A New Exoskeleton Prototype for Lower Limb Rehabilitation †

Abstract

:1. Introduction

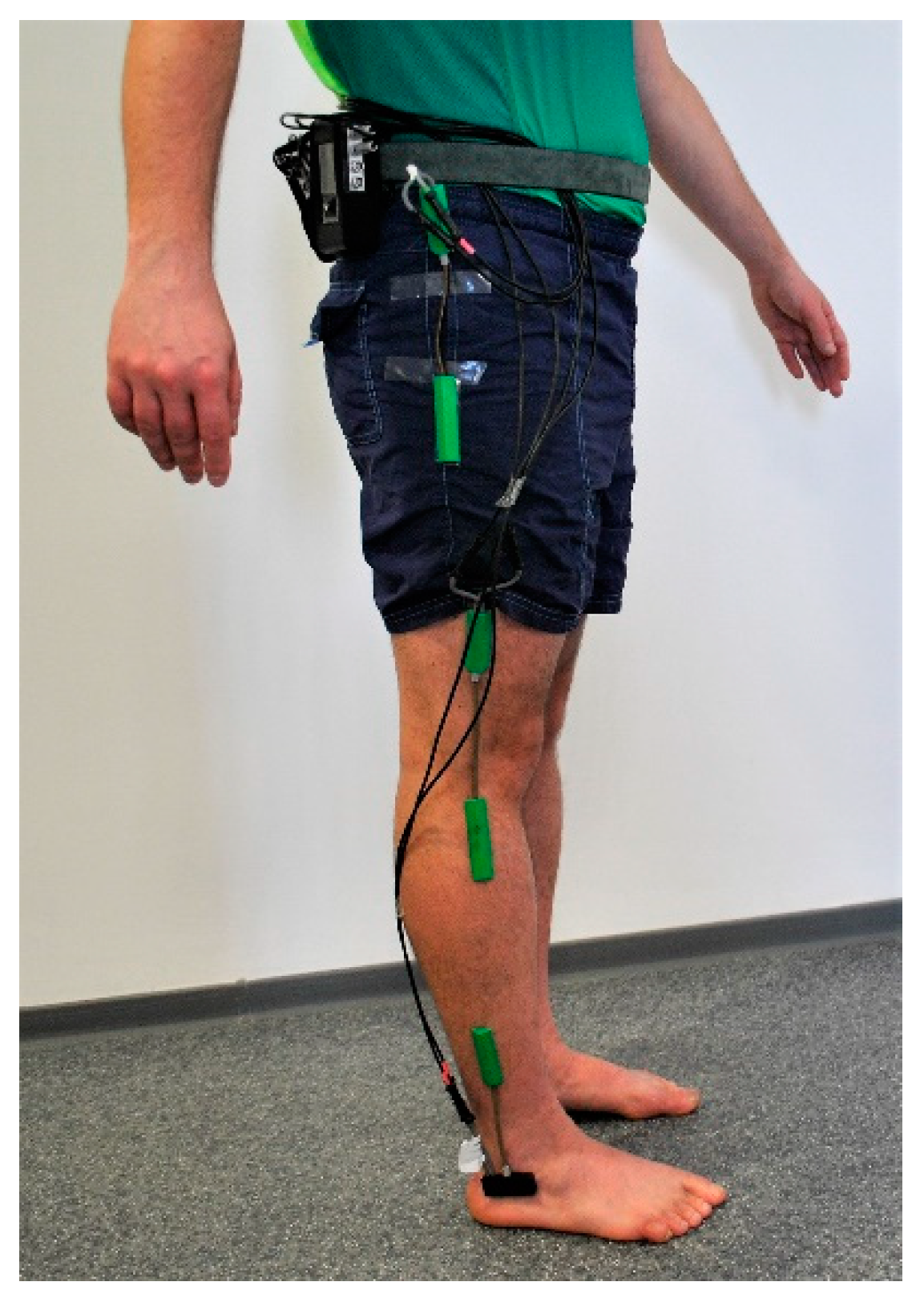

2. Human Gait Experimental Study

3. Optimal Design and Simulation Study of the Proposed Structural Solution for the Exoskeleton Leg

3.1. Kinematic Analysis of the Foot Mechanism

3.2. Designing an Optimal CAD Model of the Robotic System

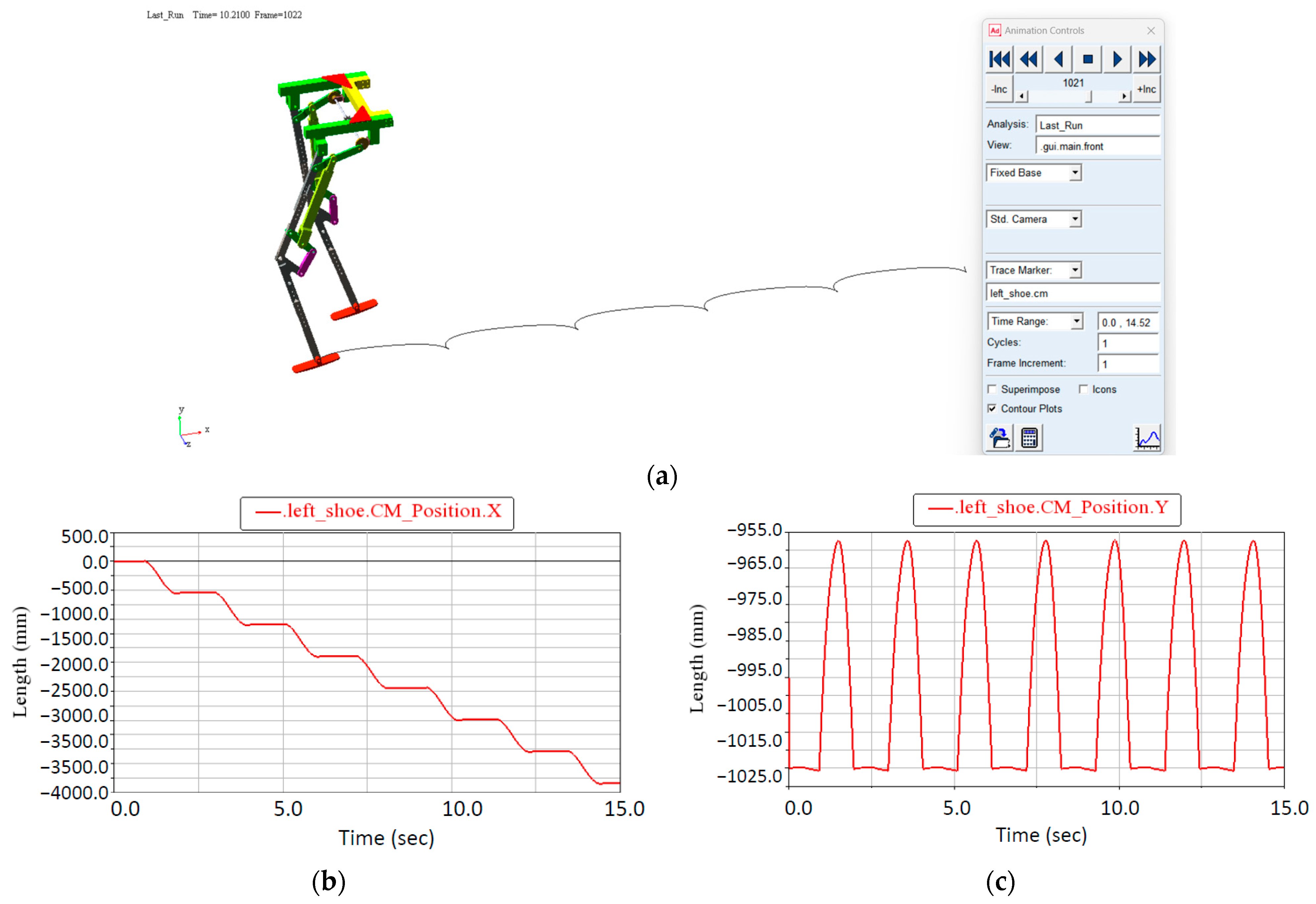

3.3. Kinematic and Dynamic Simulation of the Exoskeleton

3.4. Kinematic and Dynamic Simulation of the Exoskeleton When Performing Stair Ascent

4. Robotic System Fabrication and Experimental Motion Analysis

- -

- Fused deposition modeling (FDM)—This type is the most widely used for 3D printing. By melting a thermoplastic filament and depositing it layer by layer, the model is obtained. The material solidifies as it cools. The filament can be of different diameters, the most commonly used being 1.75 mm. The FDM process is commonly used for prototyping but can also be used for the production of series parts.

- -

- Stereolithography (SLA)—The process uses liquid resin and a UV laser as material. The UV laser traces the outline of the object after each layer of resin, solidifying the resin to the final part, but it is also toxic.

- -

- Selective laser sintering (SLS)—This process uses powdered material, most commonly a thermoplastic or metal, that is selectively fused using a high-power laser. The laser heats and melts the powder particles, thereby creating a solid layer. This process is repeated until the part is made. This produces complex, durable parts with no supporting structures during printing.

- -

- Direct metal laser sintering (DMLS)—DMLS is similar to SLS, but this process specifically uses metal powders. A high-power laser selectively fuses metal powder particles, producing complex metal parts with high strength and durability, used mainly in the aerospace, automotive and medical industries.

- -

- Printers using this technology come at affordable prices.

- -

- They accept a wide range of materials, from thermoplastics to carbon fiber.

- -

- It is easy to use, with a relatively simple set-up for printing. The slicing software is user-friendly and intuitive. The software is also compatible with standard CAD formats, making it easy to create designs.

- -

- Reduces material waste compared to traditional technology such as CNC. Waste is minimal as it is an additive manufacturing process, which means that each object is built layer by layer using the minimum amount of material.

- -

- It is used in research to create prototypes and test concepts but also has an educational role, allowing engineering design principles to be applied in practical applications.

5. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Malyuga, O.O. The Design of the Exoskeleton; IPR-Media: Saratov, Russia, 2019. [Google Scholar]

- Yagn, N. Apparatus for Facilitating Walking, Running and Jumping. U.S. Patent No. 420,179, 28 January 1890. [Google Scholar]

- Mizen, N.J. Powered Exoskeletal Apparatus for Amplifying Human Strength in Response to Normal Body Movements. Patent No. 3449769, 17 June 1969. [Google Scholar]

- Shi, D.; Zhang, W.; Zhang, W.; Ding, X. A review on lower limb rehabilitation exoskeleton robots. Chin. J. Mech. Eng. 2019, 32, 74. [Google Scholar] [CrossRef]

- Chaichaowarat, R.; Prakthong, S.; Thitipankul, S. Transformable Wheelchair–Exoskeleton Hybrid Robot for Assisting Human Locomotion. Robotics 2023, 12, 16. [Google Scholar] [CrossRef]

- Hu, B.; Liu, F.; Cheng, K.; Chen, W.; Shan, X.; Yu, H. Stiffness optimal modulation of a variable stiffness energy storage hip exoskeleton and experiments on its assistance effect. IEEE Trans. Neural Syst. Rehabil. Eng. 2023, 31, 1045–1055. [Google Scholar] [CrossRef] [PubMed]

- Carbone, G.; Laribi, M.A. Recent trends on innovative robot designs and approaches. Appl. Sci. 2023, 13, 1388. [Google Scholar] [CrossRef]

- Rodrigues-Carvalho, C.; Fernández-García, M.; Pinto-Fernández, D.; Sanz-Morere, C.; Barroso, F.O.; Borromeo, S.; Del-Ama, A.J. Benchmarking the effects on human–exoskeleton interaction of trajectory, admittance and EMG-triggered exoskeleton movement control. Sensors 2023, 23, 791. [Google Scholar] [CrossRef]

- Jayaraman, C.; Embry, K.R.; Mummidisetty, C.K.; Moon, Y.; Giffhorn, M.; Prokup, S.; Jayaraman, A. Modular hip exoskeleton improves walking function and reduces sedentary time in community-dwelling older adults. J. Neuroeng. Rehabil. 2022, 19, 144. [Google Scholar] [CrossRef]

- Arcos-Legarda, J.; Torres, D.; Velez, F.; Rodríguez, H.; Parra, A.; Gutiérrez, Á. Mechatronics Design of a Gait-Assistance Exoskeleton for Therapy of Children with Duchenne Muscular Dystrophy. Appl. Sci. 2023, 13, 839. [Google Scholar] [CrossRef]

- Veneman, J.F.; Kruidhof, R.; Hekman, E.E.; Ekkelenkamp, R.; Van Asseldonk, E.H.; Van Der Kooij, H. Design and evaluation of the LOPES exoskeleton robot for interactive gait rehabilitation. IEEE Trans. Neural Syst. Rehabil. Eng. 2007, 15, 379–386. [Google Scholar] [CrossRef]

- Huo, W.; Mohammed, S.; Moreno, J.C.; Amirat, Y. Lower limb wearable robots for assistance and rehabilitation: A state of the art. IEEE Syst. J. 2014, 10, 1068–1081. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, S.; Xue, Q. Lower limb rehabilitation exoskeleton robot: A review. Adv. Mech. Eng. 2021, 13, 16878140211011862. [Google Scholar] [CrossRef]

- Lee, H.; Ferguson, P.W.; Rosen, J. Chapter 11—Lower Limb Exoskeleton Systems Overview; Rosen, J., Ferguson, P.W., Robotics, W., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 207–229. ISBN 9780128146590. [Google Scholar] [CrossRef]

- Parra-Dominguez, G.S.; Taati, B.; Mihailidis, A. 3D human motion analysis to detect abnormal events on stairs. In Proceedings of the 2012 Second International Conference on 3D Imaging, Modeling, Processing, Visualization & Transmission, Zurich, Switzerland,, 13–15 October 2012; pp. 97–103. [Google Scholar]

- Ko, C.Y.; Ko, J.; Kim, H.J.; Lim, D. New wearable exoskeleton for gait rehabilitation assistance integrated with mobility system. Int. J. Precis. Eng. Manuf. 2016, 17, 957–964. [Google Scholar] [CrossRef]

- Chen, B. Recent developments and challenges of lower extremity exoskeletons. J. Orthop. Transl. 2016, 5, 26–37. [Google Scholar] [CrossRef]

- Anama, K.; Al-Jumaily, A.A. Active exoskeleton control systems: State of the art. Procedia Eng. 2012, 41, 988–994. [Google Scholar] [CrossRef]

- Díaz, I.; Gil, J.J.; Sánchez, E. Lower-limb robotic rehabilitation: Literature review and challenges. J. Robot. 2011, 2011, 759764. [Google Scholar] [CrossRef]

- Devi, M.G.; Amutheesan, M.; Govindhan, R.; Karthikeyan, B. A review of three-dimensional printing for biomedical and tissue engineering applications. Open Biotechnol. J. 2018, 12, 241–255. [Google Scholar] [CrossRef]

- Li, Z.; Deng, C.; Zhao, K. Human-cooperative control of a wearable walking exoskeleton for enhancing climbing stair activities. IEEE Trans. Ind. Electron. 2019, 67, 3086–3095. [Google Scholar] [CrossRef]

- Woo, H.; Kong, K.; Rha, D.W. Lower-limb-assisting robotic exoskeleton reduces energy consumption in healthy young persons during stair climbing. Appl. Bionics Biomech. 2021, 2021, 8833461. [Google Scholar] [CrossRef] [PubMed]

- Chandrapal, M.; Chen, X.; Wang, W. Preliminary evaluation of a lower-limb exoskeleton-stair climbing. In Proceedings of the 2013 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Wollongong, Australia, 9–12 July 2013; pp. 1458–1463. [Google Scholar]

- Borooghani, D.; Hadi, A.; Alipour, K. Falling Analysis and Examination of Different Novel Strategies for Preserving the Postural Stability of a User Wearing ASR-EXO during Stair Climbing. J. Intell. Robot. Syst. 2022, 105, 5. [Google Scholar] [CrossRef]

- Xu, F.; Lin, X.; Cheng, H.; Huang, R.; Chen, Q. Adaptive stair-ascending and stair-descending strategies for powered lower limb exoskeleton. In Proceedings of the 2017 IEEE International Conference on Mechatronics and Automation (ICMA), Takamatsu, Japan, 6–9 August 2017; pp. 1579–1584. [Google Scholar]

- Li, Z.; Yuan, Y.; Luo, L.; Su, W.; Zhao, K.; Xu, C.; Pi, M. Hybrid brain/muscle signals powered wearable walking exoskeleton enhancing motor ability in climbing stairs activity. IEEE Trans. Med. Robot. Bionics 2019, 1, 218–227. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhu, Y.; Zheng, T.; Zhao, S.; Ma, S.; Fan, J.; Zhao, J. Lower extremity exoskeleton for stair climbing augmentation. In Proceedings of the 2018 3rd International Conference on Advanced Robotics and Mechatronics (ICARM), Singapore, 18–20 July 2018; pp. 762–768. [Google Scholar]

- Baltrusch, S.J.; Van Dieën, J.H.; Van Bennekom, C.A.M.; Houdijk, H. The effect of a passive trunk exoskeleton on functional performance in healthy individuals. Appl. Ergon. 2018, 72, 94–106. [Google Scholar] [CrossRef]

- Ishmael, M.K.; Archangeli, D.; Lenzi, T. A powered hip exoskeleton with high torque density for walking, running, and stair ascent. IEEE/ASME Trans. Mechatron. 2022, 27, 4561–4572. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Liu, G.F.; Zheng, T.J.; Li, H.W.; Zhao, S.K.; Zhao, J.; Zhu, Y.H. Blending control method of lower limb exoskeleton toward tripping-free stair climbing. ISA Trans. 2022, 131, 610–627. [Google Scholar] [CrossRef]

- Bae, E.; Park, S.E.; Moon, Y.; Chun, I.T.; Chun, M.H.; Choi, J. A robotic gait training system with stair-climbing mode based on a unique exoskeleton structure with active foot plates. Int. J. Control Autom. Syst. 2020, 18, 196–205. [Google Scholar] [CrossRef]

- Böhme, M.; Köhler, H.P.; Thiel, R.; Jäkel, J.; Zentner, J.; Witt, M. Preliminary Biomechanical Evaluation of a Novel Exoskeleton Robotic System to Assist Stair Climbing. Appl. Sci. 2022, 12, 8835. [Google Scholar] [CrossRef]

- Joudzadeh, P.; Hadi, A.; Alipour, K.; Tarvirdizadeh, B. Design and implementation of a cable driven lower limb exoskeleton for stair climbing. In Proceedings of the 2017 5th RSI International Conference on Robotics and Mechatronics (ICRoM), Tehran, Iran, 25–27 October 2017; pp. 76–81. [Google Scholar]

- Jang, J.; Kim, K.; Lee, J.; Lim, B.; Shim, Y. Assistance strategy for stair ascent with a robotic hip exoskeleton. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea, 9–14 October 2016; pp. 5658–5663. [Google Scholar]

- Geonea, I.; Dumitru, S.; Copilusi, C.; Margine, A.; Rinderu, P. Design and numerical characterization of a leg exoskeleton linkage for motion assistance. In Proceedings of the 2018 World Congress on Engineering and Computer Science, San Francisco, CA, USA, 23–25 October 2018; pp. 23–25. [Google Scholar]

- Geonea, I.; Copilusi, C.; Margine, A.; Dumitru, S.; Rosca, A.; Tarnita, D. Dynamic Analysis and Structural Optimization of a New Exoskeleton Prototype for Lower Limb Rehabilitation. In New Trends in Medical and Service Robotics; Tarnita, D., Dumitru, N., Pisla, D., Carbone, G., Geonea, I., Eds.; Springer: Cham, Switzerland, 2023; Volume 133. [Google Scholar] [CrossRef]

- Geonea, I.; Dumitru, N.; Ceccarelli, M.; Tarnita, D. Kinematic and Dynamic Analysis of a New Mechanism for Assisting Human Locomotion. In New Trends in Medical and Service Robotics; Tarnita, D., Dumitru, N., Pisla, D., Carbone, G., Geonea, I., Eds.; Springer: Cham, Switzerland, 2023; Volume 133. [Google Scholar] [CrossRef]

| Param. | Design Point | P11—FBlend8.FD1 (mm) | P12—FBlend10.FD1 (mm) | P13—Extrude8.FD1 (mm) | P6—Solid Mass (kg) | P7—Equivalent Stress Maximum (MPa) | |

|---|---|---|---|---|---|---|---|

| No. | |||||||

| 1 | 1 DP | 3 | 3 | 12 | 0.35311 | 30.143 | |

| 2 | 2 | 2.7 | 3 | 12 | 0.35309 | 32.611 | |

| 3 | 3 | 3.3 | 3 | 12 | 0.35313 | 29.84 | |

| 4 | 4 | 3 | 2.7 | 12 | 0.35309 | 31.317 | |

| 5 | 5 | 3 | 3.3 | 12 | 0.35313 | 29.047 | |

| 6 | 6 | 3 | 3 | 10.8 | 0.34014 | 35.815 | |

| 7 | 7 | 3 | 3 | 13.2 | 0.36604 | 26.465 | |

| 8 | 8 | 2.7561 | 2.7561 | 11.024 | 0.34254 | 37.626 | |

| 9 | 9 | 3.2439 | 2.7561 | 11.024 | 0.34257 | 37.534 | |

| 10 | 10 | 2.7561 | 3.2439 | 11.024 | 0.34257 | 33.137 | |

| 11 | 11 | 3.2439 | 3.2439 | 11.024 | 0.3426 | 32.682 | |

| 12 | 12 | 2.7561 | 2.7561 | 12.976 | 0.3636 | 30.394 | |

| 13 | 13 | 3.2439 | 2.7561 | 12.976 | 0.36362 | 30.318 | |

| 14 | 14 | 2.7561 | 3.2439 | 12.976 | 0.36364 | 26.646 | |

| 15 | 15 | 3.2439 | 3.2439 | 12.96 | 0.36365 | 26.498 | |

| Name | P11—FBlend8.FD1 (mm) | P12—FBlend10.FD1 (mm) | P13—Extrude8.FD1 (mm) | P6—Solid Mass (kg) | P7—Equivalent Stress Maximum (MPa) |

|---|---|---|---|---|---|

| Output Parameter Minimums | |||||

| P5—Total Deformation Maximum | 3.3 | 3.3 | 13.2 | 0.36608 | 24.994 |

| P6—Solid Mass | 2.7 | 2.7 | 10.8 | 0.34011 | 38.982 |

| P7—Equivalent Stress Maximum | 3.3 | 3.3 | 13.2 | 0.36608 | 24.994 |

| P8—Equivalent Elastic Strain Maximum | 2.7 | 3.3 | 13.2 | 0.36606 | 25.568 |

| Output Parameter Maximums | |||||

| P5—Total Deformation Maximum | 27 | 27 | 10.8 | 0.34011 | 38.982 |

| P6—Solid Mass | 3.3 | 3.3 | 13.2 | 0.36608 | 24.994 |

| P7—Equivalent Stress Maximum | 2.7 | 2.7 | 10.8 | 0.34011 | 38.982 |

| P8—Equivalent Elastic Strain Maximum | 3.3 | 2.7 | 10.8 | 0.34015 | 38.493 |

| Optimization study | |||

| Minimize P6; P7 ≤ 33 MPa | Goal, minimize P6 (default importance) | ||

| Minimize P7 | Strict constraint, P7 values less than or equal to 33 MPa (default importance) | ||

| Optimization Method | |||

| Screening | The Screening optimization method uses a simple approach based on sampling and sorting. It supports multiple objectives and constraints, as well as all types of input parameters. Usually, it is used for preliminary design, which may lead to the application of other methods for more refined optimization results. | ||

| Configuration | Generate 8 samples and find 3 candidates. | ||

| Status | Converged after 4 evaluations. | ||

| Candidate points | |||

| Candidate Point 1 | Candidate Point 2 | Candidate Point 3 | |

| P11—FBlend8. FD1 (mm) | 3.3 | 2.7 | 3.3 |

| P12—FBlend10. FD2 (mm) | 3.3 | 2.7 | 3.3 |

| P13—Extrude8.FD1 (mm) | 10.8 | 13.2 | 13.2 |

| P6—Solid Mass (kg) | *** 0.34019 | xxx 0.36602 | xxx 0.36608 |

| P7—Equivalent Stress Maximum (MPa) | *** 32.811 | *** 30.17 | *** 24.994 |

| Name | P11—FBlend8.FD1 (mm) | P12—FBlend10.FD1 (mm) | P13—Extrude8.FD1 (mm) | P6—Solid Mass (kg) | P7—Equivalent Stress Maximum (MPa) | ||

|---|---|---|---|---|---|---|---|

| Parameter Value | Variation from Reference | Parameter Value | Variation from Reference | ||||

| Candidate Point 1 | 3.3 | 3.3 | 10.8 | ** 0.34019 | −7.07% | ** 32.27 | 31.27% |

| Candidate Point 2 | 2.7 | 2.7 | 13.2 | xxx 0.36602 | −0.02% | ** 30.17 | 20.71% |

| Candidate Point 3 | 3.3 | 3.3 | 13.2 | xxx 0.36608 | 0.00% | ** 24.994 | 0.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geonea, I.; Copilusi, C.; Dumitru, S.; Margine, A.; Rosca, A.; Tarnita, D. A New Exoskeleton Prototype for Lower Limb Rehabilitation. Machines 2023, 11, 1000. https://doi.org/10.3390/machines11111000

Geonea I, Copilusi C, Dumitru S, Margine A, Rosca A, Tarnita D. A New Exoskeleton Prototype for Lower Limb Rehabilitation. Machines. 2023; 11(11):1000. https://doi.org/10.3390/machines11111000

Chicago/Turabian StyleGeonea, Ionut, Cristian Copilusi, Sorin Dumitru, Alexandru Margine, Adrian Rosca, and Daniela Tarnita. 2023. "A New Exoskeleton Prototype for Lower Limb Rehabilitation" Machines 11, no. 11: 1000. https://doi.org/10.3390/machines11111000

APA StyleGeonea, I., Copilusi, C., Dumitru, S., Margine, A., Rosca, A., & Tarnita, D. (2023). A New Exoskeleton Prototype for Lower Limb Rehabilitation. Machines, 11(11), 1000. https://doi.org/10.3390/machines11111000