Abstract

Additive manufacturing (AM) technology is gaining acceptance as a strategic manufacturing technique for allowing new product development. Due to ongoing process improvement, design for AM (DFAM) has become a major issue in harnessing AM’s production and development possibilities to achieve design freedom. The classical design process model does not encompass all the knowledge available to take advantage of design freedom. Therefore, a conceptual and in-depth analysis of design alternatives is necessary to determine the manufacturing process. As a result, this research proposed a design process model for a DFAM to attain design freedom with a unique approach and resource selection steps for fused deposition modeling (FDM) that uses an information model based on evolving knowledge and addressing the challenges. The proposed design process model uses an event knowledge graph (EKG) to outline the product manufacturability from the perspective of DFAM limitations. Event-based knowledge representation provides causality information for knowledge-based reasoning in causality analysis tasks. A relationship-aware mechanism is then used to express events on the graph that are directed from entities to occurrences to efficiently extract the most relevant details. Thus, this implements a step-by-step approach to process and resource specifications during the design stage. Consequently, it offers a comprehensive learning approach for establishing and modeling intrinsic relationships to attain flexibility and design freedom. The efficacy and feasibility of the proposed approach are verified by using an application case study of an intake system based on the airflow sensing rate and controls how much air is fed into the engine.

1. Introduction

Additive manufacturing (AM) is an umbrella term for a variety of manufacturing techniques that aim to create complex three-dimensional (3D) forms by layering materials preceding each other [1,2]. Many factors, including useable material, material characteristics, and design limitations, vary according to the AM process. AM technology allows the production of objects with complex forms and heterogeneous materials that are impossible to produce using subtractive manufacturing techniques [3,4,5]. In the manufacturing industry, AM has the potential to be a disruptive technology for component manufacturing. Weight reduction, design flexibility, prototypes, decreased development time, rapid resolution of supply chain difficulties, and cost reductions are all factors that make this technology appealing for production [6,7]. This complexity is heightened with AM technologies due to unique AM properties and AM standards, guidelines, tools, and procedures in development. These factors are highlighted using a parametric design for additive manufacturing (DFAM) strategy. Designing a product or component for simplicity in manufacturing is known as DFAM [8,9]. DFAM offers fewer manufacturing restrictions for AM components than several manufacturing methods, enabling an additional optimization-driven design procedure and higher-value features [10,11].

Therefore, AM techniques used the DFAM concept expressly to assess their design limitations throughout the design phase. Furthermore, the assessment of manufacturability and the selection of the manufacturing process are essential in making decisions for any manufacturing methods, including AM, which must be made using design for manufacturing (DFM) activities [12,13]. These obligations must be completed while incorporating both opposing characteristics and various organization requirements, as well as the investigation of manufacturability and process choice. The complexity of AM technologies has grown due to specific DFAM attributes, guidelines, standards, tools, and procedures, which are now being developed due to ongoing DFAM process improvement [12,13,14]. These factors show the importance of offering a flexible design process for the DFAM approach. Despite the improvements, the DFAM design process model still has challenges with constant process improvement [2,12,15].

As knowledge graph (KG) technology in the AM sector advances, it rapidly transforms from data intelligence to cognitive intelligence [16,17]. The comprehensive identification of the conceptual relationships of the design process is necessary for design freedom and flexibility [2,18]. Thus, to build a DFAM method for AM technology, it is essential to simultaneously investigate the problems associated with procedure selection and manufacturing capability [1]. Thus, KGs can further investigate and help identify the conceptual relationships of the design process required to achieve design freedom based on heterogeneous knowledge and pertinent algorithms [19,20]. KGs provide significant support for a thorough AM-specific design process that can adapt continuously to the improvement of the DFAM process [16]. Furthermore, KGs can provide design recommendations through mapping intents to support the current design standards and provide potential ways to establish design standards to achieve design freedom and flexibility [21].

However, an effective and precise technique for resource modeling for AM is needed to use KGs for the process knowledge to improve the design process model and offer design freedom and flexibility [2,22]. As a result, this paper presents an event KG (EKG) to examine product manufacturability from the perspective of the design process model by considering creative strategies and implementing a step-by-step approach to process and resource specifications. It considers the limitations of the current DFAM attributes, guidelines, standards, tools, and procedures problems during the design stage. A fundamental and in-depth investigation of manufacturing and design possibilities must be performed simultaneously to choose the production method. Therefore, based on various parameters, this method chooses the optimal design procedure and resources from several AM technologies and machines.

The following are the primary contributions of this research that set it apart from other studies:

- A design process model based on EKG is proposed to break down the roles of the crucial attributes in DFAM development. As a result, this offers a comprehensive learning approach for establishing and modeling intrinsic relationships to attain flexibility and design freedom.

- The event-based knowledge representation provides a causality-based investigation for the production feasibility to accommodate the design process model’s creativity strategies. This provides an organized approach to process and resource specifications, which include integrating functions and structural simplification.

- The relationship-aware based on knowledge representation represents the value of FDM-based DFAM by combining functions and structural simplification of products to achieve the desired design freedom.

2. Related Work

2.1. The State-of-the-Art DFAM Development Approaches

According to Von Stamm [23], innovation cannot exist without the design phase. The foundation of an innovation process is the design process. Incorporating idea research and providing a basic plan, as Segonds [24] stated, the initial design phases are essential for creative design. This research offers an in-depth examination of the DFAM problem regarding methods, design guiding concepts, and design procedure models. Several other reviews have been conducted in recent years [10,13,25].

Additionally, this work introduces a unique design procedure for AM from a design engineer’s viewpoint and a DFAM development method that addresses every stage of the pattern process and connects the current design resources and approaches for each phase [25]. Fitzgerald et al. [26] presented methods to design objects and a particular viewpoint on the design approach illustrated by Tomiyama et al. [27]. Although all product lifecycle aspects are considered by introducing complete knowledge, methods, or measurements, DFX revolutionizes design practice. As a result, DFAM techniques are committed solely to the AM paradigm. They are meant to make thinking about AM specifics easier and allow you to rethink manufacturing design to benefit from the distinctive abilities of such innovations [28].

Laverne et al. [29] created the design with AM approach (DWAM) to include AM knowledge (AMK) contributions throughout the initial stages of design. Due to the intake of AMK that is appropriate for the initial design procedure, this aims to fill the research gap. Thus, utilizing a creative AM method can also encourage the design team to use greater creativity in the initial phases of the design procedure. Hao et al. [30] propose a knowledge-graph-based method for engineering design decision-related knowledge extraction from unstructured texts. The method’s performance depends on quality, and its applicability to additional design contexts needs further evaluation.

Thompson et al. [31] extensively discuss AM’s design benefits, such as complicated geometries and bespoke items. It also addresses material selection, optimization of processes, and design for manufacturability issues. Pan et al. [32] examine KGs in engineering design. However, their study does not cover AM. This study shows the general trends in KG adopting robust reasoning in design and how our work is unique in applying it in the AM domain.

2.2. Knowledge Graph Construction Frameworks

KG is known for its structured data encapsulating entities and their relationships [33]. Typically, triplets make up a KG (h, r, t). The triplet denotes a relationship of type r between the head entity h and the tail entity t [1,33]. Shi et al. [34] offered instructions for the smart transition of manufacturing on the shop floor by developing KG to deliver cutting-edge resources and ideas for data management and sharing. As AM becomes more data-intensive, ontology and KG are used as a framework for reasoning and storing design knowledge of standard AM design principles driven by data [2,35]. The consensus-based AM ontology’s use encourages reusability in producing dental products [35,36].

To increase the effectiveness of fault identification for maintenance engineers, Tang et al. [37] investigate the development and use of an aviation fault knowledge graph. Their method establishes the structure layer of a fault KG by analyzing the knowledge components needed for aviation problem detection. For intelligent machine as a service (IMaaS), Liu et al. [19] offer a novel resource KG creation technique that divides between constant and dynamic entities and establishes the constant characteristics and relationships using an E-R diagram. After that, the value space is established, the triplets are given names, and a structure layer is generated. The KG is created after the data layer contains pertinent component knowledge.

Den et al. [38] suggest an EKG-based graph learning approach integrating word and relational contexts. A context-aware encoding synthesis module is shown in their approach to enhance event participants’ hidden features. It is difficult to automatically create event-centric KGs from generalized ones, as discussed by Blin et al. [39]. An event-centric KG is created using a two-step process from significant occurrences like the French Revolution. The intelligent graph traversal defines event-centric filters to refine the keyword space and an intuitive scoring for sorting nodes like events. It also recovers associated sub-events from huge, open-domain knowledge networks.

Knez et al. [22] examine the available datasets and language technologies relevant to these tasks. A comprehensive comparison of different methodologies indicates that optimal outcomes are attained through advanced models that utilize large pre-trained linguistic models. Li et al. [40] demonstrate the significance of incorporating event knowledge into KG representation development and introduce a novel EKG embedding model grounded in event-correlated transfer, effectively preserving the semantic details of occurrences, entities, and relations. Chang et al. [41] propose a construct-SCHOLAT KG approach for developing an educational EKG utilizing the learning online community SCHOLAT. The construction framework comprises two primary components: data preparation and the event extraction process.

Based on the research gaps, which do not cover all the process knowledge available for design freedom and flexibility due to the continual advancement of the DFAM. This research offers a novel approach using EKG. Through intrinsic relationship modeling, the proposed EKG-based design process model promotes flexibility and design freedom while streamlining the functions of important qualities in DFAM development. Thus, to accommodate the creativity methods of the design process model, the event-based knowledge representation integrates functions and simplifies structural features, providing a causality-based inquiry for production feasibility. By integrating functionality and structural simplicity of products to obtain the necessary design freedom, the relationship-aware, based on knowledge representation, exemplifies the value of FDM-based DFAM.

2.3. Research Gaps

Although evaluations and methods have been presented for DFAM development, there is nevertheless no comprehensive strategy that properly integrates additive manufacturing’s specific properties throughout the design process. Many studies focus on initial design phases or individual design methodologies, but they lack a comprehensive structure to accommodate AM technologies’ complexity and heterogeneity. Some approaches involve idea research or specific design viewpoints, but they often fail to address later design difficulties like manufacturability evaluation and process selection.

Most knowledge graph construction frameworks are either too general or too focused on defect identification or resource management. The KG construction approach is lacking for AM design’s complex linkages and dynamics. Existing frameworks fail to capture causality and complex connections between design events, entities, and processes in DFAM. Thus, this hinders the design process model’s support and AM design freedom and flexibility. Our research proposes an EKG-based strategy that addresses DFAM’s needs and provides a more complete and effective solution to these gaps.

3. Method

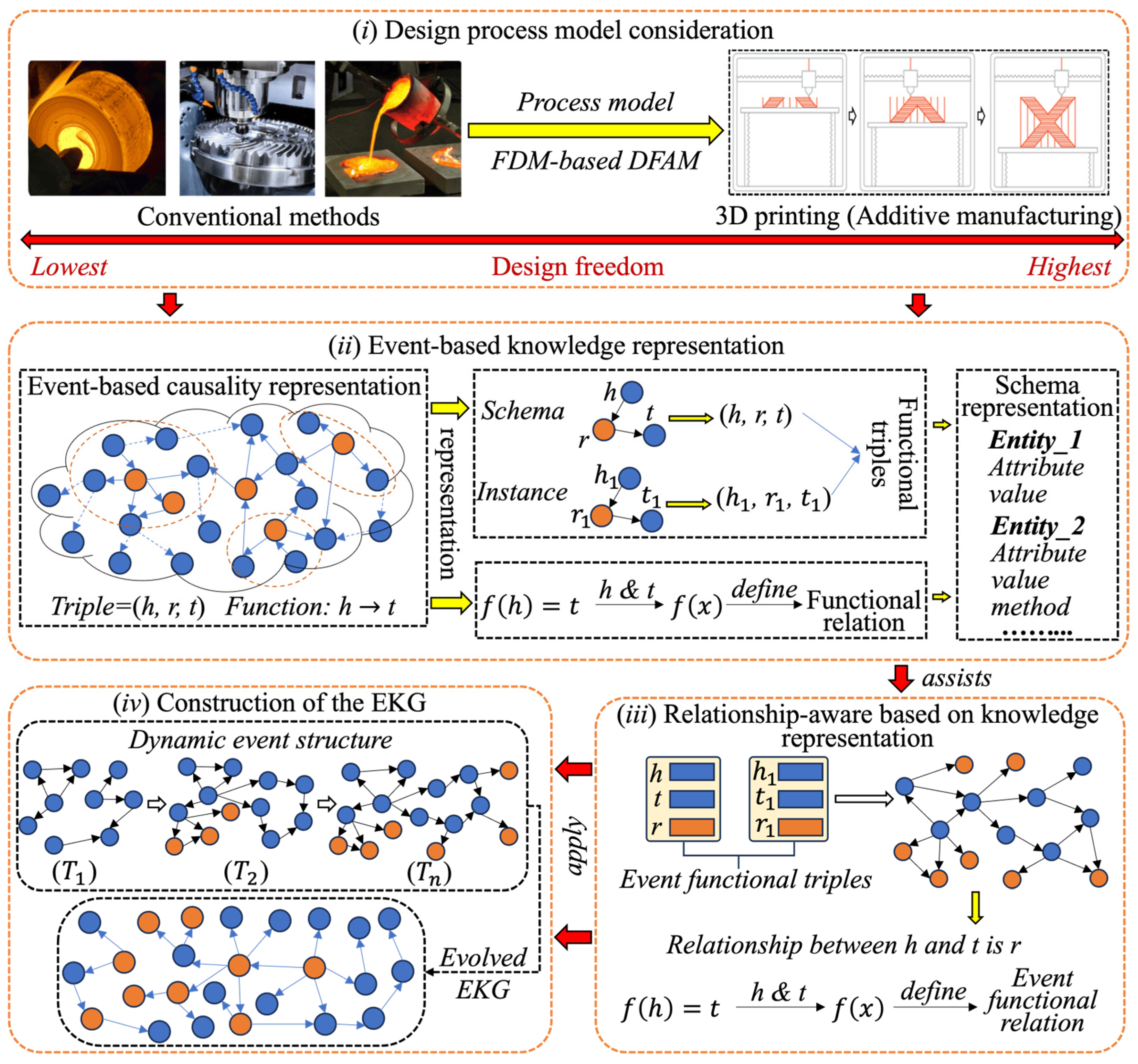

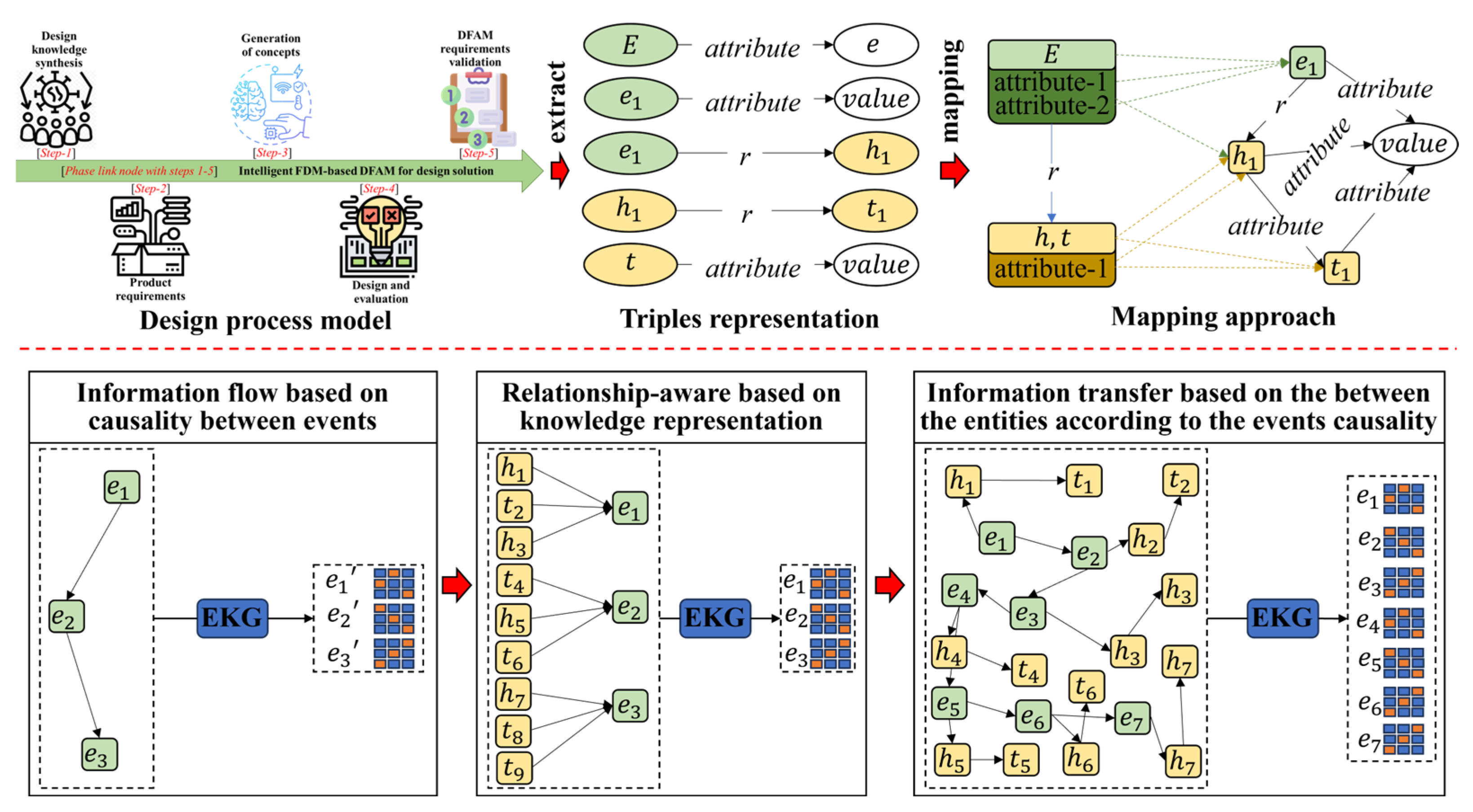

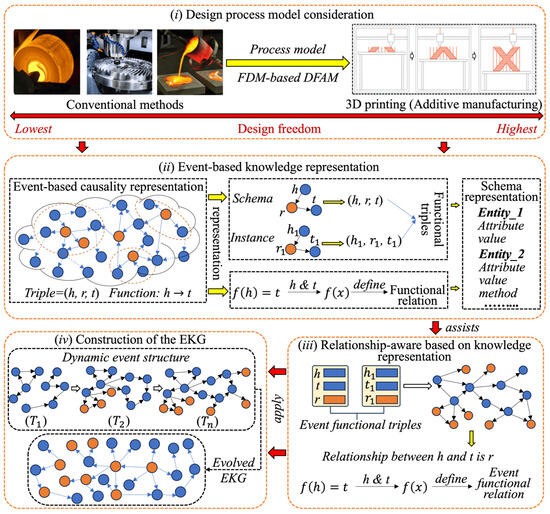

This study employs an EKG to support the design process model and offer a comprehensive learning approach for establishing and modeling intrinsic relationships, aiming to achieve flexibility and design freedom in FDM-based processes. The design process model consideration provides a viable approach by integrating knowledge-based design. The event-based knowledge representation endows the EKG with a unified semantic, facilitating cognitive reasoning and supporting semantics through causality analysis. Relationship-aware mechanisms map design intents to support the knowledge representation. Each event node is instantiated, and its triples are inherited to generate the EKG. The triple instances are continuously updated to reflect the real-world object as the structure changes dynamically.

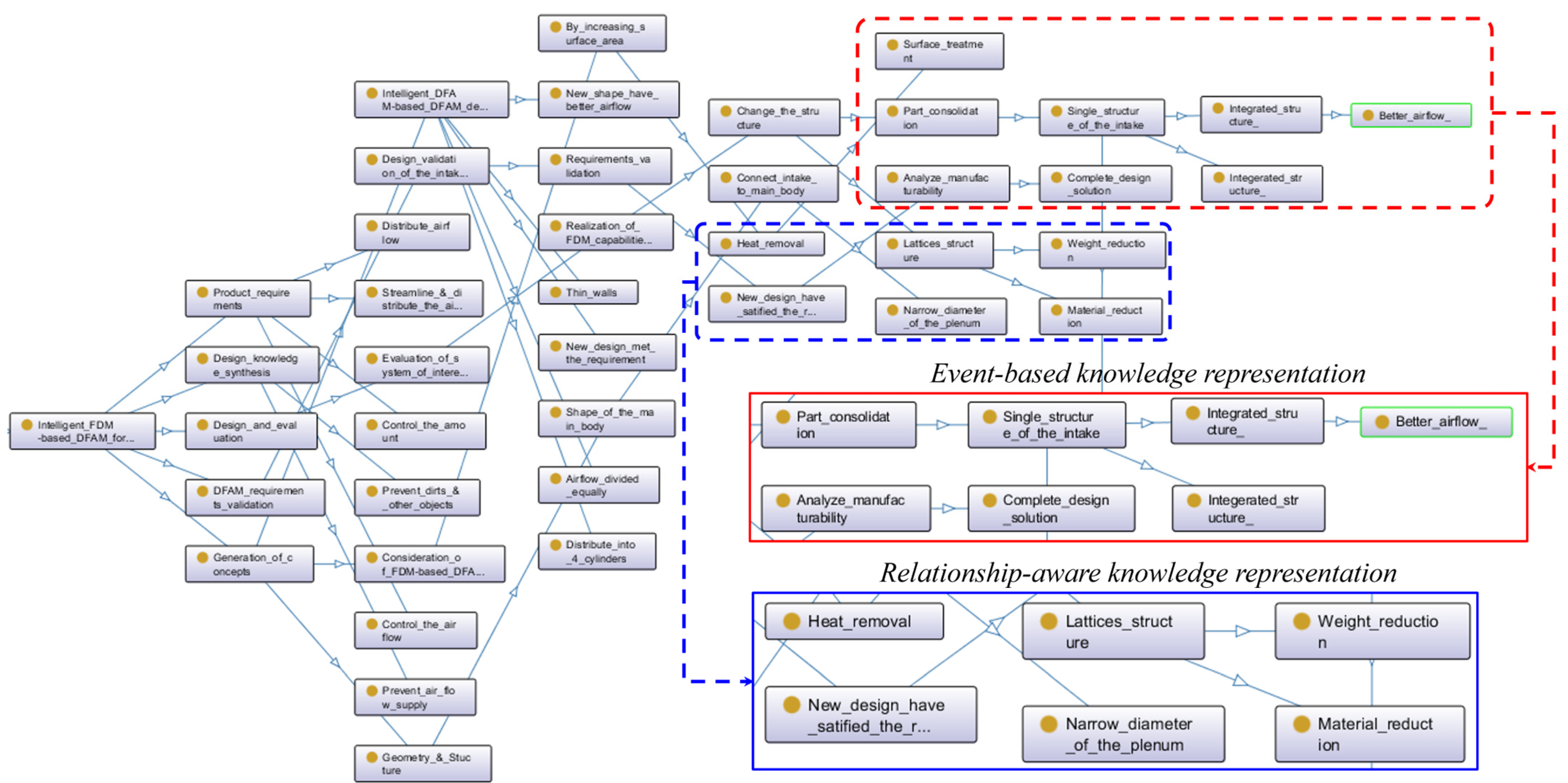

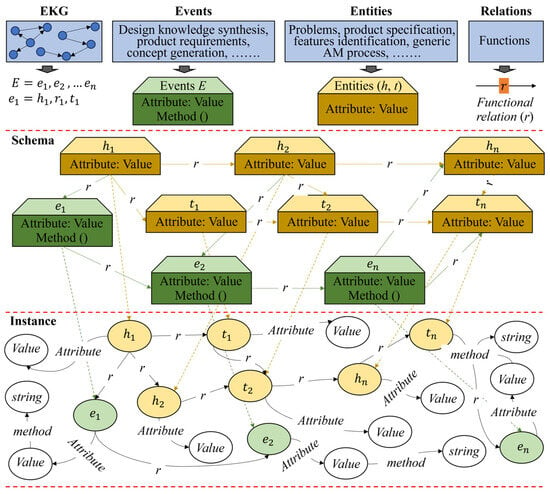

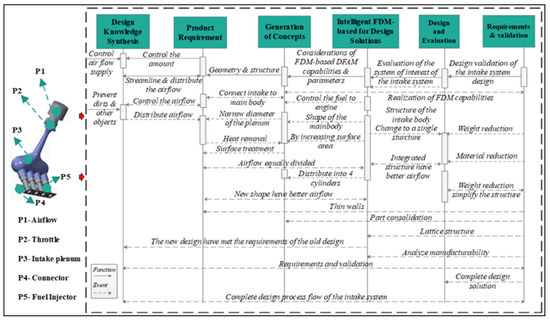

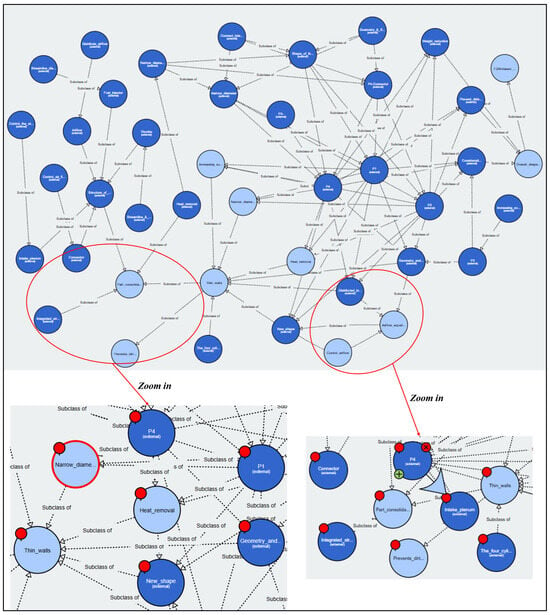

Different events and entities collaborate in various ways in the development approach. The EKG aims to capture these complex relationships. In Figure 1(iii,iv), the processes that appear to deviate from the simple h-r-t sequence represent special cases or intermediate steps in the design process. For example, when an event is triggered, it involves several intermediate processes or variables that are not basic functional relationships. The orange nodes indicate various stages or actions crucial for the design procedure but do not fit the simple head-relation-tail model. Furthermore, the EKG is constructed using several processes, including triple generation, path calculation, and event triggering. Relationships between events and entities always evolve and improve during these processes. Some of the processes may be associated with the iterative nature of the design process, wherein certain steps must be reexamined or modified in light of new data or limitations.

Figure 1.

The framework of the proposed method.

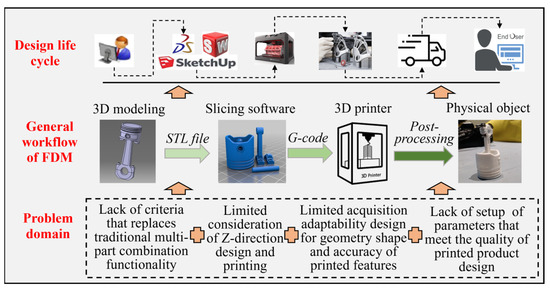

3.1. Design Process Model Consideration

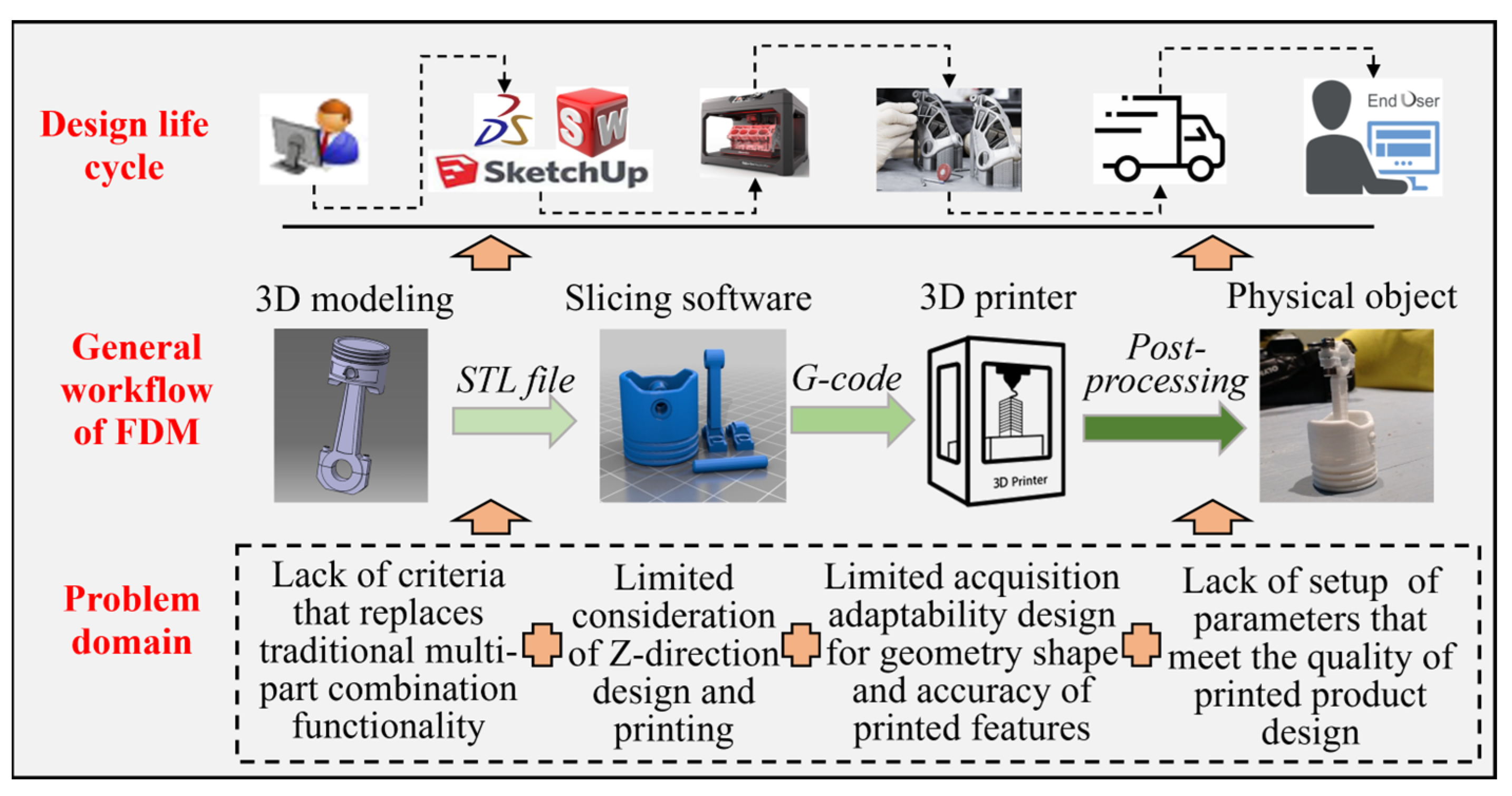

In AM, many design issues have become increasingly complex and often transcend disciplinary boundaries. Tomiyama et al. [27] pointed out that after reviewing the contributions of several experts in design methodology, classic design methodology lacks the efficiency to support current and future development efforts, thus requiring significant reform. To comprehensively capture and represent the various life cycle implications of AM products, the design service life system demands an advanced process to fully achieve the design freedom offered by design for additive manufacturing (DFAM). Although the classical DFAM design model has made progress, obstacles still prevent it from realizing the full potential of design freedom, as illustrated in Figure 2. Given the limitations of the classical model, this research proposes a design process model for intelligent FDM-based DFAM. This model aims to fulfill the complete potential of design freedom, including aspects like “design criteria for a single 3D printable part replacing traditional multi-part combination functionality”, “Z-direction design”, “process adaptability design and calibration for maintaining the geometric shape and accuracy of printed features”, and “setting up processes and process parameters that meet the quality requirements of printed product design”.

Figure 2.

The problems associated with the classical DFAM design process model.

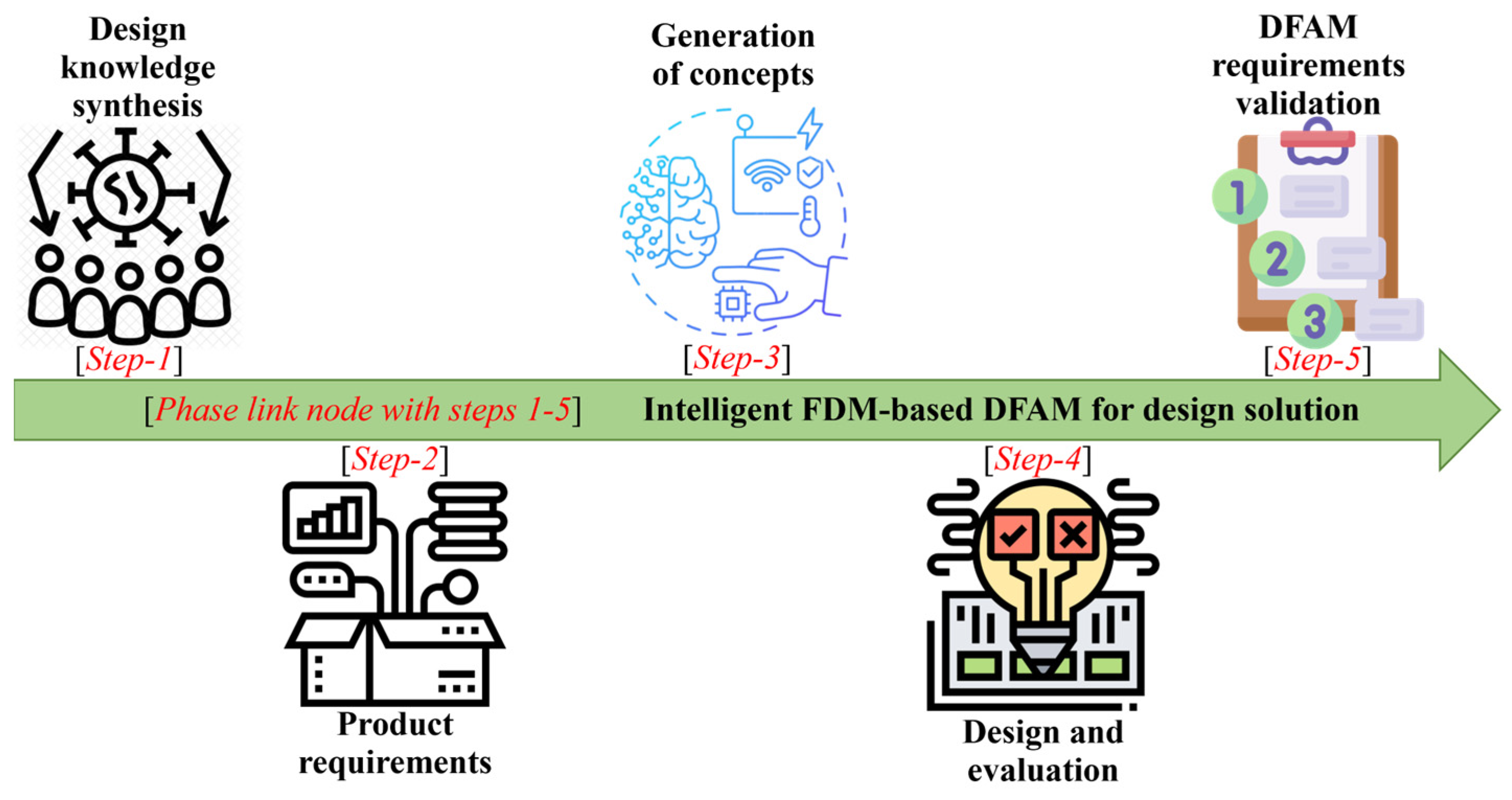

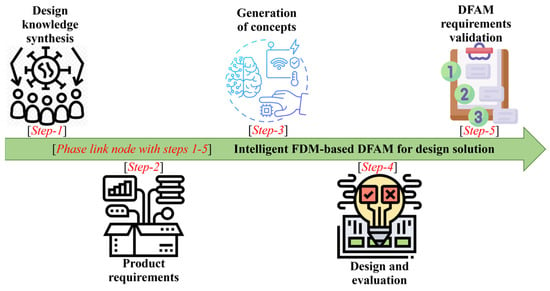

The proposed intelligent FDM-based DFAM design process model is a viable methodology that promotes design solutions by integrating knowledge-based design from the initial stage, as illustrated in Figure 3. This model consists of a single phase with five steps and information loops. Each stage aims to enhance AM-oriented designs and is designed for use by multidisciplinary teams. A sequence diagram was employed to develop the basic workflow of the DFAM process for the FDM process. The schematic design process model was developed to maximize AM’s design flexibility and ensure the FDM method’s manufacturability. Based on the DFAM development process, function models describe the rationale behind a product’s design, expressed as complex elements of various categories. The design knowledge step analyzes DFAM issues, identifies useful knowledge, and pinpoints adoption problems while considering product requirements. The concept generation step exploits FDM features. The design and evaluation step assesses industrial applicability with techniques like the Bayesian network. The requirements and validation step tests the design. The design solution step incorporates innovations into the FDM process chain to show design changes.

Figure 3.

The schematic model of the design process model for the FDM-based DFAM for innovative design solution development process.

3.2. Event-Based Knowledge Representation

This section presents the event-based knowledge representation for developing the design process model of the FDM-based DFAM for innovative design solutions. The decomposition of its development process is described using this approach. The DFAM spectrum, which forms the basis for establishing a design process, encompasses system, part, and process design. The five steps are presented in a six-class model in terms of knowledge depiction: design knowledge synthesis, product requirements, generation of concepts, design and evaluation, and DFAM requirements validation, as shown in Figure 4.

Figure 4.

Event-based knowledge representation according to property graph.

The causality information is inherently present in the design process model. The specific processes within the selected model offer a foundation for knowledge-based reasoning in causality analysis tasks. Thus, this helps reduce redundant descriptions and provides an innovative solution for the FDM-based DFAM. This causality approach based on events offers a unified semantic to enhance the EKG, enabling cognitive reasoning of events and supporting semantics through knowledge reasoning in causality analysis. Functional triples represent the event-based causality.

For instance, given a set of events E with triples (h, r, t), the function from h to t is denoted as . In the schema layer, knowledge appears as (h, r, t), and in the instance layer, if ), then the knowledge is represented as () where r is the functional relation. The EKG consists of events (), head entities (), tail entities (), and relations (). Suppose an event E represents a collection of event nodes where each event contains an event-triggered step . The relations between the entities and the events are all functional.

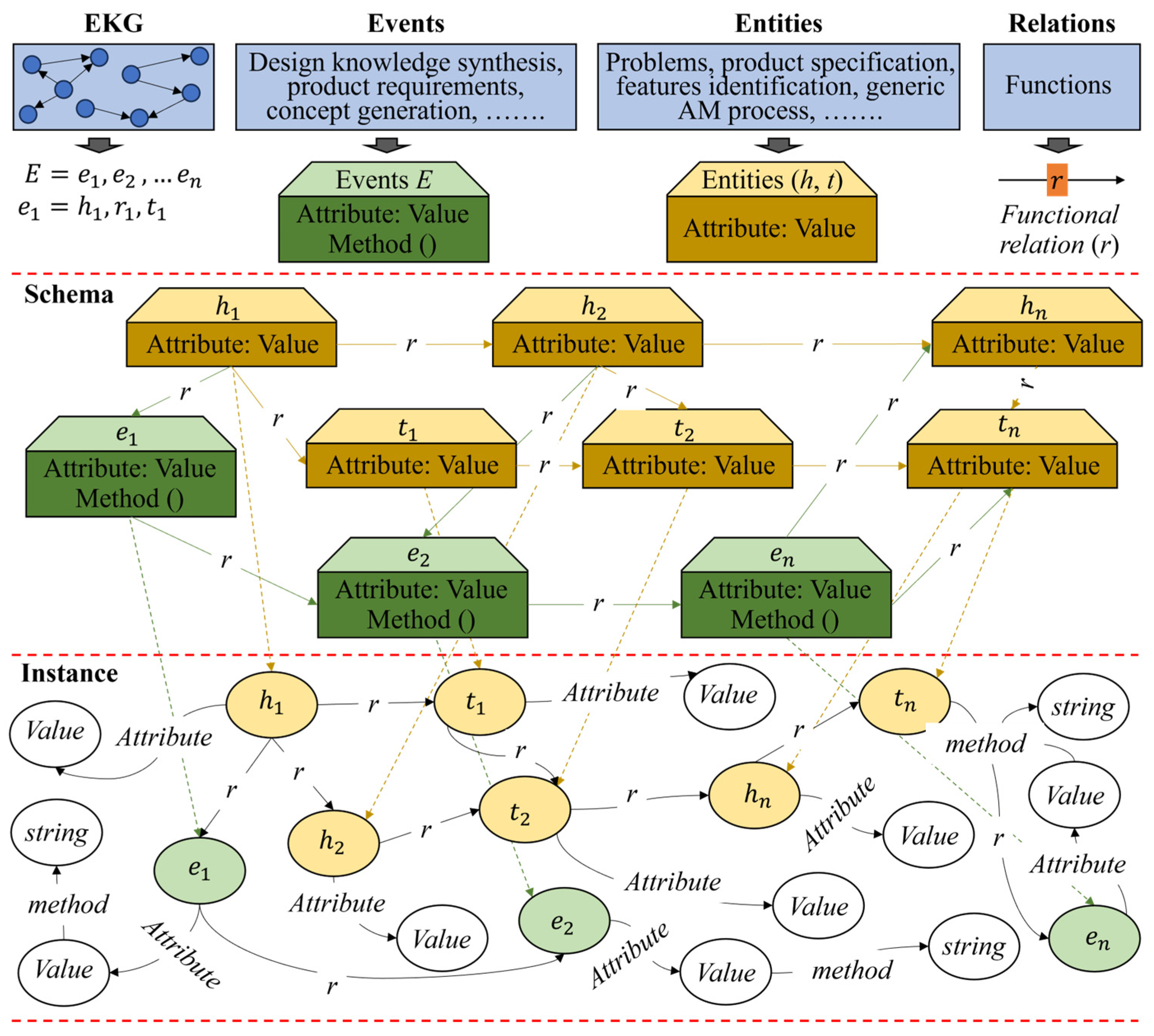

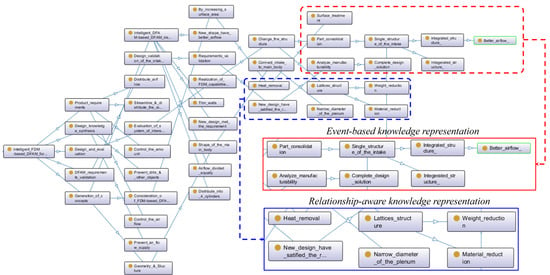

3.3. Relationship-Aware Based on Knowledge Representation

The design activities of the process model are utilized to extract the knowledge tuples. A specific format of these tuples is employed to form the dynamic part of the EKG. The schema layer links them through a direct mapping method. As demonstrated in Figure 5, causal relations convey the “information flow based on causality between events”, leading to the update of the event representation. For example, to express the collection of events related to an event (), the EKG network is used to update the event representation. Hence, the information flow based on event causality effectively provides the model with causal details. Algorithm 1 provides the information flow based on entity embedding to support the DPM in mapping design intents.

Figure 5.

Multi-layer relationship-aware based on knowledge representation.

Relationship-aware, based on knowledge representation mechanisms, are used to express events on the graph that are directed from entities to occurrences to efficiently extract the most relevant details of events in diversified graphs. It assigns suitable weights to neighboring nodes using the EKG technique. It does not require a particular network layout but concentrates on neighbor node pairs during reasoning. An adaptable linear alteration is applied to the input features to extract the more complex data features. Depending on the relationship-aware knowledge representation, each node, such as event trigger, event type, event logic, and role class, performs linear transformation based on the knowledge representation to provide the relationship-aware mapping of design intents to support the proposed design process model.

The objective of the information transfer between entities based on event causality, as shown in the lower part of Figure 5, is to fully integrate the fixed relation details among entities. The EKG employs embedding of various relation types because entities have different relation kinds. In particular, the event causality represents the connection of related entity nodes through their interactions. Subsequently, the entity representation is updated using the EKG’s information transfer method. The details of entities and events are crucial aspects of the obtained dynamic entity representation. Thus, improving the model and EKG representation learning relies on applying the information flow output based on event causality between entities. Algorithm 1 provides the method for updating the entity representation according to the entity connections.

| Algorithm 1: Information flow of causality between events based on entity embedding |

| Input: The vector format of the entities’ relationship is having edges where corresponds to the embedding of the entity node linked to the event and the entity ). Output: Information about triggered events, entities, and the relation types within the embedding of the EKG according to the causality. Entity to entity embedding → () Relation type between entity to entity embedding → ) The embedding vector dimension of the events, entities, and relation type →) Return update_triggered_event based on causality according to |

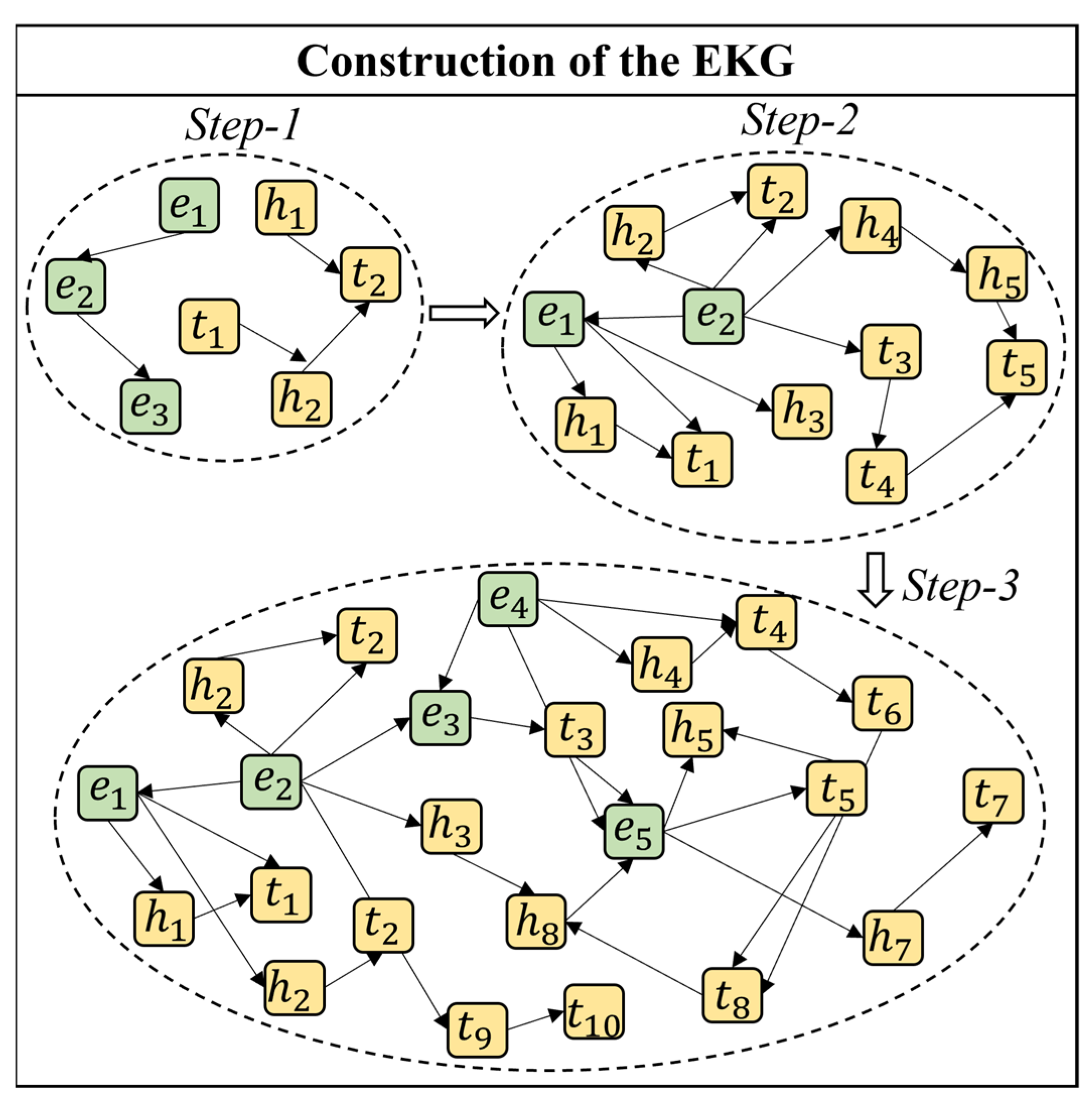

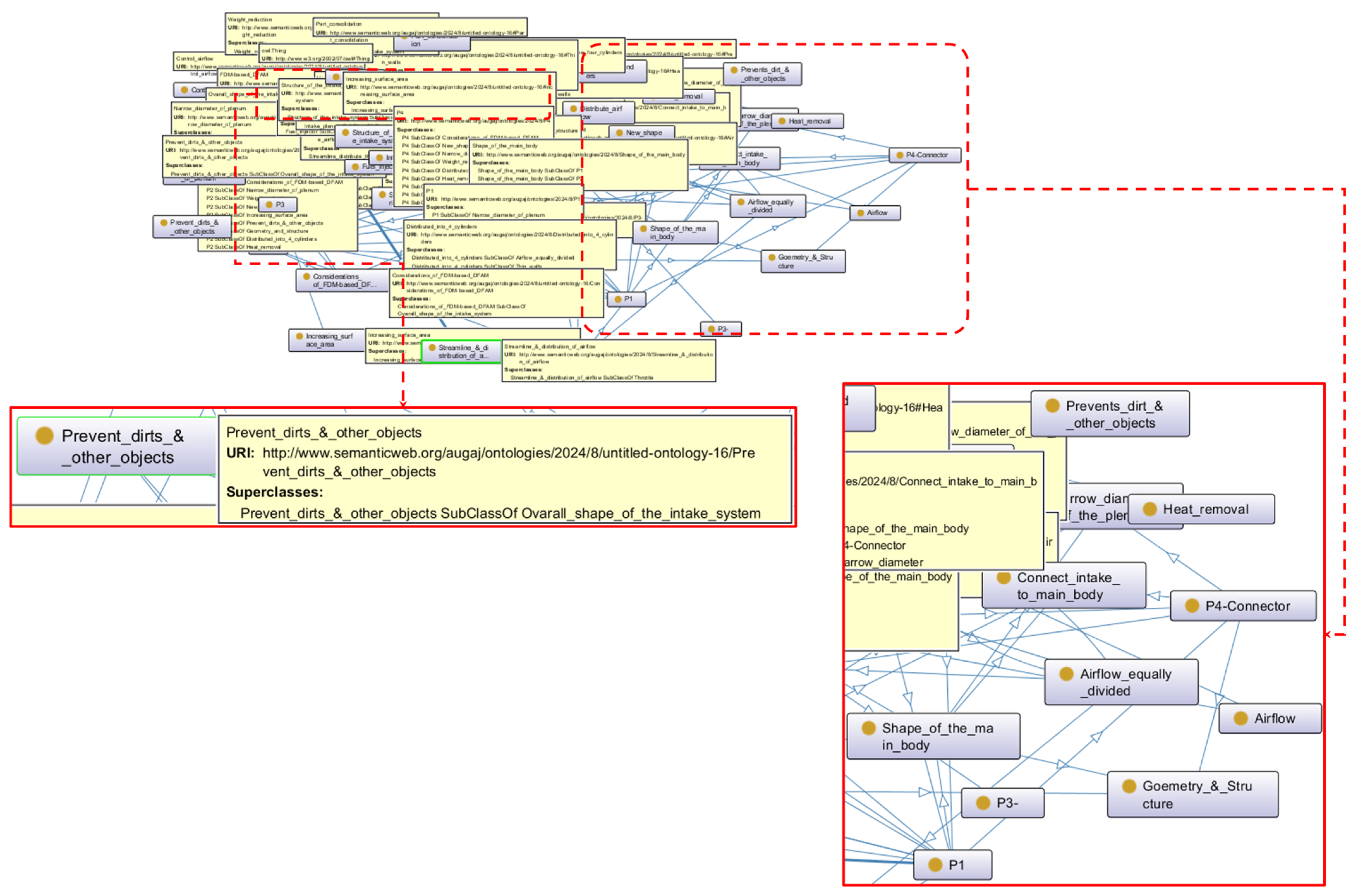

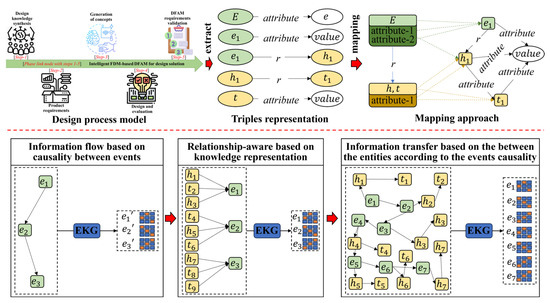

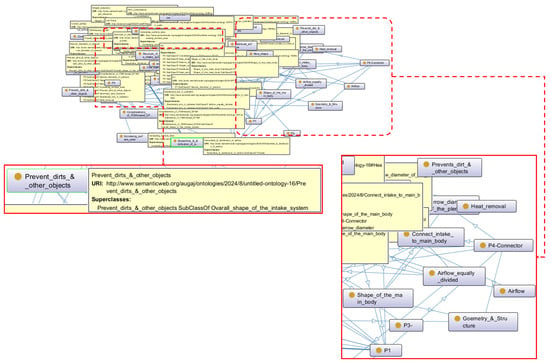

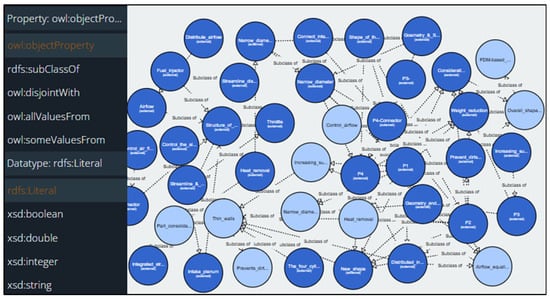

3.4. Construction of the EKG

The EKG is constructed by instantiating each event node and inheriting the triples. The dynamic construction of the EKG is shown in Figure 6. The instance of a triple is continuously updated as the entire structure dynamically changes and represents the object in the real world. This study builds the instance KG using a top-down approach. First, the entities and attributes of the design process model are abstracted and represented as objects depending on the events. Hence, this abstracts and represents the triggered procedure, events, and their properties as objects. Consequently, the EKG is created, with event occurrences, object entities, and their interconnections acting as nodes and edges, respectively. The structure of the EKG is influenced by the dynamic nature of the design process model, which constantly changes throughout specific design activities such as product requirements, concept creation, design, and evaluation stages. The event-triggered strategy of each activity during the design process causes these design activities to adapt dynamically.

Figure 6.

The dynamic construction of the EKG.

Step 1: event triggering is the causality evolution of the design process model’s design activation. According to the design process model, a new node with the event data will emerge after an event occurs. As shown in Figure 5, the procedure in the relevant event will be utilized to determine the value associated with the event characteristic using the provided information.

Step 2: path calculation is according to the relationship-aware based on knowledge representation, which calculates all the paths that start with the event triggered in the previous step according to the graph’s dynamic structure. Then, the causality of each node is calculated according to the dynamic evolution of the events and the path calculation method.

Step 3: after the path calculation, triples are generated based on the information transfer between the entities due to the causal relationships of the events. Furthermore, this creates the graph degree matrix to determine the evolution of the events and generate the triples. Based on that, the context graph is converted to a dynamic graph representation, and the newly generated triples are linked in the EKG.

The design process involves iterations and feedback loops. New information or events may necessitate the re-evaluation of prior entities or occurrences. The link from t to h may signify a scenario in which the attributes or results of a certain entity (t) influence the reassessment or alteration of another entity (h). For instance, in the design progression, the characteristics or efficacy of a component denoted as may impact the design choices concerning . Due to causality and interactions throughout the design, the EKG relationships are constantly updated and modified. Event-triggered mechanisms and the requirement to capture vital dependencies require the graph to accommodate reversing and non-linear impacts.

Algorithm 2 shows the process of constructing the EKG, which enables the reasoning process to utilize the information in the knowledge repository. Currently, Neo4j is the most widely used graph database. For the nodes, node attributes, edges, and edge attributes of the attribute graph, it creates unique storage schemes based on the attribute graph model. Neo4j can handle more than just graphs; it can manage other kinds of data. Neo4j’s robust graph exploration capabilities are useful for determining how the design activities in the model’s causality evolved. The aggregated information of neighboring nodes in the graph network creates node-level causality to assist with downstream activities. Additional information, increasing node properties, and graph nodes can all be incorporated due to the EKG’s dynamic nature. The EKG uses the measurement sequence extension information to improve the design process model.

| Algorithm 2: Construction of the EKG according to the events triggered mechanism, path calculation, and triples generation |

| Input: Input parameters triples (h, r, t) Output: build EKG for FDM-based DFAM Load events concept nodes of entities and relation For E that occurred due to the causality evolution do For triples h, r, t do Path = Determine every path in the graph that begins with the triggered event if the path starts with E Use the current triple to match every existing node If there are no nodes present then Establish nodes h and t following the event that was triggered Establish relation r for h and r Else Establish the missing nodes h and t based on the triggered event e’ Establish functional relation (r) for the missing nodes h and t based on the triggered event e’ End if End for Generate nodes and edges and then import them into the graph Return Build EKG |

4. Case Study

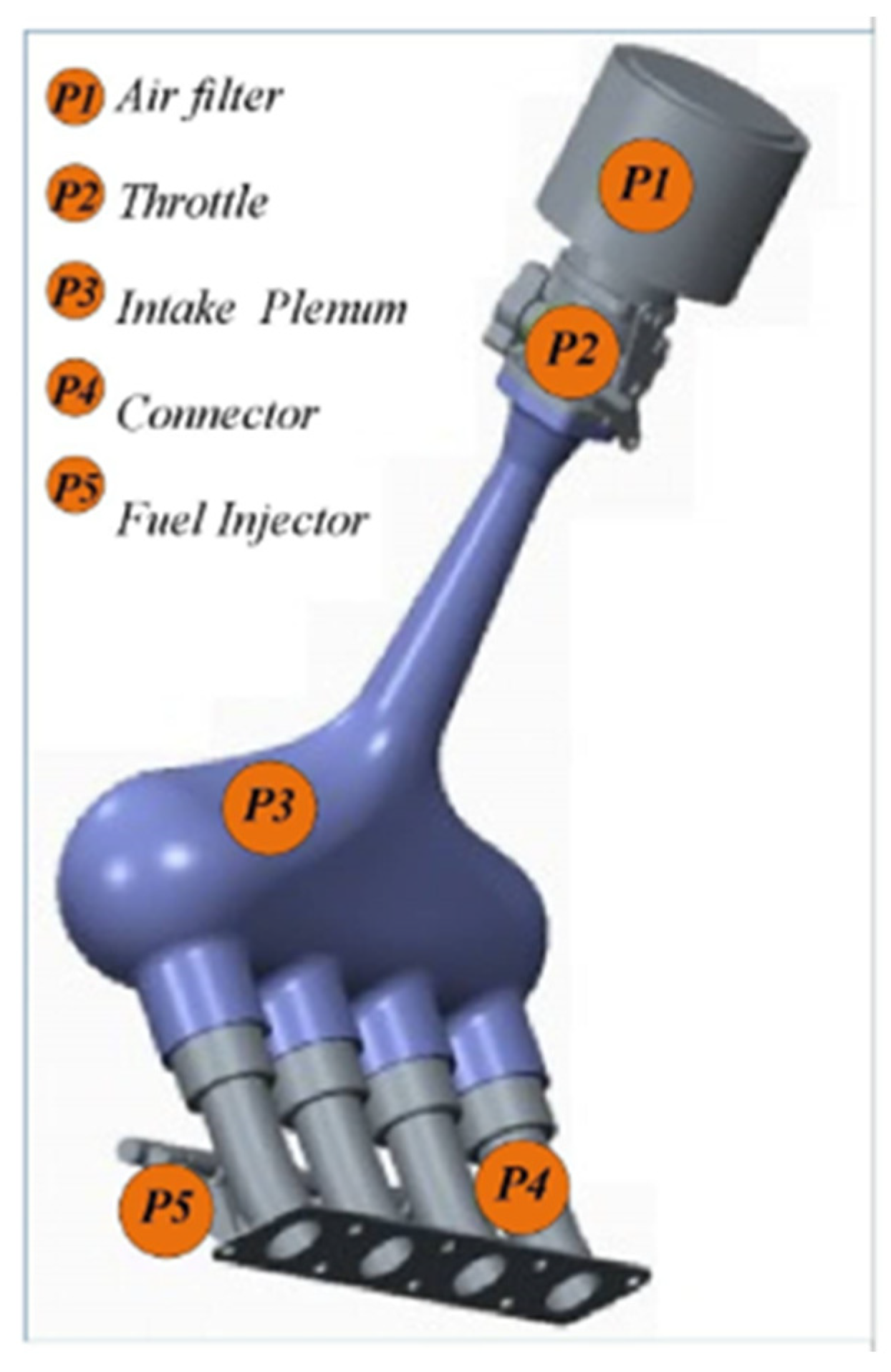

4.1. Case Introduction

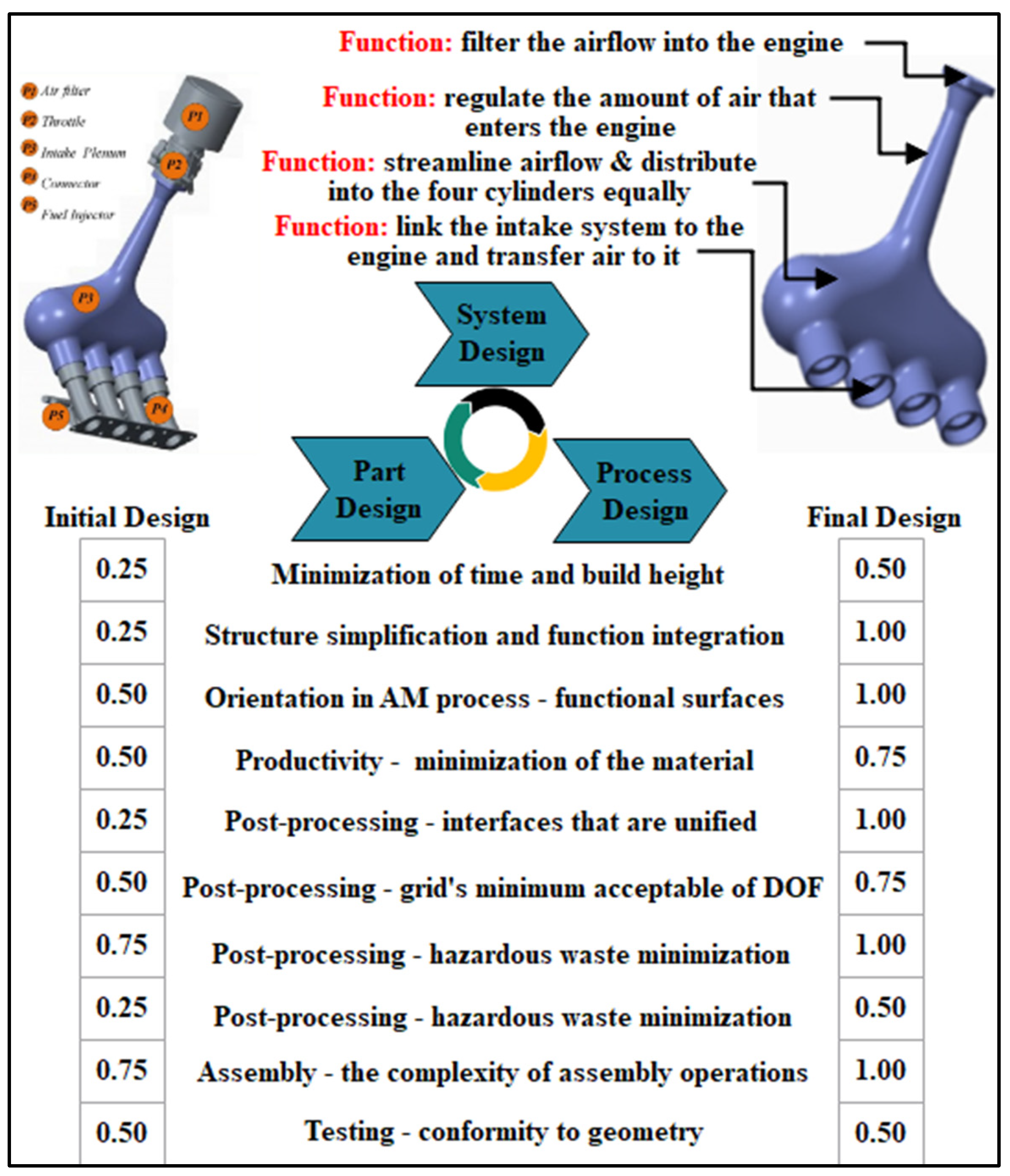

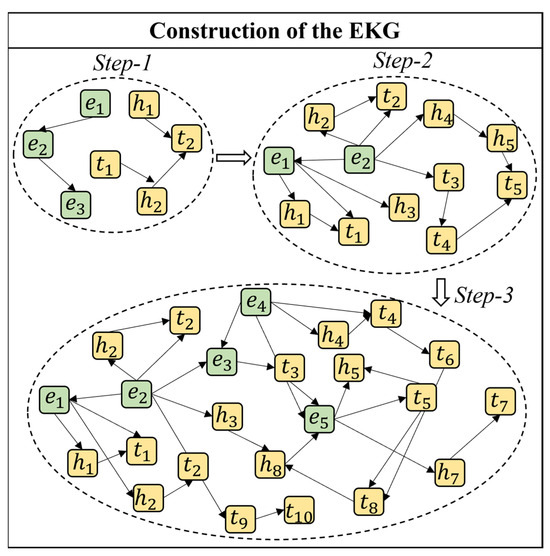

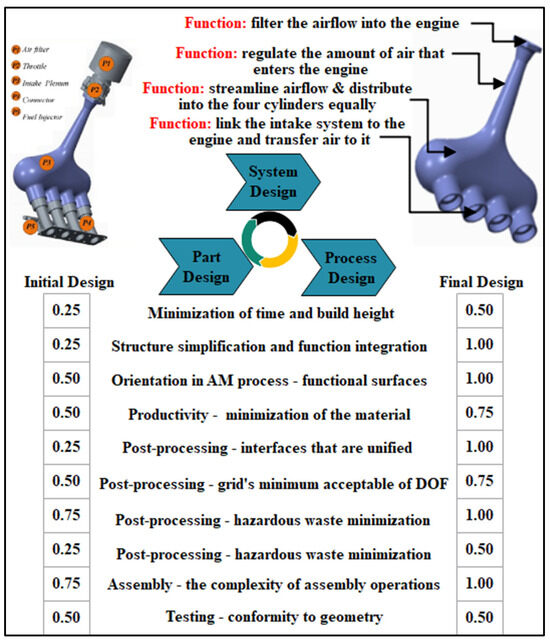

This section provides further details of a design project (intake system) to validate the proposed method. The intake system is crucial for a vehicle’s powertrain as it controls the fuel supply based on the airflow rate and air intake into the engine (see Figure 7). We investigated how the EKG aids the design process, focusing on innovation and manufacturability, and utilized it to gather designers’ knowledge and expertise. Five components were initially studied, including the functions (air filter, throttle, intake plenum, connector, and fuel injector).

Figure 7.

Details of the intake system for using the EKG to support the design process model.

The EKG’s main objective is to methodically decompose the design process into subsystems, elucidating the intricate relationships among design components, events, and entities. It helps designers extract important knowledge and explore alternative designs in an organized framework. By capturing design changes and highlighting key relationships like “intake system main body shape” and “weight reduction,” the EKG helps the design process improve manufacturability and component functionality, improving design quality and efficiency.

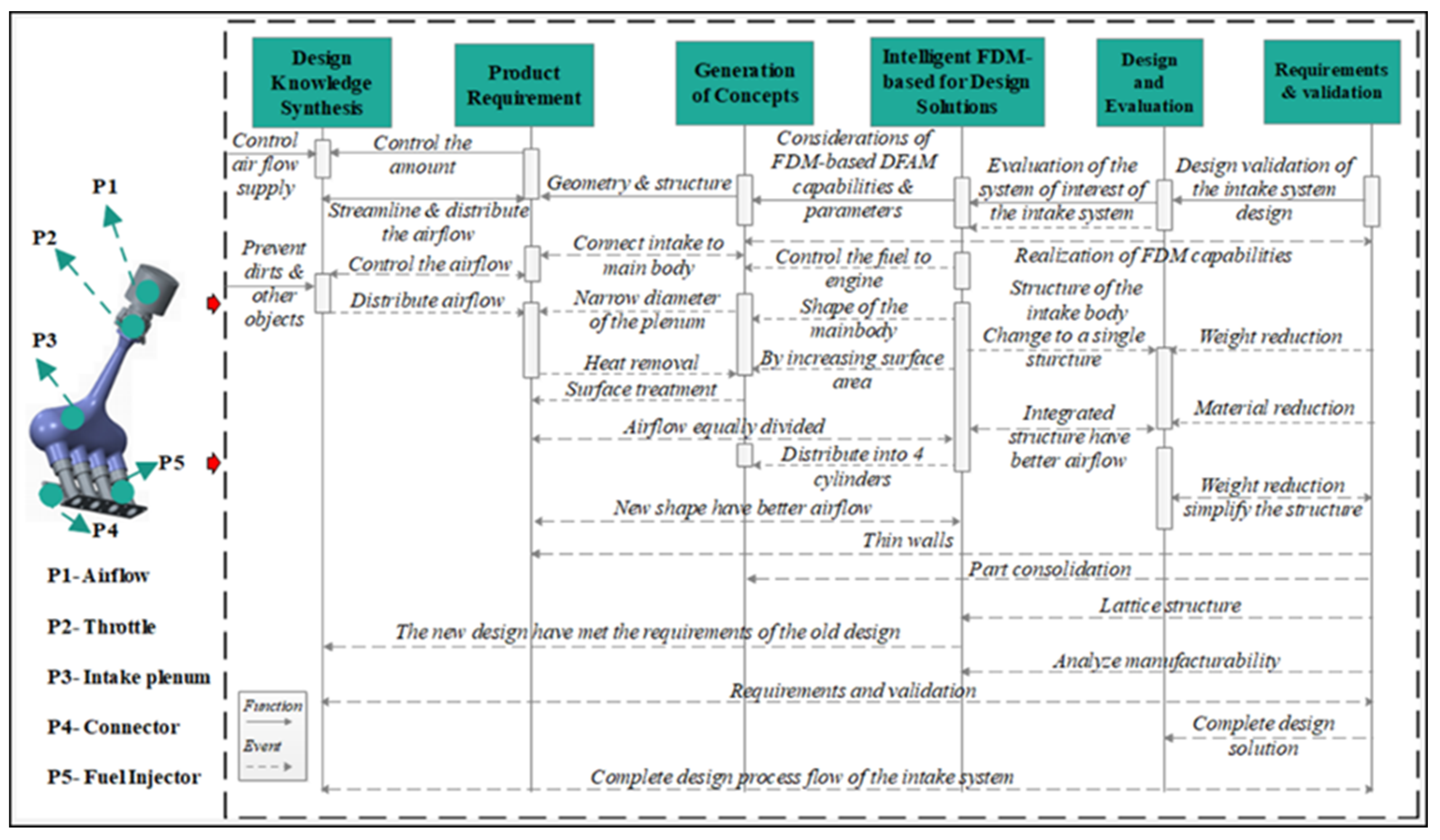

4.2. Using the EKG to Support the Design Process Model

The objective of using the EKG to support the design process model in the operation execution flow for information scheduling is to generate part shapes and dimension values that fulfill as many design requirements and limitations as possible. Traditional FDM-based DFAM approaches usually fail to meet these needs and have limitations. The EKG breaks down the problem into subsystems that reflect each phase of the design chain and performance, as demonstrated in the design flow in Figure 8. While subsystem design optimization challenges elucidate the problem formulation, the comprehensive design process does not inherently allocate optimization in this approach. This method offers the benefit of allowing independent examinations of individual subsystems throughout the FDM process.

Figure 8.

The details of the design flow of the intake system based on the EKG using a sequence diagram.

Figure 8 illustrates that the event-based representation method documents the design changes made by the system. Thus, this ensures that all relevant design information is captured during the design process. As a result, designers involved in different stages of the intake system’s development can contribute to knowledge generation while taking advantage of the EKG’s features. In Figure 9, the relationship-aware knowledge representation highlights the function of the “intake system main body shape” and its associated AM capability of “weight reduction”. The EKG records the design evolution within the system configuration to guarantee the comprehensiveness of the acquired design data. The main focus of this system is to retain knowledge about the design process. By using this organized approach to handle design issues, designers can obtain useful knowledge. Hence, designers working on various problems throughout the intake system’s development can contribute to knowledge generation while benefiting from the EKG.

Figure 9.

The details of the design flow according to event-based and relationship-aware representations.

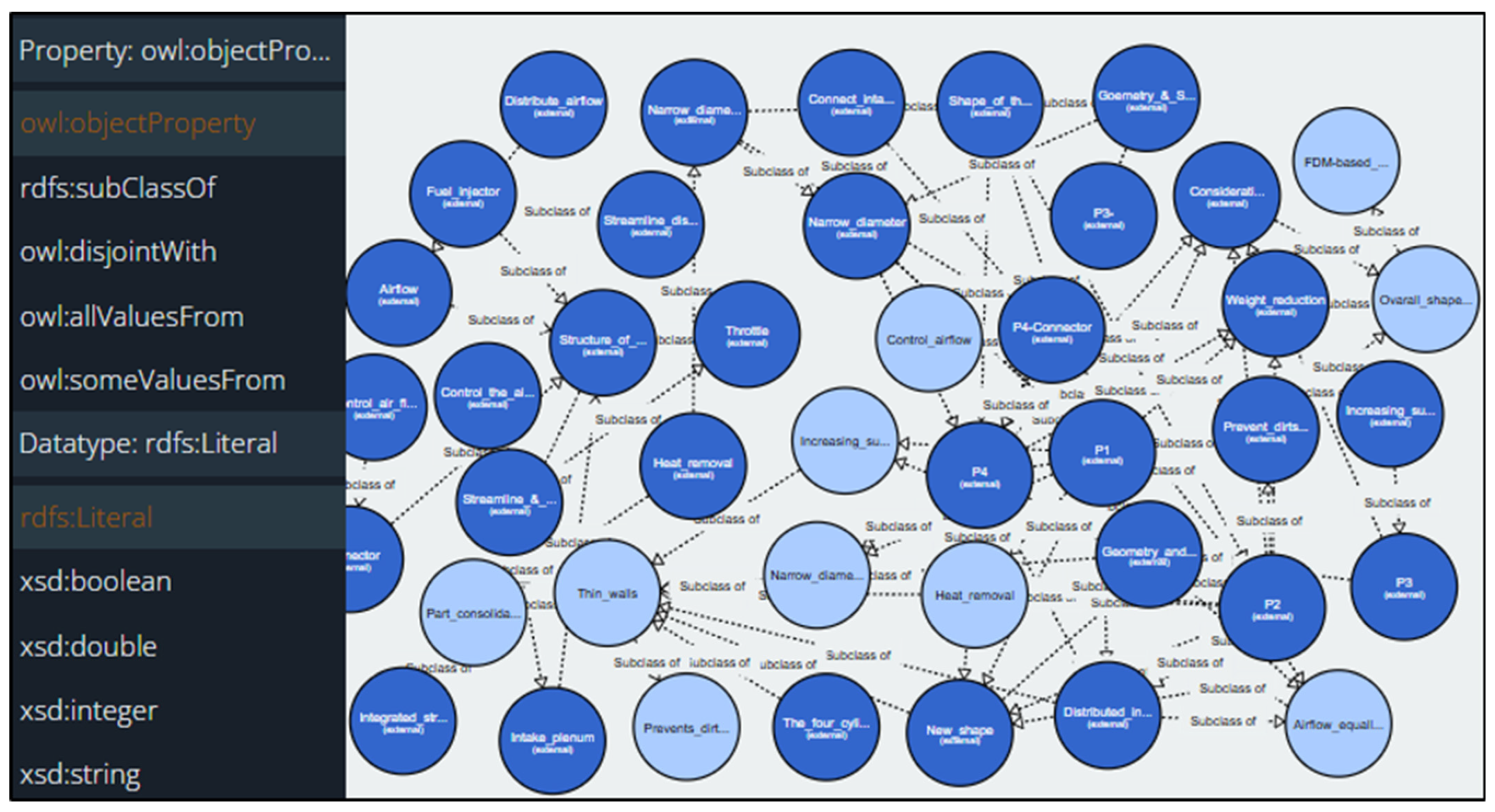

4.3. Application of the EKG for the Intake System Project

The proposed design process model uses the EKG to represent rules and process information that must be identified and made accessible to designers from the company after determining the needed knowledge in this case study of the intake system. Figure 8 depicts the overall synthetic approach and the primary contributions of the method. DFAM approaches are employed in the “design and evaluation” node since the design centers on the product (5 components and functions). During the “DFAM requirements validation” node, dimensional constraints roughness statistics are checked to the CAD standard configuration. Thus, process variables such as extruder intensity, support, filament amount dropped, and part orientation were modified to comply with the specifications. Figure 10 visually represents how the EKG is applied to showcase the value of FDM-based DFAM by integrating functions and simplifying structures to achieve the desired design freedom. It clearly illustrates the connection between the EKG and the design process, enabling designers to better comprehend how the proposed method works. Presenting a specific example of the intake system shows how the EKG can effectively guide the design process and help meet the design requirements.

Figure 10.

Applying the EKG to represent the value of FDM-based DFAM by combining functions and structural simplification of products to achieve the desired design freedom.

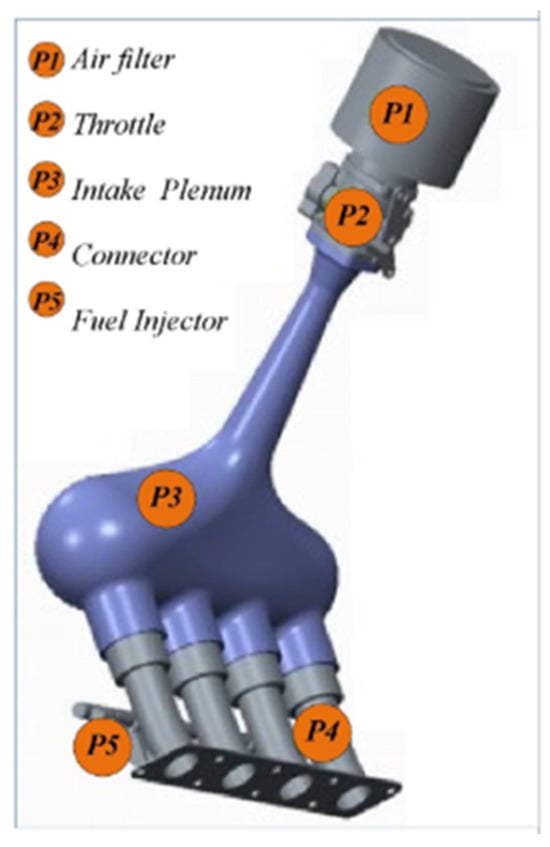

Figure 11 depicts the chronological design activity flow and its corresponding construction results of the EKG. This figure is essential for understanding the dynamic nature of the EKG during the design process. It allows readers to follow the sequence of events and see how the EKG evolves, providing insights into the decision-making process based on the EKG’s subgraphs. It also helps evaluate the stability and effectiveness of the design process model. The Neo4j graph records the design evolution generated by the EKG, ensuring that all design information obtained during the design process is comprehensive. This enables designers to work on various issues within the intake system’s development and contribute to knowledge generation while leveraging the benefits of the EKG. Figure 11 presents the function of the “intake system main body shape” and its related AM capability of “weight reduction.” The design evolution records are created within the EKG setup to guarantee the completeness of the design data. The system primarily focuses on retaining knowledge about the design process. Through this comprehensive knowledge organization approach, designers can gain valuable knowledge when handling design issues. Therefore, those involved in the intake system’s development can contribute to knowledge creation while enjoying the advantages of the EKG.

Figure 11.

Chronological design activity flow and its corresponding construction results of the EKG.

Figure 11 depicts the chronological design activity flow and its corresponding construction results of the EKG. This figure is essential for understanding the dynamic nature of the EKG during the design process. It allows readers to follow the sequence of events and see how the EKG evolves, providing insights into the decision-making process based on the EKG’s subgraphs. It also helps evaluate the stability and effectiveness of the design process model. The Neo4j graph records the design evolution generated by the EKG, ensuring that all design information obtained during the design process is comprehensive. This enables designers to work on various issues within the intake system’s development and contribute to knowledge generation while leveraging the benefits of the EKG. Figure 11 presents the function of the “intake system main body shape” and its related AM capability of “weight reduction”. The design evolution records are created within the EKG setup to guarantee the completeness of the design data. The system primarily focuses on retaining knowledge about the design process. Through this comprehensive knowledge organization approach, designers can gain valuable knowledge when handling design issues. Therefore, those involved in the intake system’s development can contribute to knowledge creation while enjoying the advantages of the EKG.

5. Discussion

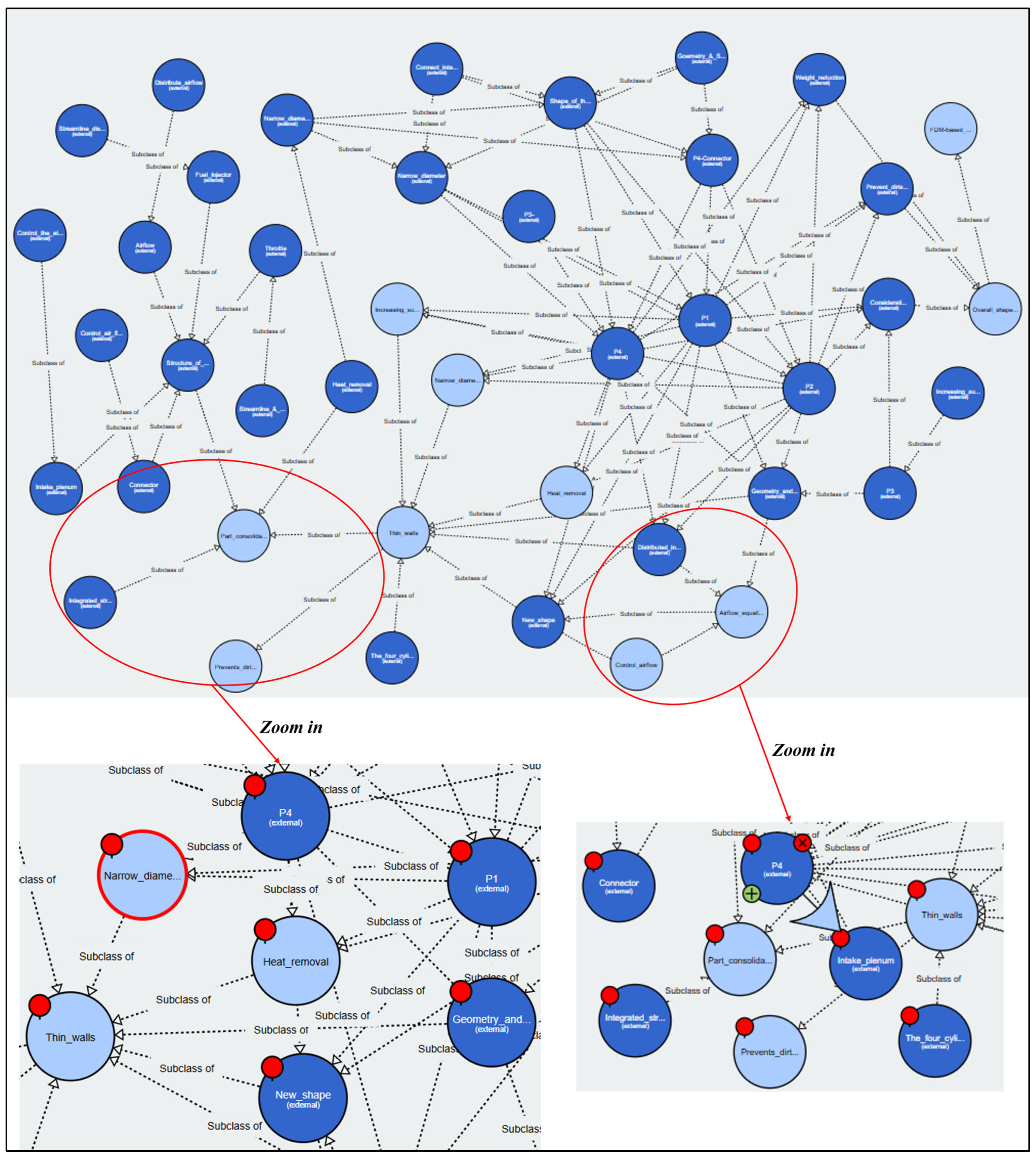

This section examines the case study using the EKG to support the design process model. The core logic of events lies within the event and dynamic knowledge of the EKG. It also helps with causality analysis through the event-triggering mechanism. Another way to conceive of the multi-hop reasoning for the causality analysis tasks is as link prediction. In Section 3.2, the development of event causality is evaluated. Then, as shown in Figure 5 of Section 3.3, a triple format is utilized to form the dynamic part of the EKG. The schema layer connects these triples by a direct mapping technique based on the relationship-aware embedding strategies related to the EKG. The stability and dynamic learning of the EKG are achieved by gathering the multi-order neighbor information of the triggered events. Figure 12 demonstrates the use of the EKG’s causality reasoning to support the dynamic process stability evaluation. It shows how the combination of functions and structural simplification is achieved through the EKG’s analysis and reasoning.

Figure 12.

Using causality reasoning of the EKG to support dynamic process stability evaluation of combining functions and structural simplification to achieve the desired design freedom.

Using causality reasoning of the EKG is vital for justifying the feasibility and superiority of the proposed approach, as it showcases the ability of the EKG to handle complex design problems and make informed decisions. During the design process, the EKG subgraphs associated with the event-triggered strategy of each activity make these design activities change dynamically. Thus, this involves processes like event triggering, path calculation, and triple generation. The event-triggered mechanism of the EKG provides causal reasoning, which is then transformed into a computational probability and a link reasoning task. Eventually, the subgraphs of the EKG with stable and unstable nodes are used to make design decisions. This example shows how the EKG helps the design process model achieve design freedom through its analysis and reasoning methods. Using the event-based causality analysis approach provides a better understanding of FDM-based DFAM. This is achieved by integrating the functions and simplifying the structure of products to gain the desired design freedom and workable solutions for decision-making.

The anticipated activity model for the DFAM design stage for the FDM process is presented in this dissertation. Figure 13 shows an excerpt from several DFAM database entries in the middle column, which may be used to evaluate the success of both ideas using an additional block to the scaled achievement score. In this case, the requirements channeling effect may allow for a more rapid and efficient evaluation of crucial design requirements without unnecessary terminology. Theoretically and experimentally, results from testing the design process model in realistic parts and assemblies and in-field data will increasingly be included in databases.

Figure 13.

The evaluation of the intake system’s overall performance based on the correlation and compatibility analysis stage.

The intake system’s overall performance is evaluated based on the correlation and the compatibility score. The development approach in Figure 13 is based on a series of correlation matrices with fundamental data on procedures, components, and design characteristics. The EKG approach aids in the systematic organization and analysis of design processes and information. The design process model contains several steps, and the connections between various activities and design aspects are captured. In event-based knowledge representation, the reasoning is grounded in the causality information that is a part of the design process. The EKG shows how the intake system’s design of various parts (entities) is connected to events (such as changes in structure simplification and function integration) and how these connections vary as the design process progresses. The Verein Deutscher Ingenieure (VDI) guideline is used to score properties on a scale of zero (unsatisfactory) to four (exceptional) [42]. As a result, the sum of the most crucial elements for each attribute is what is known as the nominal condition ( Equaling four). Therefore, this improves the design process and enables better-informed design decisions.

During the design and analysis process of the intake system using the FDM-based DFAM approach, data related to each evaluation metric is collected. For example, measurements or estimations of the wall thickness and its quality characteristics are recorded for thin walls at different design and production stages. Similarly, information about the number of parts combined, the integrity of the consolidated structure, etc., is gathered for part consolidation. Each data point for a particular metric is assigned a score based on predefined criteria or standards. These criteria could be related to industry best practices, design requirements, or the specific goals of the research. For instance, if the thin walls are within a certain thickness range and have acceptable structural integrity, they are given a corresponding score.

Thus, to calculate the average score for each metric, the sum of all the scores for that metric is divided by the total number of data points. If there are data points for thin walls with scores , the average scores for thin walls are calculated in Equation (1). The sample standard deviation method measures score distribution around the average in Equation (2). where is the sample mean, and is the number of data points. Thus, this indicates the variability in the scores for each metric, helping to understand the consistency of the performance across different design iterations or samples. This clarifies the reliability of the outcomes across various design iterations by indicating the variability in the results for each parameter.

As observed in the right-most column of Table 1, this process chain map for the execution flow in the DFAM development process of the intake system meets all requirements. For example, part consolidation contributes to the shape of the main body and structure of the intake body but does not impact airflow intake. Weight reduction affects the surface finish and contributes to surface mechanical properties (surface treatments typically induce heat removal). The most common design problems were topology optimization (4.54 avg) and thin walls (3.83 avg). For more information, see Table 2. We also compared current part designs to the ratings on the page for those parts. The sheet ratings remained consistent even at the boundaries between the two rating levels.

Table 1.

The realization of AM capabilities according to the design functions intake system.

Table 2.

The average and standard deviation of scores were reported from the FDM-based DFAM worksheet during the execution flow of the intake system design analysis.

Table 3 compares the proposed method against other methods in detail. The proposed design aid tool uses knowledge reasoning; Fitzgerald et al. [26] use analogical reasoning, and Segonds et al. [24] emphasize design rationale. The proposed method records design evolution and changes more thoroughly than the other two. Five design stages are defined in the proposed method, compared to none in Fitzgerald et al. [26] and four in Segonds et al. [24]. The proposed strategy improves five major measures, whereas the other two do not. This comparison shows how the proposed strategy is unique and advantageous for design process models.

Table 3.

Evaluating the proposed approach in comparison to other approaches.

6. Conclusions

This research established an EKG to develop a design process model for the FDM-based DFAM. The intelligent FDM-based DFAM for design solutions based on EKG breaks down the roles of curial attributes of the design process to support the feasibility of components and products made with FDM technology. Thus, this offers a comprehensive learning approach for establishing and modeling intrinsic relationships to attain flexibility and design freedom. Consequently, the event-based knowledge representation offers a feasible strategy that promotes innovation by incorporating the design process with knowledge-based design from the initial design process. Hence, this provides a causality-based investigation for the production feasibility to accommodate the design process model’s creativity strategies.

Furthermore, the relationship-aware, based on knowledge representation, provides the EKG with a dynamic interaction of relationships among design activities, design events, etc. As a result, this enhances the feasibility of in-depth analysis of production and design alternatives necessary to determine the manufacturing process, and this provides solutions to the limitations imposed by the traditional FDM-based DFAM. The case study of an intake system demonstrated the efficacy of the proposed approach. The proposed approach provides a new development mode for FDM-based DFAM that increases the viability of the design considerations, which the conventional design process models cannot achieve. Although progress has been achieved, it is anticipated that more time series data types will be gathered from the industry and that interconnections between various data kinds will be built at the semantic level for further research. Thus, this will assist in determining the root-cause evaluation of manufacturing failure concerns and the reasons and consequences of printing quality issues.

Author Contributions

Conceptualization, A.H.; Methodology, G.C. and A.H.; Software, G.C., A.H., L.L. and K.E.; Writing—original draft, G.C. and A.H.; Writing—review and editing, K.N. and Y.L.; Visualization, A.H. and Y.C.; Funding acquisition, K.N. and Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by Shenzhen Science and Technology Program [Grant number: JCYJ20220530161801003], the National Natural Science Foundation of China (Grant numbers: 12172290, 52250410345).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding authors.

Acknowledgments

We express our deepest gratitude to Ahmad Bala Alhassan, whose expertise and knowledge were invaluable during this research.

Conflicts of Interest

Author Guohui Chen was employed by the company AVIC Xi’an Aviation Brake Technology Co. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Haruna, A.; Yang, M.; Jiang, P.; Ren, H. Collaborative Task of Entity and Relation Recognition for Developing a Knowledge Graph to Support Knowledge Reasoning for Design for Additive Manufacturing. Adv. Eng. Inform. 2024, 60, 102364. [Google Scholar] [CrossRef]

- Haruna, A.; Yang, M.; Jiang, P. Design for Additive Manufacturing: A Three Layered Conceptual Framework for Knowledge-Based Design. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022, 237, 1405–1421. [Google Scholar] [CrossRef]

- Xiong, Y.; Tang, Y.; Zhou, Q.; Ma, Y.; Rosen, D.W. Intelligent Additive Manufacturing and Design State of the Art and Future Perspectives. Addit. Manuf. 2022, 59, 103139. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Y.; Bernard, A. Lightweight Porous Support Structure Design for Additive Manufacturing via Knowledge-Based Bio-Inspired Volume Generation and Lattice Configuration. Virtual Phys. Prototyp. 2022, 17, 894–918. [Google Scholar] [CrossRef]

- Taheri-Mousavi, S.M.; Xu, M.; Hengsbach, F.; Houser, C.; Ge, Z.; Glaser, B.; Wei, S.; Schaper, M.; LeBeau, J.M.; Olson, G.B.; et al. Additively Manufacturable High-Strength Aluminum Alloys with Thermally Stable Microstructures Enabled by Hybrid Machine Learning-Based Design. arXiv 2024, arXiv:2406.17457. [Google Scholar]

- Lu, C.; Jia, X.; Lee, J.; Shi, J. Knowledge Transfer Using Bayesian Learning for Predicting the Process-Property Relationship of Inconel Alloys Obtained by Laser Powder Bed Fusion. Virtual Phys. Prototyp. 2022, 17, 787–805. [Google Scholar] [CrossRef]

- Hadian, A.; Fricke, M.; Liersch, A.; Clemens, F. Material Extrusion Additive Manufacturing of Zirconia Parts Using Powder Injection Molding Feedstock Compositions. Addit. Manuf. 2022, 57, 102966. [Google Scholar] [CrossRef]

- Haruna, A.; Jiang, P. A Design for Additive Manufacturing Framework: Product Function Integration and Structure Simplification. IFAC Pap. 2021, 53, 77–82. [Google Scholar] [CrossRef]

- Borgue, O.; Müller, J.; Leicht, A.; Panarotto, M.; Isaksson, O. Constraint Replacement-Based Design for Additive Manufacturing of Satellite Components: Ensuring Design Manufacturability through Tailored Test Artefacts. Aerospace 2019, 6, 124. [Google Scholar] [CrossRef]

- Kadkhoda-Ahmadi, S.; Hassan, A.; Asadollahi-Yazdi, E. Activity Modeling of Preliminary Additive Manufacturing Process Planning. Procedia CIRP 2019, 84, 874–879. [Google Scholar] [CrossRef]

- Xiong, Y.; Tang, Y.; Kim, S.; Rosen, D.W. Human-Machine Collaborative Additive Manufacturing. J. Manuf. Syst. 2023, 66, 82–91. [Google Scholar] [CrossRef]

- Haruna, A.; Jiang, P. Adaptability Analysis of Design for Additive Manufacturing by Using Fuzzy Bayesian Network Approach. Adv. Eng. Inform. 2022, 52, 101613. [Google Scholar] [CrossRef]

- Wiberg, A.; Persson, J.; Ölvander, J. Design for Additive Manufacturing—A Review of Available Design Methods and Software. Rapid Prototyp. J. 2019, 25, 1080–1094. [Google Scholar] [CrossRef]

- Belkadi, F.; Sanfilippo, E.M.; Bernard, A.; Vidal, L.M. A Product-Process Model for Decision-Aid Perspective in Additive Manufacturing Field. Comput. Aided. Des. Appl. 2020, 17, 1278–1293. [Google Scholar] [CrossRef]

- Haruna, A.; Noman, K.; Li, Y.; Shah, I.A. A Framework for FDM-Based DFAM: Key Enabling Technologies for Knowledge-Based Design. J. Phys. Conf. Ser. 2024, 2762, 12087. [Google Scholar] [CrossRef]

- Zhou, B.; Shen, X.; Lu, Y.; Li, X.; Hua, B.; Liu, T.; Bao, J. Semantic-Aware Event Link Reasoning over Industrial Knowledge Graph Embedding Time Series Data. Int. J. Prod. Res. 2023, 61, 4117–4134. [Google Scholar] [CrossRef]

- Lussenburg, K.; Sakes, A.; Breedveld, P. Design of Non-Assembly Mechanisms: A State-of-the-Art Review. Addit. Manuf. 2021, 39, 101846. [Google Scholar] [CrossRef]

- Bu, L.; Chen, C.H.; Ng, K.K.H.; Zheng, P.; Dong, G.; Liu, H. A User-Centric Design Approach for Smart Product-Service Systems Using Virtual Reality: A Case Study. J. Clean. Prod. 2021, 280, 1–32. [Google Scholar] [CrossRef]

- Liu, Y.; Han, J.; Yan, P.; Li, B.; Yang, M.; Jiang, P. A Novel Kind of Knowledge Graph Construction Method for Intelligent Machine as a Service Modeling. Machines 2024, 12, 723. [Google Scholar] [CrossRef]

- Li, Q.; Jiang, P.; Wang, J.; Yang, M.; Yang, Y. A Kind of Intelligent Dynamic Industrial Event Knowledge Graph and Its Application in Process Stability Evaluation. J. Intell. Manuf. 2024, 2024, 1–18. [Google Scholar] [CrossRef]

- Jiang, J. A Survey of Machine Learning in Additive Manufacturing Technologies. Int. J. Comput. Integr. Manuf. 2023, 36, 1258–1280. [Google Scholar] [CrossRef]

- Knez, T.; Žitnik, S. Event-Centric Temporal Knowledge Graph Construction: A Survey. Mathematics 2023, 11, 4852. [Google Scholar] [CrossRef]

- Von Stamm, B. Managing Innovation, Design and Creativity; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Segonds, F. Design By Additive Manufacturing: An Application in Aeronautics and Defence. Virtual Phys. Prototyp. 2018, 13, 237–245. [Google Scholar] [CrossRef]

- Segonds, F.; Cohen, G.; Véron, P.; Peyceré, J. PLM and Early Stages Collaboration in Interactive Design, a Case Study in the Glass Industry. Int. J. Interact. Des. Manuf. 2016, 10, 95–104. [Google Scholar] [CrossRef]

- Fitzgerald, D.P.; Herrmann, J.W.; Schmidt, L.C. A Conceptual Design Tool for Resolving Conflicts between Product Functionality and Environmental Impact. J. Mech. Des. Sep. 2010, 132, 091006. [Google Scholar] [CrossRef]

- Tomiyama, T.; Gu, P.; Jin, Y.; Lutters, D.; Kind, C.; Kimura, F. Design Methodologies: Industrial and Educational Applications. CIRP Ann. 2009, 58, 543–565. [Google Scholar] [CrossRef]

- Alfaify, A.; Saleh, M.; Abdullah, F.M.; Al-Ahmari, A.M. Design for Additive Manufacturing: A Systematic Review. Sustainability 2020, 12, 7936. [Google Scholar] [CrossRef]

- Laverne, F.; Anwer, N.; Coq, M.L.E.; St, I.U.T.; Tech, P.; Cpi, L.; Cachan, E.N.S.; Cedex, C. DFAM in the Design Process: A Proposal of Classification to Foster Early Design Stages. In Proceedings of the CONFERE 2014 CROATIE, Sibenik, Croatia, 3–4 July 2014. [Google Scholar]

- Hao, J.; Zhao, L.; Milisavljevic-Syed, J.; Ming, Z. Integrating and Navigating Engineering Design Decision-Related Knowledge Using Decision Knowledge Graph. Adv. Eng. Inform. 2021, 50, 101366. [Google Scholar] [CrossRef]

- Tompson, M.K.; Moroni, G.; Vaneker, T.H.J.; Fadel, G.; Campbell, I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B. Design for Additive Manufacturing: Trends, Opportunities, Considerations, and Constraints. CIRP Ann. Manuf. Technol. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Pan, X.; Li, X.; Li, Q.; Hu, Z.; Bao, J. Evolving to Multi-Modal Knowledge Graphs for Engineering Design: State-of-the-Art and Future Challenges. J. Eng. Des. 2024, 1–40. [Google Scholar] [CrossRef]

- Gaur, M.; Faldu, K.; Sheth, A. Semantics of the Black-Box: Can Knowledge Graphs Help Make Deep Learning Systems More Interpretable and Explainable? IEEE Internet Comput. 2021, 25, 51–59. [Google Scholar] [CrossRef]

- Shi, H.; Yang, M.; Jiang, P. Social Production System: A Three-Layer Smart Framework for Implementing Autonomous Human-Machine Collaborations in a Shop Floor. IEEE Access 2021, 9, 26696–26711. [Google Scholar] [CrossRef]

- Wang, R.; Cheung, C.F. Knowledge Graph Embedding Learning System for Defect Diagnosis in Additive Manufacturing. Comput. Ind. 2023, 149, 103912. [Google Scholar] [CrossRef]

- Dinar, M.; Rosen, D.W. A Design for Additive Manufacturing Ontology. J. Comput. Inf. Sci. Eng. 2017, 17, 021013. [Google Scholar] [CrossRef]

- Tang, X.; Chi, G.; Cui, L.; Ip, A.W.H.; Yung, K.L.; Xie, X. Exploring Research on the Construction and Application of Knowledge Graphs for Aircraft Fault Diagnosis. Sensors 2023, 23, 5295. [Google Scholar] [CrossRef]

- Deng, S.; Rangwala, H.; Ning, Y. Dynamic Knowledge Graph Based Multi-Event Forecasting. In Proceedings of the 26th ACM SIGKDD International Conference on Knowledge Discovery & Data Mining, Virtual, 6–10 July 2020; pp. 1585–1595. [Google Scholar] [CrossRef]

- Amsterdam, V.U.; Laboratories-paris, S.C.S. ChronoGrapher: Event-Centric Knowledge Graph Construction via Informed Graph Traversal. Semant. Web 2024. Available online: https://www.semantic-web-journal.net/content/chronographer-event-centric-knowledge-graph-construction-informed-graph-traversal (accessed on 31 March 2024).

- Li, D.; Yan, L.; Zhang, X.; Jia, W.; Ma, Z. EventKGE: Event Knowledge Graph Embedding with Event Causal Transfer. Knowl.-Based Syst. 2023, 278, 110917. [Google Scholar] [CrossRef]

- Chang, C.; Tang, Y.; Long, Y.; Hu, K.; Li, Y.; Li, J.; Wang, C.D. Multi-Information Preprocessing Event Extraction with BiLSTM-CRF Attention for Academic Knowledge Graph Construction. IEEE Trans. Comput. Soc. Syst. 2023, 10, 2713–2724. [Google Scholar] [CrossRef]

- Eder, W.E.; Weber, C. Comparisons of design theories. In Proceedings of the 15th Anniversary of the AEDS SIG-Applied Engineering Design Science Special Interest Group in Pilsen, Pilsen, Czech Republic, 27–28 October 2006. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).