Circular Economy in Practice: Building a Simple Greenhouse from Recycled Plastic

Abstract

1. Introduction

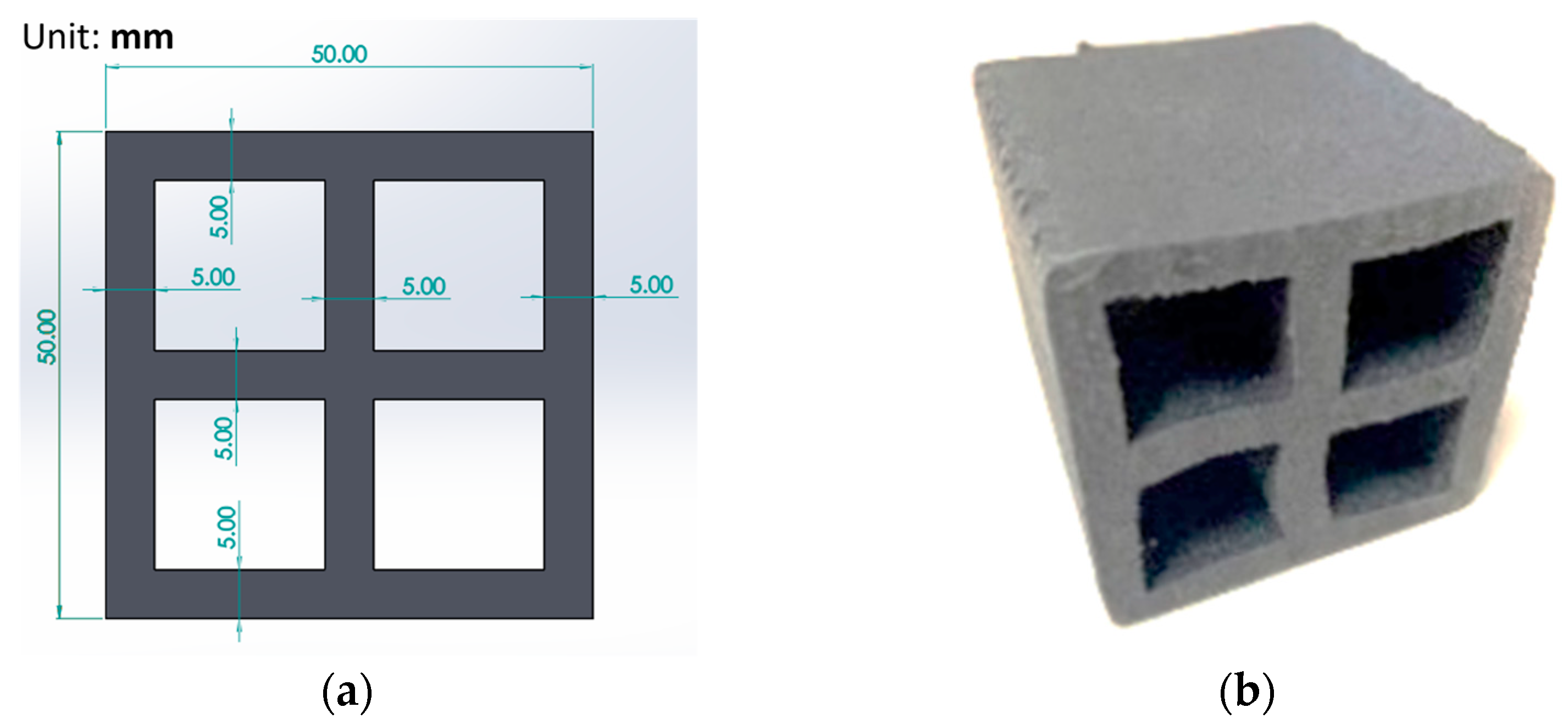

2. Materials

3. Methods

- Step #1

- Design the geometries of rods and fasteners.

- Step #2

- Run static stress analyses.

- Step #3

- Check is the results fit the safety requirements or not. If the safety requirements are not satisfied, return to Step #1.

- Step #4

- Run dynamic force analyses.

- Step #5

- Check if the results fit safety requirements or not. If the safety requirements are not satisfied, return to Step #1.

- Step #6

- Build the simple greenhouse.

4. Results

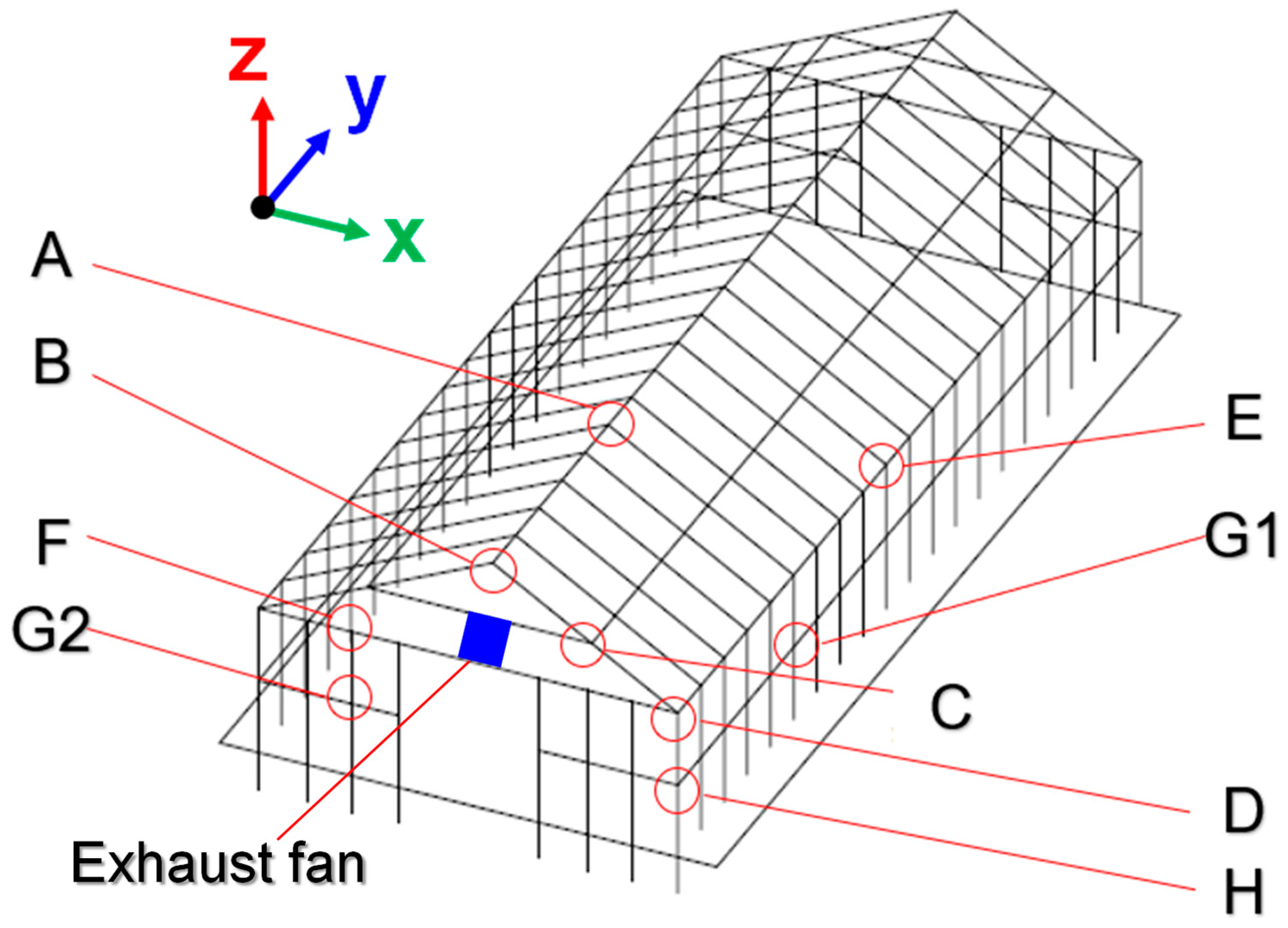

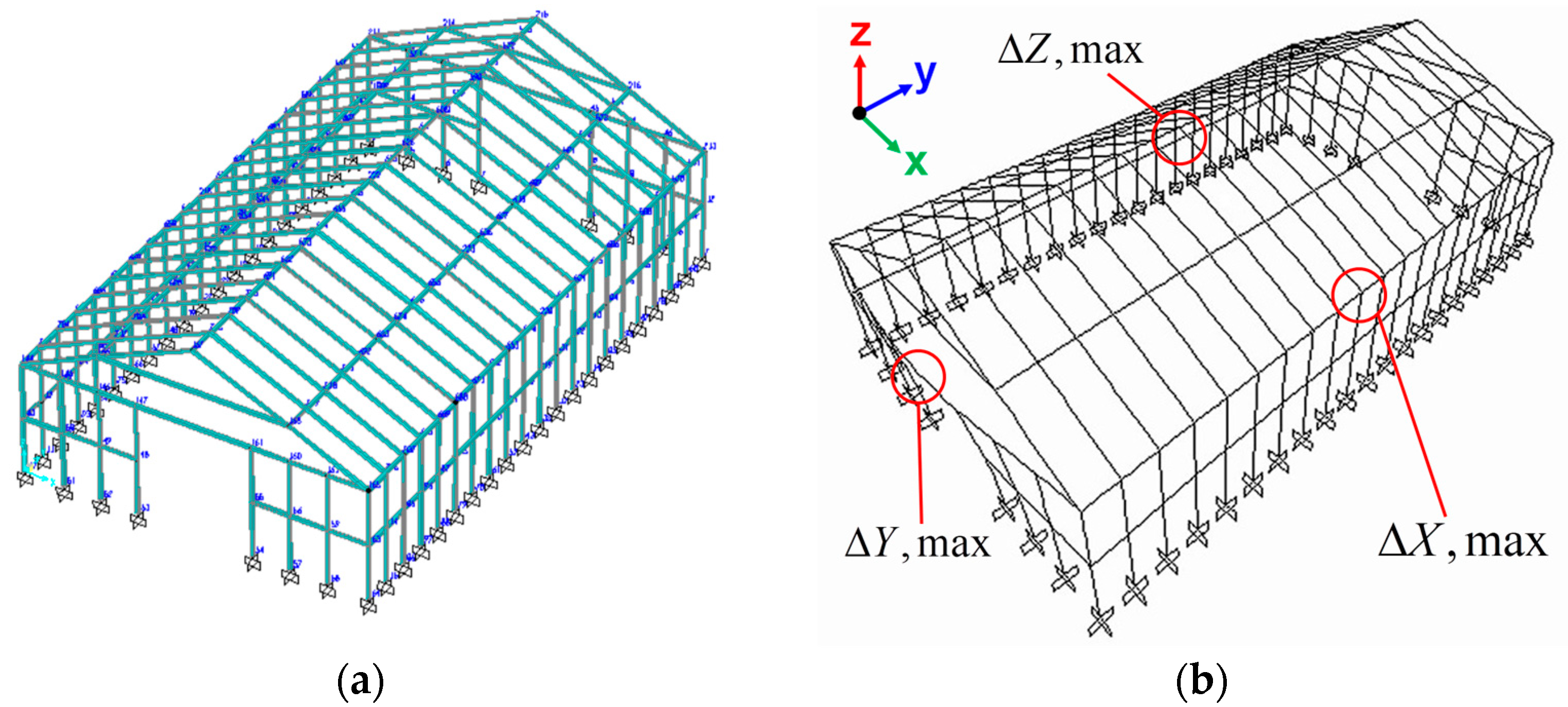

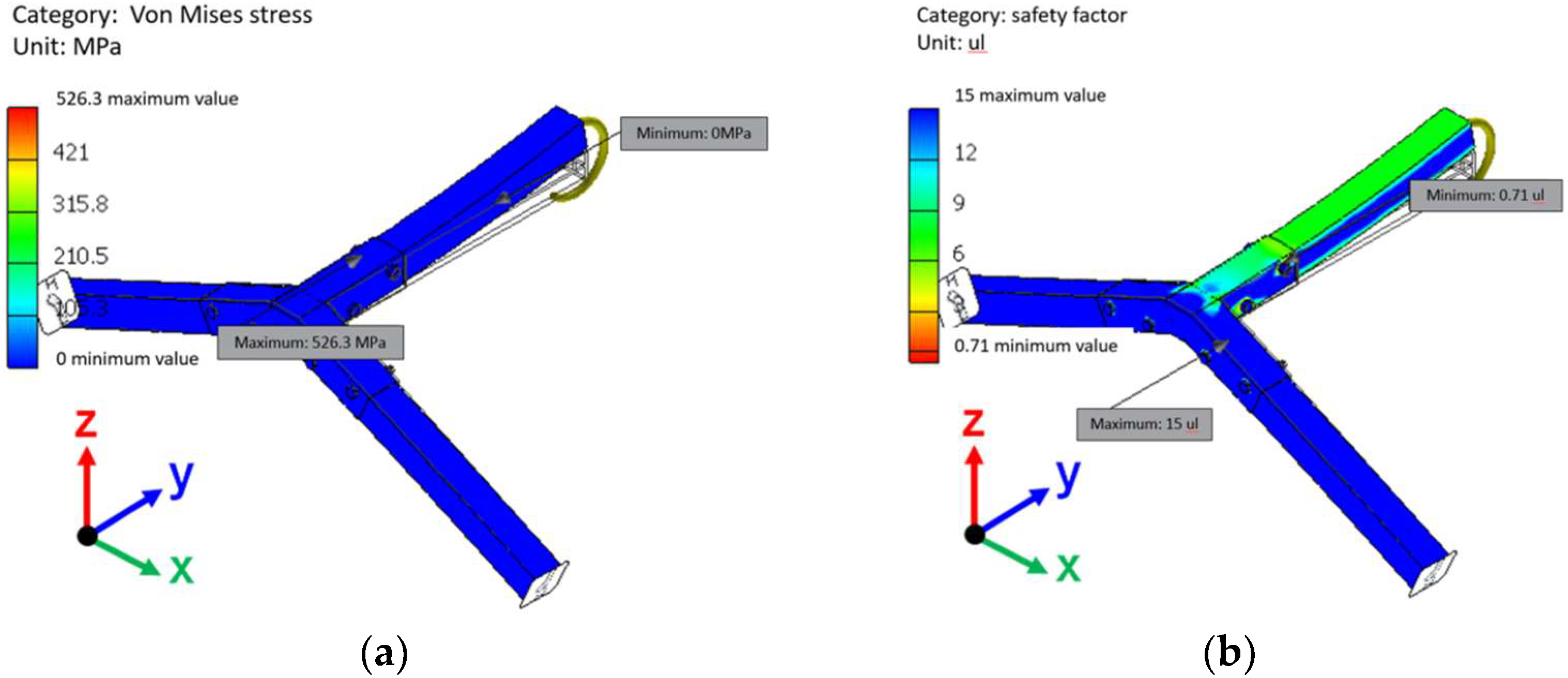

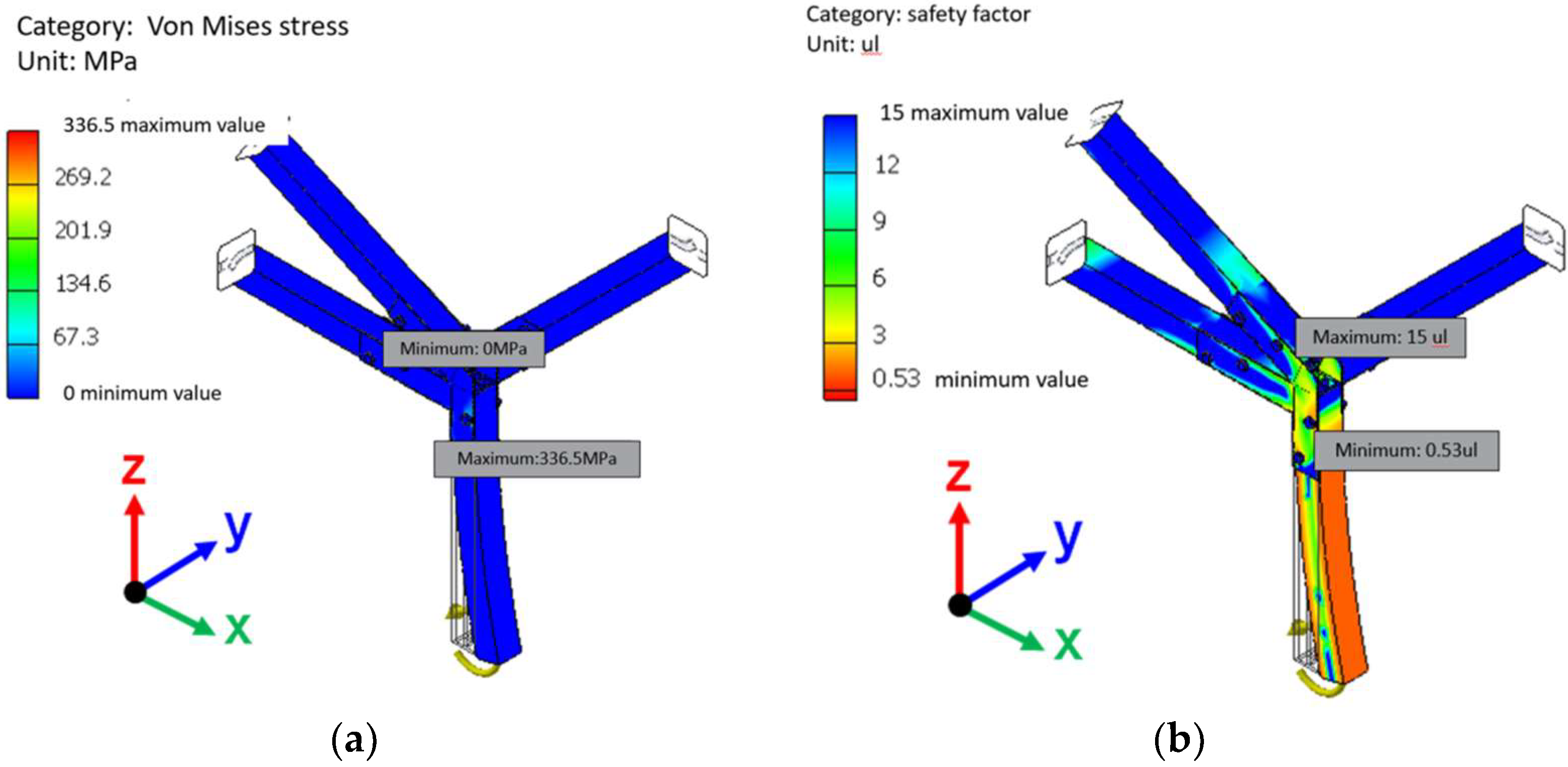

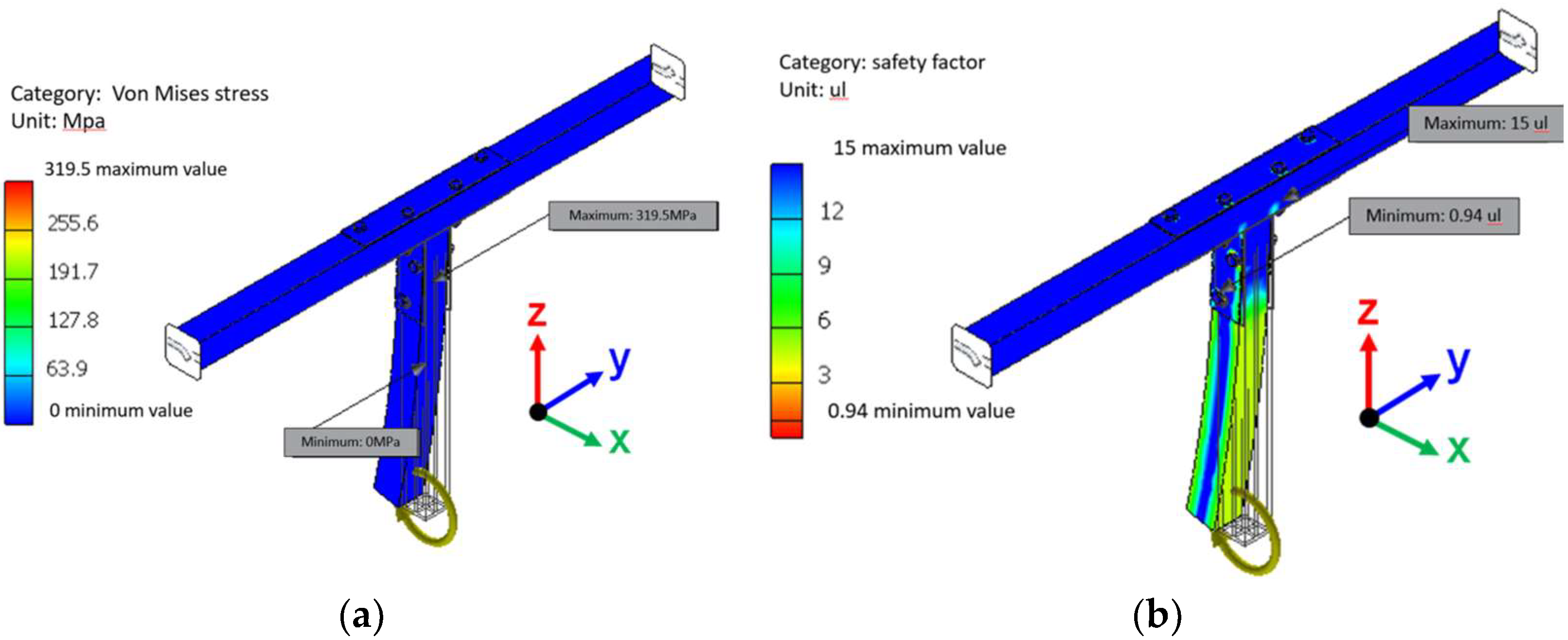

4.1. Static Force Analysis

4.2. Dynamic Force Analysis

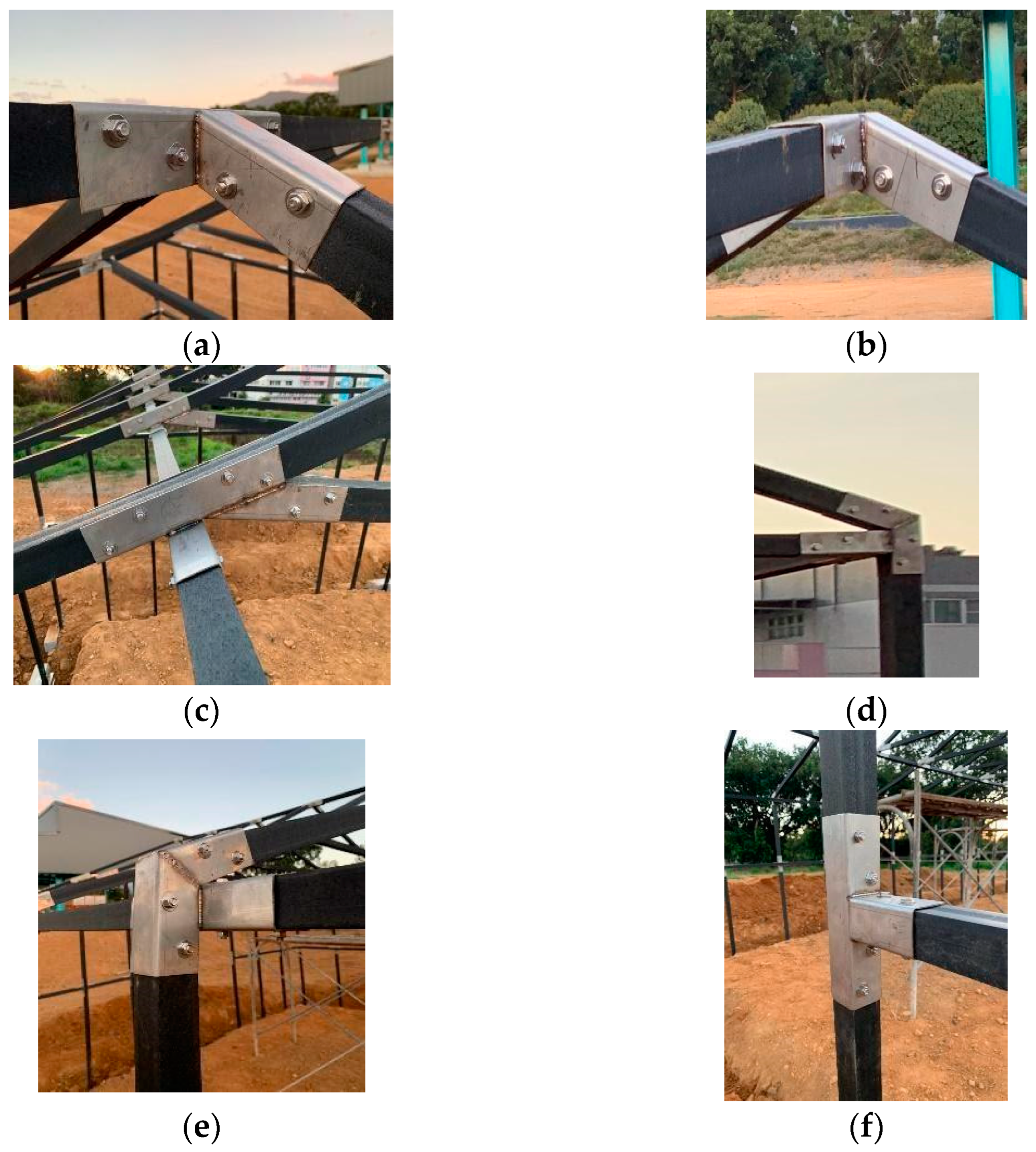

4.3. On-Site Construction of the Greenhouse

5. Discussion

6. Conclusions

- (1)

- Recycled composite plastic rods made by mixing discarded fishing nets and car bumpers were successfully used in the design and construction of a simple greenhouse. The safety of the design was ensured through static and dynamic force analysis, and it was verified by on-site construction.

- (2)

- The static force analysis (axial tensile force, x-axis bending moment, and y-axis bending moment) showed that the bolt hole of the rod would be enlarged during an encounter with force 11 strength winds, but that this deformation would not affect the overall structural safety.

- (3)

- The dynamic force analysis results show that no resonance will occur at the joint under typical earthquake and exhaust fan frequencies and, thus, that the greenhouse design is safe.

- (4)

- Finally, the design was further verified by construction of a greenhouse covering an area of 60 m2.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hurtalova, L.; Tillova, E.; Chalupova, M. The structure analysis of secondary (recycled) AlSi9Cu3 cast alloy with and without heat treatment. Eng. Trans. 2013, 61, 197–218. [Google Scholar]

- Ho, C.S.; Ab Rani, M.A.; Nor, M.K.M.; Ma’At, N.; Sultan, M.T.H.H.; Lajis, M.A.; Yusuf, N.K. Characterization of Anisotropic Damage Behaviour of Recycled Aluminium Alloys AA6061 Undergoing High Velocity Impact. Int. J. Integr. Eng. 2019, 11. [Google Scholar] [CrossRef]

- Hýsek, M.; Frydrych, M.; Herclík, L.; Fridrichová, P.; Louda, R.; Van Knížek, S.L.; Le Chi, H. Permeable water-resistant heat insulation panel based on recycled materials and its physical and mechanical properties. Molecules 2019, 24, 3300. [Google Scholar] [CrossRef] [PubMed]

- Kayili, M.T.; Celebi, G. Environmental properties of environmentally friendly construction materials: Recycled ldpe composites filled by blast furnace dust. J. Green Build. 2021, 16, 135–153. [Google Scholar] [CrossRef]

- Fonseca, J.H.; Quagliato, L.; Yun, S.; Han, D.; Kim, N.; Lee, H. Preliminary design of an injection-molded recycled-carbon fiber–reinforced plastic/metal hybrid automotive structure via combined optimization techniques. Struct. Multidiscip. Optim. 2021, 64, 2773–2788. [Google Scholar] [CrossRef]

- Liu, C.-X.; Qi, G.; Li, P. Crashworthy characteristics of sustainable thin-walled tubes: A study on recycled beverage cans. Mech. Adv. Mater. Struct. 2022, 29, 3222–3236. [Google Scholar] [CrossRef]

- Janssen, G.M.; Hendriks, C. Sustainable use of recycled materials in building construction. In Advances in Building Technology; Elsevier: Amsterdam, The Netherlands, 2002; pp. 1399–1406. [Google Scholar] [CrossRef]

- Molenaar, A.A.; van Niekerk, A.A. Effects of gradation, composition, and degree of compaction on the mechanical characteristics of recycled unbound materials. Transp. Res. Rec. 2002, 1787, 73–82. [Google Scholar] [CrossRef]

- Barreca, F.; Gabarron, A.M.; Yepes, J.A.F.; Pérez, J.J.P. Innovative use of giant reed and cork residues for panels of buildings in Mediterranean area. Resour. Conserv. Recycl. 2019, 140, 259–266. [Google Scholar] [CrossRef]

- Ricciardi, P.; Torchia, F.; Belloni, E.; Lascaro, E.; Buratti, C. Environmental characterisation of coffee chaff, a new recycled material for building applications. Constr. Build. Mater. 2017, 147, 185–193. [Google Scholar] [CrossRef]

- Diarte, J.; Shaffer, M.; Obonyo, E. Developing a panelized building system for low-cost housing using waste cardboard and re-purposed wood. In Proceedings of the 18th International Conference on Non-Conventional Materials and Technologies, “Construction Materials & Technologies for Sustainability”, Nairobi, Kenya, 24–26 July 2019. [Google Scholar]

- Sormunen, P.; Kärki, T. Compression Molded Thermoplastic Composites Entirely Made of Recycled Materials. Sustainability 2019, 11, 631. [Google Scholar] [CrossRef]

- Perera, S.; Arulrajah, A.; Wong, Y.C.; Horpibulsuk, S.; Maghool, F. Utilizing recycled PET blends with demolition wastes as construction materials. Constr. Build. Mater. 2019, 221, 200–209. [Google Scholar] [CrossRef]

- Laria, J.G.; Gaggino, R.; Kreiker, J.; Peisino, L.E.; Positieri, M.; Cappelletti, A.L. Mechanical and processing properties of recycled PET and LDPE-HDPE composite materials for building components. J. Thermoplast. Compos. Mater. 2020. [Google Scholar] [CrossRef]

- Rincón, L.; Coma, J.; Pérez, G.; Castell, A.; Boer, D.; Cabeza, L.F. Environmental performance of recycled rubber as drainage layer in extensive green roofs. A comparative Life Cycle Assessment. Build. Environ. 2014, 74, 22–30. [Google Scholar] [CrossRef]

- Intini, F.; Kühtz, S. Recycling in buildings: An LCA case study of a thermal insulation panel made of polyester fiber, recycled from post-consumer PET bottles. Int. J. Life Cycle Assess. 2011, 16, 306–315. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M. Plastic Pollution; Our World in Data: Oxford, UK, 2018. [Google Scholar]

- Peng, Y.; Wu, P.; Schartup, A.T.; Zhang, Y. Plastic waste release caused by COVID-19 and its fate in the global ocean. Proc. Natl. Acad. Sci. USA 2021, 118, 47. [Google Scholar] [CrossRef] [PubMed]

- Mistriotis, A.; Briassoulis, D. Numerical estimation of the internal and external aerodynamic coefficients of a tunnel greenhouse structure with openings. Comput. Electron. Agric. 2002, 34, 191–205. [Google Scholar] [CrossRef]

- Ren, J.; Wang, J.; Guo, S.; Li, X.; Zheng, K.; Zhao, Z. Finite element analysis of the static properties and stability of a large-span plastic greenhouse. Comput. Electron. Agric. 2019, 165, 104957. [Google Scholar] [CrossRef]

- Wang, C.; Jiang, Y.; Bai, Y.; Wang, T. Numerical study on static properties and failure mechanisms of landing assembled Chinese solar greenhouses. Comput. Electron. Agric. 2021, 188, 106347. [Google Scholar] [CrossRef]

- Hur, D.-J.; Kwon, S. Fatigue Analysis of Greenhouse Structure under Wind Load and Self-Weight. Appl. Sci. 2017, 7, 1274. [Google Scholar] [CrossRef]

- Ataei, A.; Bradford, M.A.; Valipour, H.R.; Liu, X. Experimental study of sustainable high strength steel flush end plate beam-to-column composite joints with deconstructable bolted shear connectors. Eng. Struct. 2016, 123, 124–140. [Google Scholar] [CrossRef]

- Xiao, J.; Chen, Z.; Ding, T.; Xia, B. Effect of recycled aggregate concrete on the seismic behavior of DfD beam-column joints under cyclic loading. Adv. Struct. Eng. 2021, 24, 1709–1723. [Google Scholar] [CrossRef]

- Jin, D.; Hou, C.; Shen, L.; Han, L.-H. Numerical performance of blind-bolted demountable square CFST K-joints. J. Build. Eng. 2021, 33, 101646. [Google Scholar] [CrossRef]

- Choi, M.-K.; Ryu, H.-R.; Cho, M.-W.; Yu, I.-H. Effect of the Member Joint on Structural Performance of an Arch-type Multi-span Greenhouse: A Full-scale Experimental and Numerical Study. Prot. Hortic. Plant Fact. 2017, 26, 402–410. [Google Scholar] [CrossRef]

- Tsai, M.-H.; Lee, Y.-C. Practical Structural Design and Construction of an Innovative Composite Plastic Greenhouse. Agriculture 2021, 11, 1051. [Google Scholar] [CrossRef]

- National Architecture Association, China. Six Types of Agricultural Greenhouse Standard Drawings and Structure Calculations. 2022. Available online: https://www.naa.org.tw/ (accessed on 3 June 2022).

- Ove, H.S. Risk and Safety in Technology. In Handbook of the Philosophy of Science, Philosophy of Technology and Engineering Sciences; North Holland: Amsterdam, The Netherlands, 2009; pp. 1069–1102. [Google Scholar]

| Characteristic | Value |

|---|---|

| melting point (°C) | 230 |

| glass transition temperature (°C) | 72 |

| heat resistance temperature (°C) | 210 |

| maximum tensile strength (MPa) | 71.7847 |

| elongation (%) | 6.5 |

| maximum bending strength (MPa) | 122.5831 |

| flexural modulus of elasticity (GPa) | 4.4130 |

| hardness (Shore D) ASTM D2240 | 80 |

| density (g/cm3) | 1.43 |

| Fastener | Axial Tension (N) | X-Axis Bending Moment (N mm) | Y-Axis Bending Moment (N mm) |

|---|---|---|---|

| A | 2169.23 | 249,932.28 | 208,126.53 |

| B | 1737.10 | 249,932.30 | 208,126.50 |

| C | 1941.72 | 59,085.10 | 226,268.80 |

| D | 2004.48 | 164,339.80 | 649,484.60 |

| E | 2144.71 | 399,503.31 | 646,375.91 |

| F | 2004.48 | 201,193.23 | 190,347.08 |

| G1 | 2156.48 | 189,895.97 | 189,895.97 |

| G2 | 2156.48 | 189,895.97 | 189,895.97 |

| H | 1796.58 | 201,193.23 | 91,417.59 |

| Axial Tension Force | X-Axis Bending Force | Y-Axis Bending Force | ||||

|---|---|---|---|---|---|---|

| Fastener | von Mises (MPa) | Safety Factor (μL) | von Mises (MPa) | Safety Factor (μL) | von Mises (MPa) | Safety Factor (μL) |

| A | 16.33 | 8.15 | 117.5 | 1.93 | 139.6 | 1.37 |

| B | 316.7 | 1.2 | 526.3 | 0.71 | 261.4 | 1.25 |

| C | 56.23 | 3.65 | 51.58 | 4.43 | 198.5 | 1.84 |

| D | 37.9 | 5.99 | 99.93 | 1.91 | 336.5 | 0.53 |

| E | 139.3 | 2.06 | 274.2 | 0.93 | 540.3 | 0.47 |

| F | 15.27 | 9.16 | 98.82 | 1.57 | 319.5 | 0.94 |

| G1 | 14.59 | 10.03 | 158.4 | 1.84 | 83.57 | 1.71 |

| G2 | 23.47 | 6.79 | 182.4 | 1.82 | 78.89 | 1.86 |

| H | 12.92 | 11.65 | 97.4 | 1.74 | 68.35 | 4.14 |

| Fastener | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Frequency (Hz) | A | B | C | D | E | F | G1 | G2 | H |

| F1 | 219.57 | 187 | 217.28 | 179.9 | 194.82 | 215.73 | 214.64 | 194.92 | 202.84 |

| F2 | 220.07 | 199.01 | 220.45 | 181.1 | 196.17 | 264.2 | 216.31 | 209.31 | 204.81 |

| F3 | 224.59 | 224.76 | 234.38 | 212.19 | 223.53 | 264.52 | 253.71 | 222.44 | 222.58 |

| F4 | 278.8 | 586.76 | 277.51 | 220.23 | 249.13 | 683.12 | 257.22 | 257.38 | 249.18 |

| F5 | 280.34 | 598.12 | 280.45 | 236.46 | 261.19 | 686.03 | 272.97 | 267.17 | 264.43 |

| F6 | 1037.22 | 638.96 | 592.46 | 606.93 | 655.45 | 689.34 | 692.2 | 604.44 | 659.33 |

| F7 | 1109.22 | 942.11 | 627.35 | 649.66 | 671.46 | 1072.69 | 705.02 | 627.11 | 662.78 |

| F8 | 1125.7 | 970.63 | 636.89 | 678.37 | 716.4 | 1243.86 | 705.42 | 699.79 | 679.57 |

| F9 | 1153.65 | 1076.54 | 966.17 | 839.54 | 923.45 | 1274.13 | 1056.12 | 993.8 | 1005.71 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.-J.; Lin, M.-J.; Chen, P.-T.; Chiu, H.-L. Circular Economy in Practice: Building a Simple Greenhouse from Recycled Plastic. Machines 2022, 10, 1207. https://doi.org/10.3390/machines10121207

Yang C-J, Lin M-J, Chen P-T, Chiu H-L. Circular Economy in Practice: Building a Simple Greenhouse from Recycled Plastic. Machines. 2022; 10(12):1207. https://doi.org/10.3390/machines10121207

Chicago/Turabian StyleYang, Cheng-Jung, Mei-Jyun Lin, Po-Tuan Chen, and Hsin-Lin Chiu. 2022. "Circular Economy in Practice: Building a Simple Greenhouse from Recycled Plastic" Machines 10, no. 12: 1207. https://doi.org/10.3390/machines10121207

APA StyleYang, C.-J., Lin, M.-J., Chen, P.-T., & Chiu, H.-L. (2022). Circular Economy in Practice: Building a Simple Greenhouse from Recycled Plastic. Machines, 10(12), 1207. https://doi.org/10.3390/machines10121207