The initial research on the FJSP predominantly focused on single-objective optimization paradigms, with primary emphasis on minimizing key performance indicators such as makespan, economic costs, energy consumption, total tardiness, and total flow time. This approach laid the foundation for understanding the fundamental trade-offs inherent in complex manufacturing scheduling scenarios.

We present a comprehensive methodology that includes problem formulation, algorithm development, and experimental results. Our approach is evaluated on a series of test instances, demonstrating its effectiveness in generating high-quality schedules that balance multiple objectives under various constraints.

This research contributes to the field of production scheduling by providing a robust framework for addressing complex, real-world scheduling scenarios in flexible job shop environments. The insights gained from this study have significant implications for improving operational efficiency in manufacturing systems, particularly in industries where due date adherence and storage management are critical factors.

1.1. Literature Review

The FJSP is a complex scheduling problem that extends the classical JSP by allowing operations to be processed on any machine from a given set of compatible machines. This flexibility adds a layer of complexity to the already challenging task of optimizing production schedules.

The FJSP is characterized by a set of jobs, each consisting of a sequence of operations, and a set of machines capable of performing these operations [

11]. Unlike the traditional job shop problem, where each operation is assigned to a specific machine, FJSP allows for machine flexibility [

15]. This means that an operation can be processed on any machine from a predefined set of compatible machines, with potentially different processing times. Key characteristics of the FJSP include the following:

The system is initially empty, meaning no jobs are present at the start of the scheduling horizon.

All machines are available at time zero.

All jobs are available after the release dates.

Operations can be assigned to multiple compatible machines.

Each machine can only perform one operation at a time.

The processing time of an operation may vary depending on the assigned machine.

Operations within a job must be processed in a specific order.

There are no precedence constraints among operations of different jobs.

Preemption is not allowed; once an operation starts on a machine, it must be completed without interruption.

Machines operate under deterministic conditions with no unplanned stoppages, breakdowns, or capacity reductions.

All operations are assumed to be completed successfully on the first attempt, with a zero scrap rate.

Buffers with infinite capacity are available for all machines, ensuring unrestricted intermediate storage for operations waiting to be processed.

The FJSP plays a crucial role in modern manufacturing and production environments, offering significant advantages in modeling flexible manufacturing systems where machines are multi-purpose and capable of handling various operations [

16]. This approach enhances resource utilization by enabling better workload balancing and increased overall efficiency through the assignment of operations to multiple machines. The FJSP also improves production adaptability, allowing for quicker responses to changes in production requirements or machine availability. Furthermore, the additional degrees of freedom in scheduling decisions provided by the FJSP create opportunities for optimizing various performance metrics, ultimately leading to more efficient and cost-effective manufacturing processes.

Solving the FJSP is considerably more challenging than the classical job shop problem due to its increased complexity. Some of the main challenges include the following:

The FJSP is an NP-hard combinatorial optimization problem, meaning that finding optimal solutions becomes computationally intractable as the problem size increases [

17].

The FJSP requires solving two interrelated subproblems simultaneously, as follows [

1]:

The flexibility in machine assignments significantly expands the solution space, making it more difficult to explore effectively.

Real-world applications often require considering multiple, sometimes conflicting, objectives such as minimizing makespan, reducing tardiness, and balancing machine workloads.

In practical settings, the FJSP often needs to account for dynamic factors such as machine breakdowns, rush orders, or changes in processing times, further complicating the scheduling process.

To address these challenges, researchers have developed various approaches, including metaheuristics, mathematical programming, and hybrid methods. These approaches aim to find high-quality solutions within reasonable computational times, often trading off optimality for practicality in large-scale problems [

18].

One approach for handling these disruptions is the selection of the appropriate rescheduling schemes, which can significantly impact production efficiency. A decision-making framework utilizing the G1-improved entropy method and improved TOPSIS (Technique for Order Preference by Similarity to Ideal Solution) has been proposed to evaluate and rank alternative rescheduling strategies. This model considers production loss cost, completion time, machine load balancing rate, and additional machine energy consumption, providing a structured approach to selecting the most effective rescheduling method in dynamic environments [

19].

Scheduling objectives play a pivotal role in defining the performance metrics and goals for production scheduling problems, including the FJSP. Makespan, the time required to complete all jobs in a given schedule, is a fundamental objective in scheduling problems, particularly in manufacturing environments [

20]. The importance of makespan minimization lies in its ability to increase overall production efficiency, reduce the idle time of machines and resources, and improve throughput and capacity utilization [

21,

22]. Minimizing makespan typically involves the efficient allocation of operations to machines, optimizing the sequence of operations on each machine, and balancing workload across available resources [

23]. However, it is important to note that focusing solely on makespan can sometimes lead to suboptimal solutions in terms of other critical factors such as due dates or resource utilization [

24].

E/T minimization aims to complete jobs as close as possible to their due dates [

25]. This objective is particularly relevant in just-in-time production environments and industries where storage costs or penalties for late deliveries are significant [

26]. Earliness is defined as the positive time difference between a job’s due date and its actual completion time when the job is finished early, while tardiness represents the positive time difference between the actual completion time and the due date when the job is completed late. These metrics quantify the deviation from the desired completion time in both directions.

Minimizing E/T involves balancing early completion (which may incur storage costs) with late completion (which may result in penalties or customer dissatisfaction), considering individual job priorities and due dates, and potentially allowing for idle time between operations to avoid early completion of certain jobs [

27].

Real-world scheduling problems often require the consideration of multiple, sometimes conflicting, objectives. Balancing these objectives is a complex task that aims to find solutions that perform well across various performance metrics [

28]. Common approaches to multi-objective scheduling include the following:

Weighted sum method: Assigning weights to different objectives and optimizing their weighted sum [

29].

Pareto optimization: Finding a set of non-dominated solutions that represent different trade-offs between objectives [

30].

Lexicographic ordering: Prioritizing objectives and optimizing them in order of importance [

31].

Goal programming: Setting target levels for each objective and minimizing deviations from these targets [

32].

Challenges in multi-objective scheduling include determining the appropriate weights or priorities for different objectives, handling conflicting objectives, increased computational complexity due to the need to evaluate multiple criteria, and presenting and interpreting results to decision-makers [

33].

Overall, the choice and balancing of scheduling objectives should be tailored to the specific needs and constraints of the production environment, taking into account factors such as customer requirements, resource limitations, and the strategic goals of the organization [

34].

The FJSP has garnered significant attention in the field of operations research due to its applicability to complex manufacturing systems [

35]. Since its inception as an extension of the classical JSP, researchers have proposed a plethora of models and algorithms to address the increased complexity arising from machine flexibility and dynamic job constraints [

1]. The methodologies for solving the FJSP can be categorized into three primary classifications as follows: exact methods, heuristics, and metaheuristics.

Initial research efforts focused on MILP models, which provided optimal solutions for small-scale FJSP instances [

36]. However, the combinatorial explosion of variables as the problem size increases limits the scalability of exact methods. Branch-and-bound (B&B) and branch-and-cut techniques have been explored, but their computational complexity restricts their application to relatively small job sets [

37].

To mitigate scalability issues, researchers have employed heuristic methods such as dispatching rules and greedy algorithms [

38]. These approaches generate feasible schedules by prioritizing jobs based on criteria such as earliest due date or shortest processing time, while computationally efficient, heuristic methods often fail to guarantee optimality and may require significant parameter tuning to adapt to specific production environments [

39].

Recent research has witnessed a paradigm shift towards metaheuristic algorithms, including GAs, SA, ant colony optimization (ACO), and PSO. These approaches have demonstrated efficacy in solving large-scale FJSPs due to their ability to explore the solution space more comprehensively and escape local optima [

40]. For instance, hybrid algorithms combining GA with local search techniques have been utilized to balance the trade-off between solution quality and computational effort [

41,

42].

Beyond conventional techniques, reinforcement learning (RL) has gained prominence in scheduling research, offering adaptive decision-making capabilities that enhance scheduling flexibility and robustness. Methods such as Q-learning and deep Q-networks (DQN) enable real-time adaptation to dynamic production environments, allowing optimization strategies to effectively respond to uncertainties. Recent studies have explored hybrid optimization techniques that integrate RL into metaheuristics, known as Ensemble Meta-Heuristic and Reinforcement Learning (E-MHRL). A comprehensive review [

43] highlights the growing application of RL in conjunction with metaheuristic algorithms such as GA, PSO, and SA. These hybrid models improve scheduling efficiency by dynamically adjusting search strategies and fine-tuning algorithmic parameters. The study emphasizes that E-MHRL approaches significantly outperform traditional scheduling methods by leveraging RL’s learning capabilities to optimize decision-making policies and enhance computational efficiency.

Expanding on this trend, a multi-objective flexible job shop scheduling framework has been proposed, leveraging Graph Attention Networks (GATs) and RL to optimize scheduling efficiency. The approach employs a dual GAT structure to capture machine and operation features, while an Actor-Critic RL model dynamically adjusts scheduling strategies to balance makespan, maximum machine load, and total machine load. Comparative experiments demonstrate that this hybrid method achieves superior Pareto front solutions, outperforming state-of-the-art multi-objective evolutionary algorithms in both solution quality and generalization to larger scheduling instances [

44].

The literature also explores various FJSP extensions, such as the multi-objective FJSP, where factors like machine energy consumption, setup times, and workforce constraints are considered alongside E/T penalties [

45,

46]. Furthermore, the inclusion of dynamic FJSPs, where machine availability and job arrival times are stochastic, reflects more realistic production environments and introduces additional layers of complexity [

47,

48]. The development of efficient algorithms for the FJSP remains an active area of research, with metaheuristics playing a pivotal role in addressing the problem’s combinatorial complexity and multi-objective nature. These approaches not only improve machine utilization but also minimize penalties related to job E/T, contributing to significant gains in production efficiency [

49].

The scheduling of jobs to minimize E/T penalties is a critical area of study in operations research, particularly within the domain of production scheduling [

50]. The field of scheduling algorithms encompasses a variety of established techniques designed to effectively manage due date constraints, which are essential for optimizing operational efficiency and minimizing tardiness across various applications, particularly within complex manufacturing environments [

51].

Priority rules involve assigning precedence values to tasks based on factors such as due date, processing time, and setup time. Tasks with higher priority values are scheduled before those with lower values, ensuring urgent tasks are addressed promptly. This method is particularly effective in task assignment problems where prioritization is based on due dates and processing times [

52]. However, while effective for straightforward scenarios, priority rules can struggle with complex dependencies and dynamic environments [

53].

Deadline adjustment algorithms dynamically modify task deadlines to ensure schedule feasibility while minimizing tardiness. These iterative techniques adjust deadlines based on task dependencies and execution risks [

54]. While they enhance flexibility and adaptability in scheduling, they may require significant computational resources for real-time adjustments in large-scale systems [

55].

Constraint programming (CP) offers a declarative approach that leverages constraint resolution algorithms to tackle scheduling challenges. By integrating domain-specific knowledge into the constraint set, such as precedence relations and heuristic rules, CP enhances problem-solving capabilities [

56]. This method is particularly suited for complex scheduling problems where constraints are numerous and interdependent. However, the effectiveness of CP can be limited by the complexity of the constraint model and the computational effort required to solve it.

GAs utilize a population-based approach to optimize scheduling solutions iteratively. By simulating natural selection principles, GAs generate increasingly effective schedules over successive generations [

57]. They are recognized for their robustness in handling complex scheduling problems but may require the careful tuning of parameters such as mutation rates and crossover strategies to avoid the premature convergence or excessive computation times.

Simulated annealing is a heuristic optimization technique inspired by the physical process of metal cooling. It explores potential solutions by gradually reducing the likelihood of accepting inferior solutions as the process progresses [

58]. This method is effective in generating high-quality schedules under due date constraints by exploring various configurations and converging towards optimal solutions. Its main limitation is its sensitivity to the cooling schedule, which must be carefully designed to balance exploration and exploitation.

Backward scheduling starts from the due date and works in reverse to establish start times for each task. This method ensures alignment with deadlines and has been shown to enhance timeliness in task completion across various applications [

59], while effective for ensuring deadline adherence, backward scheduling may not effectively account for resource availability or task dependencies without additional adjustments.

Improvement heuristics involve iterative techniques aimed at refining existing schedules. These heuristics facilitate adjustments in response to fluctuations in demand or changes in capacity while maintaining a focus on due date constraints [

60,

61]. They enhance responsiveness and adaptability but may require frequent recalibration to remain effective as conditions change.

B&B algorithms have been extensively studied and applied to solve single-machine scheduling problems with E/T penalties. These algorithms have proven to be effective in finding optimal solutions for various E/T scheduling problems. The validity of the B&B algorithm for single-machine problems with E/T penalties has been proven by utilizing lower bounds based on LP relaxation [

62]. In the context of just-in-time manufacturing, B&B algorithms have been effectively applied to scheduling problems with quadratic E/T costs [

63]. For problems involving job families, the sum of maximum earliness and maximum tardiness has been successfully minimized using B&B algorithms [

64]. Additionally, B&B algorithms have demonstrated their versatility by being applied to related problems such as aircraft landing scheduling, which share similarities with E/T scheduling problems [

65]. In the context of the FJSP with E/T penalties, B&B approaches have been enhanced to consider multiple time constraints, including setup times, transportation times, and delivery times [

66]. Furthermore, B&B techniques have been integrated into other optimization methods to improve the solution quality and computational efficiency for FJSP problems with E/T considerations [

67]. This integration has led to the development of hybrid approaches that can effectively handle the increased complexity of FJSP while still maintaining the ability to find optimal or near-optimal solutions for E/T objectives [

68].

LP models play a crucial role in addressing E/T scheduling issues, particularly when integrated with frameworks like the S-graph. These models incorporate machine-to-operation assignments and sequencing constraints, allowing for dynamic adjustments as new constraints are introduced during the scheduling process [

69]. The integration of LP models within a B&B framework facilitates real-time updates, ensuring that optimal solutions are maintained throughout the iterative process. The incorporation of these diverse techniques into scheduling algorithms enables organizations to effectively address due date constraints and minimize tardiness in complex manufacturing operations. The integration of these methodologies not only optimizes resource utilization but also enhances overall productivity and operational efficiency.

Recent studies have also extended FJSP models to incorporate energy efficiency as a key objective. In energy-intensive industries, scheduling optimization plays a crucial role in minimizing unnecessary energy consumption while balancing production constraints. Stochastic multi-objective models integrating energy and time-related criteria have been developed, using hybrid metaheuristics combined with simulation-based evaluation methods to optimize both total tardiness and energy usage [

70]. Furthermore, distributed FJSP research has explored cooperative artificial bee colony algorithms with learning-driven mechanisms, addressing challenges such as preventive maintenance and transportation constraints. These approaches enhance scheduling robustness by integrating Q-learning-based strategies into multi-factory production environments [

71].

In this direction, recent research has explored hybrid metaheuristic-based scheduling strategies aimed at optimizing both makespan and energy efficiency in smart manufacturing. A hybrid model integrating real-time adaptability mechanisms and predictive maintenance strategies has been developed to enhance scheduling robustness while minimizing energy costs. By dynamically adjusting schedules in response to machine failures and fluctuating energy demands, this approach improves energy efficiency without compromising production performance. Experimental evaluations confirm the effectiveness of this method in reducing energy waste while maintaining scheduling quality, making it a promising solution for modern smart factory environments [

72].

These advancements highlight the ongoing shift towards intelligent, self-adaptive scheduling methods. Future research is expected to further develop deep reinforcement learning techniques, real-time scheduling adaptations, and multi-agent RL models to enhance performance in complex and dynamic manufacturing systems.

1.2. Problem Definition

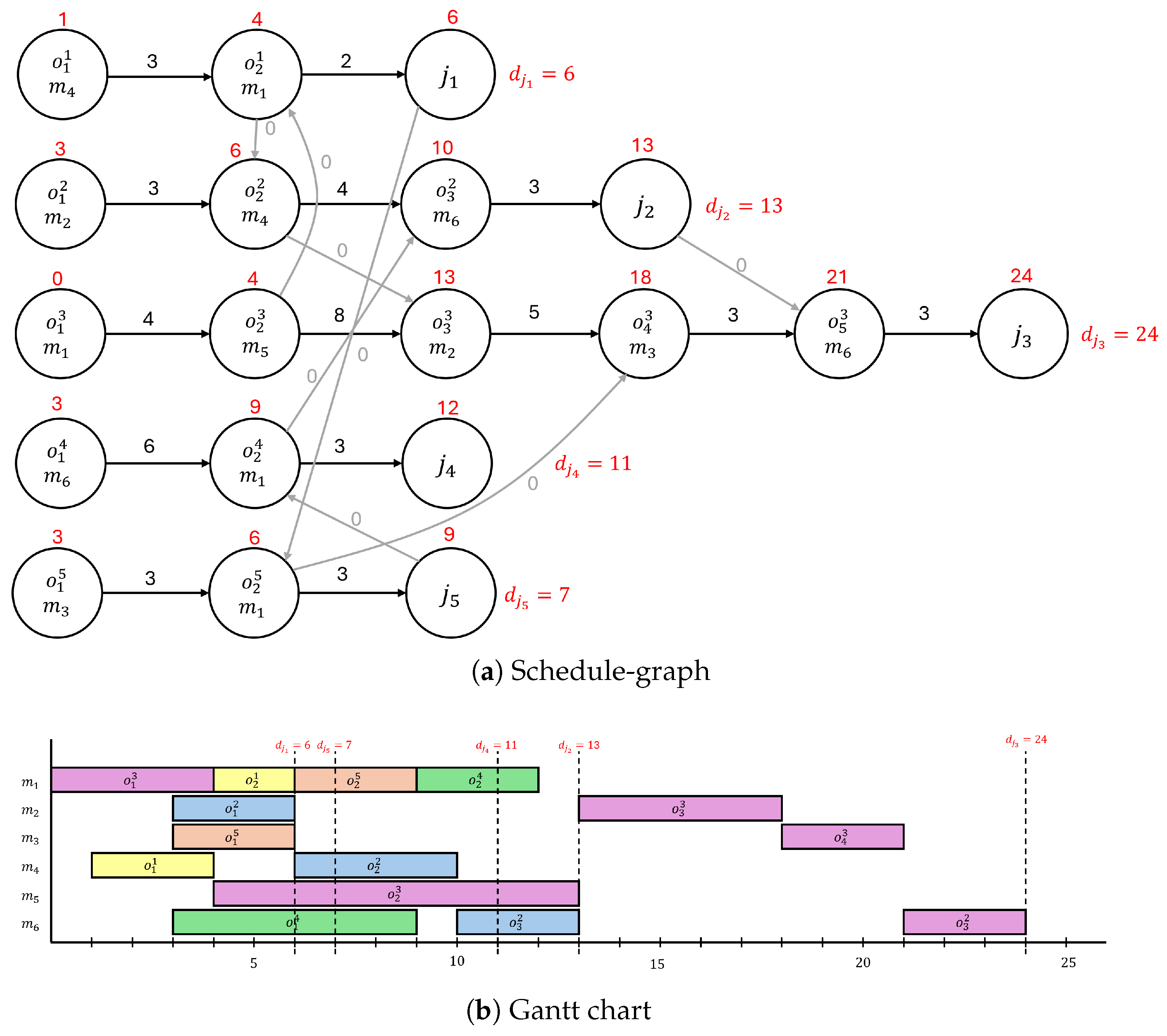

The FJSP addressed in this study focuses on scheduling a set of jobs, where each job consists of a sequence of operations. Each operation can be processed on one of several available machines, introducing flexibility in machine assignments. This flexibility, combined with job-specific due dates and precedence constraints between operations, makes the scheduling problem complex. The primary goal is to minimize both the earliness and tardiness of job completions, while optimizing machine assignments and operation sequencing.

To formally define the problem, let J represent the set of jobs, where . Each job is composed of a set of operations, denoted by . The complete set of operations across all jobs is . Each operation must be assigned to a machine from the set of available machines; and denotes the set of machines capable of performing operation . Each machine can process specific operations, and the processing time of operation o on machine m is denoted by . This processing time varies depending on the machine chosen, adding complexity to the scheduling process.

Precedence constraints exist within each job, meaning certain operations must be completed before others can begin. For each operation , let represent the set of prerequisite operations that must be finished before operation o can start.

Precedence constraints within jobs play a fundamental role in the scheduling process. Each operation follows a defined sequence, where an operation can only begin once its designated predecessor is completed. This establishes a structured progression, ensuring that each step follows a logical order without unnecessary dependencies.

A schedule can be represented as , where o is assigned to machine m, with a start time and a finish time . The problem is formally classified using the notation as . In this notation, the following hold:

represents the Flexible Job Shop structure, where each operation can be processed on a subset of eligible machines, with machine choice affecting the processing time.

refers to the precedence constraints between operations within a job, including AND-type constraints and potential parallel execution.

The objective represents minimizing both E/T across all jobs.

Each job has a distinct due date (), specifying a target completion time that, if exceeded, incurs penalties. Additionally, processing times () vary based on machine selection, influencing scheduling decisions and overall efficiency.

Several key challenges arise when solving the FJSP. First, machine flexibility requires determining the optimal machine for each operation, as the processing time differs across machines, and not all machines can process every operation. This introduces complexity in balancing machine assignments to minimize both job completion times and penalties. Second, precedence constraints within jobs ensure that certain operations are completed before others can start. For example, if operation o precedes , the start time of , denoted by , must satisfy , where is the start time of o. Third, due date constraints enforce job-specific due dates, requiring the scheduler to minimize penalties for both early () and tardy () job completions.

Furthermore, the scheduling process is affected by two different storage policies. Under the No Intermediate Storage (NIS) policy, machines must wait for material transfers between operations, which can result in machine idle times. Conversely, the Unlimited Intermediate Storage (UIS) policy allows operations to proceed independently of material transfers, offering more flexibility and reducing potential delays due to machine idle times.

If the due date is not given for a job, then it is defined based on the total processing time of all its operations [

73,

74], scaled by a factor

f [

75]. The due date for job

j is given by the following:

This approach ensures that due dates are proportional to the expected processing times but does not directly account for system congestion. Congestion effects can be modeled by adjusting the factor

f, depending on the system’s load ratio. The parameter

f serves as a tightness factor, influencing the strictness of due dates. A value of

was applied in this case, as an increase in

f results in a relaxation in due dates, making the scheduling problem easier [

76]. Setting

, however, is generally not advisable, as it assumes that jobs will not experience any waiting time, leading to overly strict due dates that may not be achievable in a congested system [

75]. In addition, the framework allows for the specification of job-specific due dates as input parameters, thereby accommodating scheduling problems with heterogeneous temporal constraints. This functionality enhances the model’s versatility, enabling it to address a broader spectrum of real-world scheduling scenarios where individual job due dates are critical factors.

The goal of the FJSP is to minimize the total penalties for E/T across all jobs. Let

denote the completion time of job

j. The earliness

is defined as

, and it occurs when a job finishes before its due date. The tardiness

is defined as

, and it occurs when a job finishes after its due date. The total objective function can be written as follows:

where

and

represent the job-specific penalty weights assigned to the E/T of job

j, respectively. In many practical applications, tardiness is often penalized more heavily than earliness, as delays can result in missed deadlines, contract violations, or customer dissatisfaction. However, these penalty weights may vary for each job based on its priority, urgency, or contractual requirements. While these weights affect the evaluation of the schedule’s optimality, they do not alter the core functionality of the proposed methodology, which remains applicable regardless of the specific penalty structure.

This FJSP presents a significant scheduling challenge due to the flexibility in machine assignments, the need to respect precedence constraints, and the variability in processing times. The goal is to develop an efficient schedule that minimizes both E/T while adhering to the operational constraints of the production environment.