1. Introduction

Industrial robots have been widely used in the manufacturing system of the current production process due to their high levels of efficiency, accuracy, and flexibility, and carry out numerous critical tasks such as welding [

1], polishing [

2], assembling [

3], spraying [

4], carrying [

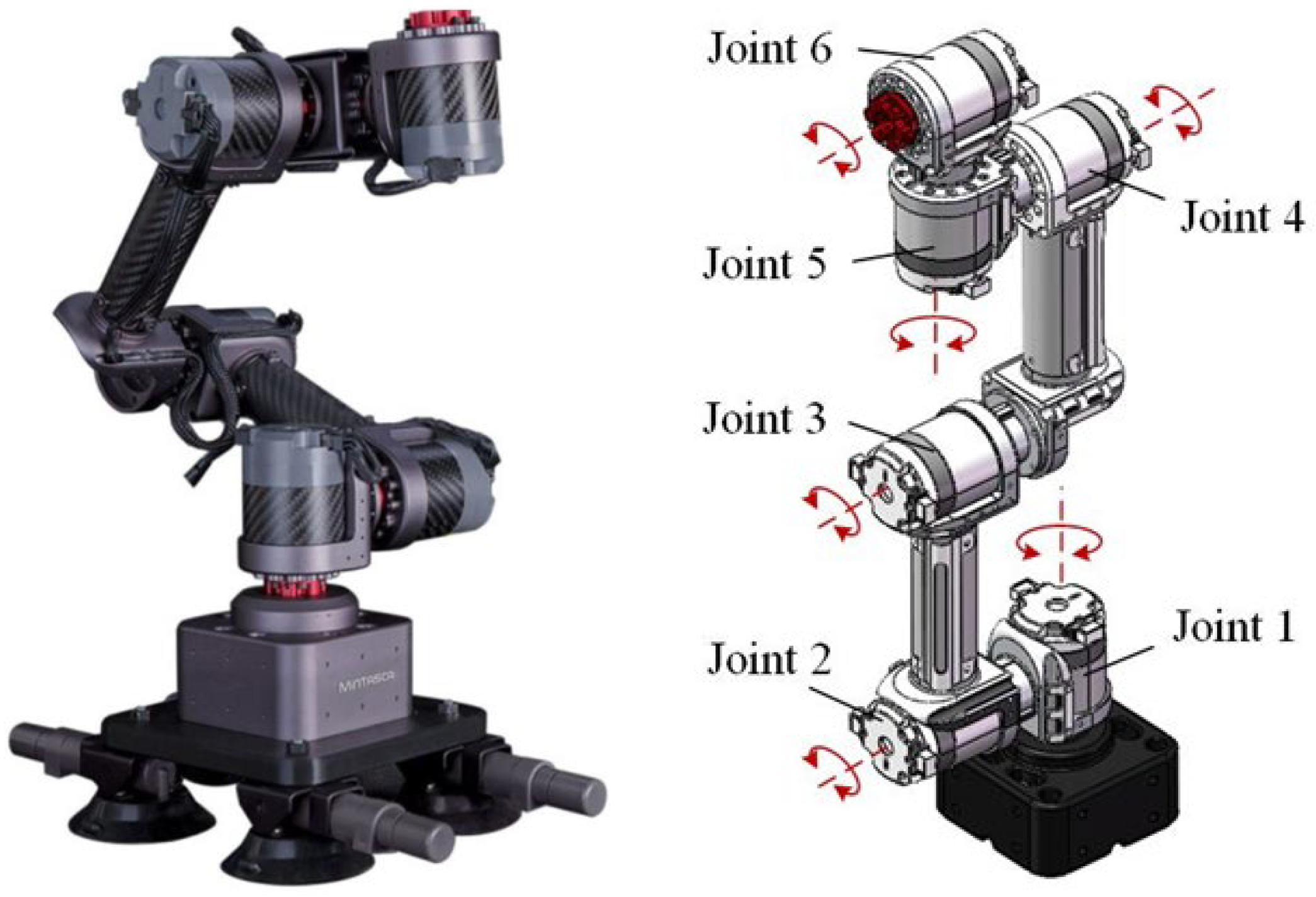

5], and so on. When certain industrial robots malfunction, it often results in a stalled production line, the consumption of human and material resources, and even the personal safety of employees. The rotating joints, as the main component of the mechanical transmission system, are the critical structure for transferring motion and force for a multi-joint robot. Rolling element bearings are the most likely to lose efficacy among the rotating machinery included in the joints due to volatile loads and speeds. As a result, it is critical to implement timely and effective fault diagnosis to monitor the running state of industrial robots, particularly the health state of bearings located in rotating joints, in order to ensure the long-term safe and reliable operation of mechanical equipment.

At present, the issue of fault diagnosis has attracted widespread attention from researchers in engineering application fields, and more diagnostic methods have been proposed. Wu et al. [

6] proposed a dynamic model for squirrel-caged induction to analyze broken-rotor-bar and turn-to-turn short faults. Song et al. [

7] proposed a new heavy tail degradation model for predicting rolling bearings’ useful life. Furthermore, machine learning is a technology that can automatically learn features from collected data and create an intelligent prediction model. Jaber et al. [

8] proposed a method for detecting gearbox faults in the PUMA 560 robot that uses a discrete wavelet transform (DWT) to extract time-frequency features and an artificial neural network (ANN) to realize fault classification. Hsu et al. [

9] used multi-class support vector machines (SVMs) in conjunction with principal component analysis (PCA) to diagnose several real aging-related faults on a six-axis robot, and the experimental results validated their findings effectively. Lu et al. [

10] designed an enhanced k-nearest neighbor (KNN) embedded with a sparse filtering extractor that can select the health state label of rotating machinery adaptively based on the optimized correlation vectors. Fang et al. [

11] used data dimension reduction and random forest (RF) to detect loose screw faults in the SCARA robot, and the applied design shows a good performance. However, the above-mentioned methods have limitations in complicated feature extraction and insufficient generalization, so deep learning (DL)-based methods are proposed to address these shortcomings.

DL is an important branch of machine learning that has expanded the field of artificial intelligence applications. Because of its end-to-end characteristics and adaptive feature extraction abilities, DL can significantly reduce reliance on human intervention and has numerous successful application cases in the fault diagnosis field [

12]. Jiao et al. [

13] used an improved D-S evidence theory and a deep belief network (DBN) to predict bearing failure on the industrial robot’s joint, eventually achieving an average accuracy of about 98%. Pan et al. [

14] developed a deep convolutional neural network (DCNN)-based fused sensor and actuator fault diagnosis model for the robot joint and demonstrated its effectiveness by achieving high fault recognition accuracy. Hong et al. [

15] developed an attitude data-based intelligent fault identification approach by training a deep sparse auto-encoder network (DSAE), which has effective performance for multi-joint robot fault identification. Xia et al. [

16] proposed a novel deep perceptual adversarial domain adaptive (DPADA) method for fault diagnosis of robot bearings under varying conditions, which outperforms convolutional neural network (CNN) and conditional domain-adversarial network (CDAN)-based methods.

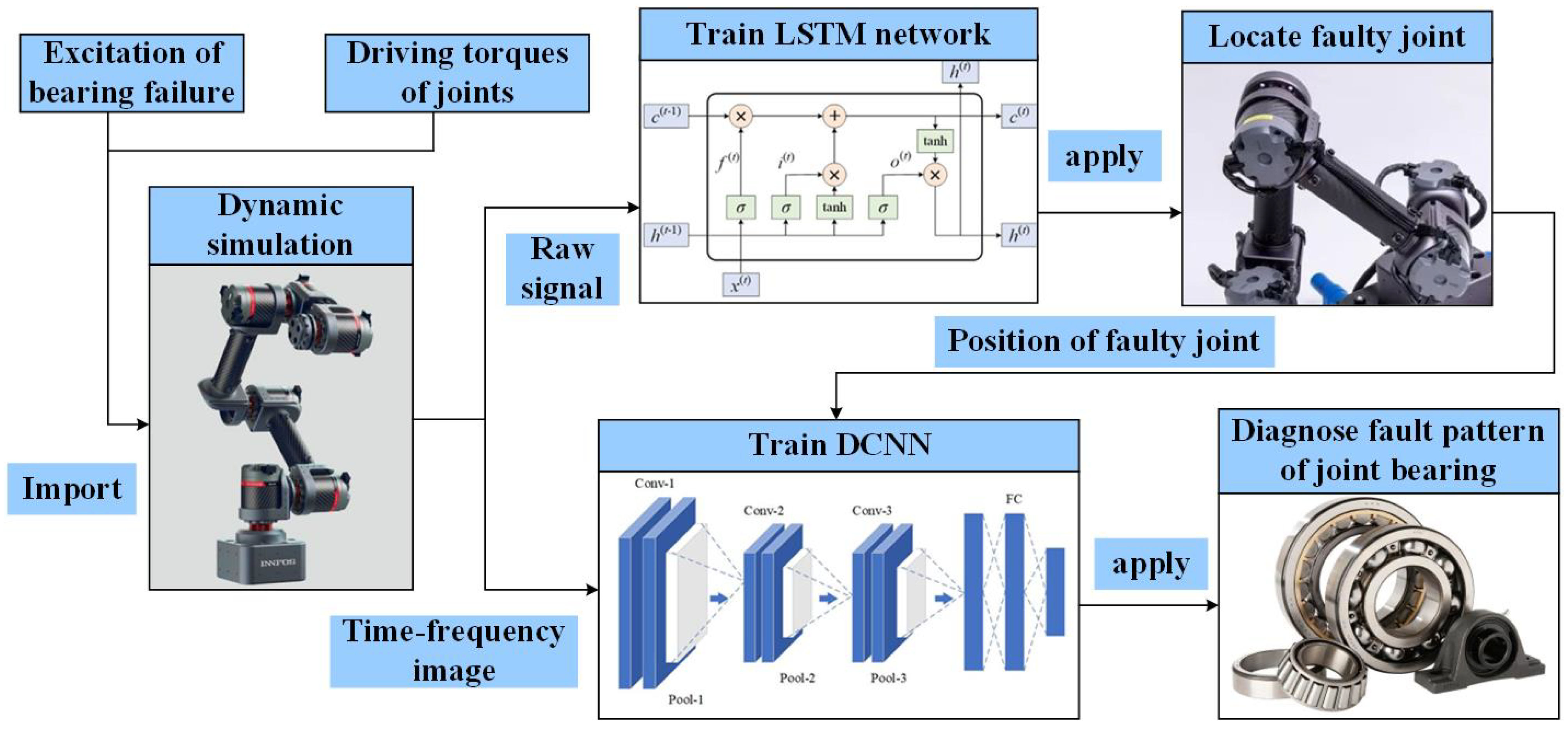

Even though these DL-based methods have increased the practicability and generalizability of the algorithm, there are still several issues and deficiencies that have not been addressed. It has been discovered that researchers tend to investigate failures on a few specific joints without considering the state of others in a multi-joint robot, resulting in insufficient attention to the overall system’s running state. Furthermore, few works simultaneously take the failure pattern of rotating machinery and the location of fault joints into account so that the amount of identifiable failure patterns is limited. It is difficult to collect characteristic signals corresponding to the fault state under more complicated conditions due to the limitations of some realistic factors. Therefore, we proposed a novel dynamic modeling method for multi-joint robots that can simulate rotating machinery faults on different robot joints and allow us to investigate more types of faulty operating states. Furthermore, we used DL-based methods to complete the diagnosis tasks in stages and achieved high accuracies to validate the superior performance of the used models. In summary, the following are the main contributions of this work:

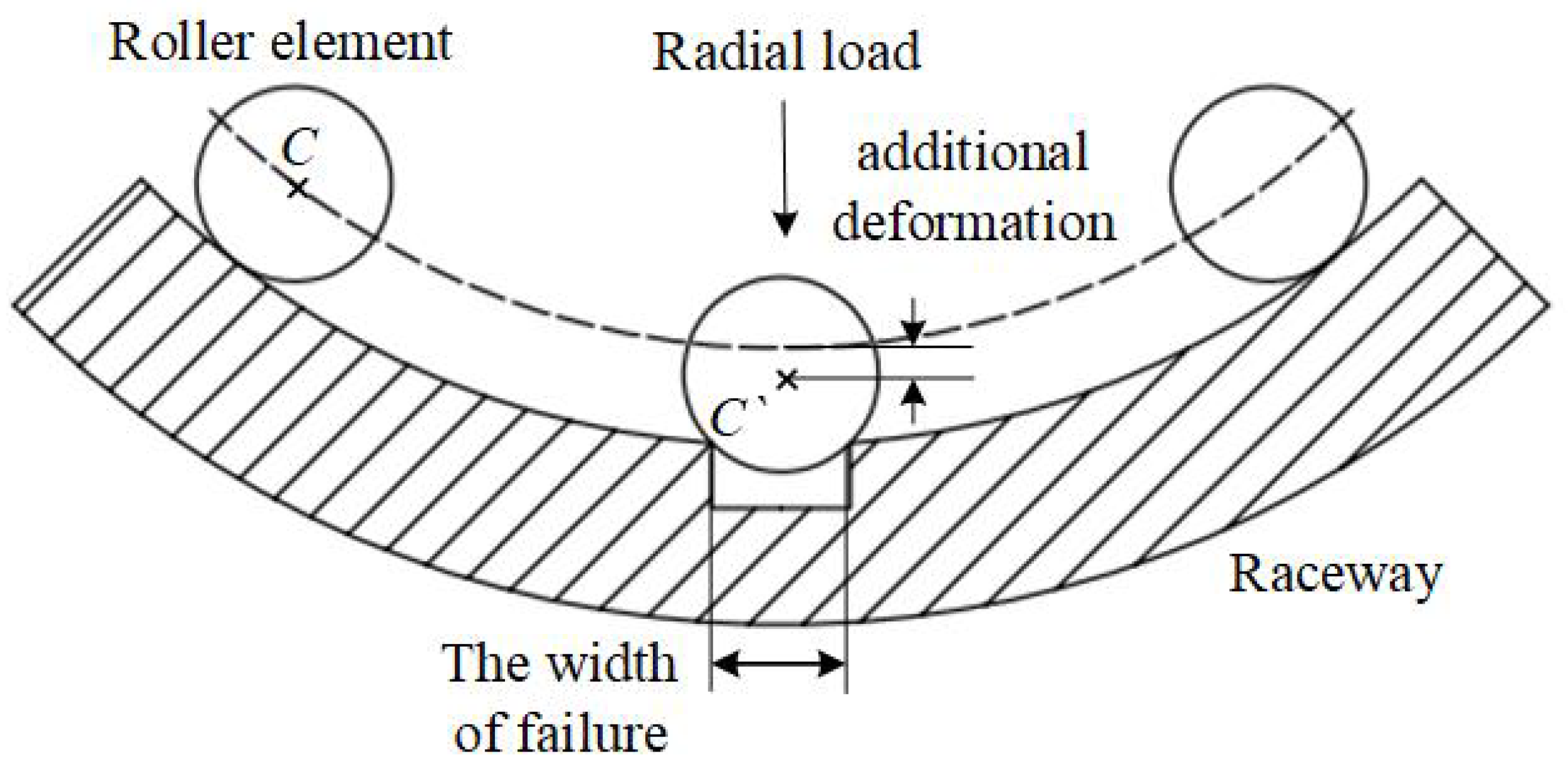

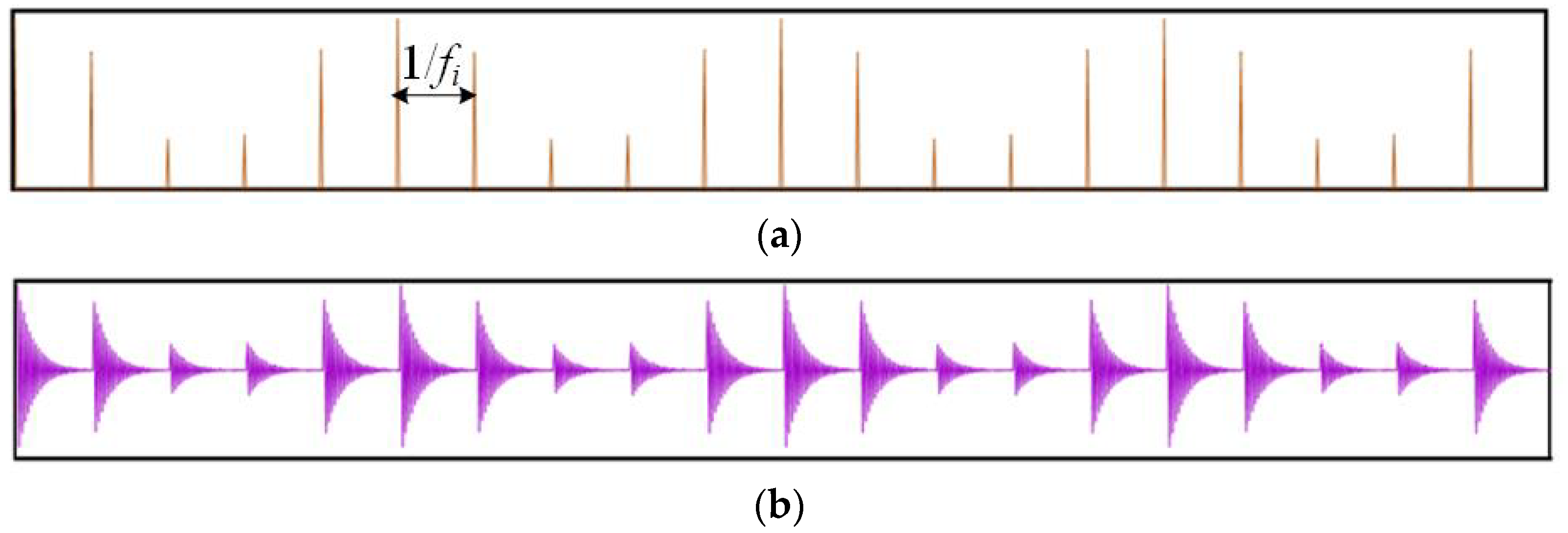

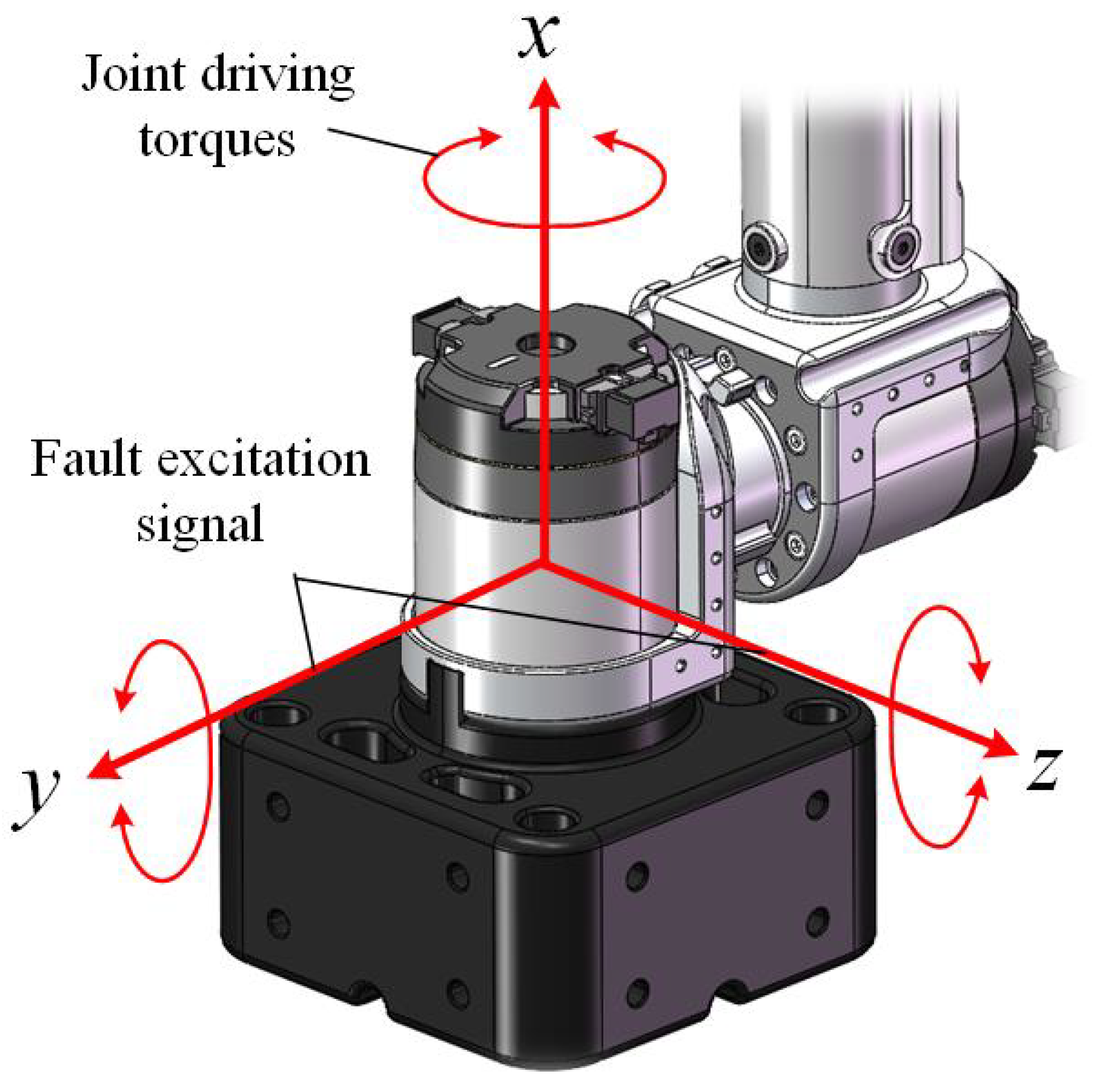

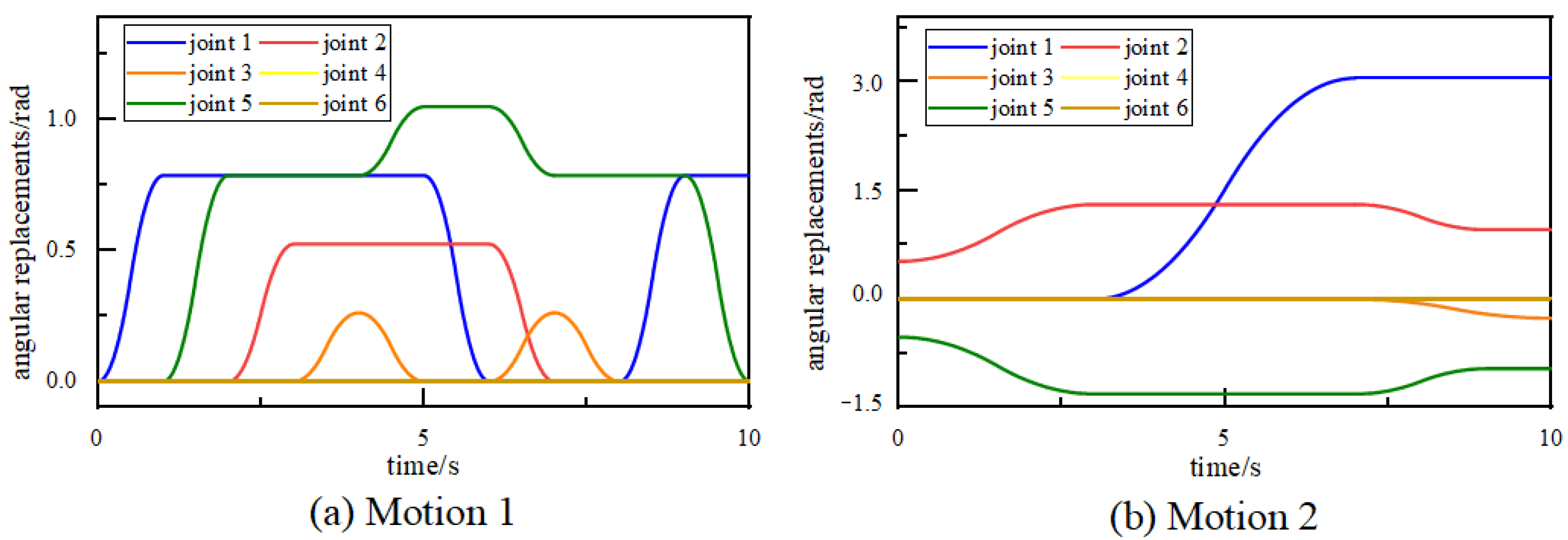

The failure mechanism of rotating machinery is investigated, with the rolling element bearing serving as the primary research object. The effects of bearing failures corresponding to different faulty joint locations are considered in the multi-joint robot’s dynamic simulation, so that more possible failure modes can be investigated by collecting vibration signals from all joints.

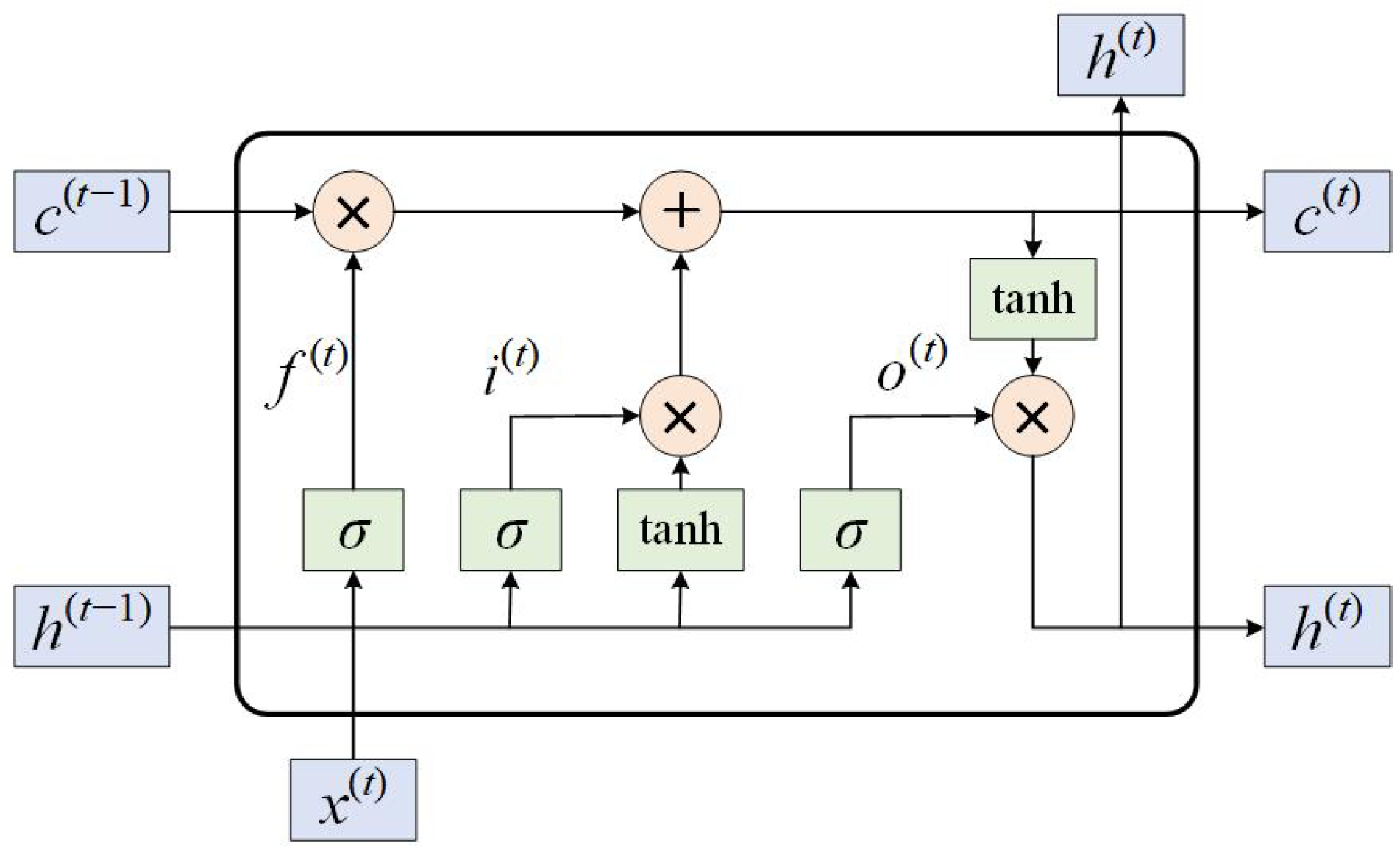

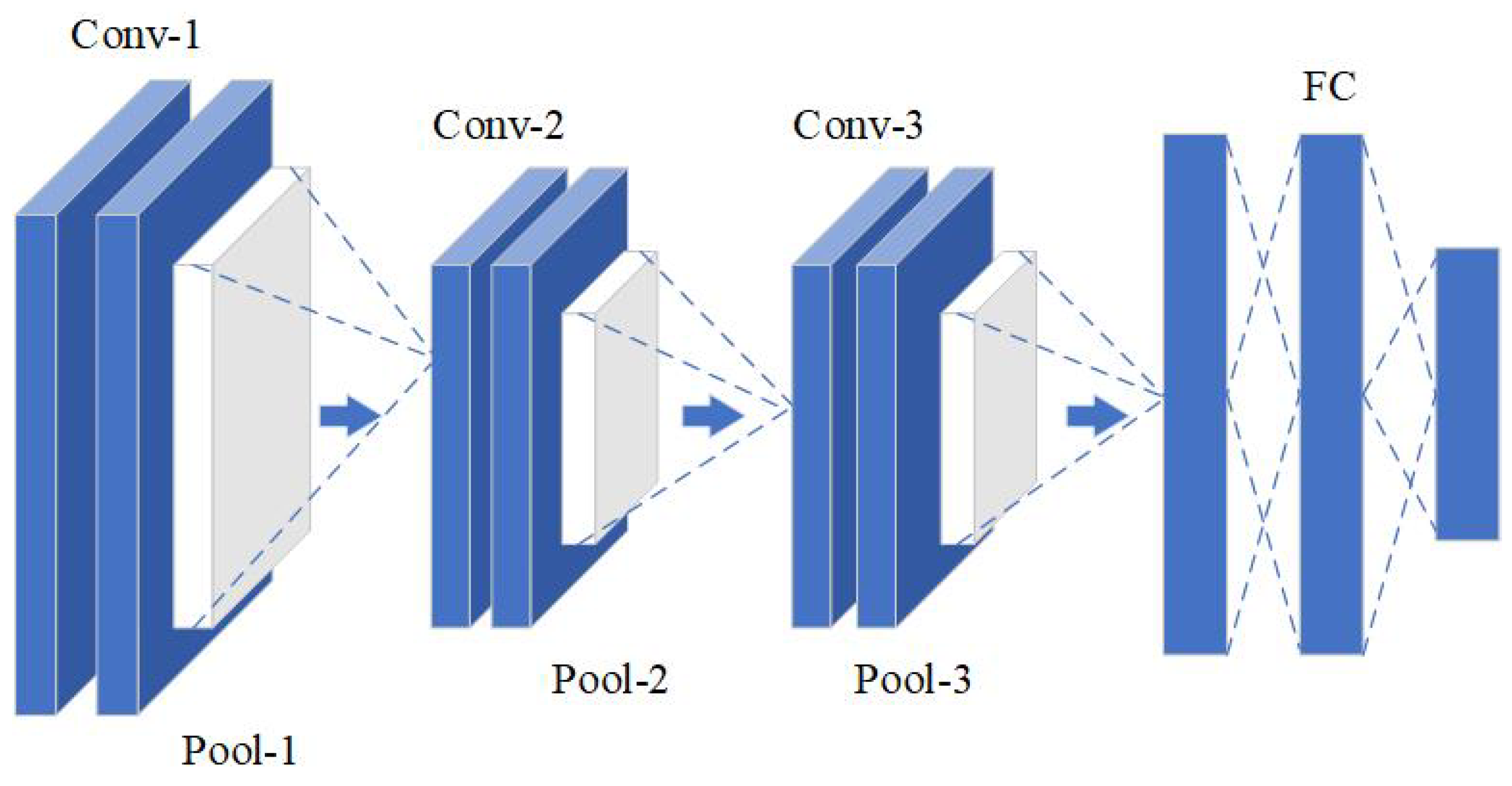

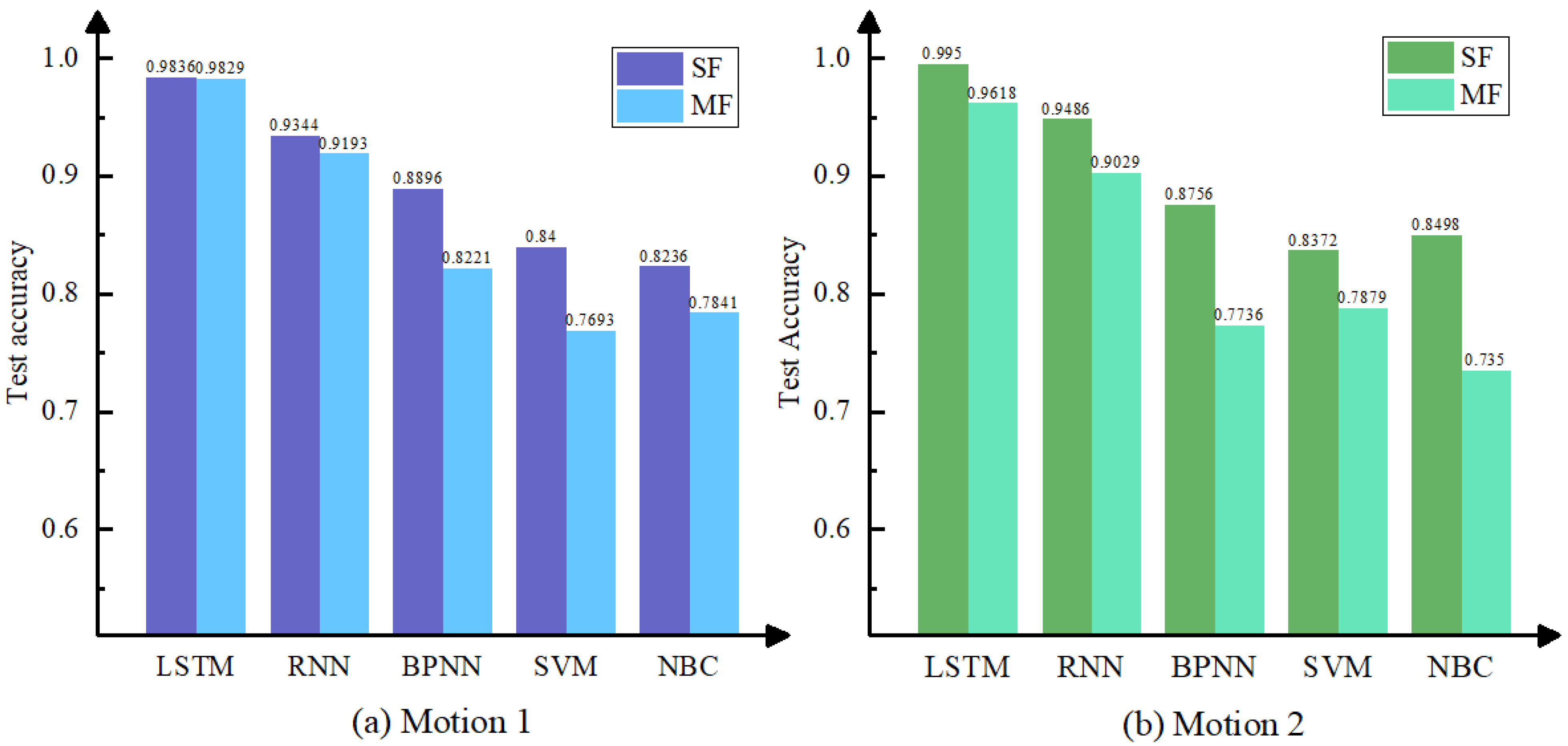

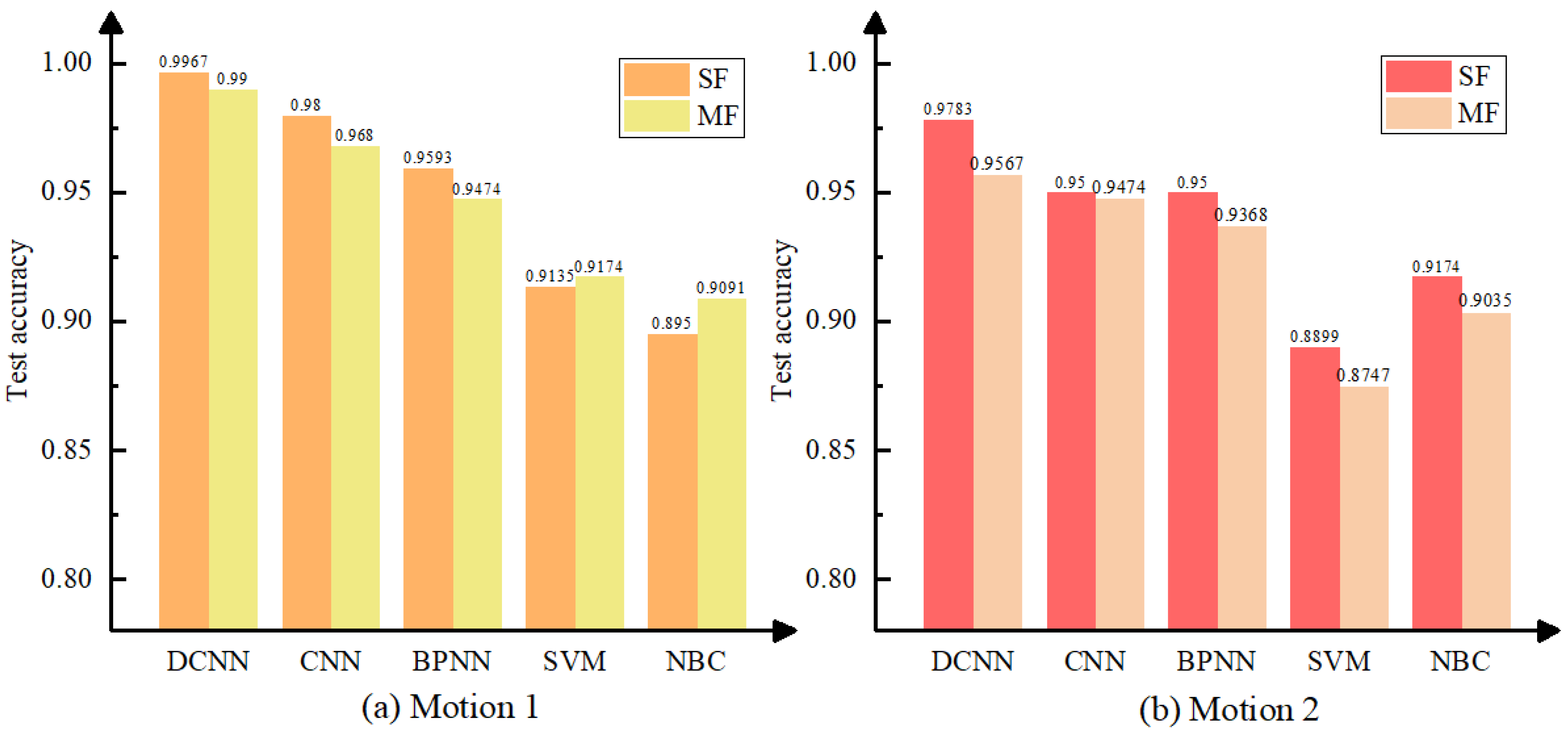

We developed a staged workflow for detecting bearing failures in multi-joint robots. The long short-term memory (LSTM) network is introduced in the first stage to recognize the health status of each joint and lock the positions of faulty joints. In the second stage, the signals of the faulty joint are extracted separately, time-frequency imaging is implemented, and then DCNN is used to identify the detailed failure form of the roller element bearings of the faulty joints. This allows for the determination of both fault locations and causes.

In addition to LSTM and DCNN, other fault diagnosis methods such as back-propagation neural network (BPNN), support vector machine (SVM), and naive Bayes classifier (NBC) are tested and used as comparing algorithms to provide a comprehensive performance evaluation.

The remainder of this paper can be summarized as follows:

Section 2 introduces the research object and methods used in this work, such as the kinetic and dynamic analysis of the multi-joint robot, the fundamental theories of the deep learning algorithms used, LSTM and CNN, and the general procedure of the research workflow in this work.

Section 3 explains the rolling bearing fault principle and demonstrates the dynamic simulation process of a multi-joint robot with bearing failure.

Section 4 focuses on the experimental results obtained, including data visualization, the introduction of some experimental details, algorithm performance validation, and result comparisons.

Section 5 presents the conclusions and future work.

5. Conclusions

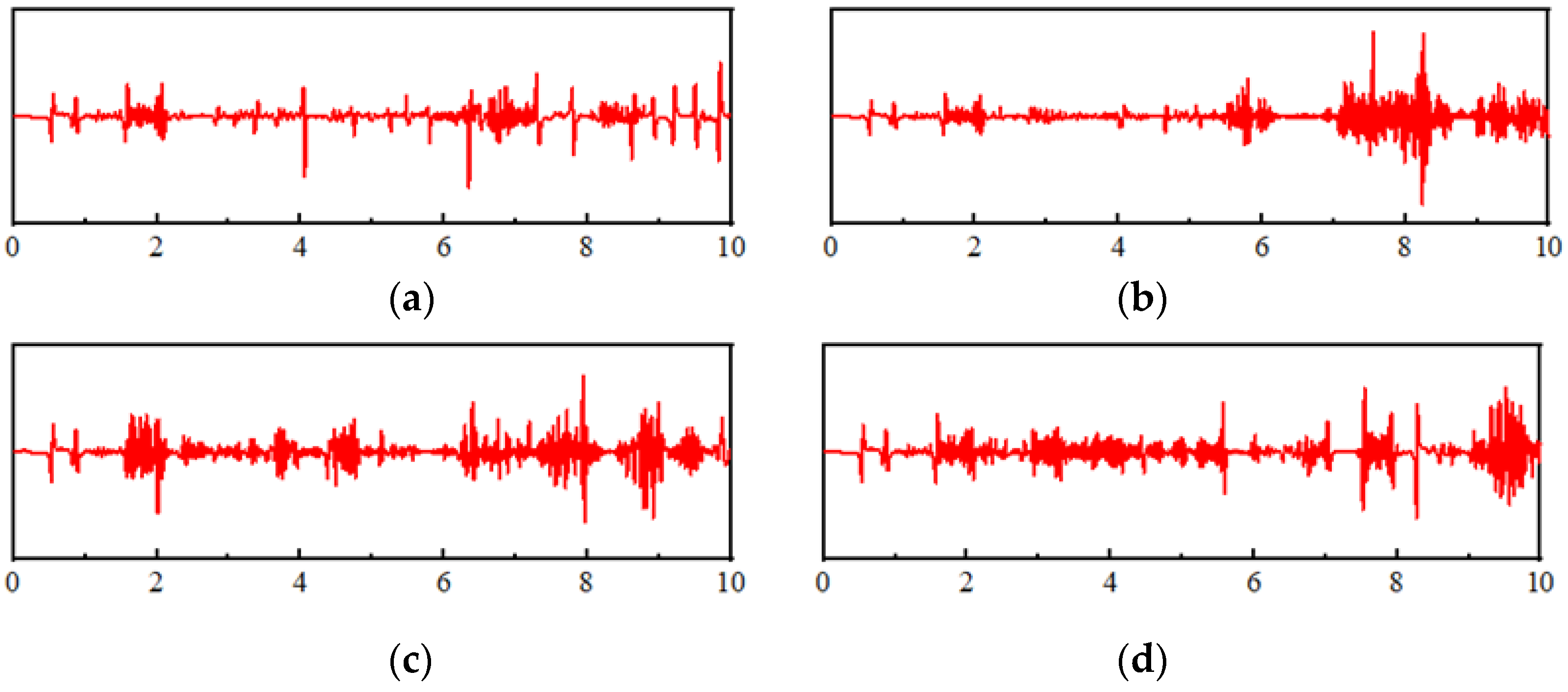

We conducted a complete procedure in this work, from dynamics modeling to fault diagnosis, for potential failures likely to exist in the rotating machinery of robot joints, and several valuable conclusions were obtained through this research process. First of all, the proposed simulation method is validated as feasible to simulate complex and diverse fault situations of the multi-joint robot due to the successful acquisition of vibration signals representing different failure features. Second, the LSTM is certified compatible with high accuracy in recognizing multi-channel vibration signals in diagnosis tasks such as locating faulty joints. Third, when time-frequency imaging is used, the DCNNs, which perform excellently in image recognition, can also be used to diagnose faults in rotating machinery. As a result, our proposed method for dynamics modeling and fault diagnosis is a feasible way to develop programs that recognize various types of failure in a mechanical system.

However, all our work is based on data acquired in a virtual simulation environment that differs from reality and does not take into account the effects of numerous external disturbance factors. It may cause performance reduction of our trained algorithms when they are directly used in reality. Therefore, some transfer learning ideas, such as domain adaptation, are probably necessary for future works to compensate for the difference between simulation and reality, which requires combining data collected from the real-world scene.