1. Introduction

Dimensional accuracy is a fundamental aspect of contemporary manufacturing, influencing the functional performance, safety, and compliance with regulations of precision-engineered components used in the aerospace, automotive, biomedical, and energy industries [

1,

2,

3]. This importance is particularly highlighted in recent machining studies, demonstrating that surface integrity and dimensional conformity are directly affected by the specific behaviors of materials under turning conditions [

4,

5]. As manufacturing evolves towards tighter tolerances and increasingly intricate geometries, it is essential to ensure not only precise measurements but also reliable measurement quantification [

6,

7]. In this scenario, managing uncertainty becomes a crucial element; it is vital for confirming product conformity, enhancing quality control strategies, and establishing metrological systems that are both traceable and repeatable [

8,

9].

Manual tools, such as the Digital Vernier Caliper (DVC), are widely used in shop-floor inspections due to their simplicity and affordability. Nevertheless, their dependence on the operator’s skill, vulnerability to surface variations, and lack of automation result in significant inconsistencies, which can compromise the reliability of high-precision evaluations [

10]. This measurement inconsistency has also been noted in comparative analyses between contact-based and automated surface inspection methods [

11]. In contrast, Coordinate Measuring Machines (CMMs) have set the benchmark in industrial metrology, providing enhanced precision, automation, and reproducibility [

12]. However, a significant gap still exists in understanding how error and uncertainty progress within each system, especially when measurements are conducted across various machining zones and materials under the same production conditions [

13,

14,

15].

Recent studies have highlighted that material characteristics, notably thermal conductivity and hardness, are crucial in determining surface quality and dimensional stability, especially in unsupported axial zones where fixture rigidity is reduced and thermal gradients become more pronounced [

16]. These spatial effects lead to dynamic measurement variability that static evaluations typically overlook. To tackle this issue, root-sum-square (RSS) modeling has been effective in estimating how localized uncertainties accumulate along the length of a machined component, providing a more realistic insight into dimensional error propagation in real manufacturing conditions [

17].

Building on this foundation, the current study presents a zone-specific experimental framework to systematically evaluate how measurement error and uncertainty develop along the axial length of CNC-turned components. Five industrially relevant materials, Aluminum Alloy 6061, Brass C26000, Bronze C51000, Carbon Steel 1020 Annealed, and Stainless Steel 304 Annealed, were chosen to represent a broad spectrum of thermal and mechanical properties. Dimensional measurements were carried out using both DVC and CMM systems across five distinct axial machining zones, facilitating a thorough assessment of how spatial location and material characteristics collectively impact metrological reliability. RSS-based error propagation modeling was used to quantify the cumulative effects of local deviations, emphasizing the sensitivity of manual systems to operator influence and surface evolution, compared to the steadiness provided by automated measurements.

This approach transcends traditional pointwise comparisons by offering a spatially detailed, material-centric viewpoint on dimensional metrology. It highlights the limitations of manual tools in high-precision applications and demonstrates the advantages of automation in minimizing measurement variability. The results provide a solid basis for selecting suitable metrology systems based on material characteristics and machining intricacy, which, in turn, impact quality assurance, process management, and integration into Industry 4.0 systems.

2. Materials and Methods

2.1. Experimental Setup

The experimental campaign utilized a high-precision Gate-Eclipse ECL-400 CNC lathe (Gate Machinery International Ltd., Derbyshire, UK), featuring a Fagor CNC control system. The lathe’s structural rigidity and thermal stability were crucial for minimizing mechanical drift and thermal deformation throughout the machining process, thereby ensuring consistent dimensional accuracy. All operations took place in a regulated laboratory environment, maintained at a temperature of 22 ± 1 °C and a relative humidity of 45 ± 5%, in accordance with ISO 230-3:2020 standards for environmental stability in precision machine tool testing [

18].

Five engineering materials relevant to industry were chosen to illustrate a wide array of mechanical and thermal properties that impact metrological performance: Aluminum Alloy 6061, Brass C26000, Bronze C51000, Carbon Steel 1020 Annealed, and Stainless Steel 304 Annealed (SpecLine Arabia Company Ltd. and Al Mokahal Co. Location, Al-Jubail, Saudi Arabia). These materials exhibit notable differences in hardness, thermal conductivity, and machinability, creating an optimal basis for examining how inherent material attributes influence measurement uncertainty and error propagation during dimensional evaluations.

Each cylindrical workpiece, measuring 25 mm in diameter and 45 mm in length, was machined into five sequential axial zones (F1 to F5). These zones represented specific distances from the chuck face to capture the spatial variations typical in elongated workpieces during CNC turning. The machining parameters consisted of four cutting speeds (30, 60, 90, and 120 m/min) and four feed rates (0.05, 0.10, 0.15, and 0.20 mm/rev), with a constant depth of cut maintained at 0.25 mm. All machining operations were conducted under dry conditions to remove the effects of cutting fluids and focus solely on the influence of material–tool interactions on surface integrity and dimensional changes.

The tooling used Sandvik CNMG 120408-PM 4425 classified tungsten carbide inserts (nose radius 0.8 mm), coated with titanium aluminum nitride (TiAlN), to provide thermal resistance and wear durability [

19]. While the CNMG 120408-PM 4425 insert is optimized for P (steel) and K (cast iron) materials, it was used across all alloys in this study for experimental consistency. We acknowledge that this choice may contribute to surface artifacts in non-P/K materials, such as brass, bronze, and aluminum. Inserts were either indexed or replaced when flank wear exceeded 0.3 mm, in accordance with the guidelines of ISO 3685:1993 for tool life testing in metal cutting [

20]. Work-holding was maintained with a self-centering three-jaw chuck, with radial runout limited to within ±0.01 mm. This was verified through procedures aligned with ISO 230-1:2012 [

21], ensuring accuracy and consistency in alignment.

This experimental setup enabled the precise management of machining conditions and the tailored response of materials. As a result, any variations in dimensional measurements could be reliably linked to the properties of the materials and the capabilities of the measurement instruments, rather than to unpredictable processes or environmental factors. A detailed schematic of the CNC machining platform, workpiece fixturing, and axial machining zones (F1–F5) is provided in our prior works [

22,

23], which employed the same experimental setup as used in this study.

2.2. Measurement Protocols

Dimensional assessments were conducted using two metrological systems to facilitate a thorough comparison of the reliability of manual and automated measurements: a Preisser Messtechnik Digital Vernier Caliper (DVC) and a Millennium DIGI-MET Coordinate Measuring Machine (CMM). The CMM, produced by Millennium Measurement Machines Ltd. in Leicestershire, UK, provides a volumetric accuracy of ±0.001 mm within a 0–200 mm working range and meets the ISO 10360-2:2021 certification for coordinate measuring system performance [

22]. The reported volumetric accuracy of ±0.001 mm is based on the manufacturer’s specification for this model, as verified under the controlled laboratory conditions used in this study. These two devices were chosen to represent contrasting yet commonly used methods in industrial dimensional metrology: operator-dependent, portable manual gauging versus automated, high-resolution coordinate-based inspection. Each method offers unique advantages in accuracy, repeatability, environmental resilience, and sensitivity to human error.

The DVC offers a resolution of ±0.02 mm across a range of 0–150 mm and undergoes daily calibration utilizing ISO/IEC 17025:2017-accredited gauge blocks of 10 mm, 50 mm, and 100 mm lengths [

23]. The DVC resolution is based on the manufacturer specification for the Preisser Messtechnik model employed. Each calibration’s deviations were recorded to maintain traceability to international standards. A single trained operator conducted the measurements to minimize inter-operator variability, taking five repeated readings for each feature with orthogonally aligned jaws and a standardized clamping force. All measurements were performed on a vibration-damped granite table to minimize mechanical disturbances and enhance data consistency.

In comparison, the CMM provided enhanced resolution (±0.001 mm) and was calibrated before each session with a 25.000 mm precision reference sphere (Class 1) along with 50 mm and 100 mm gauge artifacts. This calibration process strictly followed ISO 10360-2 standards [

22], resulting in a mean calibration deviation of ±0.0008 mm. Workpieces were mounted on an air-bearing granite table to prevent vibrational interference, with each surface feature being probed at ten evenly spaced points across three distinct measurement cycles. A least-squares fitting algorithm facilitated geometric reconstruction, yielding statistically robust feature values while mitigating localized probe deflection or noise effects.

The repeatability of both systems was assessed by calculating the standard deviation from repeated trials within each material and machining zone. As anticipated, the DVC exhibited higher variability influenced by operator-dependent factors and heightened material hardness, especially in the later machining zones (F4 and F5). In contrast, the CMM’s automated process significantly minimized measurement variance, establishing it as a reliable benchmark for evaluating propagated error, material response, and uncertainty distribution in CNC-machined components.

This dual-instrumentation approach facilitated a regulated and repeatable examination of dimensional variability in relation to measurement system type, machining zone, and material properties. The results backed the comparative assessment of systemic uncertainty factors and the measurement of reliability loss between manual and automated dimensional inspection systems.

2.3. Measurement Techniques

To methodically explore the performance differences between manual and automated dimensional inspection systems for CNC-turned components, two key metrological tools were used: a Digital Vernier Caliper (DVC) and a Coordinate Measuring Machine (CMM). These tools were specifically selected for both their operational differences and their significance in the industry, illustrating the balance between cost-effectiveness, precision, and repeatability commonly encountered in manufacturing settings.

The Digital Vernier Caliper (DVC), manufactured by Preisser Messtechnik, is a portable contact gauge offering a resolution of ±0.02 mm and a measurement range of 0 to 150 mm. It was employed to take five repeated measurements for each feature in every zone. To reduce variability, each measurement was conducted by a single trained operator on a granite surface that was isolated from vibrations. The caliper’s jaws were orthogonally aligned with the cylindrical surface, and consistent pressure was applied during measurements. Despite these precautions, the DVC remains susceptible to human-induced variability, which includes angular misalignment, inconsistent clamping force, visual misinterpretations of digital readouts, and sensitivity to local surface roughness or deformation, particularly when measuring ductile or thermally responsive materials such as Aluminum 6061. The expanded uncertainty in DVC readings was estimated using the standard propagation formula:

where

represents the standard deviation of repeated measurements,

corresponds to the caliper’s resolution (±0.02 mm), and

accounts for traceable deviations from ISO 17025-certified gauge block calibrations [

23]. A coverage factor of

k = 2 was used to provide a 95% confidence level.

In contrast, the Millennium DIGI-MET model of the Coordinate Measuring Machine (CMM) offers automated probing accuracy of ±0.001 mm within a range of 0–200 mm. By utilizing programmed path control and consistent probe force, the CMM effectively removes operator influence, significantly improving measurement repeatability and reliability. Each cylindrical feature was probed at ten distinct locations with a touch-trigger stylus, and this process was repeated over three full cycles. Parts were securely positioned on an air-bearing granite base to minimize thermal drift and mechanical vibrations. The expanded uncertainty in CMM measurements was determined using a similar root-sum-square (RSS) method:

where

corresponds to the standard deviation of repeated scans,

accounts for uncertainty due to probe tip deflection, and

arises from ISO 10360-2-compliant calibration trials using certified artifacts (25.000 mm sphere, 50 mm and 100 mm gauge blocks) [

22]. A coverage factor of

k = 2 was applied for a 95% confidence level.

We acknowledge that the DVC and CMM sampling sizes are not perfectly balanced; however, the analysis focused on system repeatability within each method, and ANOVA was conducted with appropriate caution regarding variance assumptions.

Table 1 outlines the metrological specifications and calibration performance of the two measurement systems. The CMM exhibited a remarkable improvement in precision and repeatability, showing average deviations about 19 times lower than those observed for the DVC. This underscores its superior ability for high-accuracy dimensional evaluations.

The comparative analysis highlights an almost nineteen-fold enhancement in average measurement deviation when utilizing the CMM instead of the DVC. This significant contrast demonstrates that operator-independent, probe-based inspection achieves greater consistency in high-accuracy applications. Although the DVC is a helpful resource for quick on-site evaluations, its susceptibility to manual influence and material response traits restricts its effectiveness in settings where metrological traceability and dimensional conformity are crucial.

2.4. Evaluation Metrics and Data Analysis

A thorough comparative analysis of manual and automated dimensional measurement systems requires capturing raw dimensional deviations and examining the evolution and propagation of uncertainty under realistic machining conditions. Consequently, we systematically assessed three key metrological indicators: absolute error, expanded uncertainty, and propagated error. These indicators were central to our quantitative framework for evaluating measurement reliability in CNC-turned parts.

Absolute error serves as a direct metric to quantify deviation from the nominal dimension. It is defined as

where

is the measured value obtained from the DVC or CMM, and

is the reference (true) dimension.

To guarantee comparability among materials and zones with varying dimensional magnitudes, we also calculated the relative error as

These metrics allowed for the normalization of measurement deviations and supported comparisons across different materials. The expanded measurement uncertainty (

U) was assessed for both systems following the Guide to the Expression of Uncertainty in Measurement (GUM) [

17]. This uncertainty model combined both Type A (repeatability) and Type B (instrument resolution and calibration bias) sources. For the Digital Vernier Caliper (DVC), the uncertainty was calculated as

where

represents the standard deviation of repeated measurements,

is the instrument resolution (±0.02 mm for DVC and ±0.001 mm for CMM), and

reflects bias from gauge block or artifact calibration (certified per ISO 17025 [

23]). A coverage factor

k = 2 was used to provide a 95% confidence level.

To assess the impact of minor input variations on overall metrological reliability, error propagation was analyzed using the root-sum-square (RSS) method. This technique illustrates how local measurement variations accumulate into broader assessment errors, especially across different machining zones. The generalized propagation model is stated as

where

f(

X) is the function describing the measured characteristic, and

E1,

E2, …,

En are the individual measurement errors associated with input variables

X1,

X2, …,

Xn.

This formulation enabled the estimation of cumulative metrological degradation from Zone F1 to Zone F5, illustrating realistic production scenarios in which fixture effects, residual stress, and surface irregularities increase with axial progression.

To guarantee statistical reliability, we assessed each measurement set (for each zone and material) using the mean and standard deviation, which provided a quantitative evaluation of each system’s repeatability and precision.

Ultimately, trend analysis was performed to link measurement deviations and uncertainty behaviors with essential material properties, such as hardness and thermal conductivity. This facilitated a more profound understanding of how specific cutting responses of materials (e.g., work hardening in stainless steel or surface smearing in brass) affect the metrological performance of both manual and automated systems. This evaluation framework offered a scientifically sound, comprehensive foundation for analyzing the comparative dimensional reliability of the DVC and CMM systems in CNC-turned parts by integrating absolute and relative error quantification, GUM-based uncertainty modeling, error propagation assessment, and statistical trend analysis.

3. Results and Discussion

3.1. Interdependence of Measurement Uncertainty and Error Metrics

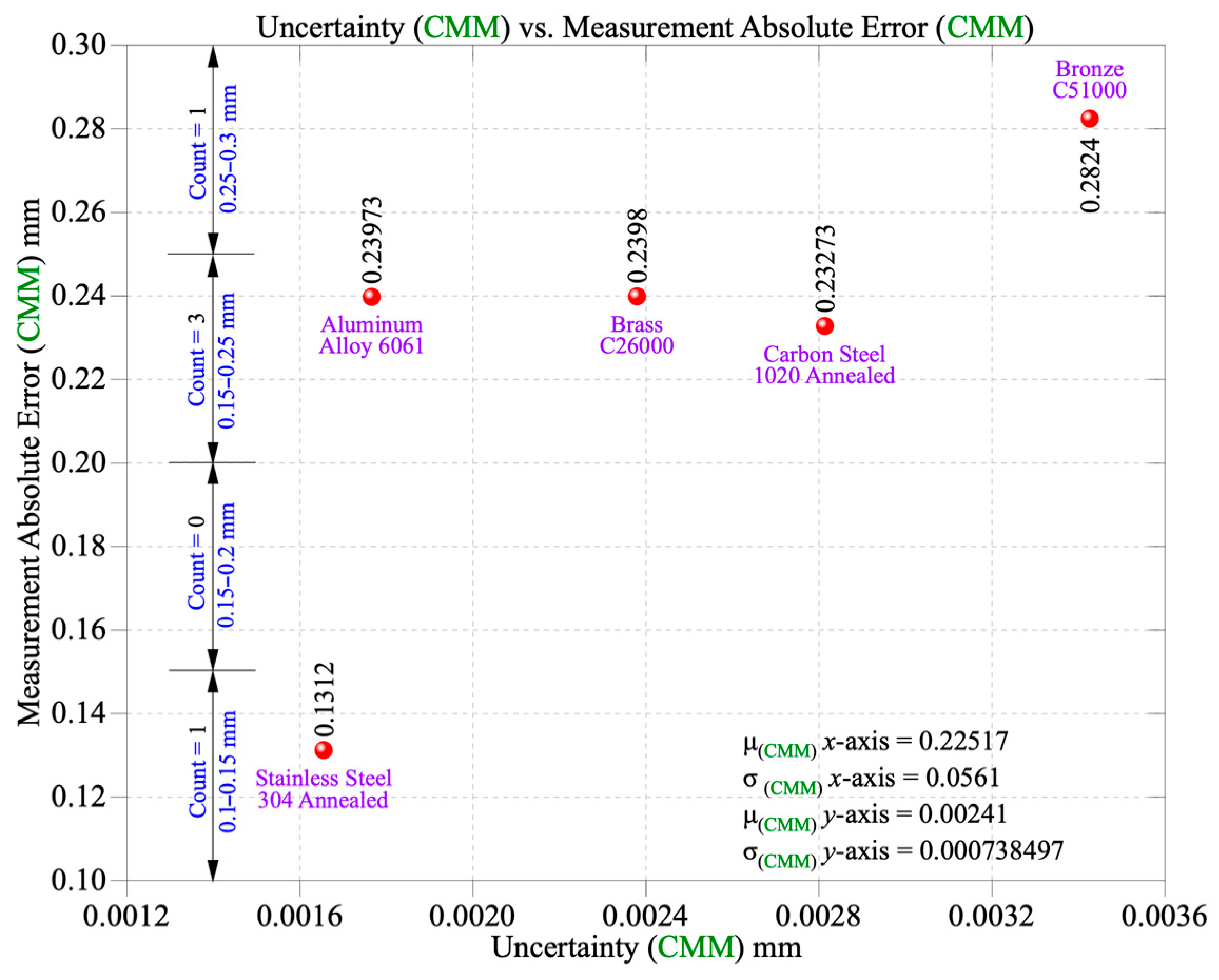

Figure 1 shows a quantitative analysis of the connection between measurement uncertainty and absolute error in axial length conducted with a Coordinate Measuring Machine (CMM) across five different engineering materials. The findings reveal a direct correlation: with increasing uncertainty comes a rise in absolute error, emphasizing how material-specific machining reactions affect metrological stability.

It is important to note that absolute error reflects geometric deviations resulting from machining and material behavior, whereas uncertainty quantifies the repeatability of the measurement system itself. Therefore, large ratios between observed error and system uncertainty are expected and physically meaningful in this context.

Stainless Steel 304 Annealed demonstrated the highest metrological stability, consistent with its hardness and low thermal conductivity. The CMM effectively mitigated machining-induced distortions, maintaining low uncertainty and error. In contrast, Bronze C51000 exhibited the most significant measurement variability, with higher uncertainty and error values due to residual stresses, burr formation, and microstructural non-uniformity.

Aluminum Alloy 6061, renowned for its high thermal conductivity (167 W/m·K) and low hardness (95 HBW), exhibited an uncertainty of 0.00177 mm and an absolute error of 0.2397 mm. It generally features a smooth surface finish, a result of excellent machinability, which may exhibit slight inconsistencies during probing, potentially explaining the increased error. Meanwhile, Brass C26000 and Carbon Steel 1020 Annealed demonstrated intermediate behaviors. Brass recorded an uncertainty of 0.00238 mm and an error of 0.2398 mm. In contrast, carbon steel showed 0.00281 mm and 0.2327 mm, revealing that moderate hardness or thermal properties can introduce slight variability in dimensional assessments.

A direct comparison of Bronze C51000 and Stainless Steel 304 shows that an increase of approximately ~0.00177 mm in uncertainty resulted in about a 0.15 mm rise in absolute error. This highlights how sensitive axial length accuracy is to slight fluctuations in uncertainty. Furthermore, it emphasizes that micro-topographical features, changes in tool wear, and the material’s response to machining can amplify deviations, even when utilizing high-precision systems.

In conclusion,

Figure 1 sets a metrological standard for CMM-based inspection by closely connecting uncertainty with absolute deviation. It illustrates that reducing uncertainty through enhanced surface finish, refined machining parameters, and effective thermal control is crucial for achieving precise dimensional accuracy. This knowledge is crucial for engineers aiming to maintain measurement traceability in quality-sensitive manufacturing settings.

Figure 2 examines the relationship between measurement uncertainty and absolute error in axial length conducted with the Digital Vernier Caliper (DVC). A distinct upward trend is noted, showing that the absolute error also increases as uncertainty rises. This highlights the vulnerability of manual measurement systems to both material characteristics and variability introduced by the operator.

Aluminum Alloy 6061 exhibited favorable manual measurement performance, benefiting from its excellent machining characteristics and smooth surface finish. This resulted in relatively stable DVC readings. In contrast, Bronze C51000 presented the highest measurement variability with the DVC, due to its higher hardness and surface irregularities, which exacerbated the limitations of manual probing and operator influence.

Brass C26000 and Carbon Steel 1020 Annealed exhibited intermediate manual measurement performance with the DVC. Brass demonstrated good machinability and thermal stability, supporting relatively consistent readings. In contrast, Carbon Steel exhibited somewhat better repeatability, though its measurements were affected by residual stresses and localized hardening, particularly in the early machining zones. Despite its high hardness, Stainless Steel 304 Annealed performed relatively well in manual inspections with the DVC. This consistency is likely due to its smooth surface finish and stable thermal response, which helped mitigate the effects of operator variability during manual probing.

The comparison between Aluminum 6061 and Bronze C51000 highlights that even small differences in uncertainty can lead to substantial increases in absolute error when using manual metrology systems. This underscores the sensitivity of DVC measurements to material-induced surface variations and tactile inconsistencies, which can significantly impact dimensional accuracy in precision-critical applications. In contrast to CMM systems, DVC does not provide automated compensation for factors such as surface curvature, thermal gradient, or edge alignment, all of which significantly affect reliability in harder alloys.

Ultimately,

Figure 2 emphasizes the metrological trade-off linked to manual measurement systems. Although DVC is beneficial for quick and budget-friendly evaluations in well-machinable materials, its accuracy is significantly restricted by the operator’s technique and the material’s response. For applications requiring high tolerance or components with residual stress, surface waviness, or intricate geometries, the variability that comes with DVC use calls for a switch to automated systems like CMM. These systems provide multi-point sampling and environmental control, ensuring accuracy that is statistically traceable.

Figure 1 and

Figure 2, along with the summarized classifications in

Table 2 and

Table 3, provide a comprehensive view of how measurement error, uncertainty, and material properties interact in CNC-machined components. The analysis reveals evident trends in both absolute error and uncertainty across different materials and measurement systems, highlighting the unique performance of the Digital Vernier Caliper (DVC) and Coordinate Measuring Machine (CMM).

Stainless Steel 304 Annealed consistently exhibited the highest metrological stability among the tested materials, with low absolute errors and uncertainty in both CMM and DVC measurements. Despite its tendency to work-harden, the material’s excellent surface integrity under controlled machining allowed for dependable dimensional evaluation, particularly with CMM, where automated probing effectively mitigated measurement variability.

Aluminum Alloy 6061 performed well in CMM evaluations, with low uncertainty and acceptable dimensional accuracy. However, its relatively soft nature posed challenges for consistent manual measurements using the DVC, highlighting the sensitivity of contact-based tools to material deformation effects. Brass C26000 and Carbon Steel 1020 demonstrated medium levels of error and uncertainty, indicating how their intermediate hardness and ductility can lead to moderate instability during manual measurements. Conversely, Bronze C51000 exhibited the highest levels of measurement error and uncertainty in both DVC and CMM evaluations. This confirms the significant metrological challenges posed by this material, mainly due to its strain-hardening behavior, residual stresses, and surface irregularities.

A comparative analysis of

Table 2 and

Table 3 highlights the strengths and weaknesses of each system. While the absolute error rankings were consistent primarily between DVC and CMM, their classifications of uncertainty differed due to their unique operational principles. CMM’s point-based, automated measurements were less affected by environmental and human-induced variability, allowing for better repeatability, especially in materials with reliable machinability such as Stainless Steel 304 and Aluminum 6061. In contrast, DVC’s manual interface introduced variability in harder materials like Brass and Bronze, where surface irregularities and user alignment considerably influence uncertainty.

These data highlight that measurement uncertainty arises not only from device resolution or calibration but also from the dynamic interplay between tool mechanics and changes in material surfaces. This is particularly evident in the case of DVC measurements on Carbon Steel 1020, where the material’s stable surface response and minimal spring-back contributed to lower uncertainty compared to other harder alloys.

From a process control and cost-efficiency perspective, these insights emphasize the strategic necessity of aligning measurement systems with material behavior. Materials deemed low-error and low-uncertainty, such as Stainless Steel 304 under CMM, facilitate predictable and repeatable machining with a diminished necessity for corrective inspection. In contrast, materials exhibiting greater variability require more stringent control strategies and may benefit from the integration of automated metrology.

In summary, this comparative classification offers a quantitative basis for optimizing metrology in various engineering materials. The systematic distinctions between DVC and CMM not only demonstrate the trade-offs between accessibility and precision but also emphasize the vital importance of uncertainty modeling when choosing appropriate tools for high-tolerance manufacturing.

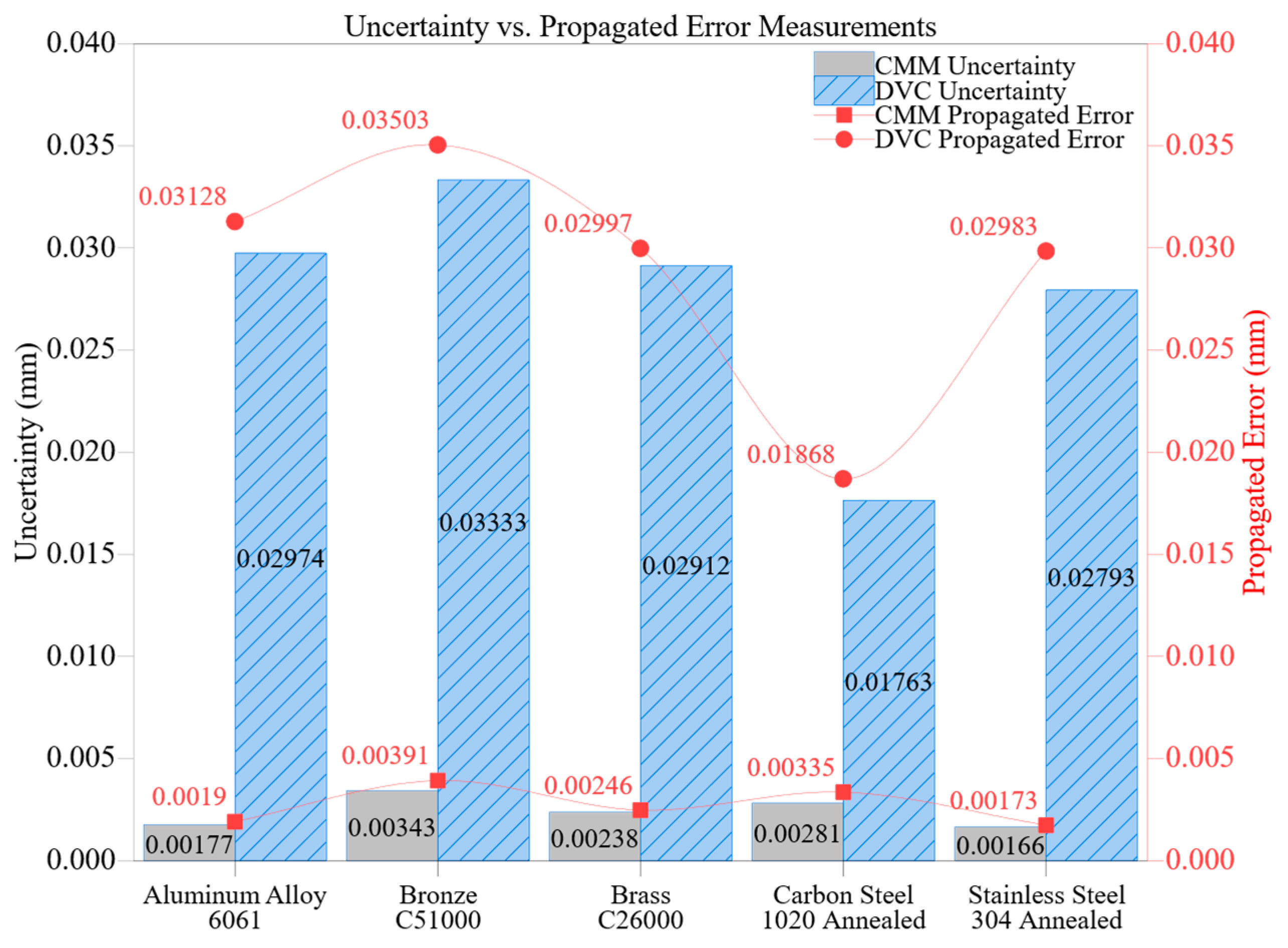

Figure 3 offers a comparative measurement uncertainty analysis for the Digital Vernier Caliper (DVC) and the Coordinate Measuring Machine (CMM) across five engineering materials. It highlights clear trends in metrological consistency and the devices’ sensitivity to material characteristics. Although earlier analyses indicated that CMM has better repeatability, this figure clearly quantifies the differences in uncertainty levels related to each measurement method and type of material.

Stainless Steel 304 Annealed exhibited the best stability for both systems, with CMM showing the lowest uncertainty at (0.00166 mm) and DVC having a relatively modest measurement of 0.01763 mm. This result highlights the material’s resilience to surface deformation during manual probing and confirms its adequacy for precision metrology, even when using handheld tools. Nevertheless, the significant tenfold disparity between the two devices underscores the inherent constraints of DVC in tight-tolerance scenarios.

Aluminum Alloy 6061, known for its excellent machinability and smooth surface finish, showed the largest uncertainty gap between DVC (0.02974 mm) and CMM (0.00177 mm). This result highlights that surface smoothness does not guarantee measurement consistency, especially when operator influence, alignment errors, varying pressure, and subjective scale interpretation notably impact DVC performance, particularly in low-resistance materials.

Bronze C51000 exhibited the greatest absolute DVC uncertainty (0.03333 mm), with CMM uncertainty recorded at 0.00343 mm, resulting in the largest discrepancy (0.02990 mm) across all materials. The high hardness of bronze, combined with its propensity for strain-hardening during machining, likely leads to surface irregularities that aggravate variability in manual tooling. The increased edge hardness and the possibility of microstructural heterogeneity pose challenges for the DVC in delivering consistent contact-based measurements.

Brass C26000 exhibits moderate hardness and machinability, showing an uncertainty difference of 0.02674 mm (CMM: 0.00238 mm vs. DVC: 0.02912 mm). This indicates the DVC’s vulnerability to micro-burrs and subtle edge irregularities that typically arise during brass turning, thereby affecting repeatability when based on tactile scale interpretation.

Carbon Steel 1020 Annealed exhibited the second-smallest uncertainty gap (0.02627 mm) between the CMM (0.00281 mm) and DVC (0.02793 mm), despite its higher hardness. This is likely due to its consistent surface topography after machining and moderate work hardening, resulting in more uniform contact behavior during measurements.

The error evolution across different zones clearly shows that material hardness, machining stability, and surface texture development collectively influence the precision of manual measurements. The trends further reveal DVC’s susceptibility to human factors, including reading alignment and pressure application, particularly in the later zones where surface irregularities and heat effects are more noticeable. Moreover, material thermal conductivity influences measurement variability, particularly in manual methods. Low-conductivity materials, such as Stainless Steel 304 and Bronze C51000, tend to accumulate heat during machining, promoting surface strain and residual stress that exacerbate uncertainty in DVC readings.

3.2. Quantitative Modeling of Error Propagation

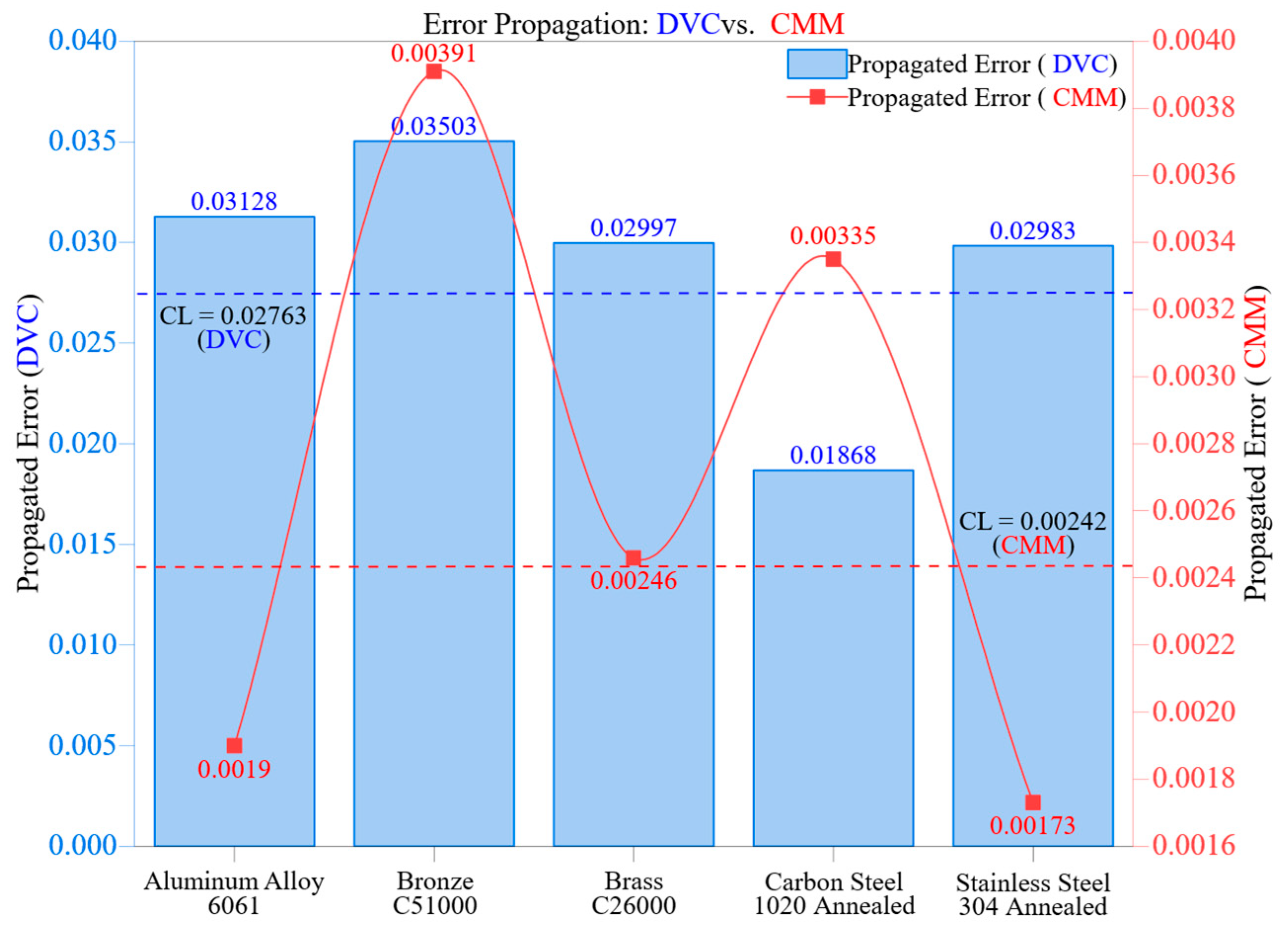

Figure 4 illustrates the measurement uncertainty distribution across five materials when utilizing both a Digital Vernier Caliper (DVC) and a Coordinate Measuring Machine (CMM). It emphasizes how initial uncertainties accumulate to create substantial inaccuracies in dimensions. This figure indicates that the DVC displays significantly greater propagated errors than the CMM for all materials tested, largely due to its reliance on the operator.

For Aluminum Alloy 6061, CMM measurements demonstrated a clear precision advantage over DVC measurements. This highlights that even machinable, low-hardness materials can exhibit noticeable error amplification when measured manually, due to sensitivity to alignment errors and operator inconsistencies.

In Brass C26000 and Bronze C51000, DVC measurements exhibited substantially greater propagated errors compared to CMM measurements. This indicates that even moderately hard or ductile materials experience amplified deviations during manual measurements, driven by inconsistent surface contact and operator variability. Notably, the brass sample exhibited particularly pronounced propagated error, reflecting the influence of microstructural surface factors on DVC performance.

Carbon Steel 1020 Annealed, despite its relatively higher hardness, exhibited lower propagated error in DVC measurements compared to other harder materials, likely due to its smoother surface response during manual probing. Nevertheless, CMM measurements consistently maintained superior performance, reinforcing that automated systems are more effective in controlling the amplification of minor input uncertainties.

Stainless Steel 304 Annealed, identified as one of the most challenging materials in this study, exhibited notable manual measurement error propagation due to surface resistance, thermal distortion, and work-hardening effects. These influences were effectively mitigated in CMM measurements through consistent automated probing and robust geometric reconstruction.

Overall, the data confirm that error propagation is influenced not only by the material but also significantly by the measurement technique employed. While DVC measurements exhibited consistently higher propagated errors, CMM measurements remained well within acceptable limits across all materials. These results highlight that if left unregulated, measurement systems with even slight intrinsic uncertainties can amplify discrepancies throughout the measurement chain, potentially jeopardizing product conformity in precision-critical industries.

By measuring this amplification, this study provides an essential reference for metrology decisions, particularly in high-accuracy fields, such as aerospace and biomedical machining, where dimensional conformity directly impacts safety and functionality.

Figure 5 illustrates a comparative analysis of the expanded measurement uncertainty and its propagated error for the Coordinate Measuring Machine (CMM) and the Digital Vernier Caliper (DVC) across five engineering materials. This cohesive visualization showcases clear patterns of metrological stability and error amplification between automated and manual measurement systems operating under the same machining conditions.

CMM data, represented by the grey bars and red markers, consistently show low uncertainty values (ranging from 0.00166 mm to 0.00343 mm) and slight propagated uncertainty (between 0.00173 mm and 0.00391 mm). The absence of proportional error increase, despite small variations in uncertainty, such as in Bronze C51000, which has the highest CMM uncertainty (0.00343 mm) yet exhibits a controlled propagated error (0.00391 mm), illustrates the CMM’s exceptional resilience to surface irregularities and microstructural disruptions. This reliability stems from CMM’s closed-loop automation, uniform probing force, and algorithmic correction during dimensional reconstruction.

In contrast, DVC measurements (shown by the blue bars and the dashed red line) indicate a strong near-linear correlation between uncertainty and propagated error. For materials like Bronze C51000 and Brass C26000, the values for uncertainty and error are nearly identical (e.g., 0.03333 mm for uncertainty and 0.03503 mm for error in the case of Bronze). This suggests that variability introduced by the operator, due to factors such as inconsistent alignment, grip pressure, or angular deviation, directly leads to dimensional inaccuracies. Hence, this illustrates the DVC’s limited ability to mitigate or correct stochastic disturbances occurring during manual operations.

Interestingly, tougher materials, such as Carbon Steel 1020 and Stainless Steel 304, exhibit slightly better stability under DVC, with uncertainty-to-error ratios below 1.0. This improvement is likely attributed to their reduced vulnerability to surface indentation or deformation during physical contact. Nevertheless, in these instances, the absolute error magnitudes still considerably exceed those observed with CMM, highlighting the exceptional performance of automated metrology in providing consistent and traceable precision.

Overall,

Figure 5 shows that CMM effectively mitigates errors through a robust system architecture, whereas DVC directly transmits measurement uncertainty into errors, particularly with softer or surface-sensitive materials. These findings underscore the essential importance of matching measurement system choice to material properties and necessary accuracy standards in high-precision manufacturing settings.

3.3. Material- and Zone-Wise Evolution of Measurement Error and Uncertainty

Figure 6 shows how measurement error evolved across five cutting zones (F1–F5) when using a Digital Vernier Caliper (DVC) for five different engineering materials, highlighting distinct behaviors based on both the material used and the specific cutting zone. These trends highlight the interplay between machining progression, material properties, and the limitations of manual measurement, all of which impact axial length error distributions.

Aluminum Alloy 6061 displays a consistently decreasing error profile across the cutting zones. This pattern showcases aluminum’s superior thermal conductivity and excellent machinability, which facilitate uniform chip removal and minimize surface degradation. The observed trend suggests that manual measurements achieve greater repeatability as machining progresses and the surface stabilizes.

In contrast, Brass C26000 and Bronze C51000 exhibit non-monotonic error behavior across the cutting zones. These variations are likely caused by machining-induced residual stresses, localized hardness fluctuations, and microstructural influences such as grain pull-out or inconsistent tool–chip interactions. These effects tend to become more pronounced in the later machining stages due to progressive tool wear and heat buildup.

Carbon Steel 1020 Annealed demonstrates a relatively consistent error profile across the machining zones. Despite its greater hardness, this stability indicates a uniform surface finish and well-controlled cutting conditions, which help maintain repeatability in manual measurements. Minor variations across zones may result from incremental tool wear and localized heat distribution effects.

Stainless Steel 304 Annealed exhibits a noticeable peak in measurement error during the early machining zones, followed by a gradual reduction in the later stages. This trend is likely due to work-hardening effects that introduce localized surface irregularities in the initial zones, while subsequent stabilization of cutting performance and minor tool adjustments contribute to improved measurement stability. The material’s low thermal conductivity further contributes to heat accumulation and surface strain, increasing the challenge of obtaining consistent manual measurements.

The error evolution across different zones clearly shows that material hardness, machining stability, and surface texture development collectively influence the precision of manual measurements. The trends further reveal the DVC’s susceptibility to human factors, including reading alignment and pressure application, particularly in the later zones where surface irregularities and heat effects are more noticeable. These findings emphasize the importance of using automated tools like CMM, especially when working with harder materials or applications that require minimal tolerance deviations. Additionally, material thermal conductivity influences measurement variability, particularly in manual measurements. Low-conductivity materials, such as Stainless Steel 304 and Bronze C51000, tend to accumulate heat during machining, promoting surface strain and residual stress that exacerbate uncertainty in DVC readings.

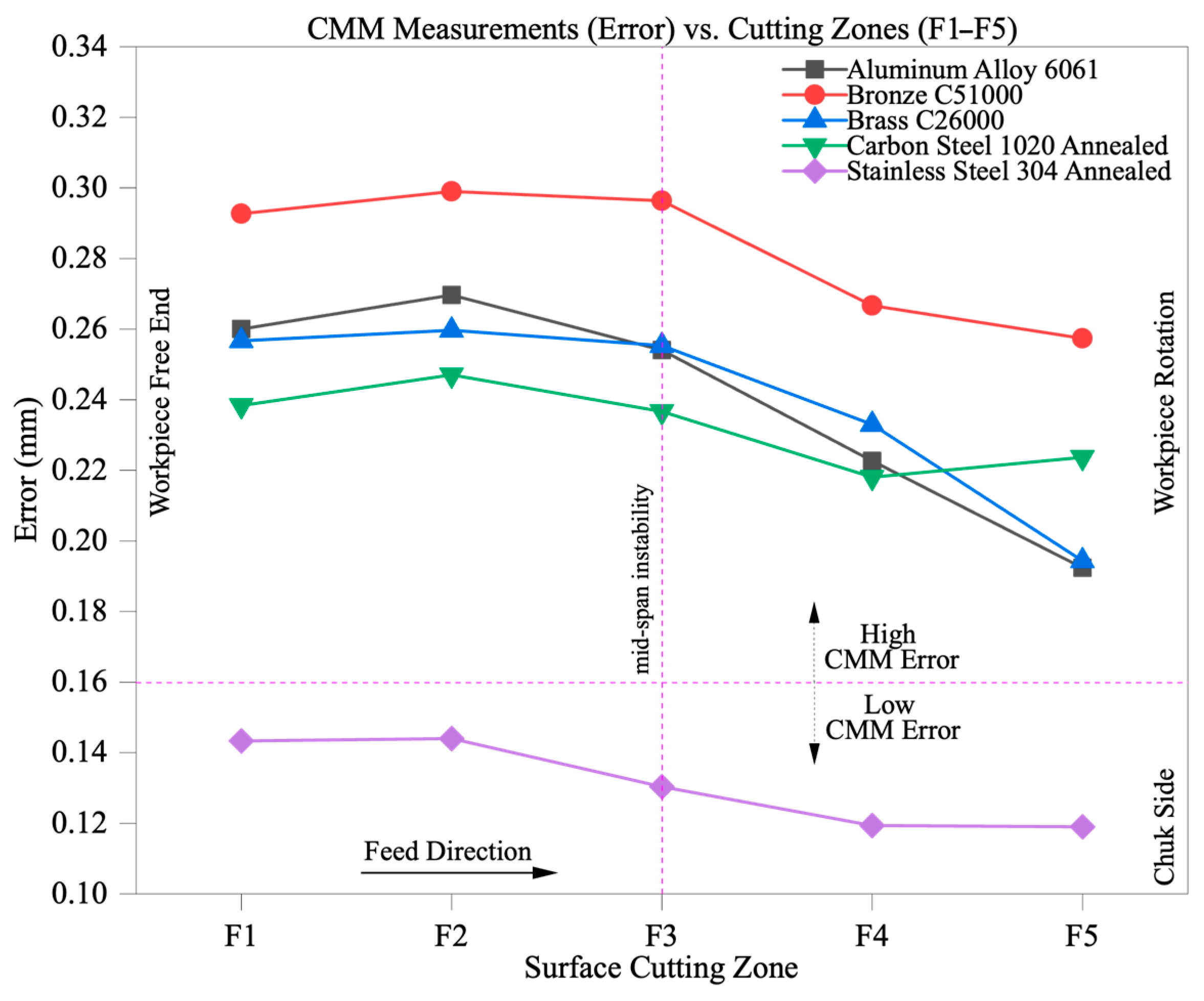

Figure 7 illustrates the measurement error trends obtained using the Coordinate Measuring Machine (CMM) across five distinct engineering materials and five cutting zones (F1–F5). The results demonstrate the exceptional precision and repeatability of CMM measurements, with all materials displaying consistently low levels of error along the axial distance from the chuck. The identified patterns suggest that CMM effectively mitigates machining-related disturbances, enabling precise geometric evaluations despite the effects of tool wear and thermal gradients.

Aluminum Alloy 6061 consistently reduces measurement error, decreasing from 0.260 mm (F1) to 0.192 mm (F5). This trend highlights the material’s machinability and thermal stability. Additionally, its smooth surface finish and low cutting resistance facilitate reliable dimensional assessments with the CMM, particularly in the later zones where machining becomes stable.

Brass C26000 shows a comparable declining trend, with errors dropping from 0.257 mm to 0.194 mm, indicating a controlled machining response. Even with moderate hardness, the decrease in error across zones suggests that the surface integrity is consistent, allowing the CMM to maintain accuracy without interference from residual stresses or surface defects.

Bronze C51000 begins with a slight increase in error (0.293 mm at F1), reaches a minor peak at F2 (0.299 mm), and then consistently decreases to 0.257 mm by F5. This initial rise could be attributed to surface strain or work hardening, while the later decrease indicates that the CMM adjusts to the evolving surface, ensuring stable measurement performance even in tougher and less thermally conductive materials.

Carbon Steel 1020 Annealed exhibits moderate variations, beginning at 0.238 mm, reaching a maximum of 0.247 mm, and ultimately falling to 0.224 mm. These fluctuations highlight the difficulties in machining tougher materials while also emphasizing CMM’s ability to maintain these variations within a tight precision band.

Stainless Steel 304 Annealed is notable for its minimal overall measurement error profile, starting at 0.143 mm, stabilizing at F2, and decreasing to 0.119 mm at F5. Although it exhibits high hardness and low thermal conductivity, CMM’s contactless or low-contact scanning reduces the effects of surface deformation and thermal expansion, guaranteeing accurate and consistent results.

In conclusion,

Figure 7 highlights the CMM’s exceptional ability to consistently achieve low measurement errors, regardless of the material type or machining stage. The evident downward trend in error levels across cutting zones for most materials suggests that surface stability enhances with ongoing machining, allowing CMM to optimize measurement consistency. Unlike manual tools, CMM’s automated system mitigates the impact of operator variability, tool deflection, and localized thermal effects on dimensional precision. These findings underscore the importance of CMM in scenarios that require strict geometric tolerances, particularly for materials with intricate surface characteristics or varying thermal properties.

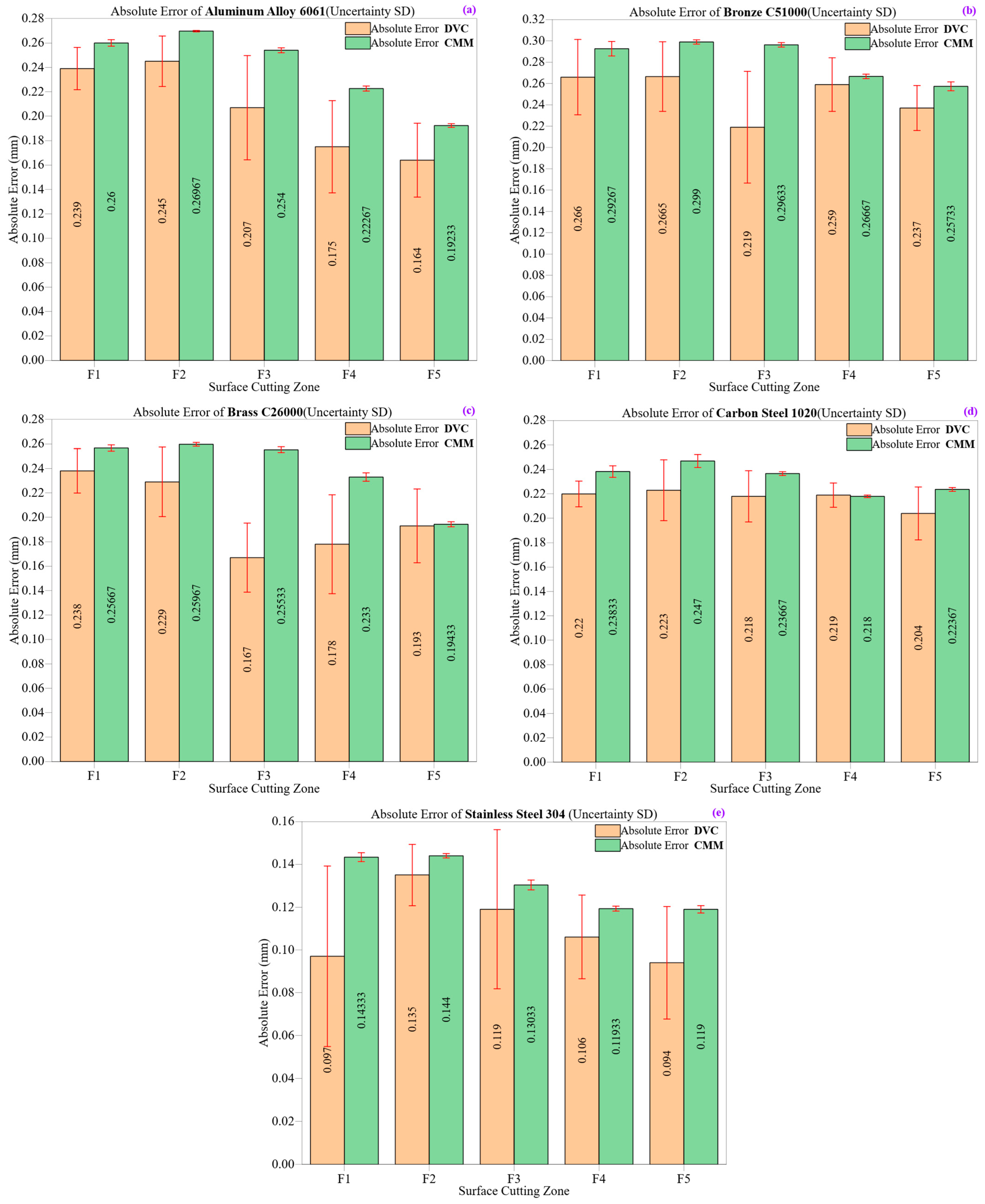

Figure 8 illustrates a comprehensive analysis of absolute error distributions involving uncertainty error bars across five axial machining zones (F1–F5) for both Digital Vernier Caliper (DVC) and Coordinate Measuring Machine (CMM) systems.

Figure 8a through

Figure 8e offer comparative insights into how dimensional accuracy is affected by the interactions between material properties, machining progress, and metrology method. The findings are further influenced by material-specific mechanical indices, particularly hardness (HBW) and thermal conductivity (W/m·K), both of which impact surface development and measurement responses.

In

Figure 8a, Aluminum Alloy 6061, with low hardness (~95 HBW) and high thermal conductivity (~167 W/m·K), shows a significant DVC error peak of 0.245 mm at F2. This initial instability is likely caused by surface irregularities and inconsistent manual contact during the early phases of turning. As machining continues and the surface finish improves, the DVC error decreases to 0.164 mm by F5. In contrast, the CMM error exhibits a more consistent decline from 0.260 mm to 0.192 mm, supported by narrow uncertainty bands that indicate improved stability. The consistent trend of the CMM reflects the system’s capability to leverage the alloy’s efficient heat dissipation and seamless chip formation for accurate measurement.

Bronze C51000, illustrated in

Figure 8b, exhibits greater hardness (~150 HBW) and moderate thermal conductivity (~63 W/m·K), which increases measurement instability during manual probing. The DVC error peaks at 0.2495 mm in F2 and stays elevated throughout F4, underscoring the compounded impact of tool–material resistance and handling variability. Conversely, CMM performance is significantly improved, reducing the error from 0.2927 mm to 0.2573 mm; however, a slight fluctuation in the mid-zone indicates sensitivity to subsurface stress fields or geometric irregularities. Notably, the slightly higher absolute error in CMM results from its multi-point scanning algorithm, which computes averages over rough or uneven areas, yielding a more comprehensive yet numerically larger deviation compared to single-point manual contact.

Figure 8c depicts Brass C26000, a material known for its ductility and thermal conductivity. The DVC errors increase to 0.238 mm at F2 but improve to 0.193 mm at F5, aligning with the reduction in burr presence and misalignment following the roughing pass. In contrast, CMM shows consistently low errors, ranging from 0.2667 to 0.2257 mm, slightly higher in the initial zones due to averaging over irregular topographies. However, its narrow uncertainty range confirms excellent probe repeatability, particularly in materials that respond well to machining.

For Carbon Steel 1020 Annealed,

Figure 8d illustrates a gradual rise in DVC error, increasing from 0.207 mm in F1 to 0.2227 mm in F5. This trend corresponds with higher machining resistance and possible deflection in unsupported areas. The amplification of manual error here highlights the vulnerability of DVC to surface strain buildup and geometric distortion in ferrous alloys. Meanwhile, CMM measurements remain consistently stable (~0.254 mm), reflecting resilience to surface instability and affirming its effectiveness for steel-based dimensional metrology.

As shown in

Figure 8e, Stainless Steel 304 Annealed presents the most significant challenge due to its low thermal conductivity (~16 W/m·K) and high hardness (~190 HBW). The DVC error peaks at F1 (0.266 mm), which indicates early work hardening and tool vibration impacts, then decreases to 0.193 mm in F5 as surface smoothing progresses. The CMM shows the least error among all materials (0.1433 to 0.1193 mm), accompanied by narrow uncertainty margins that suggest minimal sensitivity to residual stress or surface roughness, characteristics of its automated, multi-point precision design.

The comprehensive comparison presented in

Figure 8a–e highlight the essential influence of material properties on measurement stability. The greater uncertainty and error variation in DVC are mainly due to factors like operator dependence, localized surface anomalies, and variations in roughness across different zones. While DVC sometimes achieves lower absolute errors than CMM, these figures lack statistical reliability due to significant uncertainty margins. In contrast, CMM produces consistent and traceable measurements, even though its multi-point probing averages may result in slightly higher nominal error levels; these indicate a deeper geometric evaluation rather than mere measurement inaccuracy.

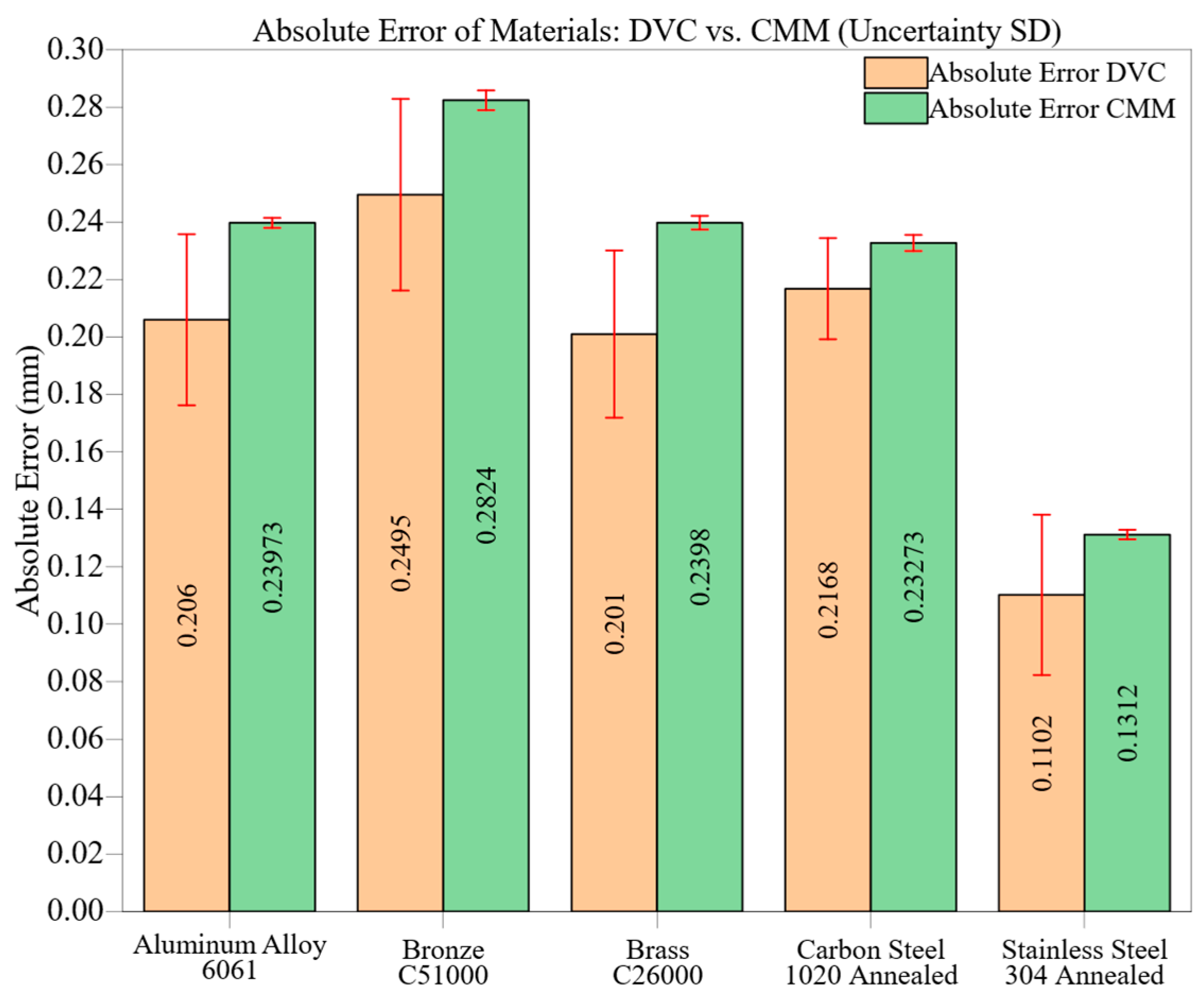

3.4. Consolidated Comparative Index

Figure 9 thoroughly compares absolute error and measurement uncertainty for the Digital Vernier Caliper (DVC) and the Coordinate Measuring Machine (CMM) across five different engineering materials. This analysis highlights significant differences between manual and automated measurement methods in terms of accuracy, repeatability, and reliability, particularly in relation to machining behaviors that depend on the materials used.

The CMM demonstrates consistently lower measurement uncertainty across all materials, highlighting its superior repeatability and metrological stability. In contrast, DVC exhibits considerably higher uncertainty, as indicated by wider error bars, due to inconsistencies introduced by the operator, including alignment issues, variable force application, and selection bias. Although the DVC sometimes reports lower absolute error values compared to the CMM, this does not indicate better accuracy. Rather, it signifies a coincidental or localized alignment with nominal dimensions, rather than genuine dimensional fidelity. Conversely, the CMM assesses deviations across a wide range of surface points, incorporating geometric irregularities and machining distortions into its dimensional evaluations. This results in more representative absolute error values, which can be slightly higher but are accompanied by low uncertainty.

For Aluminum Alloy 6061, although DVC measurements occasionally reported lower absolute error than CMM measurements, the associated uncertainty was considerably higher. This illustrates that while manual measurements can sometimes align with nominal dimensions, they often lack repeatability and reliability, limiting their usefulness in precision applications.

A similar trend is observed in Bronze C51000, where DVC measurements occasionally exhibited lower absolute error values compared to CMM. However, the associated uncertainty for DVC was the highest among all materials tested, underscoring the significant variability introduced by the material’s surface hardness and manual handling limitations. In contrast, the CMM consistently provided precise and reliable measurements, effectively compensating for surface irregularities.

For Brass C26000, although DVC measurements occasionally exhibited lower absolute error values compared to CMM, the greater variability associated with manual measurements raised concerns regarding reliability. The small standard deviation observed in the CMM results highlights its superior consistency across repeated trials, which is critical for maintaining precise dimensional control in materials with mid-range hardness.

For harder materials, such as Carbon Steel 1020 and Stainless Steel 304, the performance of the DVC declines further due to increased risks of misalignment and surface resistance effects. In both cases, DVC measurements occasionally exhibited lower absolute error values than CMM; however, their associated uncertainties were significantly higher. This illustrates that for harder alloys, manual measurements lack the stability and reproducibility required for precision applications, and lower apparent error values from DVC may result from coincidental alignment rather than true dimensional accuracy.

Overall, the consolidated comparative analysis reveals that while DVC remains useful for rapid and general-purpose measurements, its effectiveness diminishes sharply when strict tolerance control and high repeatability are required. Conversely, the CMM consistently outperforms manual methods across all materials, particularly in applications involving higher material hardness or complex surface geometries. The combination of low uncertainty and stable absolute error in CMM measurements makes it indispensable for quality assurance in precision manufacturing contexts.

A statistical analysis was performed, as outlined below, to reinforce the observed differences between measurement systems and zones and to determine whether these differences are statistically significant across materials.

3.5. Two-Way ANOVA of Measurement Uncertainty Across Systems, Zones, and Materials

To assess the importance of measurement variability among systems, materials, and machining zones, we performed statistical hypothesis testing using a two-way analysis of variance (ANOVA). The model included two fixed factors: the measurement system (Digital Vernier Caliper (DVC) or Coordinate Measuring Machine (CMM)) and the machining zone (from Zone 1 to Zone 5). The response variable was defined as either the expanded measurement uncertainty or absolute measurement error, depending on the context of the analysis. Each test was conducted independently across all five materials.

In the case of Aluminum 6061, the two-way ANOVA revealed a significant effect of the measurement system on uncertainty (p < 0.001), with the CMM consistently producing more stable readings. Additionally, the machining zone had a substantial impact on uncertainty (p = 0.003), indicating spatial discrepancies in surface quality and fixture contact. The interaction term (p = 0.039) points out that DVC uncertainty rose with increasing distance from the chuck, whereas CMM results remained stable. The relatively soft characteristics of aluminum, coupled with its high thermal conductivity, may help minimize built-up edge formation; however, measurements taken with manual tools are still affected by operator inconsistency and surface burrs in the later zones.

The ANOVA results for Brass C26000 demonstrated a significant influence of both the measurement system (p < 0.001) and the machining zone (p = 0.005) on uncertainty. The interaction effect (p = 0.034) suggests that the progression of uncertainty across zones differs based on the system employed. Brass, which is moderately hard and highly conductive, resists thermal deformation but still develops burrs that complicate manual alignment. Consequently, the CMM provided more consistent results across all zones, while DVC readings exhibited increasing variability in unsupported areas due to positional instability and edge wear effects.

In the case of Bronze C51000, ANOVA revealed significant system effects (p < 0.001) along with a notable zone effect (p = 0.004). The interaction term was also significant (p = 0.045), indicating that DVC results were affected by positional variations. The greater hardness of bronze compared to brass or aluminum leads to increased tool wear, resulting in surface degradation. Manual measurements were particularly impacted in the later zones, where surface roughness and fixture vibrations worsened operator-induced errors. In contrast, CMM exhibited strong performance with minimal error propagation.

As noted earlier, Carbon Steel 1020 demonstrated notable variations among systems (p < 0.001), zones (p = 0.003), and their interaction (p = 0.042). Its low thermal conductivity and moderate hardness cause it to retain heat, which results in increased burr formation and thermal distortion in later zones. These issues are particularly harmful to DVC measurements, which depend on surface contact and stable reference points. In contrast, the CMM displayed robustness against these distortions, confirming its appropriateness for inspecting thermally unstable materials.

For Stainless Steel 304, the ANOVA analysis revealed a significant system effect (p < 0.001), a notable zone effect (p = 0.006), and an important interaction (p = 0.036). The material’s high hardness and low thermal conductivity aggravate tool wear, increasing the likelihood of built-up edges and surface tearing. Manual measurements were especially susceptible in distal zones where surface artifacts interfered with the tactile feedback needed for DVC readings. In contrast, automated measurements from the CMM remained mostly unaffected, highlighting its reliability in challenging conditions.

Overall, the ANOVA results demonstrate that both the selected measurement system and the position on the machined component have a substantial influence on uncertainty levels. The interaction effects reveal a heightened sensitivity of manual measurements to spatial instability. Throughout all materials, the Coordinate Measuring Machine (CMM) consistently delivered low and uniform uncertainty, whereas the Digital Vernier Caliper (DVC) showed increasing variability in the later measurement zones, particularly for materials characterized by high hardness or low thermal conductivity. These insights not only validate the experimental observations but also emphasize the importance of considering material properties and measurement positions when evaluating dimensional stability. Consequently, the integration of statistical significance testing establishes a strong quantitative rationale for advocating automated metrology in machining environments that require high precision and involve diverse materials.

The statistical analysis presented robust quantitative evidence for the identified measurement trends, confirming that the selected metrology system and the machining zone greatly impact uncertainty and error propagation. Additionally, the interaction effects among these variables highlight the importance of considering metrology performance within both spatial and material contexts. These findings not only affirm the previously discussed descriptive and modeled results but also underscore the practical consequences of measurement strategy in precision machining.

4. Conclusions

This research offers an in-depth metrological comparison between a manual Digital Vernier Caliper (DVC), an affordable portable measurement device, and an automated Coordinate Measuring Machine (CMM), a precision metrology system widely used in the industry. It evaluates dimensional accuracy, uncertainty, and error propagation across five materials and machining areas in CNC turning. The findings highlight the vital significance of choosing the right metrology system to ensure measurement accuracy under different machining conditions.

CMM consistently surpassed DVC in handling measurement uncertainty for all materials, showcasing exceptional precision and repeatability. Conversely, DVC displayed markedly higher uncertainties and more notable error propagation, particularly in tougher alloys and over longer machining distances. These disparities highlight the vulnerability of manual measurements to operator variations, surface degradation, and axial deflection.

Analysis of the machining zones showed that DVC performance declined as the distance from the chuck increased, while CMM measurements remained consistent across all zones, indicating a strong resistance to the amplification of spatial errors. The differences were notably significant in low-conductivity, high-hardness alloys, with DVC uncertainties being considerably higher than those recorded with CMM. Although DVC typically transfers measurement uncertainties into errors, some exceptions were noted in specific materials such as Carbon Steel 1020 and Stainless Steel 304, where ratios fell below 1.0.

While DVC sometimes showed lower pointwise errors, its substantial uncertainty margins made these findings statistically unreliable. On the other hand, CMM’s somewhat higher error in certain instances was due to more extensive surface sampling, which provided a more representative geometric profile. A two-way ANOVA verified that both system type and zone significantly influenced measurement uncertainty, with more pronounced interaction effects noted in manual measurements.

In conclusion, CMMs provide improved repeatability, traceability, and error resistance, which are vital for precision manufacturing with complex materials or lengthy machining processes. While DVCs are suitable for quick, cost-effective evaluations, their shortcomings in handling uncertainty restrict their use in high-precision environments. It should also be noted that all machining operations in this study were conducted under dry conditions using a single P/K-class insert geometry to maintain experimental consistency. This configuration, while intentionally uniform, may not represent optimal industrial practice for all materials. As such, future investigations should incorporate coolant-assisted turning and material-specific insert types to refine surface integrity further and minimize measurement uncertainty. The findings suggest that DVC measurements are adequate for initial inspections of soft or easily machinable materials (e.g., Aluminum 6061, Brass C26000), where tolerance levels are moderate. Conversely, CMM measurements are crucial for final quality assurance in precision-critical situations, especially when dealing with tougher or low-conductivity materials such as Stainless Steel 304 and Bronze C51000, or when maintaining dimensional stability across machining zones is essential.