Analysis of Friction Torque Characteristics of a Novel Ball–Roller Composite Turntable Bearing

Abstract

1. Introduction

2. Relevant Fundamental Theories

2.1. Kinematic Characteristics of Rolling Elements

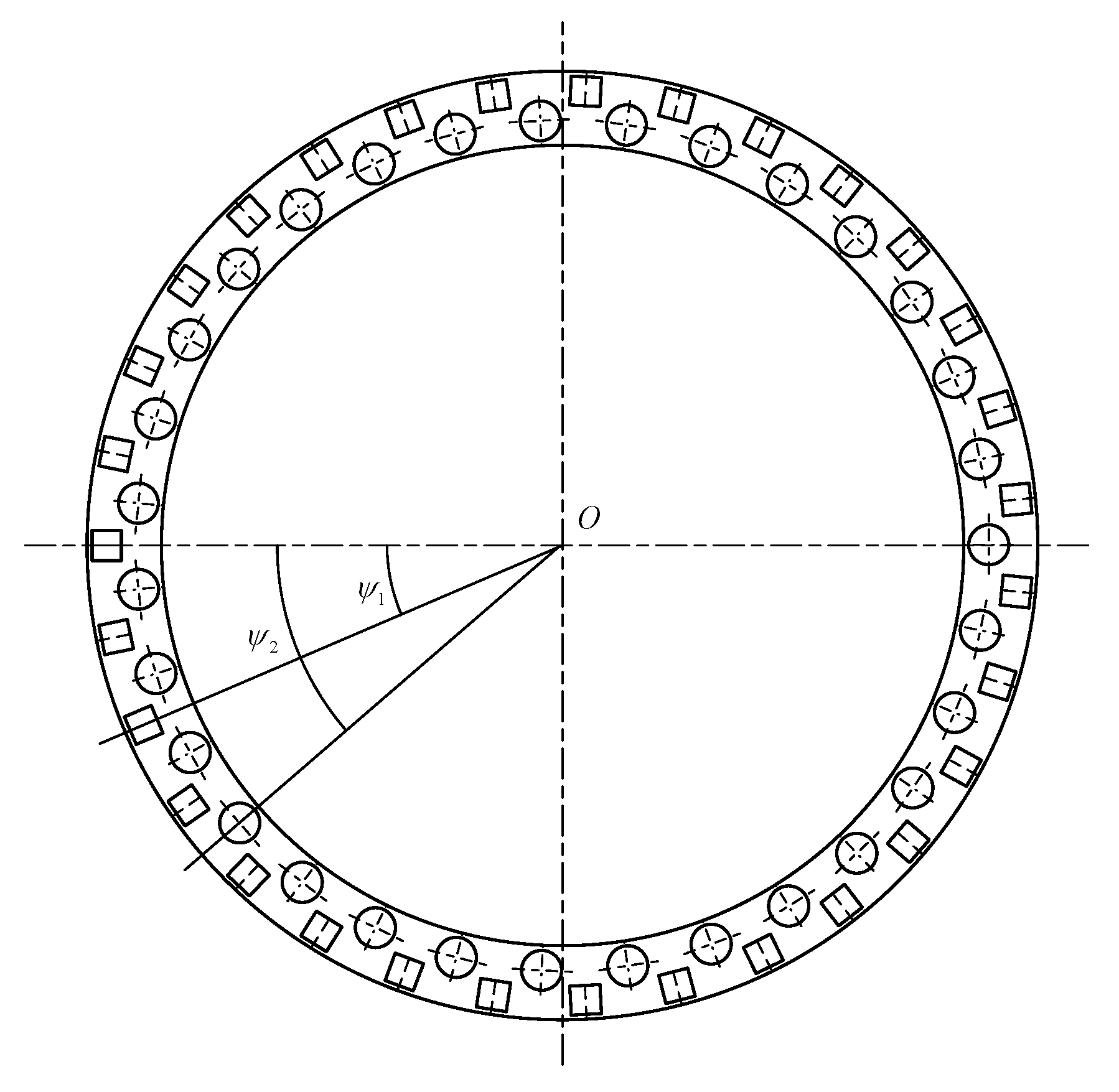

2.2. Contact Load and Distribution Characteristics

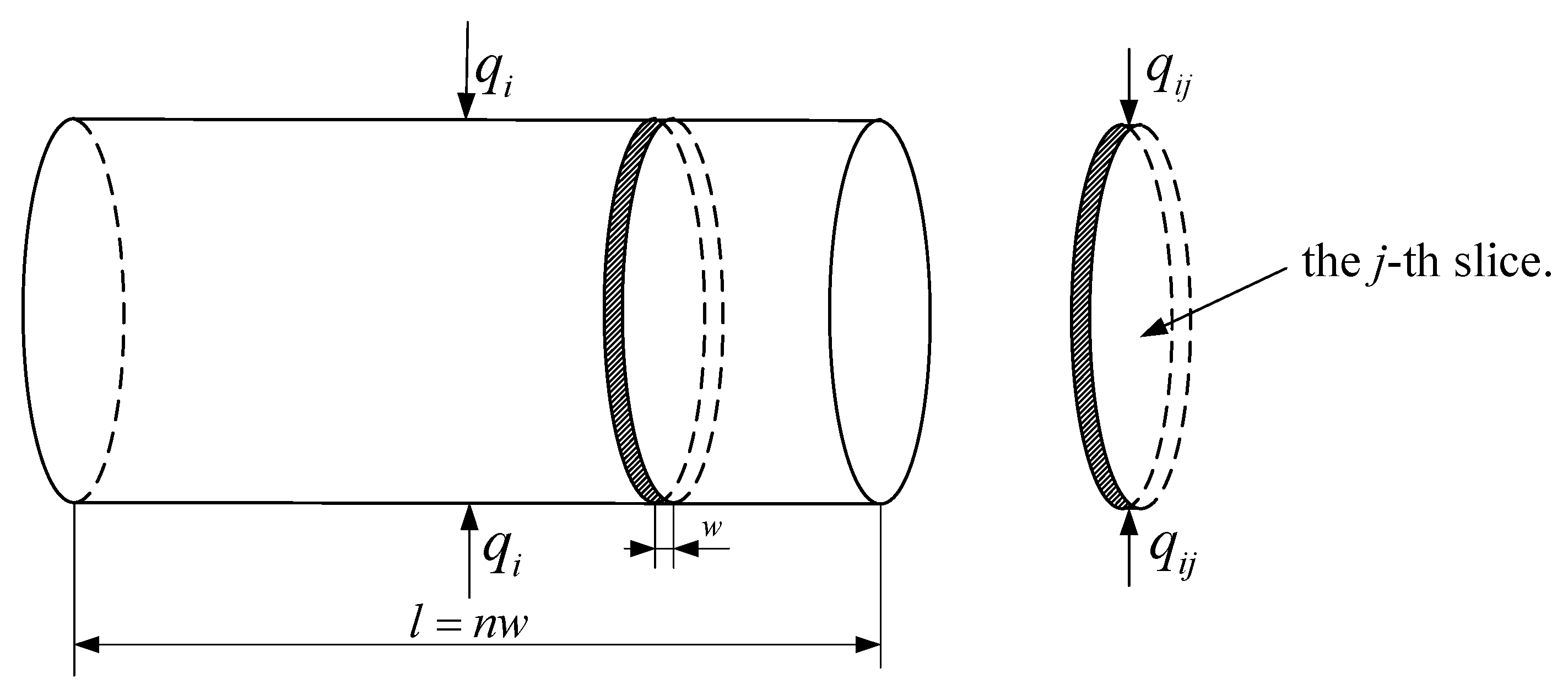

2.3. Fundamental Principles of the Slice Method

3. Static Model of the Novel Ball–Roller Composite Turntable Bearing

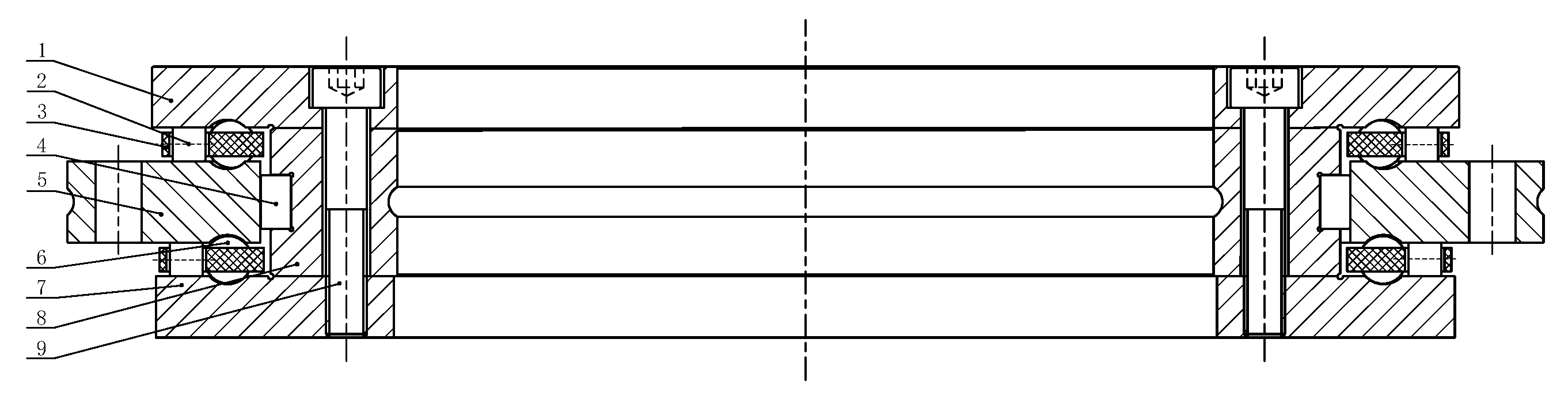

3.1. Bearing Structure

3.2. Static Modeling and Reasonable Assumptions

3.3. Force Analysis

3.3.1. Contact Load Analysis Between Axial Cylindrical Rollers and Raceways

3.3.2. Contact Load Analysis Between Axial Steel Balls and Raceways

3.3.3. Contact Load Analysis Between Radial Cylindrical Rollers and Raceways

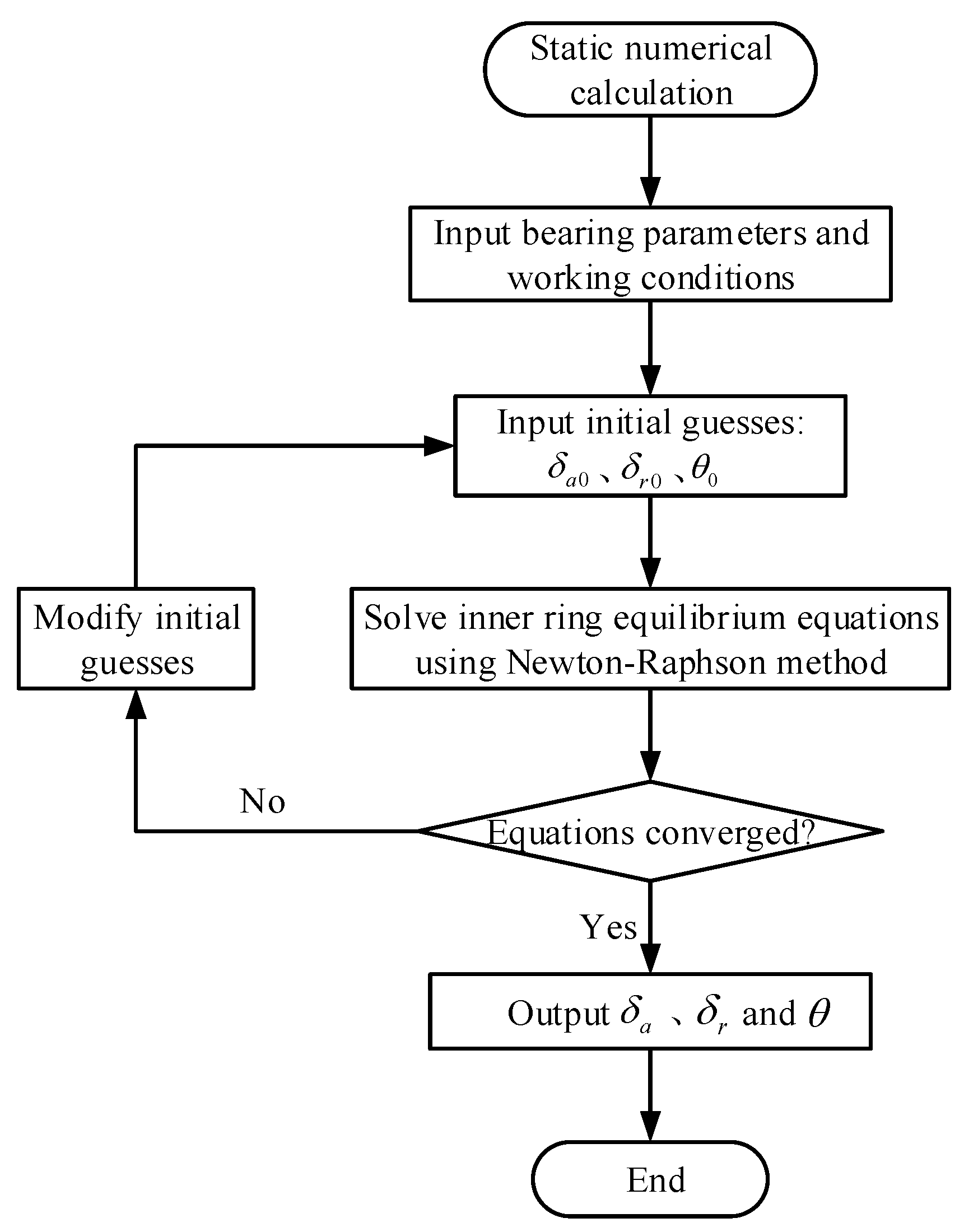

3.4. Mechanical Equilibrium Equations of the Bearing Inner Ring and Numerical Solution

3.5. Kinematic Analysis

4. Calculation of Bearing Friction Torque

4.1. Friction Torque Caused by Elastic Hysteresis of Cylindrical Rollers and Steel Balls

- (1)

- Friction torque generated by elastic hysteresis of cylindrical rollers.

- (2)

- Friction torque caused by elastic hysteresis of steel balls [5].

4.2. Friction Torque Caused by Differential Sliding of Cylindrical Rollers

4.3. Friction Torque Caused by Viscous Friction of Rollers and Steel Balls

- (1)

- The friction torque of the roller due to the viscosity of the lubricant.

- (2)

- The friction torque generated by the viscosity of the lubricating grease on the axial steel balls.

4.4. Friction Torque Due to Spinning and Sliding of Axial Steel Balls

4.5. Friction Torque Due to Sliding Friction Between Retainer and Guide Surface

4.6. Total Friction Torque of the Bearing

5. Experimental Verification of Bearing Friction Torque

5.1. Friction Torque Testing

5.2. Test Bearing-Related Parameters

5.3. Analysis of Test Results

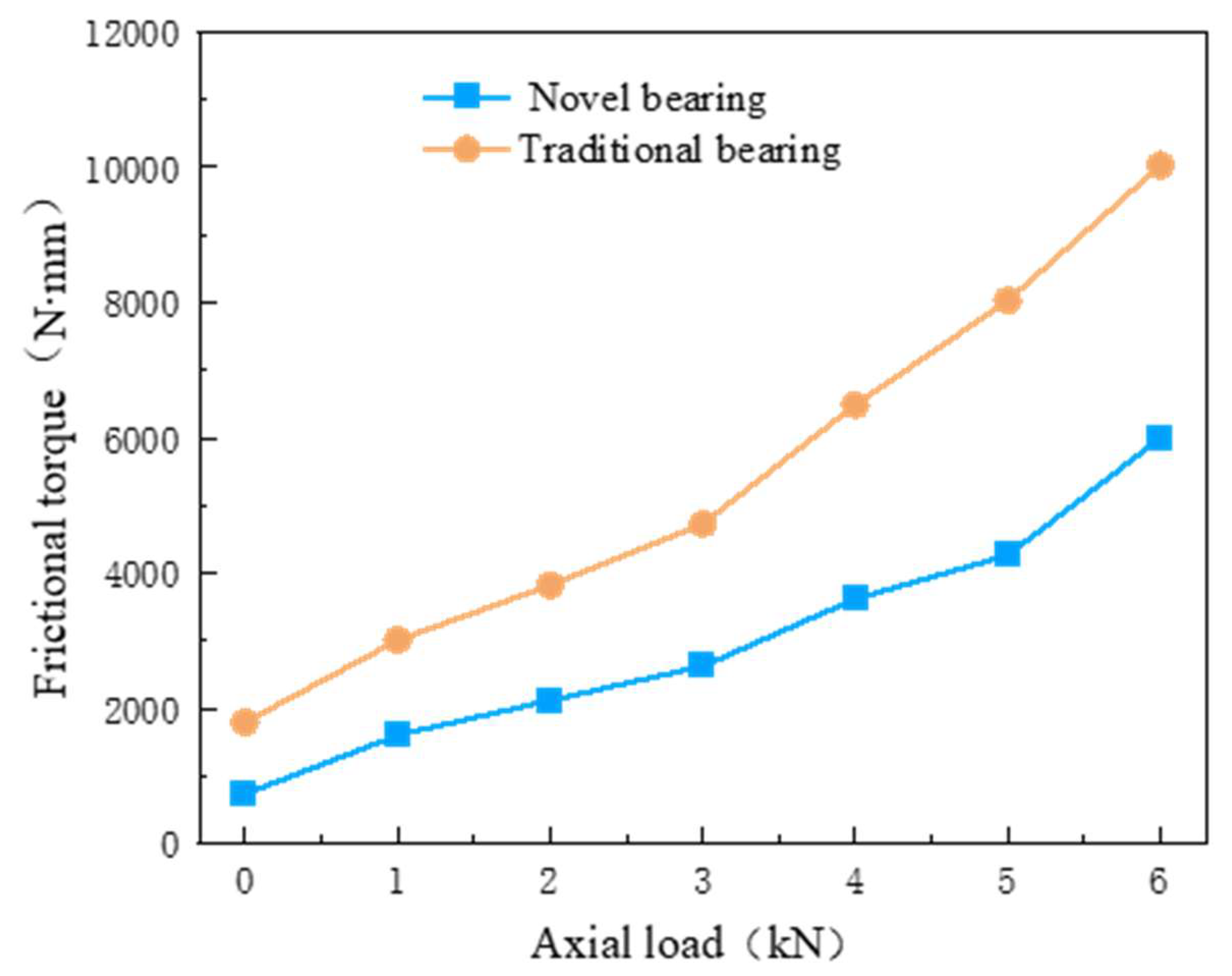

5.3.1. Comparative Analysis of Experimental Results Between the Novel and Conventional Bearings

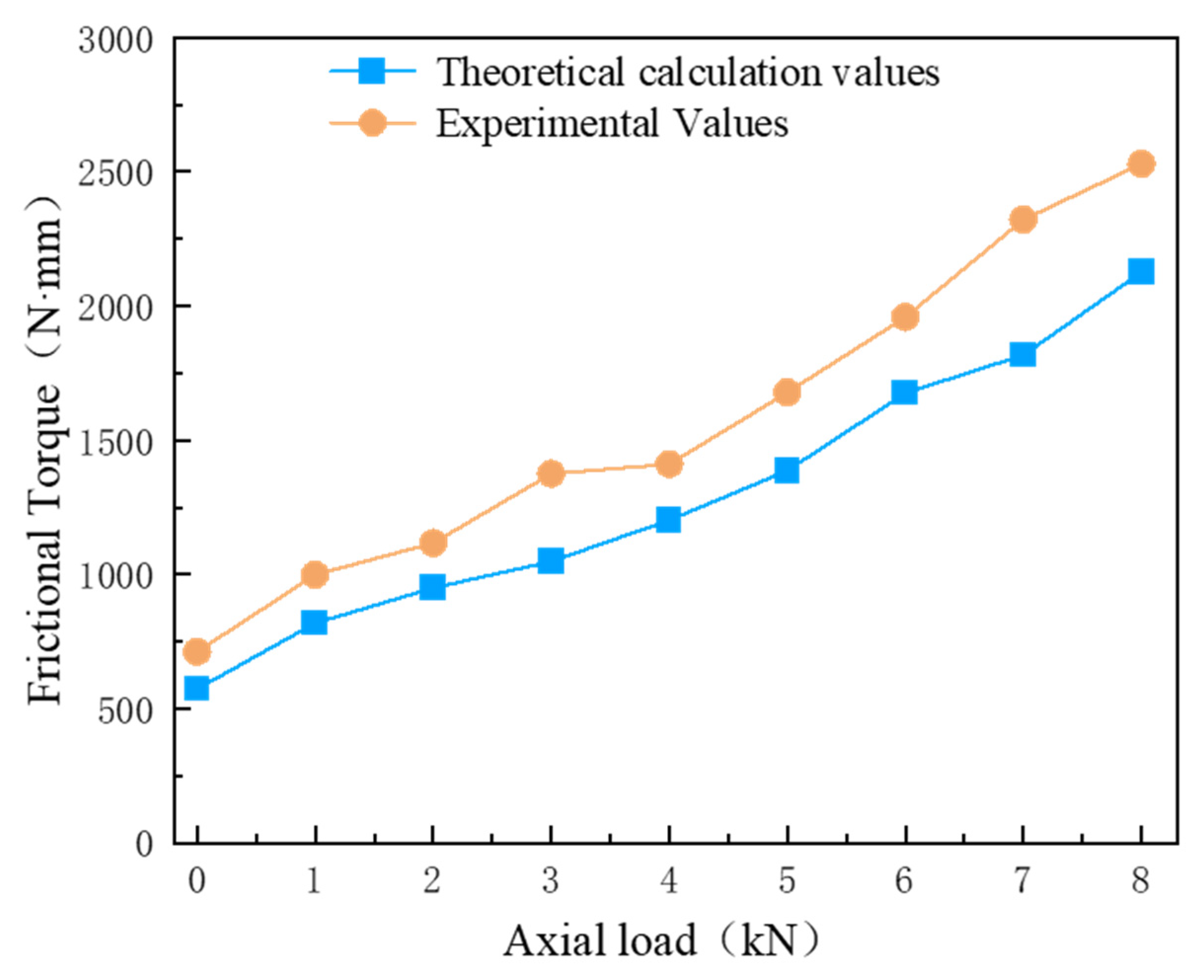

5.3.2. Experimental Results Analysis of the Novel Ball–Roller Composite Turntable Bearing

- (1)

- Test results of bearing friction torque under different rotational speeds.

- (2)

- Test results of bearing friction torque under different axial loads.

- (3)

- Test results of bearing friction torque under different overturning moments.

6. Analysis of Friction Torque Characteristics for Novel Ball–Roller Composite Turntable Bearings

6.1. Single-Factor Influence Analysis

6.1.1. Influence of Axial Clearance on Bearing Friction Torque

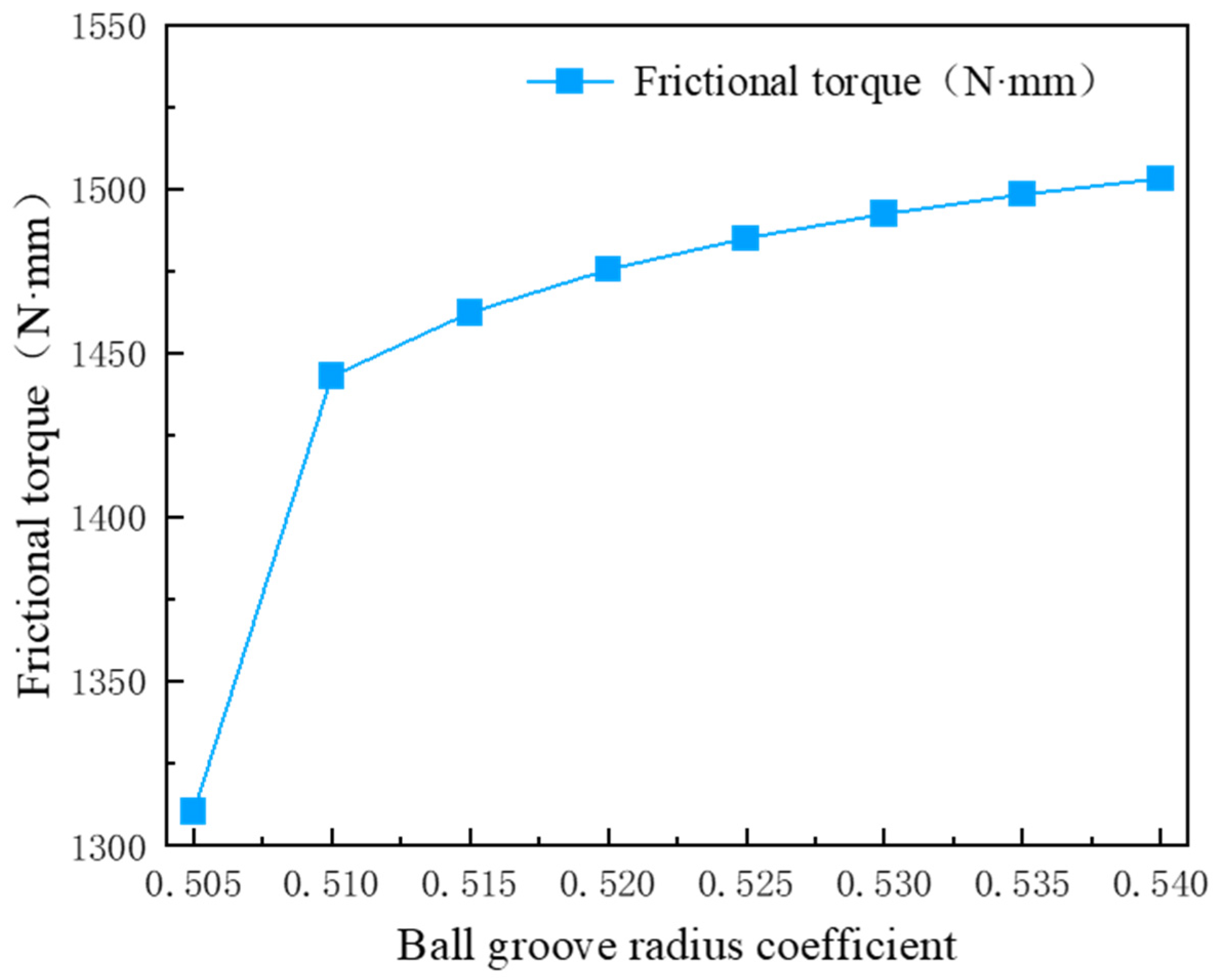

6.1.2. Influence of Axial Steel Ball Groove Curvature Radius Coefficient on Bearing Friction Torque

6.1.3. Influence of Axial Load Application Position on Bearing Friction Torque

6.1.4. Influence of the Numerical Ratio of Axial Steel Balls to Rollers on Bearing Friction Torque

6.1.5. Influence of Roller Crowning Methods on Bearing Friction Torque

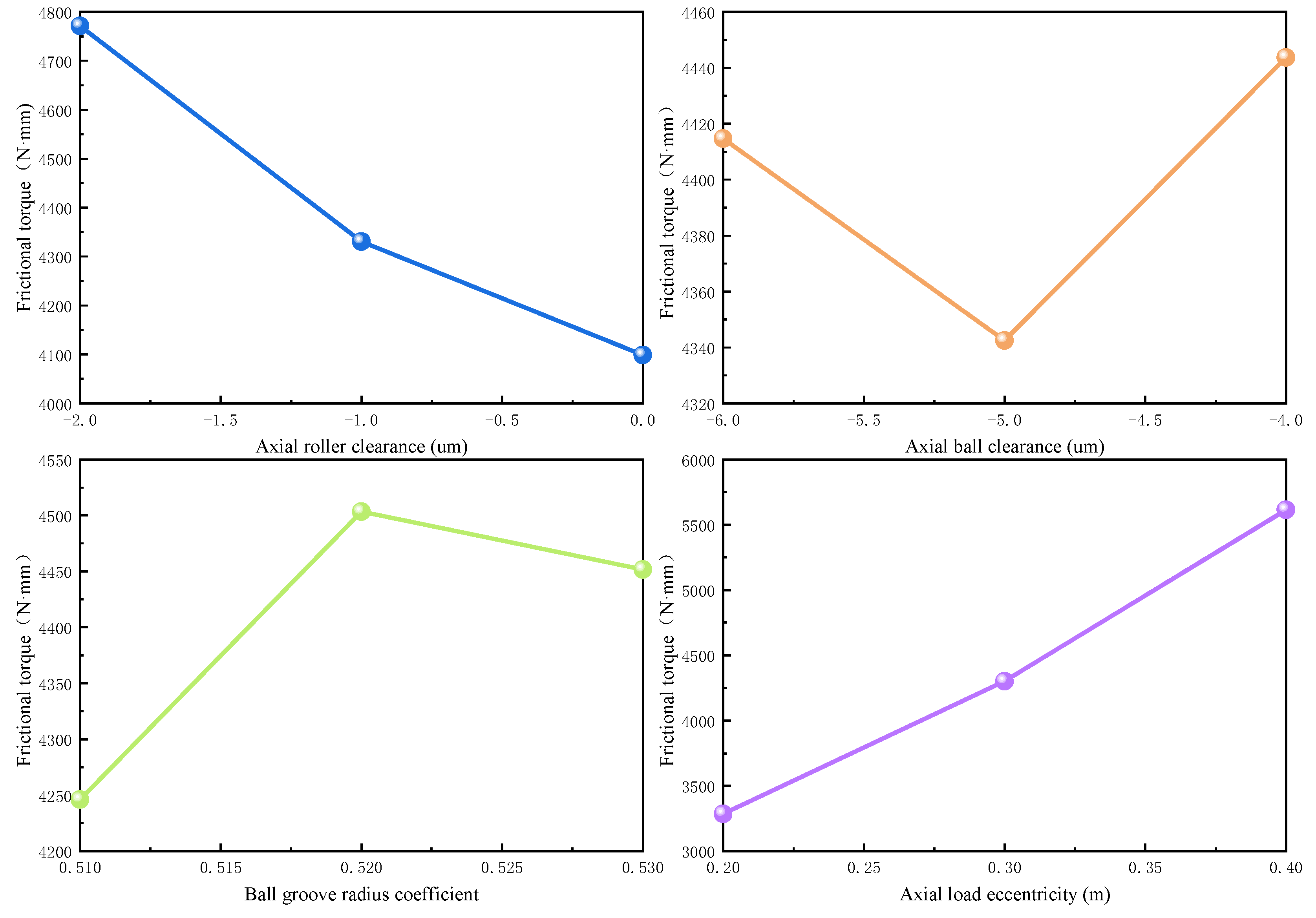

6.2. Analysis of Multi-Factor Coupling Effects

- (1)

- (2)

- Evaluation of the influence degree of each factor on the friction torque.

7. Conclusions

- (1)

- The friction torque of the novel ball–roller composite turntable bearing is primarily generated by the rollers. The negative axial roller clearance has a significant impact on the friction torque. By appropriately adjusting the clearance parameters—specifically, setting the axial roller clearance to -1 μm and the axial steel ball clearance to −5 μm—it is possible to achieve a more balanced load distribution between the axial rollers and the steel balls, thereby reducing the overall friction torque;

- (2)

- By comparing the friction torque and contact stress at various ratios of steel balls to rollers, it is observed that a 1:1 ratio of axial steel balls to rollers yields optimal friction and load-carrying performance, demonstrating excellent overall operational characteristics;

- (3)

- The curvature radius coefficient of the axial steel ball raceway significantly influences the friction torque; as this coefficient increases, the friction torque also increases markedly. Considering the challenges associated with processing and structural adaptability, the recommended range for the curvature radius coefficient is between 0.515 and 0.53;

- (4)

- The eccentric distance of the axial load significantly influences the friction torque. As the eccentric distance increases, the friction torque also rises. Therefore, in engineering design and application, it is essential to minimize load eccentricity to enhance the operational stability and service life of the bearing;

- (5)

- Different cylindrical roller crowning methods significantly influence the friction characteristics and contact stress distribution of bearings. Notably, the cylindrical roller structure featuring logarithmic crowning demonstrates superior performance in reducing friction torque and alleviating contact stress.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Palmgren, A. Ball and Roller Bearing Engineer, 3rd ed.; Svenska Kullager Fabriken (SKF) Industries Incorporration: Philadelphia, PA, USA, 1959. [Google Scholar]

- Chiu, Y.P.; Myers, M. A rational approach for determining permissible speed for needle roller bearings. SAE Trans. 1998, 107, 330–337. [Google Scholar]

- Ghanbari, A.; Khanmohamadi, S. A new test rig for friction torque measurement in ball bearing. Wseas Trans. Syst. 2006, 9, 2172–2177. [Google Scholar]

- Li, X.; Liu, J.; Huang, S.; Pan, G. Friction moment calculation method for tapered roller bearings under combined loads. Sci. China Technol. Sci. 2024, 67, 2565–2578. [Google Scholar] [CrossRef]

- Ye, B.; Zhang, K.; Zuo, Q.; Zhang, L.; Shan, X. Test and analysis of friction torque of double-row angular contact ball bearing under vacuum environment. Ind. Lubr. Tribol. 2024, 76, 160–166. [Google Scholar] [CrossRef]

- Fernandes, C.; Martins, R.; Seabra, J. Friction torque of thrust ball bearings lubricated with wind turbine gear oils. Tribol. Int. 2013, 58, 47–54. [Google Scholar] [CrossRef]

- Hammami, M.; Martins, R.; Fernandes, C.; Seabra, J.; Abbes, M.S.; Haddar, M. Friction torque in rolling bearings lubricated with axle gear oils. Tribol. Int. 2018, 119, 419–435. [Google Scholar] [CrossRef]

- Zhang, K.; Li, J. Analyzing Calculation for Friction Moment of Ball Bearings. Bearing 2001, 1, 8–11. [Google Scholar]

- Deng, S.; Jia, Y. Friction Torque Characteristics of Thrust Ball Bearings. Acta Armamentarii 2015, 36, 1615–1623. [Google Scholar]

- Deng, S.; Li, M.; Lu, Y.; Dai, Y. Study of Friction Torque of Needle Roller Thrust Bearings. Acta Armamentarii 2015, 36, 1347–1355. [Google Scholar]

- Goncz, P.; Potočnik, R.; Glodež, S. Computational model for determination of static load capacity of three-row roller slewing bearings with arbitrary clearances and predefined raceway deformations. Int. J. Mech. Sci. 2013, 73, 82–92. [Google Scholar] [CrossRef]

- Zupan, S.; Prebil, I. Carrying angle and carrying capacity of a large single row ball bearing as a function of geometry parameters of the rolling contact and the supporting structure stiffness. Mech. Mach. Theory 2001, 36, 1087–1103. [Google Scholar] [CrossRef]

- Amasorrain, J.; Sagartzazu, X.; Damián, J. Load distribution in a four contact-point slewing bearing. Mech. Mach. Theory 2003, 38, 479–496. [Google Scholar] [CrossRef]

- Chen, G.; Xu, S.; Yang, Y.; Wang, Y.; Deng, S. Contact stress analysis on large-sized four-contact-point ball bearing with negative axial play. J. Mech. Transm. 2009, 33, 83–85, 91. [Google Scholar]

- Deng, B. Analysis of the influence of raceway structure on contact characteristics of turntable bearing. J. Phys. 2021, 1732, 012192. [Google Scholar] [CrossRef]

- Krynke, M.; Borkowski, S.; Selejdak, J. Analysis of influence of bearing clearance on the static carrying capacity of multi-row slewing bearings. Period. Polytech. Transp. Eng. 2014, 42, 43–48. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, S.; Dou, Y.; Fan, H.; Wang, Y. Mechanical model and contact properties of double row slewing ball bearing for wind turbine. Rev. Adv. Mater. Sci. 2021, 60, 112–126. [Google Scholar] [CrossRef]

- Peter, G.; Miran, U.; Srecko, G. Computational assessment of the allowable static contact loading of a roller-slewing bearing’s case-hardened raceway. Int. J. Mech. Sci. 2015, 94, 174. [Google Scholar]

- Ju, S.; Horng, T.; Cha, K. Comparisons of contact pressures of crowned rollers. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2000, 214, 147. [Google Scholar] [CrossRef]

- Wang, H.; Hu, B.; Chen, Y. Calculation on friction torque of blade bearings without load based on finite element analysis. Bearing 2011, 1–3. [Google Scholar] [CrossRef]

- Wang, S.; Xu, M.; Shi, X. Comparative analysis on mechanical properties for two categories of slewing bearings. Chin. J. Constr. Mach. 2010, 8, 24–28. [Google Scholar]

- Gärtner, M.; Brecher, C.; Neus, S.; Eckel, H.-M.; Bartelt, A.; Hoppert, M.; Ilkhani, M.R. The friction of radially loaded hybrid spindle bearings under high speeds. Machines 2023, 11, 649. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, T.; He, L.; Bu, L.; Liu, M.; Li, M. Friction torque characteristic of large-size double row four-point contact ball bearings. Acta Energiae Solaris Sin. 2021, 42, 356–363. [Google Scholar]

- Li, J.; Li, Y.; Zhong, Z. Analysis of friction torque of wind turnine main bearing with three-row rollers under combined loads. Acta Energiae Solaris Sin. 2024, 45, 597–606. [Google Scholar]

- Zhang, Z.; Zhou, P.; Li, W.; Wang, H. Study of friction torque characteristics of YRT rotary table bearing. Acta Armamentarii 2019, 40, 1495–1502. [Google Scholar]

- Zhang, Z.; Zhang, K.; Wang, H. Friction torque characteristic of ball-roller combined turntable bearing. Aerosp. Power 2020, 35, 2664–2672. [Google Scholar]

- Deng, S.; Xue, J.; Niu, R. Principles of Rolling Bearing Design; Standards Press of China: Beijing, China, 2023. [Google Scholar]

- Deng, S.; Sheng, M.; Deng, K.; Dai, Y. Friction torque of double-row spherical roller bearings. Aerosp. Power 2017, 32, 1666–1675. [Google Scholar]

- Wang, Y.; Deng, S.; Yang, H. Analysis for traction characteristics of HKD aviation lubricating oil in rolling/sliding contacts. Acta Armamentarii 2009, 30, 958–961. [Google Scholar]

- Deng, S. Constitutive equation of a new aviation lubricating oil. Chin. J. Mech. Eng. 2007, 20, 28. [Google Scholar] [CrossRef]

- Matsuyama, H. High efficiency and tribology in rolling bearings. Jtekt Eng. J. 2012, 1009, 108–113. [Google Scholar]

| Parameter | Value |

|---|---|

| Inner diameter/mm | 120 |

| Outer diameter/mm | 210 |

| Pitch circle diameter of axial upper and lower row rollers/mm | 167 |

| Pitch circle diameter of axial upper and lower row steel balls/mm | 177.8 |

| Pitch circle diameter of radial rollers/mm | 155.25 |

| Number of axial row rollers/pcs | 31 × 2 |

| Number of axial row steel balls/pcs | 31 × 2 |

| Number of radial row rollers/pcs | 97 |

| Axial roller diameter/mm | 4 |

| Axial roller effective length/mm | 4.8 |

| Axial steel ball diameter/mm | 6 |

| Radial roller diameter/mm | 5 |

| Radial roller effective length/mm | 8 |

| Factor Number | Name | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|

| A | Axial roller clearance/um | 0 | −1 | −2 |

| B | Axial ball clearance/um | −4 | −5 | −6 |

| C | Groove curvature radius coefficient | 0.51 | 0.52 | 0.53 |

| D | Axial load eccentricity/m | 0.2 | 0.3 | 0.4 |

| Test No | A (Axial Roller Clearance/um) | B (Axial Ball Clearance/um) | C (Groove Curvature Radius Coefficient) | D (Axial Load Eccentricity/m) | Friction Torque/N·mm |

|---|---|---|---|---|---|

| 1 | 0 | 4 | 0.51 | 0.2 | 2871.7 |

| 2 | 0 | 5 | 0.52 | 0.3 | 4045.4 |

| 3 | 0 | 6 | 0.53 | 0.4 | 5379.6 |

| 4 | −1 | 4 | 0.52 | 0.4 | 5692.0 |

| 5 | −1 | 5 | 0.53 | 0.2 | 3208.1 |

| 6 | −1 | 6 | 0.51 | 0.3 | 4092.0 |

| 7 | −2 | 4 | 0.53 | 0.3 | 4767.5 |

| 8 | −2 | 5 | 0.51 | 0.4 | 5774.0 |

| 9 | −2 | 6 | 0.52 | 0.2 | 3772.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, H.; Li, W.; Shao, X.; Zhang, Z.; Zhang, W. Analysis of Friction Torque Characteristics of a Novel Ball–Roller Composite Turntable Bearing. Machines 2025, 13, 588. https://doi.org/10.3390/machines13070588

Tian H, Li W, Shao X, Zhang Z, Zhang W. Analysis of Friction Torque Characteristics of a Novel Ball–Roller Composite Turntable Bearing. Machines. 2025; 13(7):588. https://doi.org/10.3390/machines13070588

Chicago/Turabian StyleTian, Heng, Weiwang Li, Xiuhua Shao, Zhanli Zhang, and Wenhu Zhang. 2025. "Analysis of Friction Torque Characteristics of a Novel Ball–Roller Composite Turntable Bearing" Machines 13, no. 7: 588. https://doi.org/10.3390/machines13070588

APA StyleTian, H., Li, W., Shao, X., Zhang, Z., & Zhang, W. (2025). Analysis of Friction Torque Characteristics of a Novel Ball–Roller Composite Turntable Bearing. Machines, 13(7), 588. https://doi.org/10.3390/machines13070588