Estimation of Tire Side-Slip Angles Based on the Frequency Domain Lateral Acceleration Characteristics Inside Tires

Abstract

1. Introduction

2. Experimental Device and Design

2.1. Design of Intelligent Tire Testing System

2.2. Experimental Design

3. Analysis of Lateral Acceleration-Related Side-Slip Angle Characteristics

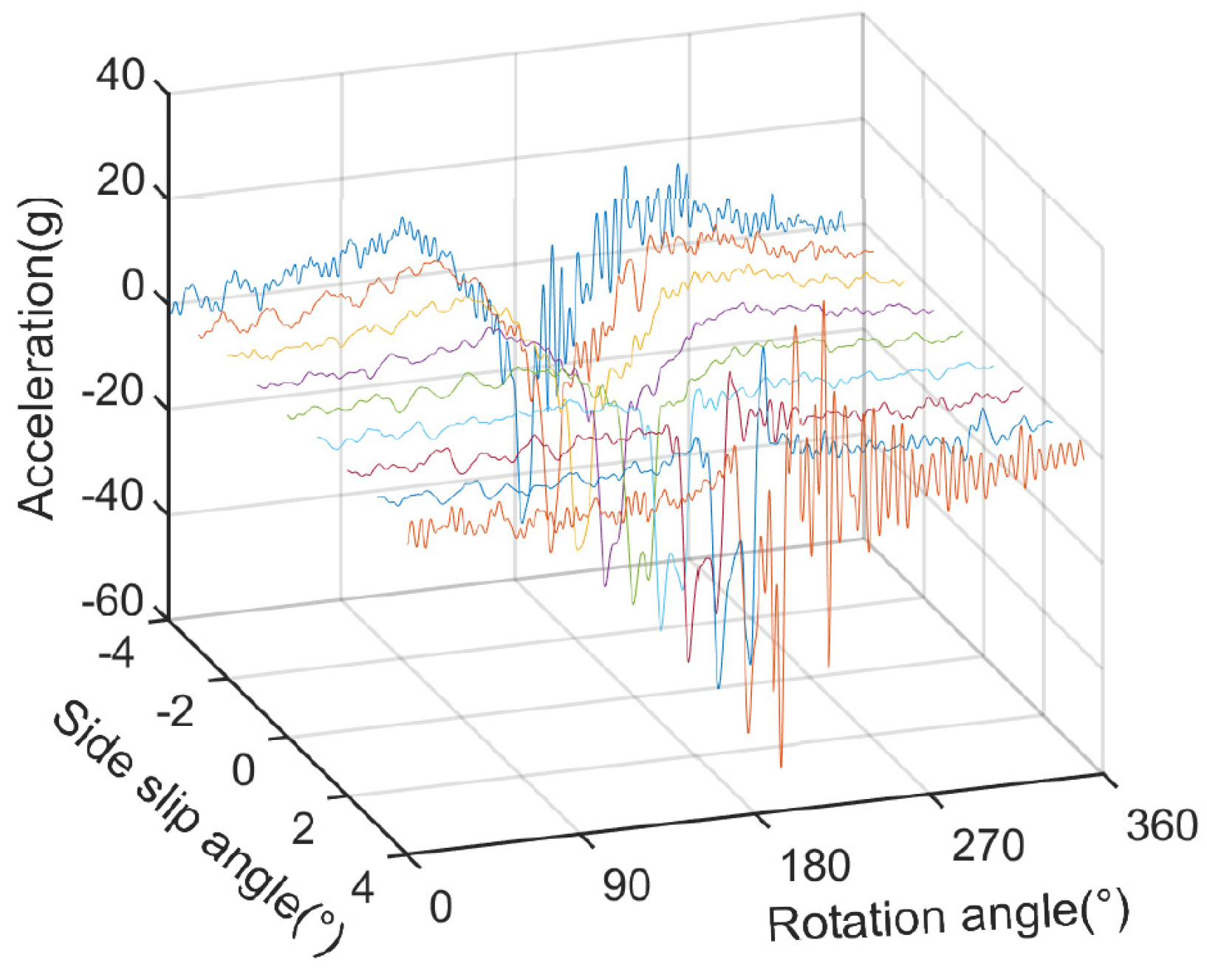

3.1. Effect of Side-Slip Angle on the Acceleration Ay3 in Time and Frequency Domains

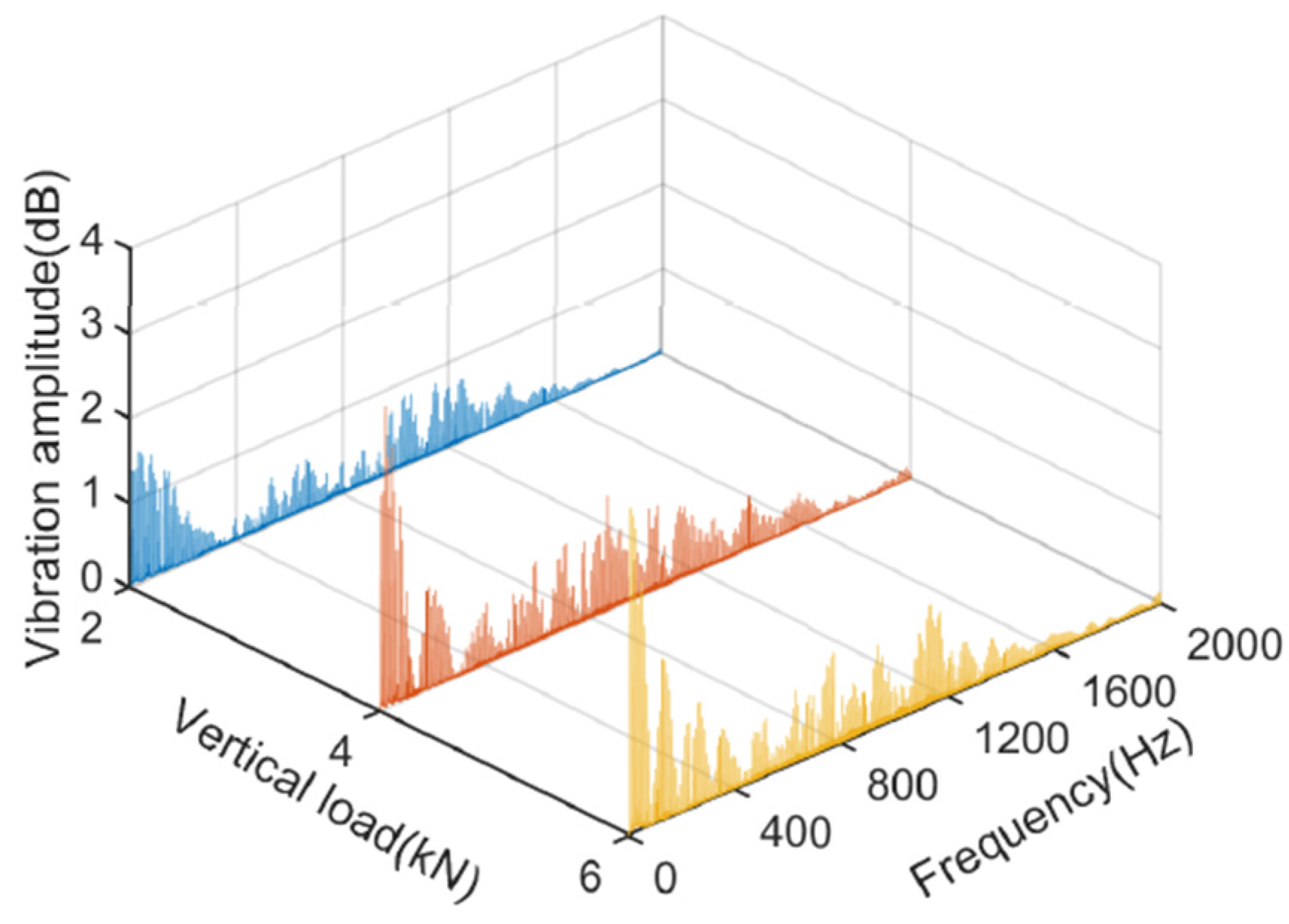

3.2. Effect of Vertical Load on Acceleration Frequency Domain Signal

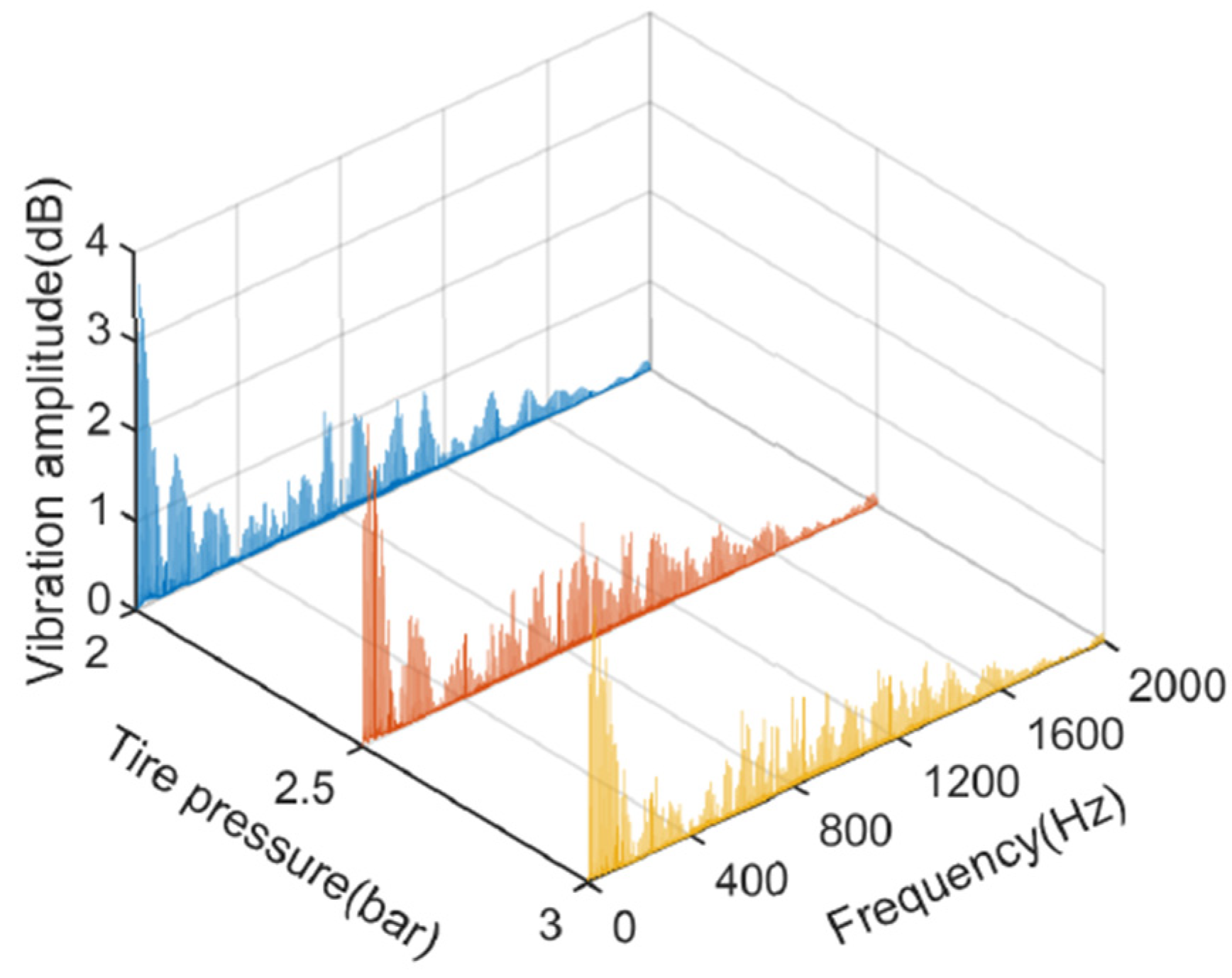

3.3. Effect of Tire Pressure on Acceleration Frequency Domain Signal

4. Estimating Side-Slip Angle Based on Support Vector Machines

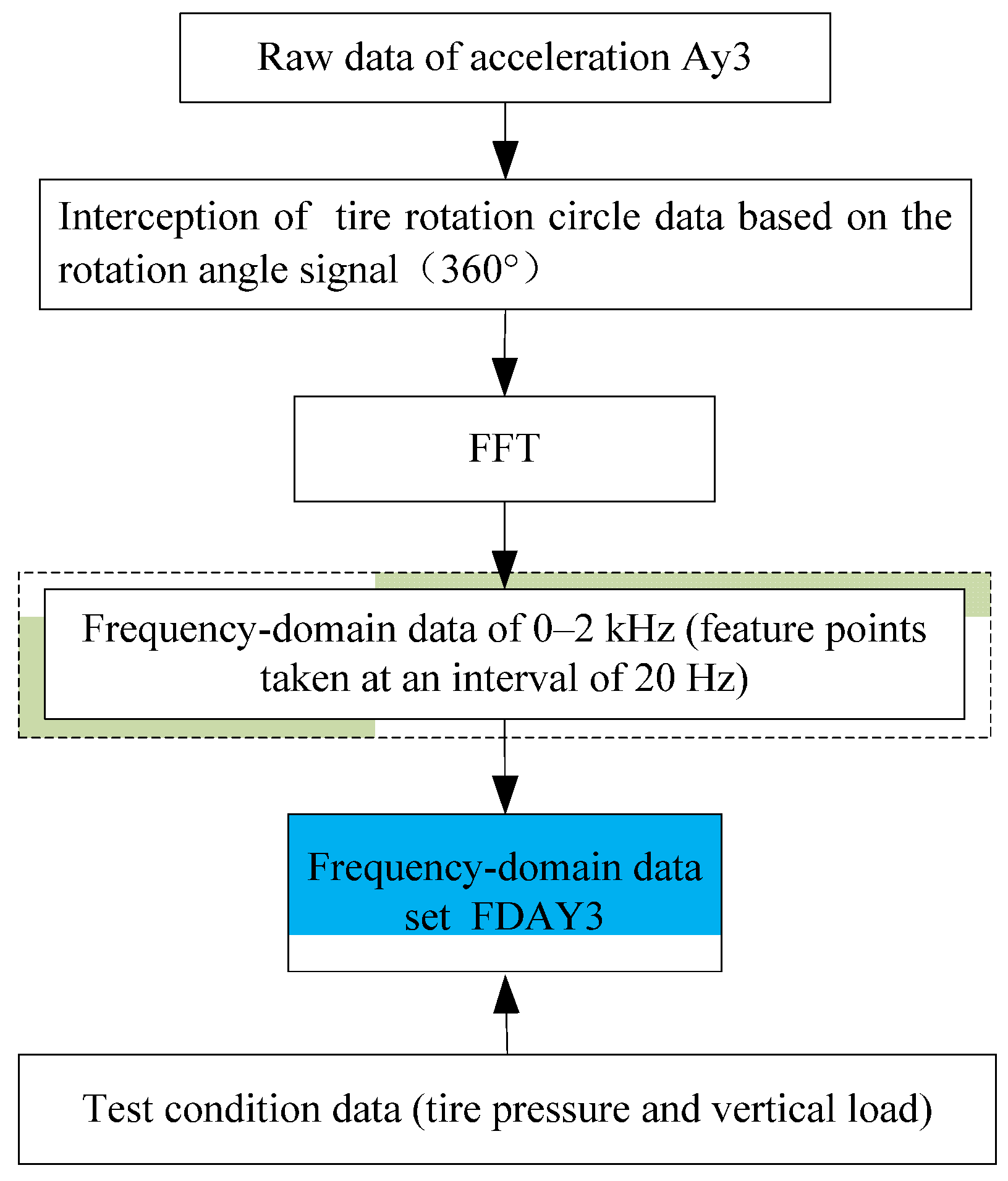

4.1. Data Set Construction

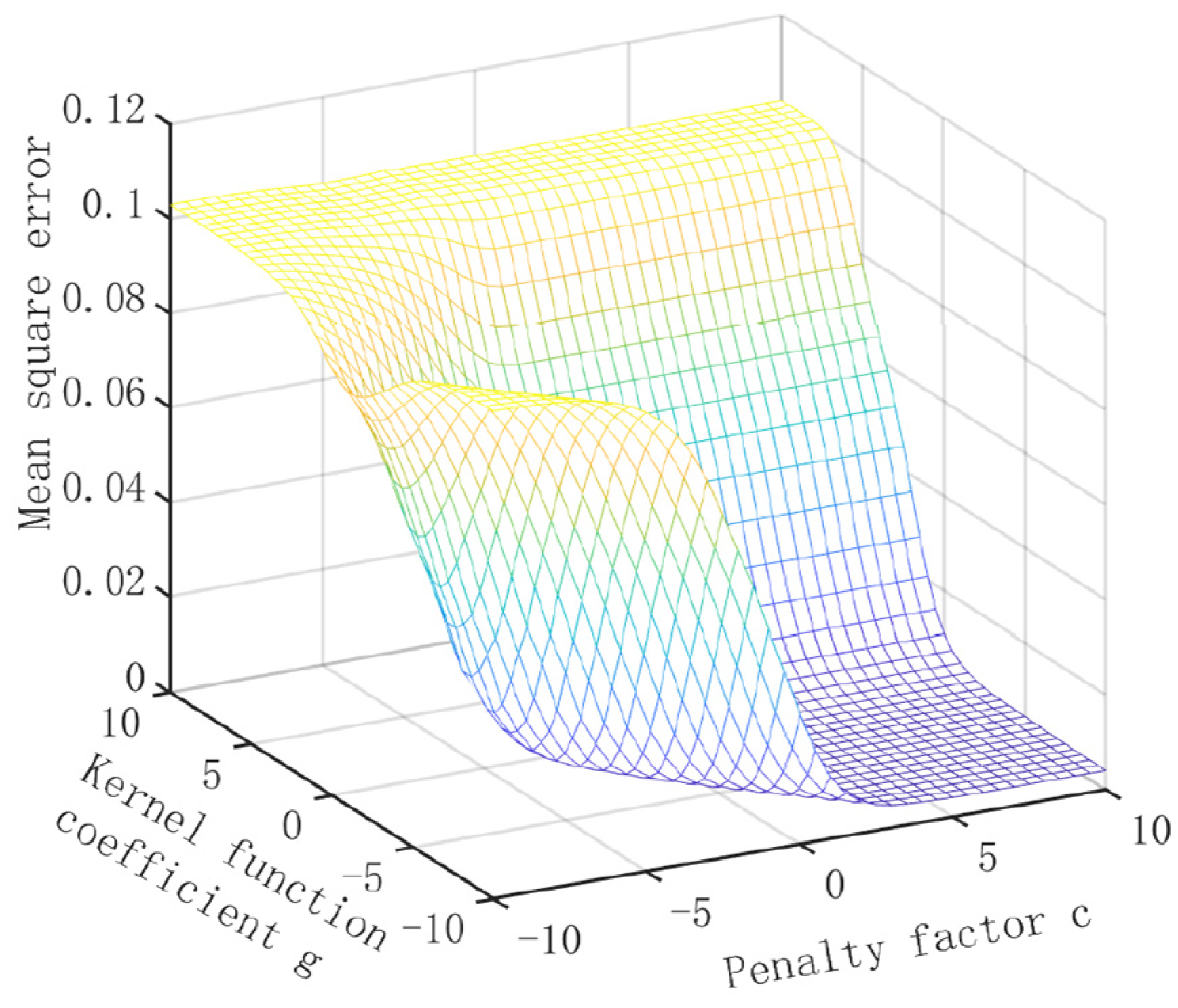

4.2. SVM Parameter Optimization

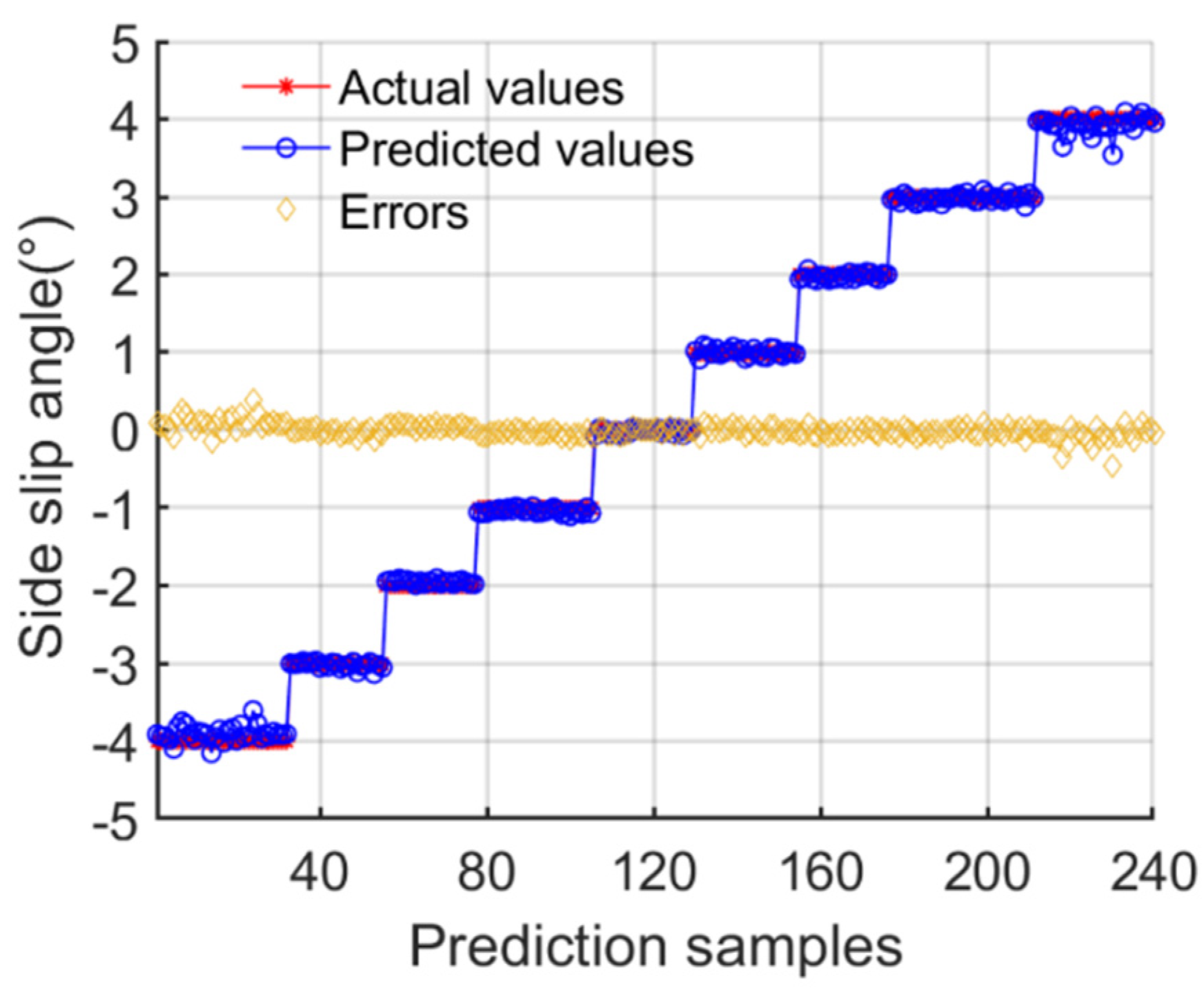

4.3. Model Estimation and Analysis

5. Conclusions

- (1)

- This paper conducted lateral deflection tests by arranging one triaxial acceleration at the right sidewall position of the tire and building a smart tire test system on a Flat Trac bench with 3 mite 120 grit sandpaper on the road surface. When the camber angle is 0, it is found that the vibration amplitude of lateral acceleration Ay3 decreases gradually with the increase in the lateral deflection angle from −4° to 4° in the frequency domain of 400 Hz, and the vibration amplitude is significantly correlated with the lateral deflection angle in the range of 0.5~2 kHz. The influence of rotational speed on frequency response is not checked in this paper and will be discussed in the future.

- (2)

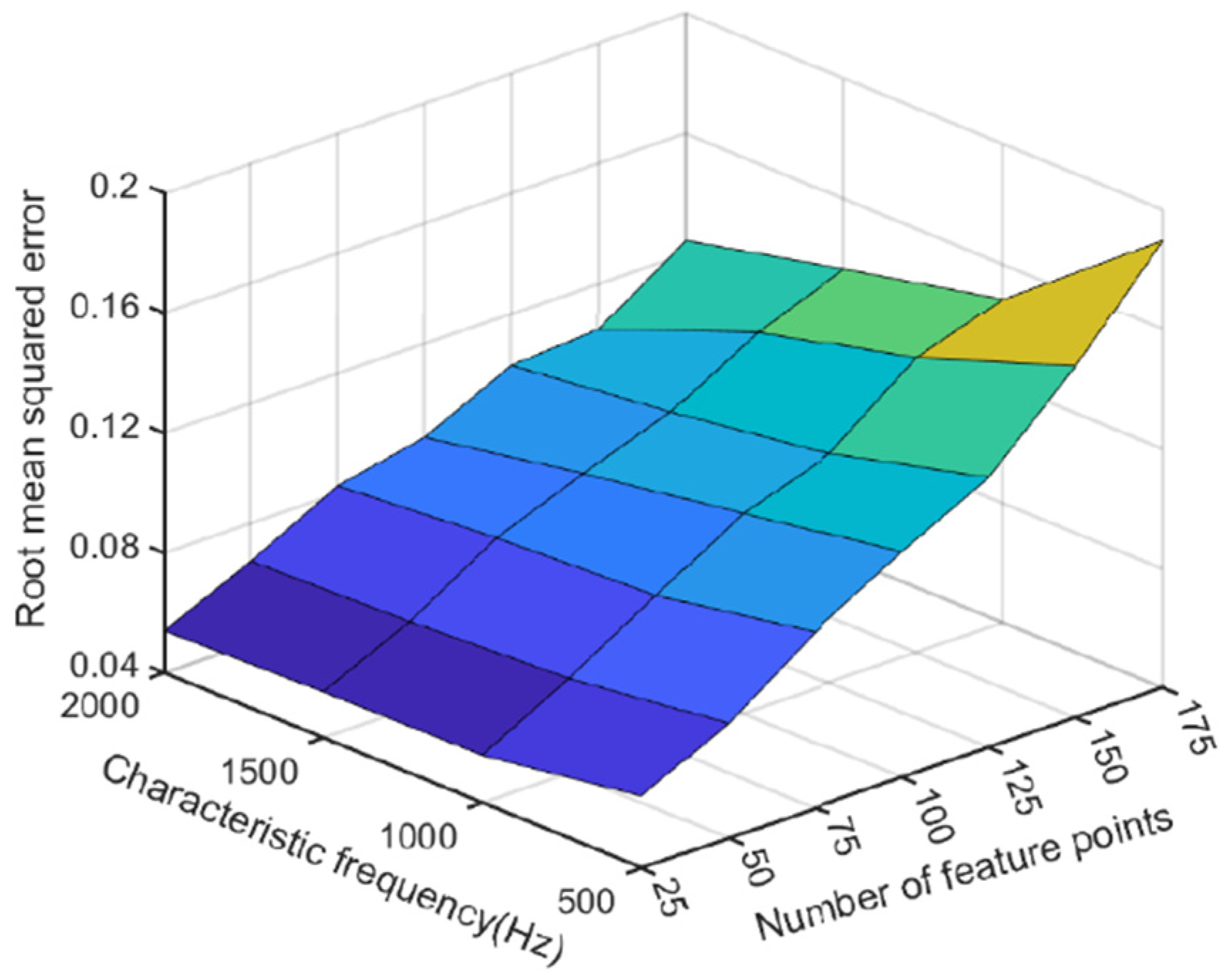

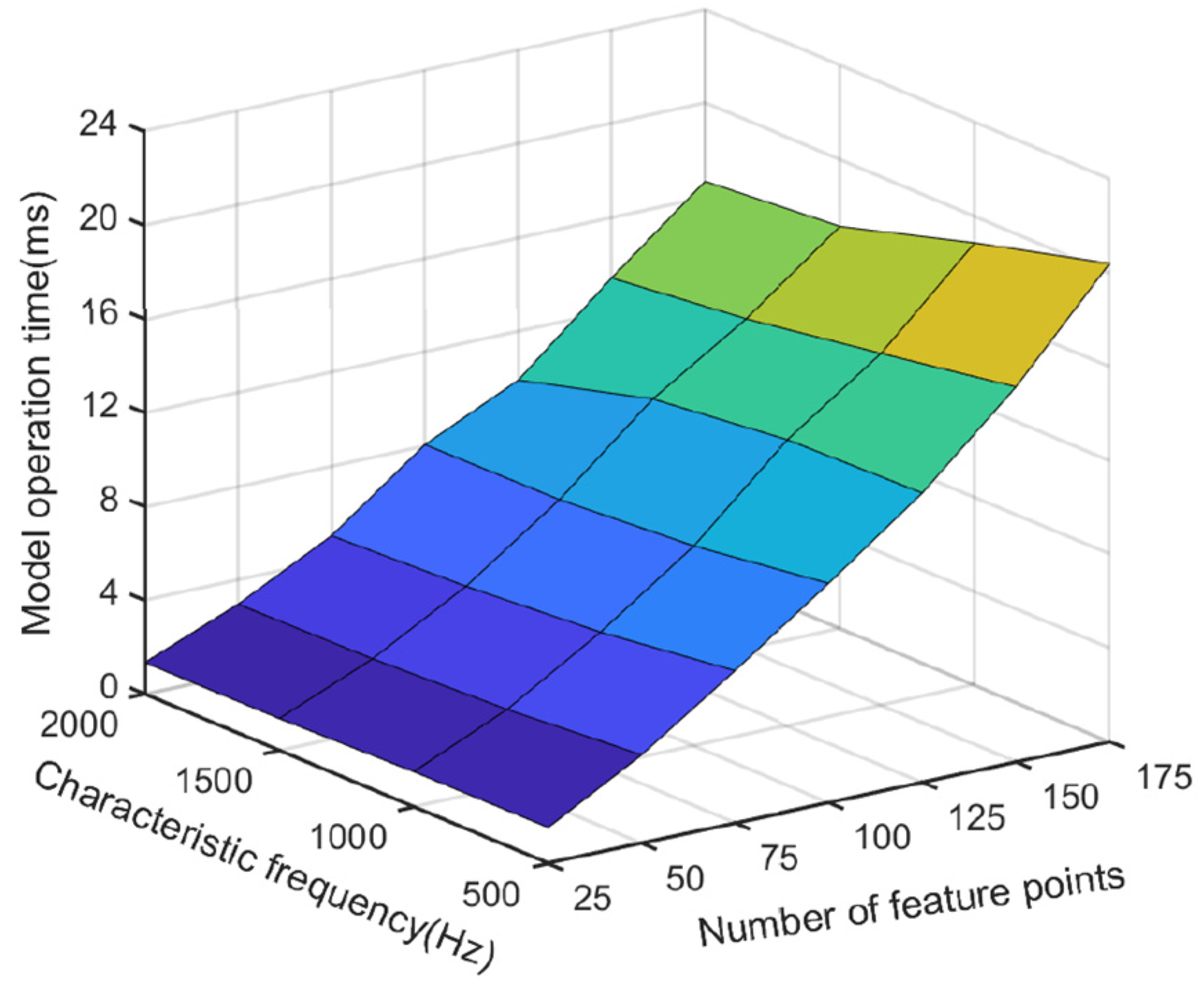

- Based on the characteristic frequency band and the number of feature points, the frequency domain vibration amplitude of lateral acceleration Ay3 was extracted to construct a data set, and SVM was employed to predict the tire side-slip angle. Then, by taking the characteristic frequency band and the number of feature points as independent variables, multiple sets of frequency domain data sets were established and applied to the model. The results indicated that when the characteristic frequency band was selected within 500 Hz, the Ay3 data set with 25 feature points contributed to the optimal prediction accuracy and real-time performance. The tire side deflection angle estimation method proposed in this paper has been validated on the bench, but considering the applicability of the method on actual road surfaces, road studies will be carried out at a later stage for correcting the side deflection angle estimation model. In practice, the acceleration sampling frequency of the Infineon-based SP40T controller can reach more than 1 kHz. Therefore, this study provides a new method for side-slip angle estimation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yu, Z.; Gao, X. Review of vehicle state estimation problem under driving situation. Image. Chin. J. Mech. Eng. 2009, 45, 20–33. [Google Scholar] [CrossRef]

- Li, K.; Luo, Y.; Chen, H.; Bian, M.; Zhao, Z.; Chen, L.; Chu, W.; Dai, Y.; Gao, B. State Estimation and Identification of Advanced Electric Vehicle; China Machine Press: Beijing, China, 2019. [Google Scholar]

- Xiong, Y.; Saif, M. Sliding mode observer for nonlinear uncertain systems. IEEE Trans. Autom. Control 2001, 46, 2012–2017. [Google Scholar] [CrossRef]

- Marino, R.; Scalzi, S. Asymptotic sideslip angle and yaw rate decoupling control in four-wheel steering vehicles. Veh. Syst. Dyn. 2010, 48, 999–1019. [Google Scholar] [CrossRef]

- Baffet, G.; Charara, A.; Lechner, D. Estimation of vehicle sideslip, tire force and wheel cornering stiffness. Control Eng. Pract. 2009, 17, 1255–1264. [Google Scholar] [CrossRef]

- Lian, Y.F.; Zhao, Y.; Hu, L.L.; Tian, Y.T. Cornering stiffness and sideslip angle estimation based on simplified lateral dynamic models for four-in-wheel-motor-driven electric vehicles with lateral tire force information. Int. J. Automot. Technol. 2015, 16, 669–683. [Google Scholar] [CrossRef]

- Mosconi, L.; Farroni, F.; Sakhnevych, A.; Timpone, F.; Gerbino, F. Adaptive vehicle dynamics state estimator for onboard automotive applications and performance analysis. Veh. Syst. Dyn. 2022, 61, 1–25. [Google Scholar] [CrossRef]

- Cheli, F.; Sabbioni, E.; Pesce, M.; Melzi, S. A methodology for vehicle sideslip angle identification: Comparison with experimental data. Veh. Syst. Dyn. 2007, 45, 549–563. [Google Scholar] [CrossRef]

- Li, S.; Wang, G.; Yang, Z.; Wang, X. Dynamic joint estimation of vehicle sideslip angle and road adhesion coefficient based on DRBF-EKF algorithm. Chin. J. Theor. Appl. Mech. 2022, 54, 1853–1865. [Google Scholar]

- Chindamo, D.; Gadola, M. Estimation of vehicle side-slip angle using an artificial neural network. MATEC web of conferences. EDP Sci. 2018, 166, 02001. [Google Scholar]

- Zhang, X.; Chen, B.; Song, J.; Wang, Q. Test method research on vehicle’s tire side slip angle in extreme driving conditions. Trans. Chin. Soc. Agric. Mach. 2014, 45, 31–36. [Google Scholar]

- Reina, G.; Ishigami, G.; Nagatani, K.; Yoshida, K. Vision-based estimation of slip angle for mobile robots and planetary rovers. In Proceedings of the 2008 IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 486–491. [Google Scholar]

- Xiong, L.; Xia, X.; Lu, Y.; Liu, W.; Gao, L.; Song, S.; Han, Y.; Yu, Z. IMU-based automated vehicle slip angle and attitude estimation aided by vehicle dynamics. Sensors 2019, 19, 1930. [Google Scholar] [CrossRef] [PubMed]

- Joa, E.; Yi, K.; Hyun, Y. Estimation of the tire slip angle under various road conditions without tire–road information for vehicle stability control. Control Eng. Pract. 2019, 86, 129–143. [Google Scholar] [CrossRef]

- Waluś, K.J. Experimental determination of vehicle lateral drift characteristics under laboratory conditions. Appl. Mech. Mater. 2012, 232, 836–840. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Kamai, K.; Seki, R. Intelligent tires for identifying coefficient of friction of tire/road contact surfaces using three-axis accelerometer. Smart Mater. Struct. 2014, 24, 025010. [Google Scholar] [CrossRef]

- Mancosu, F.; Brusarosco, M.; Arosio, D. Method and System for Determining a Cornering Angle of a Tyre During the Running of a Vehicle. U.S. Patent 8024087, 20 September 2011. [Google Scholar]

- Xu, N.; Huang, Y.; Askari, H.; Tang, Z. Tire slip angle estimation based on the intelligent tire technology. IEEE Trans. Veh. Technol. 2021, 70, 2239–2249. [Google Scholar] [CrossRef]

- Singh, K.B.; Taheri, S. Accelerometer based method for tire load and slip angle estimation. Vibration 2019, 2, 174–186. [Google Scholar] [CrossRef]

- Mancosu, F.; Brusarosco, M.; Arosio, D. Method and System for Determining a Cornering Angle of a Tyre During the Running of a Vehicle. U.S. Patent 7552628, 30 June 2009. [Google Scholar]

- Erdogan, G.; Alexander, L.; Rajamani, R. A novel wireless piezoelectric tire sensor for the estimation of slip angle. Meas. Sci. Technol. 2009, 21, 015201. [Google Scholar] [CrossRef]

- Tao, L.; Zhang, D.; Zhang, X.; Pan, D.; Zhan, Q. Design and experiment of special rim assembly for intelligent tire development platform. China Mech. Eng. 2023, 34, 1111–1119. [Google Scholar]

- Manfred, M.; Henning, W. Dynamik der Kraftfahrzeuge; Tsinghua University Press: Beijing, China, 2009. [Google Scholar]

- Zhang, X.; Chen, B.; Song, J.; Pan, D. Experimental research on real-time prediction method for road slope based on support vector machine. Trans. Chin. Soc. Agric. Mach. 2014, 45, 14–19. [Google Scholar]

- Wang, Y.; Liang, G.; Wei, Y. Road identification algorithm od intelligent tire based on support vector machine. Automot. Eng. 2020, 42, 9. [Google Scholar]

| No. | Vertical Load (N) | Tire Pressure (bar) | Speed (km/h) | Side-Slip Angle (°) | Duration of Each Side-Slip Angle (s) |

|---|---|---|---|---|---|

| 1 | 2000 | 3.0 | 60 | 0 ±1 ±2 ±3 ±4 | 10 |

| 2 | 4000 | ||||

| 3 | 6000 | ||||

| 4 | 2000 | 2.5 | |||

| 5 | 4000 | ||||

| 6 | 6000 | ||||

| 7 | 2000 | 2.0 | |||

| 8 | 4000 | ||||

| 9 | 6000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Y.; Tao, L.; Li, Y.; Zhang, D.; Zhang, X. Estimation of Tire Side-Slip Angles Based on the Frequency Domain Lateral Acceleration Characteristics Inside Tires. Machines 2024, 12, 229. https://doi.org/10.3390/machines12040229

Tang Y, Tao L, Li Y, Zhang D, Zhang X. Estimation of Tire Side-Slip Angles Based on the Frequency Domain Lateral Acceleration Characteristics Inside Tires. Machines. 2024; 12(4):229. https://doi.org/10.3390/machines12040229

Chicago/Turabian StyleTang, Yu, Liang Tao, Yuanqiang Li, Dashan Zhang, and Xiaolong Zhang. 2024. "Estimation of Tire Side-Slip Angles Based on the Frequency Domain Lateral Acceleration Characteristics Inside Tires" Machines 12, no. 4: 229. https://doi.org/10.3390/machines12040229

APA StyleTang, Y., Tao, L., Li, Y., Zhang, D., & Zhang, X. (2024). Estimation of Tire Side-Slip Angles Based on the Frequency Domain Lateral Acceleration Characteristics Inside Tires. Machines, 12(4), 229. https://doi.org/10.3390/machines12040229