Optimization of the Surface Roughness and Chip Compression Ratio of Duplex Stainless Steel in a Wet Turning Process Using the Taguchi Method

Abstract

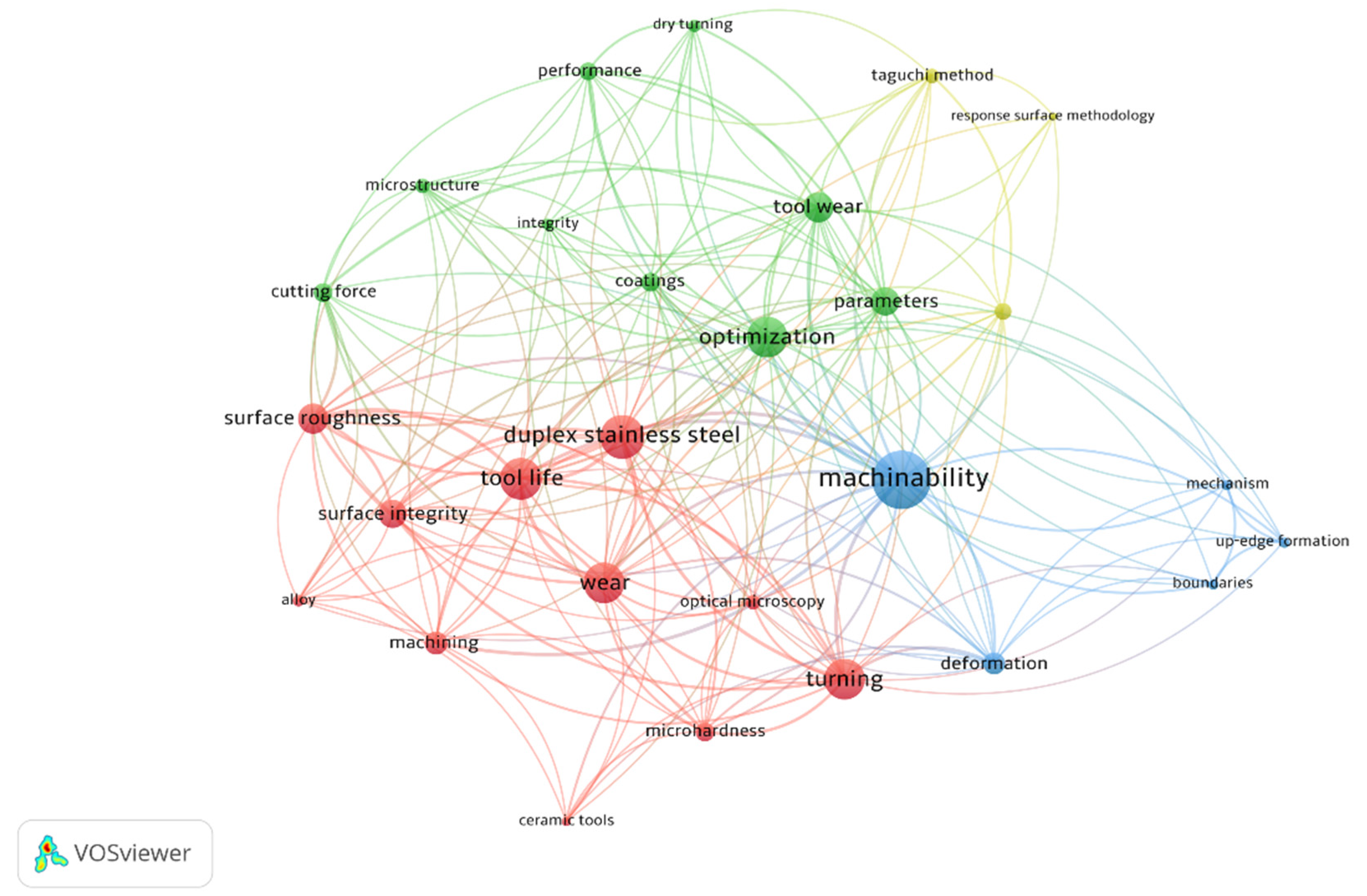

1. Introduction

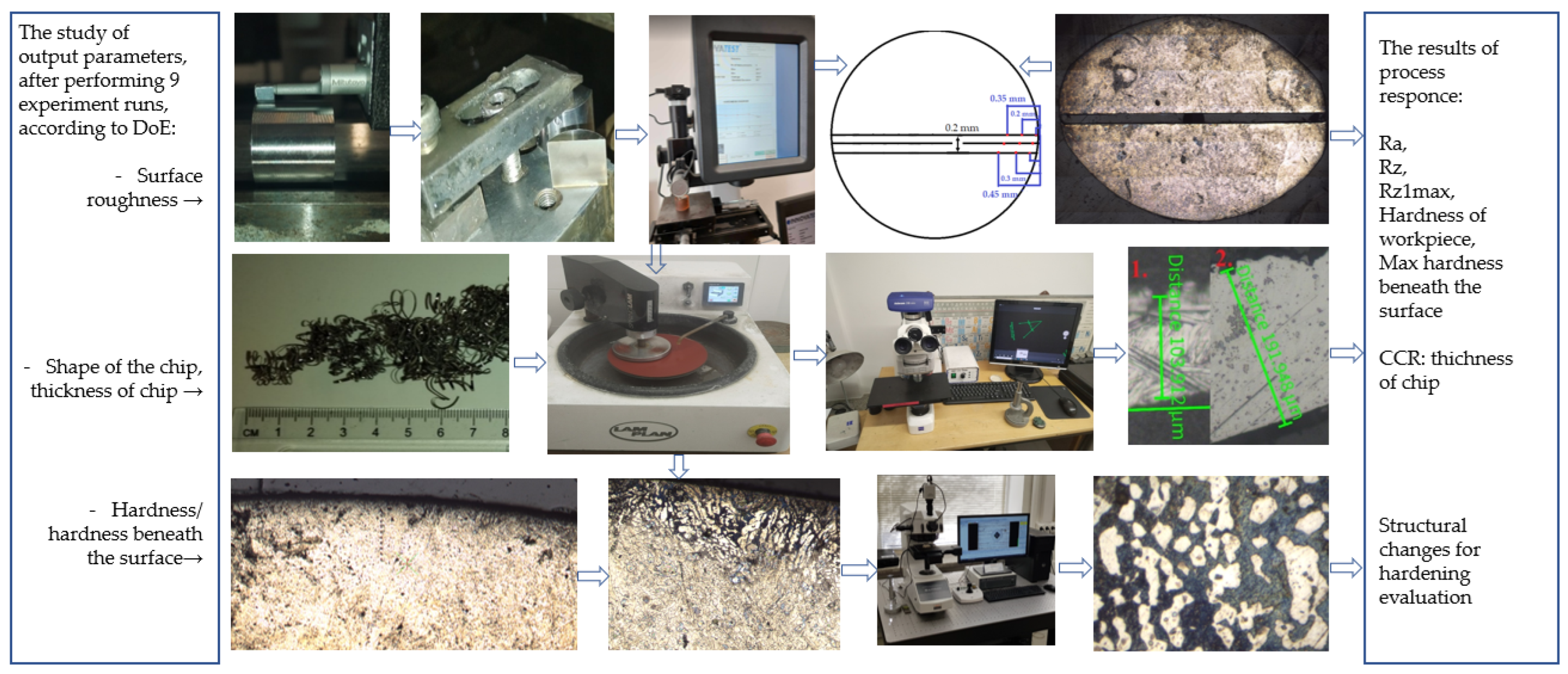

2. Materials and Methods

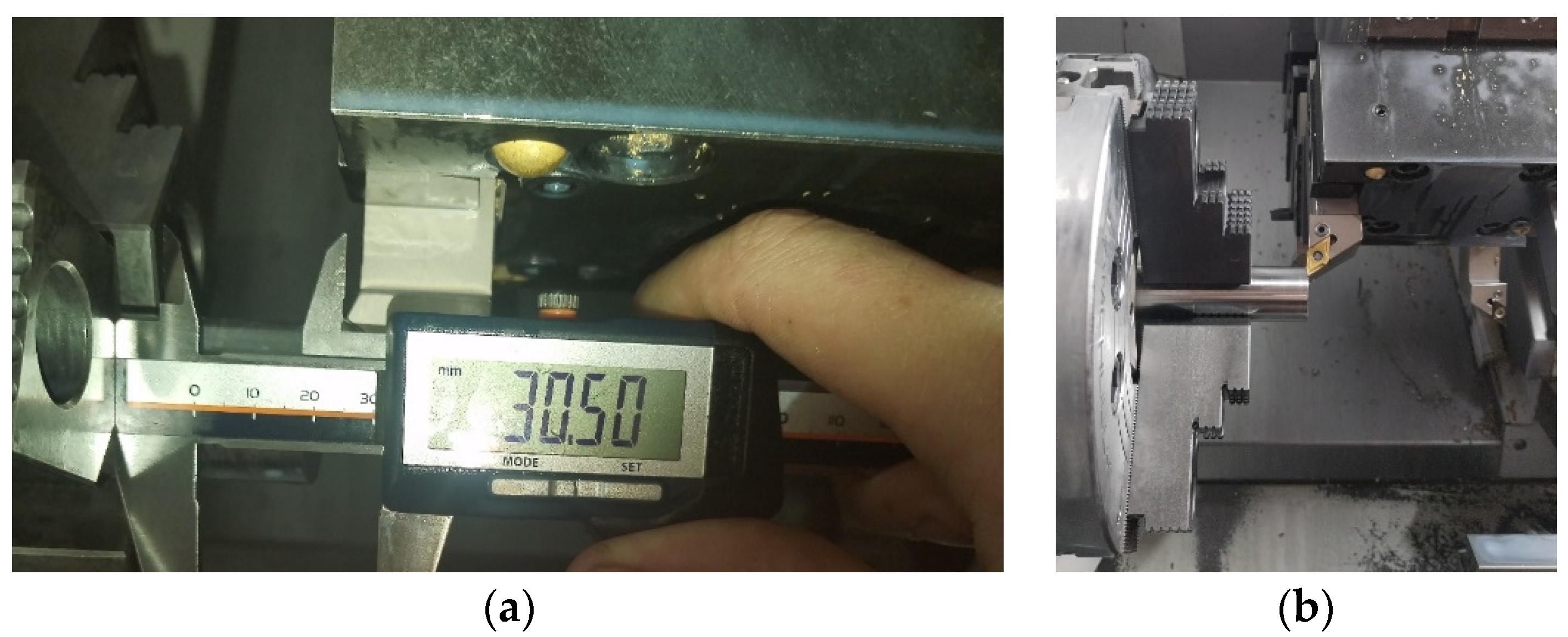

2.1. Experimental Setup

2.2. Design of Experiments

3. Results and Discussions

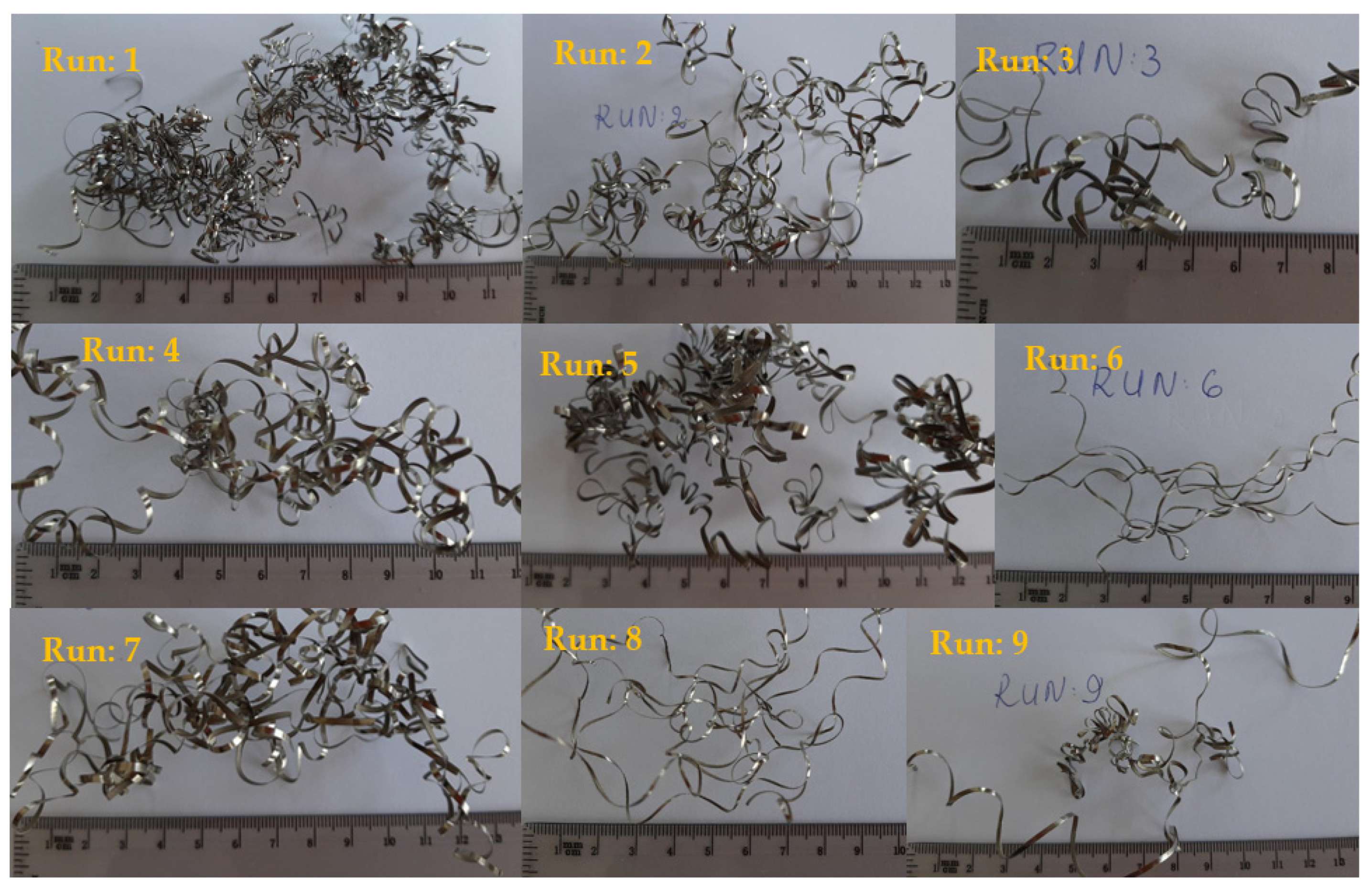

3.1. Experimental Results

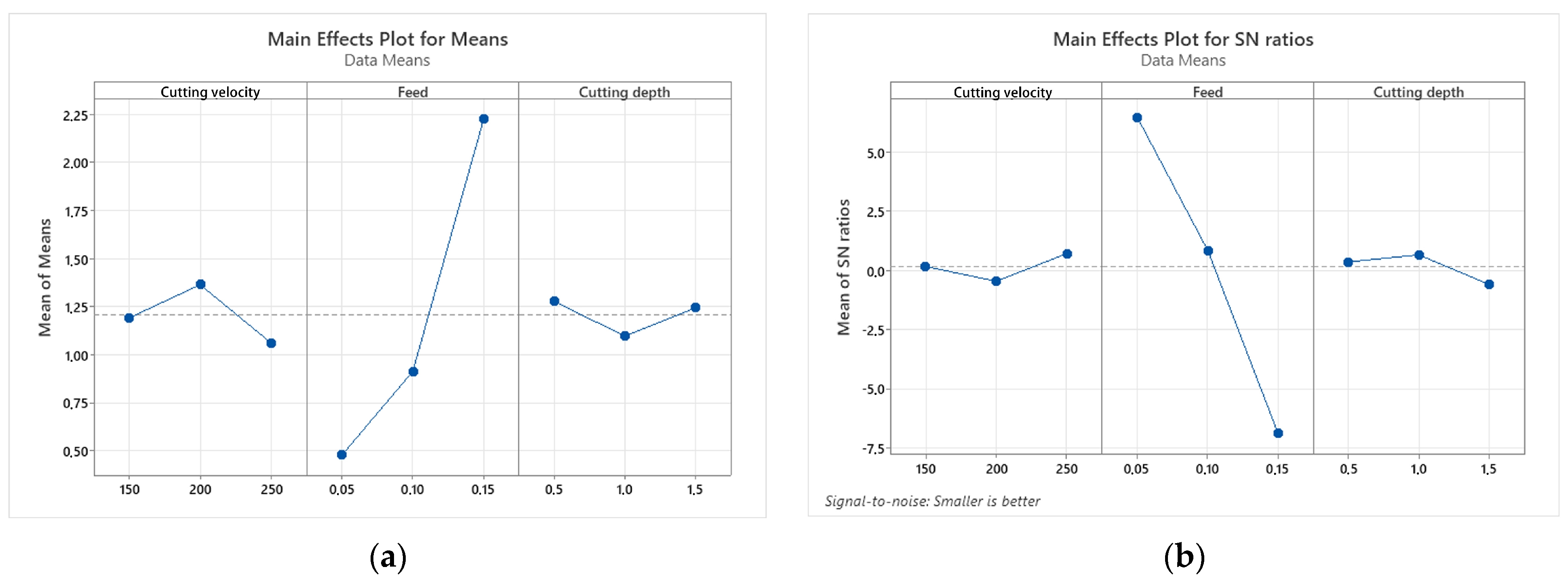

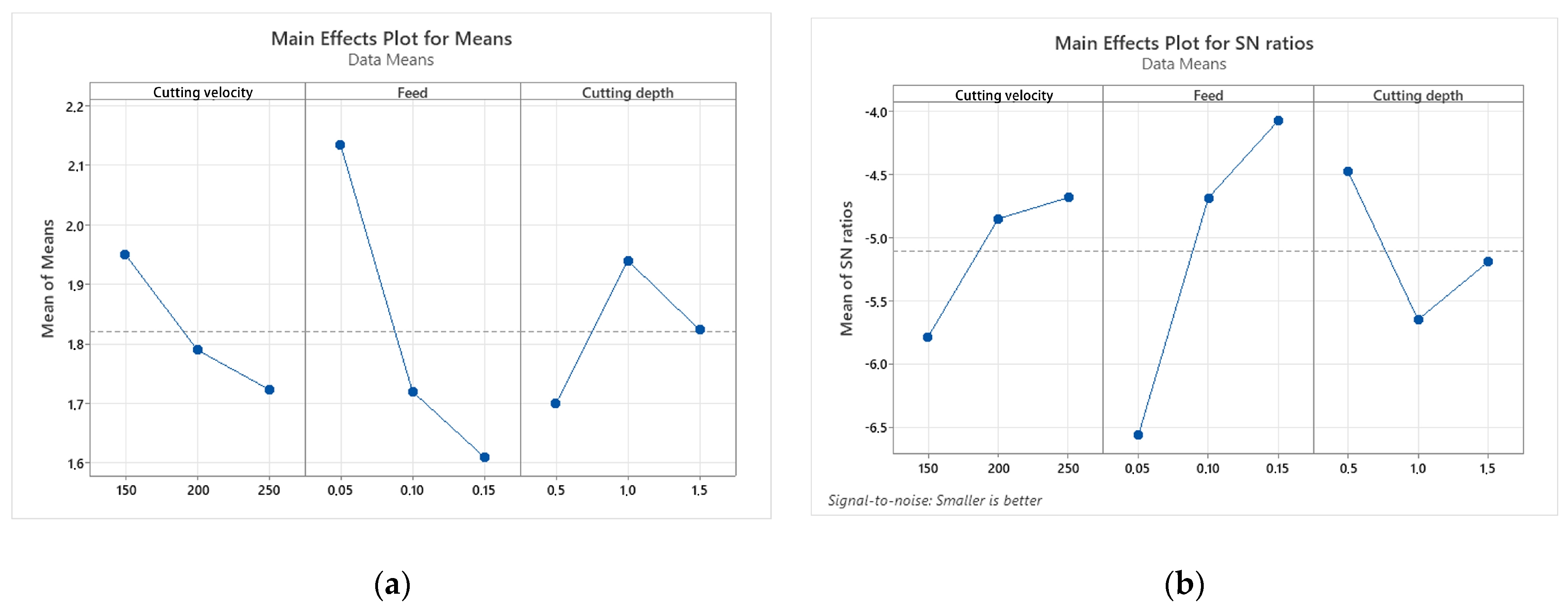

3.2. Taguchi Analysis

3.3. Analysis of Variance

4. Conclusions

- A cutting velocity of 200 m/min, feed of 0.05 mm/rev, and cutting depth of 1 mm are found to give the lowest surface roughness Ra that is equal to 0.433 µm;

- A cutting velocity of 200 m/min, feed of 0.15 mm/rev, and cutting depth of 0.5 mm are found to give the smallest CCR that is equal to 1.39, indicating the smallest plastic deformation during the material removal process;

- The experimental results proved that additional cooling allows us to achieve better surface roughness quality compared to dry and wet turning;

- The experimental data could be useful in collecting as much data as possible for the use of artificial intelligence techniques, i.e., for the training and validation of models; the lack of data provides overfitted models.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Koyee, R.D.; Heisel, U.; Eisseler, R.; Schmauder, S. Modeling and optimization of turning duplex stainless steels. J. Manuf. Process. 2014, 16, 451–467. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, V.; Newman, S. Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int. J. Mach. Tools Manuf. 2012, 57, 83–101. [Google Scholar] [CrossRef]

- Sonawane, G.D.; Sargade, V.G. Machinability Study of Duplex Stainless Steel 2205 during Dry Turning. Int. J. Precis. Eng. Manuf. 2020, 21, 969–981. [Google Scholar] [CrossRef]

- Fountas, N.A.; Papantoniou, I.; Manolakos, D.E.; Vaxevanidis, N.M. Implementation of Grey Wolf, Multi-Verse and Ant Lion Metaheuristic Algorithms for Optimizing Machinability of Dry CNC Turning of Annealed and Hardened UNIMAX® Tool Steel. Machines 2024, 12, 156. [Google Scholar] [CrossRef]

- Ulas, H.B.; Ozkan, M.T. Turning processes investigation of materials austenitic, martensitic and duplex stainless steels and prediction of cutting forces using artificial neural network (ANN) techniques. Indian J. Eng. Mat. Sci. 2019, 26, 93–104. [Google Scholar]

- Selvaraj, D.P.; Chandramohan, P.; Mohanraj, M. Optimization of surface roughness, cutting force and tool wear of nitrogen alloyed duplex stainless steel in a dry turning process using Taguchi method. Measurement 2014, 49, 205–215. [Google Scholar] [CrossRef]

- Rajaguru, J.; Arunachalam, N. Coated tool Performance in Dry Turning of Super Duplex Stainless Steel. Procedia Manuf. 2017, 10, 601–611. [Google Scholar] [CrossRef]

- Krolczyk, G.; Legutko, S. Investigations into Surface Integrity in the Turning Process of Duplex Stainless Steel. Trans. FAMENA 2014, 38, 77–82. [Google Scholar]

- Krolczyk, G.; Nieslony, P.; Legutko, S.; Hloch, S.; Samardzic, I. Investigation of Selected Surface Integrity Features of Duplex Stainless Steel (DSS) after Turning. Metalurgija 2015, 54, 91–94. [Google Scholar]

- Krolczyk, G.; Nieslony, P.; Legutko, S.; Stoic, A.; Samardzic, I. Microhardness Changes Gradient of the Duplex Stainless Steel (DSS) Surface Layer After Dry Turning. Metalurgija 2014, 53, 529–532. [Google Scholar]

- Krolczyk, G.; Nieslony, P.; Legutko, S. Microhardness and Surface Integrity in Turning Process of Duplex Stainless Steel (DSS) for Different Cutting Conditions. J. Mater. Eng. Perform. 2014, 23, 859–866. [Google Scholar] [CrossRef]

- Krolczyk, G.; Nieslony, P.; Maruda, R.; Wojciechowski, S. Dry cutting effect in turning of a duplex stainless steel as a key factor in clean production. J. Clean. Prod. 2017, 142, 3343–3354. [Google Scholar] [CrossRef]

- Krolczyk, G.; Nieslony, P.; Legutko, S. Determination of tool life and research wear during duplex stainless steel turning. Arch. Civ. Mech. Eng. 2015, 15, 347–354. [Google Scholar] [CrossRef]

- Koyee, R.D.; Eisseler, R.; Schmauder, S. Application of Taguchi coupled Fuzzy Multi Attribute Decision Making (FMADM) for optimizing surface quality in turning austenitic and duplex stainless steels. Measurement 2014, 58, 375–386. [Google Scholar] [CrossRef]

- Gupta, M.K.; Boy, M.; Korkmaz, M.E.; Yaşar, N.; Günay, M.; Krolczyk, G.M. Measurement and analysis of machining induced tribological characteristics in dual jet minimum quantity lubrication assisted turning of duplex stainless steel. Measurement 2022, 187, 110353. [Google Scholar] [CrossRef]

- Dhananchezian, M.; Priyan, M.R.; Rajashekar, G.; Narayanan, S.S. Study the Effect of Cryogenic Cooling on Machinability Characteristics during Turning Duplex Stainless Steel 2205. Mater. Today Proc. 2018, 5, 12062–12070. [Google Scholar] [CrossRef]

- Cardoso, L.G.; Madeira, D.S.; Ricomini, T.E.P.A.; Miranda, R.A.; Brito, T.G.; Paiva, E.J. Optimization of machining parameters using response surface methodology with desirability function in turning duplex stainless steel UNS S32760. Int. J. Adv. Manuf. Technol. 2021, 117, 1633–1644. [Google Scholar] [CrossRef]

- Parsi, P.K.; Kotha, R.S.; Routhu, T.; Pandey, S.; Dwivedy, M. Machinability evaluation of coated carbide inserts in turning of super-duplex stainless steel. SN Appl. Sci. 2020, 2, 1933. [Google Scholar] [CrossRef]

- Nomani, J.; Pramanik, A.; Hilditch, T.; Littlefair, G. Stagnation zone during the turning of Duplex SAF 2205 stainless steels alloy. Mater. Manuf. Process. 2017, 32, 1486–1489. [Google Scholar] [CrossRef]

- Nomani, J.; Pramanik, A.; Hilditch, T.; Littlefair, G. Investigation on the Behavior of Austenite and Ferrite Phases at Stagnation Region in the Turning of Duplex Stainless Steel Alloys. Metall. Mater. Trans. A 2016, 47, 3165–3177. [Google Scholar] [CrossRef]

- Krolczyk, G.M.; Legutko, S. Experimental Analysis by Measurement of Surface Roughness Variations in Turning Process of Duplex Stainless Steel. Metrol. Meas. Syst. 2014, 21, 759–770. [Google Scholar] [CrossRef]

- Gamarra, J.R.; Diniz, A.E. Taper turning of super duplex stainless steel: Tool life, tool wear and workpiece surface roughness. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 39. [Google Scholar] [CrossRef]

- Benardos, P.; Vosniakos, G.-C. Predicting surface roughness in machining: A review. Int. J. Mach. Tools Manuf. 2003, 43, 833–844. [Google Scholar] [CrossRef]

- Kundrak, J.; Mamalis, A.G.; Gyani, K.; Bana, V. Surface layer microhardness changes with high-speed turning of hardened steels. Int. J. Adv. Manuf. Technol. 2011, 53, 105–112. [Google Scholar] [CrossRef]

- Faga, M.G.; Priarone, P.C.; Robiglio, M.; Settineri, L.; Tebaldo, V. Technological and sustainability implications of dry, near-dry, and wet turning of Ti-6Al-4V alloy. Int. J. Precis. Eng. Manuf. Technol. 2017, 4, 129–139. [Google Scholar] [CrossRef]

- Chetan; Ghosh, S.; Rao, P.V. Application of sustainable techniques in metal cutting for enhanced machinability: A review. J. Clean. Prod. 2015, 100, 17–34. [Google Scholar] [CrossRef]

- Krolczyk, G.M.; Maruda, R.W.; Krolczyk, J.B.; Wojciechowski, S.; Mia, M.; Nieslony, P.; Budzik, G. Ecological trends in machining as a key factor in sustainable production—A review. J. Clean. Prod. 2019, 218, 601–615. [Google Scholar] [CrossRef]

- Kaladhar, M.; Sahu, G.; Kumar, S.M.; Nag, B.K.; Aditya, V.S.; Kaushik, G.S. Evaluation and Optimization of Machinability Issues in Dry Turning of DSS 2205. J. Vib. Eng. Technol. 2023, 11, 3135–3145. [Google Scholar] [CrossRef]

- Astakhov, V.P.; Shvets, S. The assessment of plastic deformation in metal cutting. J. Mater. Process. Technol. 2003, 146, 193–202. [Google Scholar] [CrossRef]

- Mativenga, P.T.; Abukhshim, N.A.; Sheikh, M.A.; Hon, B.K.K. An investigation of tool chip contact phenomena in high-speed turning using coated tools. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 657–667. [Google Scholar] [CrossRef]

- Schultheiss, F.; Hägglund, S.; Bushlya, V.; Zhou, J.; Ståhl, J.-E. Influence of the Minimum Chip Thickness on the Obtained Surface Roughness During Turning Operations. Procedia CIRP 2014, 13, 67–71. [Google Scholar] [CrossRef][Green Version]

- Skrzyniarz, M. A Method to Determine the Minimum Chip Thickness during Longitudinal Turning. Micromachines 2020, 11, 1029. [Google Scholar] [CrossRef] [PubMed]

- Krolczyk, G.; Legutko, S.; Gajek, M. Predicting the Surface Roughness in the Dry Machining of Duplex Stainless Steel (DSS). Metalurgija 2013, 52, 259–262. [Google Scholar]

- Aşcıoğlu, M.; Boy, M. Machining characteristics investigations of duplex stainless steel by considering dual effect of chip breaker and cooling conditions. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 7885–7898. [Google Scholar] [CrossRef]

- DIN EN 10088-1 [LST EN 10088-1:2024]; List of Stainless Steels. Lithuanian Standards Board (LST) Standards: Vilnius, Lithuania, 2024. Available online: https://vb.ktu.edu/permalink/f/1slhar4/LSDPRIMO709521 (accessed on 3 April 2024).

- ISO 4287:1997 [LST EN ISO 4287:2007]; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters. Lithuanian Standards Board (LST) Standards: Vilnius, Lithuania, 2007. Available online: https://vb.ktu.edu/primo-explore/fulldisplay?docid=KTU01000094054&vid=KTU&search_scope=KTU&tab=default_tab&lang=lt_LT&context=L (accessed on 3 April 2024).

- Canbolat, A.; Bademlioglu, A.; Arslanoglu, N.; Kaynakli, O. Performance optimization of absorption refrigeration systems using Taguchi, ANOVA and Grey Relational Analysis methods. J. Clean. Prod. 2019, 229, 874–885. [Google Scholar] [CrossRef]

- Felhő, C.; Tesfom, F.; Varga, G. ANOVA Analysis and L9 Taguchi Design for Examination of Flat Slide Burnishing of Unalloyed Structural Carbon Steel. J. Manuf. Mater. Process. 2023, 7, 136. [Google Scholar] [CrossRef]

- Kozik, V.; Barbusinski, K.; Thomas, M.; Sroda, A.; Jampilek, J.; Sochanik, A.; Smolinski, A.; Bak, A. Taguchi Method and Response Surface Methodology in the Treatment of Highly Contaminated Tannery Wastewater Using Commercial Potassium Ferrate. Materials 2019, 12, 3784. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|

| 0.03 | 1 | 2 | 0.035 | 0.015 | 21–23 | 2.5–3.5 | 4.5–6.5 | 0.1–0.22 |

| Parameters | Levels | ||||

|---|---|---|---|---|---|

| Description | Symbol | Unit | 1 | 2 | 3 |

| Cutting velocity | Vc | m/min | 150 | 200 | 250 |

| Feed | f | mm/rev | 0.05 | 0.1 | 0.15 |

| Cutting depth | ap | mm | 0.5 | 1.0 | 1.5 |

| Factors | Data of the Experiment | |||||

|---|---|---|---|---|---|---|

| Run Order | Cutting Velocity (m/min) | Feed (mm/rev) | Cutting Depth (mm) | Time of Experiment (s) | Material Removal Rate (mm3/min) | Volume of Removed Material (mm3) |

| 1 | 1 | 1 | 1 | 38 | 3750 | 2375 |

| 2 | 1 | 2 | 2 | 21 | 15,000 | 5250 |

| 3 | 1 | 3 | 3 | 15 | 33,750 | 8437.5 |

| 4 | 2 | 1 | 2 | 29 | 10,000 | 4833.3 |

| 5 | 2 | 2 | 3 | 17 | 30,000 | 8500 |

| 6 | 2 | 3 | 1 | 13 | 15,000 | 3250 |

| 7 | 3 | 1 | 3 | 24 | 18,750 | 7500 |

| 8 | 3 | 2 | 1 | 15 | 12,500 | 3125 |

| 9 | 3 | 3 | 2 | 11 | 37,500 | 6875 |

| Cutting Conditions | Output Results | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Run | Cutting Velocity | Feed | Depth of Cut | Surface Roughness | Chip Evaluation | Max Hardness | |||

| m/min | (mm/rev) | (mm) | Ra (µm) | Rz (µm) | Rz1max (µm) | Thickness (µm) | (CCR) | HV | |

| 1 | 150 | 0.05 | 0.5 | 0.448 | 3.177 | 3.373 | 105.2 | 2.1 | 241.4 |

| 2 | 150 | 0.1 | 1 | 0.974 | 5.696 | 6.502 | 189.05 | 1.9 | 266 |

| 3 | 150 | 0.15 | 1.5 | 2.155 | 10.483 | 11.056 | 277.4 | 1.85 | 235 |

| 4 | 200 | 0.05 | 1 | 0.433 | 3.133 | 3.512 | 116.7 | 2.33 | 256.2 |

| 5 | 200 | 0.1 | 1.5 | 1.023 | 6.375 | 8.009 | 164.7 | 1.65 | 277.1 |

| 6 | 200 | 0.15 | 0.5 | 2.637 | 11.993 | 12.854 | 208.33 | 1.39 | 260.7 |

| 7 | 250 | 0.05 | 1.5 | 0.554 | 3.936 | 4.497 | 98.24 | 1.97 | 248 |

| 8 | 250 | 0.1 | 0.5 | 0.746 | 4.41 | 5.098 | 160.7 | 1.61 | 248 |

| 9 | 250 | 0.15 | 1 | 1.885 | 10.473 | 12.541 | 238.6 | 1.59 | 280 |

| Run: | Cutting Conditions | ||

|---|---|---|---|

| Cutting Velocity (m/min) | Feed (mm/rev) | Cutting Depth (mm) | |

| Prediction | 250 | 0.05 | 1 |

| Level | Vc | f | ap |

|---|---|---|---|

| 1 | 0.1781 | 6.4582 | 0.3658 |

| 2 | −0.4498 | 0.8588 | 0.6643 |

| 3 | 0.7229 | −6.8658 | −0.5789 |

| Delta | 1.1728 | 13.3240 | 1.2432 |

| Rank | 3 | 1 | 2 |

| Run: | Cutting Conditions | ||

|---|---|---|---|

| Cutting Velocity (m/min) | Feed (mm/rev) | Cutting Depth (mm) | |

| Prediction | 250 | 0.15 | 0.5 |

| Level | Vc | f | ap |

|---|---|---|---|

| 1 | −5.788 | −6.560 | −4.480 |

| 2 | −4.852 | −4.687 | −5.650 |

| 3 | −4.685 | −4.077 | −5.194 |

| Delta | 1.103 | 2.483 | 1.170 |

| Rank | 3 | 1 | 2 |

| Source | DF | Seq SS | Adj SS | Adj MS | F | P | Contribution (%) | Significance |

|---|---|---|---|---|---|---|---|---|

| Cutting velocity | 2 | 2.066 | 2.066 | 1.033 | 0.31 | 0.766 | 0.74 | Non-significant |

| Feed | 2 | 268.550 | 268.550 | 134.275 | 39.71 | 0.025 | 95.94 | Significant |

| Cutting depth | 2 | 2.527 | 2.527 | 1.263 | 0.37 | 0.728 | 0.903 | Non-significant |

| Residual Error | 2 | 6.763 | 6.763 | 3.382 | ||||

| Total | 8 | 279.907 |

| Source | DF | Seq SS | Adj SS | Adj MS | F | P | Contribution (%) | Significance |

|---|---|---|---|---|---|---|---|---|

| Cutting velocity | 2 | 2.120 | 2.120 | 1.0598 | 1.81 | 0.356 | 13.74 | Non-significant |

| Feed | 2 | 10.046 | 10.046 | 5.0232 | 8.59 | 0.104 | 65.14 | Non-significant |

| Cutting depth | 2 | 2.085 | 2.085 | 1.0427 | 1.78 | 0.359 | 13.52 | Non-significant |

| Residual Error | 2 | 1.170 | 1.170 | 0.5850 | ||||

| Total | 8 | 15.421 |

| Taguchi Analysis: Surface Roughness Ra | Taguchi Analysis: CCR | ||||

|---|---|---|---|---|---|

| S | R-Sq | R-Sq(adj) | S | R-Sq | R-Sq(adj) |

| 1.8389 | 97.58% | 90.33% | 0.7648 | 92.41% | 69.65% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gyliene, V.; Brasas, A.; Ciuplys, A.; Jablonskyte, J. Optimization of the Surface Roughness and Chip Compression Ratio of Duplex Stainless Steel in a Wet Turning Process Using the Taguchi Method. Machines 2024, 12, 437. https://doi.org/10.3390/machines12070437

Gyliene V, Brasas A, Ciuplys A, Jablonskyte J. Optimization of the Surface Roughness and Chip Compression Ratio of Duplex Stainless Steel in a Wet Turning Process Using the Taguchi Method. Machines. 2024; 12(7):437. https://doi.org/10.3390/machines12070437

Chicago/Turabian StyleGyliene, Virginija, Algimantas Brasas, Antanas Ciuplys, and Janina Jablonskyte. 2024. "Optimization of the Surface Roughness and Chip Compression Ratio of Duplex Stainless Steel in a Wet Turning Process Using the Taguchi Method" Machines 12, no. 7: 437. https://doi.org/10.3390/machines12070437

APA StyleGyliene, V., Brasas, A., Ciuplys, A., & Jablonskyte, J. (2024). Optimization of the Surface Roughness and Chip Compression Ratio of Duplex Stainless Steel in a Wet Turning Process Using the Taguchi Method. Machines, 12(7), 437. https://doi.org/10.3390/machines12070437