Automatic Motion Generation for Robotic Milling Optimizing Stiffness with Sample-Based Planning

Abstract

:1. Introduction

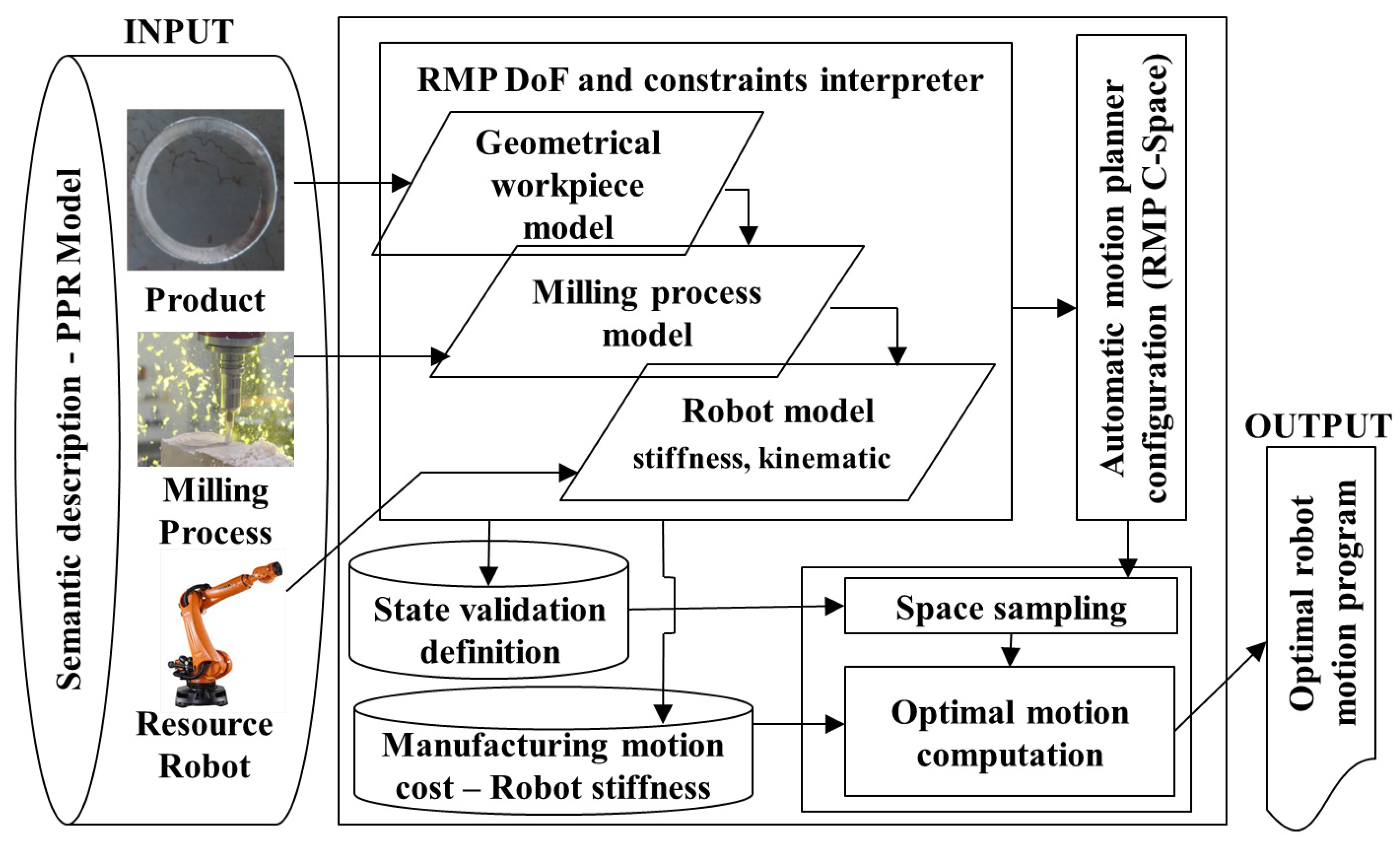

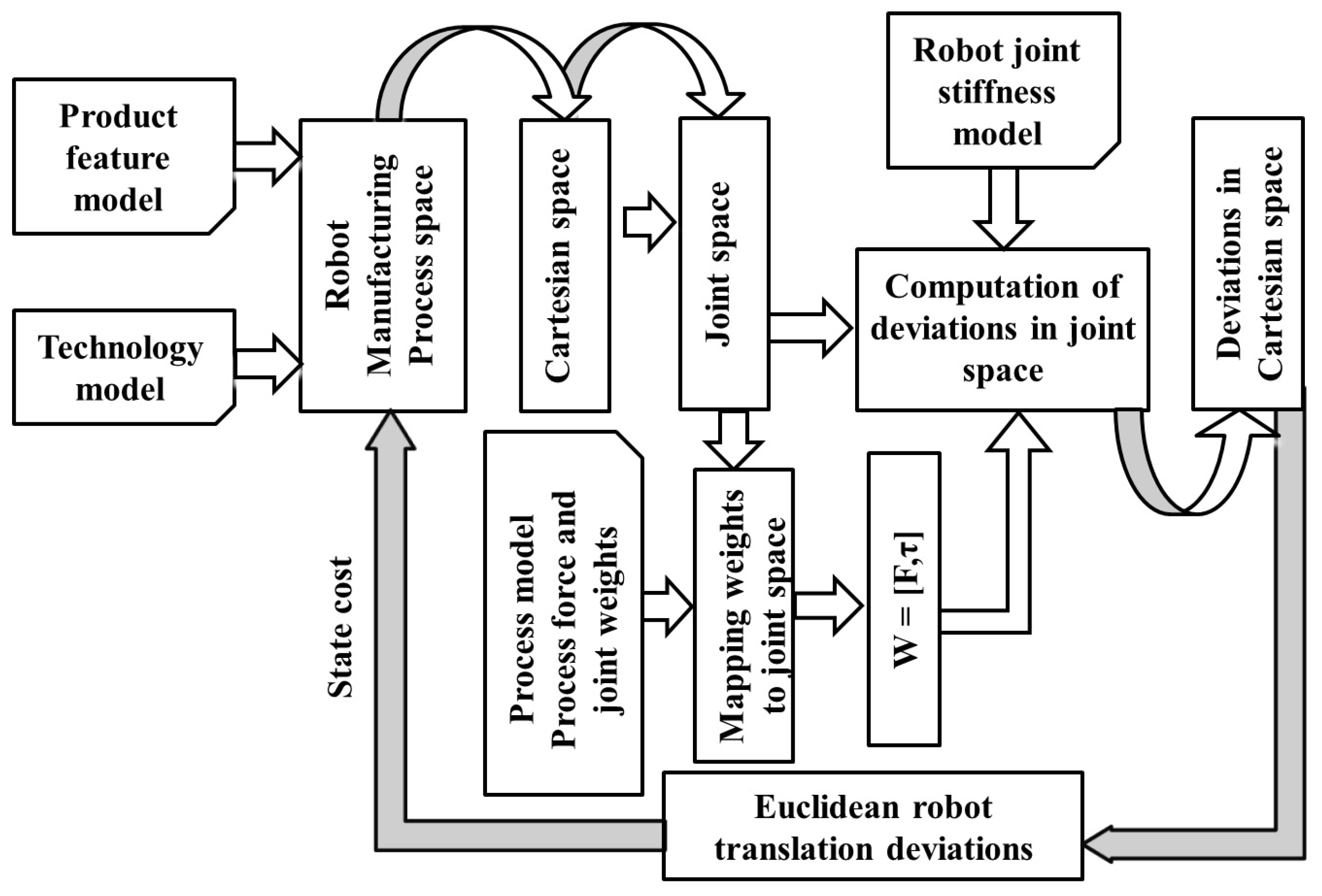

2. Problem Definition and Methodology

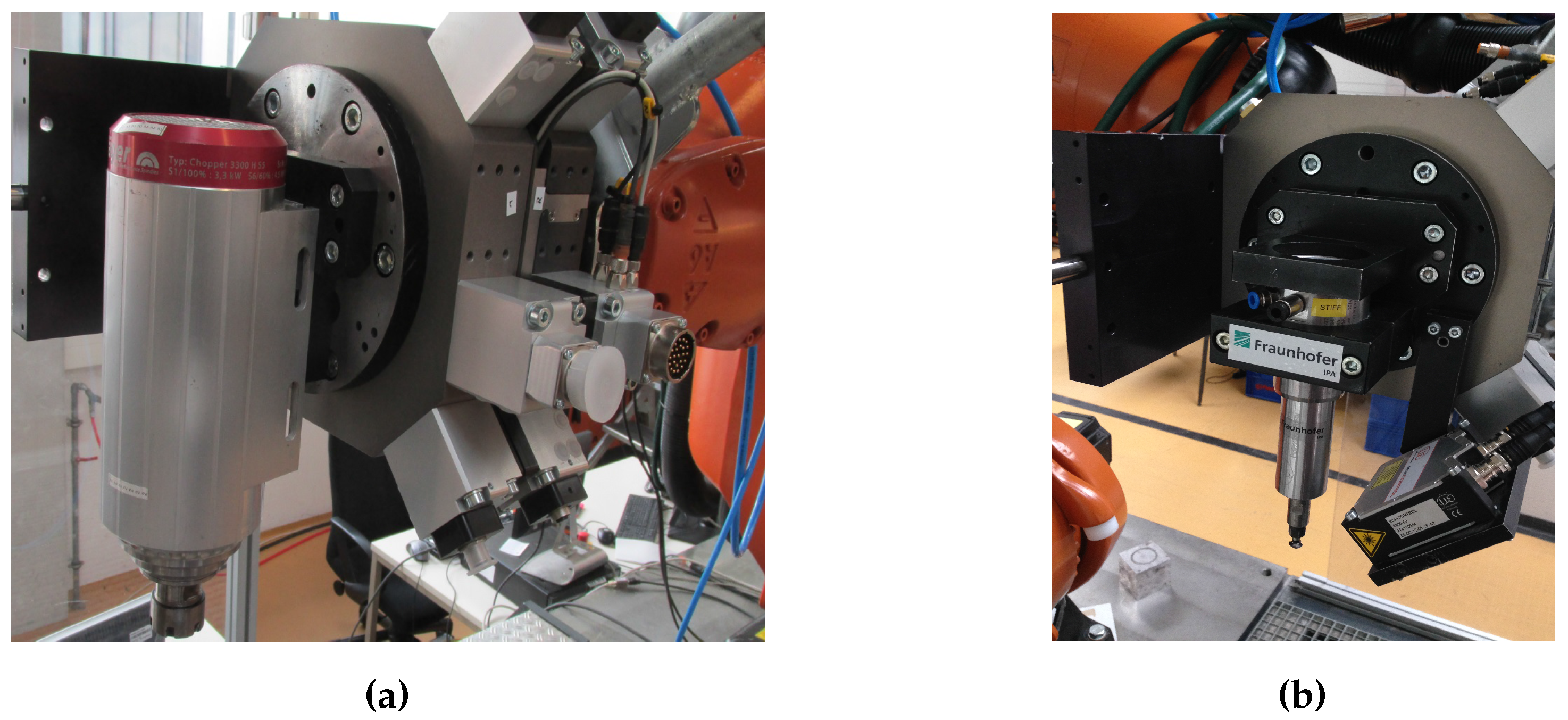

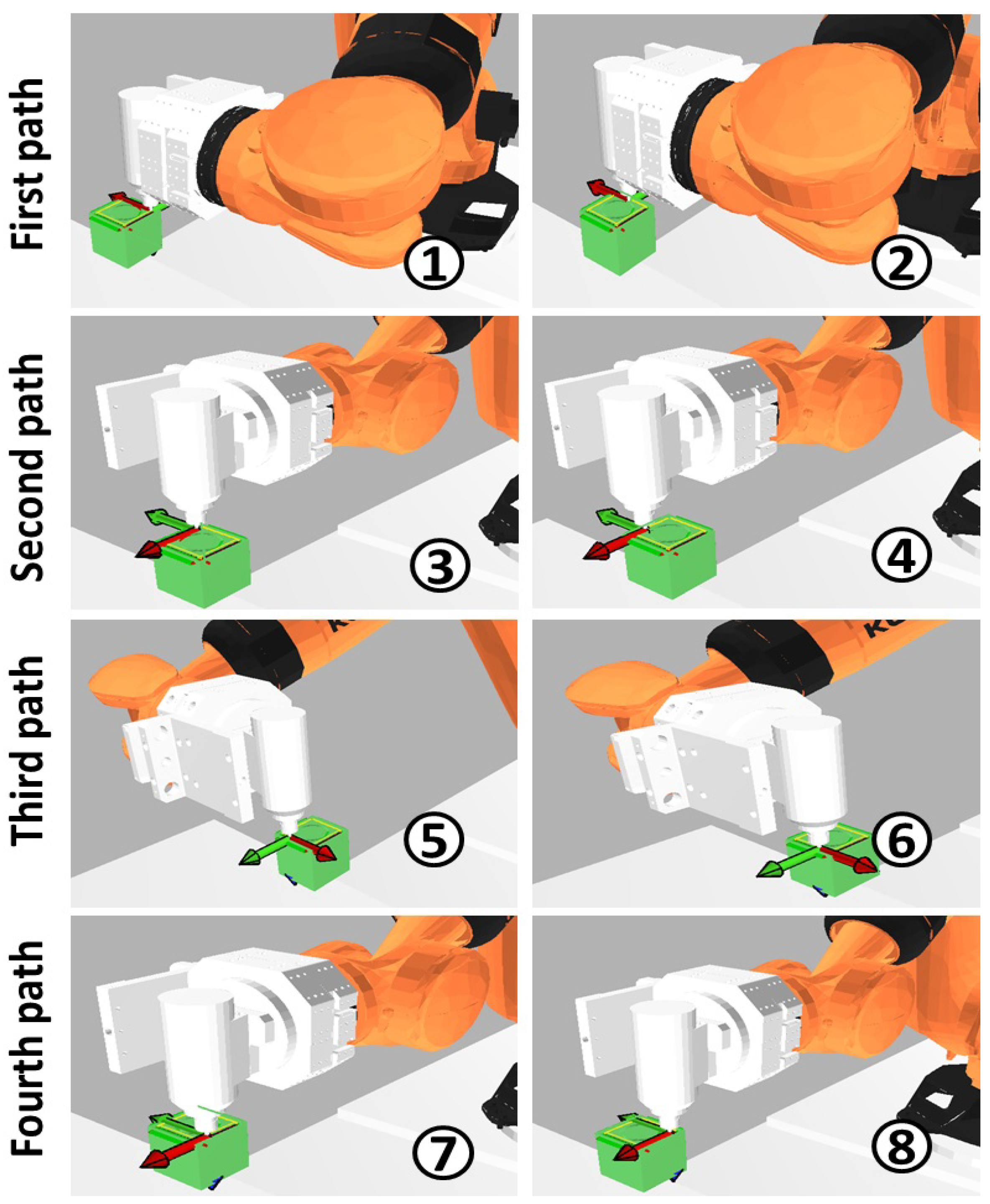

3. Experimental Setup and Simulation

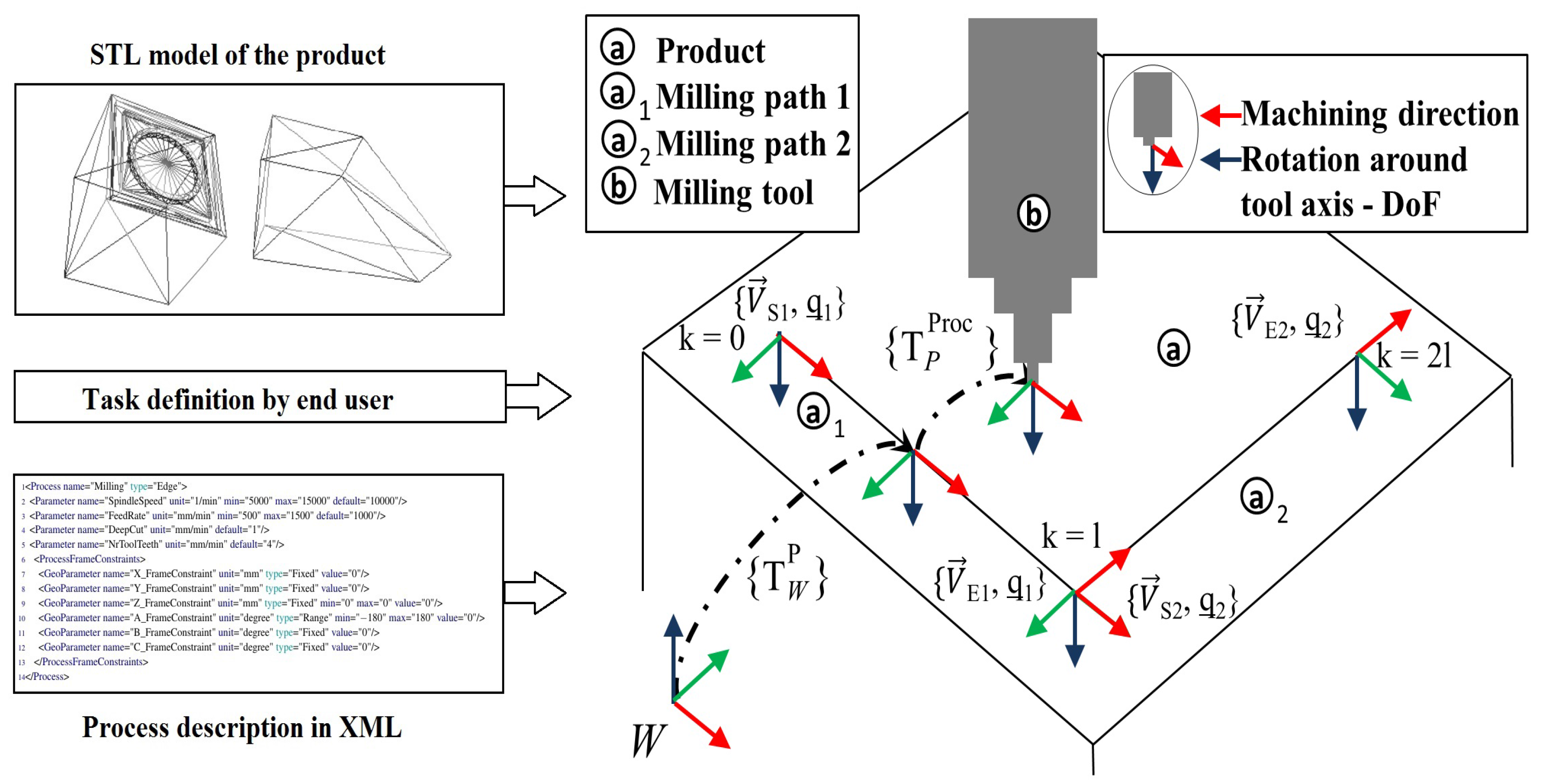

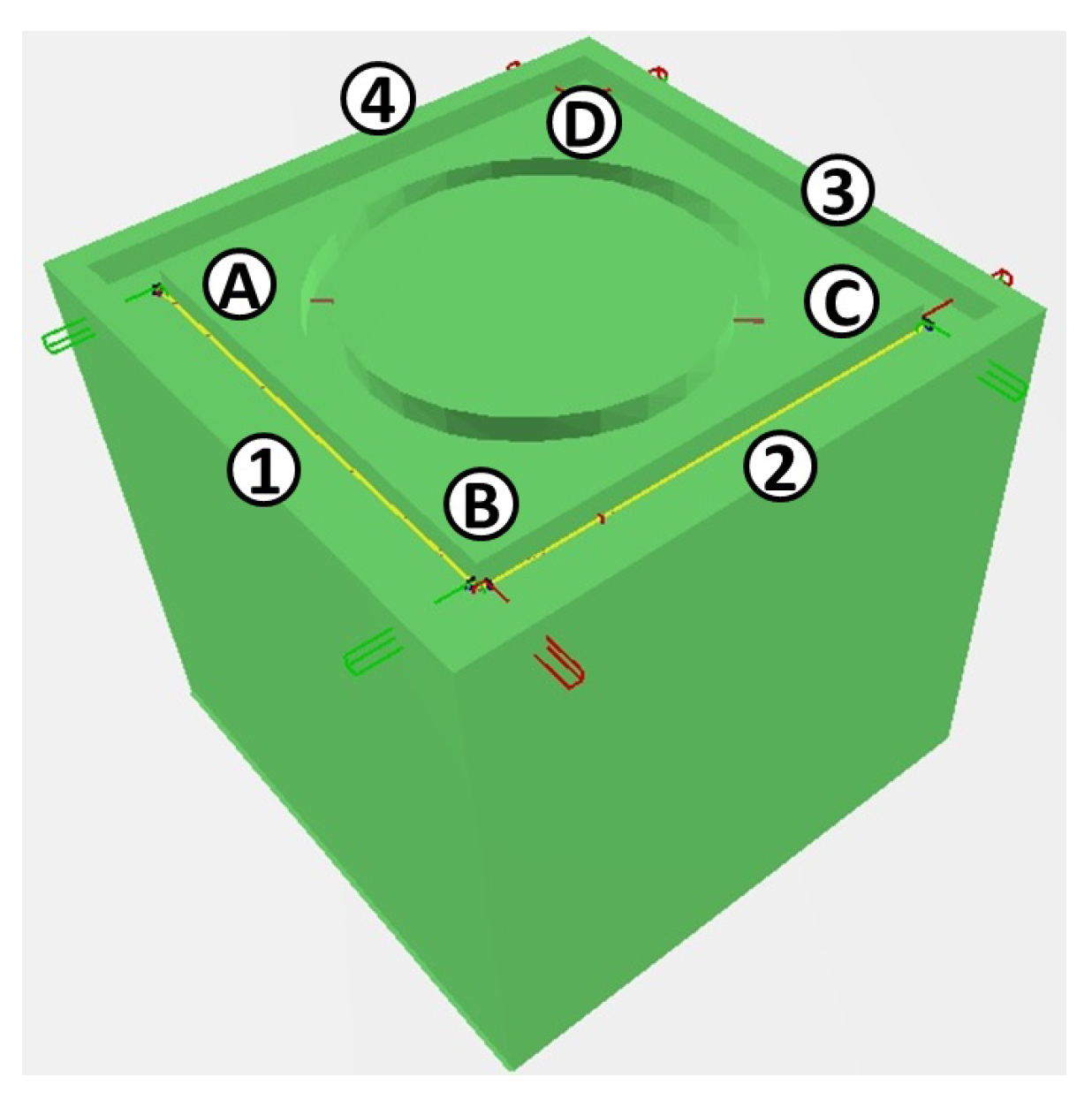

4. Product, Process and Resource Modeling for Robot Milling

4.1. Product Model

| Algorithm 1 Algorithm for automatic interpretation of the multiple seam product model. | ||

| Require: , , , n, l | ||

| 1: | ||

| 2: | ||

| 3: | if then | |

| 4: | for to n do | |

| 5: | ||

| 6: | ||

| 7: | end for | |

| 8: | endif | |

| 9: | return | |

4.2. Process Model

| 1 | <Process name=“Milling” type=“Edge”> |

| 2 | <Parameter name=“SpindleSpeed” unit=“1/min” min=“5000” max=“15000” default=“10000”/> |

| 3 | <Parameter name=“FeedRate” unit=“mm/min” min=“500” max=“1500” default=“1000”/> |

| 4 | <Parameter name=“DeepCut” unit=“mm/min” default=“1”/> |

| 5 | <Parameter name=“NrToolTeeth” unit=“mm/min” default=“4”/> |

| 6 | <ProcessFrameConstraints> |

| 7 | <GeoParameter name=“X_FrameConstraint” unit=“mm” type=“Fixed” value=“0”/> |

| 8 | <GeoParameter name=“Y_FrameConstraint” unit=“mm” type=“Fixed” value=“0”/> |

| 9 | <GeoParameter name=“Z_FrameConstraint” unit=“mm” type=“Fixed” min=“0” max=“0” value=“0”/> |

| 10 | <GeoParameter name=“A_FrameConstraint” unit=“degree” type=“Range” min=“−180” max=“180” value=“0”/> |

| 11 | <GeoParameter name=“B_FrameConstraint” unit=“degree” type=“Fixed” value=“0”/> |

| 12 | <GeoParameter name=“C_FrameConstraint” unit=“degree” type=“Fixed” value=“0”/> |

| 13 | </ProcessFrameConstraints> |

| 14 | </Process> |

4.2.1. Process Force Calculation

4.3. Resource Model: Robot

4.3.1. Forward and Inverse Kinematics

4.3.2. Wrench Computation in Joint Space Due to Process and Joint Weights

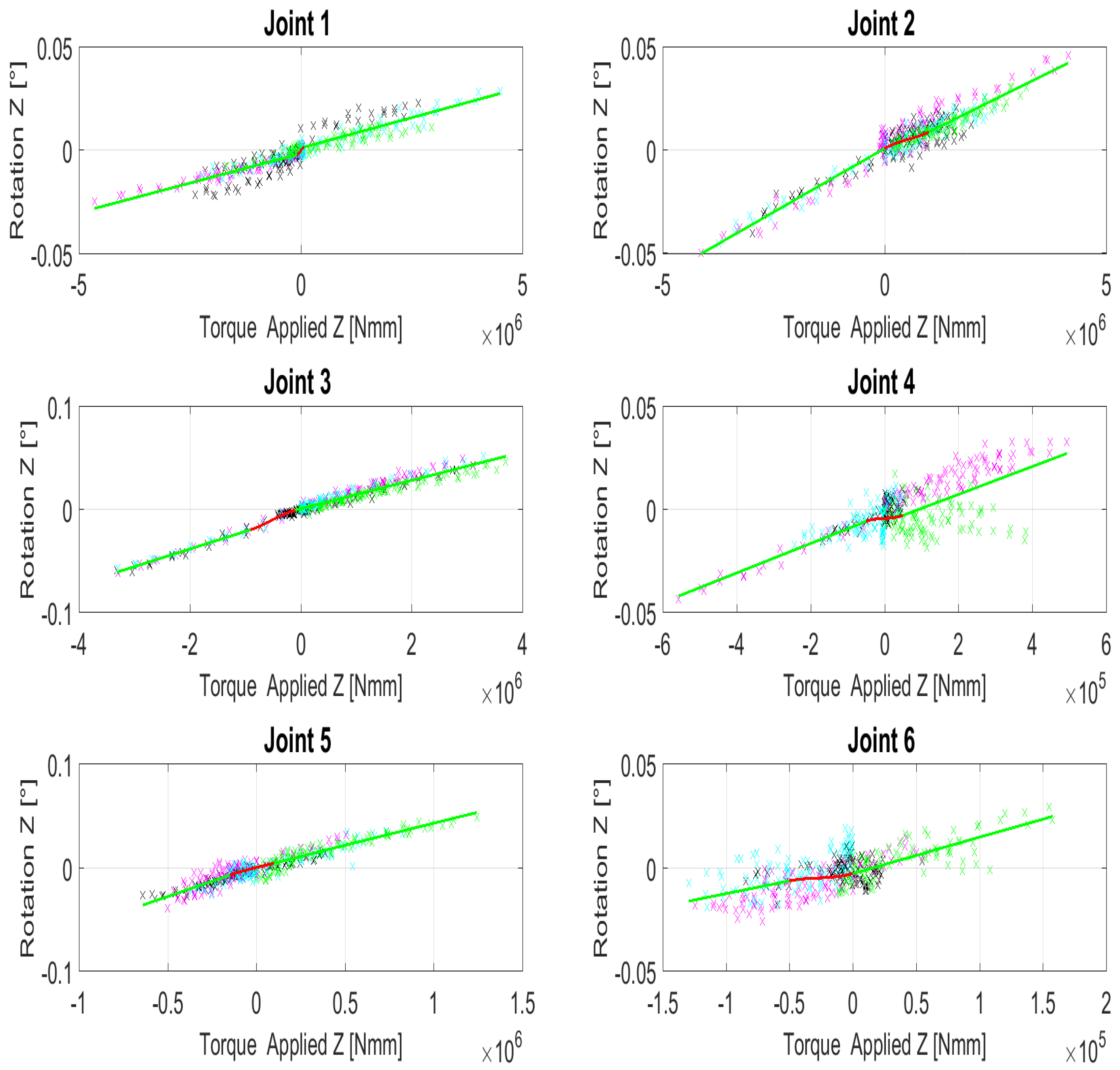

4.3.3. Robot Joint Compliance Model

5. Optimal Motion Planning with Stiffness Optimization

5.1. Product and Process Interpretation

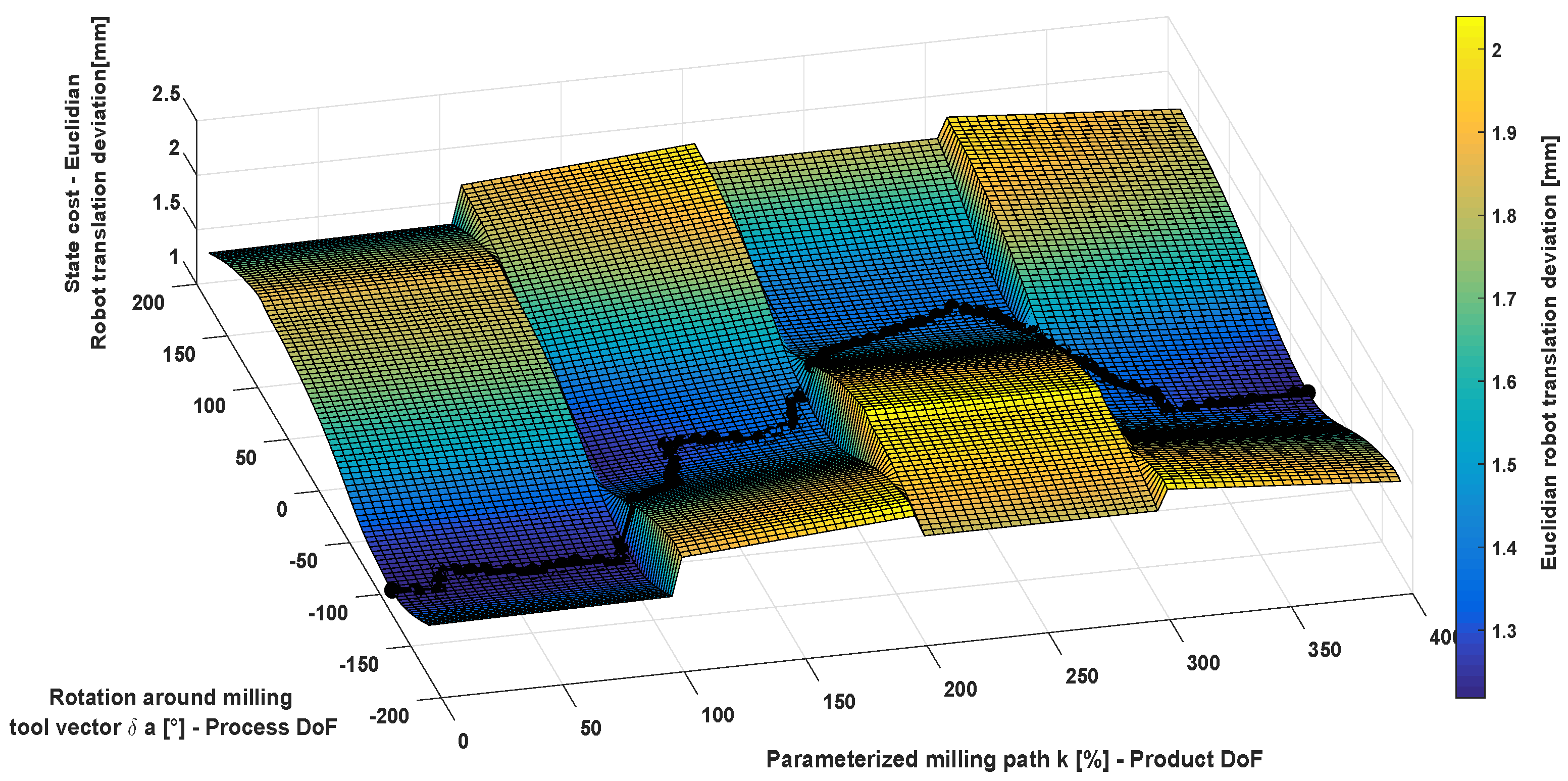

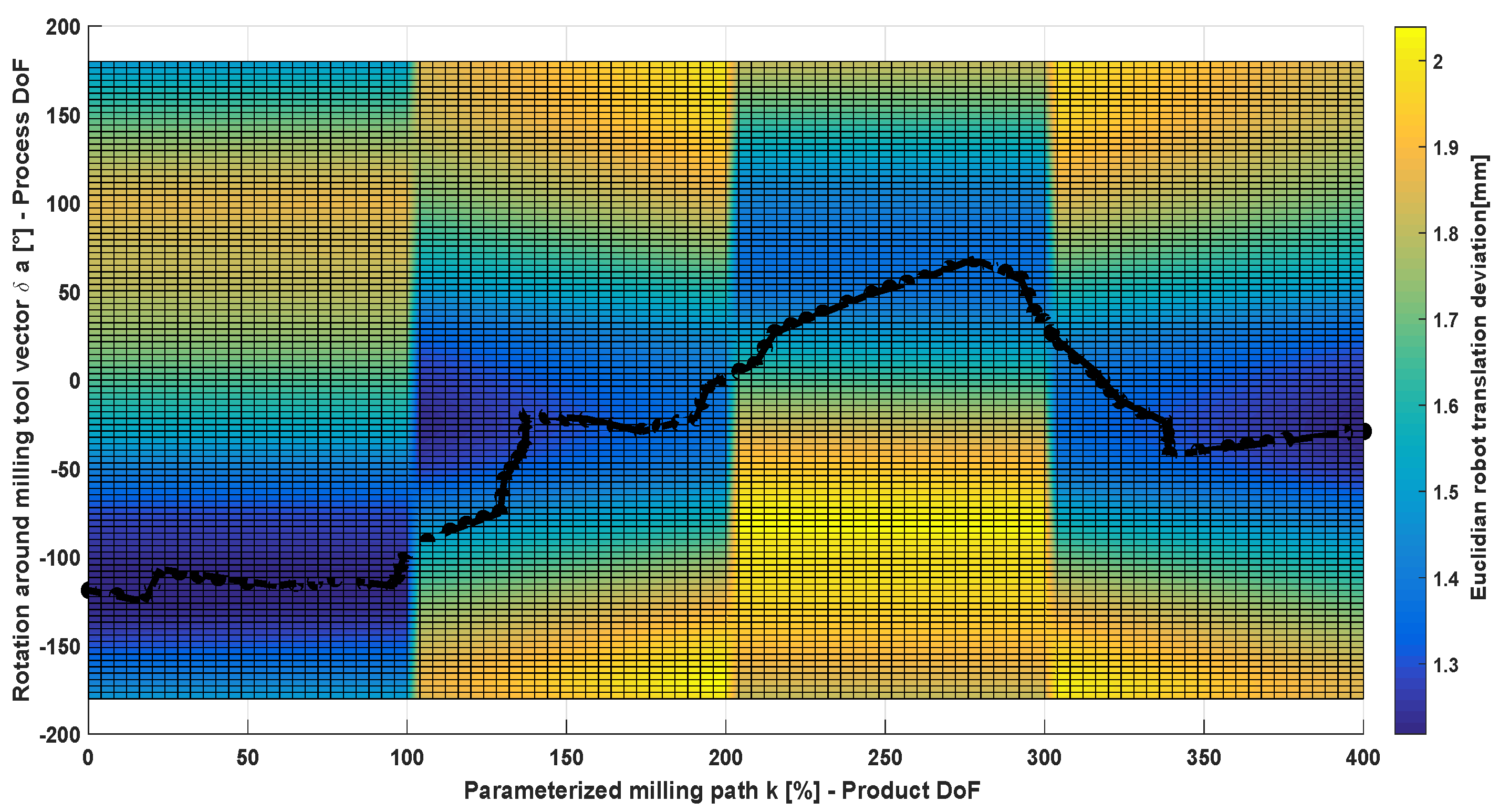

5.2. State Cost Computation

5.3. Motion Cost and Motion Planning Algorithm

5.4. Automatic Optimal Motion Planner Configuration

| Algorithm 2 Automatic interpretation and computation of robotic milling optimizing stiffness using T-RRT. | |

| Require: Interpret (World, (Equation (1)), (Equation (2)), (as defined in Section 4.3), ) | |

| 1: | |

| 2: | return |

| 3: | as in (14) |

| 4: | return |

| 5: | |

| 6: | return (, ) Sample and calculate optimal motion |

| 7: | T-RRT((, ), , , ) |

| 8: | return Optimal path |

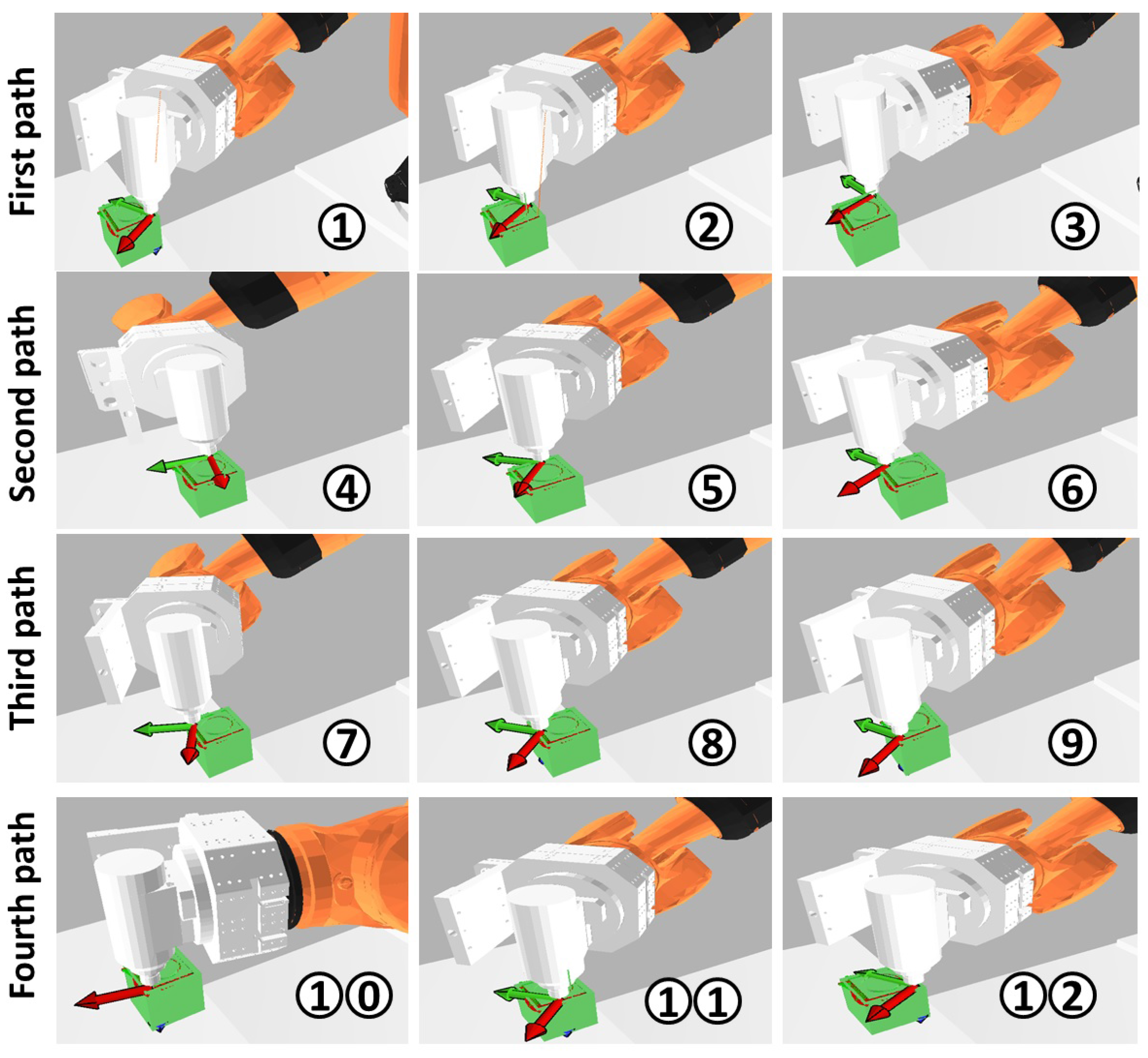

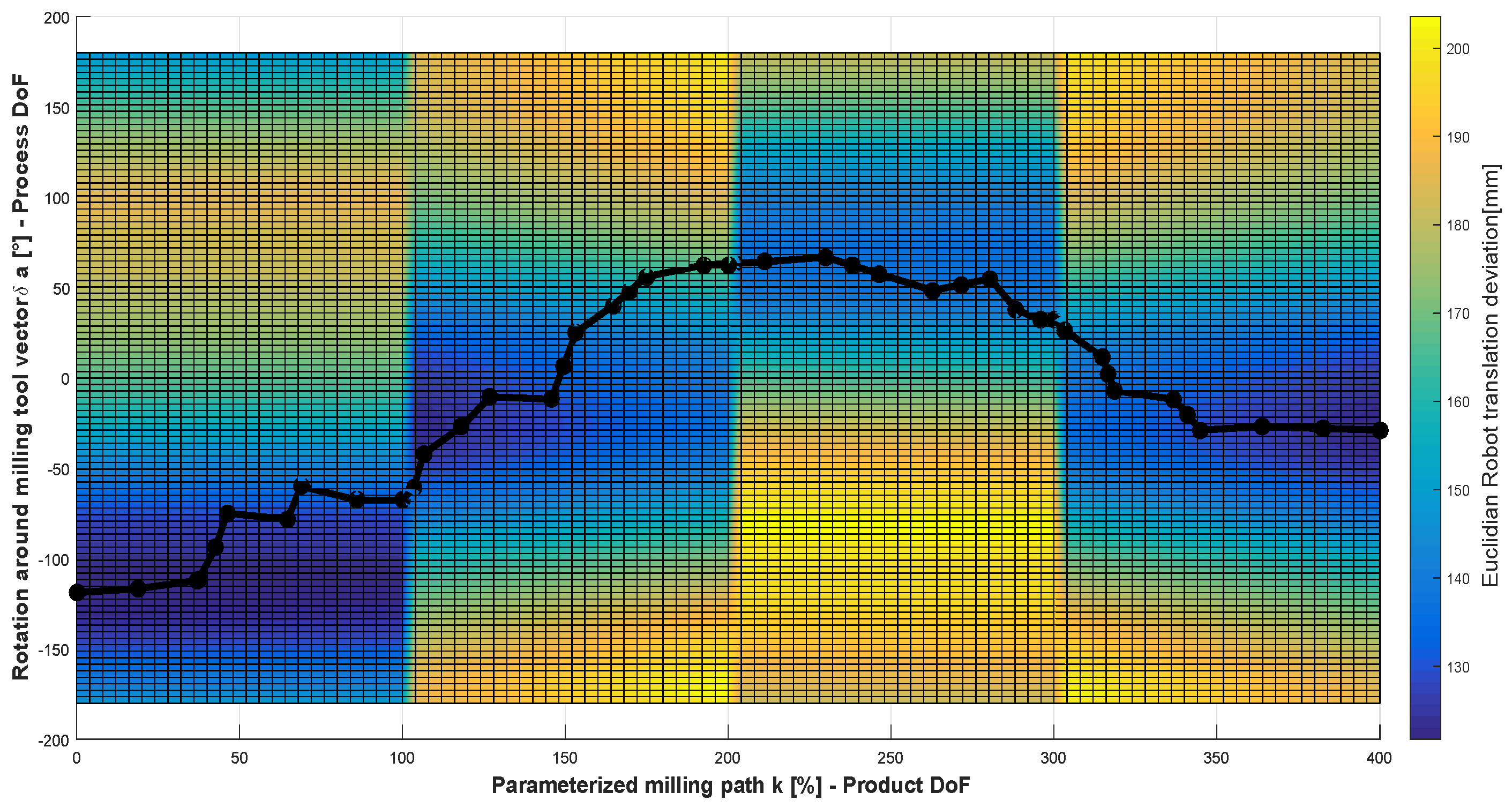

6. Optimization in CAM Software and Experimentation

6.1. Optimization in CAM Software

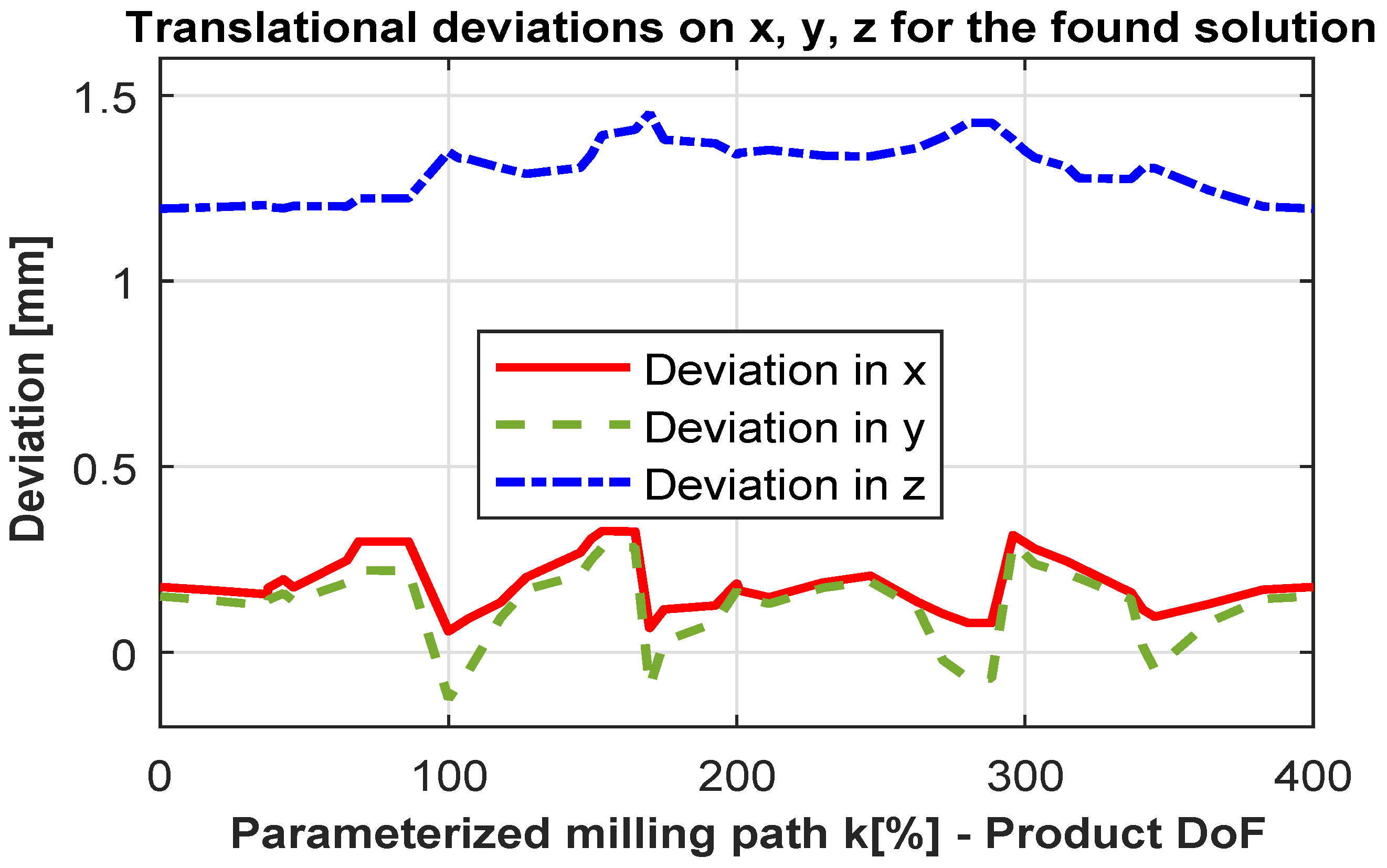

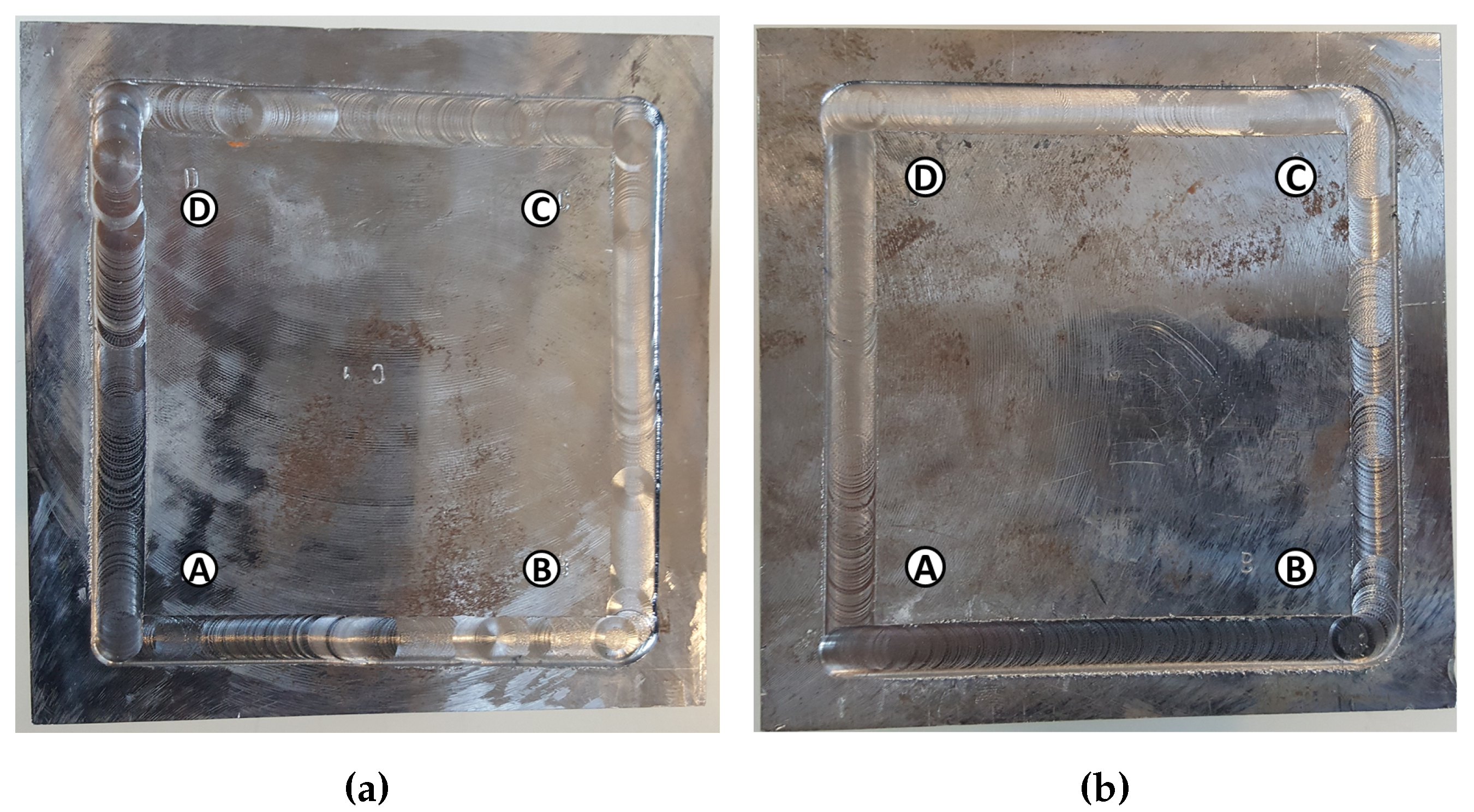

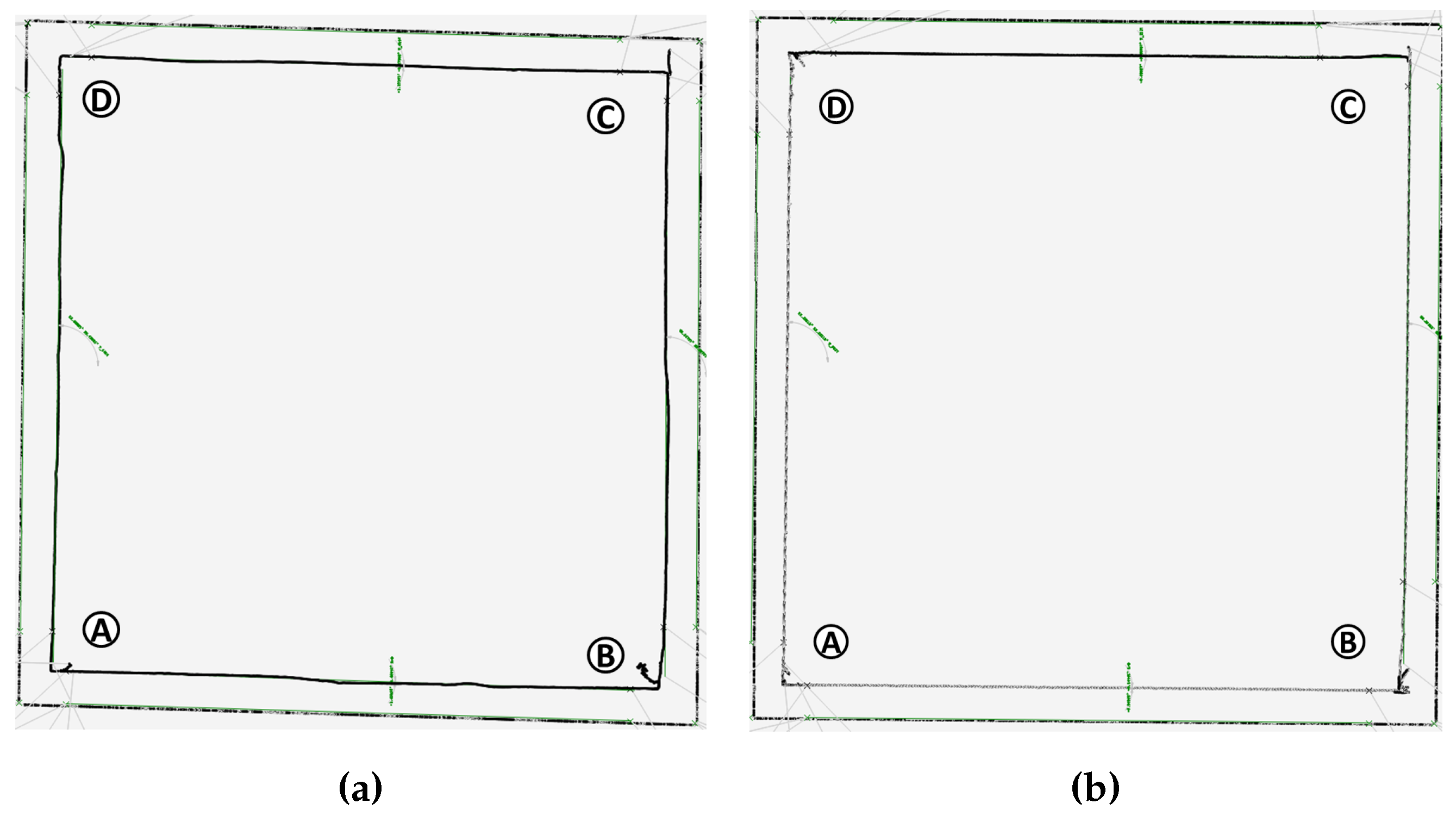

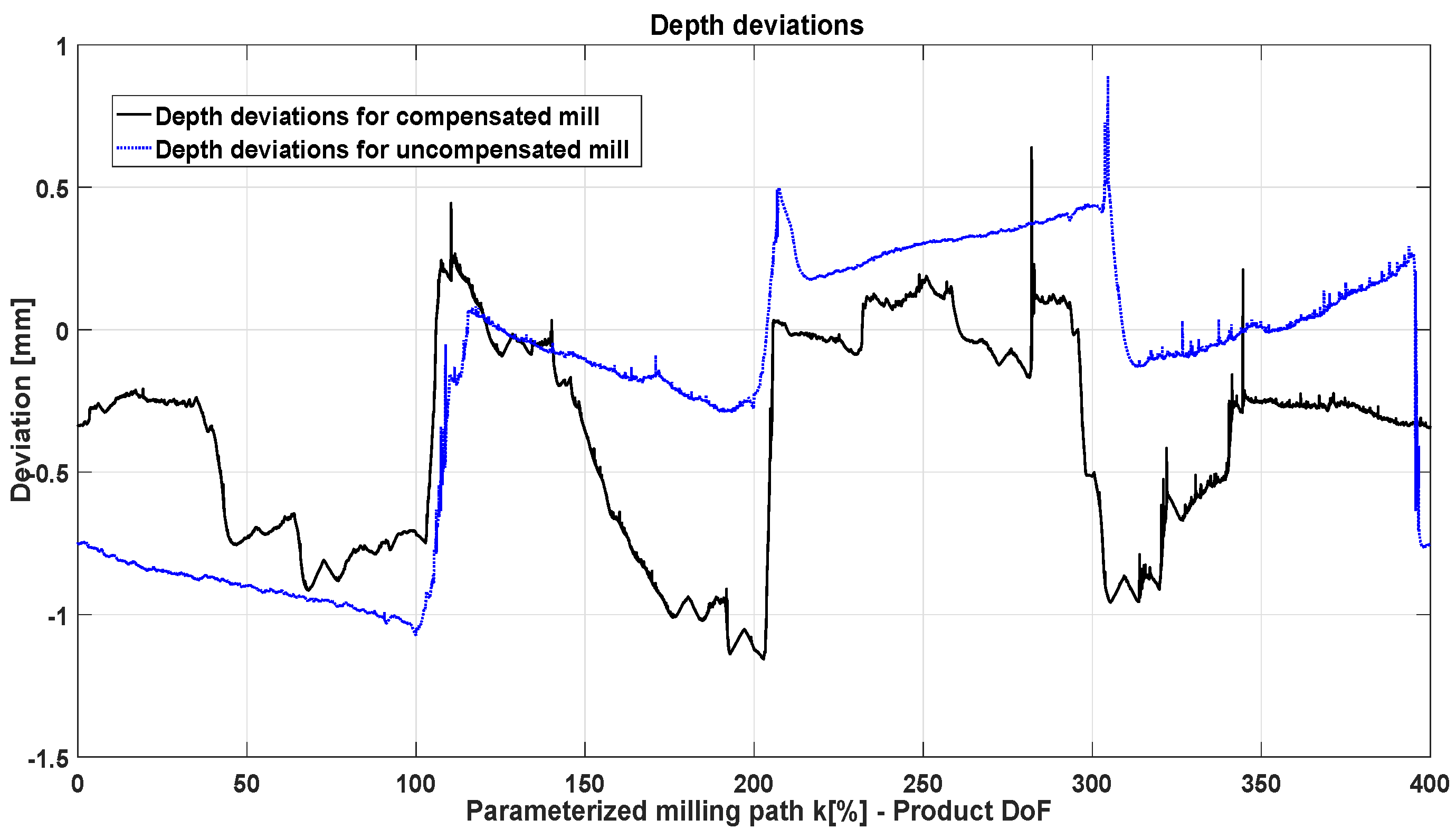

6.2. Experimentation

7. Discussion

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| 2D | Two Dimensions |

| 6D | Six Dimensions |

| AML | Automation Markup Language |

| C-space | Configuration Space |

| CAD | Computer-Aided Design |

| CAM | Computer-Aided Manufacturing |

| CMM | Coordinate-Measuring Machine |

| CNC | Computer Numeric Control |

| DoF | Degree of Freedom |

| IFR | International Federation of Robotics |

| MDPI | Multidisciplinary Digital Publishing Institute |

| OMPL | Open Motion Planning Library |

| PPR | Product, Process and Resource |

| RMP | Robot Manufacturing Process |

| STL | STereoLithography |

| T-RRT | Transition-based Rapid-Random Tree |

| TCP | Tool Center Point |

| w.r.t. | with respect to |

| XML | eXtensible Markup Language |

Appendix A. Robot Joint Mass and Center of Mass Estimation

| Joint | Mass (kg) | (mm) | (mm) | (mm) |

|---|---|---|---|---|

| Joint 1 | 395.72 | −4.24 | −3.06 | 175.3 |

| Joint 2 | 239.75 | 431.54 | 2.8 | −235.73 |

| Joint 3 | 178.30 | 222.13 | 25 | 3.36 |

| Joint 4 | 17.60 | 1.35 | 0 | −154.06 |

| Joint 5 | 57.93 | 54.3 | 0 | 37.8 |

| Joint 6 | 3.29 | 0 | 0 | 13.88 |

| Endeffector | 40.2 | −8.86 | 12.26 | 104.41 |

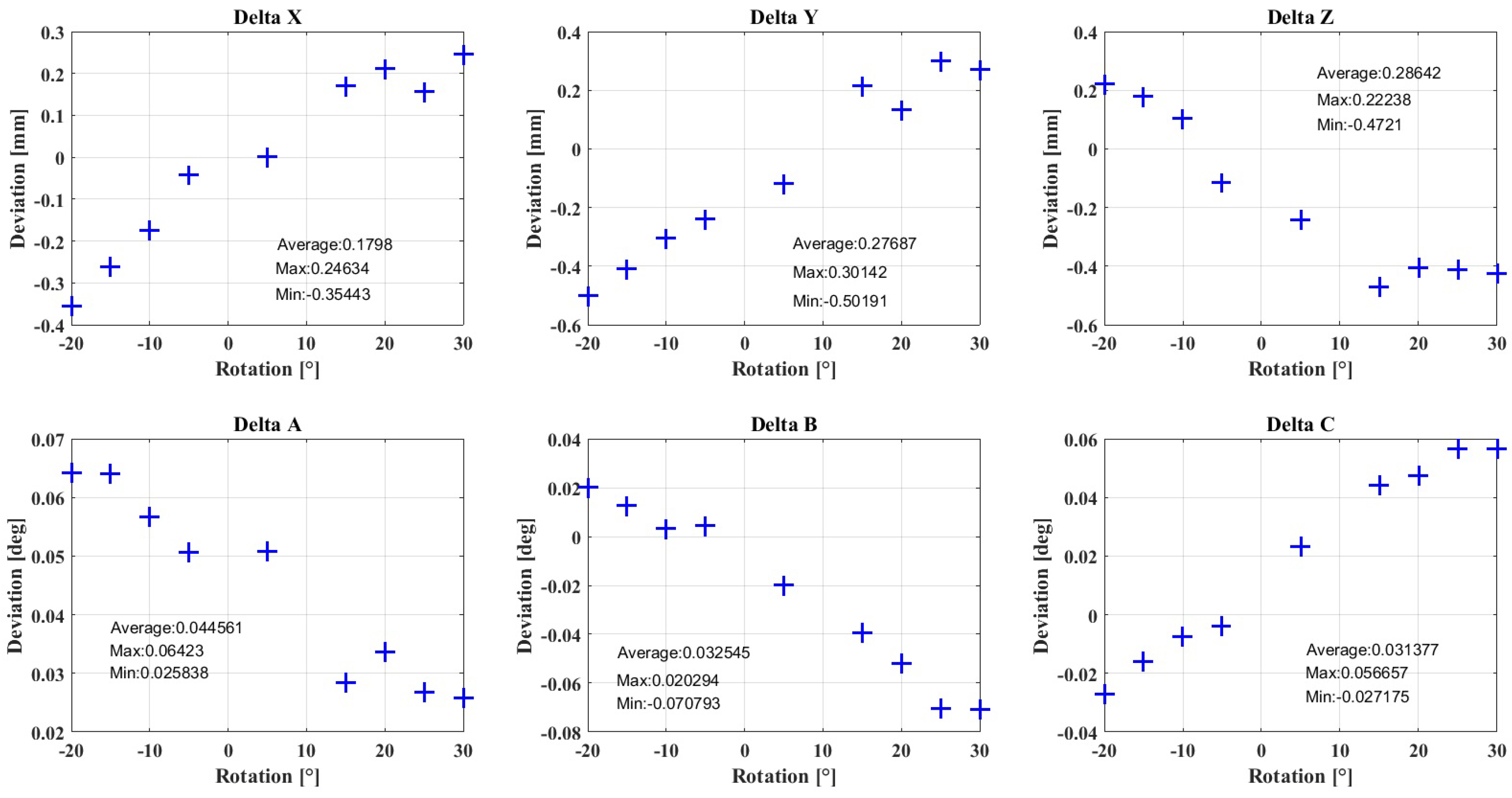

Appendix B. Robot Tool Calibration and Accuracy

References

- IFR Statistical Department. World Robotics 2014 Industrial Robots; VDMA Robotics + Automation: Frankfurt, Germany, 2014. [Google Scholar]

- Minhas, S.U.H.; Lehmann, C.; Städter, J.P.; Berger, U. Reconfigurable Strategies for Manufacturing Setups to confront Mass Customization Challenges. In Proceedings of the 21st International Conference on Production Research, Wurttemberg, Germany, 31 July–4 August 2011.

- Karim, A.; Verl, A. Challenges and obstacles in robot-machining ISR 2013. In Proceedings of the 44th Internationel Symposium on Robotics (IEEE ISR 2013), Seoul, Korea, 24–26 October 2013; pp. 1–4.

- Slavkovic, N.; Milutinovic, D.; Glavonjic, M. A method for off-line compensation of cutting force-induced errors in robotic machining by tool path modification. Int. J. Adv. Manuf. Technol. 2014, 70, 2083–2096. [Google Scholar] [CrossRef]

- Iglesias, I.; Sebastián, M.A.; Ares, J.E. Overview of the State of Robotic Machining: Current Situation and Future Potential. Proced. Eng. 2015, 132, 911–917. [Google Scholar] [CrossRef]

- Schneider, U.; Diaz Posada, J.R.; Drust, M.; Verl, A. Position control of an industrial robot using an optical measurement system for machining purposes. In Advanced Manufacturing Technology XXVII, Proceedings of the 11th International Conference on Manufacturing Research 2013, Incorporating the 28th National Conference on Manufacturing Research 2013, Cranfield, UK, 19 September 2013; pp. 307–312.

- Schneider, U.; Drust, M.; Ansaloni, M.; Lehmann, C.; Pelliciari, M.; Leali, F.; Gunnink, J.W.; Verl, A. Improving robotic machining accuracy through experimental error investigation and modular compensation. Int. J. Adv. Manuf. Technol. 2016, 85, 3–15. [Google Scholar] [CrossRef]

- Diaz Posada, J.R.; Schneider, U.; Pidan, S.; Geravand, M.; Stelzer, P.; Verl, A. High accurate robotic drilling with external sensor and compliance model-based compensation. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 3901–3907.

- Schneider, U.; Diaz Posada, J.R.; Verl, A. Automatic pose optimization for robotic processes. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 2054–2059.

- Lehmann, C.; Halbauer, M.; Euhus, D.; Overbeck, D. Milling with industrial robots: Strategies to reduce and compensate process force induced accuracy influences. In Proceedings of the 17th IEEE International Conference on Emerging Technologies & Factory Automation (ETFA 2012), Krakow, Poland, 17–21 September 2012; Volume 2, pp. 1075–1078.

- Tyapin, I.; Kaldestad, K.B.; Hovland, G. Off-line path correction of robotic face milling using static tool force and robot stiffness. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; pp. 5506–5511.

- Abele, E.; Von Stryk, O.; Friedmann, M.; Hemker, T. Prediction of the tool displacement for robot milling applications using coupled models of an industrial robot and removal simulation. In Proceedings of the CIRP 2nd International Conference Process Machine Interactions, Vancouver, BC, Canada, 10–11 June 2010.

- Abele, E.; Bauer, J.; Rothenbücher, S.; Stelzer, M.; Von Stryk, O. Prediction of the Tool Displacement by Coupled Models of the Compliant Industrial Robot and the Milling Process. In Proceedings of the International Conference on Process Machine Interactions, Hannover, Germany, 3–4 September 2008.

- Bauer, J. Methoden der Offline-Bahnkorrektur für die spanende Bearbeitung mit Industrierobotern; Schriftenreihe des PTW: Innovation Fertigungstechnik; Epubli-Verlag: Berlin, Germany, 2011. [Google Scholar]

- Haage, M.; Halbauer, M.; Lehmann, C.; Staedter, J.P. Increasing Robotic Machining Accuracy Using Offline Compensation Based on Joint-Motion Simulation. In Proceedings of the 41st International Symposium on Robotics (ISR/Robotik 2014), Munich, Germany, 24 June 2014; pp. 1–8.

- Dumas, C.; Caro, S.; Cherif, M.; Garnier, S.; Furet, B. A methodology for joint stiffness identification of serial robots. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Taipei, Taiwan, 18–22 October 2010; pp. 464–469.

- Klimchik, A.; Wu, Y.; Dumas, C.; Caro, S.; Furet, B.; Pashkevich, A. Identification of geometrical and elastostatic parameters of heavy industrial robots. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation (ICRA), Karlsruhe, Germany, 6–10 May 2013.

- Abele, E.; Weigold, M.; Rothenbücher, S. Modeling and Identification of an Industrial Robot for Machining Applications. CIRP Ann. Manuf. Technol. 2007, 56, 387–390. [Google Scholar] [CrossRef]

- Pan, Z.; Zhang, H. Robotic Machining from Programming to Process Control. In Proceedings of the 2008 7th World Congress on Intelligent Control and Automation (WCICA 2008), Chongqing, China, 25–27 June 2008; pp. 553–558.

- Pan, Z.; Zhang, H. Robotic machining from programming to process control: A complete solution by force control. Ind. Robot 2008, 35, 400–409. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, H.; Fuhlbrigge, T. Improving machining accuracy with robot deformation compensation. In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems, St. Louis, MO, USA, 10–15 October 2009; pp. 3826–3831.

- Liu, Y.; Cheng, T.; Zuo, L. Adaptive Control Constraint of Machining Processes. Int. J. Adv. Manuf. Technol. 2001, 17, 720–726. [Google Scholar] [CrossRef]

- Sörnmo, O.; Olofsson, B.; Schneider, U.; Robertsson, A.; Johansson, R. Increasing the Milling Accuracy for Industrial Robots Using a Piezo-Actuated High-Dynamic Micro Manipulator. In Proceedings of the 2012 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Kaohsiung, Taiwan, 11–14 July 2012; pp. 104–110.

- Schneider, U.; Momeni-K, M.; Ansaloni, M.; Verl, A. Stiffness modeling of industrial robots for deformation compensation in machining. In Proceedings of the 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems, Chicago, IL, USA, 14–18 September 2014; pp. 4464–4469.

- Schneider, U.; Ansaloni, M.; Drust, M.; Leali, F.; Verl, A. Experimental Investigation of Sources of Error in Robot Machining. In Proceedings of International Workshop, WRSM 2013, Porto, Portugal, 26–28 June 2013; pp. 14–26.

- Dumas, C. Development of Methods for Metal and Composite Parts Trimming with a Robot. Ph.D. Thesis, Université de Nantes, Nantes, France, 2011. [Google Scholar]

- Schneider, U.; Diaz Posada, J.R.; Drust, M.; Verl, A.; van der Zwaag, J. Combining holistic programming with kinematic parameter optimization for robot machining. In Proceeding of the 41st International Symposium on Robotics (ISR/Robotik 2014), 2–3 June 2014; pp. 524–530.

- Matsuoka, S.; Shimizu, K.; Yamazaki, N.; Oki, Y. High-speed end milling of an articulated robot and its characteristics. J. Mater. Process. Technol. 1999, 95, 83–89. [Google Scholar] [CrossRef]

- Budak, E.; Tekeli, A. Maximizing Chatter Free Material Removal Rate in Milling through Optimal Selection of Axial and Radial Depth of Cut Pairs. CIRP Ann. Manuf. Technol. 2005, 54, 353–356. [Google Scholar] [CrossRef]

- Elbanhawi, M.; Simic, M. Sampling-Based Robot Motion Planning: A Review. IEEE Access 2014, 2, 56–77. [Google Scholar] [CrossRef]

- LaValle, S.M. Motion Planning: The Essentials. IEEE Robot. Autom. Soc. Mag. 2011, 18, 79–89. [Google Scholar] [CrossRef]

- Karaman, S.; Frazzoli, E. Sampling-based Algorithms for Optimal Motion Planning. Int. J. Rob. Res. 2011, 30, 846–894. [Google Scholar] [CrossRef]

- Tsianos, K.I.; Şucan, I.A.; Kavraki, L.E. Sampling-Based Robot Motion Planning: Towards Realistic Applications. Comput. Sci. Rev. 2007, 1, 2–11. [Google Scholar] [CrossRef]

- Ioan, A.Ş.; Mark, M.; Lydia, E.K. The Open Motion Planning Library. IEEE Robot. Autom. Mag. 2012, 19, 72–82. [Google Scholar]

- Diaz Posada, J.R.; Dietz, T.; Ockert, P.; Kuss, A.; Hägele, M.; Verl, A. Automatic Optimal Motion Generation for Robotic Manufacturing Processes: Optimal Collision Avoidance in Robotic Welding. In Proceedings of the 2016 12th Conference on Automation Science and Engineering (CASE), Fort Worth, TX, USA, 21–24 August 2016; pp. 154–161.

- Diaz Posada, J.R.; Kumar, S.; Kuss, A.; Schneider, U.; Drust, M.; Dietz, T.; Verl, A. Automatic Programming and Control for Robotic Deburring. In Proceedings of the ISR 2016: 47st International Symposium on Robotics, Munich, Germany, 21–22 June 2016; pp. 1–8.

- Kuss, A.; Drust, M.; Verl, A. Detection of workpiece shape deviations for tool path adaptation in robotic deburring systems. In Proceedings of the 49th CIRP CMS Conference on Manufacturing Systems: Factories of the Future in the Digital Environment, Stuttgart, Germany, 25–27 May 2016.

- Sang, S.C.; Tae, H.Y.; Sang, D.N. XML-based neutral file and PLM integrator for PPR information exchange between heterogeneous PLM systems. Int. J. Comput. Integr. Manuf. 2010, 23, 216–228. [Google Scholar]

- Drath, R.; Lüder, A.; Peschke, J.; Hundt, L. AutomationML—The glue for seamless automation engineering. In Proceedings of the International Conference on Emerging Technologies and Factory Automation (ETFA), Hamburg, Germany, 15–18 September 2008; pp. 616–623.

- Gomeringer, R. Tabellenbuch Metall, 46., neu bearb. und erweitere Auflage; Verlag Europa Lehrmittel: Haan-Gruiten, Germany, 2014. [Google Scholar]

- Jaillet, L.; Cortés, J.; Siméon, T. Sampling-based path planning on configuration-space costmaps. IEEE J. Robot. Autom. 2016, 26, 635–646. [Google Scholar] [CrossRef]

- Jaillet, L.; Cortés, J.; Siméon, T. Transition-based RRT for path planning in continuous cost spaces. In Proceedings of the International Conference on Intelligent Robots and Systems (IROS), Nice, France, 22–26 September 2008; pp. 2145–2150.

| Joint | S | S | S | S | S | S | S | S |

|---|---|---|---|---|---|---|---|---|

| 1 | – | – | - | |||||

| 2 | – | – | ||||||

| 3 | – | – | – | |||||

| 4 | – | – | – | – | ||||

| 5 | – | |||||||

| 6 | – | – |

| Compliance Limits | Joint 1 | Joint 2 | Joint 3 | Joint 4 | Joint 5 | Joint 6 |

|---|---|---|---|---|---|---|

| – | 0 | – | – | – | – | |

| – | 0 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diaz Posada, J.R.; Schneider, U.; Sridhar, A.; Verl, A. Automatic Motion Generation for Robotic Milling Optimizing Stiffness with Sample-Based Planning. Machines 2017, 5, 3. https://doi.org/10.3390/machines5010003

Diaz Posada JR, Schneider U, Sridhar A, Verl A. Automatic Motion Generation for Robotic Milling Optimizing Stiffness with Sample-Based Planning. Machines. 2017; 5(1):3. https://doi.org/10.3390/machines5010003

Chicago/Turabian StyleDiaz Posada, Julian Ricardo, Ulrich Schneider, Arjun Sridhar, and Alexander Verl. 2017. "Automatic Motion Generation for Robotic Milling Optimizing Stiffness with Sample-Based Planning" Machines 5, no. 1: 3. https://doi.org/10.3390/machines5010003

APA StyleDiaz Posada, J. R., Schneider, U., Sridhar, A., & Verl, A. (2017). Automatic Motion Generation for Robotic Milling Optimizing Stiffness with Sample-Based Planning. Machines, 5(1), 3. https://doi.org/10.3390/machines5010003