1. Introduction

Efficient assembly of industrial equipment structures is paramount in the realm of mechanical equipment development. It holds a pivotal role in determining production costs, development timelines, and the ultimate performance of the equipment. In fact, assembly alone accounts for a substantial 45% of the overall production process, underscoring its significance [

1]. As we delve into the modern era of high-performance industrial equipment design and manufacturing, the demand for precision or even ultra-precision in component design and processing has become the norm [

2]. However, achieving the desired performance and quality of assembled equipment hinges on a sufficient understanding of the state of the assembly structure and reasonable planning and execution of the assembly process [

3].

This challenge is particularly pronounced when dealing with large-scale and non-standard industrial equipment, characterized by unique designs, irregular shapes, and specialized functionalities [

4,

5,

6]. Unlike standardized components, large non-standard structures require highly customized solutions, making the assembly process complex and reliant on precision engineering.

When comparing the assembly of large non-standard structures to conventional ones, several unique challenges emerge, including customization and variability, geometric assurance, material and manufacturing variability, support for process equipment, and feasibility verification, as shown in

Table 1.

Large non-standard structures demand extensive customization, often leading to substantial rework and component rearrangement to accommodate design changes. Achieving precision in these scenarios is challenging due to the custom nature of components. Moreover, material and manufacturing variations add complexity to the assembly, even if individual components meet design standards [

7]. Often, a relatively small variation in a component, due to its large size, will lead to significant variation in the final assembly. Typically, it necessitates multiple rounds of trial fitting, adjustments, and, in some cases, even disassembly and rework, which results in greater cost consumption in terms of economy, energy and time [

8].

Facilitating the assembly of large non-standard structures presents unique challenges. It often involves custom process equipment, meticulous assembly route planning, and access to ample environmental resources, diverging from standard setups. These distinctive demands amplify the complexities of assembling large non-standard structures. Additionally, evaluating the viability of manual assembly processes becomes crucial, especially when human operators are required for specific tasks within the structure. Ensuring safety, ergonomics, and efficiency in such scenarios is a multifaceted endeavor.

Given these pressing issues, it becomes evident that the development and expansion of enabling technologies for the assembly of large-scale, non-standard equipment structures are of paramount engineering importance. The application and advancement of emerging technologies such as artificial intelligence (AI), Internet of Things (IoT), and Big Data in the mechanical manufacturing process serve as crucial catalysts for driving the transformation of the traditional manufacturing industry [

9,

10]. The integration of a new generation of information technologies (New ITs) and the manufacturing industry has resulted in the emergence of novel technological methods, business forms, and development models [

11,

12,

13]. In this context, digital twin (DT) technologies, along with the Industrial Internet and Cyber Physical System (CPS), are driving the digitalization of manufacturing. This has ushered in the era of intelligent assembly for mechanical systems, emphasizing the seamless integration of digital and physical information in the assembly process [

14,

15]. Technologies such as DT are employed to enable the digital application of multi-domain models and facilitate global process intelligence optimization in the assembly of mechanical products.

From the standpoint of equipment structure assembly, DT technologies facilitate data exchange between physical and digital spaces. Through continuous exploration by experts and scholars in the field of DT-based assembly at the equipment level, several key aspects have been identified, including DT model construction, assembly process optimization and the integrated application of intelligent assembly technologies [

16,

17,

18]. Regarding DT virtual modeling, Liu et al. [

19] proposed a method for expressing the DT assembly model that integrates multi-level information. By employing techniques such as point cloud fitting, homogeneous coordinate transformation, and Hertz contact theory, they successfully constructed the DT model of assembly parts. Schleich et al. [

20], on the other hand, utilized a comprehensive digital model based on the concept of skin model shape to represent complex products virtually. They discussed the conceptualization, representation, and implementation of models in the product life cycle using this DT modeling technology. Concerning assembly process optimization, Hu et al. [

21] investigated the method for characterizing the assembly process by coupling offline and online data. They employed DT technology to achieve operational process control and data processing for mechanical equipment at different abstraction levels. Li et al. [

22] designed a DT system that supports real-time monitoring of aircraft assembly processes. Based on the hierarchical representation of time series information and the construction of multi-dimensional data cubes, the efficient collection and traceability of assembly data were achieved. Zhang et al. [

23] conducted research on process optimization technologies for micro assembly products based on DT, achieving evaluation and guidance of processes from the perspectives of the process optimization rate and process confidence. Furthermore, in the context of integrated intelligent assembly technologies, researchers have explored innovative engineering applications in assembly visualization guidance, data management, traceability, and shop control by integrating DT concepts [

24,

25,

26]. These advancements have enabled the seamless integration of virtual and physical information, leading to enhanced collaboration and coordination between digital and physical entities during assembly operations. These studies demonstrate the value and innovation of integrated intelligent assembly technologies, highlighting the potential for improving transparency, accuracy, and efficiency in industrial equipment production processes.

However, within the context of large-scale non-standard structural assembly, certain gaps exist. A dedicated DT-based intelligent assembly technology for such structures is lacking, necessitating a holistic solution that accounts for discrete manufacturing and human intervention. Furthermore, the integration of structural and assembly DT models is often overlooked. Practical applications of DT technologies in large-scale industrial equipment contexts remain limited.

This paper aims to develop a technology paradigm for the intelligent assembly of large-scale non-standard equipment structures using DT. It focuses on real-time mapping, integration, and interactive updating of geometric states, physical characteristics, behavioral aspects, and rule information of the assembly process. The proposed technologies are validated in the assembly of a piece of large-scale aerodynamic experimental equipment, offering a viable pathway for the intelligent assembly of industrial equipment structures.

2. Dual-Level Mapping Model for Large Equipment Intelligent Assembly Driven by DT

In the quest for achieving assembly excellence in the context of large non-standard equipment structures, the pressing need for adopting an integrated structural and process modeling paradigm becomes increasingly evident. These expansive structures require a comprehensive approach that goes beyond traditional methodologies. The assembly process, both intricate and pivotal, extends beyond the physical act of component integration. It represents a fusion of design intricacies, structural soundness, and logistical efficiency. This calls for a synchronized interplay between the tangible and the digital, where the physical world converges with the virtual realm.

DT construction for large non-standard equipment structure assembly primarily achieves a dual-level mapping. At the lower level, it involves mapping the physical model to a digital representation of the equipment, while at the higher level, it encompasses mapping the real assembly process to a digital representation. The mapping at the lower level eliminates the need for physically constructing the equipment model, while simultaneously facilitating design rationality analysis and the prediction of structural performance. On the other hand, the mapping at the higher level enables planning, verification, and evaluation of equipment assembly processes.

In this paper, the model of the equipment structure and assembly process built based on DT is defined as the DT-Based Large-Scale Assembly Model (DT-LAM). DT-LAM is divided into two sub-models, the DT-Based Large Assembly Object Model (DT-LAOM) and the DT-Based Large Assembly Process Model (DT-LAPM), based on the two levels of classification. DT-LAOM encompasses component models and related information for each level of the assembly, and DT-LAPM consists of assembly process plan information, including the assembly sequence, assembly path, and assembly simulation analysis results.

The DT-LAM plays a crucial role in encompassing, processing, and analyzing the information related to structural assembly across various physical fields, dimensions, and levels of granularity throughout the actual assembly process. It enables the evaluation, simulation, and prediction of assembly models and processes, ultimately achieving the objective of aligning the real and virtual aspects of large and complex assembly processes. This integration ensures the accuracy and rationality of the actual assembly, contributing to improved assembly precision and process control. The flow of the DT-LAM-based intelligent assembly technology implementation is shown in

Figure 1.

2.1. DT-Based Large Assembly Object Model (DT-LAOM)

In the context of large-scale assembly, DT-LAOM plays a pivotal role as a mapping object within the virtual environment. It represents the intricate entities involved in the assembly process. For the assembly of sizable structures, DT-LAOM must encapsulate the entire assembly process, offering support for collaborative process design and enabling comprehensive simulation analysis of global model characteristics. This is essential given the magnitude of large-scale assembly projects, where precision and efficiency are paramount. DT-LAOM encompasses data ranging from individual components to subassemblies and the assembly structure itself, providing a multi-level view of the assembly. What sets it apart in the realm of large structures is the integration of actual measured structural data, such as point cloud model information. This fusion of commonly used CAD model representations and real-world engineering measurements ensures the fidelity of DT-LAOM, allowing for structural accuracy assessment and high-precision geometric simulations tailored to various assembly scenarios.

2.2. DT-Based Large Assembly Process Model (DT-LAPM)

In the context of the discrete assembly of large and non-standard equipment, DT-LAPM represents an indispensable bridge between the digital and physical realms. It harmonizes model-based definition process model information with real-time assembly process data from the assembly site. Herein lies a unique challenge: the scale and complexity of large assembly structures necessitate a meticulous division of DT-LAPM into two crucial components—the Assembly In-Process Model (AIPM) and the Assembly Process Information Data (APID). The relationship between DT-LAPM, AIPM, and APID is represented as:

AIPM comprises the assembly process model of the current completed assembly and the models of parts to be assembled in subsequent steps of the process. It is initialized based on the parts involved and their assembly order in the first assembly process, and it iteratively evolves as the actual assembly process progresses until all assembly steps are completed. The evolution of AIPM can be expressed as:

where

i denotes the

ith assembly process,

k denotes the current assembly step within the

ith process,

n represents the total number of assembly steps for the

ith process, and

P represents the parts assembled in the current step.

APID encompasses all of the assembly process information input into the actual assembly process, consisting of As-Built Assembly Process Information (AAPI) and Pre-Planned Assembly Process Information (PAPI). It is evident that AAPI is an updated version of PAPI based on the actual assembly situation and contributes to the establishment of a closed-loop optimized product assembly process system. This dynamic integration of data is essential for establishing a closed-loop optimized assembly process system, a critical need in the context of large-scale assembly where efficiency and precision are paramount. Thus, APID is defined as a collection of PAPI and AAPI, and its Assembly Mapping Rule (AMR) from the physical space to virtual space can be represented as:

The precise construction and application of DT-LAOM and DT-LAPM present a unique challenge driven by the sheer complexity and scale of the associated assembly. By rationalizing and clarifying the composition and expression of the dual-level mapping model of a large equipment assembly, it provides a theoretical basis for the creation and application of the DT model of the assembly structure and process for each level.

3. DT-LAOM for Large Non-Standard Industrial Equipment

3.1. DT-LAOM Information Composition

In the context of assembling large non-standard industrial equipment, the assembly process unfolds in a distinct manner, encompassing various phases and stages. These stages include partial and total assembly, resulting in the gradual formation of structural components within the equipment. Given this intricate process, the DT-LAOM must meticulously encompass all geometric and physical state information concerning these component entities throughout the entire assembly, a crucial requirement for its effectiveness.

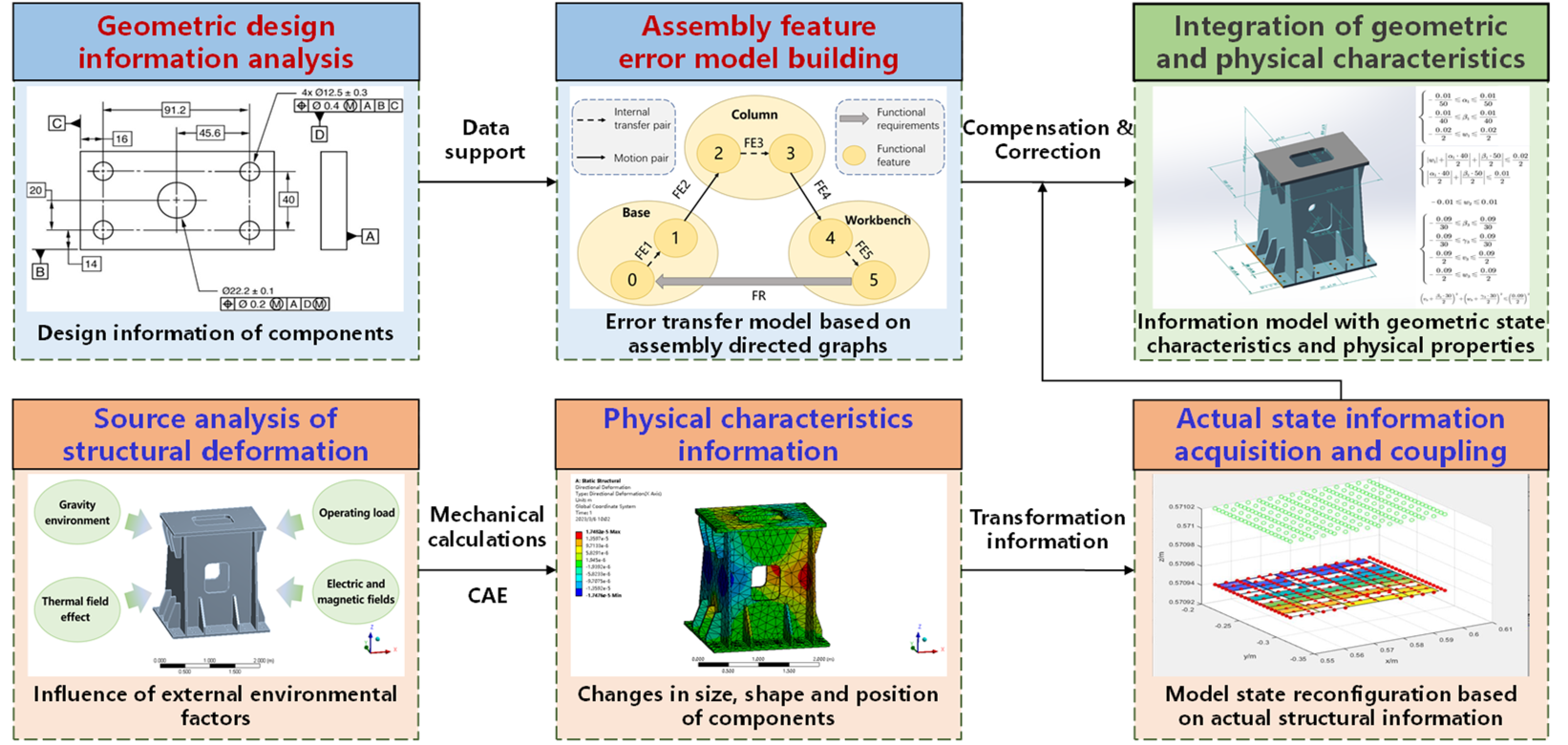

The establishment of DT-LAOM in various assembly process units demands the effective integration and coherent representation of multi-domain information for real parts [

27]. In the context of intelligent industrial equipment assembly applications, a DT-LAOM information structure based on assembly process units is illustrated in

Figure 2. Within each assembly process unit, the entities categorized as “to-be-assembled”, “being assembled”, and “after assembly” possess hierarchical information aligned with the same architecture. The DT-LAOM information structure delineates a structural assembly information hierarchy comprising a geometric design information layer and a physical characteristics information layer. This structure facilitates a systematic and comprehensive representation of the equipment assembly, encompassing crucial data related to geometry and physical attributes for effective intelligent assembly operations.

The geometric design information layer within DT-LAOM encompasses critical parameters of structural characteristics, GD&T (geometric dimensioning and tolerancing), and model reconstruction data, among others. These components collectively provide a complete representation of the structural morphology, component relationships, and dimensional errors within the digital space, supporting essential functions such as model visualization, tolerance evaluation, and data-driven model updating. The physical characteristic information layer of DT-LAOM comprises crucial attributes such as the positional attitude of components, material properties of the structure, and assembly loads. This layer equips the model with multiple physical attributes, including kinematics, dynamics, and thermodynamics. Leveraging this information layer, the calibration and analysis of the mechanical properties of the assembly structure can be effectively realized. Moreover, upon acquiring the actual attribute information of the component objects in the physical space, it becomes essential to integrate the real measurement data into the assembly structure model in the digital space. This integration drives the model to undergo iterative updating, ensuring a high level of consistency between the constructed digital model and the actual physical structure. Consequently, this process guarantees the authenticity and accuracy of subsequent simulation and optimization work based on DT-LAOM.

3.2. Data-Driven Geometric Feature Update

To realize the iteration and reconfiguration of the geometric shape of DT-LAOM with the state of the physical structure, this section proposes a data-driven technical route for updating the geometric features of DT-LAOM. The primary objective of the geometric feature update process is to synchronize the geometric shape of DT-LAOM with the physical structure’s actual state. This is especially pertinent for large-scale structures, as deviations between planned and real dimensions can readily arise during the complex development and production phases. These deviations are often inherent in the related part manufacturing processes such as casting, welding, and milling. Effectively addressing these deviations is essential, as they can have profound implications for cost and delivery time, particularly in the assembly phase.

The update of DT-LAOM is grounded in key information gathered throughout the structural prototype design, manufacturing, and assembly processes. Building upon previous work on geometric model updating methods [

28], the implementation of the DT-LAOM update process is primarily based on two technical approaches: the updating of the parametric driving model, and the updating of the measurement data fitting driving model.

The parametric driving model utilizes parameters derived from the main feature data obtained through dimensional detection after manufacturing and processing completion. This method is commonly applied to parts with simple structures, such as large plane structures, which are relatively simple to reconstruct. The technical means employed in the parametric driving model include parametric modeling technology and synchronous modeling technology. Conversely, in the context of intricate and mission-critical component structures, the measurement data fitting driving model takes precedence. This model relies on point cloud fitting modeling technology, adept at acquiring surface data and ultimately generating a comprehensive 3D model through the processing of collected point cloud data [

29]. This approach becomes indispensable when grappling with non-standard components featuring intricate free-form surfaces. The overall technical solution is presented in

Figure 3.

The operational protocols for both parametric and synchronous modeling share analogous characteristics, encompassing the determination of size parameters, the extraction of actual parameter values from measurement data, and the subsequent modification of size parameters based on real-world data. In contrast, point cloud fitting modeling, while more intricate, proves to be indispensable for the meticulous reconstruction of intricate components.

During the active operational phase, a series of well-defined steps are meticulously adhered to. Initially, geometric features integral to the assembly function of the components earmarked for updates are meticulously segmented. Subsequently, a sequence of preprocessing operations, including denoising, registration, and down-sampling, are judiciously applied to the amassed point cloud data. These operations, designed to streamline the extraction of point cloud data pertinent to target features, serve as a preparatory phase. In conclusion, the geometric feature profiles are precisely fitted through the judicious utilization of point cloud data, thereby enabling the systematic replacement and reconstruction of corresponding profiles within the structural model. This methodical approach ensures the meticulous geometric feature reconstruction of DT-LAOM, thereby guaranteeing an elevated level of precision and fidelity in its representation.

3.3. Rapid Evaluation of Multi-Plane Accuracy of Assembly Components

For the effective assembly of large structures, the meticulous validation of manufactured part accuracy and the integrity of assembled components take on paramount significance. To this end, it becomes imperative to substantiate structural soundness through precise data measurements conducted post-manufacturing and assembly. Large-scale assembly structures, characterized by their sizable but intricate geometric features, often elude traditional point-to-point measurement methods. However, it is possible to assess whether these structures align with the design specifications by leveraging point cloud data derived from the critical surfaces within the constructed DT-LAOM.

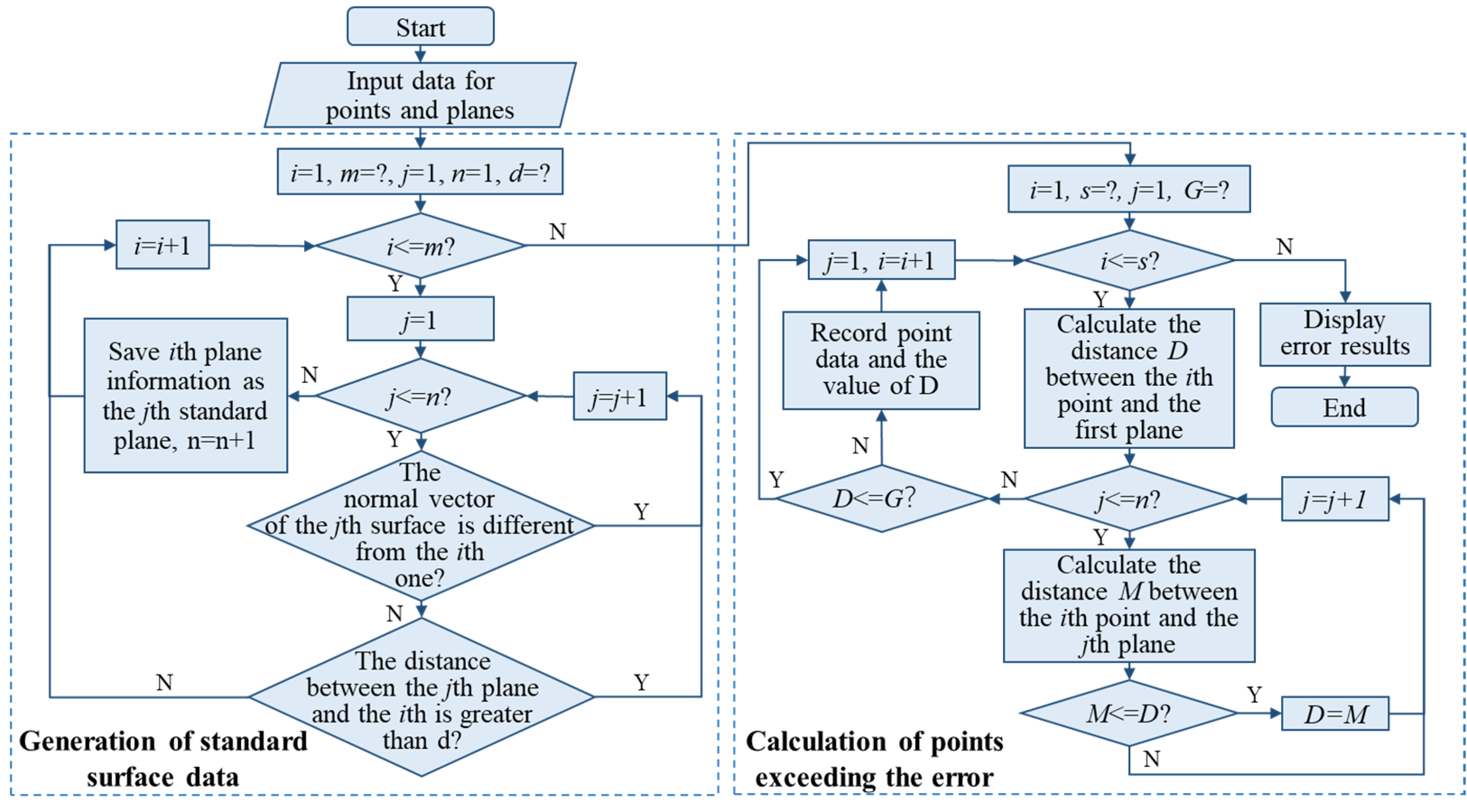

In response to the distinct requirements of large-scale structures, this paper introduces a rapid and tailored evaluation method designed specifically to gauge the multi-plane accuracy of structural components, with a keen focus on large-scale assembly structures. This method, as illustrated in

Figure 4, offers an efficient means of ascertaining whether each plane falls within the predetermined design tolerance range. It furnishes numerical results, establishing a closed-loop process that seamlessly integrates modeling and evaluation feedback into the DT-LAOM framework. Ultimately, this approach serves as an indispensable tool to ensure that the actual assembly process adheres to rigorous quality standards while enhancing operational efficiency— a vital undertaking in the context of large-scale assembly structures where precision and efficiency are paramount.

In

Figure 4,

i,

j, and

n are loop variables,

m represents the number of triangular facets,

d is the predetermined minimum part thickness,

s denotes the predetermined limit on the number of calculation points,

G stands for the predetermined tolerance requirements, and

D indicates the offset distance from the calculation points to the respective surfaces.

The evaluation method for assessing the multi-plane accuracy of the structure comprises two primary modules: (1) the generation of standard surface data; and (2) the calculation of points exceeding the error. Firstly, the ideal model is exported in the STL format, providing vertex and normal vector information for m triangular surface facets. From this, the standard surface planes are represented by point normal equations and stored in normal vectors and any point of the three vertices. To filter redundant information, planes are compared for parallelism and proximity based on the minimum wall thickness d of the part. Once all standard plane data are obtained, the point cloud coordinates acquired from the actual scan are analyzed and processed. Using the point-plane distance formula, the distance between the ith point and the jth standard plane is calculated, determining its offset distance D from the nearest reference standard plane. The evaluation process involves checking if the offset distance falls within the pre-set tolerance requirement G, categorizing it as super close. Traversing all point cloud coordinate values enables the completion of the evaluation process and the generation of exceeding error data and associated visualization results for actual complex planar feature parts.

According to the proposed method, a piece of the support beam structure is selected as the measurement object, and the actual data acquisition and processing analysis of its important planes are realized. The result output and visualization comparison of the excess error points based on the structural point cloud are shown in

Figure 5.

This method allows for the geometric evaluation of multi-planar complex models by adjusting key parameters such as wall thickness and tolerance. It facilitates the direct input of ideal STL models and point cloud data sampled from DT-LAOM, providing output display of exceeded error results. It enables efficient capture and processing of out-of-tolerance areas, facilitating the realization of DT-LAOM-based on-site repair guidance for the actual assembly process.

4. DT-LAPM for Large Non-Standard Industrial Equipment

4.1. DT-LAPM Information Composition

Within the domain of intelligent assembly of industrial equipment, DT-LAPM takes on the crucial role of a digital representation meticulously mirroring the actual assembly process of the equipment structure. It encompasses a comprehensive repository of process information for each assembly stage, fulfilling essential functions such as recording, expression, and planning throughout the assembly process. The inherent dynamism of assembly states across various stages of structure assembly is meticulously addressed. Each assembly state corresponds to a specific assembly process model, fostering a nuanced understanding of the assembly dynamics.

To cater to the intricacies of large assembled structures, this paper introduces a DT-LAPM information architecture rooted in assembly process units, as depicted in

Figure 6. Within this architectural framework, each assembly process unit boasts a hierarchical information structure encompassing pending, in-execution, and executed assembly processes. This meticulous categorization extends to the attribute information hierarchy of the process model, which is further subdivided into an assembly behavior information layer and an assembly rules information layer. Such an organization paves the way for efficient management and optimization of the assembly process.

The assembly behavior information layer encapsulated within DT-LAPM is particularly salient for large structures. It holds critical details, including the structural assembly sequence, component connection methods, and assembly process operations. This layer provides comprehensive insights into the structural assembly functions and process attributes within the process model, thereby enabling dynamic process planning and automation applications grounded in the model. Such capabilities become indispensable when dealing with the intricacies of large-scale assembly structures.

The assembly rules information contained within DT-LAPM constitutes a valuable resource for optimizing assembly solutions in the context of large structures. It encompasses process standard requirements, expert experience knowledge, and assembly resource allocation, among other essential elements. Through the utilization of advanced techniques like data mining and knowledge model reasoning, this information reveals assembly general rules and potential optimization strategies. It thereby serves as a foundational basis for making intelligent decisions and optimizing assembly solutions based on the model, aligning perfectly with the intricacies and scale of large assembly structures.

The attribute information within DT-LAPM is amenable to synchronous mapping and real-time updates in response to the evolving assembly process. This feature enables real-time guidance and optimization of assembly work based on the dynamic insights afforded by DT-LAPM. In the context of large assembled structures, where precision, adaptability, and efficiency are paramount, the tailored application of DT-LAPM information composition becomes a linchpin for success, offering a comprehensive framework for addressing the unique challenges of these substantial projects.

4.2. Intelligent Assembly Implementation Framework

Throughout the entire process, from the design phase to the execution of equipment structure assembly within the ambit of large structures, the DT-LAPM information traverses distinct stages, encompassing process design and optimization, process execution, and assembly site feedback. At each stage, the corresponding process model information undergoes iterative updates, culminating in a comprehensive collection of DT-LAPM information. Grounded in the interactive mapping concept that bridges the digital information space and the actual physical space within the DT technology, and cognizant of the intricate assembly process unique to large non-standard structures, this section introduces a framework meticulously tailored to implement intelligent assembly technology founded on DT-LAPM. This framework and its various components are illustrated in the

Figure 7 below.

The technical implementation framework comprises two main components: (1) the digital assembly space and (2) the physical assembly space. In the digital assembly space, the resources from DT-LAPM, data-driven algorithms, intelligent techniques, and knowledge-driven technologies are utilized to enable planning, simulation, prediction, and optimization of the assembly process. This facilitates digital assistance and guidance for both process design and execution stages. The constantly changing DT model information and data can be reasoned and updated by integrating model parameters, operation data, and decision-making results, enabling the DT model’s self-updating, self-correcting, and self-evolution.

The physical assembly space in the intelligent assembly implementation framework focuses on the actual assembly process of a large equipment structure. It involves collecting and integrating multi-source information, such as structural components, software and hardware tools, and equipment resources at the assembly site, to precisely describe the physical element state of the DT model. This allows for the precise description of the physical element state within the DT model, forming a digital representation of the real assembly process state. By accepting and analyzing process guidance information, the physical space enables activities such as assembly sequence simulation, process equipment debugging, measurement tool arrangement, and operator training, as well as other auxiliary assembly tasks.

The dynamic transmission and communication of information between the digital and physical assembly space form the basis for the dynamic update of the DT model, real-time control of the physical equipment, and online optimization of the decision-making schemes. This integration breaks the information barriers between virtual and physical spaces, facilitating seamless sharing and integration of data and information, ultimately enhancing the efficiency and effectiveness of the entire intelligent assembly process.

5. Case Study: DT-Based Intelligent Assembly of a Piece of Large-Scale Non-Standard Experimental Equipment

To assess the practicality of the proposed DT-based intelligent assembly paradigm, this section looks into the assembly process of a piece of large-scale aerodynamic experimental equipment (LAEE) as an implementation subject. Through the application of the proposed DT-based paradigm in the actual assembly work of the LAEE, a quantitative evaluation can be conducted to measure the effectiveness and efficacy of the technical solution. This evaluation will provide valuable insights into the viability and applicability of the DT-based intelligent assembly approach in real-world equipment assembly processes.

5.1. DT-LAOM-Based Assembly Structure Accuracy Verification and On-Site Repair Guidance

The LAEE, as a piece of large-scale non-standard industrial experimental equipment characterized by its complex structural design and numerous components, poses significant challenges in ensuring the positional and dimensional accuracy of its molding components. Any manufacturing errors in the assembled components and the external loads acting on the structure can greatly impact the overall assembly accuracy. To address these issues and enable precise evaluation of critical geometric elements within the assembly, the construction technique utilizing DT-LAOM is essential. A fusion technology flow for integrating both geometric design information and physical characteristic information of the LAEE assembly structure is proposed, as depicted in

Figure 8. This approach is based on the concept of information modeling and aims to create a comprehensive and accurate DT-LAOM for the LAEE assembly. By combining geometric and physical information, this technique enables a holistic representation of the assembly process, facilitating real-time evaluations and optimizations of the structure’s performance.

In the LAEE construction project, the design information of the LAEE components was utilized to construct a comprehensive geometric information model that encompassed assembly characteristic parameters and corresponding tolerances. To digitally characterize the cumulative information of assembly error transmission, an assembly directed graph method was applied to analyze the assembly parts and components. In addition, finite element modeling and analysis technology was employed to capture the structural change information of the component structure under various multi-physical fields, which contributed to obtaining essential physical characteristic information. For completed parts, a model state reconstruction was carried out, considering the actual structural feature surfaces and physical state parameters. By integrating the geometric design information with the physical characteristic information, the resulting DT-LAOM of each component was established, ensuring precise evaluations and facilitating optimized assembly procedures.

During the LAEE structure reconstruction using the proposed DT-LAOM geometric feature reconstruction method, the model update based on measurement data presented a particular challenge compared to parameterization-driven model updates. The LAEE project involved a large-scale profile structure, demanding a high level of realism for its profile information within the DT-LAOM. To achieve this, point cloud-based measurement data for the profile surface had to be meticulously collected and registered. The process of obtaining and integrating the measurement data to update the model is depicted in

Figure 9. This step is crucial for ensuring the accuracy and authenticity of the DT-LAOM, ultimately enhancing the precision of the assembly process for the LAEE.

Prior to commencing the scanning measurement process, it was essential to plan multiple scanning areas based on the scanning requirements and the capacity of the scanning equipment. To ensure the accurate splicing of subsequent scanning areas, pre-planning an intersection calibration area for each scanning area was needed. This facilitated the seamless integration of data between adjacent scanning areas. For instance, when conducting scanning measurements on the large LAEE surface depicted in

Figure 9, the surface was divided into four scanning areas to account for the limited capacity of the scanning equipment. In addition, a number of shared scanning areas were strategically planned to enable high-precision point cloud surface registration upon completion.

Once the DT-LAOM has been constructed by updating the actual geometric and physical state information, it can be used for model evaluation, such as the multi-plane rapid accuracy evaluation mentioned previously, to realize the guidance of the assembly and rework of the assembly structure in the digital space.

Figure 10 illustrates the process of utilizing the DT-LAOM to guide the on-site repair of the LAEE structure.

Building an updatable DT-LAOM for the LAEE enabled the timely updating of key component information throughout the equipment assembly process. This established an interaction channel between the actual structure and the DT model, facilitating effective prediction of potential issues at the equipment assembly site based on the updated DT-LAOM. By integrating and analyzing geometrical and physical information consistent with the real situation, it was possible to provide precise guidance for the on-site reprocessing of equipment components. By incorporating on-site repair data and information back into the DT model, a complete DT information cycle link was established.

During the actual assembly process of the equipment structure depicted in

Figure 10, an analysis of the constructed DT-LAOM revealed the presence of 168 hard interferences in the designed structure before the actual assembly of the key components. This identification of interferences effectively prevented extensive repair work after component manufacturing and significantly reduced the overall construction time of the LAEE.

5.2. Validation of DT-LAPM Based Assembly Process Optimization

The assembly process of the LAEE presents unique challenges due to its large size, heavy weight, and high assembly accuracy requirements, all within the constraints of limited space. These specific characteristics demand careful consideration in the design, evaluation and implementation of the assembly process. Key challenges include ensuring the rationality of the assembly sequence for the equipment structure, selecting reliable assembly process tool models, determining suitable assembly process equipment operating parameters, and maintaining consistency between the assembly implementation and design criteria. Addressing these challenges is crucial to achieving efficient and effective assembly of the LAEE and other equipment with similar complexity.

To meet the high-precision analysis and verification requirements of the LAEE structure, DT-LAPM technology was implemented to digitalize and guide the entire manufacturing and assembly process in the factory. This approach generated 3D visualizations, process equipment hardware control parameters, human–machine interface, and other process documents to provide comprehensive information support for the manufacturing, repair, operation, and maintenance stages of the industrial equipment structure.

When it comes to the assembly process involving the planning and verification of the LAEE structure based on the DT-LAPM, it is essential to divide and define the assembly units according to the structure’s assembly scheme and design the corresponding tooling and equipment models. The updated DT-LAOM is then converted into a lightweight JT 3D data format and imported into the assembly process planning and simulation platform. This platform facilitates the arrangement of the assembly environment, allocation of tool resources, and distribution of assembly parts, thereby completing the assembly sequence planning and path planning for the structure. Through the utilization of appropriate digital verification methods, a comprehensive assembly process scheme is generated, enabling the simulation verification of the structural assembly process.

Figure 11 illustrates the DT-LAPM formulation and the simulation process of the LAEE structure.

After importing the LAEE structure model and assembly tooling model into the digital platform, as depicted in

Figure 11a, the model needed to be divided into units and arranged spatially based on the actual assembly scenario. Subsequently, the assembly sequence was established in the platform according to the structural assembly scheme, as shown in

Figure 11b, to facilitate subsequent analysis and optimization of the assembly process. To prevent accidental collisions during assembly, the virtual verification of the structural assembly process employed the bounding box principle to detect and highlight interference collision situations, as illustrated in

Figure 11c. Once the digital process creation based on the assembly process scheme was finalized in the platform, the relevant process was exported as a scalable and interactive DT model of the assembly process, as shown in

Figure 11d. This allowed for intuitive analysis of the assembly process and its associated characteristics, facilitating the planning and evaluation of the structural assembly process. A feasible assembly scheme was then generated based on the insights gained.

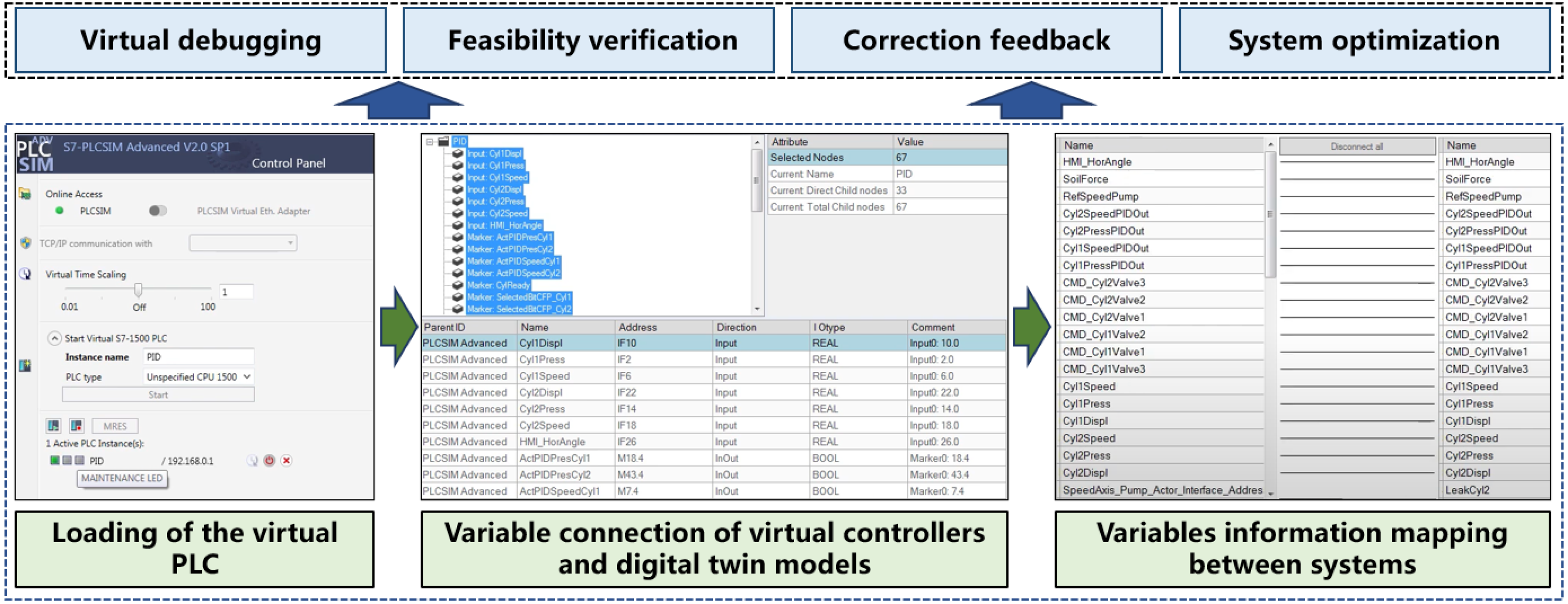

To construct the DT-LAPM, it is crucial not only to construct the DT model of the structure assembly process but also to focus on constructing the DT model of the automatic assembly equipment control logic. Within the Tecnomatix software environment, the control status of the process equipment hardware system is effectively previewed and mapped in real time through simulation and optimization techniques. This entails connecting the digital automatic control model with automated equipment such as assembly robots. During the assembly scheme planning, relevant automation equipment is configured with corresponding PLC programs. The PLC programs are then executed in the software platform to complete feasibility verification of the PLC program in the digital space. This approach helps to identify and resolve problems before the installation and commissioning of the physical automatic assembly equipment.

Figure 12 showcases the virtual commissioning of communication and control based on PLCSIM Advanced.

The virtual debugging of the PLC program and DT assembly process equipment involves using the OPC Server as a signal transfer station to facilitate interaction between the process equipment and the PLC. It achieves this by matching the signal data of the PLC address with the PLC based on the OPC unified architecture. This enables the transmission of data from the server to the simulator or vice versa, ensuring that the DT process equipment simulates movement in accordance with the signals from the PLC.

During the actual assembly process of the LAEE structure, the PLC and the related configuration files that had been debugged in the digital space were downloaded to the physical device. This allowed for the interactive mapping between the internal control logic of the device and the physical space. By employing the virtual debugging method based on DT technology to configure automatic equipment, the performance of the equipment would meet the specified requirements. This approach significantly reduced the installation and debugging costs of the equipment system and shortened the assembly time of the industrial equipment structure.

Through leveraging the assembly behavior information and assembly rule information within DT-LAPM, along with the integration of heterogeneous assembly process data, intelligent applications such as task decomposition, knowledge mining, and process decision-making can be achieved for the equipment structural assembly process. This enables effective guidance, validation, and optimization of the assembly process for large-scale and non-standard industrial equipment such as the LAEE. As a result, the success rate of equipment assembly is significantly improved, and the assembly cycle time is reduced. These encouraging outcomes serve as evidence of the feasibility and advantages of the DT-LAPM technology in driving the digitalization and intellectualization of the industrial equipment assembly process.

5.3. Comparative Analysis: Traditional Assembly vs. Intelligent Assembly for the LAEE

In this section, we present a comparative analysis of the results obtained from traditional assembly methods and the proposed intelligent assembly paradigm, specifically focusing on the construction of the bottom frame actuators in LAEE. The aim is to highlight the positive impact of the innovative DT-LAOM and DT-LAPM methodology on the actual erection process of large industrial equipment structures. The analysis compares the outcomes of assembling a set of bottom frame actuators using both the conventional and intelligent assembly methods. The results demonstrate the improvements achieved through the adoption of the intelligent assembly approach, as shown in

Table 2.

The comparative analysis reveals the substantial benefits of the intelligent assembly paradigm. Notably, the intelligent assembly approach significantly reduces the overall construction cycle time by 22.1%, minimizes the need for component reworks (a 100% reduction), and enhances actuator assembly accuracy by 75%. Moreover, the large process equipment operating time is reduced by 28.9%, and the success rate of one-time operations by operators improves by 17.1%. Most notably, the degree of digitization of key information of the real structure reaches a remarkable 100% with intelligent assembly, signifying a vast 82% improvement over traditional methods.

These results underscore the transformative potential of intelligent assembly methods in the construction of large industrial equipment structures. The intelligent assembly paradigm not only accelerates the assembly process but also enhances precision, reduces rework, and improves overall operational efficiency. It represents a substantial leap forward in the realm of large-scale industrial equipment assembly, offering a path toward greater productivity and operational excellence.

6. Conclusions and Future Work

This paper has presented a novel DT-based paradigm for the intelligent assembly of large non-standard industrial equipment, enabling the digitalization and intelligent upgrading of assembly processes. The proposed framework offers a comprehensive approach to enhancing efficiency, accuracy, and optimization in large non-standard equipment assembly. The key findings are as follows

- (1)

A dual-level mapping model driven by DT is proposed, effectively encompassing and analyzing large non-standard structure assembly information across different dimensions and granularity levels during the actual assembly process, ensuring accuracy and process control.

- (2)

A novel DT-LAOM information architecture, with geometric design and physical characteristic layers, is developed to facilitate comprehensive digitization of large assembly objects. A technical scheme for updating geometric features of DT-LAOM using actual data is introduced, along with a rapid assessment method for assembly structure accuracy.

- (3)

A DT-LAPM information architecture with assembly behavior and rule layers is generated to clarify the dynamic correspondence between physical and digital space, enhancing efficiency and intelligence in the large non-standard structure assembly process.

- (4)

The feasibility of the proposed paradigm is validated through a successful implementation for the assembly of a real large-scale industrial equipment (LAEE), demonstrating the effectiveness of the approach. The presented research lays the foundation for future advancements in the field of intelligent assembly of large structures.

In conclusion, the use of DT technology is not just beneficial but necessary when dealing with large non-standard structural assembly. Its ability to provide a virtual representation of both the structure and the assembly process aids in mitigating the unique challenges and complexity inherent in these assembly tasks, ultimately ensuring the successful and efficient assembly of large non-standard structures.

The future work for this article should focus on several key areas. First, the proposed DT-based paradigm should be optimized to enhance efficiency, accuracy, and adaptability, possibly by developing advanced DT models, improved data integration methods, and real-time control mechanisms. Second, the integration of emerging technologies like AI, IoT, and Big Data with DT should be explored to create advanced decision support systems and predictive maintenance strategies. Third, the approach to accommodate various types of large non-standard structures should be generalized. Fourth, human–machine collaboration, especially in scenarios requiring human operators within structures, should be investigated. Finally, industry-specific standards and best practices should be developed, as well as training programs for the workforce to adapt to these new assembly approaches. This comprehensive approach will drive the continued evolution of intelligent assembly technologies for large non-standard equipment structures.