Research on Adaptive Drilling Control Technology Based on Coal Rock Traits During the Drilling Process

Abstract

1. Introduction

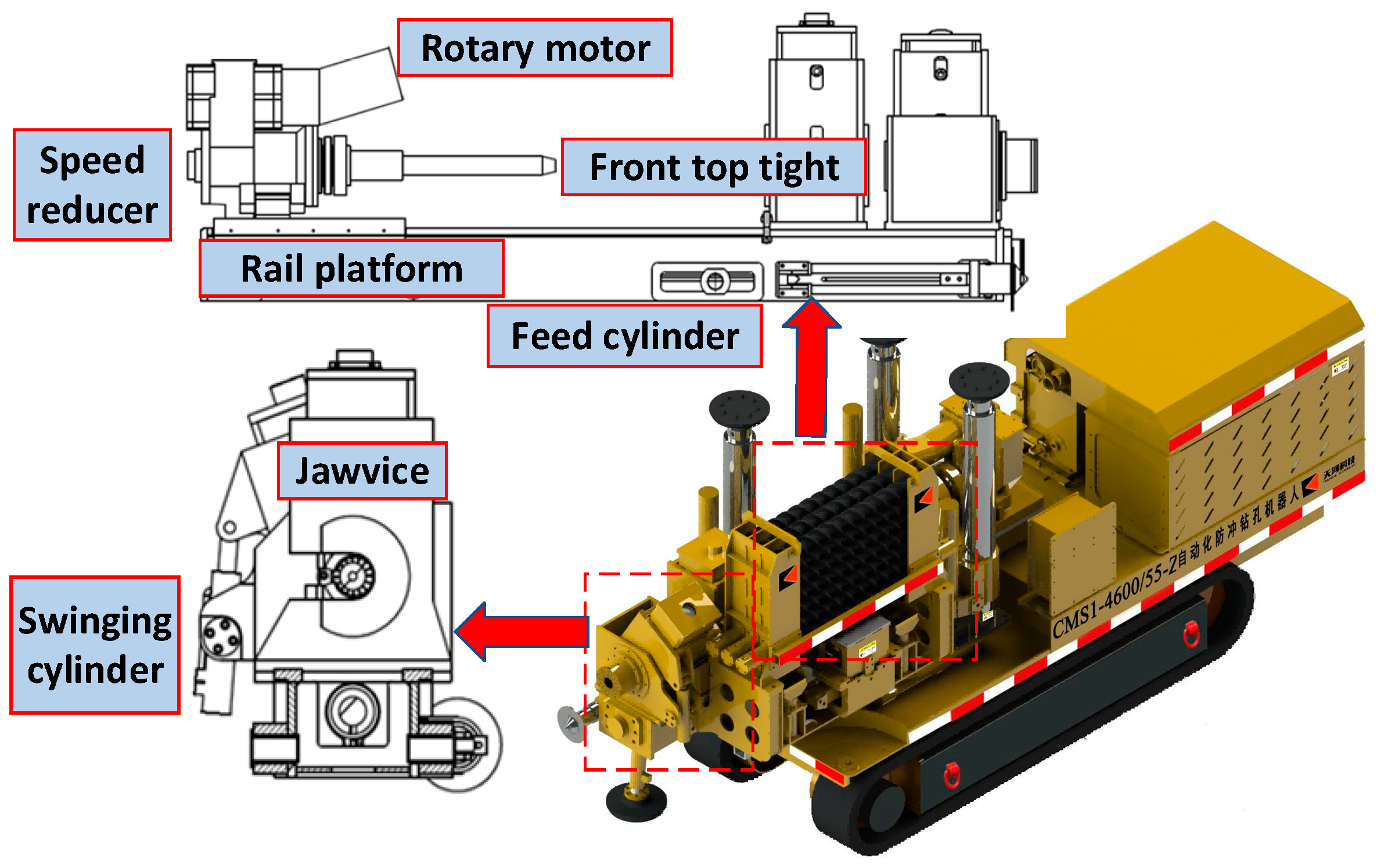

2. Composition of Drilling System and Calculation of Optimal Drilling Parameters

2.1. Drilling System Components

2.2. Drilling System Workflow

2.3. Calculation of Optimal Drilling Parameters

3. Research on Control Strategy of Drilling System

3.1. Control Program Design

3.2. Controller Design

3.2.1. ADRC Controller

3.2.2. SMC Controller

3.3. Controller Co-Simulation Model Building

4. AMESim and Simulink Joint Simulation Analysis

4.1. Slewing Speed Control Strategy Based on Self-Immunity Control

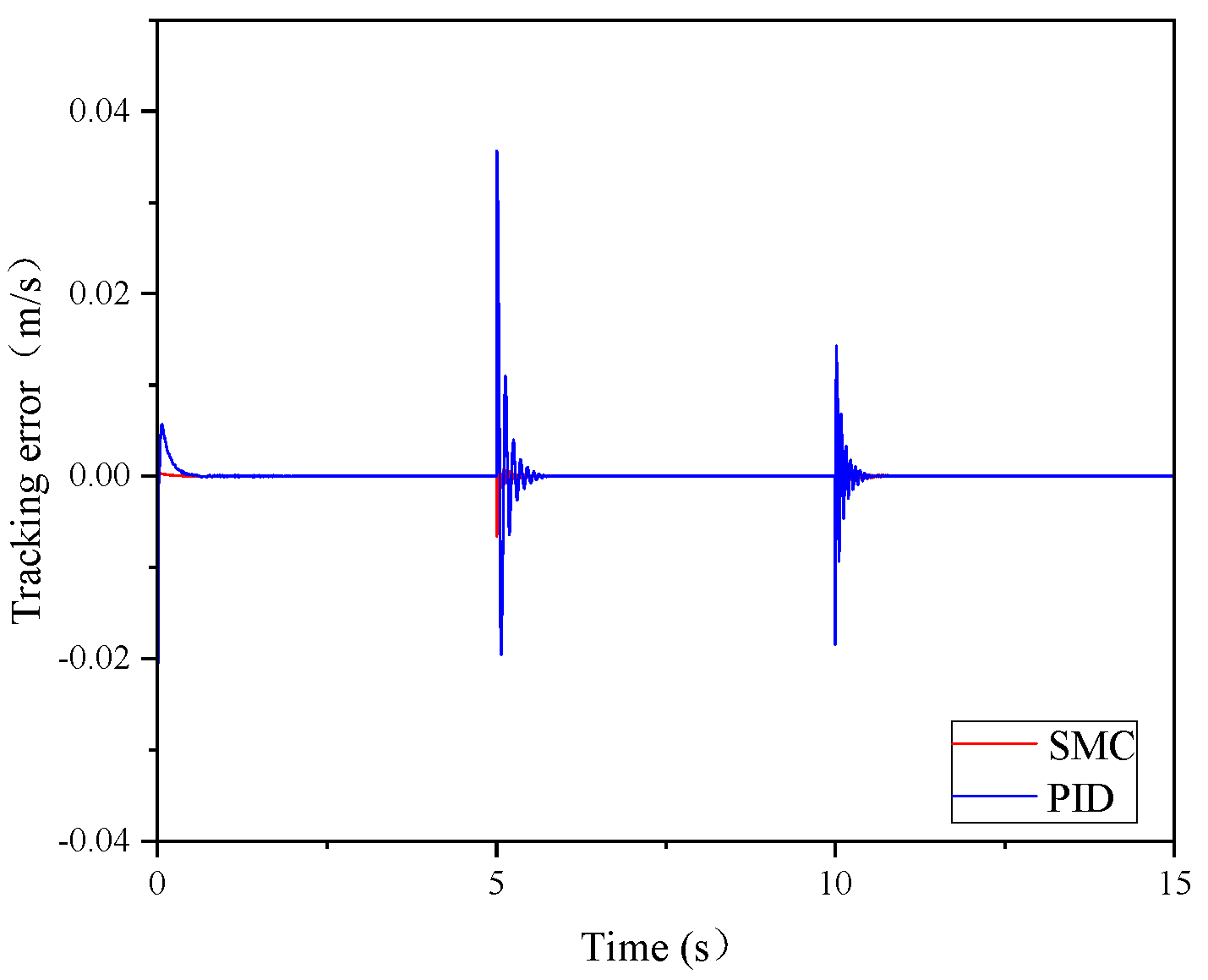

4.2. Feed Rate Control Strategy Based on Sliding Mode Variable Structure Control

5. Experimental Studies

5.1. Drilling System Experiment Platform Construction

5.2. Analysis of Experimental Results

5.2.1. Single Coal Rock Hardness Test

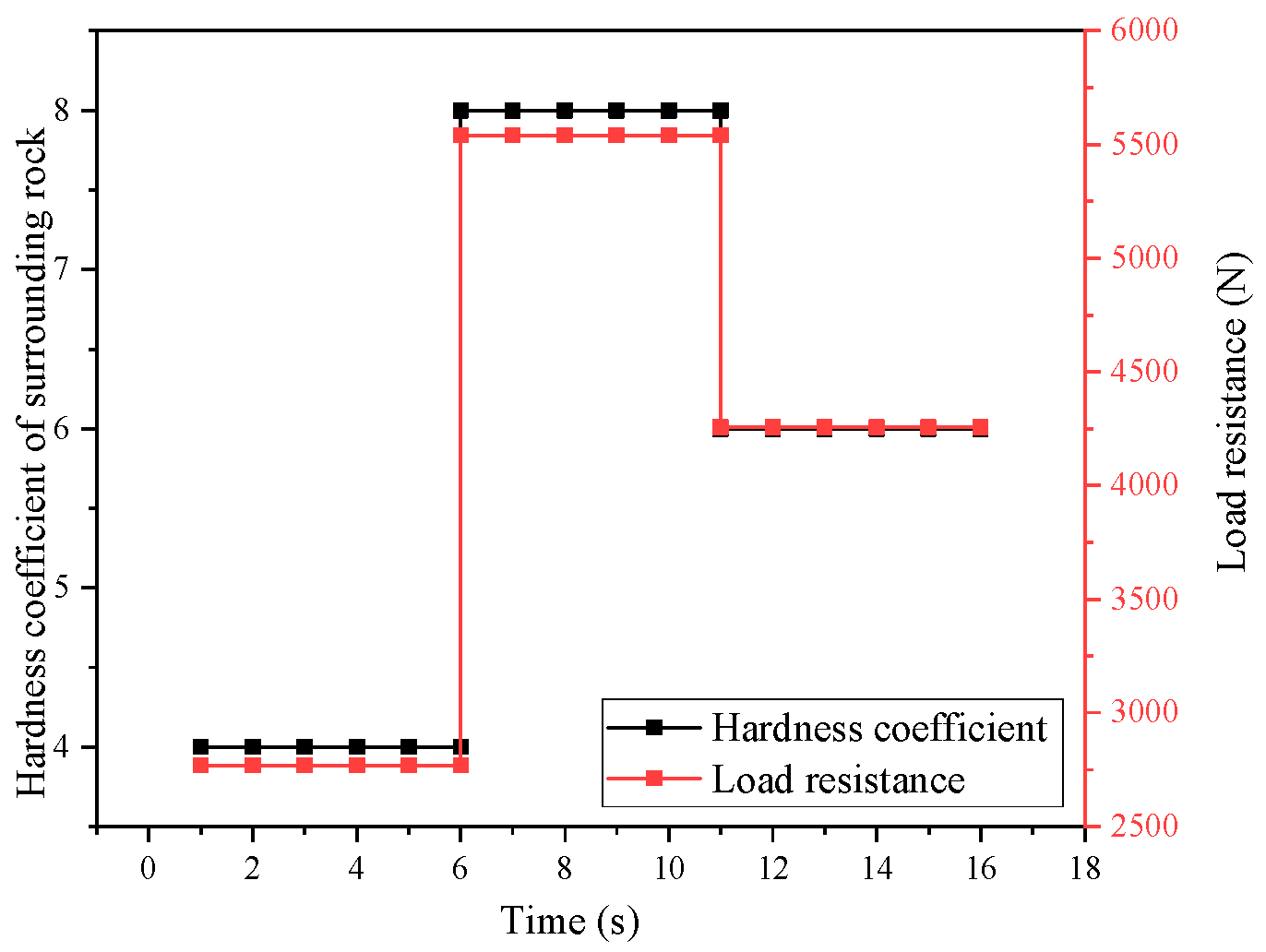

5.2.2. Mutant Coal Rock Hardness Experiment

6. Conclusions

- (1)

- By analyzing the structure of the anti-punch drilling robot and the drilling system, the workflow of system with respect to the drilling function and the cooperation relationship between the actuators was clarified and the optimal slewing speed and feed speed in the drilling process were determined through an analysis of the drilling rod force;

- (2)

- Combined with the drilling process and the working characteristics of each actuator, a control strategy for the drilling control system was proposed. A slewing control strategy based on a self-immunity control algorithm and a feed control strategy based on sliding mode variable structure control were designed. Based on the drilling system, a physical model was established in AMESim software and a mathematical model was established in Simulink software. A joint simulation was carried out, and the control performance and control effects of each controller were analyzed through the joint simulation;

- (3)

- The construction of the drilling robot drilling electrohydraulic control system experimental platform was completed by using different hardness coefficients of concrete specimens to simulate the hardness of different coal rock traits. Single coal rock hardness experiments and drilling experiments with sudden changes in coal rock hardness were conducted. The experimental results showed that the control strategy proposed in this paper meets the requirements needed to control the drilling system.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Si, L.; Wang, H.; Zhang, X.; Zhao, S.; Wei, D.; Tan, C.; Yan, H. Position solving method for anti-punch drilling robot based on spatial arrayed inertial unit. J. Coal 2022, 47, 13. [Google Scholar]

- Niu, C. Research on Drilling Control of Tooth Wheel Drilling Rig. Master’s Thesis, Jilin University, Changchun, China, 2017. [Google Scholar]

- Wang, G. Accelerating the construction of coal mine intelligence to promote the high-quality development of coal industry. China Coal 2021, 47, 2–10. [Google Scholar]

- Ge, S.; Hu, R.; Pei, W. Coal mine robot system and key technologies. J. Coal 2020, 45, 455–463. [Google Scholar]

- Hu, Z.; Sun, Y. Design and test of drilling control simulation system and control algorithm. Coal J. 2009, 34, 455–460. [Google Scholar]

- Zhao, X.Y. Control Algorithm Analysis of Rig’s Electro-Hydraulic Proportional Control System. Appl. Mech. Mater. 2013, 423–426, 2837–2840. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, H.; Chen, Y. Research on intelligent sensing and adaptive control mechanism of drilling robot for drilling working conditions. Min. Saf. Environ. Prot. 2021, 48, 1–5. [Google Scholar] [CrossRef]

- Zhao, J.; Liang, P.; Liu, Q.; Han, S.; Zhang, Y. Control algorithm of weight on bit and rate of penetration based on drilling robot. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022, 237, 2557–2566. [Google Scholar] [CrossRef]

- Cavanough, G.L.; Kochanek, M.; Cunningham, J.B.; Gipps, I.D. A Self-Optimizing Control System for Hard Rock Percussive Drilling. IEEE/ASME Trans. Mechatron. 2008, 13, 153–157. [Google Scholar] [CrossRef]

- Shi, F.; Li, L.; Zhang, Q.Z.; Rasol, N. Derivative and Integral Sliding Mode Control for Rotary Drilling System. In Proceedings of the Third International Conference on Measuring Technology & Mechatronics Automation, Shanghai, China, 6–7 January 2011; IEEE Computer Society: Washington, DC, USA, 2011. [Google Scholar]

- Haber, R.E.; del Toro, R.M.; Gajate, A. Optimal fuzzy control system using the cross-entropy method. A case study of a drilling process. Inf. Sci. 2010, 180, 2777–2792. [Google Scholar] [CrossRef]

- Kremers, N.A.H.; Detournay, E.; Van De Wouw, N. Model-Based Robust Control of Directional Drilling Systems. IEEE transactions on control systems technology: A publication of the IEEE Control Systems Society. IEEE Trans. Control Syst. Technol. 2016, 24, 226–239. [Google Scholar] [CrossRef]

- Inyang, I.J.; Whidborne, J.F. Bilinear Modelling, Control and Stability of Directional Drilling. Control Eng. Pract. 2018, 82, 161–172. [Google Scholar] [CrossRef]

- Georgiou, A.; Evangelou, S.A.; Jaimoukha, I.M.; Downton, G. Tracking Control for Directional Drilling Systems Using Robust Feedback Model Predictive Control. In Proceedings of the 21st IFAC World Congress, Berlin, Germany, 11–17 July 2020. [Google Scholar]

- Laib, A.; Talbi, B.; Krama, A.; Gharib, M. Hybrid Interval Type-2 Fuzzy PID+I Controller for a Multi-DOF Oilwell Drill-String System. IEEE Access 2022, 10, 67262–67275. [Google Scholar] [CrossRef]

- Kong, X.Z.; Jiang, S.Y.; Li, Y.B. Intelligent hybrid control of the pneumatic proportional system. Chin. J. Mech. Eng. 2009, 45, 84–88. [Google Scholar] [CrossRef]

- Li, D.; Ma, G.; Li, J. Four-point dynamic leveling method for drilling platform application. Assem. Autom. 2021, 41, 46–77. [Google Scholar] [CrossRef]

- Liu, F.C.; Jia, X.Q.; Liu, L. Pneumatic loading system modeling and nonlinear active disturbance rejection control. Control Decis. 2017, 32, 906–912. [Google Scholar]

- Buckstegge, F.; Michel, T.; Zimmermann, M.; Roth, S.; Schmidt, M. Advanced Rock Drilling Technologies Using High Laser Power. Phys. Procedia 2016, 83, 336–343. [Google Scholar] [CrossRef]

- Li, X.; Zhou, Z.; Ye, Z.; Ma, C.; Zhao, F.; Zuo, Y.; Hong, L. Mechanical characterization of rocks loaded by dynamic-static combination. J. Rock Mech. Eng. 2008, 27, 1387–1395. [Google Scholar]

- Yu, C.X. Research on the Dynamic Characteristics of Drill Pipe of TBM Machine-Mounted Anchor Drilling Rig. Master’s Thesis, East China Jiaotong University, Nanchang, China, 2020. [Google Scholar]

- Lian, C.; Sun, C.; Xiao, Y. Research on the position synchronization control of two cylinders based on self-immunity control. Mach. Tools Hydraul. 2024, 1–11. [Google Scholar]

- Wang, L.X.; Zhao, D.X.; Liu, F.C.; Meng, F.L.; Liu, Q. Self-impedance control of electro-hydraulic proportional servo force loading. J. Mech. Eng. 2020, 56, 216–225. [Google Scholar]

- Ren, L.; Cui, J.; Sun, Y.; Cheng, X. Multi-bearing remaining useful life collaborative prediction: A deep learning approach. J. Manuf. Syst. 2017, 43, 249–256. [Google Scholar] [CrossRef]

- Xiao, X. Research on fuzzy sliding mode variable structure control of hydraulic servo system. Sci. Technol. Innov. 2021, 6, 18–20. [Google Scholar]

- Chen, C. Characterization of Electro-Hydraulic Servo System and Design of Sliding Mode Variable Structure Controller. Master’s Thesis, Taiyuan University of Science and Technology, Taiyuan, China, 2014. [Google Scholar]

| Hardness Factor | Optimum Speed (r/min) | Load Torque (N-m) | Optimum Feed Speed (mm/s) | Feed Force (N) |

|---|---|---|---|---|

| 3 | 309 | 243 | 77 | 2078 |

| 4 | 232 | 324 | 58 | 2770 |

| 5 | 186 | 405 | 46 | 3463 |

| 6 | 154 | 486 | 39 | 4256 |

| 7 | 132 | 567 | 33 | 4848 |

| 8 | 116 | 648 | 29 | 5541 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, B.; Li, G.; Shan, G. Research on Adaptive Drilling Control Technology Based on Coal Rock Traits During the Drilling Process. Machines 2025, 13, 133. https://doi.org/10.3390/machines13020133

Liang B, Li G, Shan G. Research on Adaptive Drilling Control Technology Based on Coal Rock Traits During the Drilling Process. Machines. 2025; 13(2):133. https://doi.org/10.3390/machines13020133

Chicago/Turabian StyleLiang, Bin, Guang Li, and Guangpeng Shan. 2025. "Research on Adaptive Drilling Control Technology Based on Coal Rock Traits During the Drilling Process" Machines 13, no. 2: 133. https://doi.org/10.3390/machines13020133

APA StyleLiang, B., Li, G., & Shan, G. (2025). Research on Adaptive Drilling Control Technology Based on Coal Rock Traits During the Drilling Process. Machines, 13(2), 133. https://doi.org/10.3390/machines13020133