Effect of Groove Texture on Deformation and Sealing Performance of Engine Piston Ring

Abstract

1. Introduction

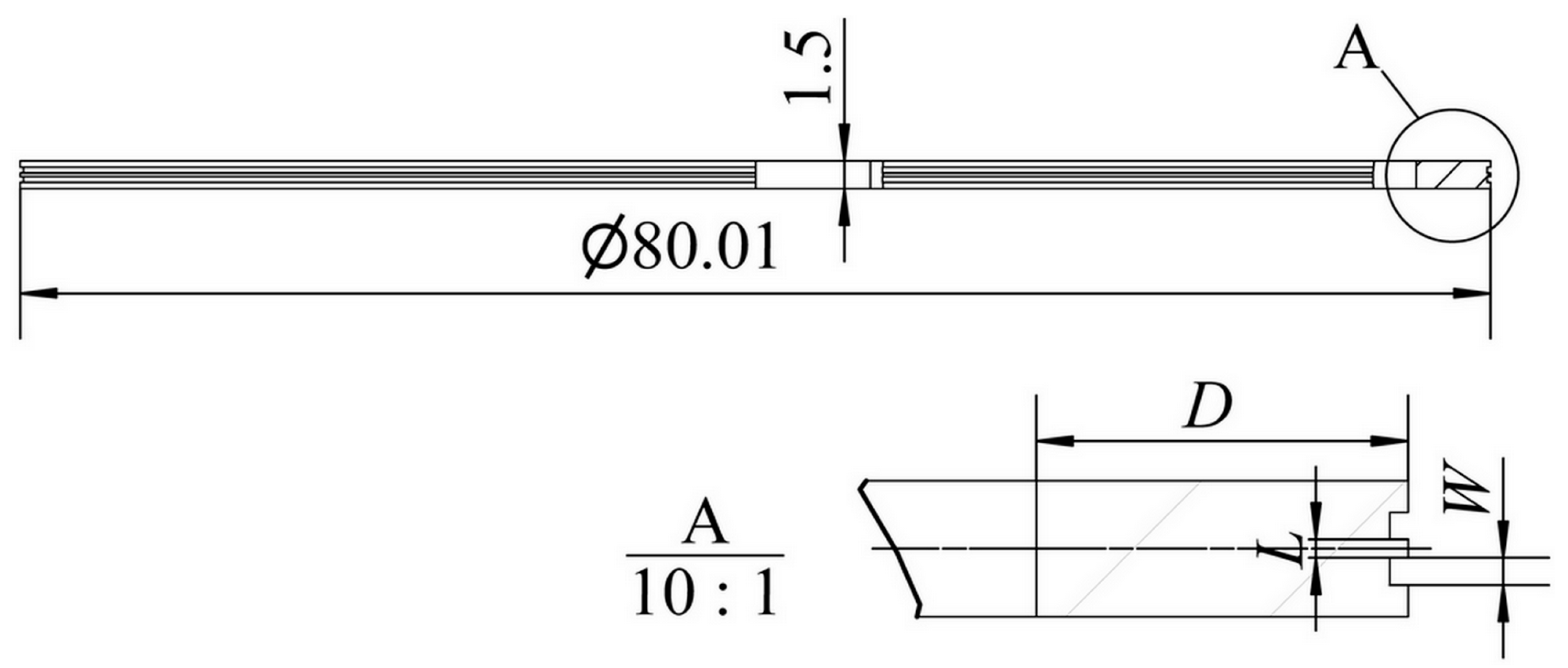

2. Design Groove Morphology on the Piston Ring Surface

3. Finite Element Analysis of Piston Ring

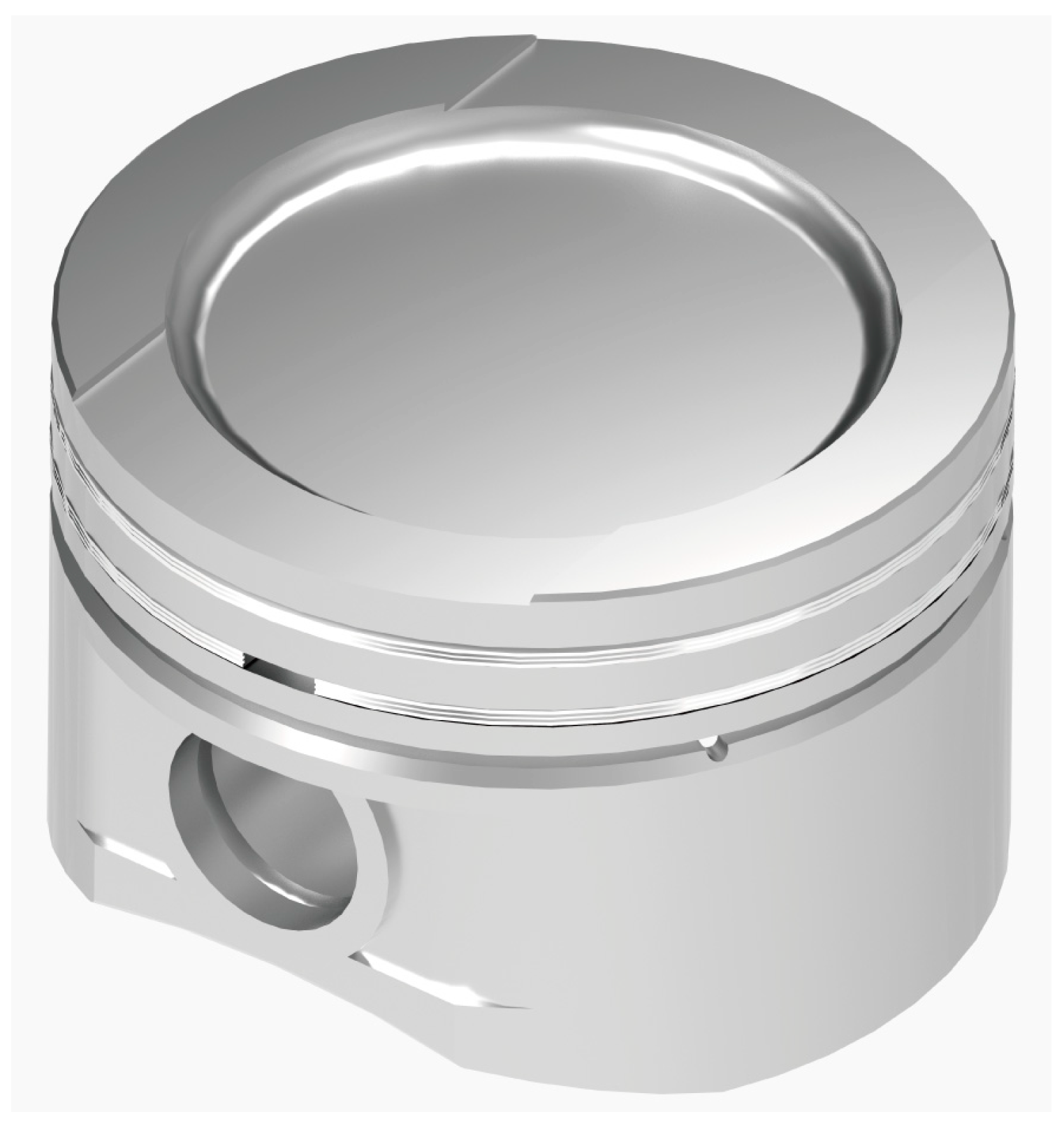

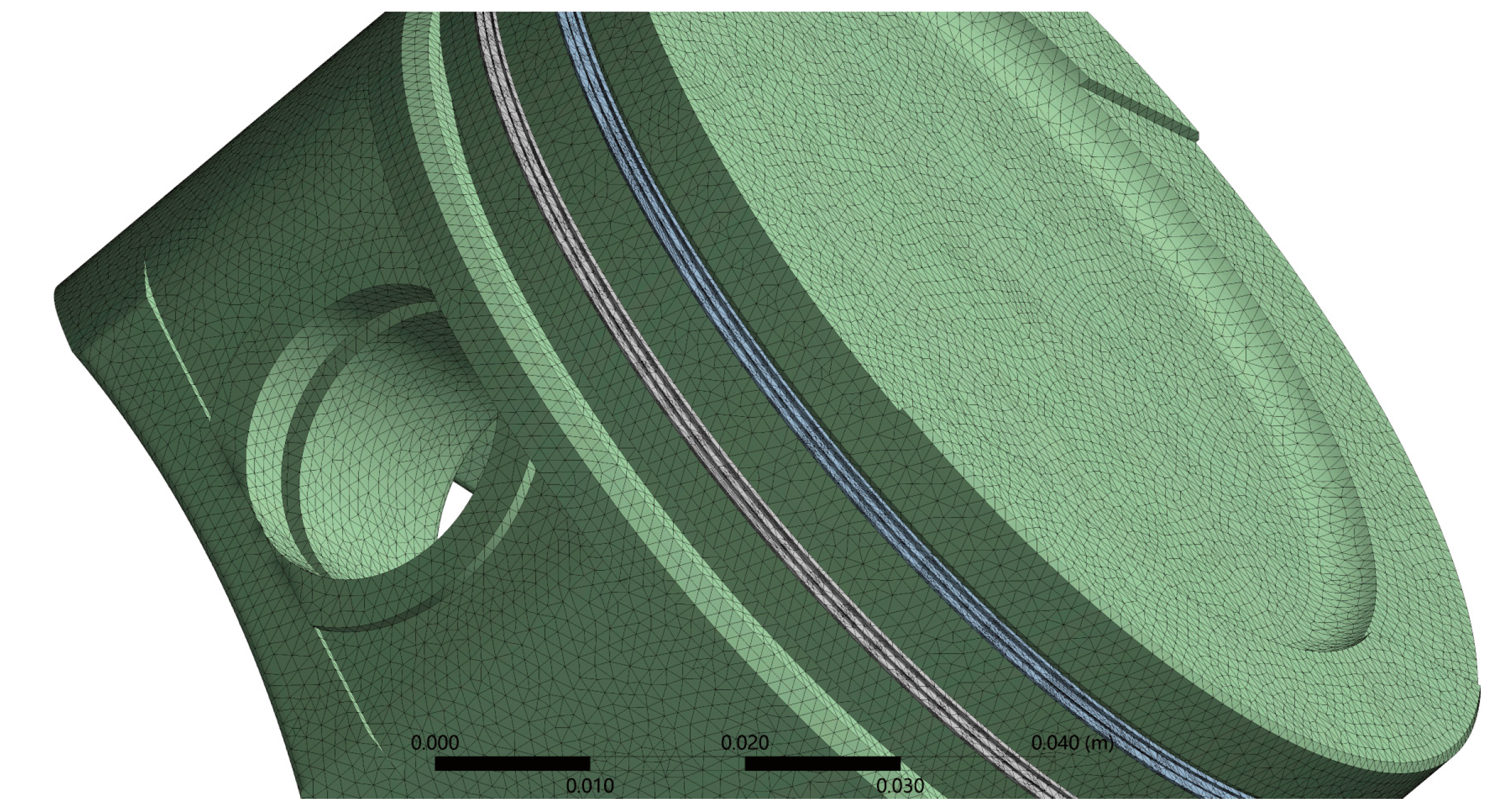

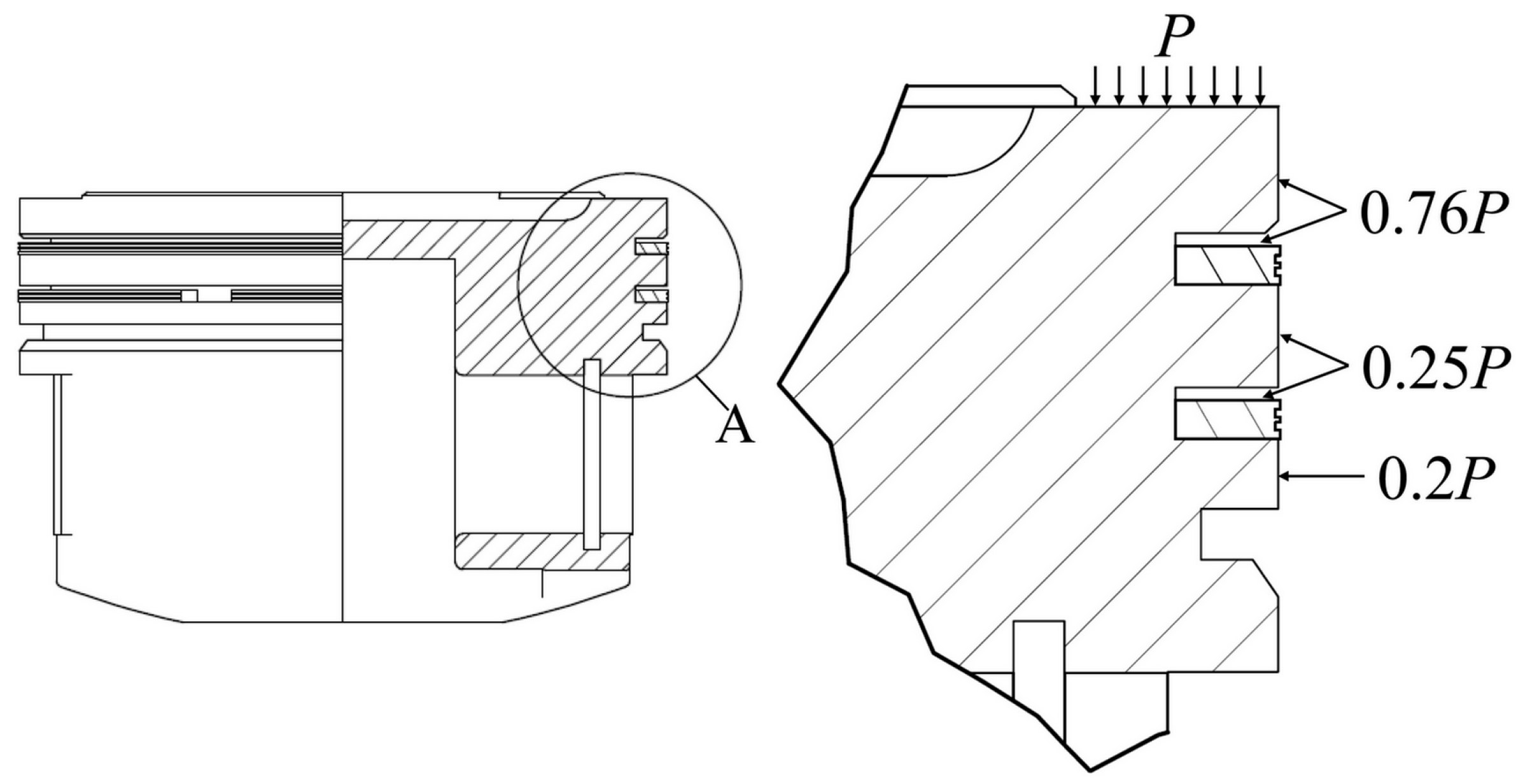

3.1. Analytical Models for Engine Piston and Piston Rings

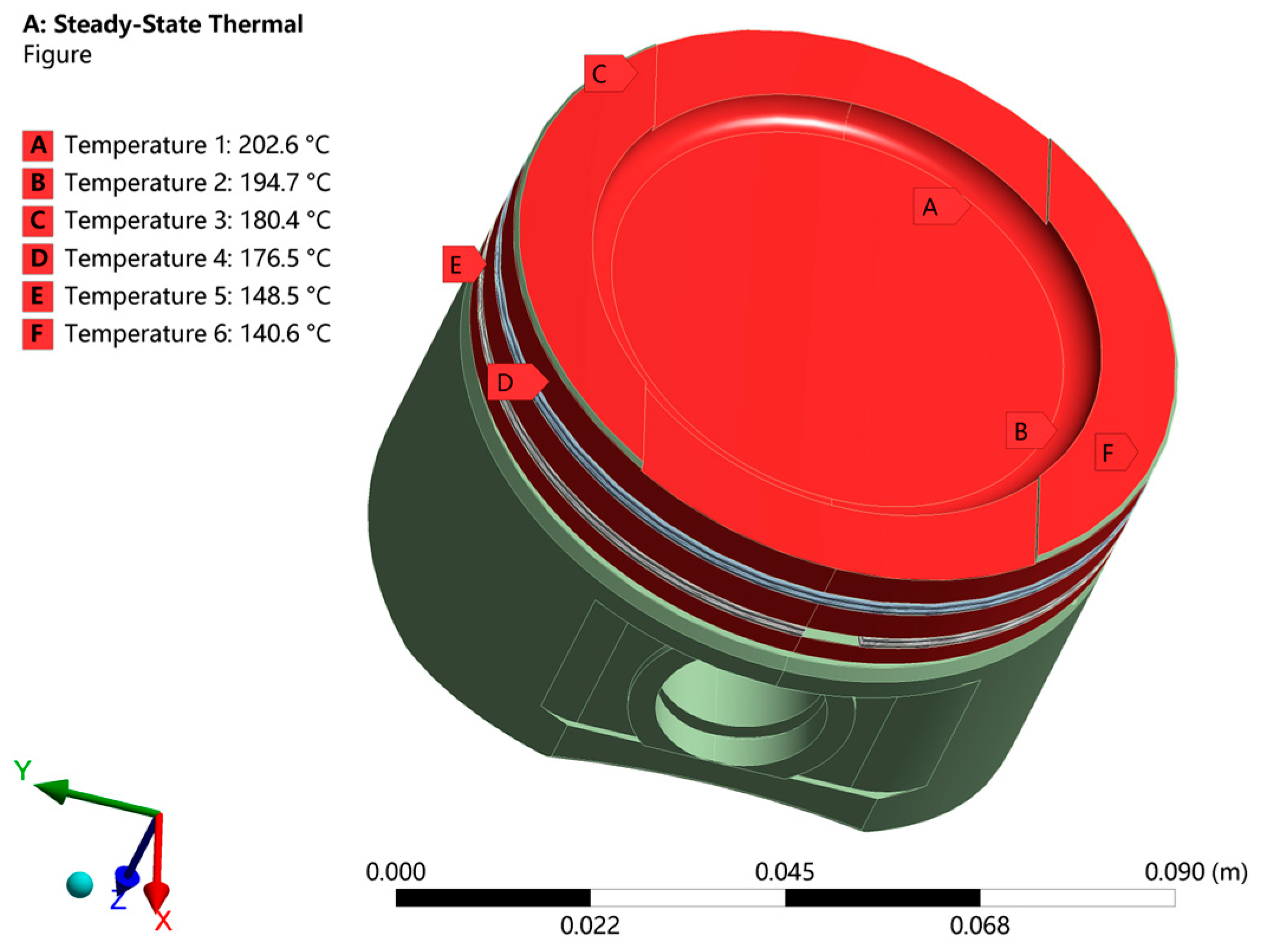

3.2. Boundary Conditions for Analysis Models

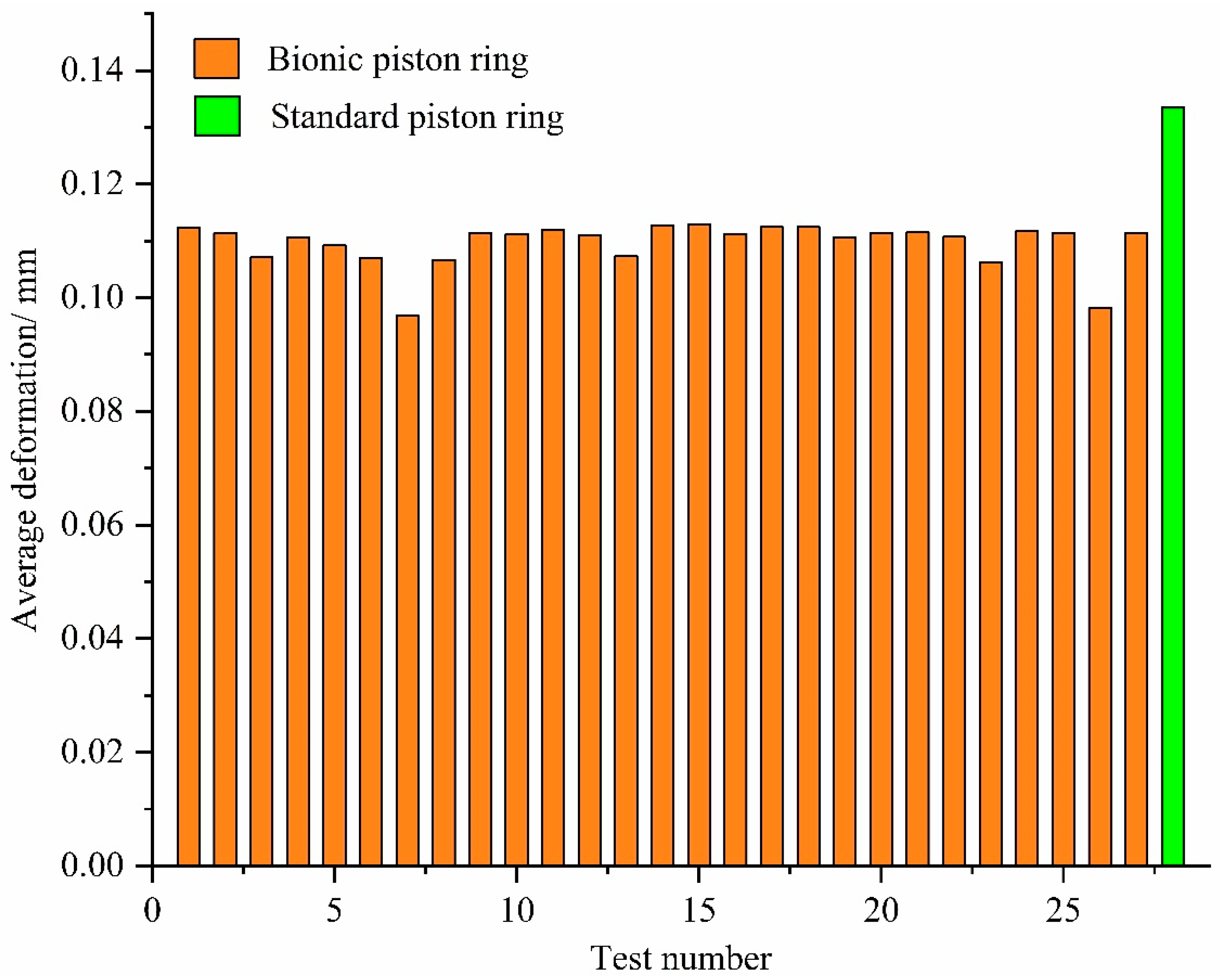

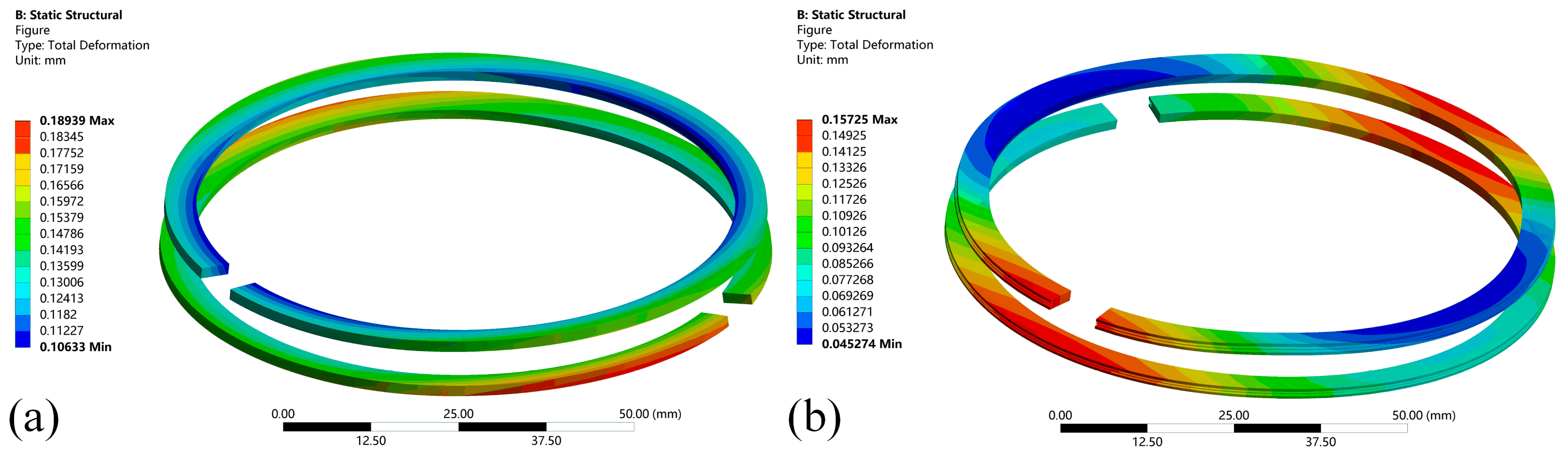

4. Finite Element Analysis Results

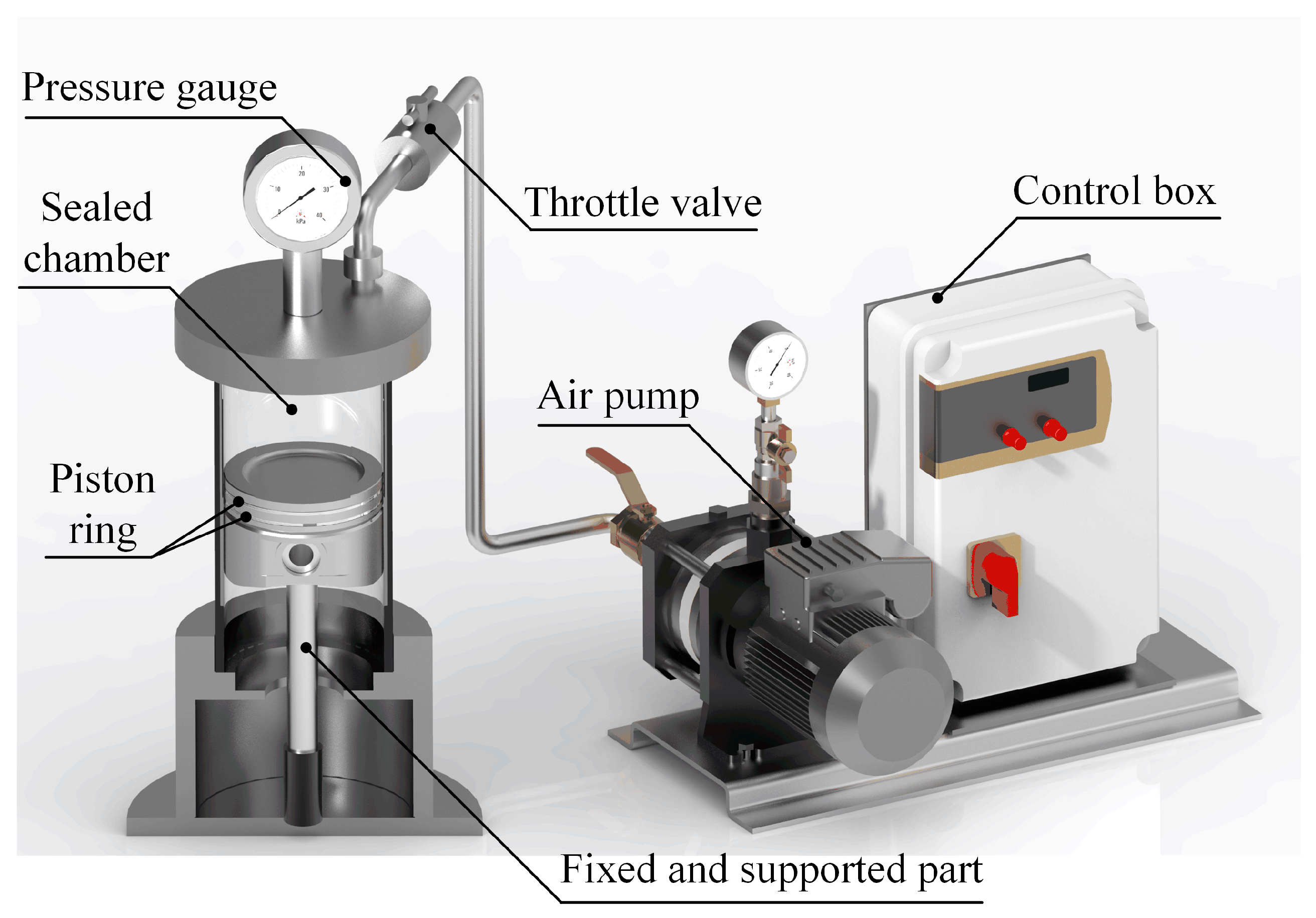

5. Piston Ring Sealing Performance Test

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dellis, P.S. Effect of friction force between piston rings and liner: A parametric study of speed, load, temperature, piston-ring curvature, and high-temperature, high-shear viscosity. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2010, 224, 411–426. [Google Scholar] [CrossRef]

- Dellis, P.S.; Arcoumanis, C. A parametric study on oil film pressure measurements in a single piston-ring configuration. Int. J. Engine Res. 2013, 14, 122–137. [Google Scholar] [CrossRef]

- Dellis, P.S. Piston-ring performance: Limitations from cavitation and friction. Int. J. Struct. Integr. 2019, 10, 304–324. [Google Scholar] [CrossRef]

- Priest, M.; Dowson, D.; Taylor, C.M. Theoretical modelling of cavitation in piston ring lubrication. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2000, 214, 435–447. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, X.; Zhu, J.; Gao, Y.; Wang, H.; Zhao, X.; Teng, Q.; Ren, Y.; Zhu, G. On the lubrication characteristics of piston ring under different engine operation conditions. Ind. Lubr. Tribol. 2020, 72, 101–108. [Google Scholar] [CrossRef]

- Kagnici, F.; Akalin, O. The Effect of Cylinder Bore Distortion on Lube Oil Consumption and Blow-By. J. Tribol. Trans. ASME 2014, 136, 011103. [Google Scholar] [CrossRef]

- Rabute, R.; Tian, T. Challenges involved in piston top ring designs for modern SI engines. J. Eng. Gas Turbines Power Trans. ASME 2001, 123, 448–459. [Google Scholar] [CrossRef]

- Morris, N.; Mohammadpour, M.; Rahmani, R.; Rahnejat, H. Optimisation of the piston compression ring for improved energy efficiency of high performance race engines. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2017, 231, 1806–1817. [Google Scholar] [CrossRef]

- Tung, S.C.; McMillan, M.L. Automotive tribology overview of current advances and challenges for the future. Tribol. Int. 2004, 37, 517–536. [Google Scholar] [CrossRef]

- Taylor, R.I.; Evans, P.G. In-situ piston measurements. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2004, 218, 185–200. [Google Scholar] [CrossRef]

- Xu, B.; Yin, B.; Gao, D.; Hua, X. Tribological performance of surface treated piston assembly with infiltrated layer. J. Mech. Sci. Technol. 2022, 36, 197–204. [Google Scholar] [CrossRef]

- Wang, Z.; Shuai, S.; Li, Z.; Yu, W. A Review of Energy Loss Reduction Technologies for Internal Combustion Engines to Improve Brake Thermal Efficiency. Energies 2021, 14, 6656. [Google Scholar] [CrossRef]

- García, C.; Rojas, J.; Abril, S. Analysis of the Influence of Textured Surfaces and Lubrication Conditions on the Tribological Performance between the Compression Ring and Cylinder Liner. Lubricants 2021, 9, 51. [Google Scholar] [CrossRef]

- Meng, F.-M.; Wang, J.-X.; Xiao, K. A study of the influences of particles in the gas flow passage of a piston ring pack on the tribological performances of the piston ring. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2010, 224, 201–215. [Google Scholar] [CrossRef]

- Mahmoud, K.G.; Knaus, O.; Parikyan, T.; Offner, G.; Sklepic, S. An integrated model for the performance of piston ring pack in internal combustion engines. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2018, 232, 371–384. [Google Scholar] [CrossRef]

- Shen, C.; Khonsari, M.M. Tribological and Sealing Performance of Laser Pocketed Piston Rings in a Diesel Engine. Tribol. Lett. 2016, 64, 26. [Google Scholar] [CrossRef]

- Ferreira, R.; Martins, J.; Carvalho, Ó.; Sobral, L.; Carvalho, S.; Silva, F. Tribological solutions for engine piston ring surfaces: An overview on the materials and manufacturing. Mater. Manuf. Process. 2019, 35, 498–520. [Google Scholar] [CrossRef]

- Madej, M.; Ozimina, D.; Gałuszka, R.; Gałuszka, G. Corrosion, friction and wear performance of diamond–Like carbon (DLC) coatings. Metalurgija 2016, 55, 679–682. [Google Scholar]

- Mustafi, L.; Rahman, M.M.; Al Nasim, M.N.E.A.; Chowdhury, M.A.; Monir, M.H. Deposition behavior and tribological properties of diamond-like carbon coatings on stainless steels via chemical vapor deposition. Int. J. Miner. Met. Mater. 2018, 25, 1335–1343. [Google Scholar] [CrossRef]

- Özkan, D.; Erarslan, Y.; Kıncal, C.; Gürlü, O.; Yağcı, M.B. Wear and corrosion resistance enhancement of chromium surfaces through graphene oxide coating. Surf. Coat. Technol. 2020, 391, 125595. [Google Scholar] [CrossRef]

- Vysotina, E.A.; Kazakov, V.A.; Polyansky, M.N.; Savushkina, S.V.; Sivtsov, K.I.; Sigalaev, S.K.; Lyakhovetsky, M.A.; Mironova, S.A.; Zilova, O.S. Investigation of the Structure and Functional Properties of Diamond-Like Coatings Obtained by Physical Vapor Deposition. J. Surf. Investig. 2017, 11, 1177–1184. [Google Scholar] [CrossRef]

- Vahidi, A.; Fonseca, D.; Oliveira, J.; Cavaleiro, A.; Ramalho, A.; Ferreira, F. Advanced tribological characterization of DLC coatings produced by Ne-HiPIMS for the application on the piston rings of internal combustion engines. Appl. Sci. 2021, 11, 10498. [Google Scholar] [CrossRef]

- Volokitina, I.; Siziakova, E.; Fediuk, R.; Kolesnikov, A. Development of a Thermomechanical Treatment Mode for Stainless-Steel Rings. Materials 2022, 15, 4930. [Google Scholar] [CrossRef] [PubMed]

- Delprete, C.; Selmani, E.; Bisha, A. Gas escape to crankcase: Impact of system parameters on sealing behavior of a piston cylinder ring pack. Int. J. Energy Environ. Eng. 2019, 10, 207–220. [Google Scholar] [CrossRef]

- Atkinson, S. Software accurately predicts piston and ring pack performance. Seal. Technol. 2019, 2019, 5. [Google Scholar] [CrossRef]

- Livanos, G.A.; Kyrtatos, N.P. Friction model of a marine diesel engine piston assembly. Tribol. Int. 2007, 40, 1441–1453. [Google Scholar] [CrossRef]

- Koszalka, G.; Guzik, M. Mathematical Model of Piston Ring Sealing in Combustion Engine. Pol. Marit. Res. 2014, 21, 66–78. [Google Scholar] [CrossRef]

- Dai, Q.W.; Li, S.Y.; Wang, X.Y.; Huang, W.; Wang, X.L. Surface texturing of different sealing materials and their lubrication and sealing performances. China Surf. Eng. 2019, 32, 21–29. [Google Scholar]

- Bathe, R.N.; Padmanabham, G.; Thirumalini, S.; Vignesh, R.V. Impact of laser surface texturing (LST) on the tribological characteristics of piston rings and cylinder liners—A review. Part 2: Application of the process. Trans. Inst. Met. Finish. 2022, 100, 119–127. [Google Scholar] [CrossRef]

- He, D.; Han, X.; Chen, G.; Wang, Z.; Chen, W.; Xu, J. Effect of geometrical morphology and arrangement of micro-texture on friction property of CKS piston ring. China Surf. Eng. 2021, 34, 59–69. [Google Scholar]

- Lu, P.; Wood, R.J.K. Tribological performance of surface texturing in mechanical applications—A review. Surf. Topogr. Metrol. Prop. 2020, 8, 043001. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R. Functional importance of honed cylinder liner surface texture: A review. Tribol. Int. 2022, 167, 107409. [Google Scholar] [CrossRef]

- Miao, J.; Li, Y.; Rao, X.; Zhu, L.; Guo, Z.; Yuan, C. Effects of different surface grooved cylinder liner on the tribological performance for cylinder liner-piston ring components. Ind. Lubr. Tribol. 2020, 72, 581–588. [Google Scholar] [CrossRef]

- Ryk, G.; Etsion, I. Testing piston rings with partial laser surface texturing for friction reduction. Wear 2006, 261, 792–796. [Google Scholar] [CrossRef]

- Rao, X.; Sheng, C.; Guo, Z. The influence of different surface textures on wears in cylinder liner piston rings. Surf. Topogr. Metrol. Prop. 2019, 7, 045011. [Google Scholar] [CrossRef]

- Xu, B.; Yin, B.; Jia, H.; Hua, X.; Wei, M. Effects of liner surface textures on the tribological performance of different production piston rings. Lubr. Sci. 2020, 34, 356–368. [Google Scholar] [CrossRef]

- Yang, C.Z.; Guo, Z.; Xu, C. Effect of grooved cylinder liner depths on the tribological performances of cylinder liner-piston ring. Ind. Lubr. Tribol. 2019, 72, 465–471. [Google Scholar] [CrossRef]

- Ren, L.Q. Regression Design and Optimization, 1st ed.; Science Press: Beijing, China, 2009. [Google Scholar]

- Golovitchev, V.I.; Yang, J. Construction of combustion models for rapeseed methyl ester bio-diesel fuel for internal combustion engine applications. Biotechnol. Adv. 2009, 27, 641–655. [Google Scholar] [CrossRef]

- Depcik, C.; Assanis, D. A universal heat transfer correlation for intake and exhaust flows in an spark-ignition internal combustion engine. SAE Trans. 2002, 111, 734–740. [Google Scholar]

| Level | Depth | Width | Spacing |

|---|---|---|---|

| D/mm | W/mm | L/mm | |

| 1 | 1 (1) | 0.1 (1) | 0.1 (1) |

| 2 | 2 (2) | 0.3 (2) | 0.2 (2) |

| 3 | 3 (3) | 0.5 (3) | 0.3 (3) |

| Test No. | D (mm) | W (mm) | L (mm) | Test No. | D (mm) | W (mm) | L (mm) |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 0.1 | 0.1 | 15 | 2 | 0.3 | 0.3 |

| 2 | 1 | 0.1 | 0.2 | 16 | 2 | 0.5 | 0.1 |

| 3 | 1 | 0.1 | 0.3 | 17 | 2 | 0.5 | 0.2 |

| 4 | 1 | 0.3 | 0.1 | 18 | 2 | 0.5 | 0.3 |

| 5 | 1 | 0.3 | 0.2 | 19 | 3 | 0.1 | 0.1 |

| 6 | 1 | 0.3 | 0.3 | 20 | 3 | 0.1 | 0.2 |

| 7 | 1 | 0.5 | 0.1 | 21 | 3 | 0.1 | 0.3 |

| 8 | 1 | 0.5 | 0.2 | 22 | 3 | 0.3 | 0.1 |

| 9 | 1 | 0.5 | 0.3 | 23 | 3 | 0.3 | 0.2 |

| 10 | 2 | 0.1 | 0.1 | 24 | 3 | 0.3 | 0.3 |

| 11 | 2 | 0.1 | 0.2 | 25 | 3 | 0.5 | 0.1 |

| 12 | 2 | 0.1 | 0.3 | 26 | 3 | 0.5 | 0.2 |

| 13 | 2 | 0.3 | 0.1 | 27 | 3 | 0.5 | 0.3 |

| 14 | 2 | 0.3 | 0.2 | 28 (standard piston ring) | 0 | 0 | 0 |

| Number | Leakage Time | Average Leakage Rate | Ratio |

|---|---|---|---|

| t/s | v/MPa·s−1 | δ | |

| Standard piston ring | 222.48 | 3595.83 | / |

| Piston ring No. 7 | 497.23 | 1608.91 | 55.26% |

| Piston ring No. 26 | 466.27 | 1715.74 | 52.29% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, T.; Wang, L.; Xu, J.; Gao, T.; Qin, X.; Yang, X.; Cong, Q.; Jin, J.; Liu, C. Effect of Groove Texture on Deformation and Sealing Performance of Engine Piston Ring. Machines 2022, 10, 1020. https://doi.org/10.3390/machines10111020

Chen T, Wang L, Xu J, Gao T, Qin X, Yang X, Cong Q, Jin J, Liu C. Effect of Groove Texture on Deformation and Sealing Performance of Engine Piston Ring. Machines. 2022; 10(11):1020. https://doi.org/10.3390/machines10111020

Chicago/Turabian StyleChen, Tingkun, Lin Wang, Jin Xu, Tianyu Gao, Xiuzhang Qin, Xiaobin Yang, Qian Cong, Jingfu Jin, and Chaozong Liu. 2022. "Effect of Groove Texture on Deformation and Sealing Performance of Engine Piston Ring" Machines 10, no. 11: 1020. https://doi.org/10.3390/machines10111020

APA StyleChen, T., Wang, L., Xu, J., Gao, T., Qin, X., Yang, X., Cong, Q., Jin, J., & Liu, C. (2022). Effect of Groove Texture on Deformation and Sealing Performance of Engine Piston Ring. Machines, 10(11), 1020. https://doi.org/10.3390/machines10111020