High Temperature Mechanical Properties and Microstructure Evolution of Ti-6Al-4V Alloy Linear Friction Welding Joints

Abstract

:1. Introduction

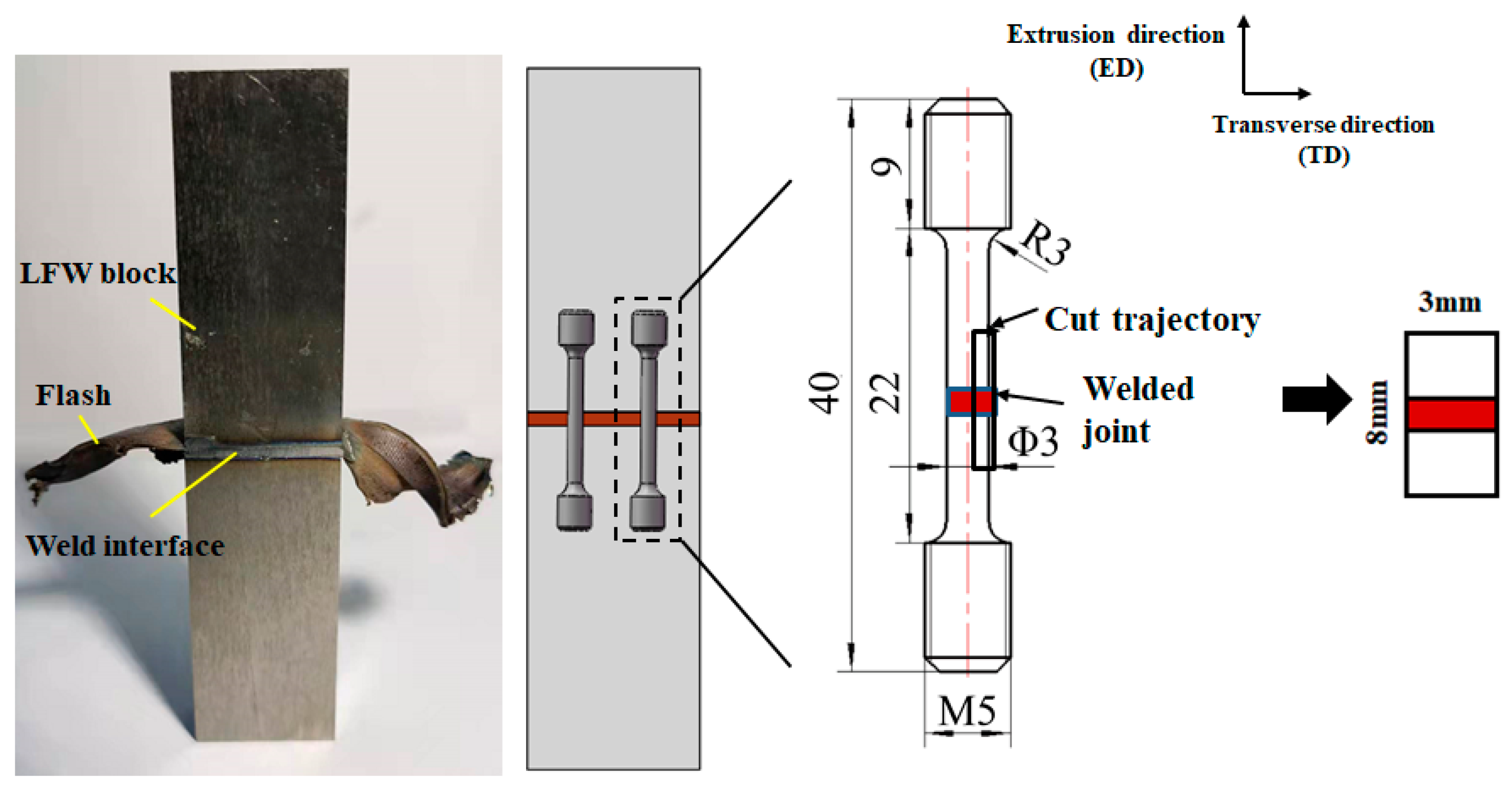

2. Materials and Methods

2.1. Material

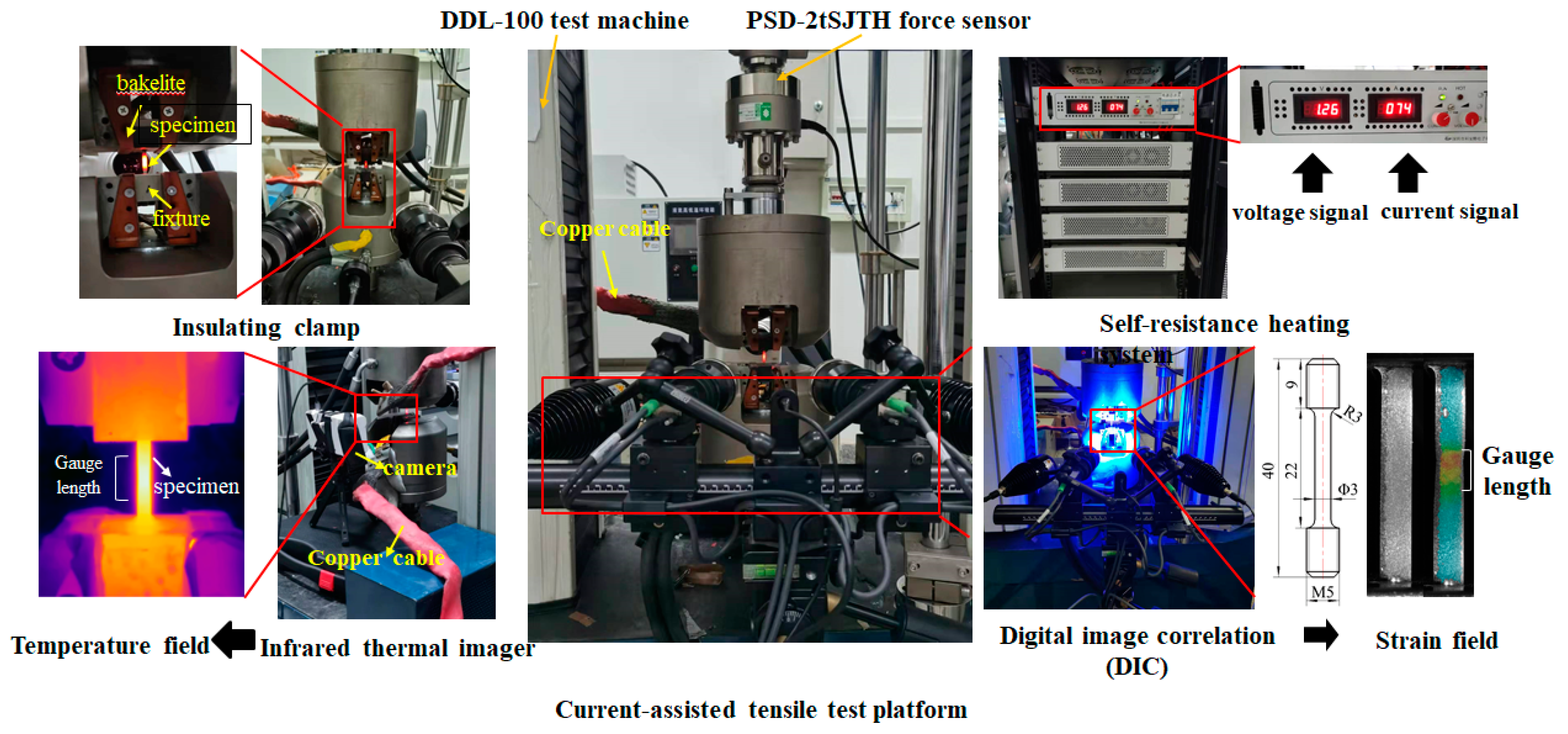

2.2. Current-Assisted High Temperature Uniaxial Tensile Test Platform

2.3. Microstructure Characterization

3. Results

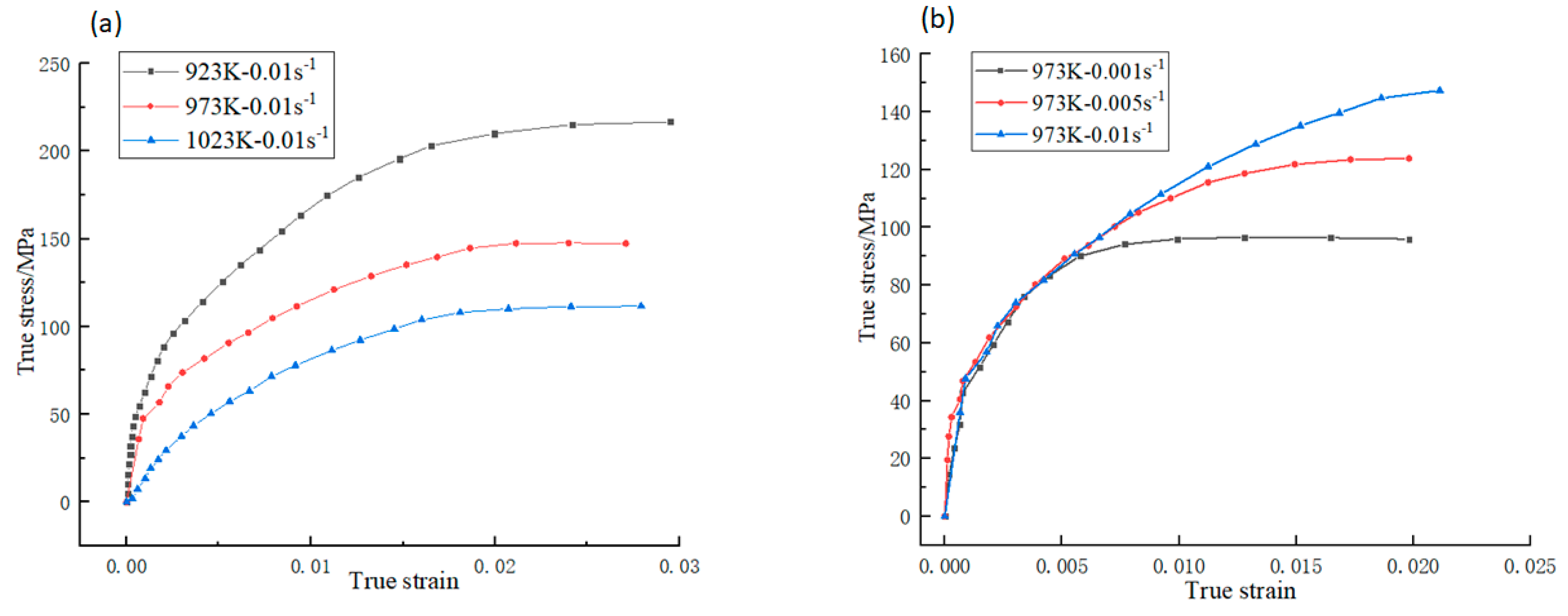

3.1. Tensile Flow Behavior at Elevated Temperatures

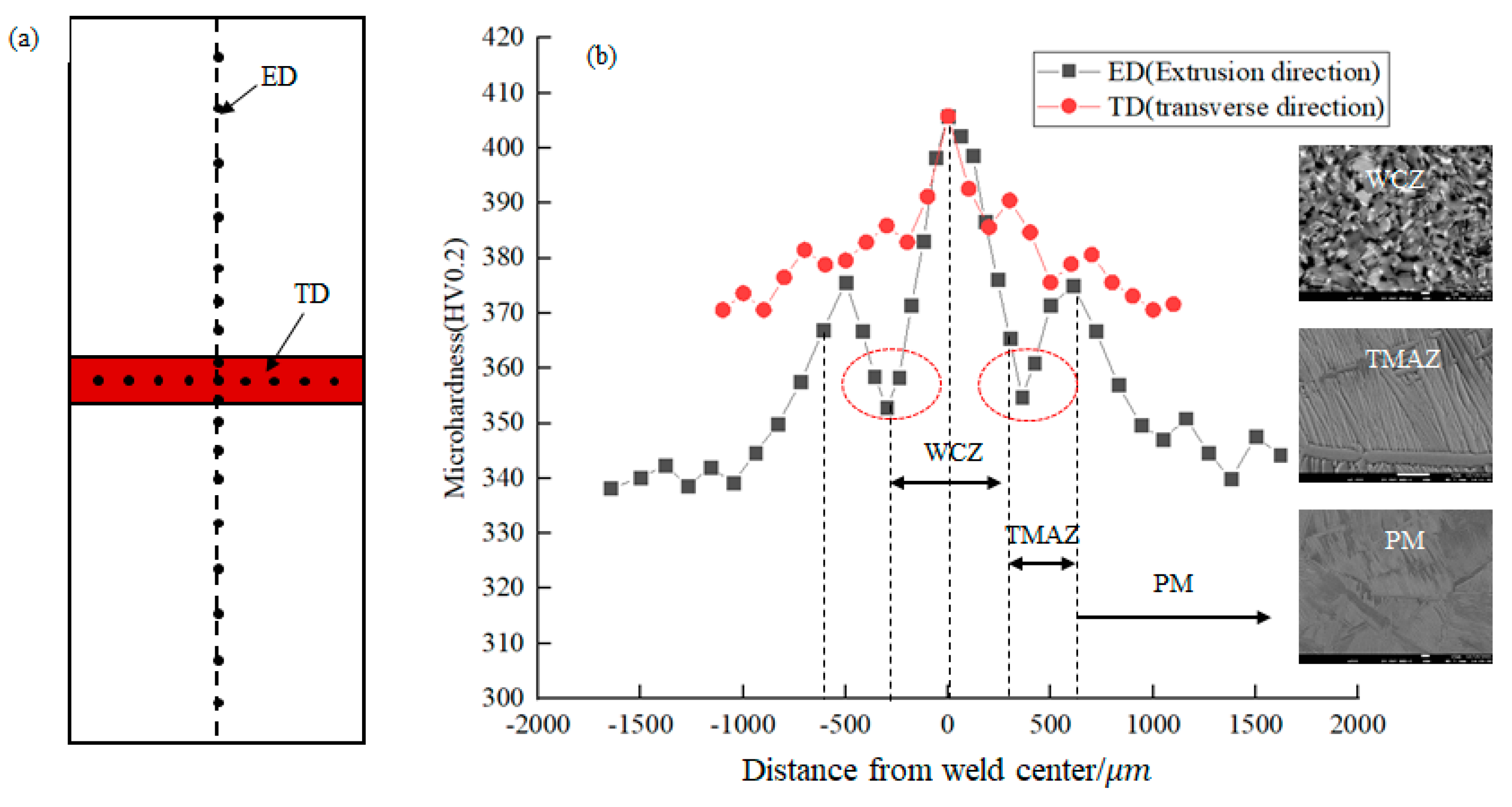

3.2. Micro-Hardness Tests

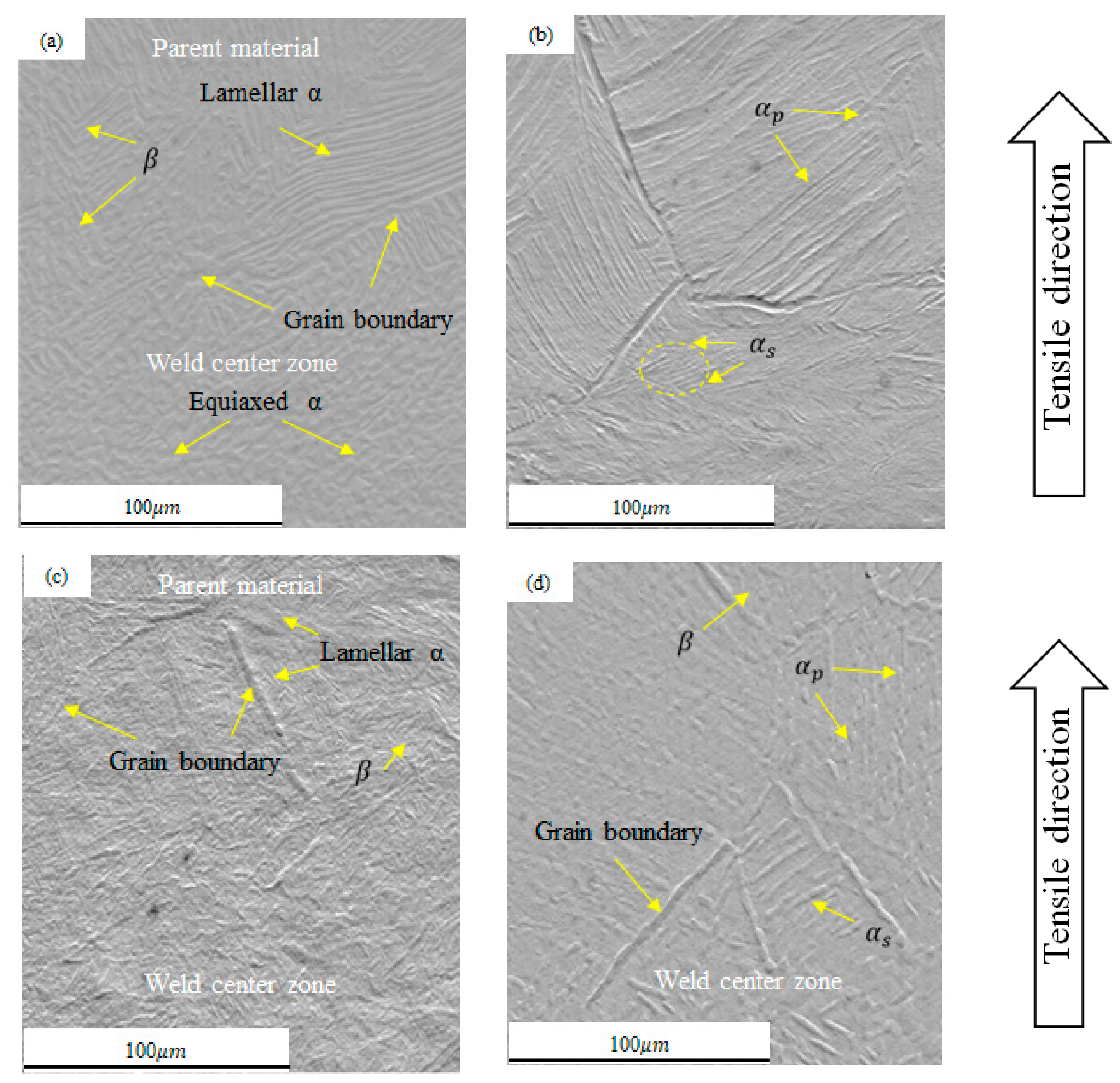

3.3. SEM Obsevation

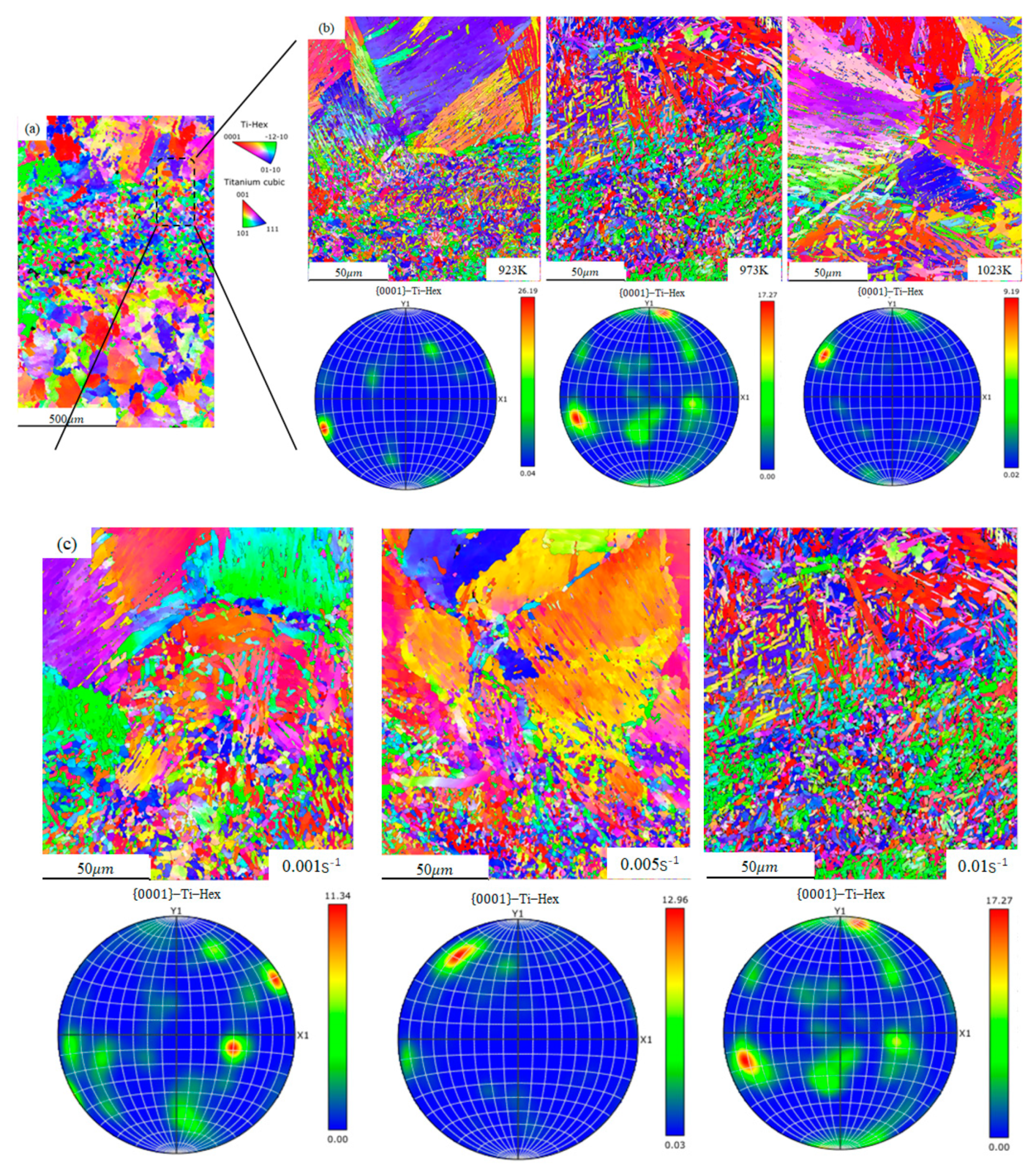

3.4. EBSD Observation

4. Discussion

4.1. Hot Deformation Mechanism of LFW Joints

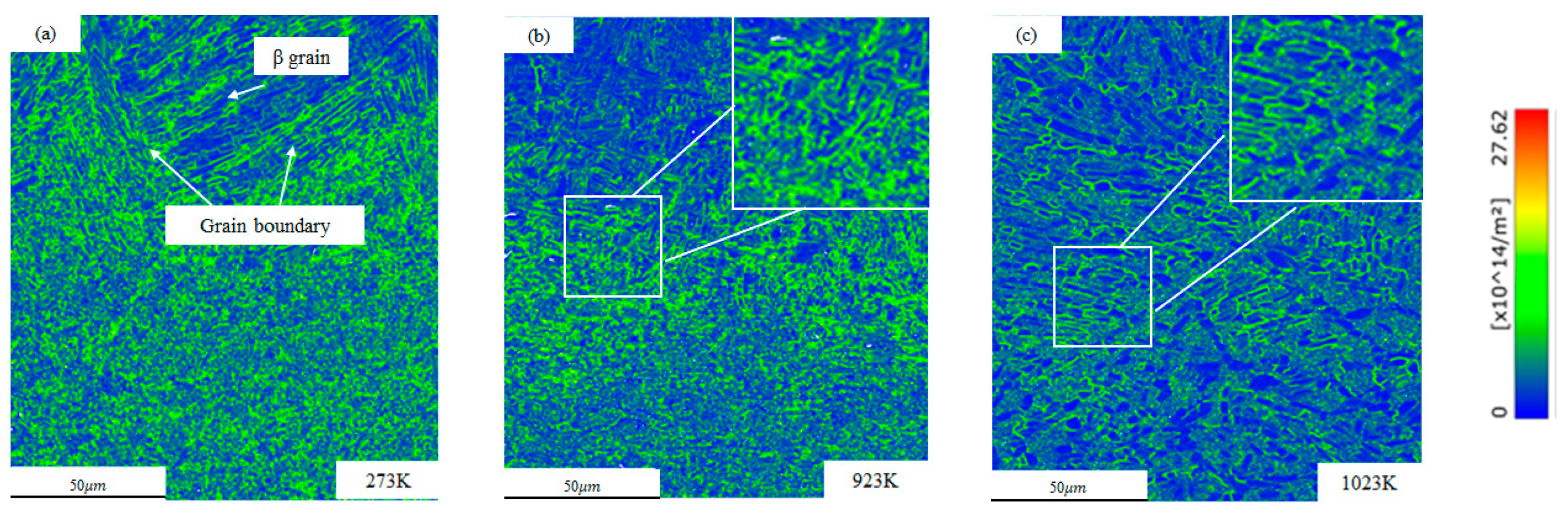

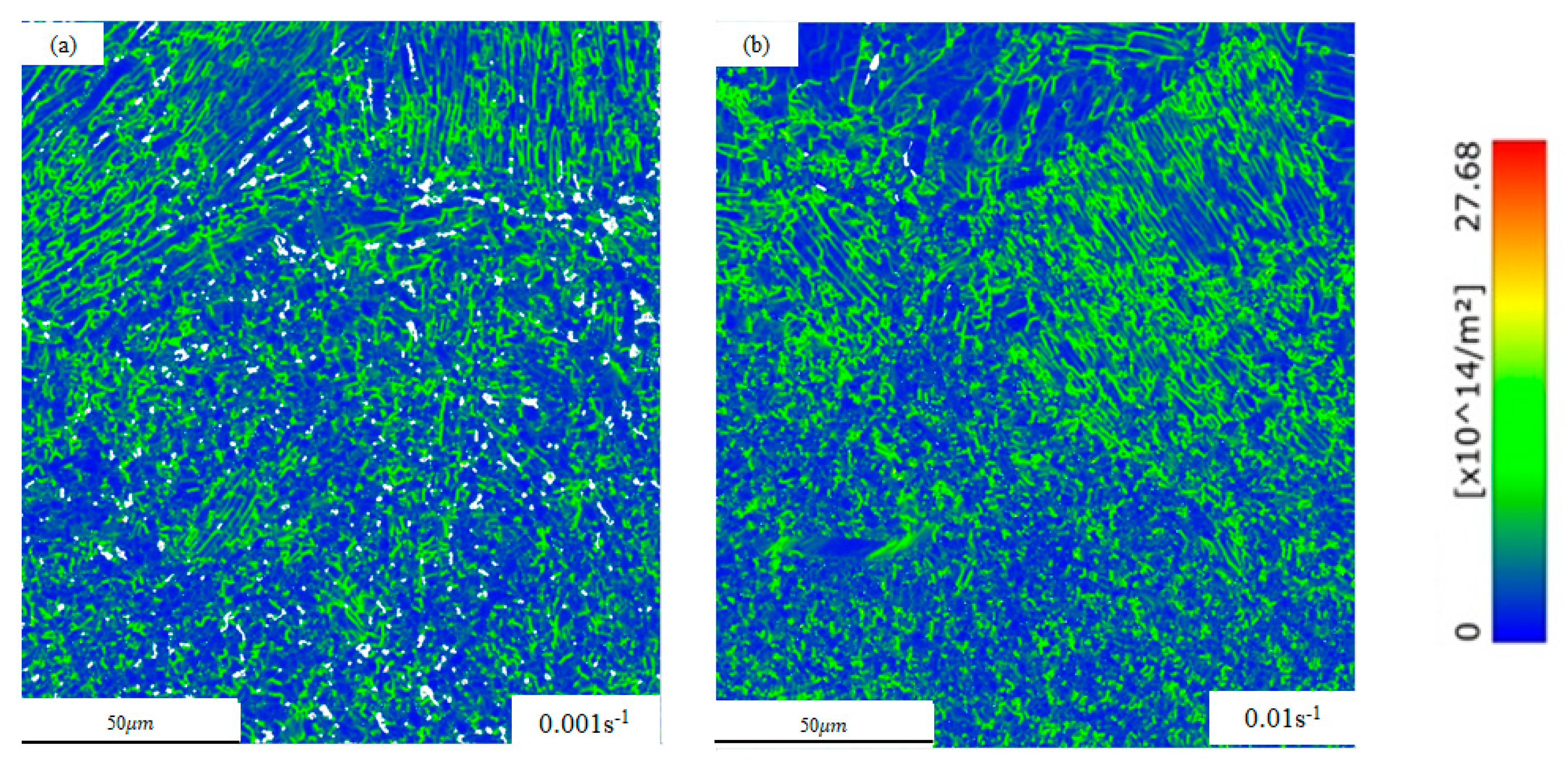

4.2. Effect of Temperature and Strain Rates on Microstructure Evolution

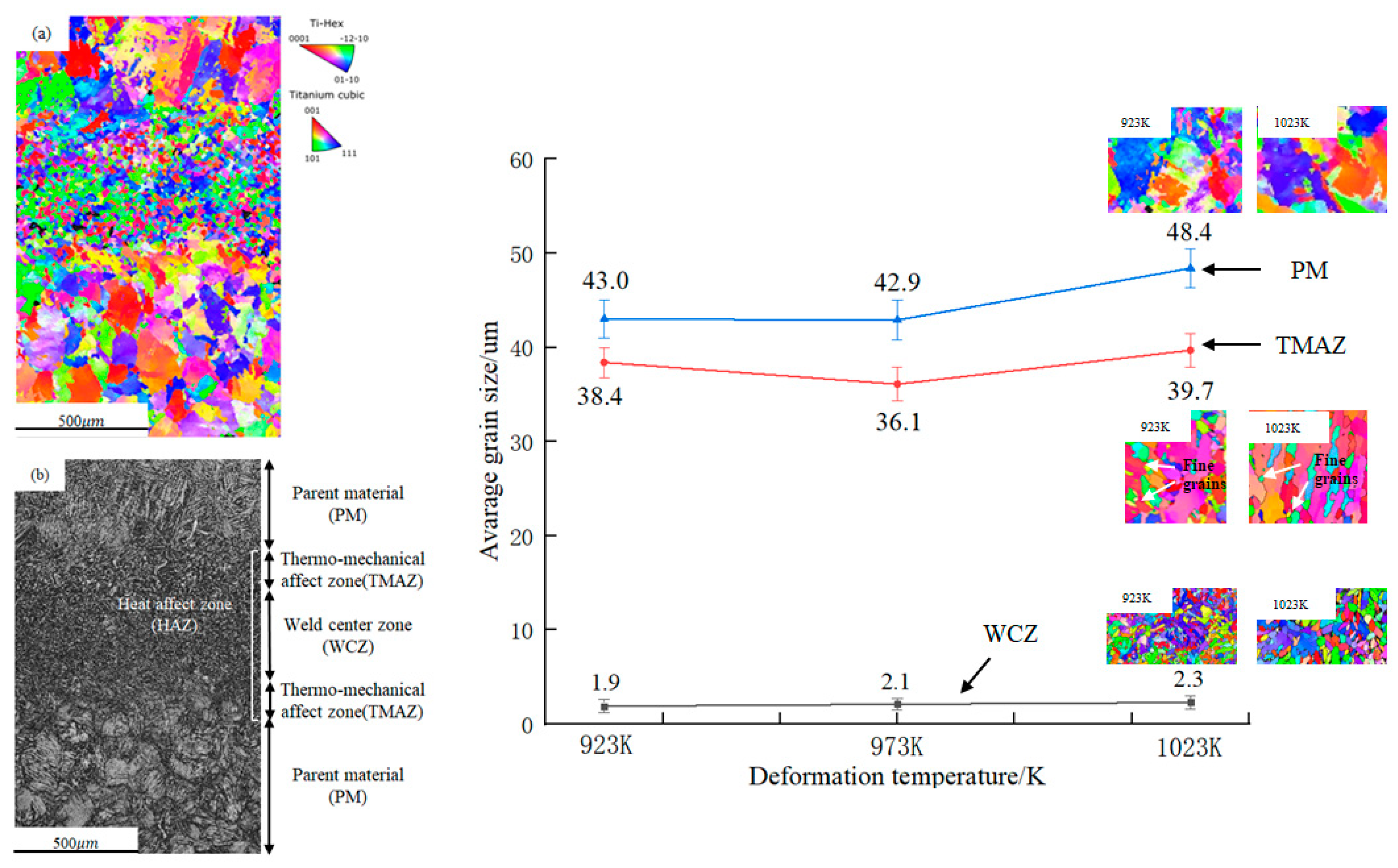

4.2.1. Grain Morphology and Size after Hot Deformation with Different Temperatures

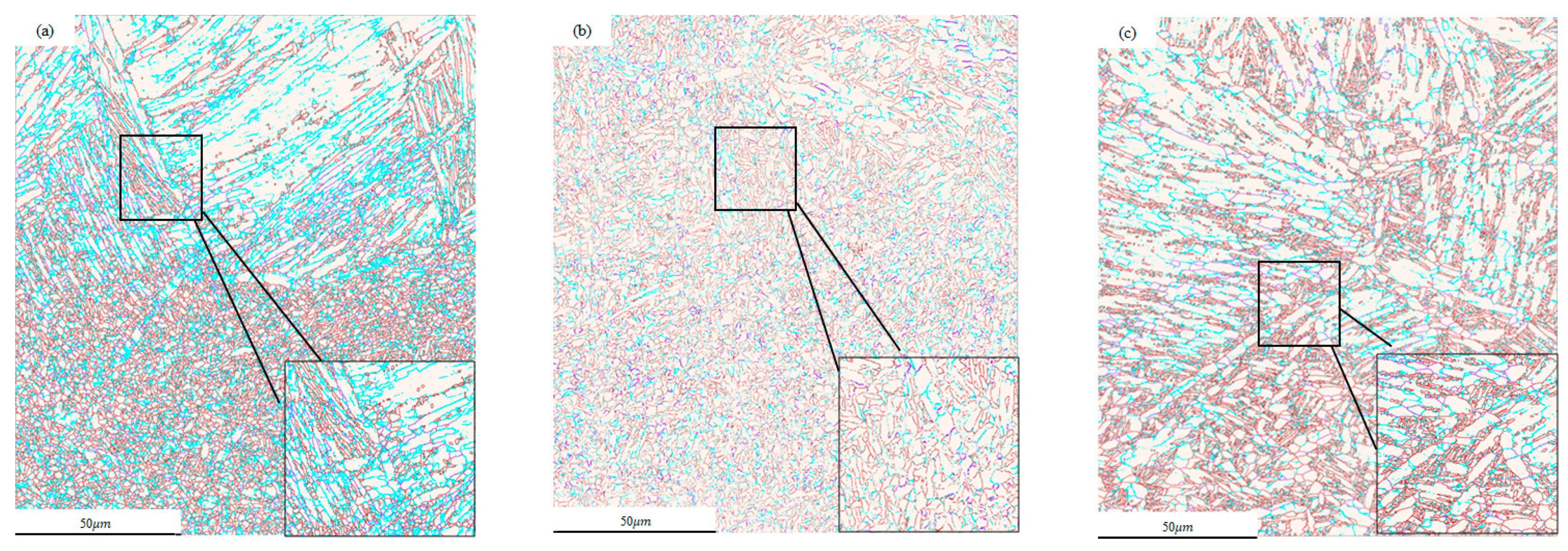

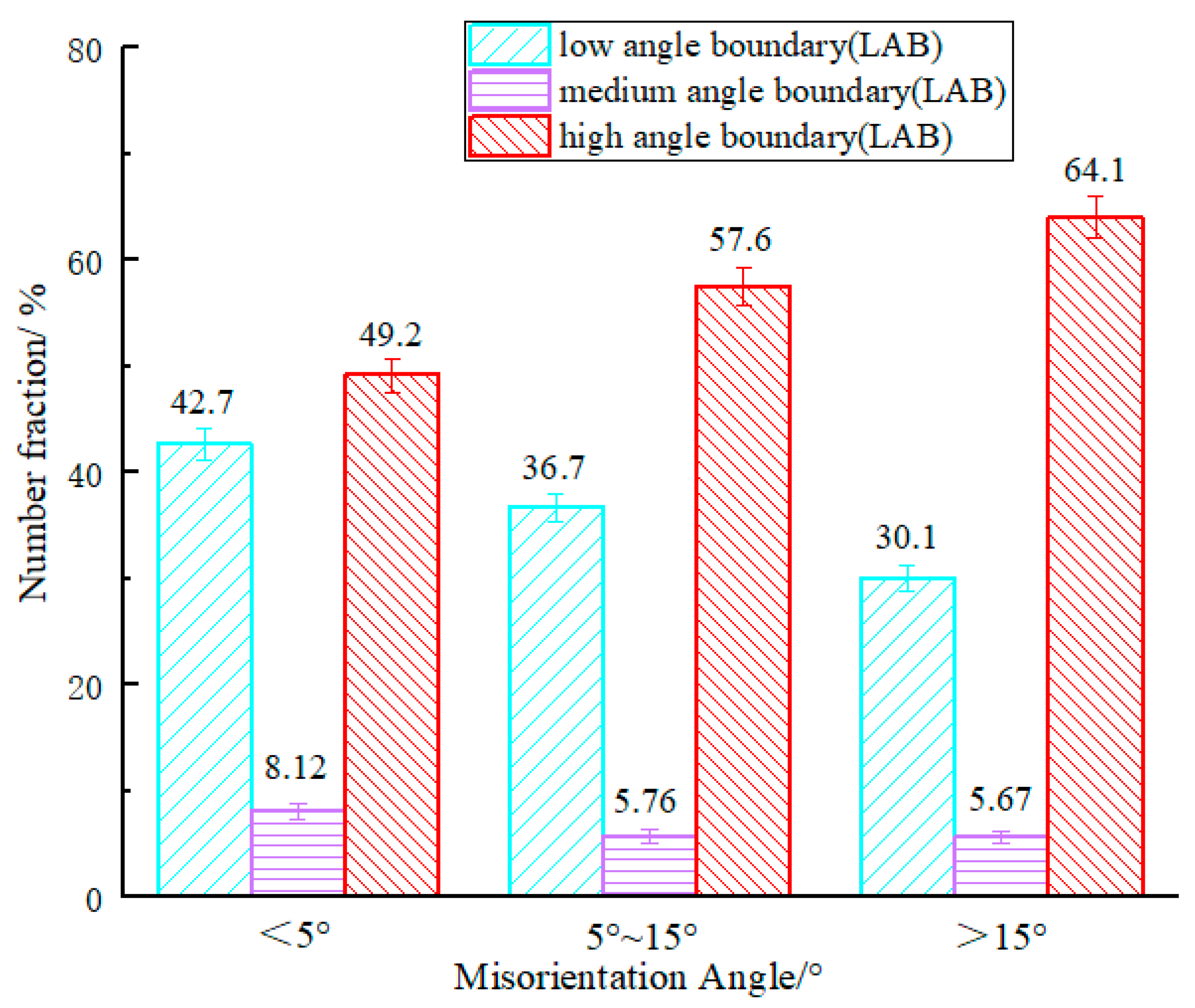

4.2.2. Grain and Subgrain Boundary (GSB) Structure Evolution after Hot Deformation

4.2.3. Temperature and Strain Rate Effect on GND Evolution

5. Conclusions

- 1.

- Despite that the high-temperature flow behavior of LFW joints shows a clear correlation between temperature and strain rate, all the flow stress curve exhibits a similar trend: Once the alloy has reached its peak value, the stress curves show a declining tendency due to high-temperature softening. The yield stress drops from 203 MPa at 923 K to 105 MPa at 1023 K, and rises from 85 MPa to 130 MPa with the strain rates increases from 0.001 s−1 to 0.01 s−1 at 973 K.

- 2.

- The hot deformation mechanism of LFW joints are various under different deformation conditions: the hot deformation mechanism changes from the mechanism of dislocation creep to the mechanism of self-diffusion as the deformation temperature increases from 923 to 1023 K.

- 3.

- The fraction of HABs rapidly rises from 49.2% to 64.1% with the increase of temperature, the discontinuous dynamic recrystallization (DDRX) become the primary mechanism of nucleation during high-temperature deformation of LFW joints.

- 4.

- The grain size in different regions of welded joints has different variation trends: the average grain size in PM increased from 43 at 923 K to 48.4 at 1023 K, while the grain size in TAMZ firstly decreased from 38.4 to 36.1 , then increased to 39.7 due to recrystallization. It is widely existed in hot deformation process of LFW joints and it will promote the rotation of subgrain to relieve the dislocation pile-up or promote the formation of high angle grain boundaries.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Li, C.-L.; Mi, X.-J.; Ye, W.-J.; Hui, S.-X.; Yu, Y.; Wang, W.-Q. A study on the microstructures and tensile properties of new beta high strength titanium alloy. J. Alloys Compd. 2012, 550, 23–30. [Google Scholar] [CrossRef]

- Li, Y.; Loretto, M.; Rugg, D.; Voice, W. Effect of heat treatment and exposure on microstructure and mechanical properties of Ti–25V–15Cr–2Al–0.2C (wt%). Acta Mater. 2001, 49, 3011–3017. [Google Scholar] [CrossRef]

- Odenberger, E.-L.; Pederson, R.; Oldenburg, M. Finite element modeling and validation of springback and stress relaxation in the thermo-mechanical forming of thin Ti-6Al-4V sheets. Int. J. Adv. Manuf. Technol. 2019, 104, 3439–3455. [Google Scholar] [CrossRef] [Green Version]

- Guo, G.; Li, D.; Li, X.; Deng, T.; Wang, S. Finite element simulation and process optimization for hot stretch bending of Ti-6Al-4V thin-walled extrusion. Int. J. Adv. Manuf. Technol. 2017, 92, 1707–1719. [Google Scholar] [CrossRef]

- Liu, B.; Liu, Y.B.; Yang, X.; Liu, Y. TITANIUM 2008: Development of international titanium industry, preparation technology and applications. Mater. Sci. Eng. Pow. Metall 2008, 14, 67–73. [Google Scholar]

- Zhao, Y.; Guo, H.; Shi, Z.; Yao, Z.; Zhang, Y. Microstructure evolution of TA15 titanium alloy subjected to equal channel angular pressing and subsequent annealing at various temperatures. J. Mater. Process. Technol. 2011, 211, 1364–1371. [Google Scholar] [CrossRef]

- Yang, H.; Fan, X.G.; Sun, Z.C.; Guo, L.; Zhan, M. Some advances in local loading precision forming of large scale integral complex components of titanium alloys. Mater. Res. Innov. 2011, 15, s493–s496. [Google Scholar] [CrossRef]

- Li, W.; Vairis, A.; Preuss, M.; Ma, T. Linear and rotary friction welding review. Int. Mater. Rev. 2016, 61, 71–100. [Google Scholar] [CrossRef]

- McAndrew, A.R.; Colegrove, P.; Bühr, C.; Flipo, B.C.; Vairis, A. A literature review of Ti-6Al-4V linear friction welding. Prog. Mater. Sci. 2018, 92, 225–257. [Google Scholar] [CrossRef]

- McAndrew, A.R.; Flipo, B.C.D. Linear Friction Welding for Near Net Shape Manufacturing of Titanium Alloy Ti-6Al-4V Aerospace Components. In Proceedings of the 2018 9th International Conference on Mechanical and Aerospace Engineering (ICMAE), Budapest, Hungary, 10–13 July 2018; pp. 126–130. [Google Scholar] [CrossRef]

- Zhao, P.; Fu, L.; Zhong, D. Numerical simulation of transient temperature and axial deformation during linear friction welding between TC11 and TC17 titanium alloys. Comput. Mater. Sci. 2014, 92, 325–333. [Google Scholar] [CrossRef]

- Vairis, A.; Frost, M. High frequency linear friction welding of a titanium alloy. Wear 1998, 217, 117–131. [Google Scholar] [CrossRef]

- Dalgaard, E.; Wanjara, P.; Gholipour, J. Linear Friction Welding of a Forged Near-α Titanium Alloy. Mater. Sci. Forum 2012, 706–709, 211–216. [Google Scholar]

- Romilly, P. Linear Friction Welding for Near Net Shape Manufacturing of Titanium Parts. In Proceedings of the 13th World Conference on Titanium, Hoboken, NJ, USA, 16–20 August 2015; pp. 1423–1427. [Google Scholar] [CrossRef]

- Moffat, M.; Romilly, P. Breakthrough technologies in aerospace industry for titanium processing. In Proceedings of the Titanium Europe 2014 Conference, Sorrento, Italy, 19–21 March 2014. [Google Scholar]

- Wanjara, P.; Jahazi, M. Linear friction welding of Ti-6Al-4V: Processing, microstructure, and mechanical-property inter-relationships. Met. Mater. Trans. A 2005, 36, 2149–2164. [Google Scholar] [CrossRef]

- Li, W.-Y.; Ma, T.; Li, J. Numerical simulation of linear friction welding of titanium alloy: Effects of processing parameters. Mater. Des. 2010, 31, 1497–1507. [Google Scholar] [CrossRef]

- Li, W.-Y.; Ma, T.; Yang, S. Microstructure Evolution and Mechanical Properties of Linear Friction Welded Ti-5Al-2Sn-2Zr-4Mo-4Cr (Ti17) Titanium Alloy Joints. Adv. Eng. Mater. 2010, 12, 35–43. [Google Scholar] [CrossRef]

- Wang, X.Y.; Li, W.Y.; Ma, T.J.; Yang, X.W. Effects of Pre- and Post-weld Heat Treatments on Microstructure and Mechanical Properties of Linear Friction Welded TC11 Titanium Alloy Joints. J. Net-Shape Form. Eng. 2019, 11, 1–7. [Google Scholar]

- Romero, J.; Attallah, M.; Preuss, M.; Karadge, M.; Bray, S. Effect of the forging pressure on the microstructure and residual stress development in Ti–6Al–4V linear friction welds. Acta Mater. 2009, 57, 5582–5592. [Google Scholar] [CrossRef]

- Karadge, M.; Preuss, M.; Lovell, C.; Withers, P.; Bray, S. Texture development in Ti–6Al–4V linear friction welds. Mater. Sci. Eng. A 2007, 459, 182–191. [Google Scholar] [CrossRef]

- Frankel, P.; Preuss, M.; Steuwer, A.; Withers, P.; Bray, S. Comparison of residual stresses in Ti–6Al–4V and Ti–6Al–2Sn–4Zr–2Mo linear friction welds. Mater. Sci. Technol. 2009, 25, 640–650. [Google Scholar] [CrossRef]

- Chen, Y.; Li, S.; Li, Y.; Wang, Y.; Li, Z.; Lin, Z. Constitutive modeling of TA15 alloy sheet coupling phase transformation in non-isothermal hot stamping process. J. Mater. Res. Technol. 2021, 12, 629–642. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, J.H.; Moon, B.G.; You, B.S. Tension–compression yield asymmetry in as-cast magnesium alloy. J. Alloys Compd. 2014, 617, 277–280. [Google Scholar] [CrossRef]

- Zhao, P.; Fu, L. Strain hardening behavior of linear friction welded joints between TC11 and TC17 dissimilar titanium alloys. Mater. Sci. Eng. A 2015, 621, 149–156. [Google Scholar] [CrossRef]

- He, D.; Zhu, J.; Lai, Z.; Liu, Y.; Yang, X. An experimental study of deformation mechanism and microstructure evolution during hot deformation of Ti–6Al–2Zr–1Mo–1V alloy. Mater. Des. 2013, 46, 38–48. [Google Scholar] [CrossRef] [Green Version]

- Lin, P.; He, Z.; Yuan, S.; Shen, J. Tensile deformation behavior of Ti–22Al–25Nb alloy at elevated temperatures. Mater. Sci. Eng. A 2012, 556, 617–624. [Google Scholar] [CrossRef]

- Rabinovich, M.; Trifonov, V. Dynamic grain growth during superplastic deformation. Acta Mater. 1996, 44, 2073–2078. [Google Scholar] [CrossRef]

- Li, F.; Bae, D.; Ghosh, A. Grain elongation and anisotropic grain growth during superplastic deformation in an Al-Mg-Mn-Cu alloy. Acta Mater. 1997, 45, 3887–3895. [Google Scholar] [CrossRef]

- Langdon, T.G. Seventy-five years of superplasticity: Historic developments and new opportunities. J. Mater. Sci. 2009, 44, 5998–6010. [Google Scholar] [CrossRef]

- Alabort, E.; Kontis, P.; Barba, D.; Dragnevski, K.; Reed, R. On the mechanisms of superplasticity in Ti–6Al–4V. Acta Mater. 2016, 105, 449–463. [Google Scholar] [CrossRef] [Green Version]

- McQueen, H. Development of dynamic recrystallization theory. Mater. Sci. Eng. A 2004, 387–389, 203–208. [Google Scholar] [CrossRef]

- Sakai, T.; Jonas, J.J. Overview no. 35 Dynamic recrystallization: Mechanical and microstructural considerations. Acta Metall. 1984, 32, 189–209. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.; Frazier, W.; Prasad, Y. Microstructural mechanisms during hot working of commercial grade Ti–6Al–4V with lamellar starting structure. Mater. Sci. Eng. A 2002, 325, 112–125. [Google Scholar] [CrossRef]

- Song, H.-W.; Zhang, S.-H.; Cheng, M. Subtransus deformation mechanisms of TC11 titanium alloy with lamellar structure. Trans. Nonferrous Met. Soc. China 2010, 20, 2168–2173. [Google Scholar] [CrossRef]

- Balasubrahmanyam, V.; Prasad, Y. Deformation behaviour of beta titanium alloy Ti–10V–4.5Fe–1.5Al in hot upset forging. Mater. Sci. Eng. A 2002, 336, 150–158. [Google Scholar] [CrossRef]

- Bao, R.-Q.; Huang, X.; Cao, C.-X. Deformation behavior and mechanisms of Ti-1023 alloy. Trans. Nonferrous Met. Soc. China 2006, 16, 274–280. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.; Morgan, J.; Malas, J.; Frazier, W.; Prasad, Y. Hot deformation and microstructural damage mechanisms in extra-low interstitial (ELI) grade Ti–6Al–4V. Mater. Sci. Eng. A 2000, 279, 289–299. [Google Scholar] [CrossRef]

- Zhang, S.; Lian, Y.; Chen, Y.; Sun, Y.; Feng, H.; Zhou, Y.; Cao, P. Hot Deformation Behavior and Microstructure Evolution of a TiBw/Near α-Ti Composite with Fine Matrix Microstructure. Metals 2019, 9, 481. [Google Scholar] [CrossRef] [Green Version]

- Hansen, N. Hall–Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Liu, Z.; Li, P.; Xiong, L.; Liu, T.; He, L. High-temperature tensile deformation behavior and microstructure evolution of Ti55 titanium alloy. Mater. Sci. Eng. A 2017, 680, 259–269. [Google Scholar] [CrossRef]

- Mandal, S.; Bhaduri, A.K.; Sarma, V.S. A Study on Microstructural Evolution and Dynamic Recrystallization During Isothermal Deformation of a Ti-Modified Austenitic Stainless Steel. Met. Mater. Trans. A 2010, 42, 1062–1072. [Google Scholar] [CrossRef]

- Lin, Y.; Wu, X.-Y.; Chen, X.-M.; Chen, J.; Wen, D.-X.; Zhang, J.-L.; Li, L.-T. EBSD study of a hot deformed nickel-based superalloy. J. Alloys Compd. 2015, 640, 101–113. [Google Scholar] [CrossRef]

- Liang, X.; Dodge, M.; Jiang, J.; Dong, H. Using transmission Kikuchi diffraction in a scanning electron microscope to quantify geometrically necessary dislocation density at the nanoscale. Ultramicroscopy 2018, 197, 39–45. [Google Scholar] [CrossRef] [PubMed]

- Humphreys, F.J.; Rohrer, G.S.; Rollett, A. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar] [CrossRef]

- Momeni, A.; Ebrahimi, G.; Jahazi, M.; Bocher, P. Microstructure evolution at the onset of discontinuous dynamic recrystallization: A physics-based model of subgrain critical size. J. Alloys Compd. 2014, 587, 199–210. [Google Scholar] [CrossRef]

- Tahreen, N.; Zhang, D.; Pan, F.; Jiang, X.; Li, D.; Chen, D. Hot deformation and processing map of an as-extruded Mg–Zn–Mn–Y alloy containing I and W phases. Mater. Des. 2015, 87, 245–255. [Google Scholar] [CrossRef]

- Ma, L.; Wan, M.; Li, W.; Shao, J.; Han, X.; Zhang, J. On the superplastic deformation mechanisms of near-α TNW700 titanium alloy. J. Mater. Sci. Technol. 2021, 108, 173–185. [Google Scholar] [CrossRef]

- Zhang, X.; Cao, L.; Zhao, Y.; Chen, Y.; Tian, X.; Deng, J. Superplastic behavior and deformation mechanism of Ti600 alloy. Mater. Sci. Eng. A 2013, 560, 700–704. [Google Scholar] [CrossRef]

| Ti | Al | V | Fe | O | N |

|---|---|---|---|---|---|

| balance | 6.26 | 4.22 | 0.10 | 0.13 | 0.01 |

| Frequency (Hz) | Amplitude (mm) | Applied Force (KN) | Friction Force (KN) | Control Mode |

|---|---|---|---|---|

| 0–60 Hz | 0–4.5 | 0–200 | 0–150 | Time, upset |

| Frequency (Hz) | Amplitude (mm) | Friction Force (KN) | Applied Force (KN) | Upset (mm) |

|---|---|---|---|---|

| 30 Hz | 2.8 | 25 | 30 | 3.0 |

| Temperature/K | Strain Rate/s−1 | n | Q/(KJ mol−1) |

|---|---|---|---|

| 923 | 0.01 | 6.06 | 323.9 |

| 973 | 5.48 | 292.8 | |

| 1023 | 4.13 | 220.7 | |

| 973 | 0.001 | 5.48 | 266.5 |

| 973 | 0.005 | 5.48 | 279.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Li, D.; Li, X.; Li, Y.; Xia, Q. High Temperature Mechanical Properties and Microstructure Evolution of Ti-6Al-4V Alloy Linear Friction Welding Joints. Machines 2022, 10, 151. https://doi.org/10.3390/machines10020151

Zhang C, Li D, Li X, Li Y, Xia Q. High Temperature Mechanical Properties and Microstructure Evolution of Ti-6Al-4V Alloy Linear Friction Welding Joints. Machines. 2022; 10(2):151. https://doi.org/10.3390/machines10020151

Chicago/Turabian StyleZhang, Chen, Dongsheng Li, Xiaoqiang Li, Yong Li, and Qin Xia. 2022. "High Temperature Mechanical Properties and Microstructure Evolution of Ti-6Al-4V Alloy Linear Friction Welding Joints" Machines 10, no. 2: 151. https://doi.org/10.3390/machines10020151

APA StyleZhang, C., Li, D., Li, X., Li, Y., & Xia, Q. (2022). High Temperature Mechanical Properties and Microstructure Evolution of Ti-6Al-4V Alloy Linear Friction Welding Joints. Machines, 10(2), 151. https://doi.org/10.3390/machines10020151