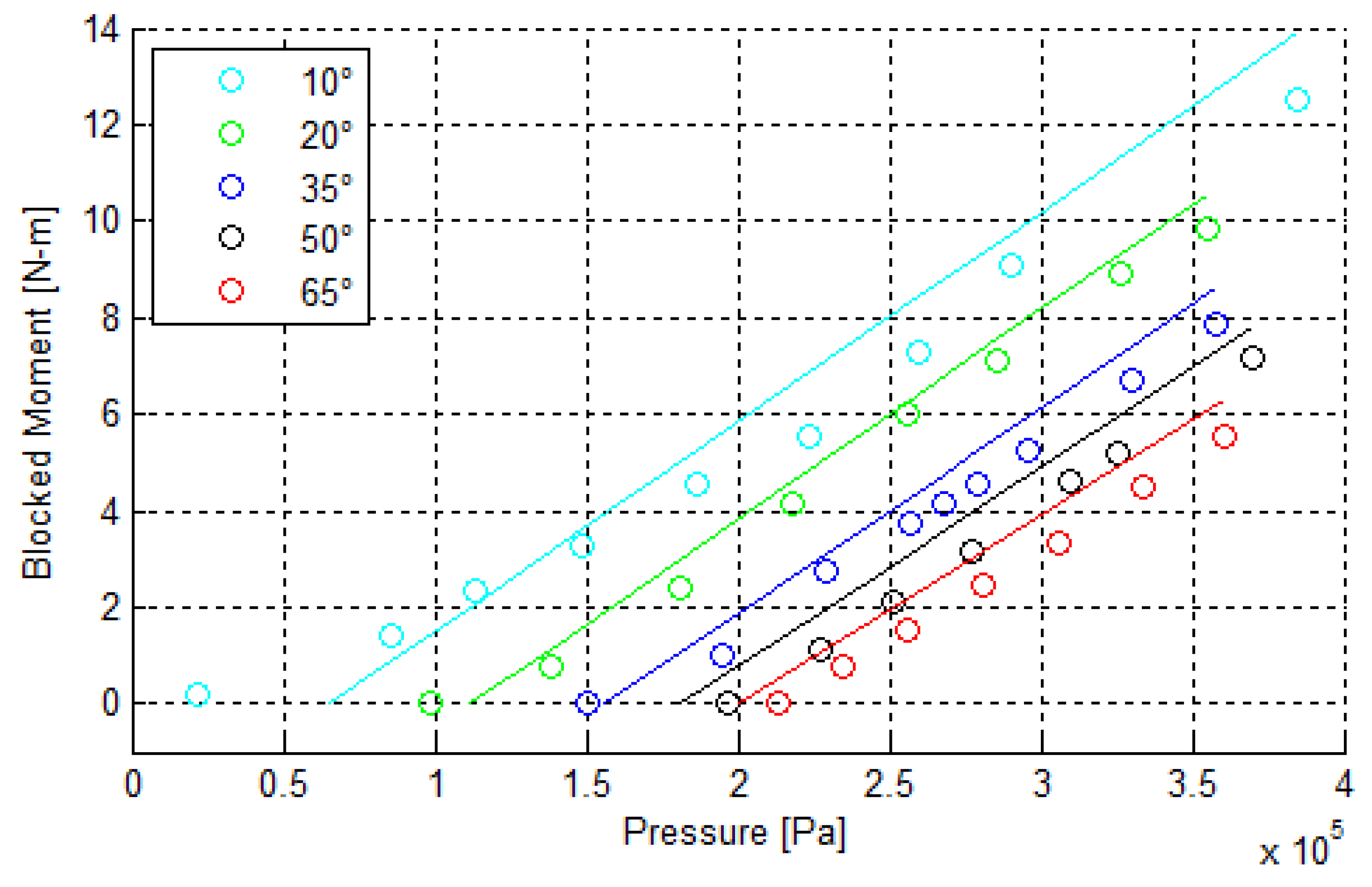

Figure 10 presents the measurements compared with theory.

Figure 10.

Blocked moment versus pressure, for prototype 3 of the HELM at different angles. Circles present experimental measurements, while lines present theoretical results.

Figure 10.

Blocked moment versus pressure, for prototype 3 of the HELM at different angles. Circles present experimental measurements, while lines present theoretical results.