Simulation Analysis on Electromagnetic Vibration and Noise of Novel Mechatronic-Electro-Hydraulic Coupler

Abstract

:1. Introduction

1.1. Research Motivation

1.2. Literature Review

1.3. Challenges and Problems

1.4. Contributions of this Work

- (1)

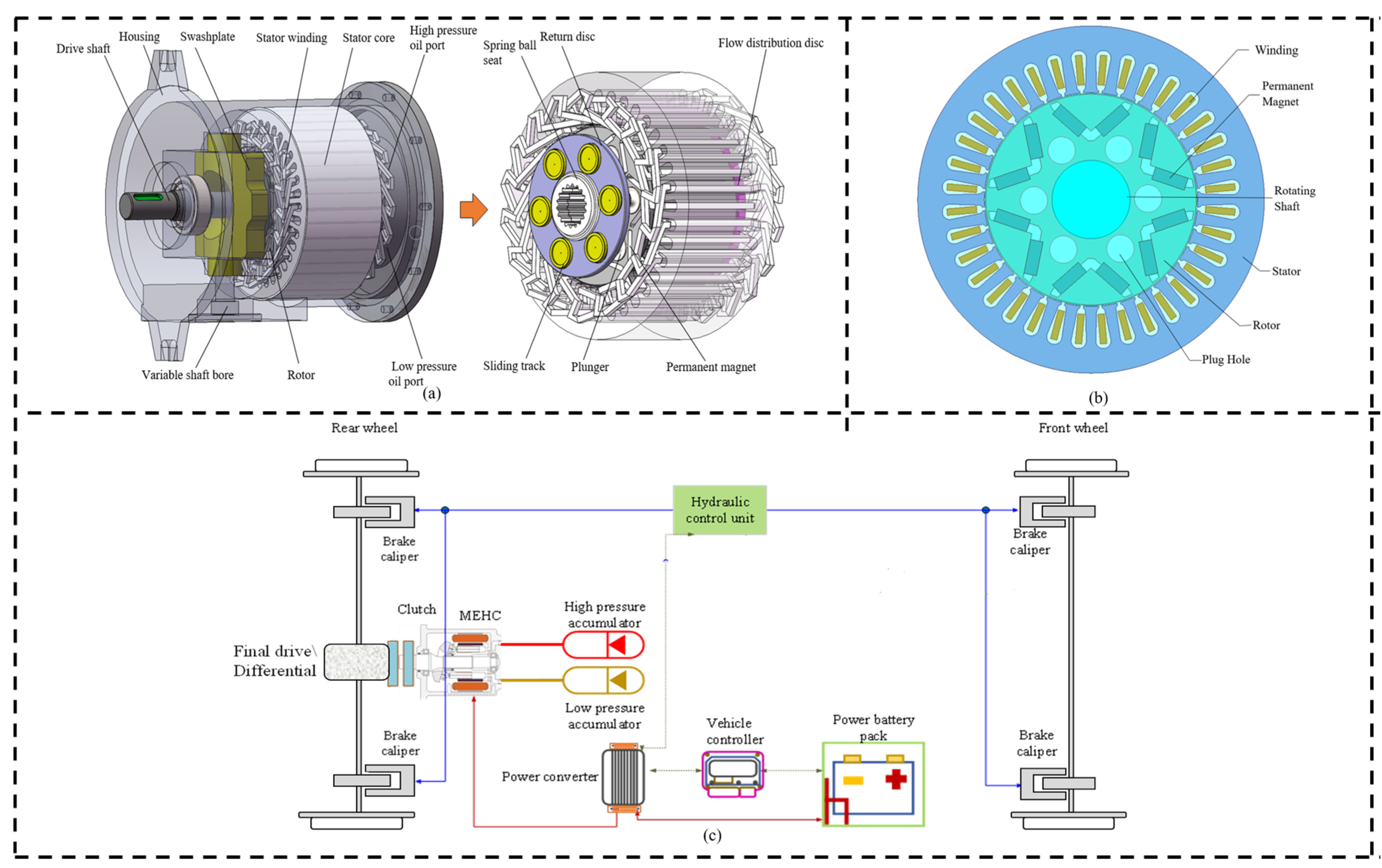

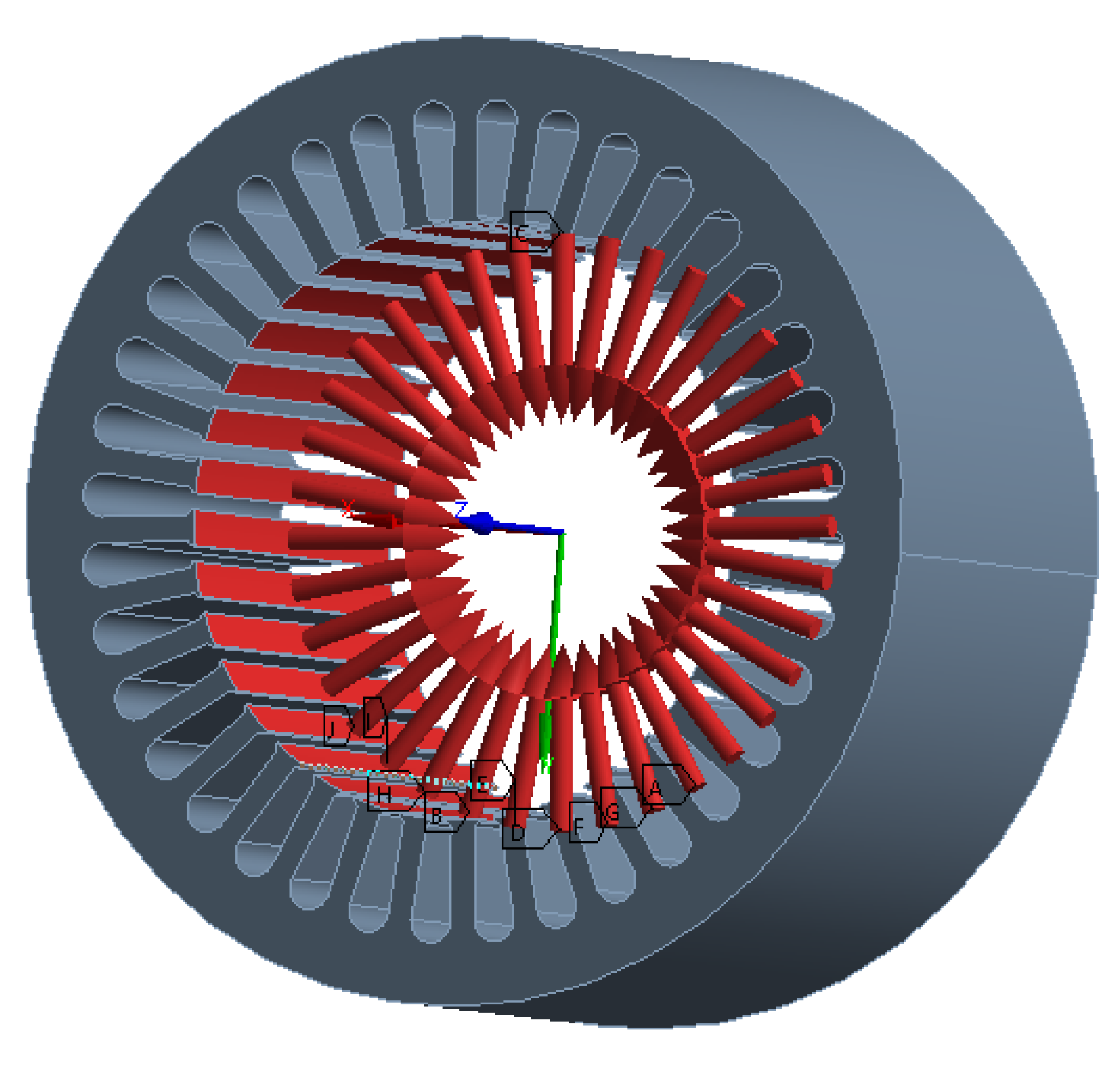

- A novel new electro-mechanical-hydraulic coupling power unit is proposed, which integrates a conventional permanent-magnet synchronous motor and a swashplate axial piston pump/motor to achieve arbitrary conversion between mechanical energy, electrical energy, and hydraulic energy.

- (2)

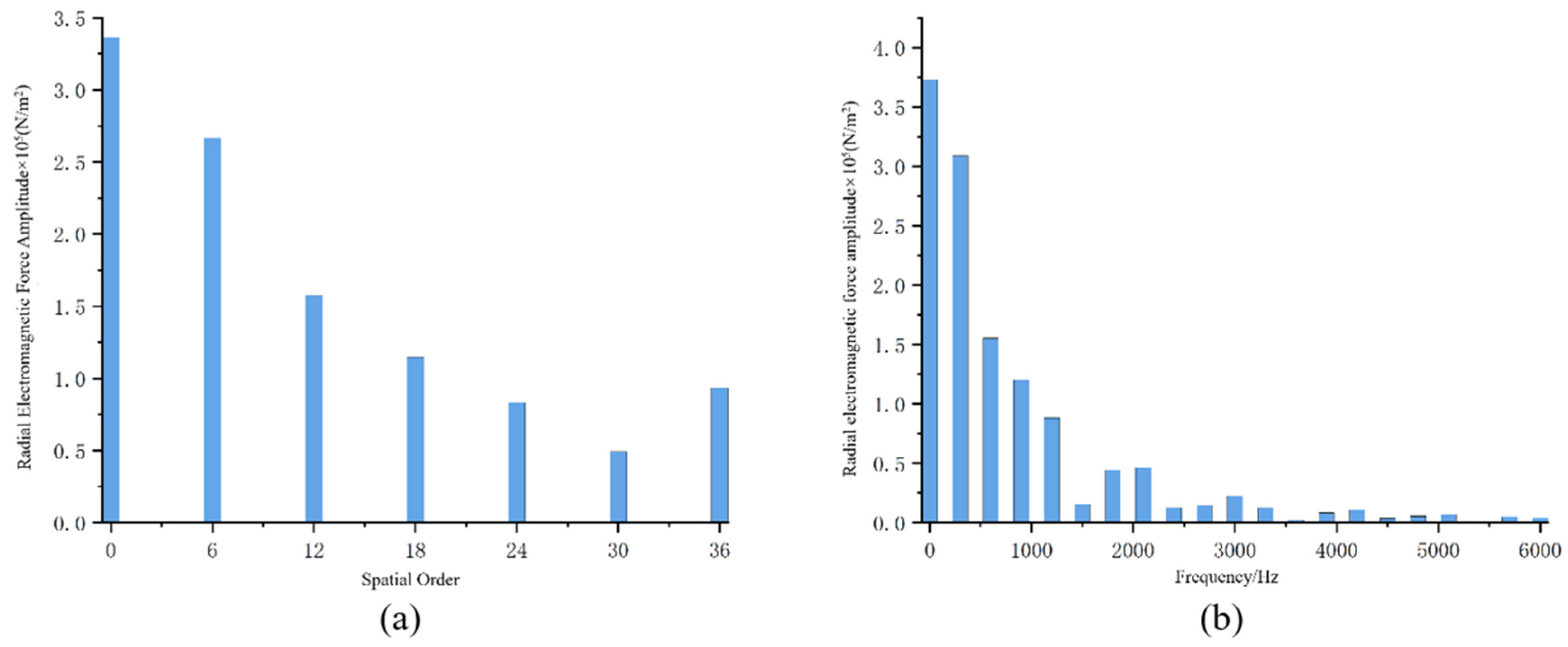

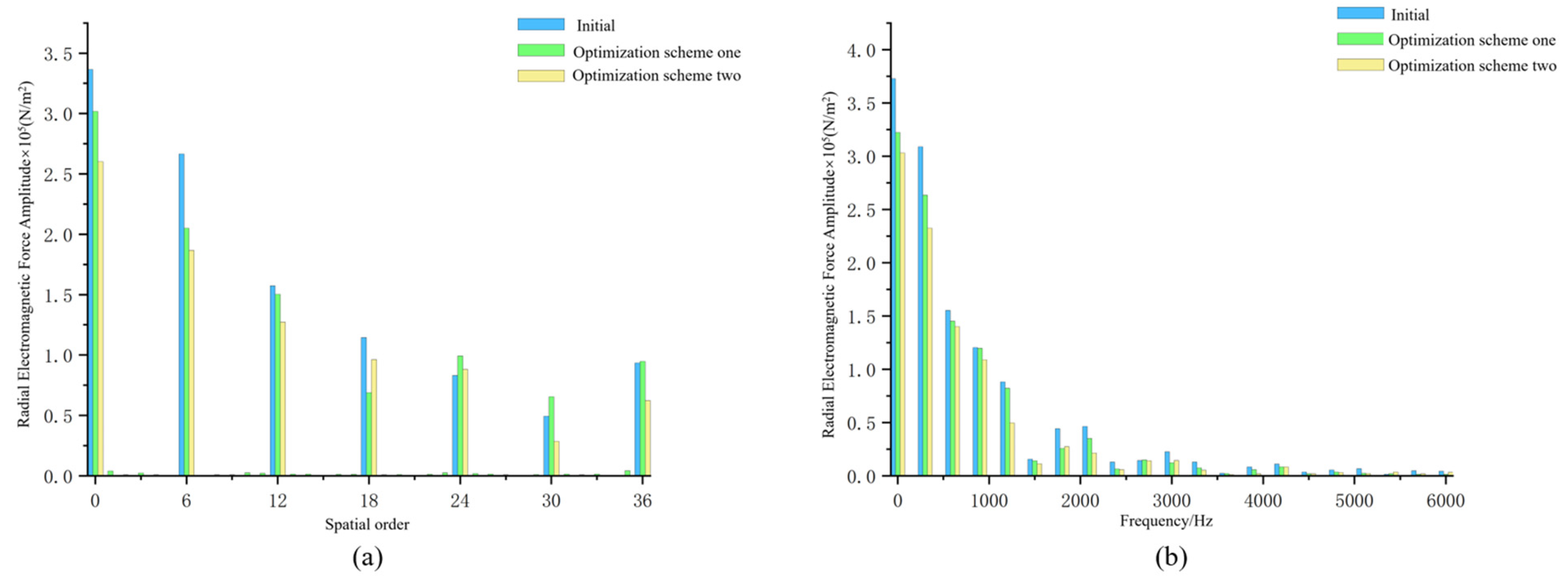

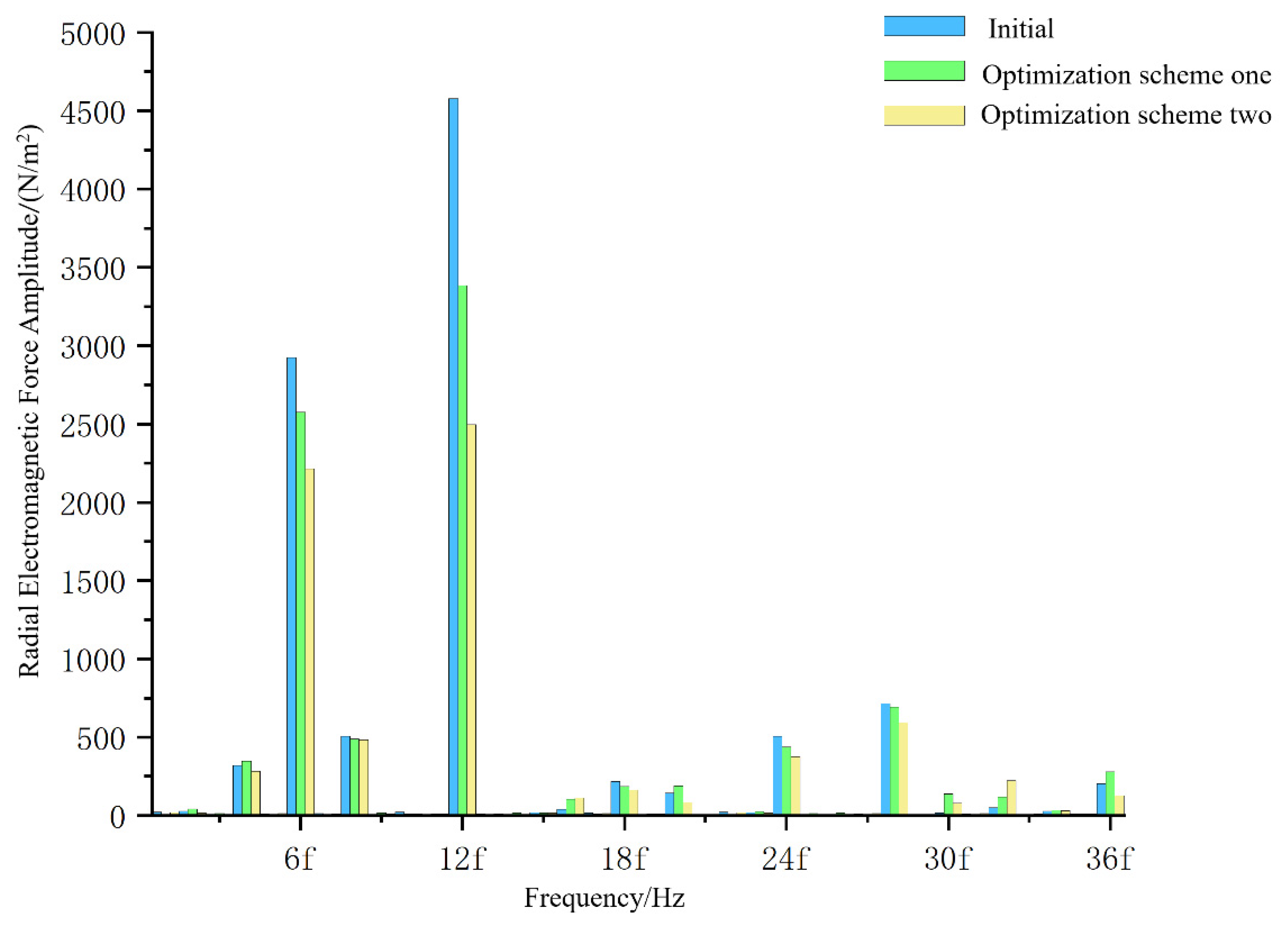

- The possible spatial order and temporal frequency of the electromagnetic forces are predicted using an analytical method and verified by electromagnetic simulations.

- (3)

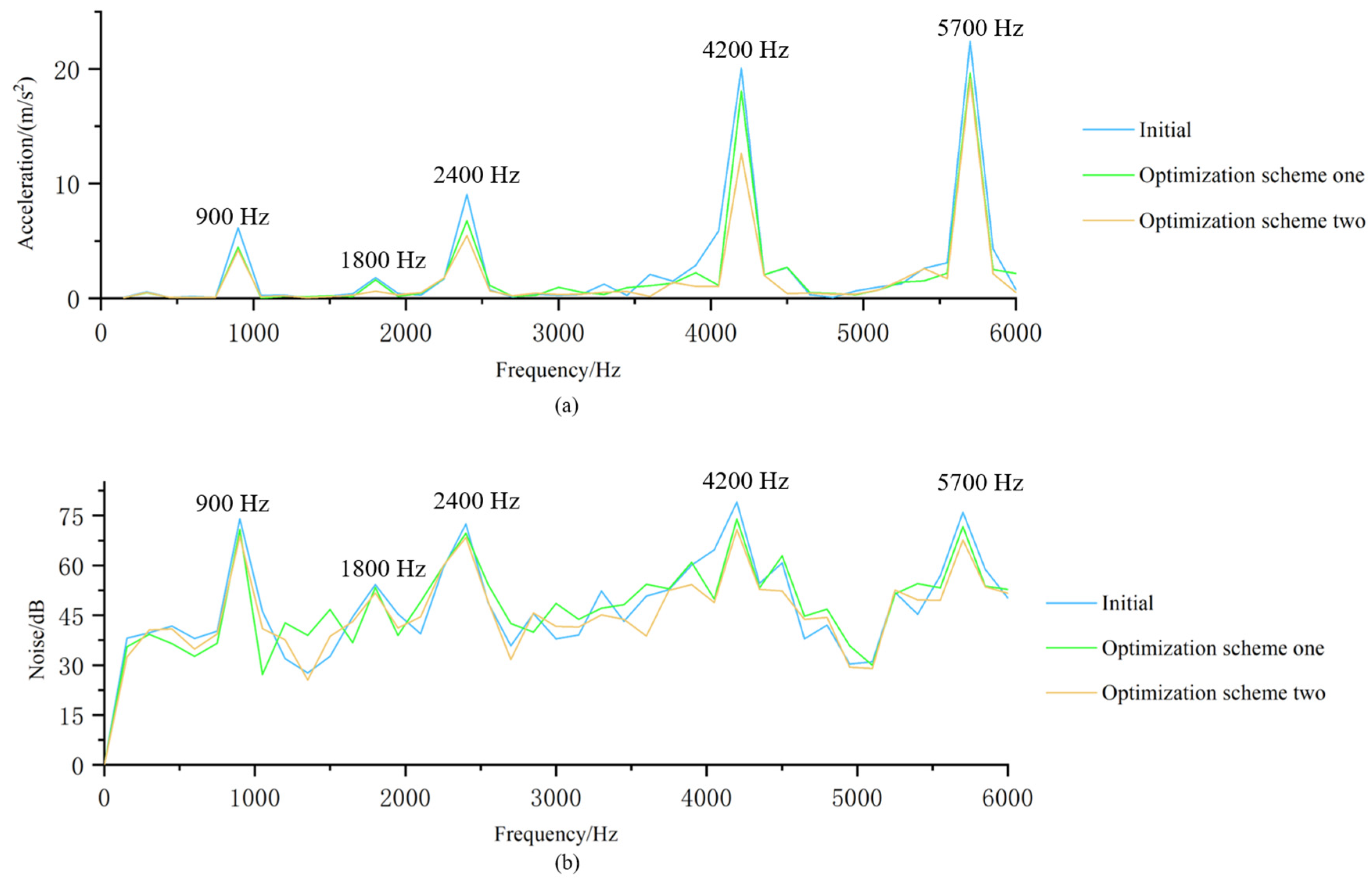

- An analysis of the modal inherent frequency of the motor stator at each order is performed. The MEHC’s vibration and noise are analysed, and two optimisation schemes are proposed to suppress the vibration and noise. It is verified through simulation that both optimisation schemes can effectively suppress the motor vibration and noise.

1.5. Organisation of the Paper

2. Structure and Working Principle of the MEHC

3. Parametric Analysis of Electromagnetic Force Wave Characteristics of MECH

3.1. Theoretical Analysis of the Characteristic Parameters of Electromagnetic Force Waves

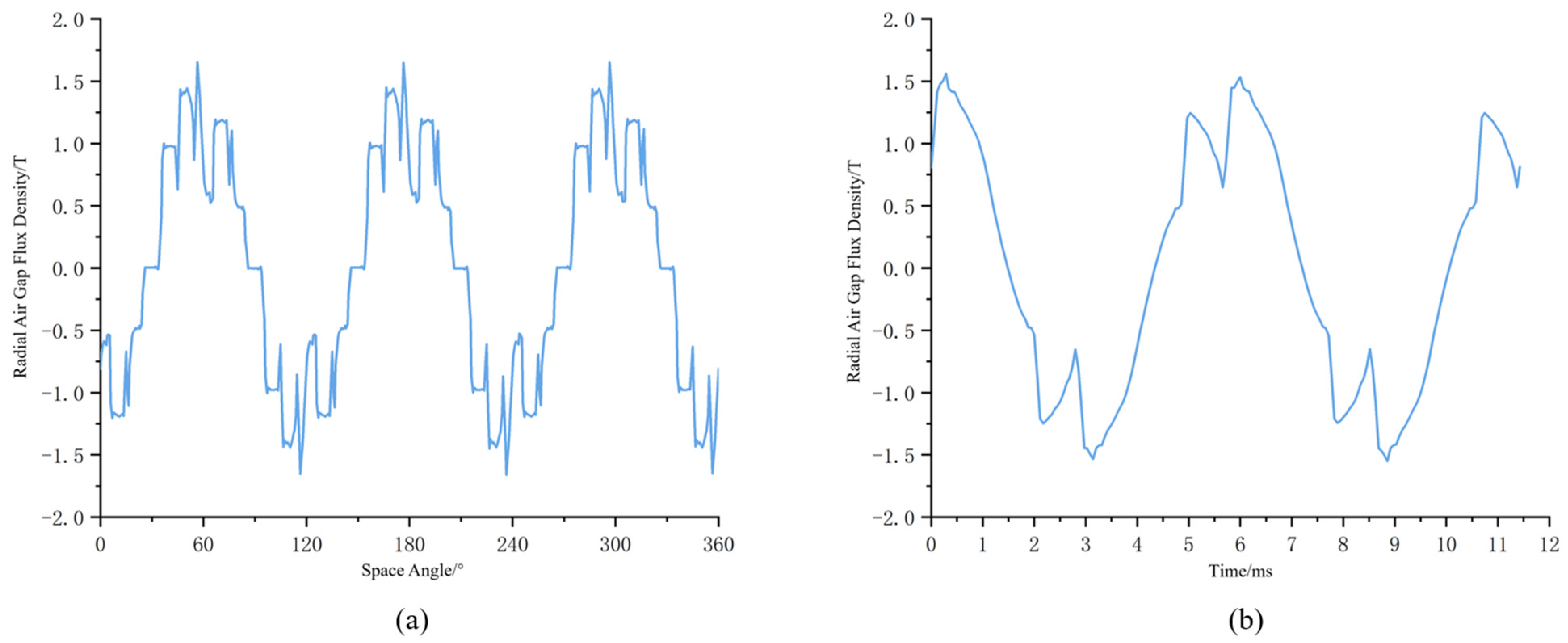

3.2. Finite Element Simulation of Electromagnetic Forces

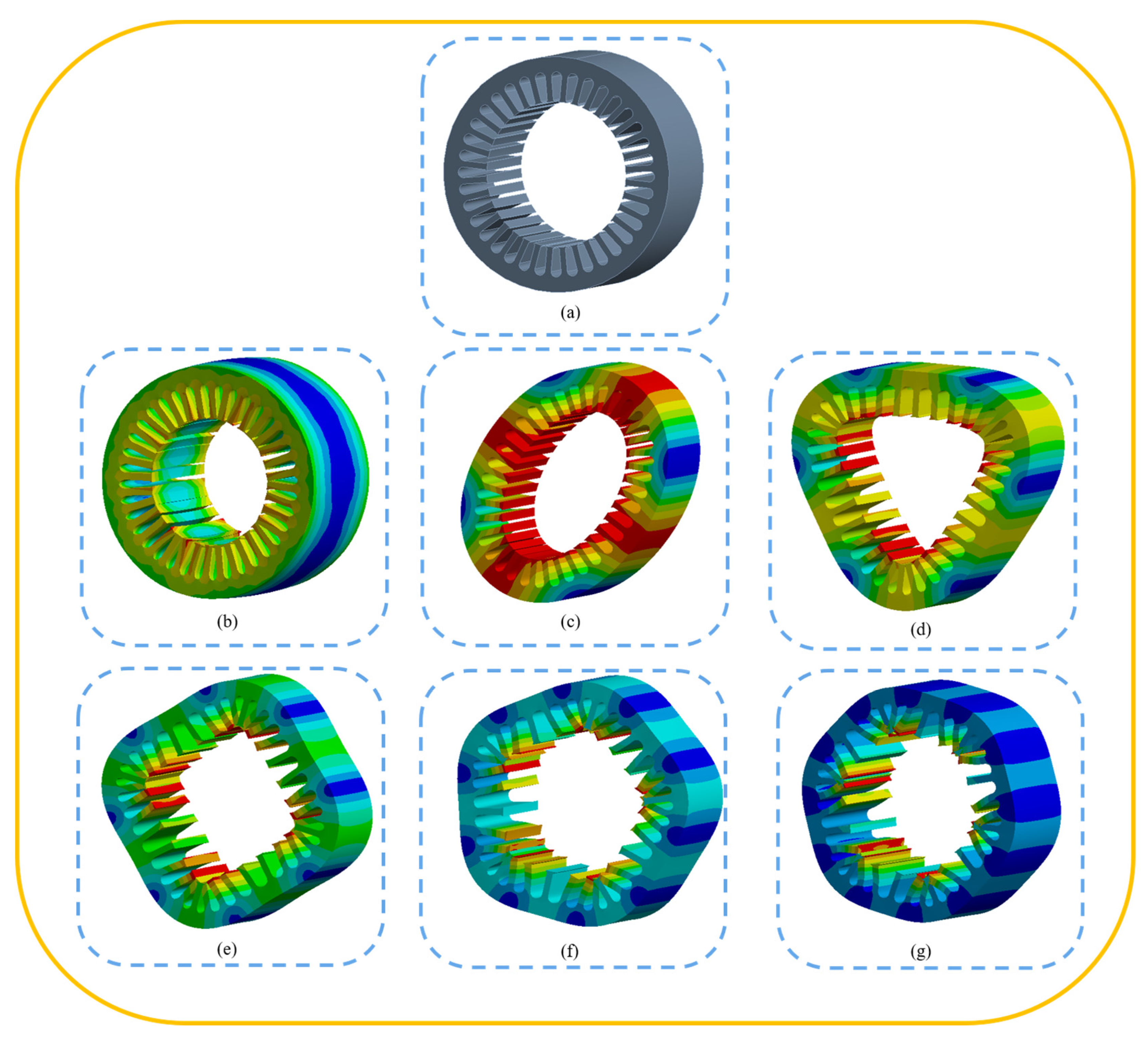

4. Stator Modal Analysis

5. Electromagnetic Vibration and Noise Analysis

5.1. Optimising Scheme Design

5.2. Vibration and Noise Analyses

6. Conclusions

- (1)

- A new type of multisource coupled power device was proposed. This paper selected the Maxwell tensor method to introduce the equation for the radial electromagnetic force and used electromagnetic simulation software to simulate and analyse the magnetic field of the MEHC motor. We analysed the air-gap magnetic density and the radial electromagnetic force by a fast Fourier transform, and the results were consistent with the analytical method.

- (2)

- Based on analysing the natural frequencies of the stator modes, the vibration of the stator was studied by coupling the electromagnetic field with the structural field. The results revealed that near the natural frequencies of each stator mode, the radial electromagnetic force excited each stator mode to cause a forced vibration, and the motor vibration was large.

- (3)

- Further, this paper simulated the noise of the MEHC motor and selected the noise spectrum of a certain point in the air domain to compare and analyse. Simulation results depicted that where the vibration was larger, the noise fluctuation was also larger. In addition, zeroth-order electromagnetic forces at 12 times the fundamental frequency also caused changes in the noise spectrum.

- (4)

- According to the simulation results of the two optimisation schemes, it was verified that the two methods could effectively reduce the radial electromagnetic force and vibration acceleration and then reduce the noise of the MEHC motor. Among them, the effect of Scheme 2 was superior, which makes it more helpful for improving the NVH performance of MEHC.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, B.; Ma, J.; Hong, H.; Yang, H.; Fang, Y. Study on fow ripple of axial piston pump with CFD simulation using compressible fuid oil. Chin. J. Mech. Eng. 2010, 23, 45–52. [Google Scholar] [CrossRef]

- Bianchini, C.; Torreggiani, A.; Davoli, M.; Bellini, A. Design of Low-Cost Synchronous Machine to Prevent Demagnetization. Energies 2020, 13, 3566. [Google Scholar] [CrossRef]

- Pan, Y.; Li, Y.; Huang, M.; Liao, Y.; Liang, D. Noise source identification and transmission path optimisation for noise reduction of an axial piston pump. Appl. Acoust. 2018, 130, 283–292. [Google Scholar] [CrossRef]

- Deng, W.; Zuo, S. Electromagnetic Vibration and Noise of the Permanent Magnet Synchronous Motors for Electric Vehicles: An Overview. IEEE Trans. Electrif. 2018, 5, 59–70. [Google Scholar] [CrossRef]

- Ye, S.-G.; Zhang, J.-H.; Xu, B. Noise Reduction of an Axial Piston Pump by Valve Plate Optimization. Chin. J. Mech. Eng. 2018, 31, 57. [Google Scholar] [CrossRef]

- Wu, S.; Li, W.; Tong, W.; Tang, R. Electromagnetic Vibration and Noise Comparison of Amorphous Metal PMSMs and Silicon Steel PMSMs. IEEE Access 2019, 7, 62672–62680. [Google Scholar] [CrossRef]

- Yang, Z.; Li, W.; Gou, Y.; Cai, T. Research on Radial Force of Permanent Magnet Synchronous Motor Based on Maxwell. J. Electr. Eng. Technol. 2020, 15, 2601–2608. [Google Scholar] [CrossRef]

- Verez, G.; Barakat, G.; Amara, Y.; Hoblos, G. Impact of Pole and Slot Combination on Vibrations and Noise of Electromagnetic Origins in Permanent Magnet Synchronous Motors. IEEE Trans. Magn. 2015, 51, 8101104. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, H.; Wang, H.; Ma, W. NVH Optimization Analysis of Permanent Magnet Synchronous Motor by Rotor Slotting. Vehicles 2020, 2, 287–302. [Google Scholar] [CrossRef]

- Hazra, S.; Reddy, J.K. An Aspect of Noise Vibration and Harshness Issues in Electric Vehicles. SAE Int. J. Veh. Dyn. Stab. NVH 2022, 6, 23–33. [Google Scholar] [CrossRef]

- Ai, L.; Zhang, G.; Jing, L.; Xu, X.; Si, J. Behaviors of axial and radial electromagnetic force for cryogenic disk motor. IEEE Trans. Energy Convers. 2021, 36, 874–882. [Google Scholar] [CrossRef]

- Xing, Z.; Wang, X.; Zhao, W. Research on weakening measure of radial electromagnetic force waves in permanent magnet synchronous motors by inserting auxiliary slots. IET Electr. Power Appl. 2020, 14, 1381–1395. [Google Scholar] [CrossRef]

- Liang, W.; Wang, J.; Luk, P.C.K.; Fei, W. The analytical study of stator tooth modulation on electromagnetic radial force in permanent magnet synchronous machines. IEEE Trans. Ind. Electron. 2020, 68, 11731–11739. [Google Scholar] [CrossRef]

- Castano, S.M.; Bilgin, B.; Lin, J.; Emadi, A. Radial forces and vibration analysis in an external-rotor switched reluctance machine. IET Electr. Power Appl. 2017, 11, 252–259. [Google Scholar] [CrossRef]

- Feng, C.; Yi, L.; Pei, Y.; Yu, Y. Analysis of radial vibration caused by magnetic force and torque pulsation in interior permanent magnet synchronous motors considering air-gap deformations. IEEE Trans. Ind. Electron. 2018, 66, 6703–6714. [Google Scholar]

- Das, S.; Hasan, I.; Sozer, Y.; Islam, R.; Ortega, A.P.; Klass, J. Noise and Vibration Performance in Fractional Slot Permanent Magnet Synchronous Machines Using Stator Bridge. In Proceedings of the IEEE Transportation Electrification Conference and Expo (ITEC), Long Beach, CA, USA, 13–15 June 2018; pp. 632–637. [Google Scholar]

- Li, X.; Zhang, L.; Ying, H.; Huang, S.; Zhang, Q. Study of suppression of vibration and noise of PMSM for electric vehicles. IET Electr. Power Appl. 2020, 14, 1274–1282. [Google Scholar] [CrossRef]

- Islam, M.S.; Islam, R.; Sebastian, T. Noise and Vibration Characteristics of Permanent-Magnet Synchronous Motors Using Electromagnetic and Structural Analyses. IEEE Trans. Ind. Appl. 2014, 50, 3214–3222. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, T. Vibroacoustic Characterization of a Permanent Magnet Synchronous Motor Powertrain for Electric Vehicles. IEEE Trans. Energy Convers. 2018, 33, 272–280. [Google Scholar] [CrossRef]

- Gao, L.; Zheng, H.; Zeng, L.; Pei, R. Evaluation Method of Noise and Vibration used in Permanent Magnet Synchronous Motor in Electric Vehicle. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Novi, MI, USA, 19–21 June 2019. [Google Scholar]

- Lin, F.; Zuo, S.-G.; Deng, W.-Z.; Wu, S.-L. Reduction of vibration and acoustic noise in permanent magnet synchronous motor by optimizing magnetic forces. J. Sound Vib. 2018, 429, 193–205. [Google Scholar] [CrossRef]

- Wang, X.; Sun, X.; Gao, P. A study on the effects of rotor step skewing on the vibration and noise of a PMSM for electric vehicles. IET Electr. Power Appl. 2020, 14, 131–138. [Google Scholar] [CrossRef]

- Hasan, I.; Sozer, Y.; Ortega, A.P.; Paul, S.; Islam, R. Investigation of design based solutions to reduce vibration in permanent magnet synchronous machines with low order radial forces. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017. [Google Scholar]

- Li, J.; Wang, K.; Li, F. Analytical prediction of optimal split ratio of consequent-pole permanent magnet machines. IET Electr. Power Appl. 2017, 12, 365–372. [Google Scholar] [CrossRef]

- Zhu, X.; Hua, W.; Wu, Z. Cogging torque minimisation in fspm machines by right-angle-based tooth chamfering technique. IET Electr. Power Appl. 2018, 12, 627–634. [Google Scholar] [CrossRef]

- Bonthu, S.S.R.; Tarek, M.T.B.; Choi, S. Optimal torque ripple reduction technique for outer rotor permanent magnet synchronous reluctance motors. IEEE Trans. Energy Convers. 2018, 3, 1184–1192. [Google Scholar] [CrossRef]

- Zhu, X.; Hua, W.; Zhang, G. Analysis and reduction of cogging torque for flux-switching permanent magnet machines. IEEE Trans. Ind. Appl. 2019, 6, 5854–5864. [Google Scholar] [CrossRef]

- Shen, J.; Chen, X.; Cui, Z.; Ma, L. Optimization design and research on vibration and noise of permanent magnet synchronous motor for vehicle. Prog. Electromagn. Res. M 2021, 100, 105–115. [Google Scholar] [CrossRef]

| Air-Gap Magnetic Density Harmonic Count | Space Order | Frequency | |

|---|---|---|---|

| bp1·bp1 | μ1 ≠ μ2 | (μ1 ± μ2)p | (μ1 ± μ2)f |

| μ1 = μ2 = μ | 2μp 0 | 2μf 0 | |

| bp1·bp2 | μ1 ≠ μ2 | μ1p ± μ2p ± kZ | (μ1 ± μ2)f |

| μ1 = μ2 = μ | 2μp ± kZ | 2μf | |

| ±kZ | 0 | ||

| bp2·bp2 | μ1 ≠ μ2 | (μ1 ± μ2)p μ1p ± μ2p ± 2kZ | (μ1 − μ2)f (μ1 + μ2)f |

| μ1 = μ2 = μ | 2(μp + kZ) 0 | 2μf 0 |

| Air-Gap Magnetic Density Harmonic Count | Space Order | Frequency | |

|---|---|---|---|

| bp1·bs1 | Μ ≠ v | (μ ± v)p | (μ ± 1)f |

| μ = v | 2μp 0 | (μ + 1)f (μ − 1)f | |

| bp1·bs2 | Μ ≠ v | μp ± vp ± kZ | (μ ± 1)f |

| μ = v | 2μp ± kZ | (μ + 1)f | |

| ±kZ | (μ − 1)f | ||

| bp2·bs1 | Μ ≠ v | μp ± vp ± kZ | (μ ± 1)f |

| μ = v | 2μp + kZ +kZ | (μ + 1)f (μ − 1)f | |

| bp2·bs2 | Μ ≠ v | μp ± vp ± kZ | (μ ± 1)f |

| μ = v | 2μp + kZ +kZ | (μ + 1)f 0 |

| Parameter | Specific Values |

|---|---|

| Number of slots/pole pairs | 36/3 |

| Rated power/kW | 18 |

| Rated current/A | 244 |

| Rated speed/(r/min) | 3000 |

| Plunger diameter d/mm | 17 |

| Diameter of plunger distribution circle D/mm | 68 |

| Frequency/Hz | Initial/(m/s2) | Scheme One/(m/s2) | Scheme Two/(m/s2) |

|---|---|---|---|

| 900 | 6.138 | 4.44 | 4.207 |

| 1800 | 1.811 | 1.601 | 0.6103 |

| 2400 | 9.0547 | 6.7623 | 5.4618 |

| 4200 | 20.056 | 18.084 | 12.64 |

| 5700 | 22.417 | 19.672 | 19.114 |

| Frequency/Hz | Initial/(m/s2) | Scheme One/(m/s2) | Scheme Two/(m/s2) |

|---|---|---|---|

| 900 | 6.138 | 4.44 | 4.207 |

| 1800 | 1.811 | 1.601 | 0.6103 |

| 2400 | 9.0547 | 6.7623 | 5.4618 |

| 4200 | 20.056 | 18.084 | 12.64 |

| 5700 | 22.417 | 19.672 | 19.114 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Zhang, T.; Zhang, H.; Zhang, Z.; Cao, Y. Simulation Analysis on Electromagnetic Vibration and Noise of Novel Mechatronic-Electro-Hydraulic Coupler. Machines 2022, 10, 762. https://doi.org/10.3390/machines10090762

Liu B, Zhang T, Zhang H, Zhang Z, Cao Y. Simulation Analysis on Electromagnetic Vibration and Noise of Novel Mechatronic-Electro-Hydraulic Coupler. Machines. 2022; 10(9):762. https://doi.org/10.3390/machines10090762

Chicago/Turabian StyleLiu, Baoquan, Tiezhu Zhang, Hongxin Zhang, Zhen Zhang, and Yang Cao. 2022. "Simulation Analysis on Electromagnetic Vibration and Noise of Novel Mechatronic-Electro-Hydraulic Coupler" Machines 10, no. 9: 762. https://doi.org/10.3390/machines10090762

APA StyleLiu, B., Zhang, T., Zhang, H., Zhang, Z., & Cao, Y. (2022). Simulation Analysis on Electromagnetic Vibration and Noise of Novel Mechatronic-Electro-Hydraulic Coupler. Machines, 10(9), 762. https://doi.org/10.3390/machines10090762