Armature Structure Optimization of Annular Multipole Solenoid Valves Based on Electromagnetic Force Distribution

Abstract

1. Introduction

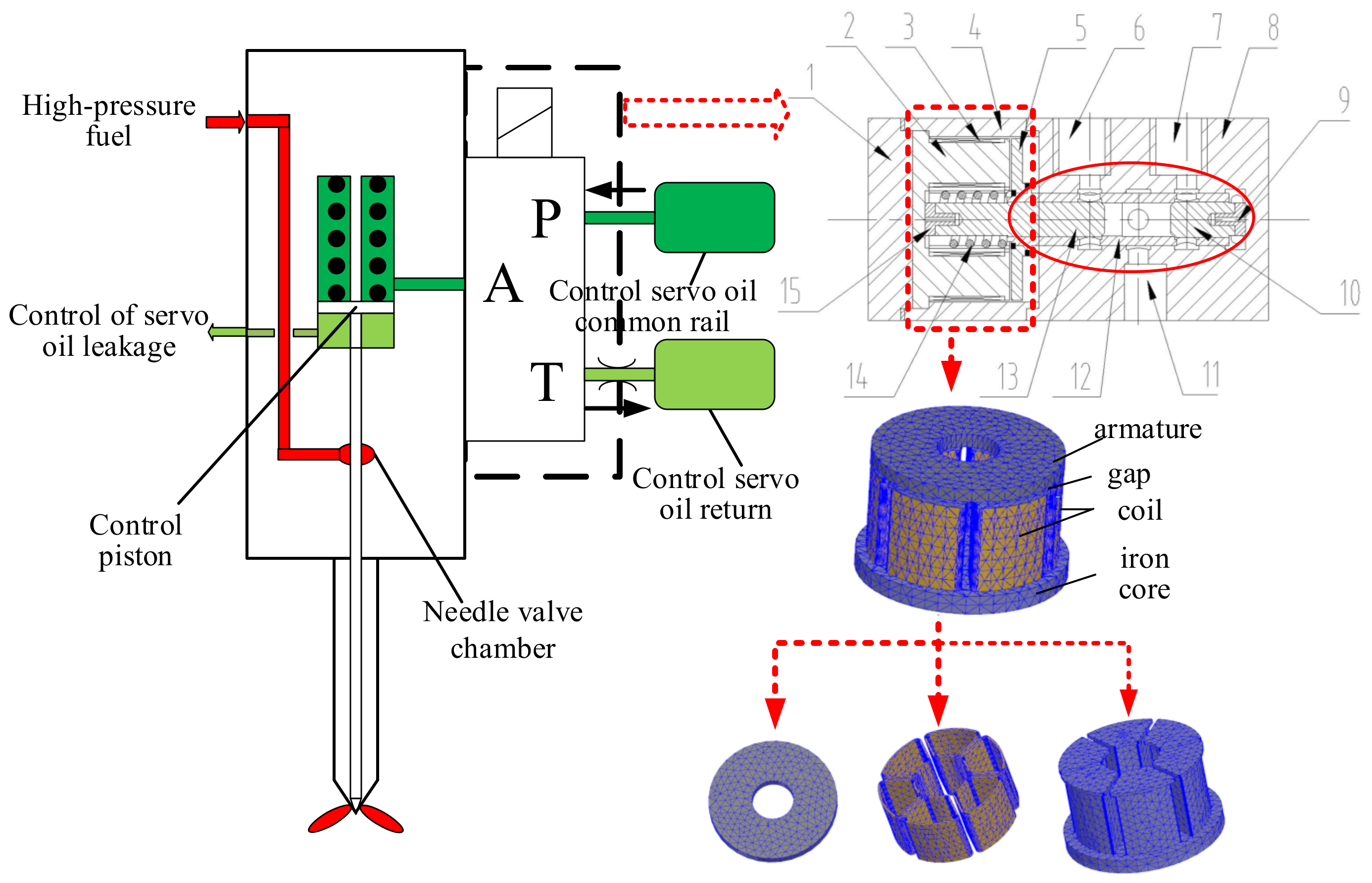

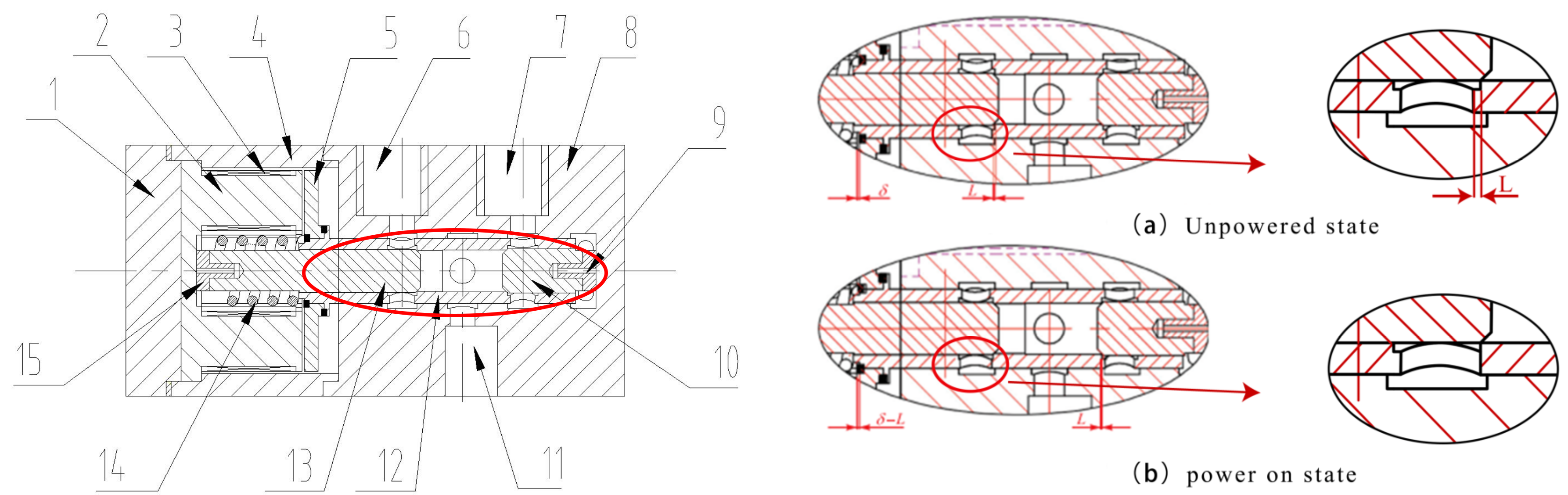

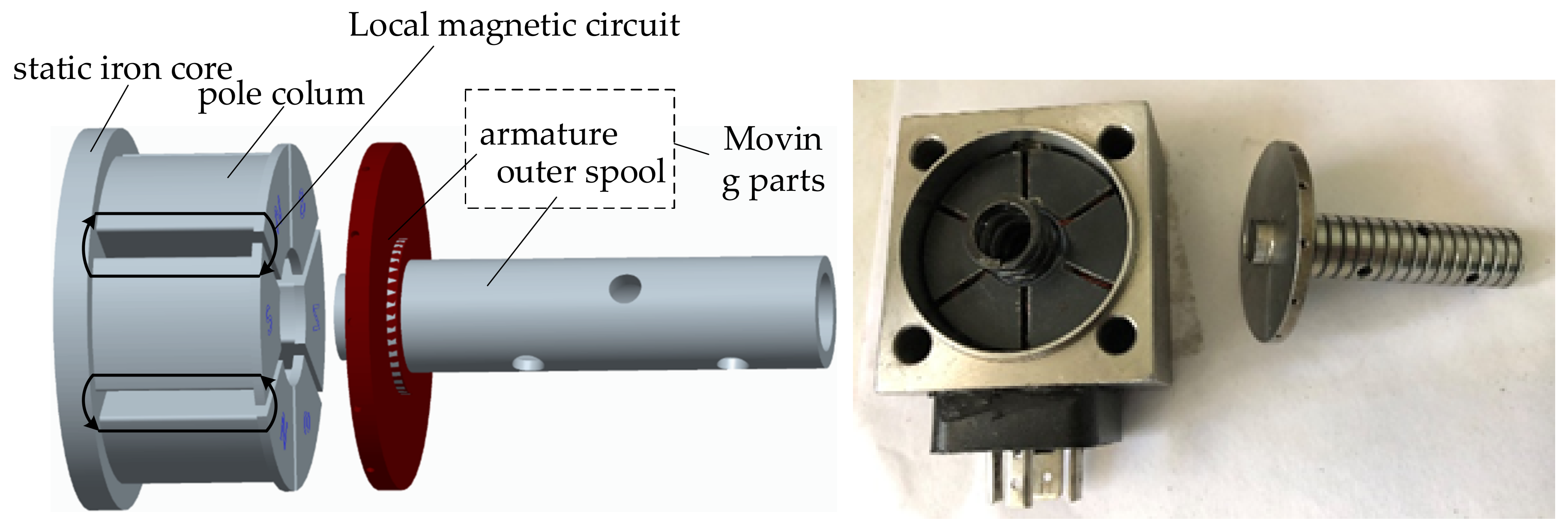

2. Structure and Principle of AMPSV and Test Bench

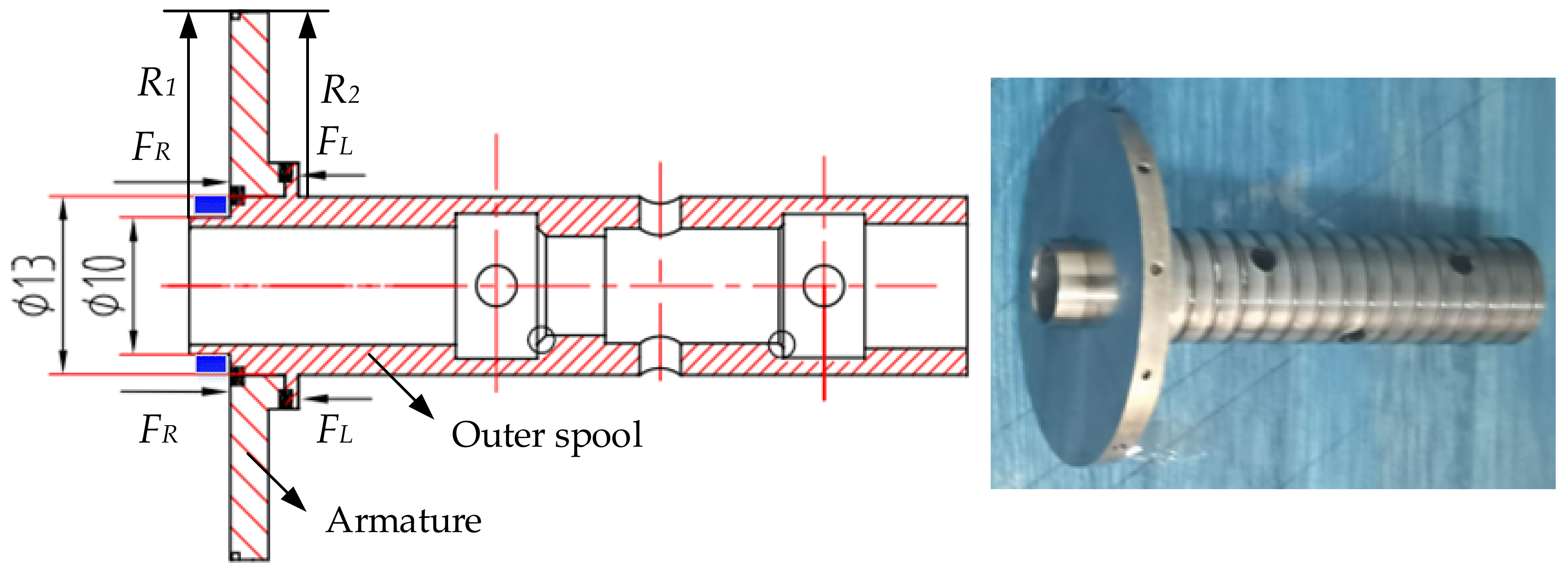

2.1. Structure and Principle of AMPSV

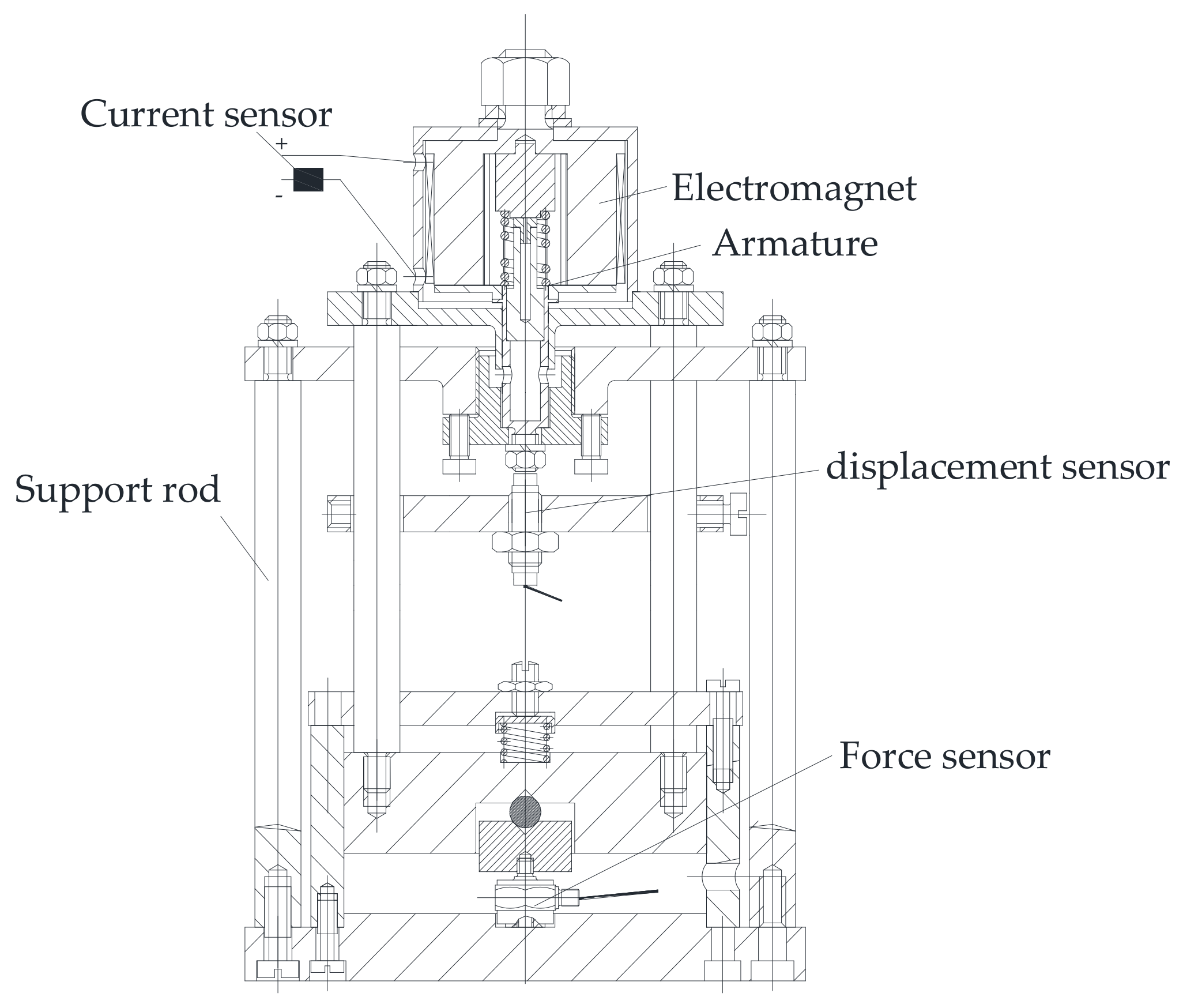

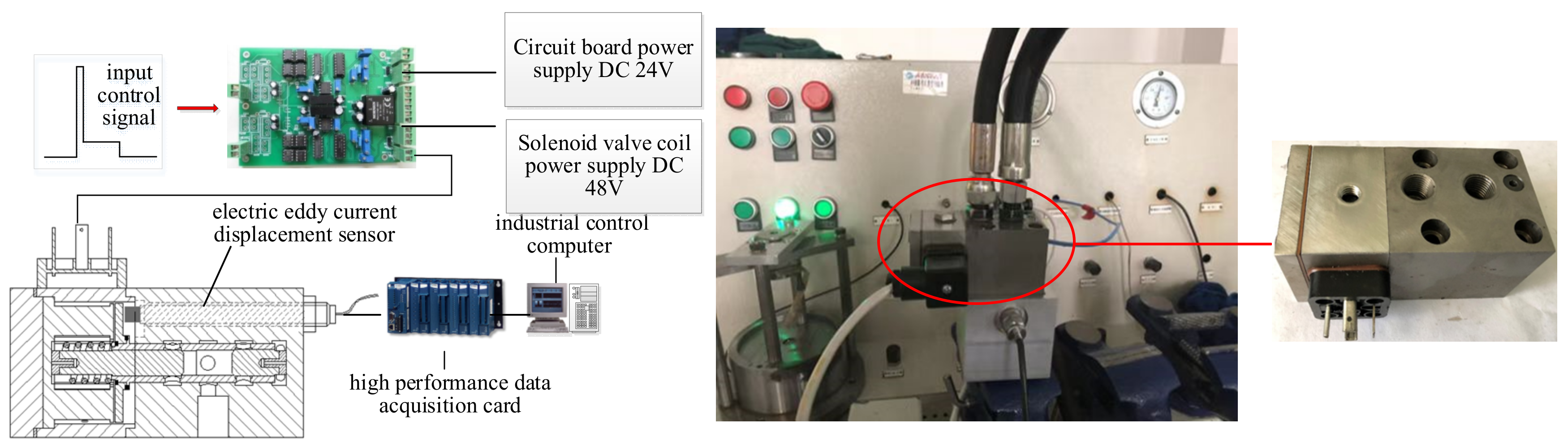

2.2. Test Bench

2.2.1. Static Electromagnetic Force Testing Device

- ➀

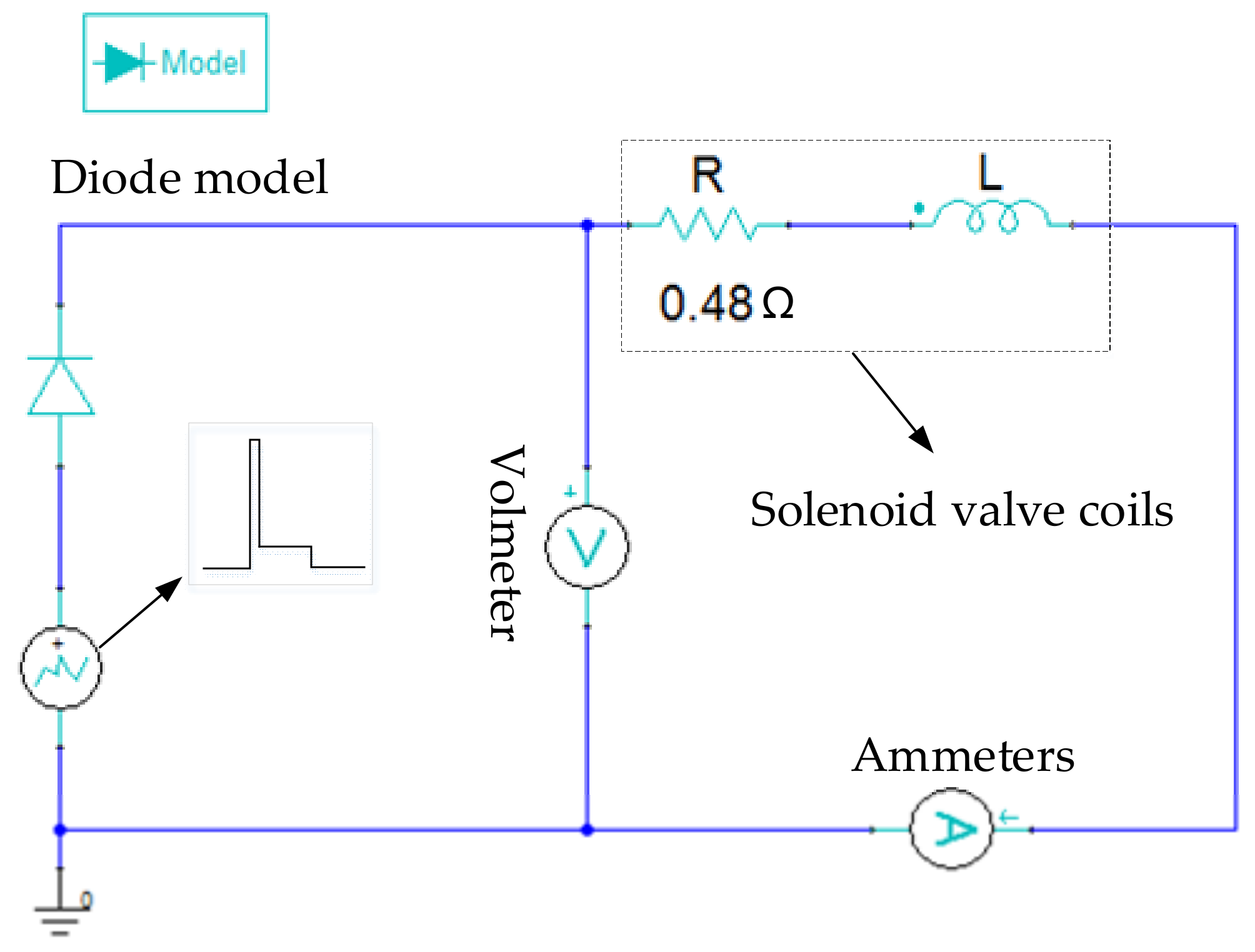

- Testing principle of excitation current

- ➁

- The principle of the armature displacement test

- ➂

- Static electromagnetic force test principle

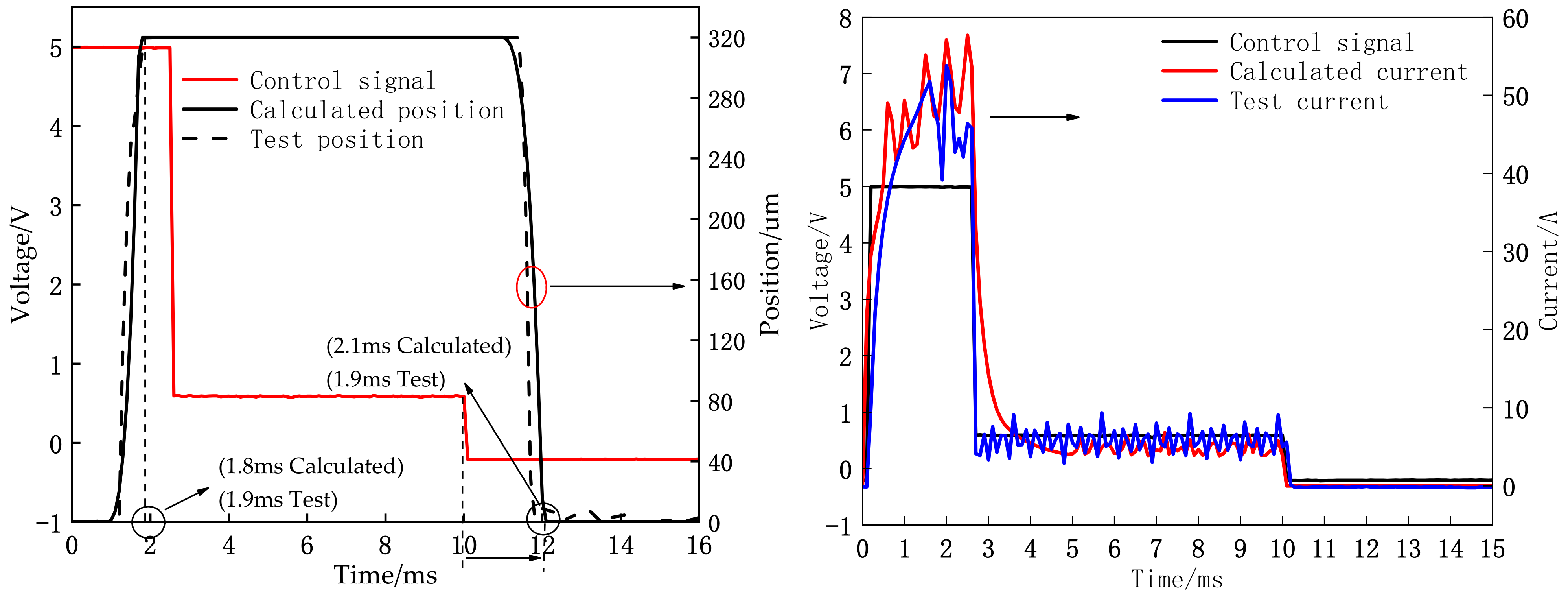

2.2.2. Solenoid Valve Dynamic Characteristics Test Bench

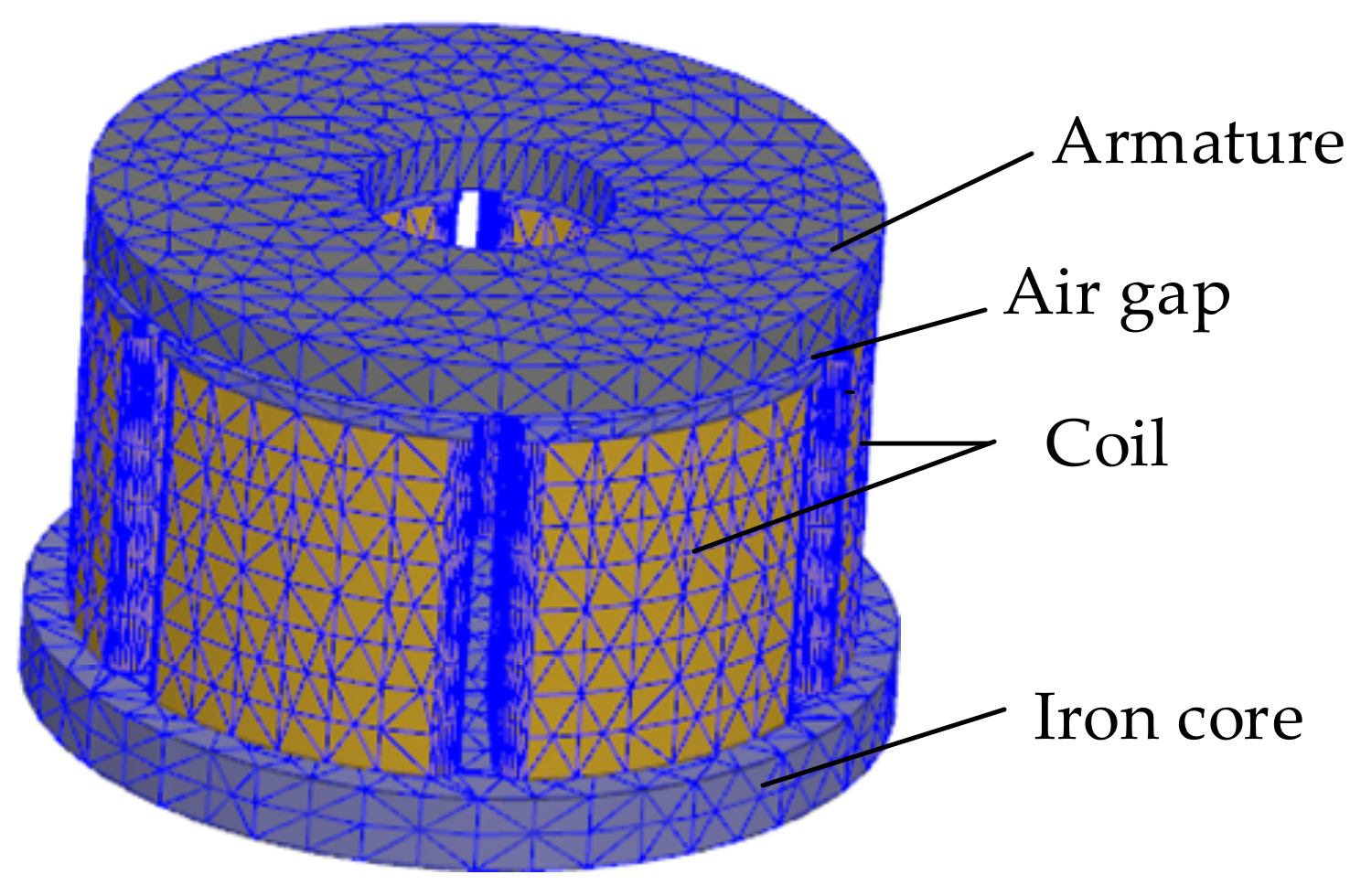

3. Finite Element Model and Validation

3.1. Mathematical Model

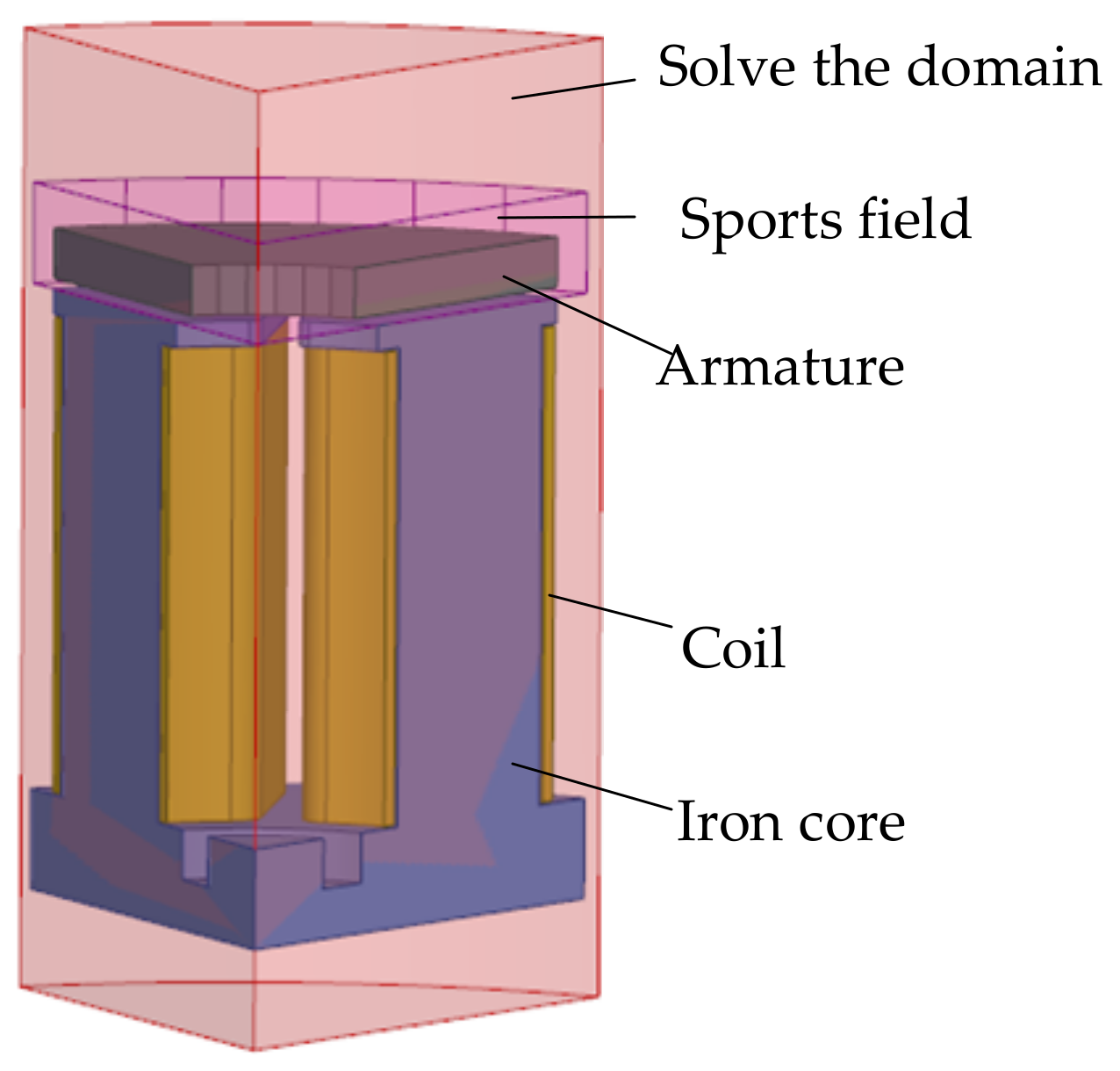

3.2. Finite Element Model and Basic Settings

3.2.1. Define the Material Properties and Movement Settings

3.2.2. Boundary Conditions, Incentive Source, Grid Section and Solution Setting

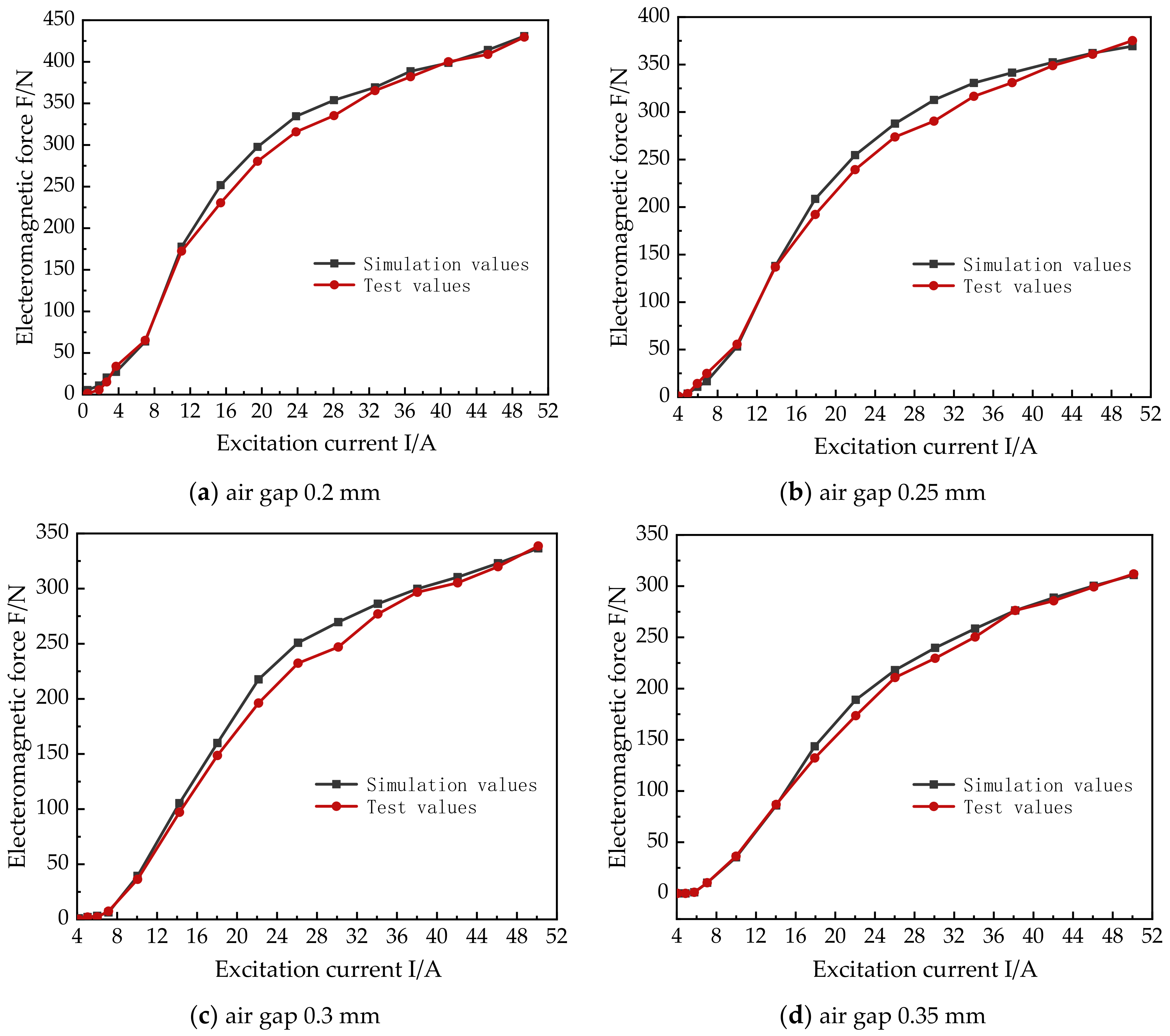

3.3. Model Test Validation

4. Effect of Armature Punching on Dynamic Response of Solenoid Valve and Electromagnetic Force

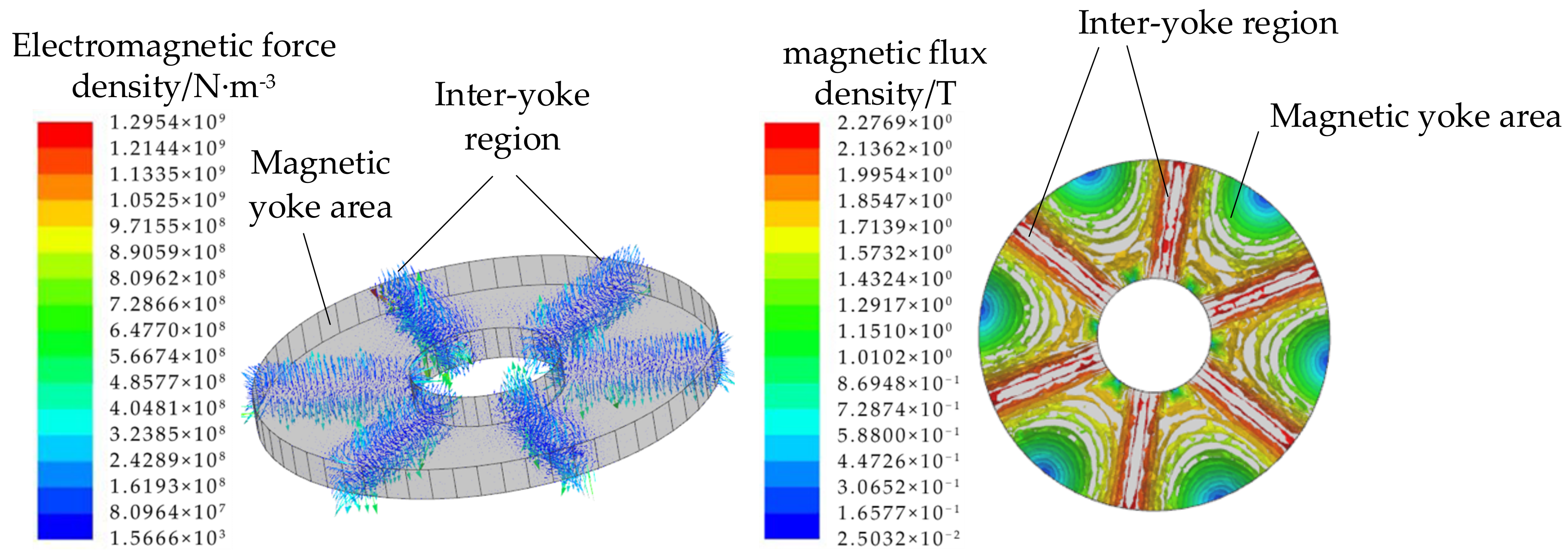

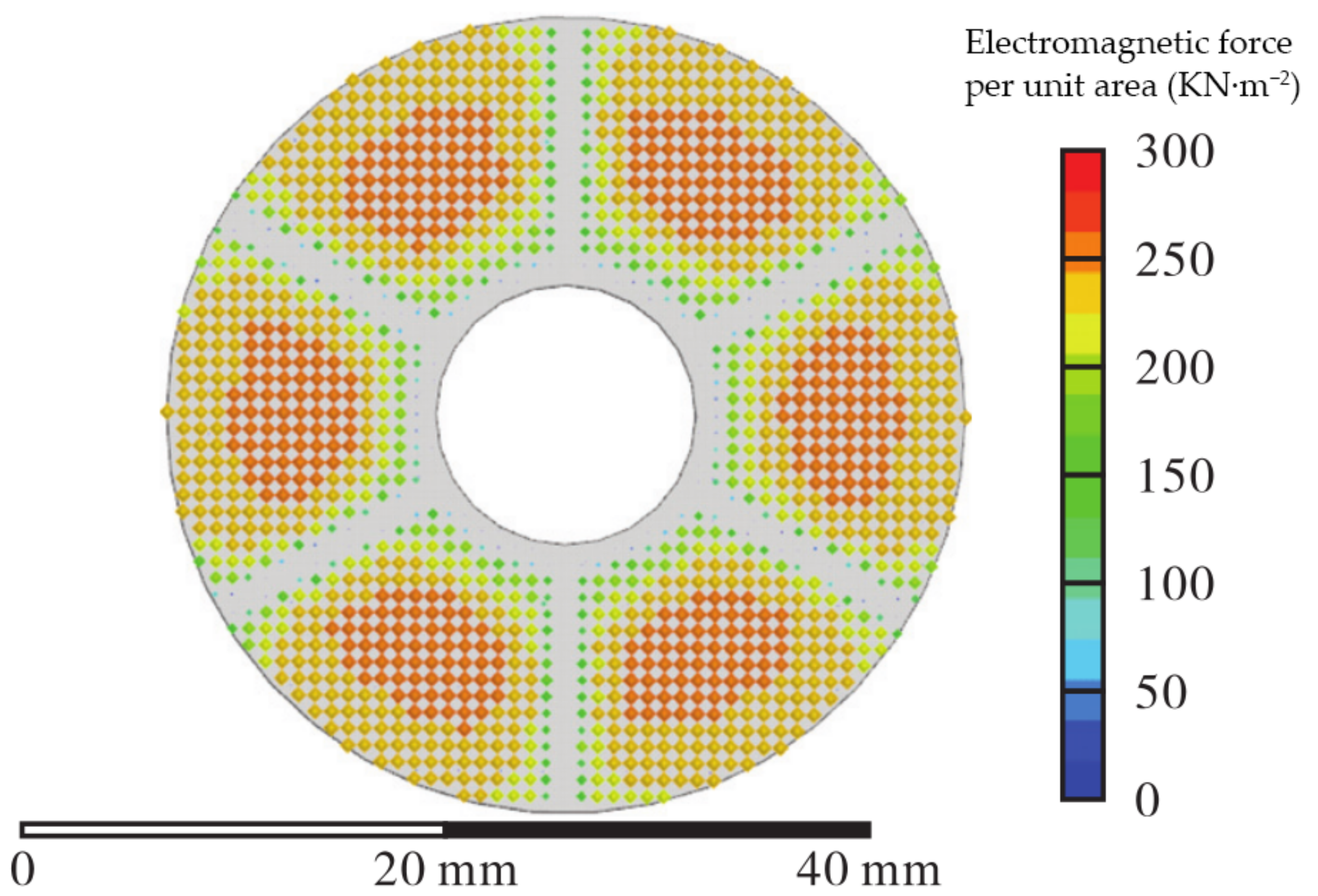

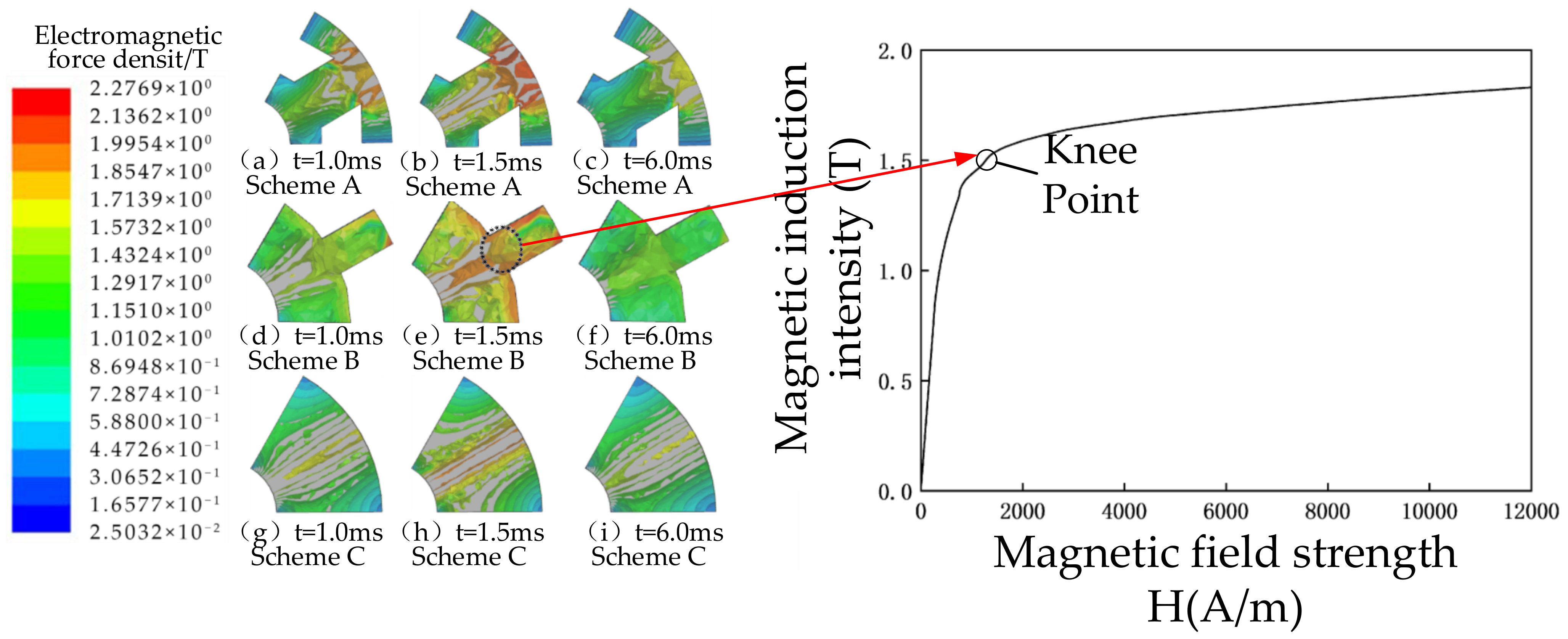

4.1. Explore the Distribution Law of Armature and Electromagnetic Force

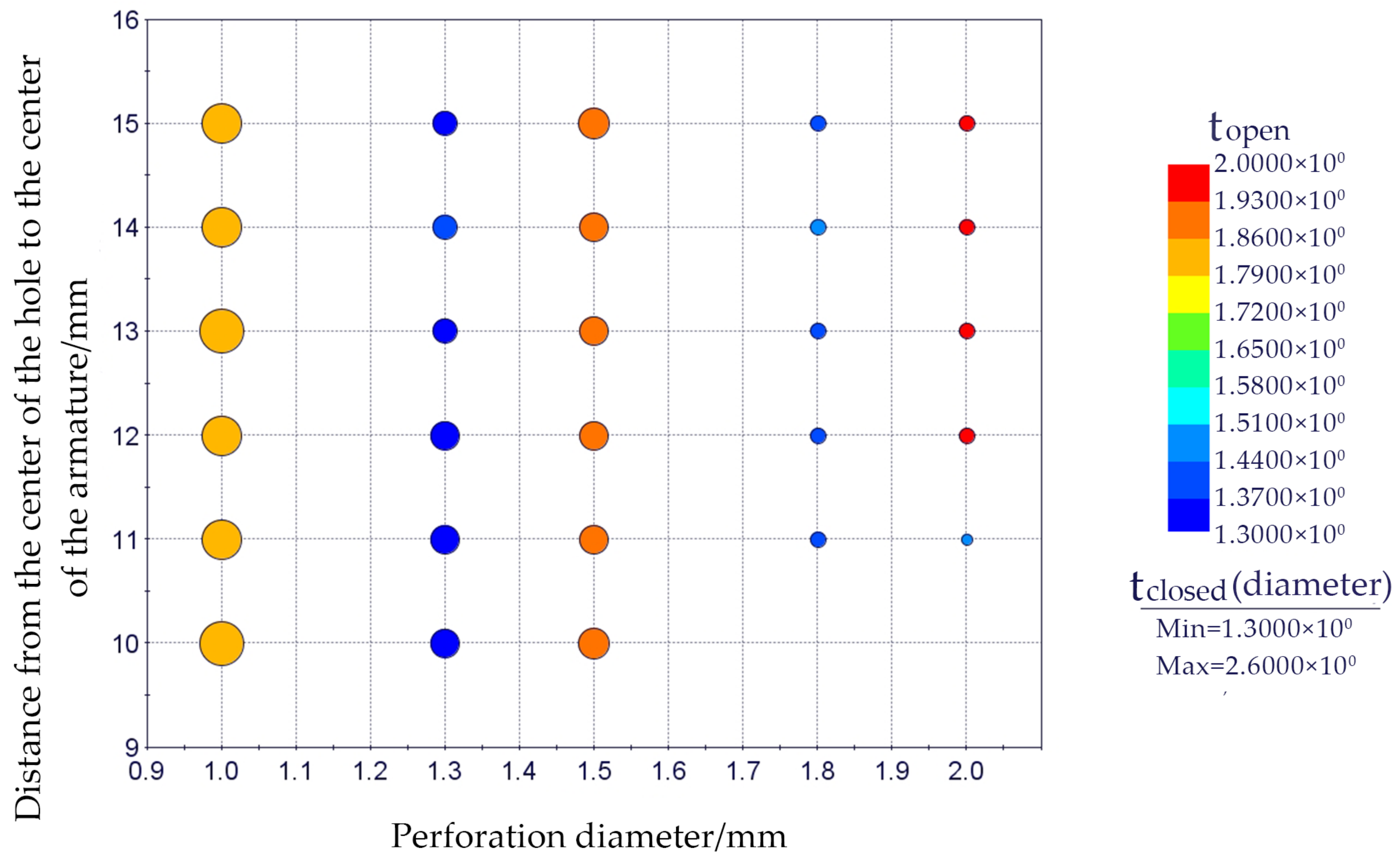

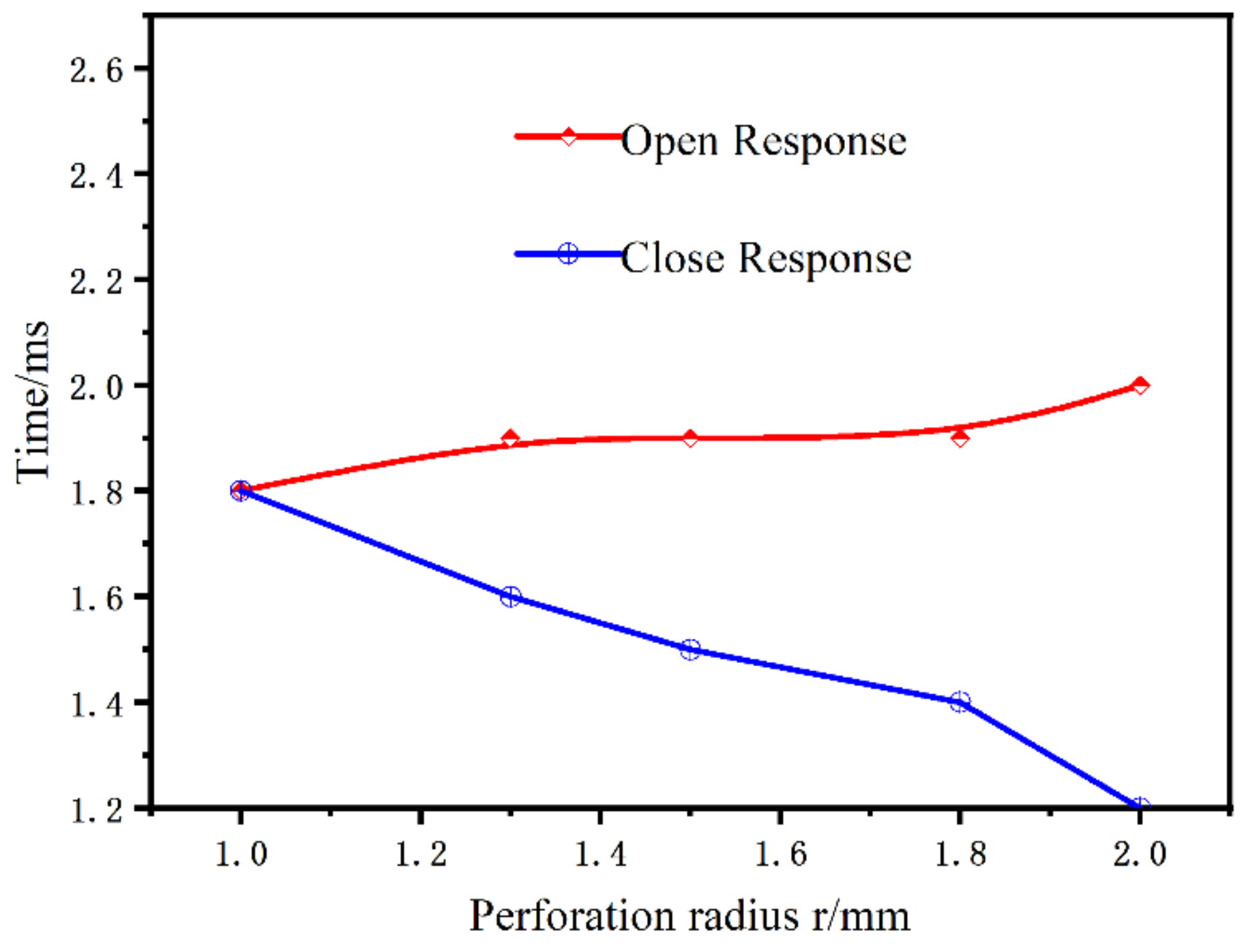

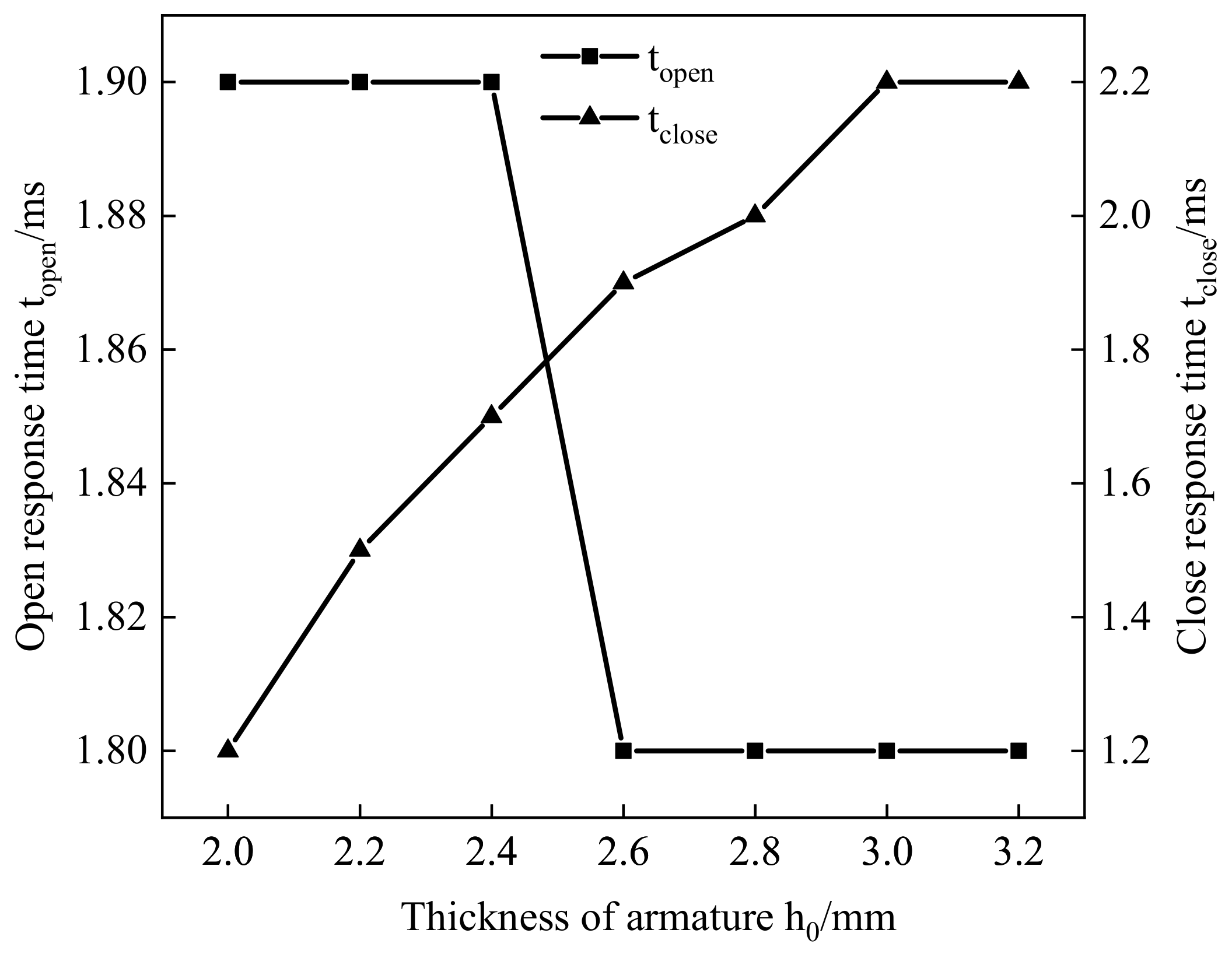

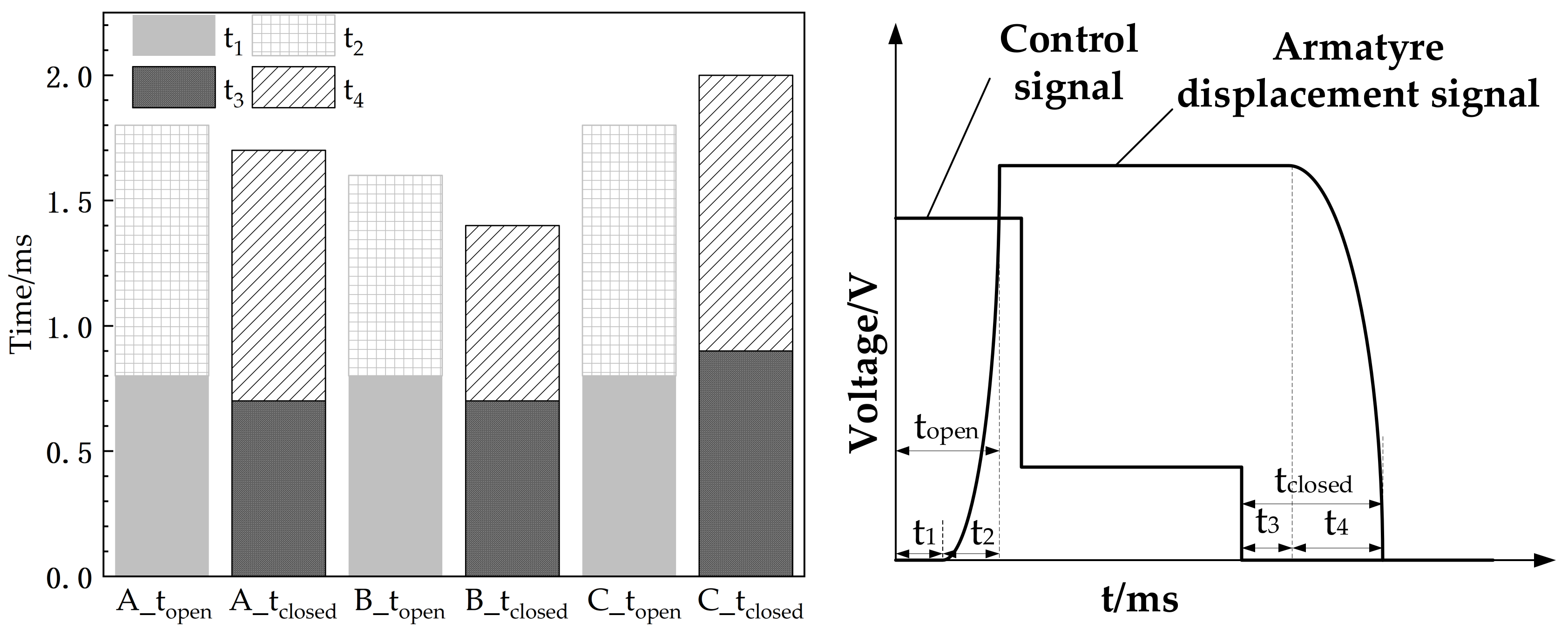

4.2. Effect of Armature Punching on the Response Time of the Solenoid Valve

5. Armature Design Scheme and Optimization

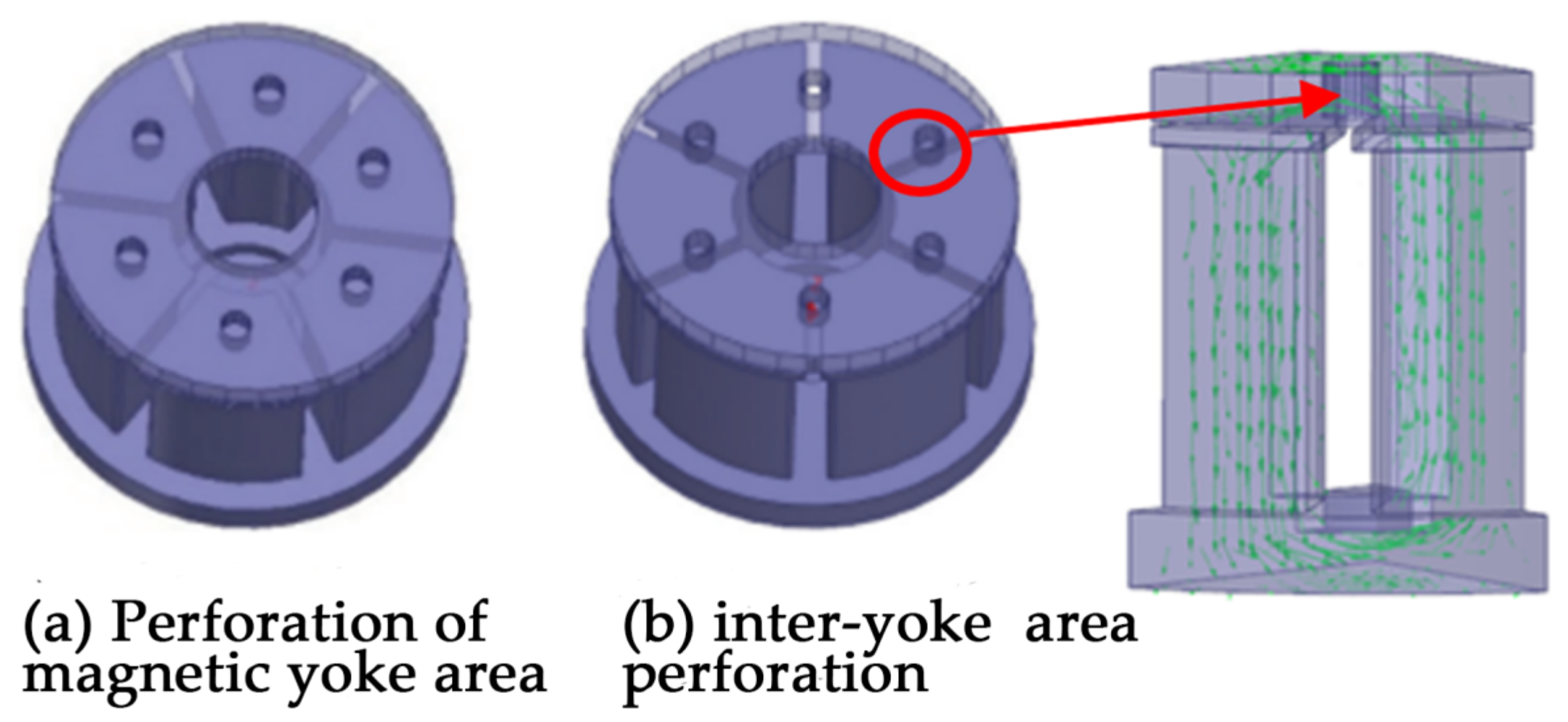

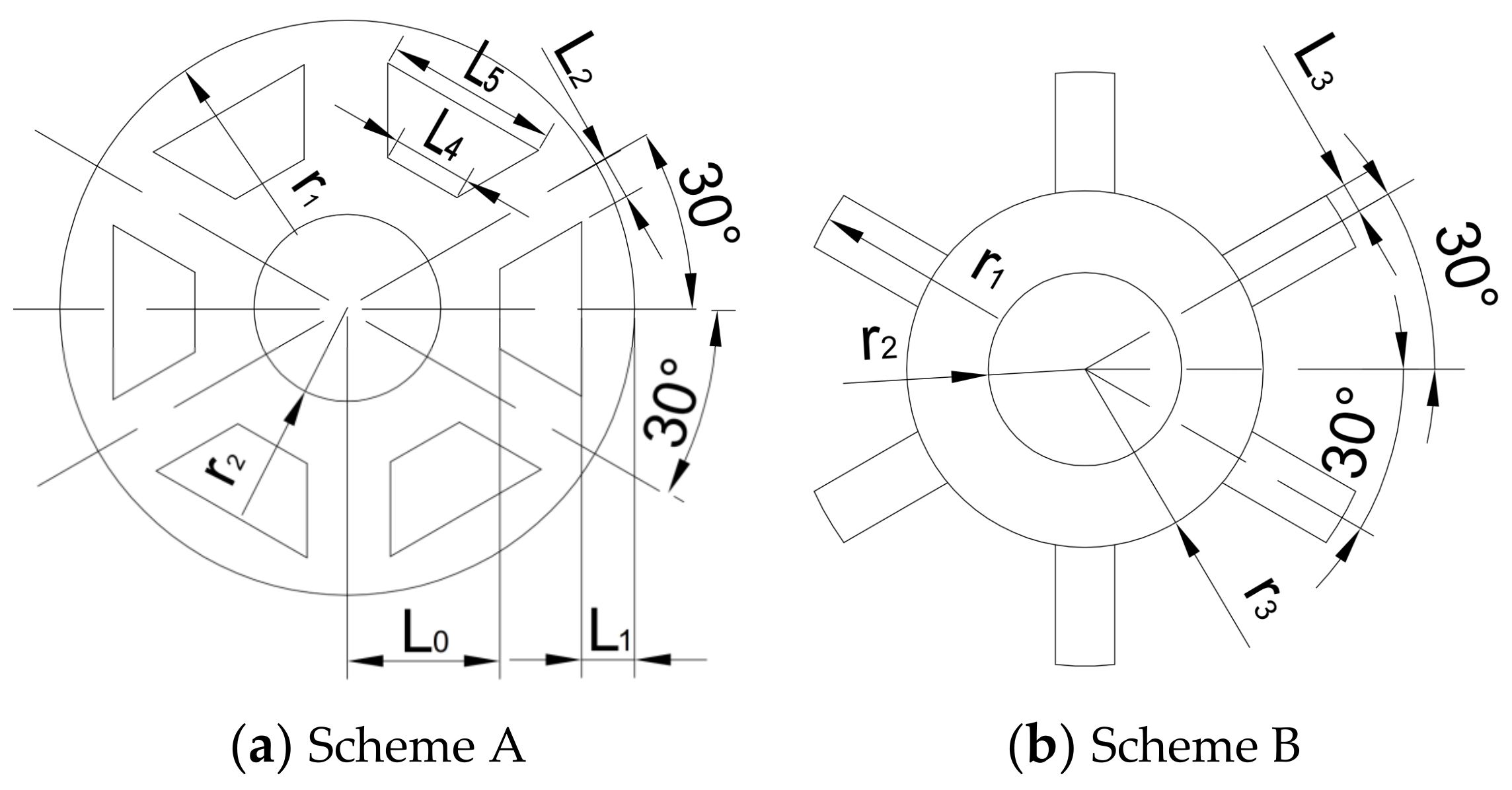

5.1. Armature Design Scheme

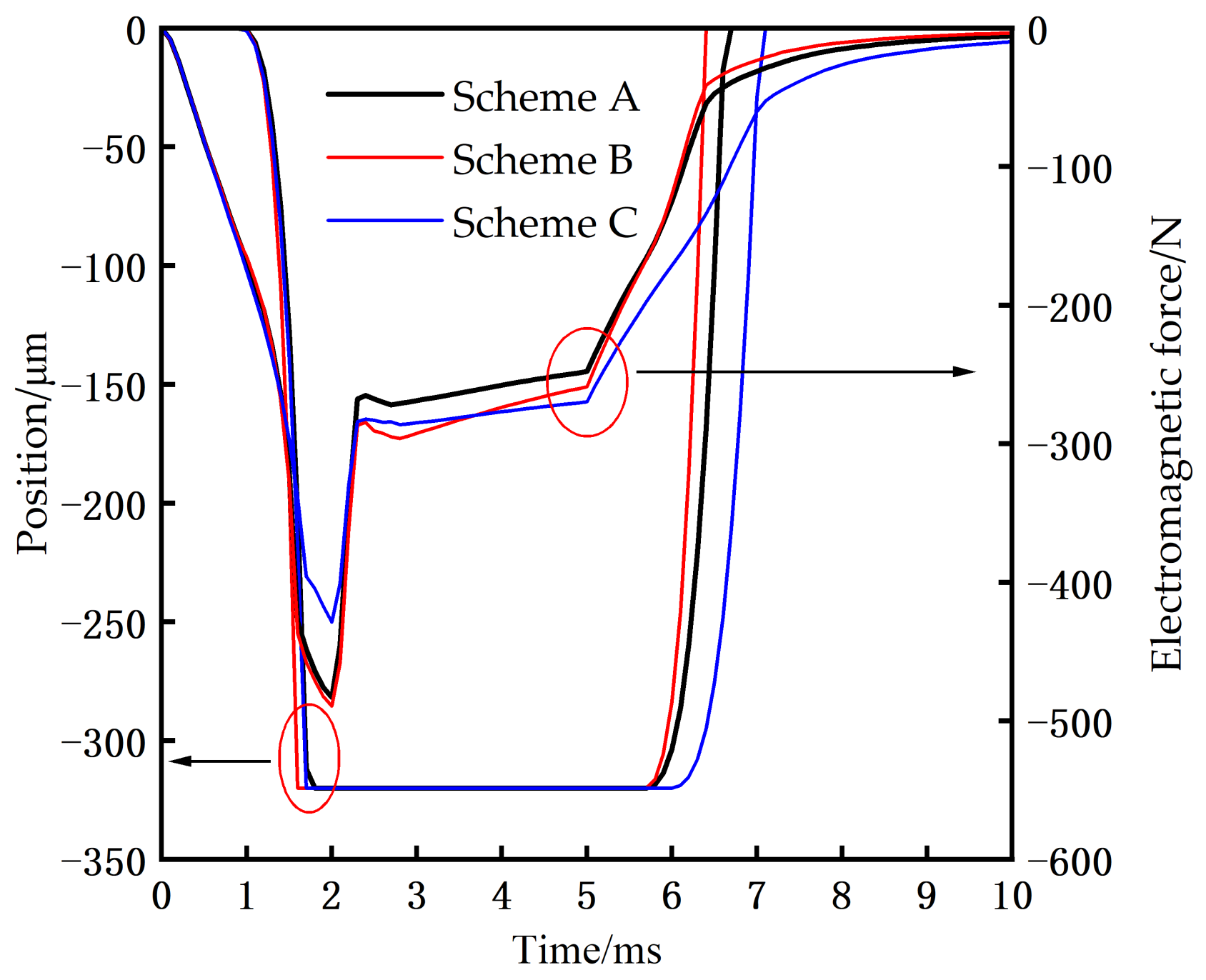

5.2. Comparison of the Two Slotting Schemes and the Armature Structure Optimization

6. Analysis and Discussion

7. Conclusions

- (1)

- The circular multipole column solenoid is present during the armature’s motion; the distribution of magnetic density and magnetic force shows a dense distribution in the inter-yoke area and a sparse distribution in the magnetic yoke region.

- (2)

- Punching in the armature yoke zone has basically no effect on the dynamic response of the solenoid valve.

- (3)

- Whether it is punched in the magnetic yoke area or the inter-yoke area, with a certain punching radius, the distance between the hole center and the armature center has less impact on the response of the solenoid valve.

- (4)

- When punching in the inter-yoke yoke area, the punching aperture has a large impact on the dynamic response of the solenoid valve. With the increase in the punching diameter, the response time of the solenoid valve opening increases, but its increase is not large. The closing response time is shortened, and the shortening range is large. Without changing the circuit and other structural parameters, Solution B is better than solution A.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| F | The combined force on the moving parts (N) | r0 | Perforation radius (mm) |

| Fs | Resetting spring force of the resetting spring (N) | r1, r2 | Radius of outer and inner circle of armature (mm) |

| Fm | Electromagnetic suction force (N) | r3 | Radius of the outer circle of the ring after slotting of the armature (mm) |

| Ff | Friction force on the outer spool (N) | Rm | Magnetic circuit reluctance (A/Wb) |

| F1 | Hydraulic pressure on the moving parts (N) | Rδ | Air gap reluctance (A/Wb) |

| FL, FR | Hydraulic pressure on the left and right sides of the moving parts (N) | S | Magnetic circuit cross-sectional area (mm2) |

| SL | Hydraulic pressure area on the left side of the moving parts (mm2) | SR | Hydraulic pressure area on the right sides of the moving parts (mm2) |

| k | Damping factor (N/(m·s−1)) | S1 | Cross-sectional area of 6 trapezoidal slots (mm2) |

| v | Instantaneous speed of the moving parts of the solenoid valve (mm/s) | S0, SA | Cross-sectional area of armature before and after slotting (mm2) |

| h0 | Distance of the centre of the hole from the centre of the armature (mm) | w | Mass fraction reduced by moving parts after perforation (%) |

| I | Coil current (A) | Φ | Magnetic flux of magnetic circuit (Wb) |

| L | Maximum displacement of armature movement (mm) | μ0 | Air Magnetic Permeability (H/m) |

| l | Length of magnetic circuit (mm) | μ1 | Magnetic permeability of vacuum (H/m) |

| L3, L4 | Length of the upper and lower bottom of the trapezoidal slot (mm) | μ | Absolute permeability of DT4C material |

| N | Number of turns of coil | ρ | Density of armature material (g·mm−3) |

| AMPSV | annular multi-pole solenoid valve | F5ms | The magnitude of the electromagnetic force at the moment the control signal is turned off (N) |

| topen | Open response time (ms) | tclosed | Close response time (ms) |

References

- Li, H.; Shi, L.; Deng, K. Development of turbocharging system for diesel engines of power generation application at different altitudes. J. Energy Inst. 2016, 89, 755–765. [Google Scholar] [CrossRef]

- Han, Y.; Zhang, L.; Tian, J. Investigation of transient deterioration mechanism and improved method for turbocharged diesel engine. Energy 2016, 116 Pt 1, 250–264. [Google Scholar] [CrossRef]

- Park, J.; Choi, J. Optimization of dual-loop exhaust gas recirculation splitting for a light-duty diesel engine with model-based control. Appl. Energy 2016, 181, 268–277. [Google Scholar] [CrossRef]

- Thangaraja, J.; Kannan, C. Effect of exhaust gas recirculation on advanced diesel combustion and alternate fuels—A review. Appl. Energy 2016, 180, 169–184. [Google Scholar] [CrossRef]

- Park, S.W. Optimization of combustion chamber geometry for stoichiometric diesel combustion using a micro genetic algorithm. Fuel Process. Technol. 2010, 91, 1742–1752. [Google Scholar] [CrossRef]

- Prasad, B.V.V.S.; Sharma, C.S.; Ravikrishna, R.V. High swirl-inducing piston bowls in small diesel engines for emission reduction. Appl. Energy 2011, 88, 2355–2367. [Google Scholar] [CrossRef]

- Su, L.; Li, X.; Liu, F. Numerical analysis on the combustion and emission characteristics of forced swirl combustion system for DI diesel engines. Energy Convers. Manag. 2014, 86, 20–27. [Google Scholar] [CrossRef]

- Zehni, A.; Saray, R.K.; Poorghasemi, K. Numerical comparison of PCCI combustion and emission of diesel and biodiesel fuels at low load conditions using 3D CFD models coupled with chemical kinetics. Appl. Therm. Eng. 2017, 110, 1483–1499. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, H.; Reitz, R.D. Homogeneous charge compression ignition (HCCI) combustion of Polyoxy methylene dimethyl ethers (PODE). Fuel 2016, 183, 206–213. [Google Scholar] [CrossRef]

- Reitz, R.D.; Duraisamy, G. Review of high efficiency and clean Reactivity controlled compression ignition (RCCI) combustion in internal combustion engines. Prog. Energy Combust. Sci. 2015, 46, 12–71. [Google Scholar] [CrossRef]

- Woo, C.; Kook, S.; Hawkes, E.R. Effect of intake air temperature and common-rail pressure on ethanol combustion in a single-cylinder light-duty diesel engine. Fuel 2016, 180, 9–19. [Google Scholar] [CrossRef]

- Qiu, T.; Dai, H.; Li, X. Optimising the cam profile of an electronic unit pump for a heavy-duty diesel engine. Energy 2015, 83, 276–283. [Google Scholar] [CrossRef]

- Chen, P.; Wang, J. Air-fraction modeling for simultaneous Diesel engine NOx and PM emissions control during active DPF regenerations. Appl. Energy 2014, 122, 310–320. [Google Scholar] [CrossRef]

- Maiti, R.; Saha, R.; Watton, J. The static and dynamic characteristics of a pressure relief valve with a proportional solenoid-controlled pilot stage. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2002, 216, 143–156. [Google Scholar] [CrossRef]

- Tao, G.; Chen, H.Y.; He, Z.B. Optimal design of the magnetic field of a high-speed response solenoid valve. J. Mater. Process. Technol. 2002, 129, 555–558. [Google Scholar] [CrossRef]

- Topçu, E.E.; Yüksel, İ.; Kamış, Z. Development of electro-pneumatic fast switching valve and investigation of its characteristics. Mechatronics 2006, 16, 365–378. [Google Scholar] [CrossRef]

- Nitu, S.; Nitu, C.; Dumitrescu, G. Electromagnetic actuator with magnetic stored energy. J. Mater. Process. Technol. 2007, 181, 153–158. [Google Scholar] [CrossRef]

- Angadi, S.V.; Jackson, R.L.; Ham, J.K. Reliability and life study of hydraulic solenoid valve. Part 1: A multi-physics finite element model. Eng. Fail. Anal. 2009, 16, 874–887. [Google Scholar] [CrossRef]

- Angadi, S.V.; Jackson, R.L.; Bae, J. Reliability and life study of hydraulic solenoid valve. Part 2: Experimental study. Eng. Fail. Anal. 2009, 16, 944–963. [Google Scholar] [CrossRef]

- Liu, Q.; Bo, H.; Qin, B. Experimental study and numerical analysis on electromagnetic force of direct action solenoid valve. Nucl. Eng. Des. 2010, 240, 4031–4036. [Google Scholar] [CrossRef]

- Liu, Q.; Bo, H.; Qin, B. Design and analysis of direct action solenoid valve based on computational intelligence. Nucl. Eng. Des. 2010, 240, 28902896. [Google Scholar] [CrossRef]

- Liu, Q.; Bo, H.; Qin, B. Optimization of direct action solenoid valve based on CloudPSO. Ann. Nucl. Energy 2013, 53, 299–308. [Google Scholar] [CrossRef]

- Wang, L.; Li, G.; Sun, S. Effect of characteristic parameters on the magnetic properties of solenoid valve for high pressure common rail diesel engine. Energy Convers. Manag. 2016, 127, 656–666. [Google Scholar] [CrossRef]

- Sun, Z.; Li, G.; Wang, J. Effects of structure parameters on the static electromagnetic characteristics of solenoid valve for an electronic unit pump. Energy Convers. Manag. 2016, 113, 119–130. [Google Scholar] [CrossRef]

- Gao, H.; Fu, X.; Yang, H.; Tsukiji, T. Numerical and experimental investigation of cavitating flow in oil hydraulic ball valve. In Proceedings of the JFPS International Symposium on Fluid Power 2002; The Japan Fluid Power System Society: Tokyo, Japan, 2002; Volume 2002, pp. 923–928. [Google Scholar]

- Xia, S.H.; Zheng, J.B.; Hou, X.J. Cavitation analysis on ball valve in solenoid injector. Neiranji Xuebao/Trans. CSICE (Chin. Soc. Intern. Combust. Engines) 2012, 30, 354–358. [Google Scholar]

- Qiu, T.; Lei, Y.; Li, B. Flow characteristics of solenoid control valve during fuel stopping process for the unit pump. Neiranji Xuebao/Trans. CSICE (Chin. Soc. Intern. Combust. Engines) 2013, 31, 367–372. [Google Scholar]

- Qiu, T.; Dai, H.; Lai, M.C. Dynamic flow behavior during fuel-offloaded process in control valve for unit pump fuel system. Appl. Therm. Eng. 2016, 106, 153–160. [Google Scholar] [CrossRef]

- He, Y.H.; Yang, J.G.; Yu, Y.H.; Li, M.; Liu, C.Y.; Fan, Y.; Gao, J. High Speed High Flow Self–Reset Solenoid Valve. CN 2014101111355, 29 June 2016. [Google Scholar]

| Sensor Name | Sensor Type | Measurement Range | Sensitivity | Precision (%) | Output Voltage (V) |

|---|---|---|---|---|---|

| Current Sensor | Hall magnetic balance type | 0~100 A | 0.1 V/A | 0.1 | 0~10 |

| Displacement Sensors | Eddy current type | 0.36~1.36 mm | 8.99 V/mm | 0.1 | 0~10 |

| Force Sensor | Piezoelectric type | 0~5.00 KN | 3.57 PC/N | 0.09 | 0~10 |

| r0/mm | ho/mm | w/% | topen/ms | tclosed/ms |

|---|---|---|---|---|

| 0.0 | 12.0 | 0.00 | 1.7 | 2.1 |

| 1.0 | 10.0 | 0.89 | 1.8 | 2.1 |

| 1.0 | 12.0 | 0.89 | 1.8 | 2.1 |

| 1.0 | 14.0 | 0.89 | 1.8 | 2.1 |

| 1.0 | 15.0 | 0.89 | 1.8 | 2.1 |

| 1.3 | 10.0 | 1.41 | 1.8 | 2.1 |

| 1.3 | 12.0 | 1.41 | 1.8 | 2.1 |

| 1.3 | 14.0 | 1.41 | 1.8 | 2.1 |

| 1.3 | 15.0 | 1.41 | 1.8 | 2.1 |

| 1.5 | 10.0 | 1.79 | 1.9 | 2.1 |

| 1.5 | 12.0 | 1.79 | 1.8 | 2.1 |

| 1.5 | 14.0 | 1.79 | 1.8 | 2.1 |

| 1.5 | 15.0 | 1.79 | 1.8 | 2.1 |

| 1.8 | 12.0 | 2.55 | 1.8 | 2.0 |

| 1.8 | 14.0 | 2.55 | 1.8 | 2.1 |

| 1.8 | 15.0 | 2.55 | 1.8 | 2.1 |

| 2.0 | 12.0 | 3.04 | 1.8 | 2.0 |

| 2.0 | 14.0 | 3.04 | 1.8 | 2.1 |

| 2.0 | 16.0 | 3.04 | 1.8 | 2.1 |

| L3/mm | r3/mm | topen/ms | tclosed/ms |

|---|---|---|---|

| 2.0 | 8.0 | Can’t open | —— |

| 2.0 | 10.0 | 2.1 | 0.9 |

| 2.0 | 14.0 | 1.6 | 1.4 |

| 2.0 | 18.0 | 1.6 | 1.9 |

| 3.0 | 10.0 | 2.0 | 1.1 |

| 3.0 | 14.0 | 1.6 | 1.6 |

| 3.0 | 18.0 | 1.6 | 1.9 |

| 4.0 | 10.0 | 1.9 | 1.2 |

| 4.0 | 14.0 | 1.6 | 1.8 |

| 4.0 | 18.0 | 1.6 | 1.9 |

| 5.0 | 10.0 | 1.9 | 1.5 |

| 5.0 | 14.0 | 1.6 | 1.9 |

| 5.0 | 18.0 | 1.6 | 1.9 |

| Parameters | Range of Values |

|---|---|

| h0/mm | 2.6~3.0 |

| L3/mm | 2.0~3.0 |

| r3/mm | 12.0~15.0 |

| Calculated Items | Range | Conditions | Objectives | Weights |

|---|---|---|---|---|

| topten | 0~3 ms | ≤ | 1.5 ms | 40% |

| tclosed | 5~8 ms | ≤ | 1.5 ms | 40% |

| F5ms | --- | ≥ | 177 N | 20% |

| Parameters | h0/mm | L3/mm | r3/mm | m0/g |

|---|---|---|---|---|

| Before optimization | 2.8 | 0 | 0 | 55.9 |

| After optimization | 2.8 | 2 | 14 | 43.8 |

| Parameters | topen/ms | tclosed/ms | F5ms/N |

|---|---|---|---|

| Before optimization | 1.8 | 2 | 261.5 |

| After optimization | 1.6 | 1.4 | 258.9 |

| Solutions | h0/mm | Slotting Situation | m0/g |

|---|---|---|---|

| A | 2.80 | Trapezoidal slot | 49.00 |

| B | 2.80 | Scalloped slot | 43.80 |

| C | 2.80 | No Slot | 55.90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Y.; Wang, H.; Xie, L.; Hu, N.; Yang, J. Armature Structure Optimization of Annular Multipole Solenoid Valves Based on Electromagnetic Force Distribution. Actuators 2023, 12, 54. https://doi.org/10.3390/act12020054

Fan Y, Wang H, Xie L, Hu N, Yang J. Armature Structure Optimization of Annular Multipole Solenoid Valves Based on Electromagnetic Force Distribution. Actuators. 2023; 12(2):54. https://doi.org/10.3390/act12020054

Chicago/Turabian StyleFan, Yu, Haonan Wang, Liangtao Xie, Nao Hu, and Jianguo Yang. 2023. "Armature Structure Optimization of Annular Multipole Solenoid Valves Based on Electromagnetic Force Distribution" Actuators 12, no. 2: 54. https://doi.org/10.3390/act12020054

APA StyleFan, Y., Wang, H., Xie, L., Hu, N., & Yang, J. (2023). Armature Structure Optimization of Annular Multipole Solenoid Valves Based on Electromagnetic Force Distribution. Actuators, 12(2), 54. https://doi.org/10.3390/act12020054