A Module Configuration Design Approach for Complex Equipment of Port Shipping Based on Heterogeneous Customer Requirements and Product Operational Data

Abstract

1. Introduction

2. Literature Review

2.1. CRs for Complex Equipment

2.2. Methods of MPP and SMC

2.3. Research Gap and Contribution

3. Preliminaries

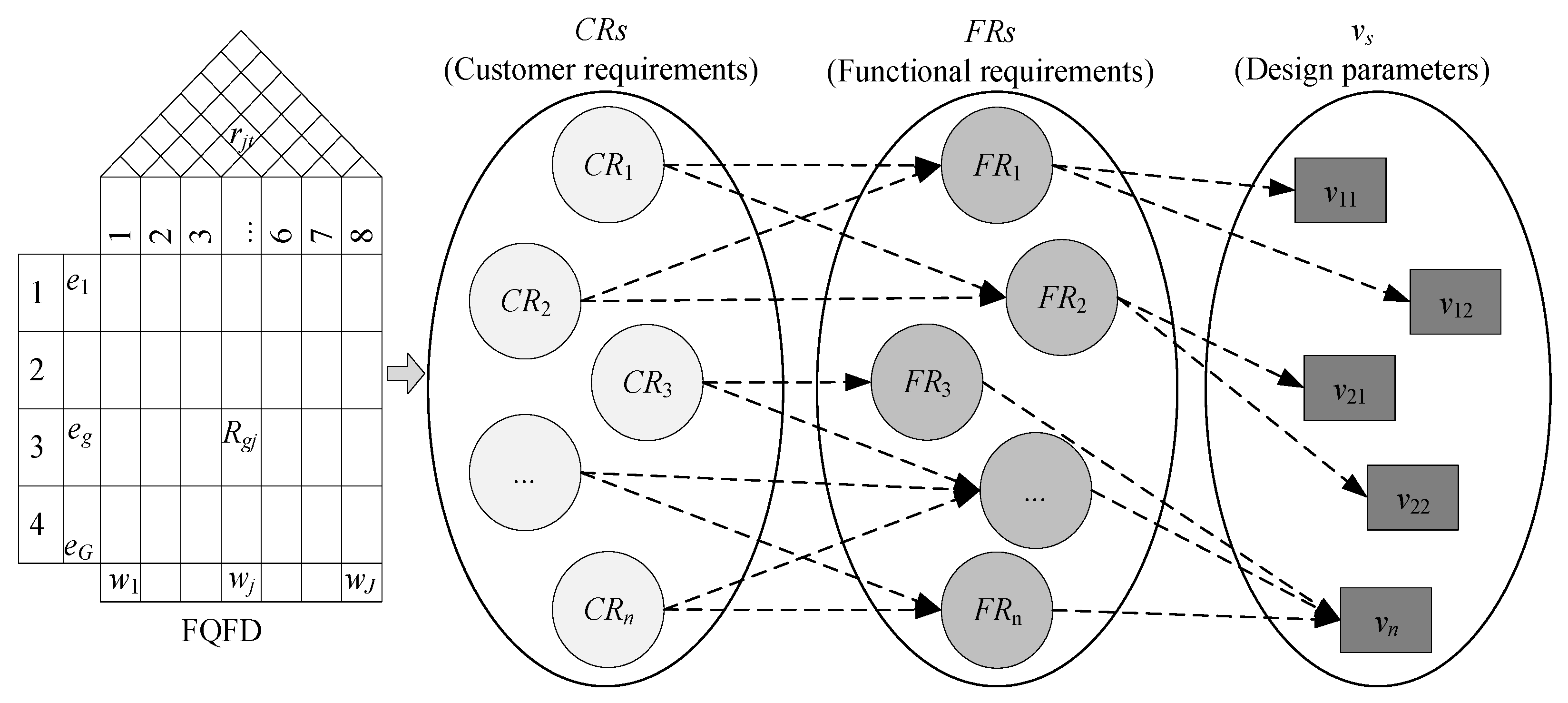

3.1. Acquisition of FRs

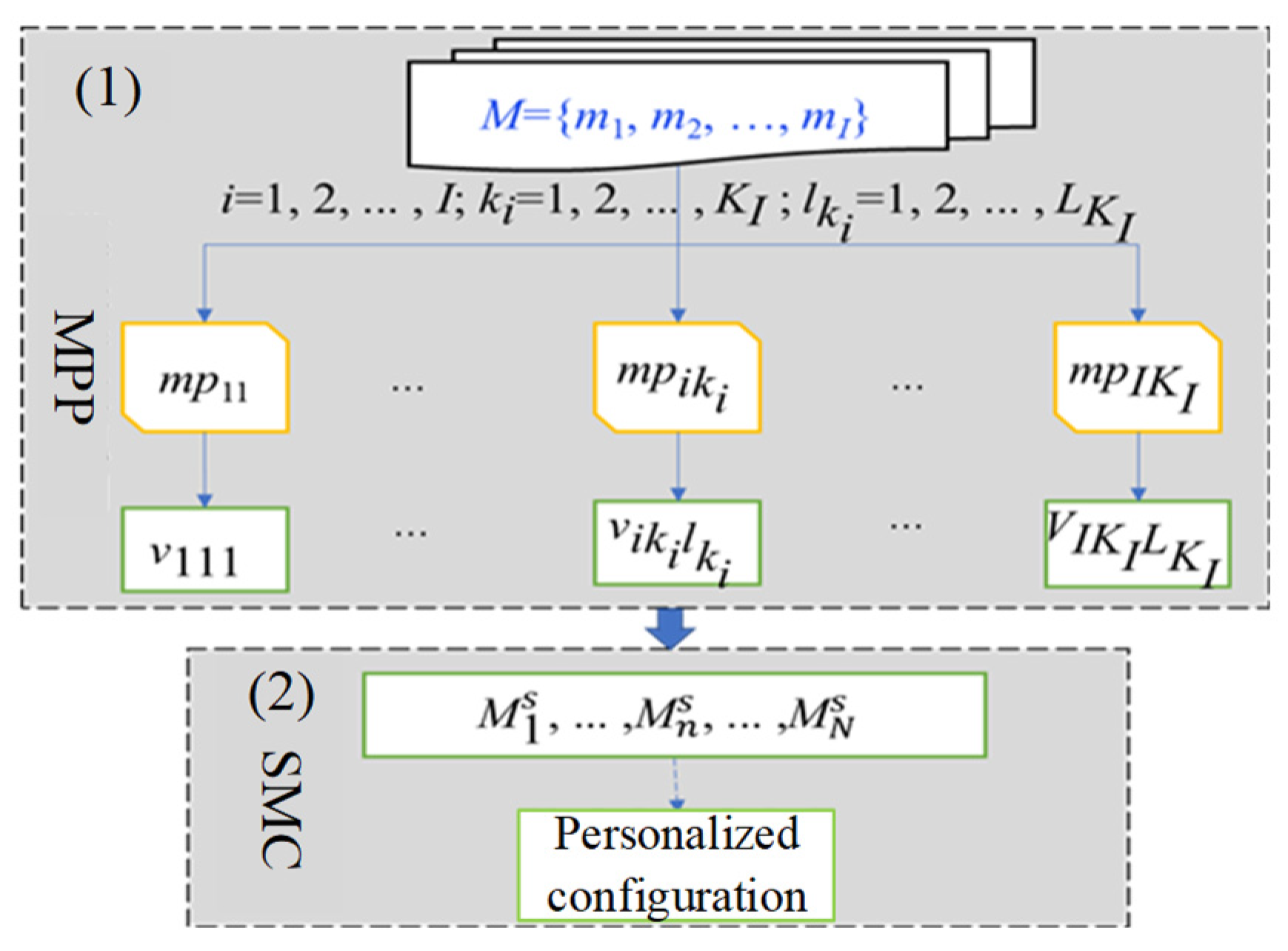

3.2. Conceptual Description of Module Configuration

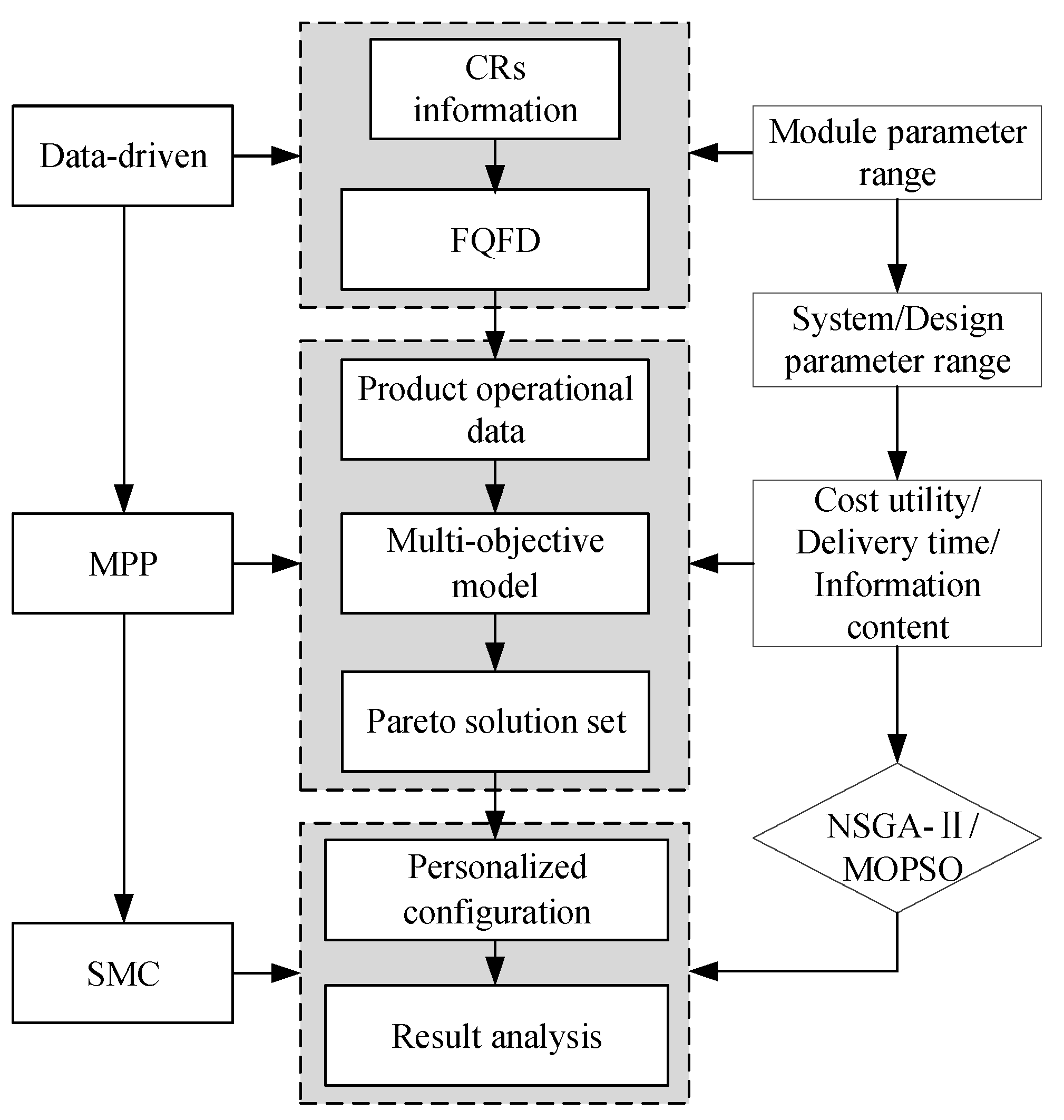

3.3. Model Construction of the MCDA

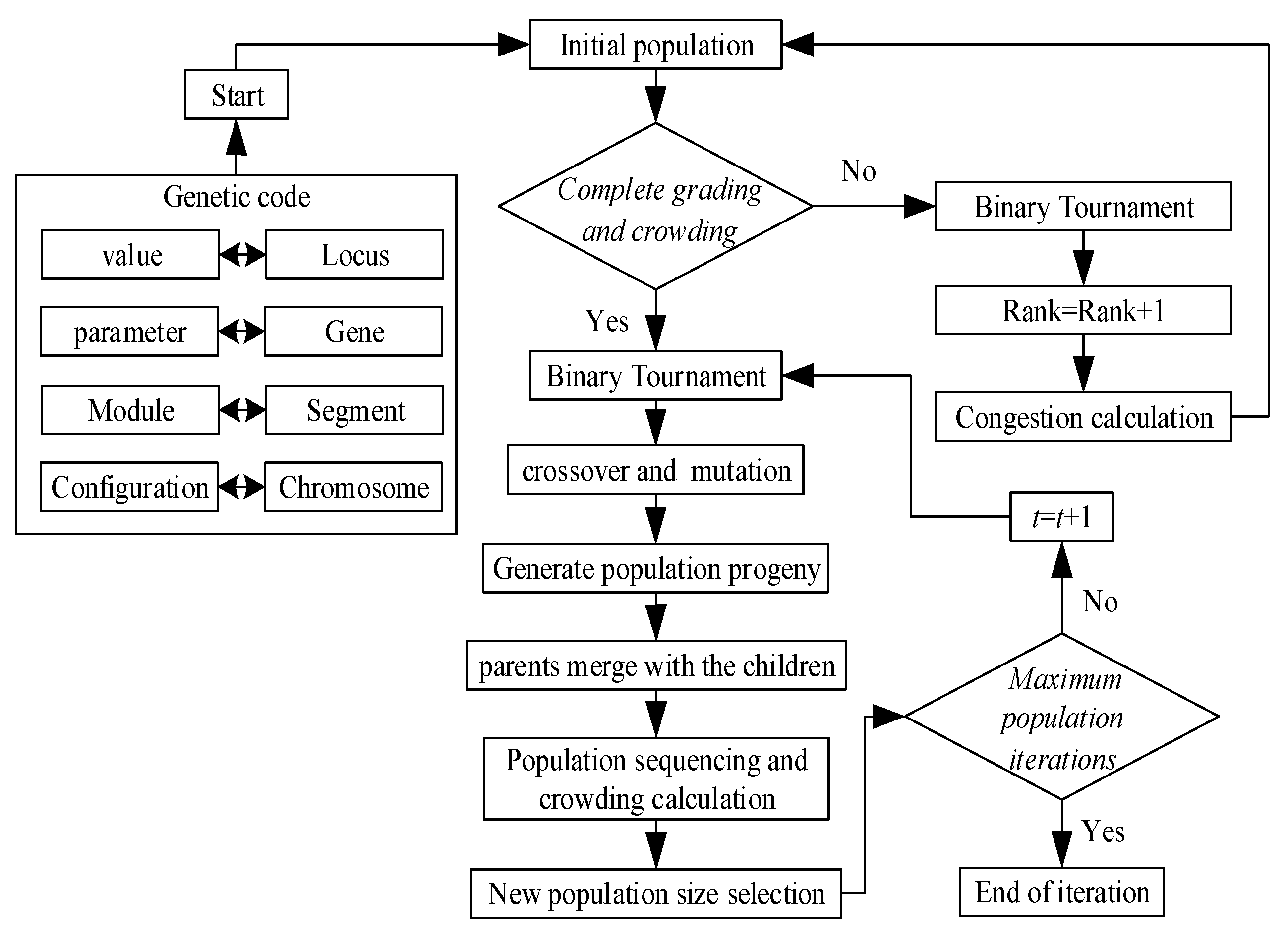

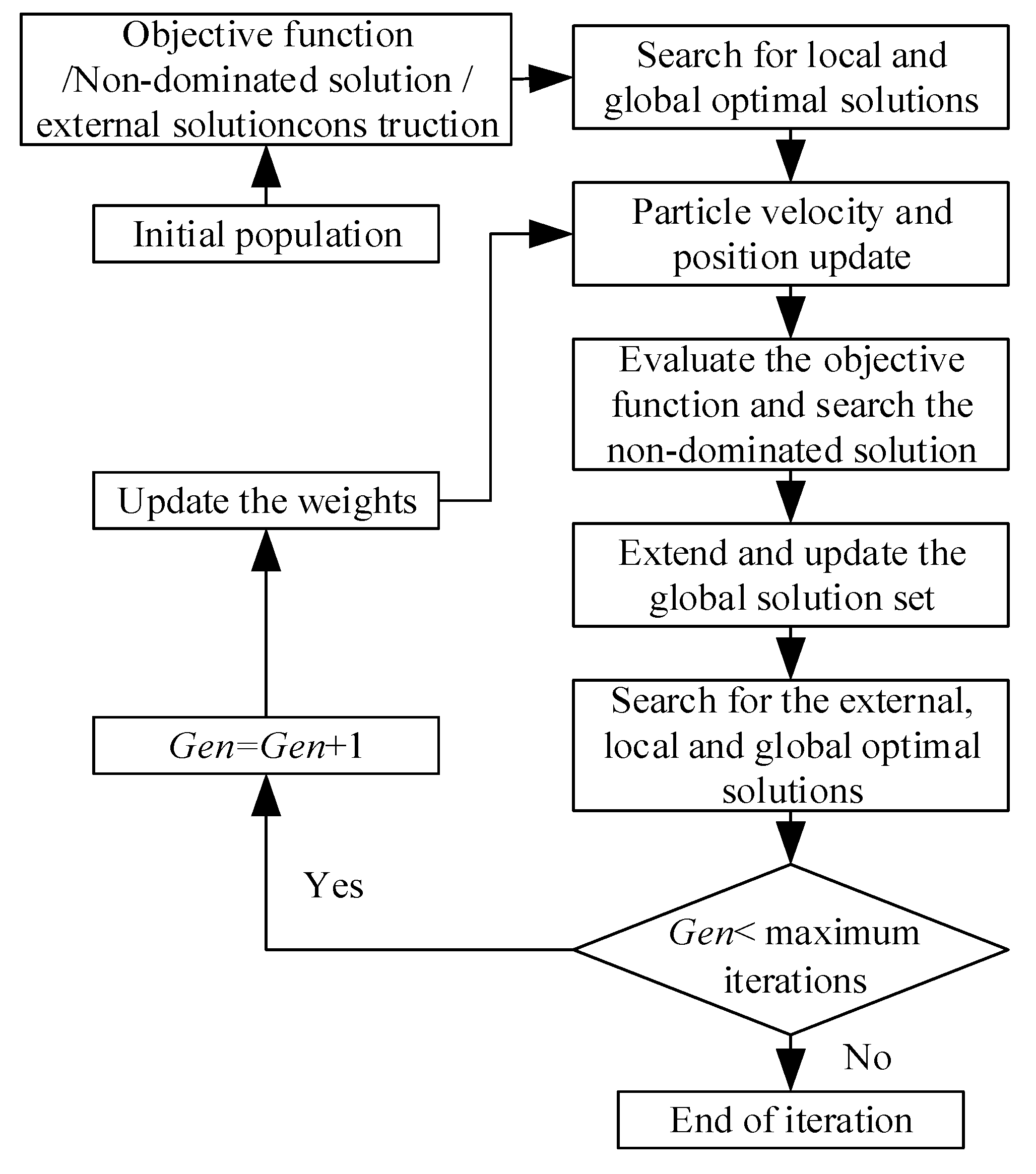

3.4. Problem-Solving Procedures of the Proposed MCDA

4. Case Study

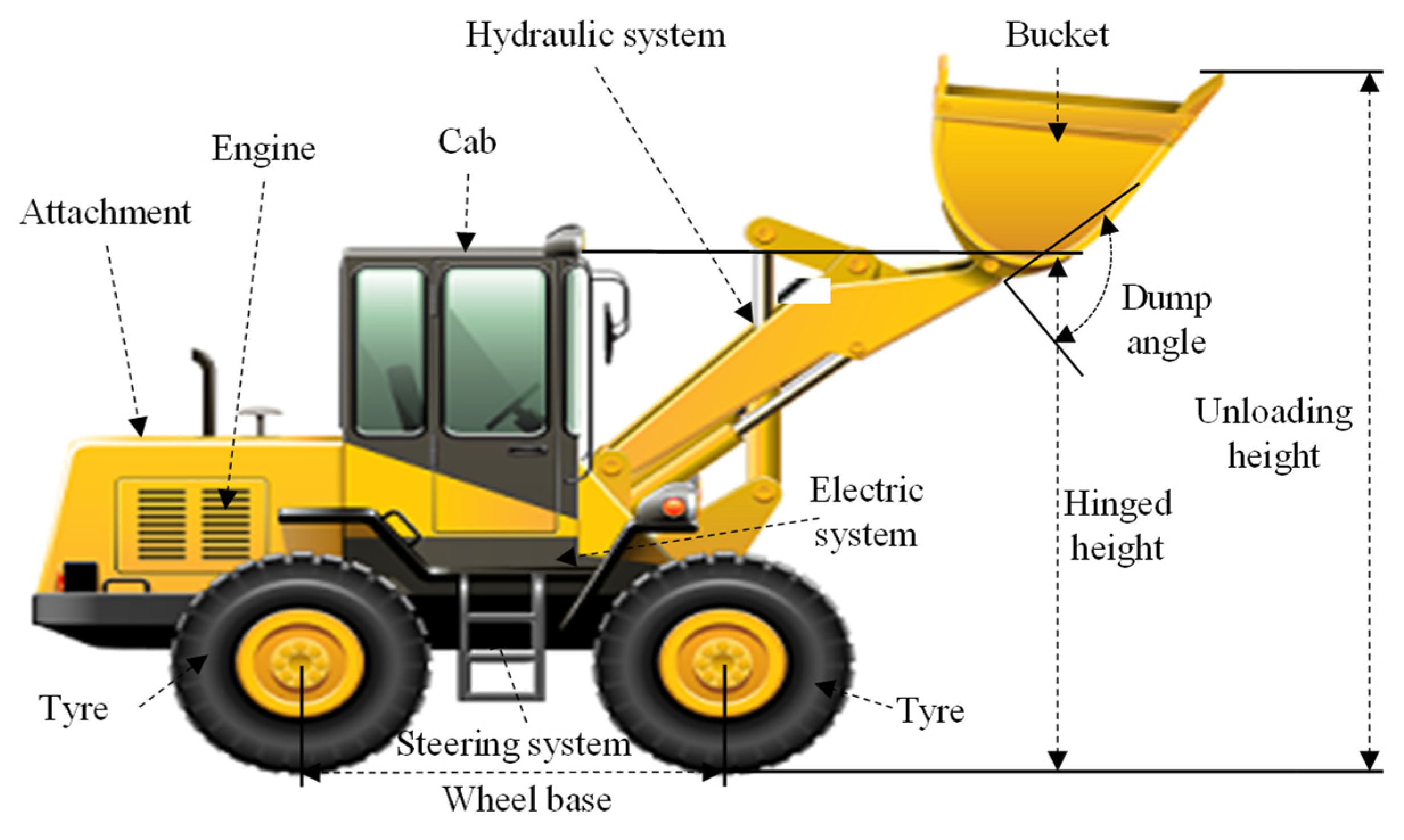

4.1. Background Illustration and FR Calculation

4.2. Calculation of Parameter Values

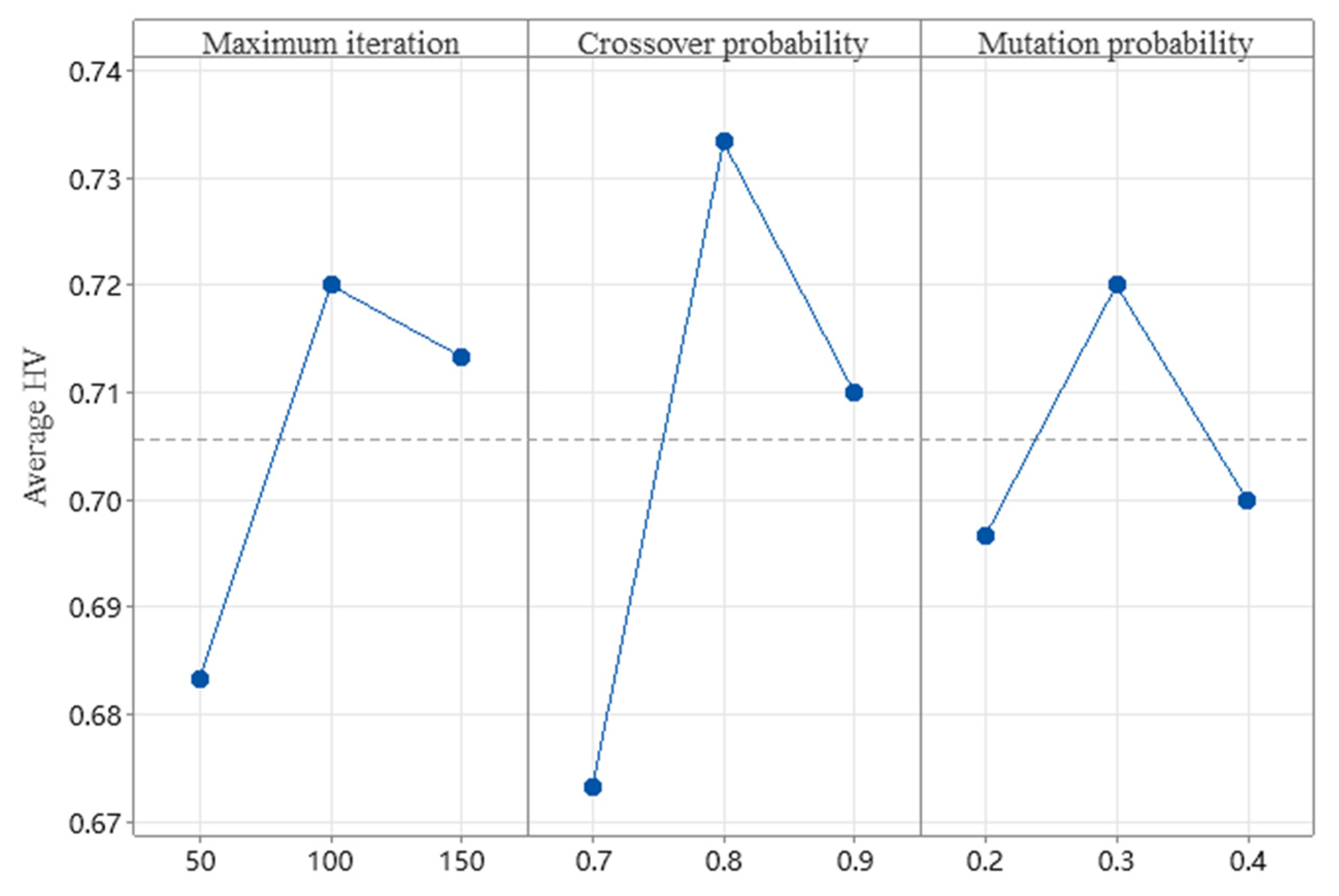

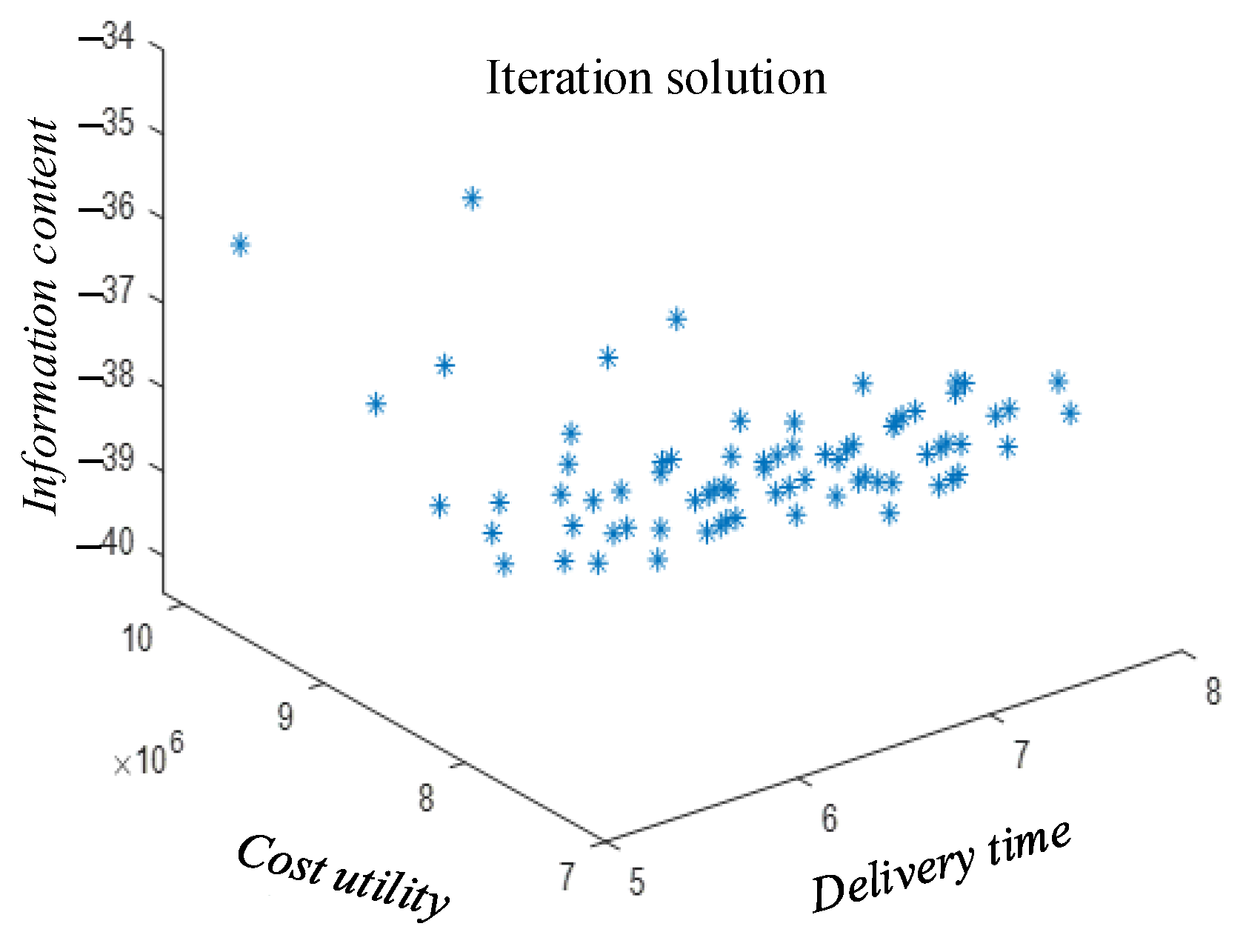

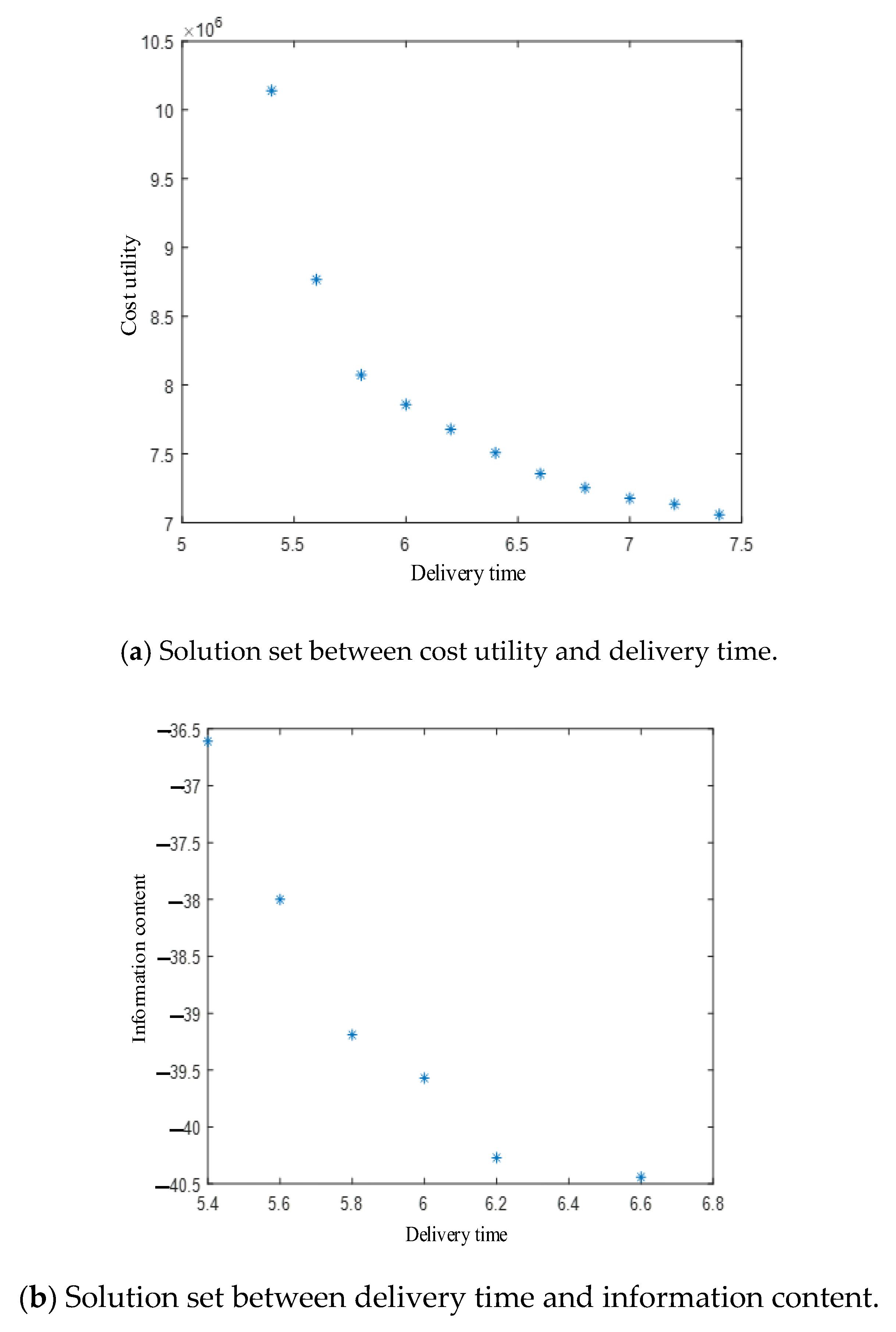

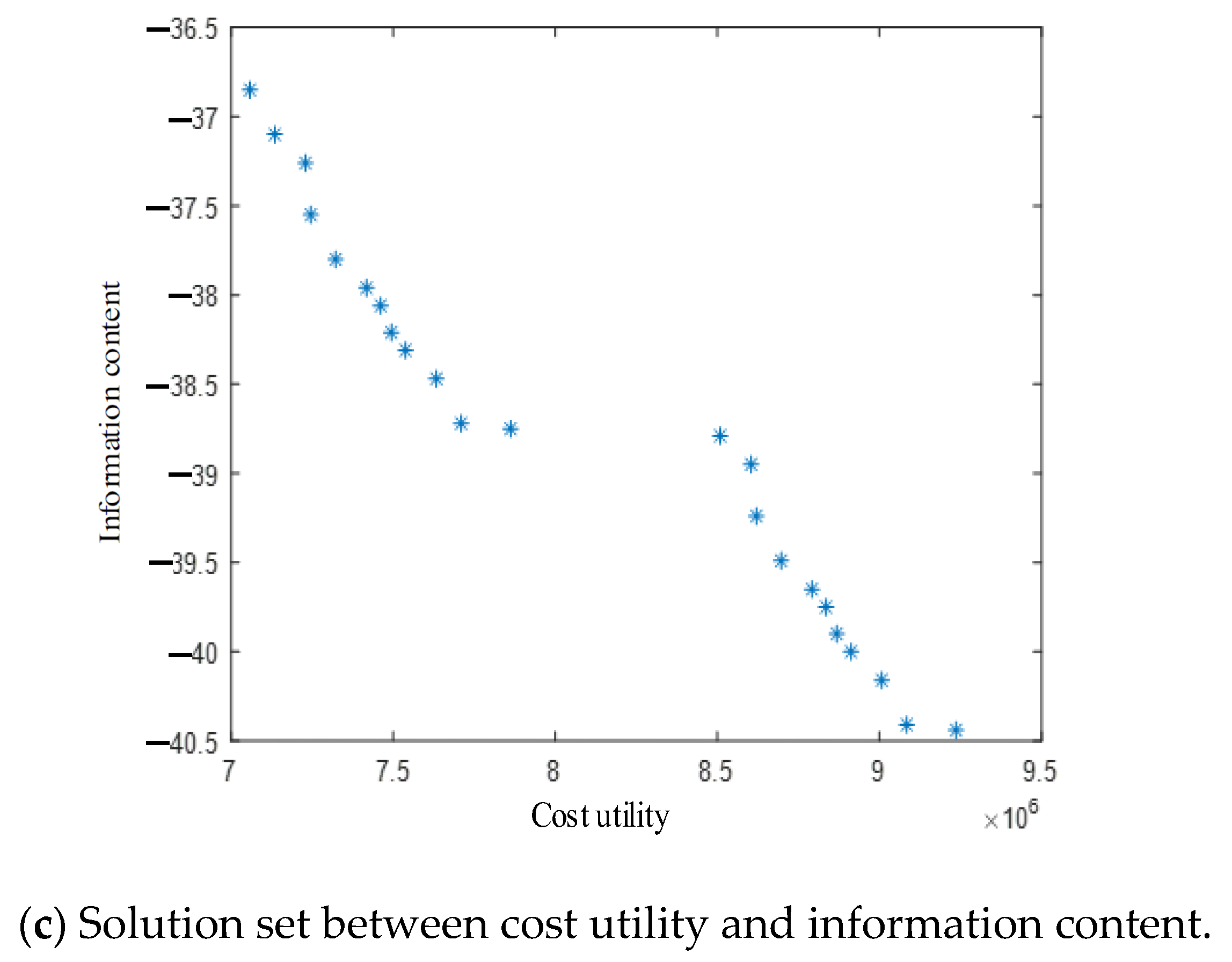

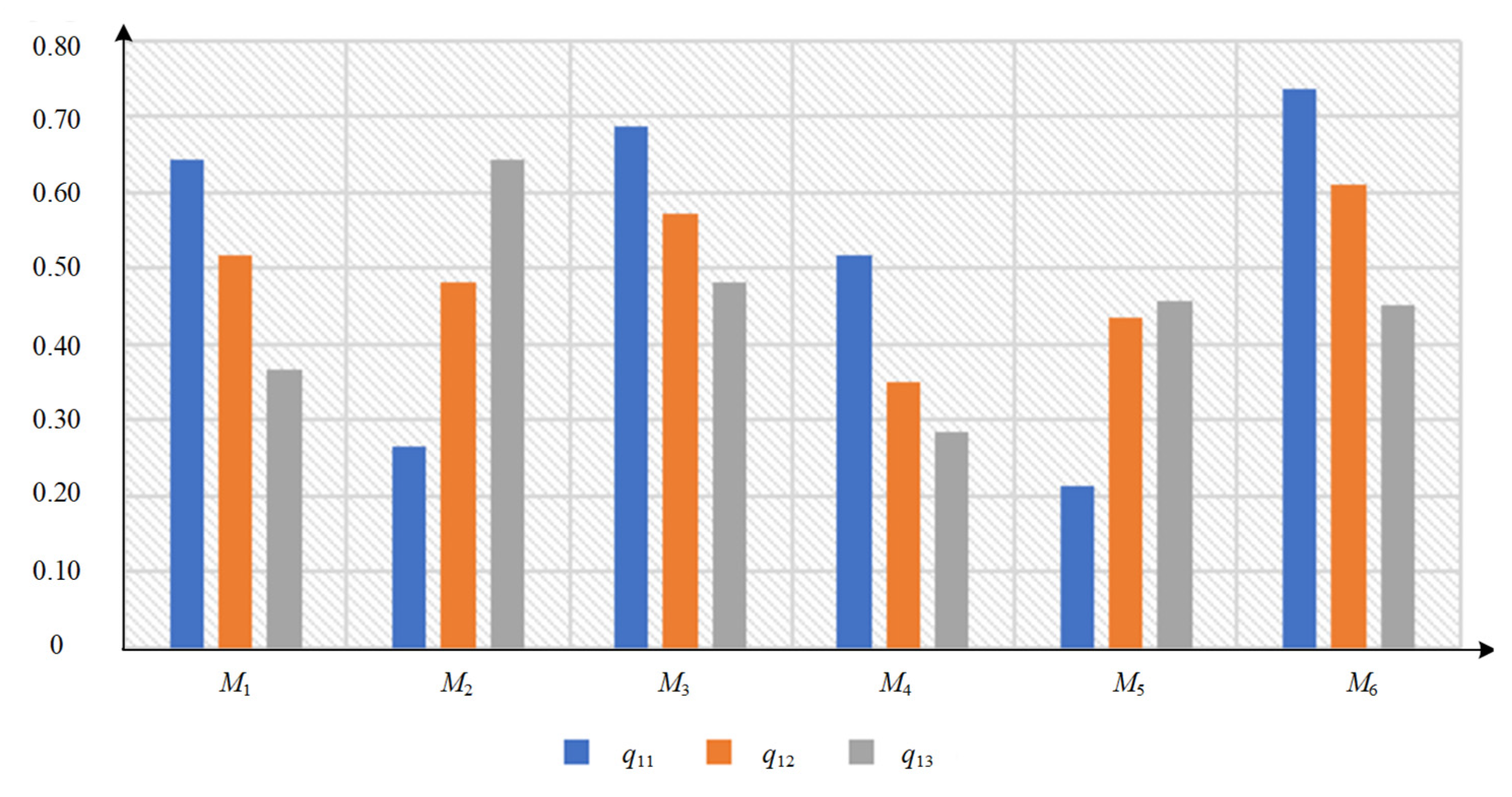

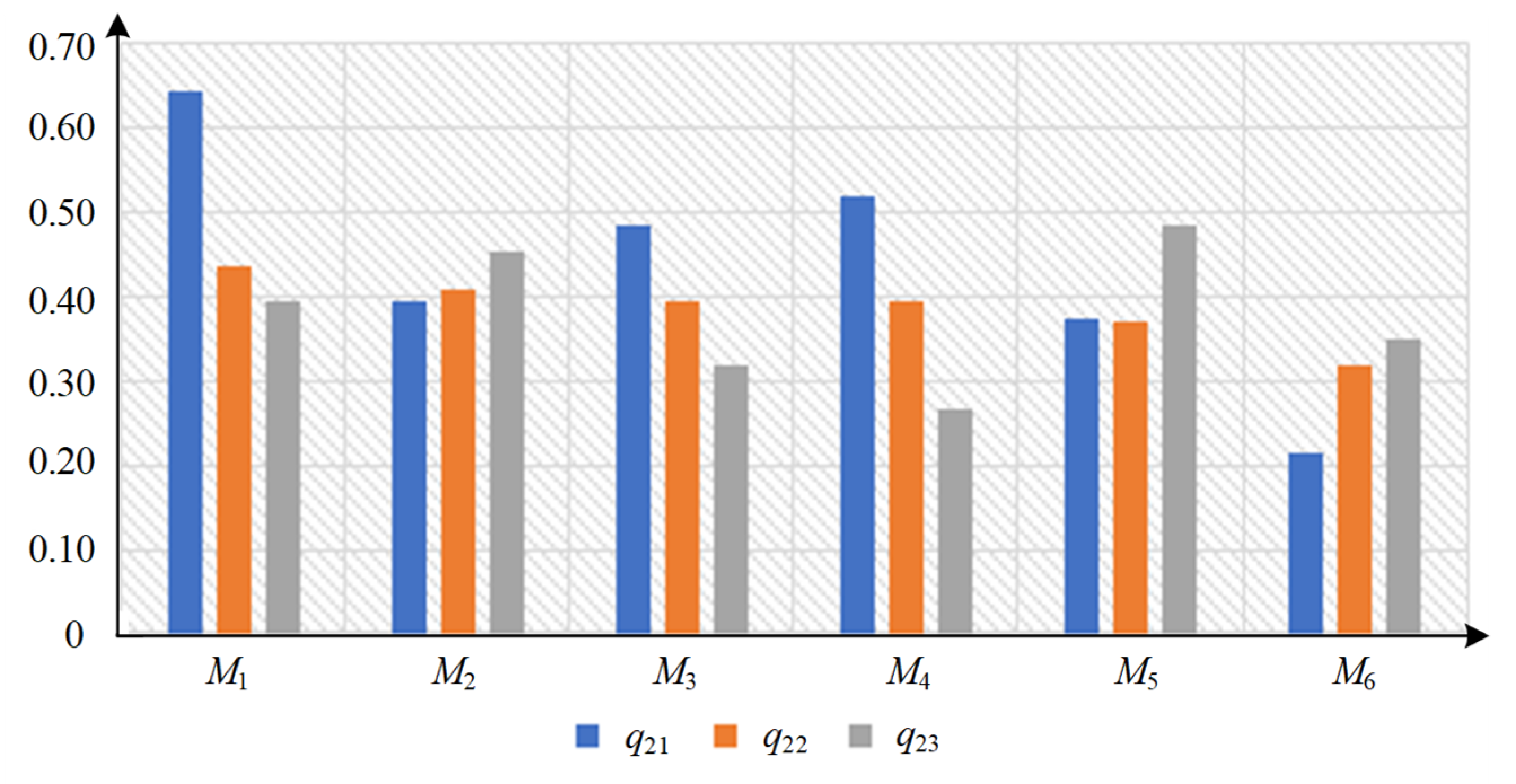

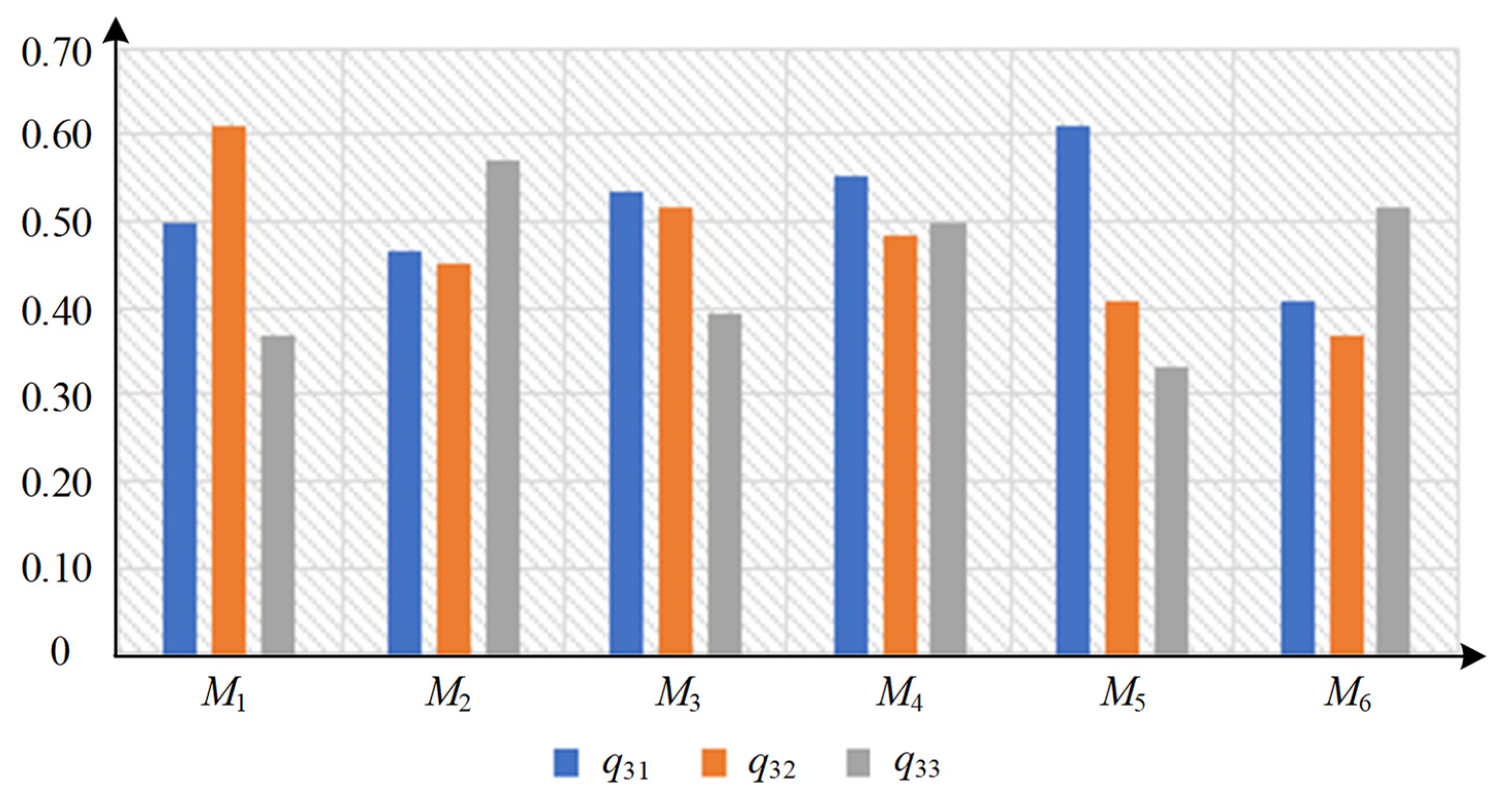

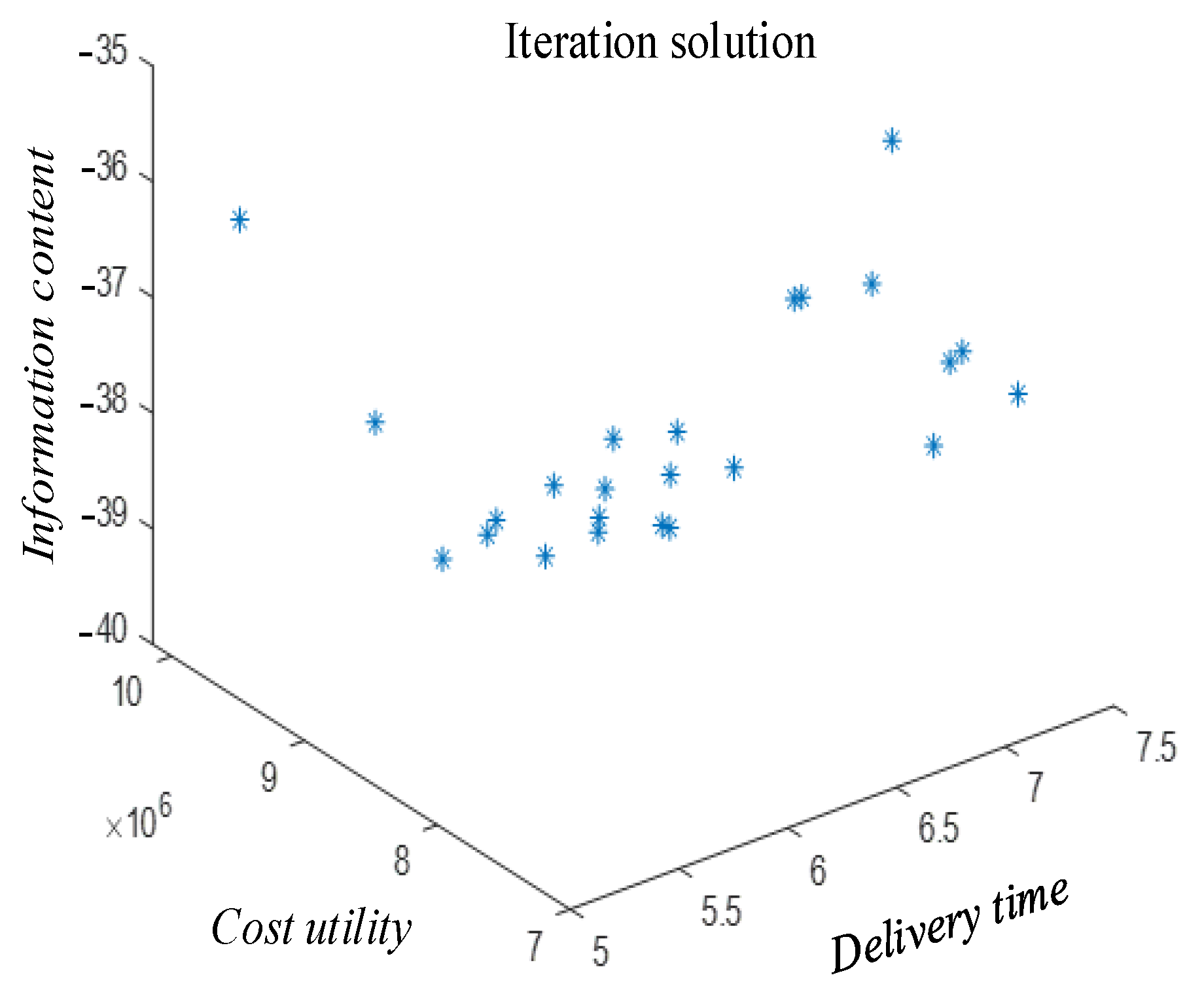

4.3. Calculation of the MCDA Based on the NSGA-II

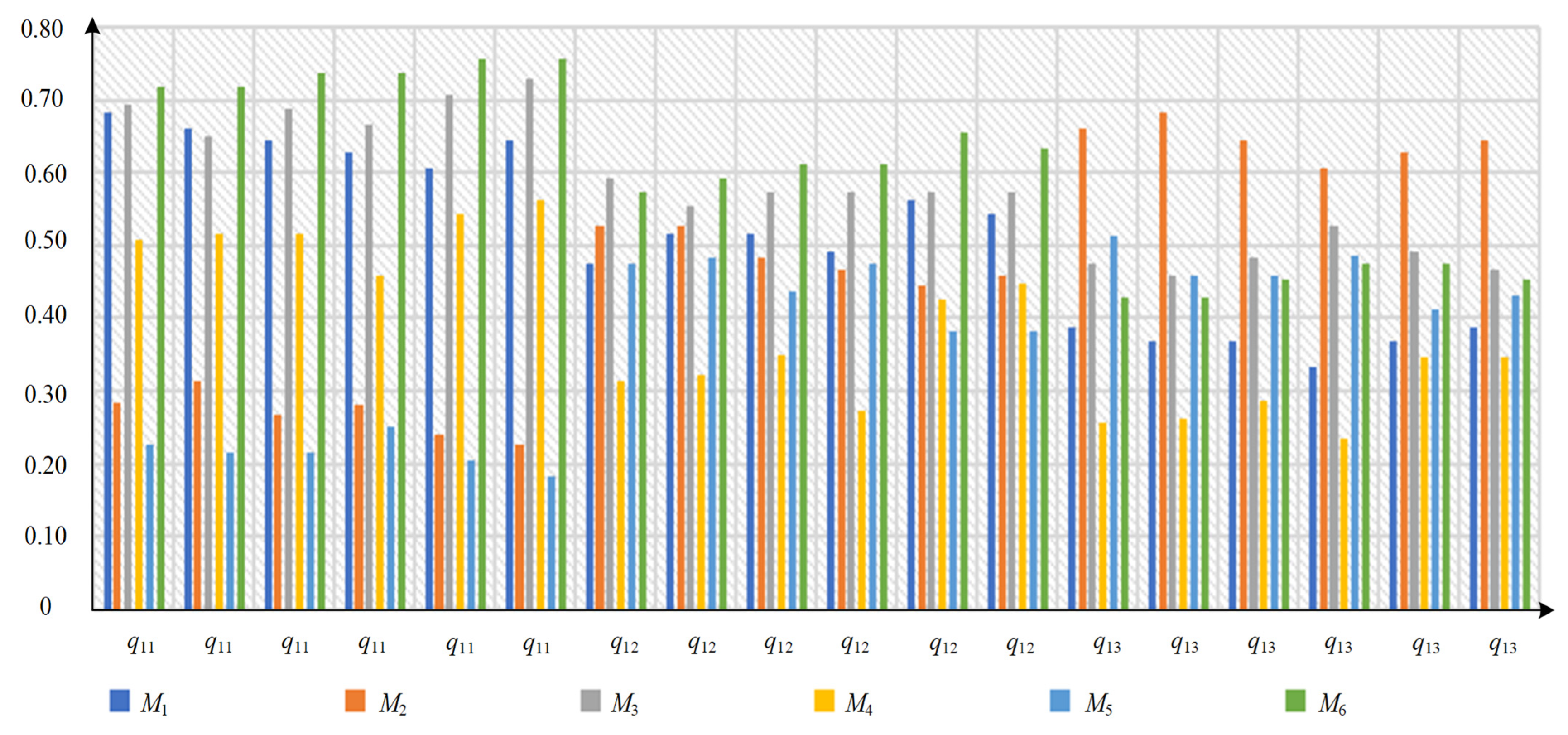

4.4. Method Comparison and Result Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Chu, X.; Chen, D.; Liu, Q.; Shen, J. An integrated module portfolio planning approach for complex products and systems. Int. J. Comput. Integr. Manuf. 2015, 28, 988–998. [Google Scholar] [CrossRef]

- Wang, T.; Wang, J.; Jin, G.; Matsukawa, H. Product platform configuration decision in NPD with uncertain demands and module options. Int. J. Prod. Res. 2023, 61, 6336–6355. [Google Scholar] [CrossRef]

- Zhang, X.; Sheng, G.J.; Chen, L.C.; Li, J. An innovative model of personalized product service system (PPSS) for open community collaborative supply (OCCS): Selection, configuration, and optimization. J. Clean. Prod. 2024, 436, 140639. [Google Scholar] [CrossRef]

- Ma, H.; Chu, X.; Wang, W.; Xue, D. A directed failure causality network (DFCN) based method for function components risk prioritization under interval type-2 fuzzy environment. Adv. Eng. Inform. 2019, 41, 100920. [Google Scholar] [CrossRef]

- Jiao, R.; Luo, J.; Malmqvist, J.; Summers, J. New design: Opportunities for engineering design in an era of digital transformation. J. Eng. Des. 2022, 33, 685–690. [Google Scholar] [CrossRef]

- Yang, N.; Li, R.; Zhang, Y.; Liu, H. Modeling and simulation technical risk diffusion in the complex product research and development projects. Syst. Eng. Theory Pract. 2019, 39, 1496–1506. [Google Scholar]

- Lin, L.; Zhang, S.; Fu, S.; Liu, Y. FD-LLM: Large language model for fault diagnosis of complex equipment. Adv. Eng. Inform. 2025, 65, 103208. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Zhong, X.; Zou, F. Identification of influential function modules within complex products and systems based on weighted and directed complex networks. J. Intell. Manuf. 2019, 30, 2375–2390. [Google Scholar] [CrossRef]

- Pakkanen, J.; Juuti, T.; Lehtonen, T.; Mämmelä, J. Why to design modular products? Procedia CIRP 2022, 109, 31–36. [Google Scholar] [CrossRef]

- Liu, Z.; Zhong, P.; Liu, H.; Jia, W.; Sa, G.; Tan, J. Module partition for complex products based on stable overlapping community detection and overlapping component allocation. Res. Eng. Des. 2024, 35, 269–288. [Google Scholar] [CrossRef]

- Chang, D.; Li, F.; Xue, J.; Zhang, L. A TRIZ-inspired knowledge-driven approach for user-centric smart product-service system: A case study on intelligent test tube rack design. Adv. Eng. Inform. 2023, 56, 101901. [Google Scholar] [CrossRef]

- Hossain, S.; Chakrabortty, R.K.; Elsawah, S.; Ryan, M.J. Modelling and application of hierarchical joint optimisation for modular product family and supply chain architecture. Int. J. Adv. Manuf. Technol. 2023, 126, 947–971. [Google Scholar] [CrossRef]

- Ulmer, J.; Braun, S.; Cheng, C.-T.; Dowey, S.; Wollert, J. A human factors-aware assistance system in manufacturing based on gamification and hardware modularisation. Int. J. Prod. Res. 2023, 61, 7760–7775. [Google Scholar] [CrossRef]

- Hou, L.; Jiao, R.J. Data-informed inverse design by product usage information: A review, framework and outlook. J. Intell. Manuf. 2020, 31, 529–552. [Google Scholar] [CrossRef]

- Gericke, K.; Eckert, C.; Campean, F.; Clarkson, P.J.; Flening, E.; Isaksson, O.; Kipouros, T.; Kokkolaras, M.; Köhler, C.; Panarotto, M.; et al. Supporting designers: Moving from method menagerie to method ecosystem. Des. Sci. 2020, 6, e21. [Google Scholar] [CrossRef]

- Kolbeck, L.; Kovaleva, D.; Manny, A.; Stieler, D.; Rettinger, M.; Renz, R.; Tošić, Z.; Teschemacher, T.; Stindt, J.; Forman, P.; et al. Modularisation Strategies for Individualised Precast Construction—Conceptual Fundamentals and Research Directions. Designs 2023, 7, 143. [Google Scholar] [CrossRef]

- Guo, X.; Yang, M.; Liu, Y.; Zhao, W.; Shi, J.; Zhang, K. Design for product resilience: Concept, characteristics and generalisation. J. Eng. Des. 2023, 34, 363–382. [Google Scholar] [CrossRef]

- Jiao, R.; Zhang, Y.; Wang, Y. A Heuristic Genetic Algorithm for Product Portfolio Planning. Comput. Oper. Res. 2007, 34, 1777–1799. [Google Scholar] [CrossRef]

- Dong, L.; Ren, M.; Xiang, Z.; Zheng, P.; Cong, J.; Chen, C.-H. A novel smart product-service system configuration method for mass personalization based on knowledge graph. J. Clean. Prod. 2023, 382, 135270. [Google Scholar] [CrossRef]

- Avikal, R. QFD and Fuzzy Kano model based approach for classification of aesthetic attributes of SUV car profile. J. Intell. Manuf. 2020, 31, 271–284. [Google Scholar] [CrossRef]

- Jiao, J.; Chen, C. Customer requirement management in product development: A review of research issues. Concurr. Eng. 2006, 14, 173–185. [Google Scholar] [CrossRef]

- Kulshreshtha, K.; Sharma, G.; Bajpai, N. Conjoint analysis: The assumptions, applications, concerns, remedies and future research direction. Int. J. Qual. Reliab. Manag. 2023, 40, 607–627. [Google Scholar] [CrossRef]

- Zheng, P.; Xu, X.; Yu, S.; Liu, C. Personalized product configuration framework in an adaptable open architecture product platform. J. Manuf. Syst. 2017, 43, 422–435. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, L.; Sheng, G.; Lu, X.; Ming, X. An innovation service system and personalized recommendation for customer-product interaction life cycle in smart product service system. J. Clean. Prod. 2023, 398, 136470. [Google Scholar] [CrossRef]

- Chiu, M.C.; Huang, J.H.; Gupta, S.; Akman, G. Developing a personalized recommendation system in a smart product service system based on unsupervised learning model. Comput. Ind. 2021, 128, 103421. [Google Scholar] [CrossRef]

- Ji, Y.; Jiao, R.J.; Chen, L.; Wu, C. Green modular design for material efficiency: A leader-follower joint optimization model. J. Clean. Prod. 2013, 41, 187–201. [Google Scholar] [CrossRef]

- Zeng, S.S.; Peng, W.P.; Yan, W. Analysis of inclusion relation of parameterized models for product platforms. China Mech. Eng. 2017, 28, 1474–1483. [Google Scholar]

- Hu, D.; Li, Y.; Li, Y. Design of customer demand products based on Kano and artificial immune system. Comput. Integr. Manuf. Syst. 2018, 24, 2536–2546. [Google Scholar]

- Cheng, X.; Qiu, H.; Wan, L.; Wang, H. Coupling analysis of product family design based on axiomatic design and modular incidence matrix. China Mech. Eng. 2019, 30, 794–803. [Google Scholar]

- Ma, H.; Chu, X.; Xue, D.; Chen, D. Identification of to-be-improved components for redesign of complex products and systems based on fuzzy QFD and FMEA. J. Intell. Manuf. 2019, 30, 623–639. [Google Scholar] [CrossRef]

- Dou, X.; Wang, J.; Wang, X.Y.; Wu, L. Analysis of user demand side response behavior of regional integrated power and gas energy systems based on evolutionary game. Proc. CSEE 2020, 40, 3775–3785. [Google Scholar]

- Qu, Y.; Wang, Y.; Ming, X.; Chu, X. Multi-stakeholder’s sustainable requirement analysis for smart manufacturing systems based on the stakeholder value network approach. Comput. Ind. Eng. 2023, 177, 109043. [Google Scholar] [CrossRef]

- Montalvillo, L.; Díaz, O. Requirement-driven evolution in software product lines: A systematic mapping study. J. Syst. Softw. 2016, 122, 110–143. [Google Scholar] [CrossRef]

- Wang, S.J.; Hou, L.; Fang, Y.; Lin, H.; Guo, T.; Jiao, J. Optimization design of wheel loader gearbox considering product operational big data. J. Mech. Eng. 2018, 54, 232–246. [Google Scholar] [CrossRef]

- Oliva, R.; Opabola, E.A. Simulating operational disruption in petrochemical facilities under natural hazard impact. Reliab. Eng. Syst. Saf. 2025, 265, 111481. [Google Scholar] [CrossRef]

- Li, Y.; Ni, Y.; Zhang, N.; Liu, Z. Modularization for the complex product considering the design change requirements. Res. Eng. Des. 2021, 32, 507–522. [Google Scholar] [CrossRef]

- Hou, L.; Wang, H.L.; Mu, R.; Huang, W.; Ling, W.G.; Lai, R.Y. Research on the evolution & innovation for modular product family. J. Mech. Eng. 2012, 48, 55–64. [Google Scholar]

- Li, Y.; Chu, X.; Chu, D.; Liu, Q. An integrated module partition approach for complex products and systems based on weighted complex networks. Int. J. Prod. Res. 2014, 52, 4608–4622. [Google Scholar] [CrossRef]

- Zhang, Y.; Du, G. Leader-follower joint optimization of product family configuration with consideration of remanufacturing. Comput. Integr. Manuf. Syst. 2018, 24, 1511–1521. [Google Scholar]

- Li, L.; Li, H.; Gu, F.; Ding, N.; Gu, X.; Luo, G. Multidisciplinary collaborative design modeling technologies for complex mechanical products based on digital twin. Comput. Integr. Manuf. Syst. 2019, 25, 1307–1319. [Google Scholar]

- Macherki, D.; Diallo, T.M.L.; Choley, J.-Y.; Barkallah, M.; Haddar, M. Self-reconfiguration of manufacturing systems using Satisfiability Modulo Theory. Int. J. Prod. Res. 2025, 1–26. [Google Scholar] [CrossRef]

- Lai, R.S.; Lin, W.G.; Wu, Y.M. Redesign priority identification of product family modules for green performance optimization. China Mech. Eng. 2019, 30, 1329–1335. [Google Scholar]

- Forti, W.; Ramos, C.; Muniz, J. Integration of design structure matrix and modular function deployment for mass customization and product modularization: A case study on heavy vehicles. Int. J. Adv. Manuf. Technol. 2023, 125, 1987–2002. [Google Scholar] [CrossRef]

- Wang, C.; Xu, J.; Qin, J. Research on modularized design and parameter matching of dual-fuel pre-cooler for chemically precooled engine. Fuel 2025, 381, 133201. [Google Scholar] [CrossRef]

- Ma, H.; Chu, X.; Li, Y. An integrated approach to identify function components for product redesign based on analysis of customer requirements and failure risk. J. Intell. Fuzzy Syst. 2019, 36, 1743–1757. [Google Scholar] [CrossRef]

- Tian, Y.; Cheng, R.; Zhang, X.; Jin, Y. PlatEMO: A MATLAB platform for evolutionary multi-objective optimization. IEEE Comput. Intell. Mag. 2017, 12, 73–87. [Google Scholar] [CrossRef]

| Section | Functional Module M | Module Instance | Module Parameter | Note |

|---|---|---|---|---|

| MPP | m1 bucket | mp11 bucket capacity | v111: 2.2 | m3 |

| v112: 3.8 | m3 | |||

| v113: 4.5 | m3 | |||

| mp12 hydraulic system | v121: quantitative | type | ||

| v122: variable | type | |||

| v123: mixed | type | |||

| mp13 equipped with load | v131: 3 | t | ||

| v132: 3.2 | t | |||

| v133: 5 | t | |||

| mp14 unloading height | v141: 2800 | mm | ||

| v142: 2965 | mm | |||

| v143: 3167 | mm | |||

| m2 engine | mp21 brand | v211: Yuchai | for 3 t | |

| v212: Shangchai | for 5 t | |||

| mp22 rated power | v221: 92 | kW | ||

| v222: 175 | kW | |||

| m3 turning radius | mp31 outer side of bucket | v311: 5860 | mm | |

| v312: 6550 | mm | |||

| v313: 7470 | mm | |||

| mp32 outer side of wheel | v321: 5500 | mm | ||

| v322: 5560 | mm | |||

| v323: 6650 | mm | |||

| m4 vehicle configuration | mp41 intelligence level | v411: low | type | |

| v412: middle | type | |||

| v413: high | type | |||

| mp42 tire type | v421: Delta | 68 days | ||

| v422: Aeolus | 75 days | |||

| v423: Michelin | 90 days | |||

| SMC | service module | technical consulting | cost index | |

| equipment maintenance | cost index | |||

| performance monitoring | cost index | |||

| fault diagnosis | cost index | |||

| part replacement | cost index | |||

| recycling services | cost index | |||

| Initial CRs | Integrated CRs | FRs and Their Design Range |

|---|---|---|

| CR1, high-temperature environment | CR1, environmental requirements | FR1, working environment. The working environment of the loader is harsh, and customer purchase orders require high-temperature and alpine working environments. Its requirement range is [−50 °C, 50 °C]. |

| CR2, alpine environment | ||

| CR3, high power for mountain rock transport | CR2, power size | FR2, power performance. The loader rated power size varies by working condition, and it is mainly equipped with different engines; the requirement range is [90 kW, 200 kW]. |

| CR4, small power for bridge and road repair | ||

| CR5, low fuel consumption | CR3, cost requirement | FR3, economic performance. The economic performance of the loader includes the purchase cost, daily fuel consumption, and maintenance cost of the whole machine or accessories, and its functional requirement range is [50 W, 80 W] RMB. |

| CR6, long life cycle of parts | ||

| CR7, site size restrictions | CR4, range of activities | FR4 has a turning radius in the range [5860 mm, 7470 mm]. The rated load of the FR5 bucket consists of a hydraulic system and bucket together, in the range [3 t, 5 t]. FR6, bucket capacity, is in the range [2.2 m3, 4.5 m3]. |

| CR8, overall vehicle weight | CR5, weight range | |

| CR9, bucket size | CR6, shovel requirement | |

| CR10, difficulty of operation | CR7, driving requirement | FR7, human–computer interaction, is medium and above, expressed as H or above by a triangular fuzzy number. |

| CR11, driving comfort | ||

| CR12, exhaust emissions | CR8, environmental requirement | FR8, environmental performance, meets the national minimum emission standards, expressed as greater than or equal to M by a triangular fuzzy number. |

| CR13, noise level |

| Weight of CRs | FR1 | FR2 | FR3 | FR4 | FR5 | FR6 | FR7 | FR8 | |

|---|---|---|---|---|---|---|---|---|---|

| 0.14 | CR1 | 0 | 0.2548 | 0.1042 | 0.1937 | 0.0747 | 0.1936 | 0.0747 | 0.1042 |

| 0.16 | CR2 | 0.1103 | 0 | 0.1104 | 0.1559 | 0.2051 | 0.2278 | 0.1066 | 0.0838 |

| 0.15 | CR3 | 0.1448 | 0.1026 | 0 | 0.1449 | 0.1026 | 0.1026 | 0.1906 | 0.2118 |

| 0.12 | CR4 | 0.1464 | 0.2140 | 0.1464 | 0 | 0.1464 | 0.1002 | 0.1002 | 0.1464 |

| 0.13 | CR5 | 0.1094 | 0.2105 | 0.2105 | 0.1094 | 0 | 0.2105 | 0.0403 | 0.1094 |

| 0.13 | CR6 | 0.1266 | 0.1851 | 0.2435 | 0.0866 | 0.2435 | 0 | 0.0466 | 0.0681 |

| 0.08 | CR7 | 0.2244 | 0.1050 | 0.2953 | 0.1535 | 0.0565 | 0.0565 | 0 | 0.1087 |

| 0.09 | CR8 | 0.1845 | 0.0679 | 0.1845 | 0.0679 | 0.1844 | 0.0679 | 0.2429 | 0 |

| Weights of FRs | 0.1222 | 0.1427 | 0.1491 | 0.1177 | 0.1290 | 0.1289 | 0.1013 | 0.1091 | |

| Module Parameter | FR1 | FR2 | FR3 | FR4 | FR5 | FR6 | FR7 | FR8 |

|---|---|---|---|---|---|---|---|---|

| v111: 2.2 | 0.078 | 0.143 | 0.056 | 0.013 | 0.093 | 0.039 | 0.090 | 0.029 |

| v112: 3.8 | 0.109 | 0.111 | 0.093 | 0.039 | 0.066 | 0.066 | 0.047 | 0.053 |

| v113: 4.5 | 0.047 | 0.079 | 0.131 | 0.066 | 0.040 | 0.118 | 0.025 | 0.078 |

| v121: quantitative | 0.047 | 0.111 | 0.168 | 0.066 | 0.093 | 0.118 | 0.047 | 0.078 |

| v122: variable | 0.078 | 0.079 | 0.131 | 0.039 | 0.066 | 0.092 | 0.069 | 0.053 |

| v123: mixed | 0.109 | 0.048 | 0.093 | 0.013 | 0.040 | 0.039 | 0.090 | 0.029 |

| v131: 3 | 0.109 | 0.079 | 0.056 | 0.013 | 0.093 | 0.118 | 0.069 | 0.053 |

| v132: 3.2 | 0.078 | 0.111 | 0.093 | 0.039 | 0.066 | 0.092 | 0.047 | 0.053 |

| v133: 5 | 0.047 | 0.143 | 0.131 | 0.066 | 0.040 | 0.066 | 0.025 | 0.078 |

| v141: 2800 | 0.078 | 0.048 | 0.019 | 0.066 | 0.093 | 0.118 | 0.069 | 0.078 |

| v142: 2965 | 0.109 | 0.079 | 0.056 | 0.092 | 0.066 | 0.092 | 0.018 | 0.078 |

| v143: 3167 | 0.141 | 0.111 | 0.093 | 0.118 | 0.040 | 0.066 | 0.069 | 0.053 |

| v211: Yuchai | 0.047 | 0.079 | 0.131 | 0.013 | 0.093 | 0.092 | 0.047 | 0.078 |

| v212: Shangchai | 0.078 | 0.111 | 0.093 | 0.039 | 0.066 | 0.118 | 0.069 | 0.053 |

| v221: 92 | 0.078 | 0.111 | 0.056 | 0.039 | 0.066 | 0.118 | 0.069 | 0.103 |

| v222: 175 | 0.109 | 0.143 | 0.093 | 0.092 | 0.093 | 0.092 | 0.090 | 0.053 |

| v311: 5860 | 0.016 | 0.048 | 0.093 | 0.039 | 0.093 | 0.118 | 0.047 | 0.078 |

| v312: 6550 | 0.047 | 0.079 | 0.131 | 0.066 | 0.066 | 0.092 | 0.069 | 0.053 |

| v313: 7470 | 0.078 | 0.111 | 0.168 | 0.092 | 0.040 | 0.066 | 0.047 | 0.029 |

| v321: 5500 | 0.047 | 0.079 | 0.056 | 0.013 | 0.093 | 0.118 | 0.047 | 0.078 |

| v322: 5560 | 0.078 | 0.111 | 0.093 | 0.039 | 0.066 | 0.092 | 0.069 | 0.078 |

| v323: 6650 | 0.109 | 0.143 | 0.131 | 0.066 | 0.040 | 0.066 | 0.047 | 0.053 |

| v411: low | 0.141 | 0.079 | 0.056 | 0.092 | 0.120 | 0.118 | 0.025 | 0.078 |

| v412: middle | 0.109 | 0.111 | 0.093 | 0.066 | 0.093 | 0.092 | 0.047 | 0.053 |

| v413: high | 0.078 | 0.143 | 0.131 | 0.039 | 0.040 | 0.039 | 0.069 | 0.029 |

| v421: Delta | 0.078 | 0.048 | 0.131 | 0.118 | 0.040 | 0.039 | 0.025 | 0.053 |

| v422: Aeolus | 0.109 | 0.079 | 0.093 | 0.092 | 0.093 | 0.066 | 0.047 | 0.078 |

| v423: Michelin | 0.141 | 0.111 | 0.056 | 0.066 | 0.120 | 0.092 | 0.069 | 0.103 |

| Value | ECi | f1 | rw | ta | f2 | ra | Process Time |

|---|---|---|---|---|---|---|---|

| v111 | 3200 | 120 | 10 | 800 | 60 | Average, 0.5 | |

| v112 | 3600 | 120 | 10 | 1200 | 60 | Fair, 0.7 | |

| v113 | 3800 | 120 | 10 | 1400 | 60 | Good, 0.9 | |

| v121 | 4000 | 4000 | Good, 0.9 | ||||

| v122 | 5000 | 5000 | Fair, 0.7 | ||||

| v123 | 6000 | 6000 | Average, 0.5 | ||||

| v131 | 3400 | 120 | 10 | 1000 | 60 | Average, 0.5 | |

| v132 | 3400 | 120 | 10 | 1000 | 60 | Fair, 0.7 | |

| v133 | 3700 | 120 | 10 | 1300 | 60 | Good, 0.9 | |

| v141 | 3600 | 120 | 10 | 1200 | 60 | Average, 0.5 | |

| v142 | 3600 | 120 | 10 | 1200 | 60 | Fair, 0.7 | |

| v143 | 3800 | 120 | 10 | 1400 | 60 | Good, 0.9 | |

| v211 | 27,200 | 23,000 | 150 | 20 | 60 | Fair, 0.7 | |

| v212 | 29,200 | 25,000 | 150 | 20 | 60 | Good, 0.9 | |

| v221 | 4200 | 150 | 20 | 60 | Good, 0.9 | ||

| v222 | 4200 | 150 | 20 | 60 | Fair, 0.7 | ||

| v311 | 3300 | 150 | 14 | 60 | Good, 0.9 | ||

| v312 | 3300 | 150 | 14 | 60 | Fair, 0.7 | ||

| v313 | 3600 | 150 | 16 | 60 | Average, 0.5 | ||

| v321 | 3000 | 150 | 12 | 60 | Good, 0.9 | ||

| v322 | 3000 | 150 | 12 | 60 | Fair, 0.7 | ||

| v323 | 3450 | 150 | 15 | 60 | Average, 0.5 | ||

| v411 | 32,000 | Average, 0.5 | |||||

| v412 | 42,000 | Fair, 0.7 | |||||

| v413 | 52,000 | Good, 0.9 | |||||

| v421 | 4600 | 1800 | 120 | 10 | 400 | 60 | Average, 0.5 |

| v422 | 5000 | 2100 | 120 | 10 | 500 | 60 | Fair, 0.7 |

| v423 | 5600 | 2600 | 120 | 10 | 600 | 60 | Good, 0.9 |

| Value | FR1 | FR2 | FR3 | FR4 | FR5 | FR6 | FR7 | FR8 |

|---|---|---|---|---|---|---|---|---|

| [−50, 50] | [90, 200] | [50, 80] | [5860, 7470] | [3, 5] | [2.2, 4.5] | [H, VH] | [M, H] | |

| v111 | [−20, 50] | [74, 116] | [55, 60] | [5500, 5860] | [3, 3.5] | [1.8, 2.6] | VH | L |

| v112 | [−30, 60] | [147, 196] | [65, 75] | [5860, 6650] | [3, 4] | [2.6, 4] | M | M |

| v113 | [−10, 40] | [92, 126] | [60, 70] | [6550, 6650] | [2.6, 3.2] | [1.8, 2.2] | L | H |

| v121 | [−40, 80] | [147, 200] | [75, 80] | [6650, 7470] | [4.5, 6] | [3.8, 4.5] | M | H |

| v122 | [−40, 70] | [90, 147] | [60, 65] | [6550, 6650] | [3.5, 5.5] | [2.6, 3.8] | H | M |

| v123 | [−20, 50] | [74, 110] | [50, 55] | [5500, 5860] | [2.2, 3.6] | [1.8, 2.2] | VH | L |

| v131 | [−40, 80] | [165, 220] | [75, 85] | [5560, 5860] | [5, 6.5] | [4.5, 5.5] | H | M |

| … | … | … | … | … | … | … | … | … |

| v323 | [−40, 70] | [92, 126] | [65, 75] | [5500, 6550] | [3.2, 4.5] | [3.8, 4.5] | M | M |

| v411 | [−30, 50] | [74, 116] | [65, 70] | [5560, 6550] | [3, 3.6] | [2.6, 3.8] | L | H |

| v412 | [−40, 60] | [74, 126] | [70, 80] | [6650, 7470] | [3, 3.2] | [4.5, 5.5] | M | M |

| v413 | [−20, 50] | [74, 96] | [50, 60] | [6550, 6650] | [3.6, 5] | [1.8, 2.6] | H | L |

| v421 | [−30, 60] | [74, 126] | [60, 70] | [5500, 7470] | [4.5, 5] | [2.6, 3.8] | L | M |

| v422 | [−40, 70] | [92, 186] | [65, 75] | [5500, 5860] | [3, 3.6] | [2.2, 3.2] | M | H |

| v423 | [−40, 60] | [74, 126] | [70, 80] | [6650, 7470] | [3, 3.2] | [4.5, 5.5] | H | VH |

| Value | FR1 | FR2 | FR3 | FR4 | FR5 | FR6 | FR7 | FR8 |

|---|---|---|---|---|---|---|---|---|

| v111 | 0.64 | 0.38 | 0.17 | 0.22 | 0.25 | 0.35 | 0.50 | 0.50 |

| v112 | 0.82 | 0.45 | 0.33 | 0.49 | 0.50 | 0.61 | 0.50 | 0.50 |

| v113 | 0.45 | 0.31 | 0.33 | 0.06 | 0.30 | 0.17 | 0.25 | 0.25 |

| v121 | 1.00 | 0.48 | 0.17 | 0.51 | 0.75 | 0.30 | 0.25 | 0.40 |

| v122 | 1.00 | 0.52 | 0.17 | 0.06 | 1.00 | 0.52 | 0.50 | 0.50 |

| v123 | 0.64 | 0.33 | 0.17 | 0.22 | 0.70 | 0.17 | 0.25 | 0.40 |

| v131 | 1.00 | 0.50 | 0.33 | 0.19 | 0.75 | 0.43 | 0.50 | 0.50 |

| v132 | 1.00 | 0.55 | 0.17 | 1.00 | 0.25 | 0.35 | 0.50 | 0.35 |

| v133 | 0.64 | 0.42 | 0.33 | 0.49 | 0.15 | 0.39 | 0.25 | 0.25 |

| v141 | 0.82 | 0.25 | 0.17 | 0.19 | 0.50 | 0.35 | 0.35 | 0.40 |

| v142 | 0.55 | 0.16 | 0.33 | 0.49 | 0.25 | 0.17 | 0.50 | 0.50 |

| v143 | 0.73 | 0.66 | 0.17 | 0.19 | 0.25 | 0.30 | 0.40 | 0.50 |

| v211 | 1.00 | 0.50 | 0.17 | 0.51 | 0.75 | 0.35 | 0.50 | 0.25 |

| v212 | 0.45 | 0.31 | 0.17 | 0.06 | 0.50 | 0.35 | 0.25 | 0.25 |

| v221 | 1.00 | 0.45 | 0.17 | 0.61 | 0.10 | 0.30 | 0.50 | 0.15 |

| v222 | 0.73 | 0.47 | 0.17 | 0.49 | 0.65 | 0.52 | 0.50 | 0.50 |

| v311 | 1.00 | 0.66 | 0.33 | 0.65 | 0.75 | 0.43 | 0.50 | 0.25 |

| v312 | 0.91 | 0.47 | 0.17 | 1.00 | 0.75 | 0.17 | 0.25 | 0.15 |

| v313 | 1.00 | 0.38 | 0.17 | 0.19 | 0.50 | 0.65 | 0.35 | 0.25 |

| v321 | 0.91 | 0.38 | 0.17 | 0.65 | 0.30 | 0.22 | 0.40 | 0.40 |

| v322 | 0.45 | 0.16 | 0.33 | 1.00 | 0.70 | 0.35 | 0.25 | 0.60 |

| v323 | 1.00 | 0.31 | 0.33 | 0.65 | 0.65 | 0.30 | 0.35 | 0.50 |

| v411 | 0.73 | 0.38 | 0.17 | 0.61 | 0.30 | 0.52 | 0.25 | 0.50 |

| v412 | 0.91 | 0.47 | 0.33 | 0.51 | 0.10 | 0.43 | 0.35 | 0.25 |

| v413 | 0.64 | 0.20 | 0.33 | 0.06 | 0.70 | 0.35 | 0.25 | 0.50 |

| v421 | 0.82 | 0.47 | 0.33 | 1.00 | 0.25 | 0.52 | 0.50 | 0.50 |

| v422 | 1.00 | 0.85 | 0.33 | 0.22 | 0.30 | 0.43 | 0.50 | 0.25 |

| v423 | 0.91 | 0.47 | 0.33 | 0.51 | 0.10 | 0.43 | 0.35 | 0.25 |

| Combinatorial Function | Function Value | MPP Scheme |

|---|---|---|

| (Delivery time, cost utility) Q1 | (5.4, 10,140,964) | 1, 2, 1, 1, 2, 2, 3, 3, 1, 1 |

| (6.4, 7,507,569) | 2, 1, 2, 1, 2, 2, 2, 2, 1, 2 | |

| (7.4, 7,058,061) | 2, 2, 1, 1, 2, 2, 3, 3, 1, 2 | |

| (Delivery time, information content) Q2 | (5.4, −36.61) | 1, 3, 1, 1, 1, 2, 3, 3, 2, 1 |

| (6.0, −39.57) | 2, 2, 1, 1, 1, 2, 2, 3, 2, 2 | |

| (6.6, −40.44) | 2, 2, 1, 3, 2, 2, 1, 3, 1, 3 | |

| (Cost utility, information content) Q3 | (7,058,061, −36.85) | 2, 1, 2, 3, 2, 2, 2, 2, 2, 2 |

| (8,509,198, −38.79) | 2, 2, 1, 3, 1, 2, 1, 3, 1, 1 | |

| (9,236,679, −40.44) | 2, 1, 2, 3, 2, 2, 2, 3, 3, 3 |

| Decision-Maker | Scheme of SMC | ||||||

|---|---|---|---|---|---|---|---|

| e1 | q11 | 0.7 | 0.1 | 0.9 | 0.5 | 0.1 | 0.9 |

| q12 | 0.5 | 0.3 | 0.5 | 0.5 | 0.3 | 0.7 | |

| q13 | 0.3 | 0.5 | 0.5 | 0.3 | 0.5 | 0.5 | |

| e2 | q11 | 0.7 | 0.5 | 0.7 | 0.7 | 0.3 | 0.7 |

| q12 | 0.5 | 0.7 | 0.5 | 0.7 | 0.3 | 0.7 | |

| q13 | 0.9 | 0.3 | 0.7 | 0.7 | 0.3 | 0.5 | |

| e3 | q11 | 0.5 | 0.7 | 0.5 | 0.7 | 0.1 | 0.7 |

| q12 | 0.5 | 0.9 | 0.3 | 0.5 | 0.5 | 0.5 | |

| q13 | 0.5 | 0.5 | 0.7 | 0.3 | 0.5 | 0.3 | |

| e4 | q11 | 0.7 | 0.5 | 0.5 | 0.5 | 0.3 | 0.7 |

| q12 | 0.3 | 0.7 | 0.5 | 0.3 | 0.5 | 0.7 | |

| q13 | 0.7 | 0.3 | 0.7 | 0.3 | 0.3 | 0.5 | |

| e5 | q11 | 0.3 | 0.5 | 0.7 | 0.3 | 0.5 | 0.7 |

| q12 | 0.5 | 0.5 | 0.7 | 0.1 | 0.7 | 0.5 | |

| q13 | 0.1 | 0.1 | 0.9 | 0.1 | 0.9 | 0.5 |

| Scheme of SMC | |||||||

|---|---|---|---|---|---|---|---|

| q11 | 0.643 | 0.267 | 0.688 | 0.516 | 0.214 | 0.736 | |

| q12 | 0.516 | 0.483 | 0.572 | 0.350 | 0.436 | 0.612 | |

| q13 | 0.368 | 0.643 | 0.483 | 0.285 | 0.458 | 0.451 |

| Scheme of SMC | |||||||

|---|---|---|---|---|---|---|---|

| q21 | 0.643 | 0.394 | 0.483 | 0.516 | 0.374 | 0.214 | |

| q22 | 0.436 | 0.408 | 0.394 | 0.394 | 0.368 | 0.316 | |

| q23 | 0.394 | 0.451 | 0.316 | 0.267 | 0.483 | 0.350 |

| Scheme of SMC | |||||||

|---|---|---|---|---|---|---|---|

| q31 | 0.500 | 0.466 | 0.535 | 0.552 | 0.612 | 0.408 | |

| q32 | 0.612 | 0.451 | 0.516 | 0.483 | 0.408 | 0.368 | |

| q33 | 0.368 | 0.572 | 0.394 | 0.500 | 0.332 | 0.516 |

| Combinatorial Function | Function Value | MPP Scheme |

|---|---|---|

| (Delivery time, cost utility) Q1 | (5.6, 8,766,561) | 1, 1, 1, 1, 1, 2, 2, 2, 1, 1 |

| (6.4, 7,507,569) | 2, 1, 2, 1, 2, 2, 2, 2, 1, 2 | |

| (7.4, 7,058,061) | 2, 2, 1, 1, 2, 2, 3, 3, 1, 2 | |

| (Delivery time, information content) Q2 | (5.4, −36.61) | 1, 3, 1, 1, 1, 2, 3, 3, 2, 1 |

| (5.8, −39.19) | 2, 2, 1, 1, 1, 2, 2, 3, 2, 2 | |

| (6.2, −40.27) | 2, 2, 1, 3, 2, 2, 1, 3, 1, 3 | |

| (Cost utility, information content) Q3 | (7,058,061, −36.85) | 2, 1, 2, 3, 2, 2, 2, 2, 2, 2 |

| (8,509,198, −38.79) | 2, 2, 1, 3, 1, 2, 1, 3, 1, 1 | |

| (9,236,679, −40.44) | 2, 1, 2, 3, 2, 2, 2, 3, 3, 3 |

| Times of Weight Perturbation (Weights of Decision-Maker) | Scheme of SMC | ||||||

|---|---|---|---|---|---|---|---|

| 1 (0.1 0.2 0.3 0.1 0.3) | q11 | 0.682 | 0.283 | 0.694 | 0.508 | 0.225 | 0.718 |

| q12 | 0.475 | 0.526 | 0.592 | 0.314 | 0.475 | 0.572 | |

| q13 | 0.387 | 0.660 | 0.475 | 0.256 | 0.512 | 0.429 | |

| 2 (0.1 0.1 0.3 0.3 0.2) | q11 | 0.660 | 0.313 | 0.649 | 0.516 | 0.214 | 0.718 |

| q12 | 0.516 | 0.526 | 0.553 | 0.322 | 0.483 | 0.592 | |

| q13 | 0.368 | 0.682 | 0.459 | 0.262 | 0.458 | 0.429 | |

| 3 (0.2 0.2 0.2 0.2 0.2) | q11 | 0.643 | 0.267 | 0.688 | 0.516 | 0.214 | 0.736 |

| q12 | 0.516 | 0.483 | 0.572 | 0.350 | 0.436 | 0.612 | |

| q13 | 0.368 | 0.643 | 0.483 | 0.285 | 0.458 | 0.451 | |

| 4 (0.2 0.1 0.1 0.3 0.3) | q11 | 0.627 | 0.281 | 0.665 | 0.459 | 0.252 | 0.736 |

| q12 | 0.491 | 0.467 | 0.572 | 0.274 | 0.475 | 0.612 | |

| q13 | 0.332 | 0.607 | 0.526 | 0.235 | 0.486 | 0.475 | |

| 5 (0.3 0.3 0.1 0.2 0.1) | q11 | 0.607 | 0.239 | 0.706 | 0.544 | 0.203 | 0.755 |

| q12 | 0.562 | 0.444 | 0.572 | 0.425 | 0.381 | 0.654 | |

| q13 | 0.368 | 0.627 | 0.491 | 0.347 | 0.411 | 0.475 | |

| 6 (0.3 0.3 0.2 0.1 0.1) | q11 | 0.643 | 0.227 | 0.730 | 0.562 | 0.182 | 0.755 |

| q12 | 0.544 | 0.459 | 0.572 | 0.447 | 0.381 | 0.633 | |

| q13 | 0.387 | 0.643 | 0.467 | 0.347 | 0.432 | 0.451 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lian, X.; Luo, X.; Su, D. A Module Configuration Design Approach for Complex Equipment of Port Shipping Based on Heterogeneous Customer Requirements and Product Operational Data. Machines 2025, 13, 1125. https://doi.org/10.3390/machines13121125

Lian X, Luo X, Su D. A Module Configuration Design Approach for Complex Equipment of Port Shipping Based on Heterogeneous Customer Requirements and Product Operational Data. Machines. 2025; 13(12):1125. https://doi.org/10.3390/machines13121125

Chicago/Turabian StyleLian, Xiaozhen, Xinyi Luo, and Deying Su. 2025. "A Module Configuration Design Approach for Complex Equipment of Port Shipping Based on Heterogeneous Customer Requirements and Product Operational Data" Machines 13, no. 12: 1125. https://doi.org/10.3390/machines13121125

APA StyleLian, X., Luo, X., & Su, D. (2025). A Module Configuration Design Approach for Complex Equipment of Port Shipping Based on Heterogeneous Customer Requirements and Product Operational Data. Machines, 13(12), 1125. https://doi.org/10.3390/machines13121125