Effects of Coolant and Working Temperature on the Cavitation in an Aeronautic Cooling Pump with High Rotation Speed

Abstract

1. Introduction

2. Numerical Model

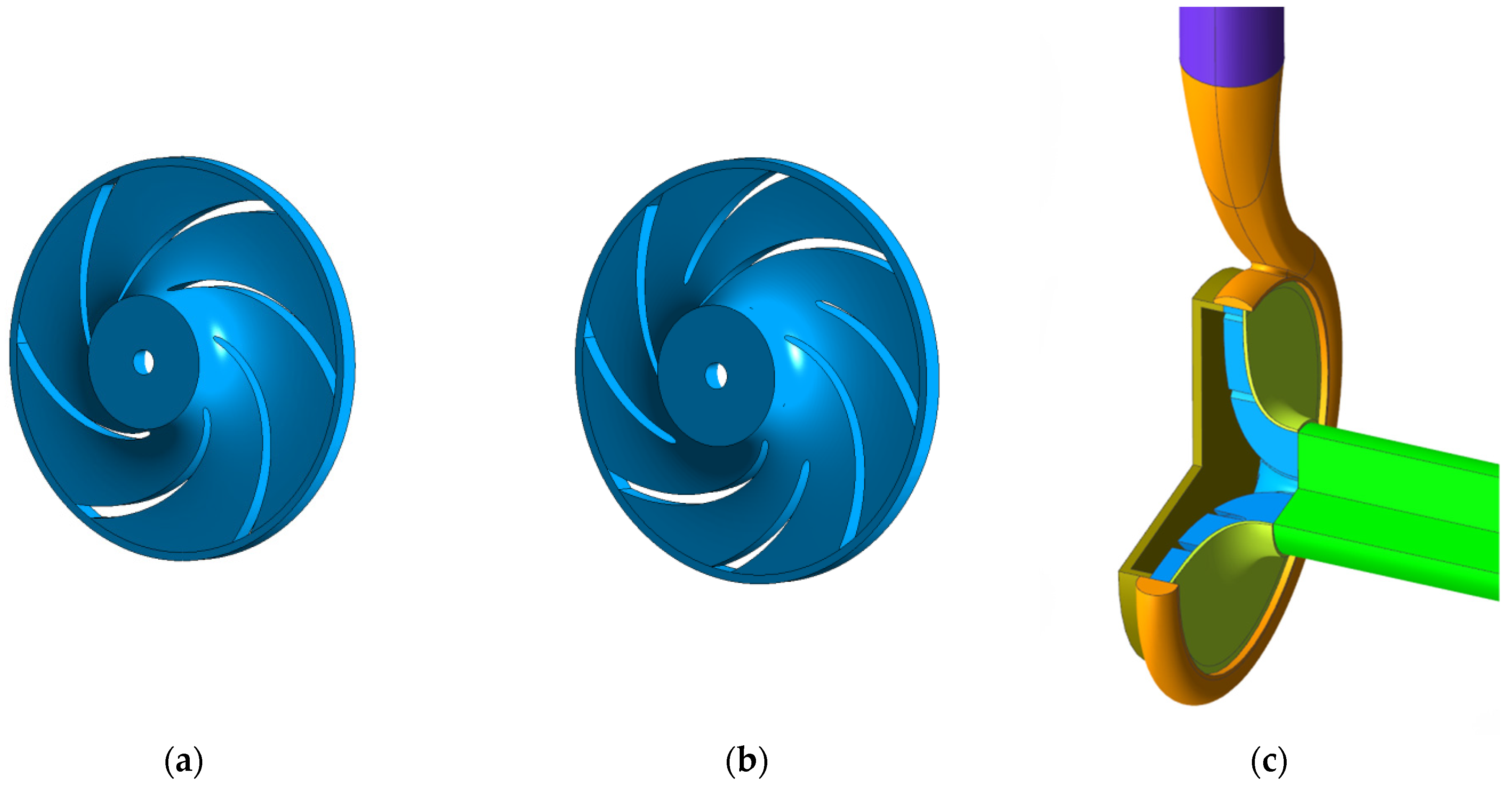

2.1. Physical Model

2.2. Governing Equations

2.3. Boundary Conditions and Settings

3. Experimental Validation

3.1. Experimental Facilities

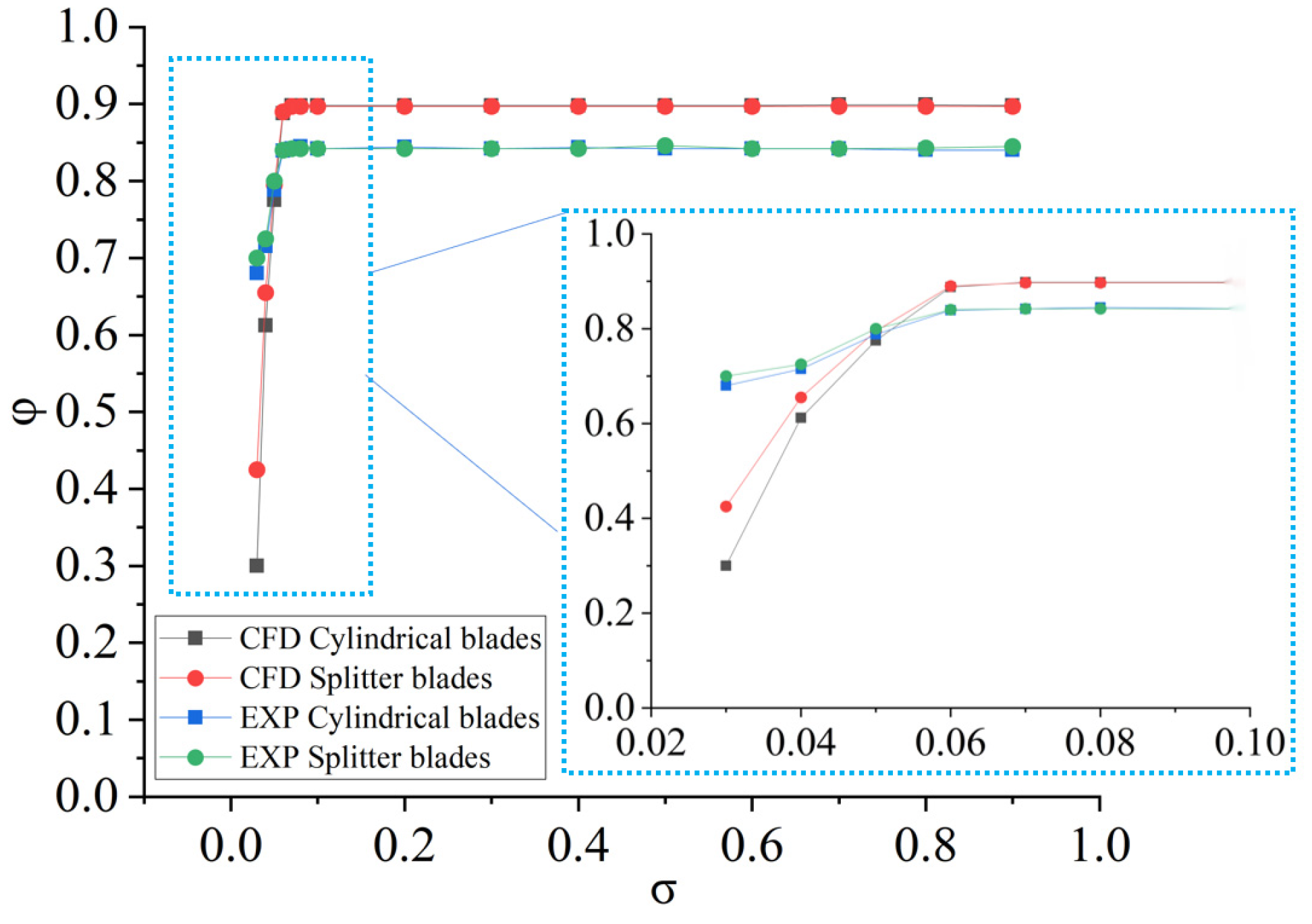

3.2. Validation of Hydraulic and Cavitation Performances

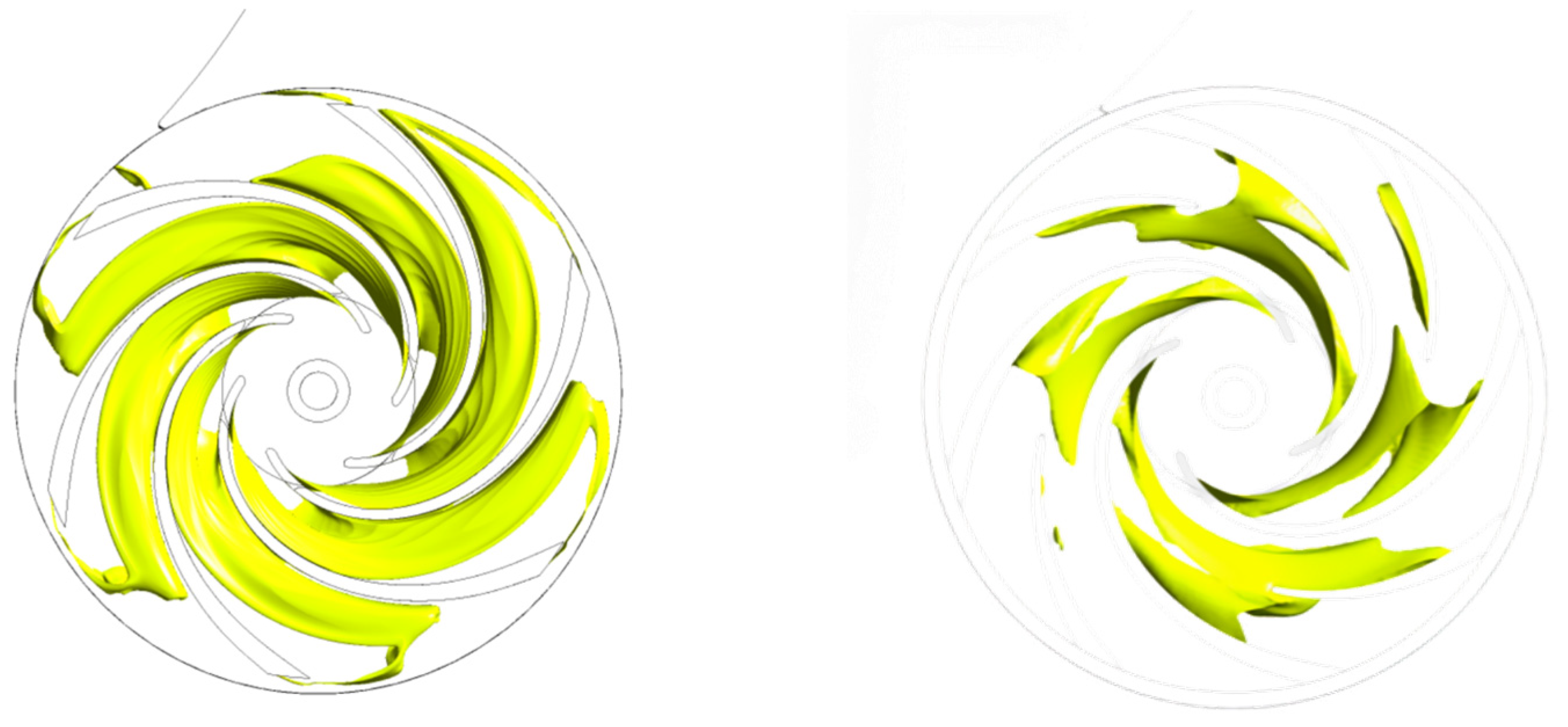

3.3. Validation of Cavitation Visualization

4. Results and Discussion

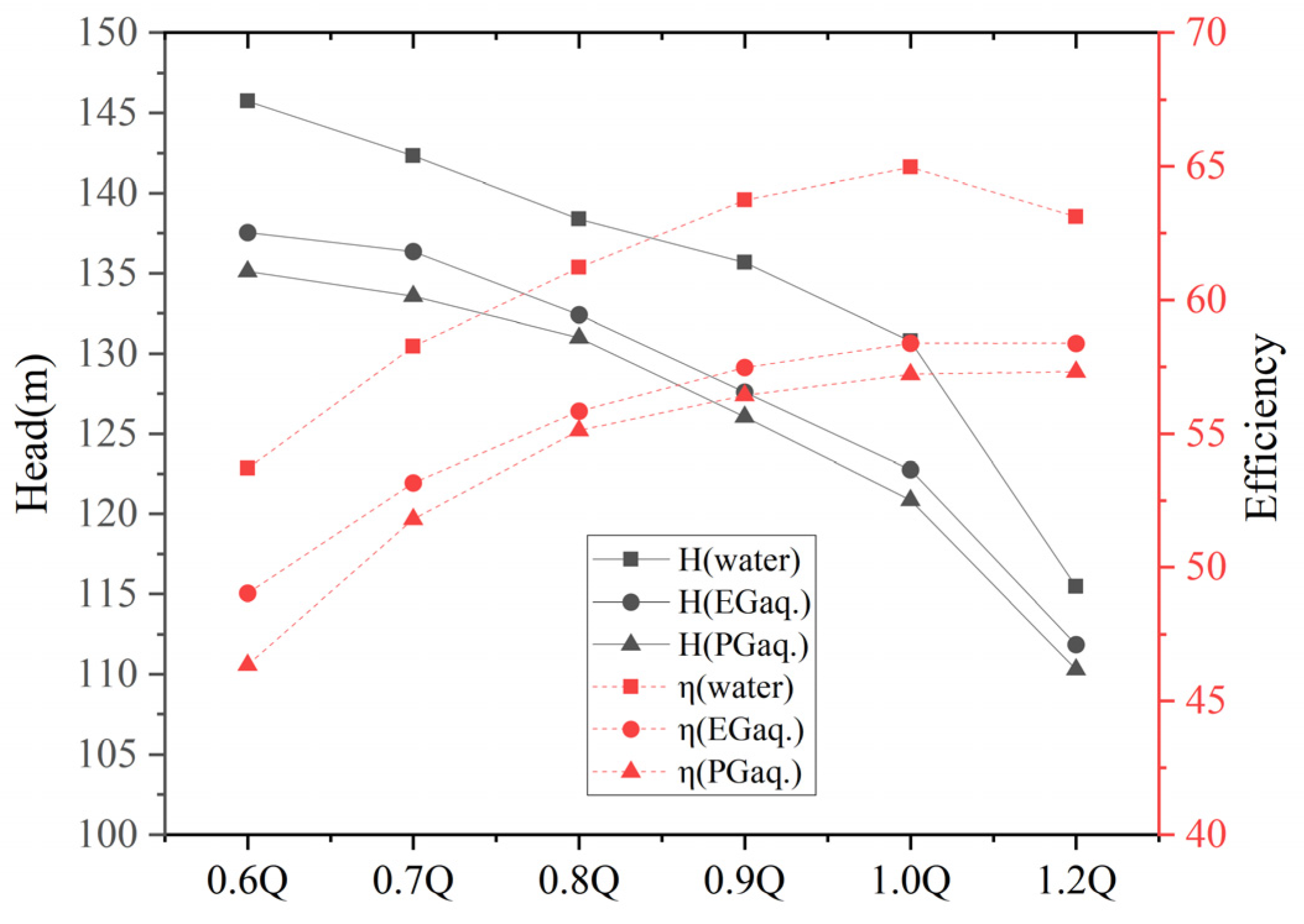

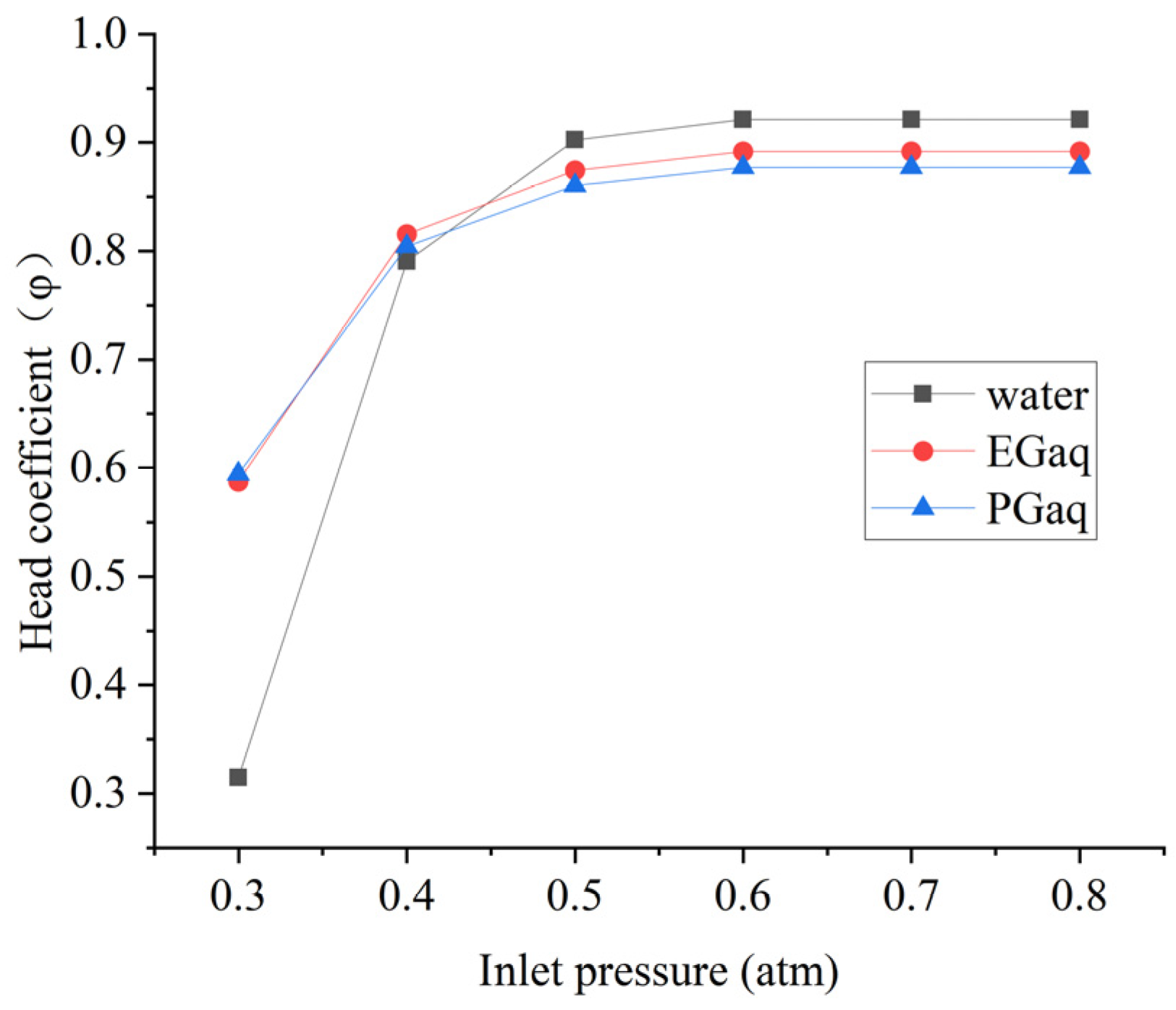

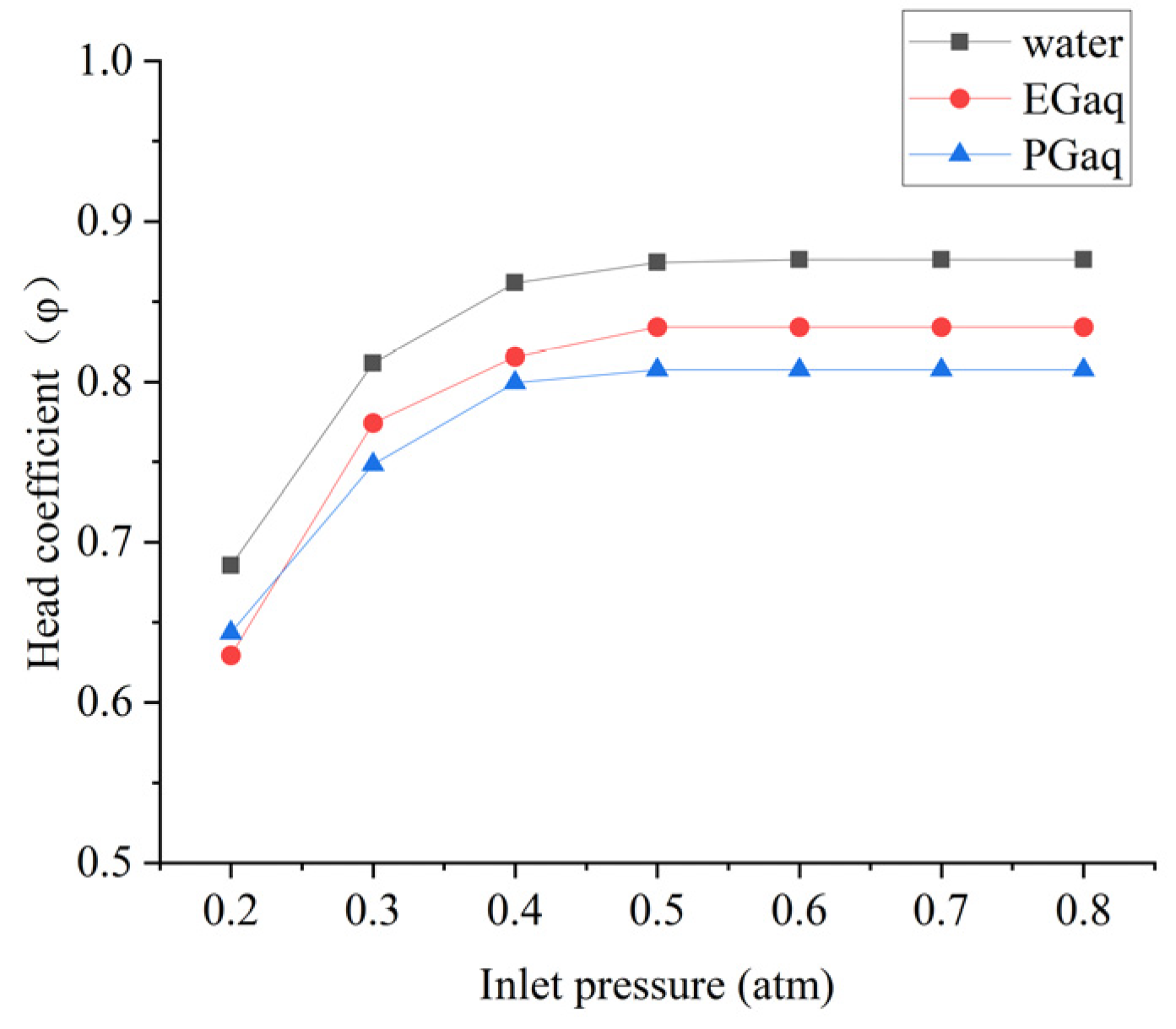

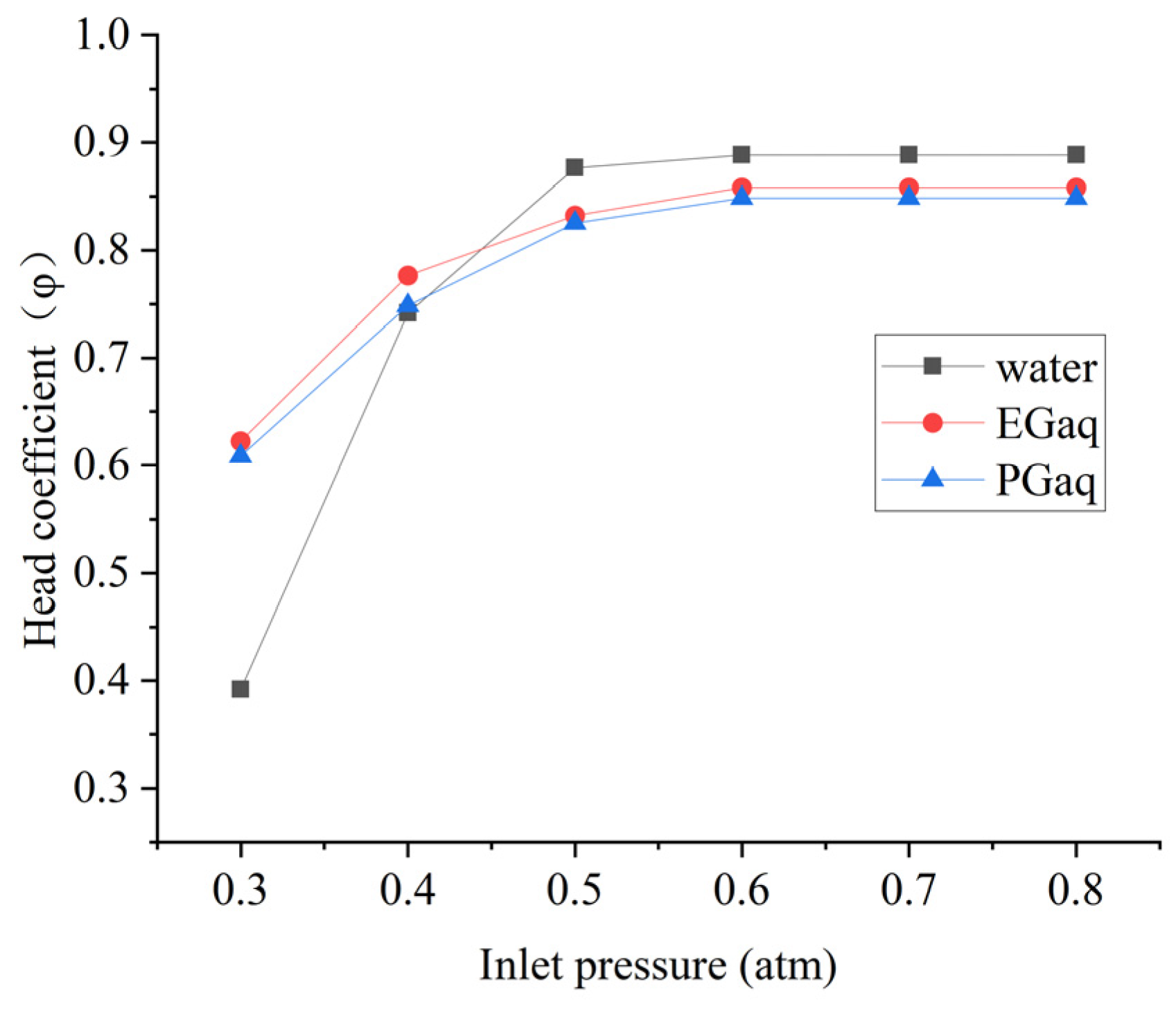

4.1. Characteristics of Pump Hydraulic Performance

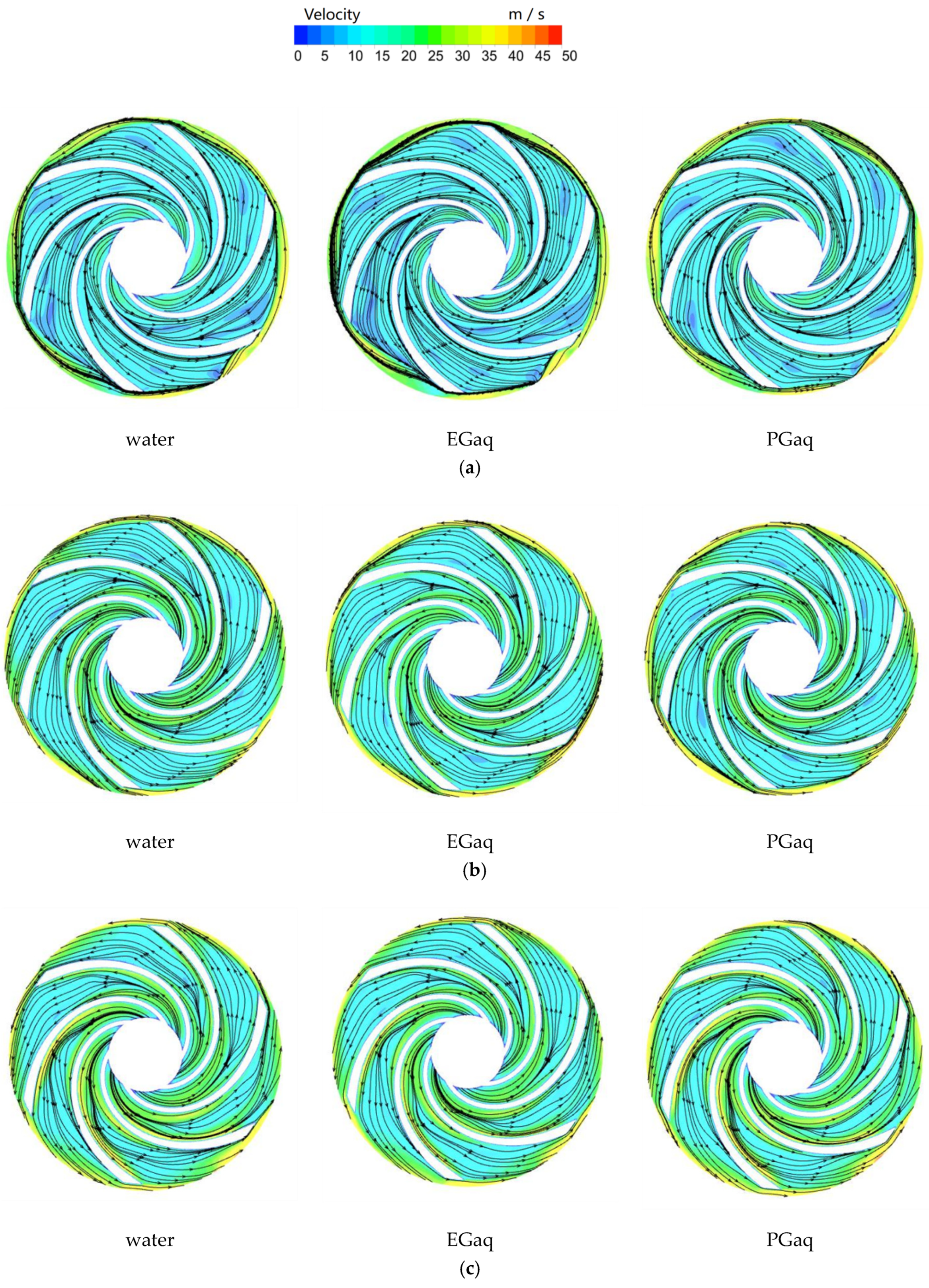

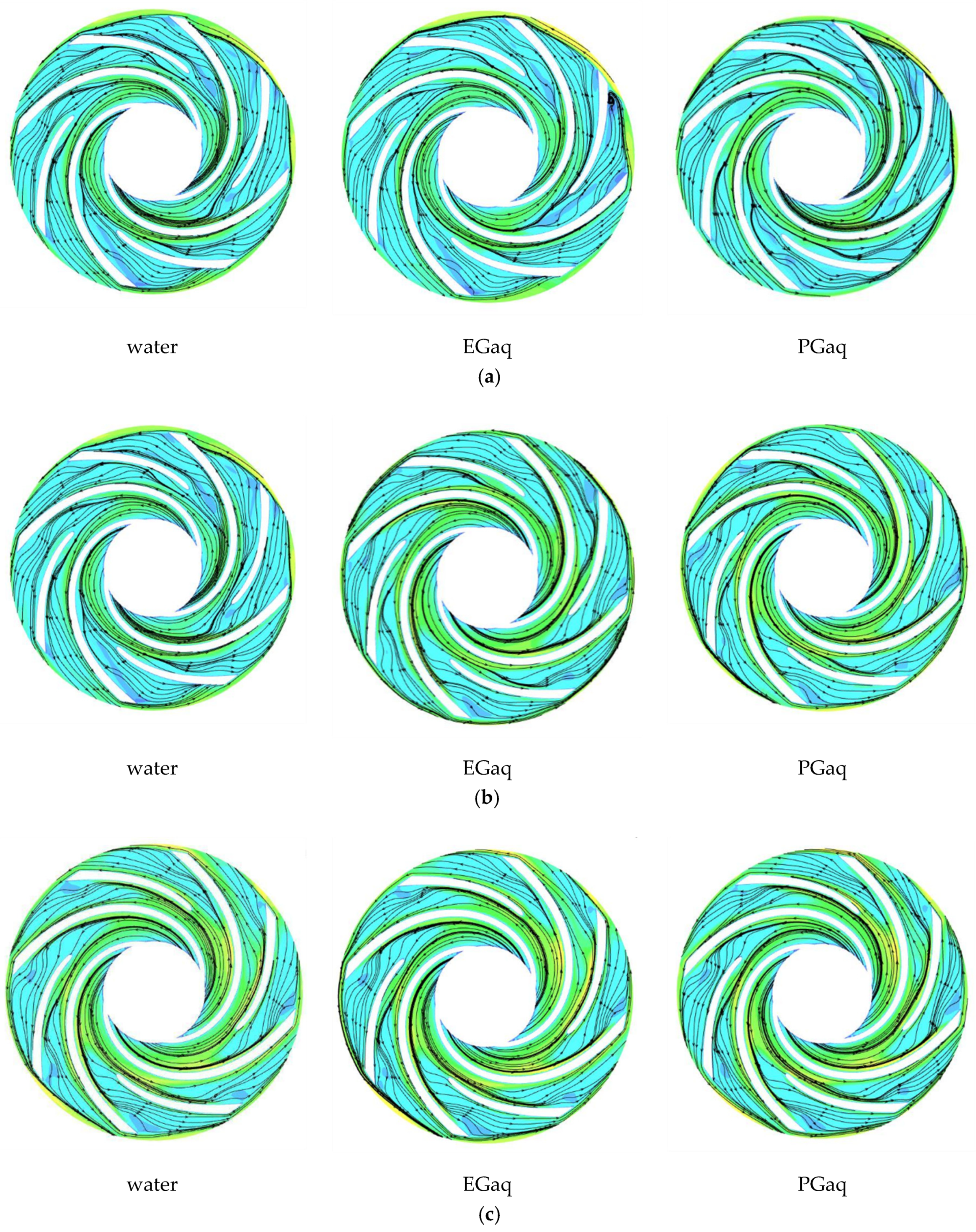

4.2. Characteristics of Pump Internal Flow

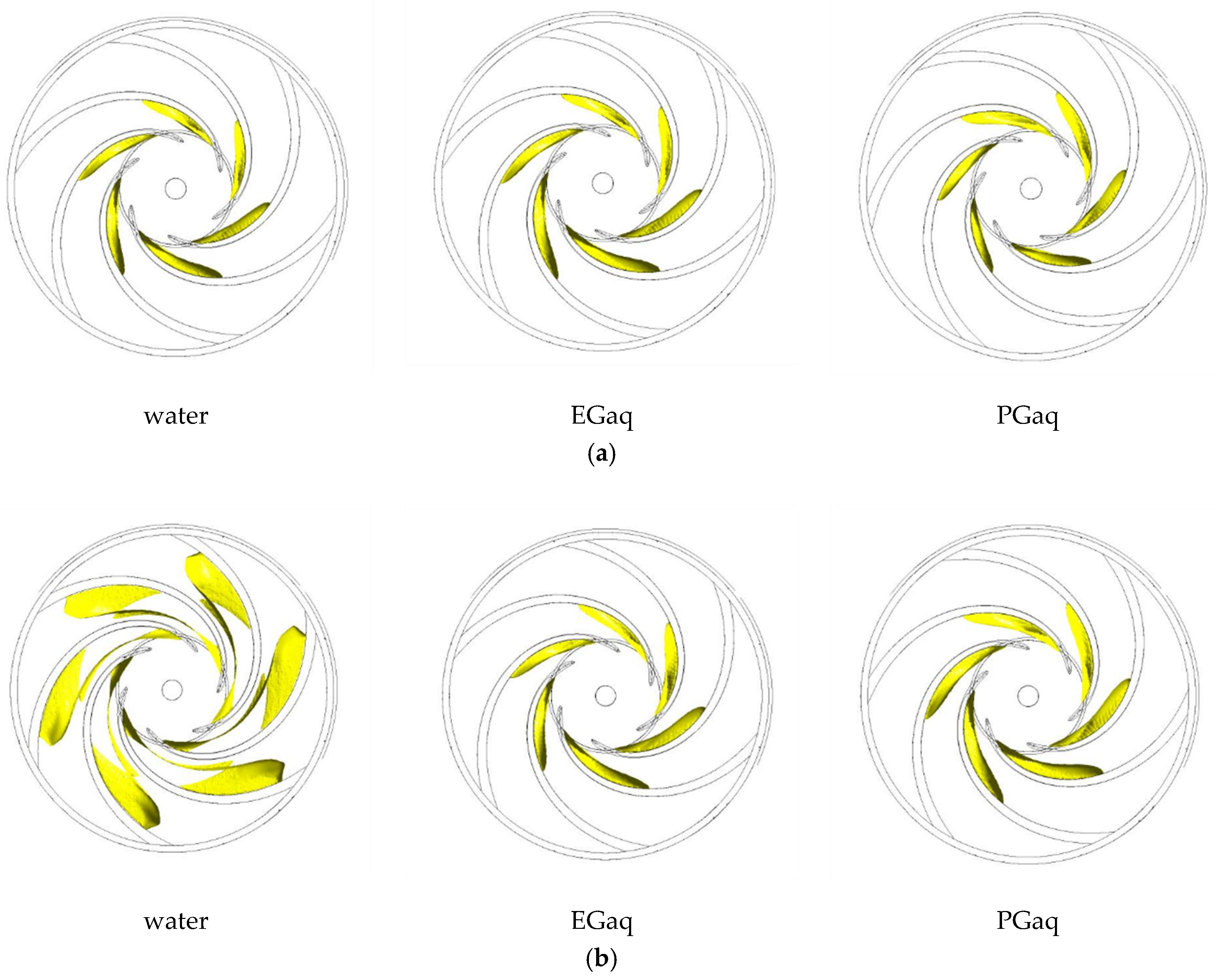

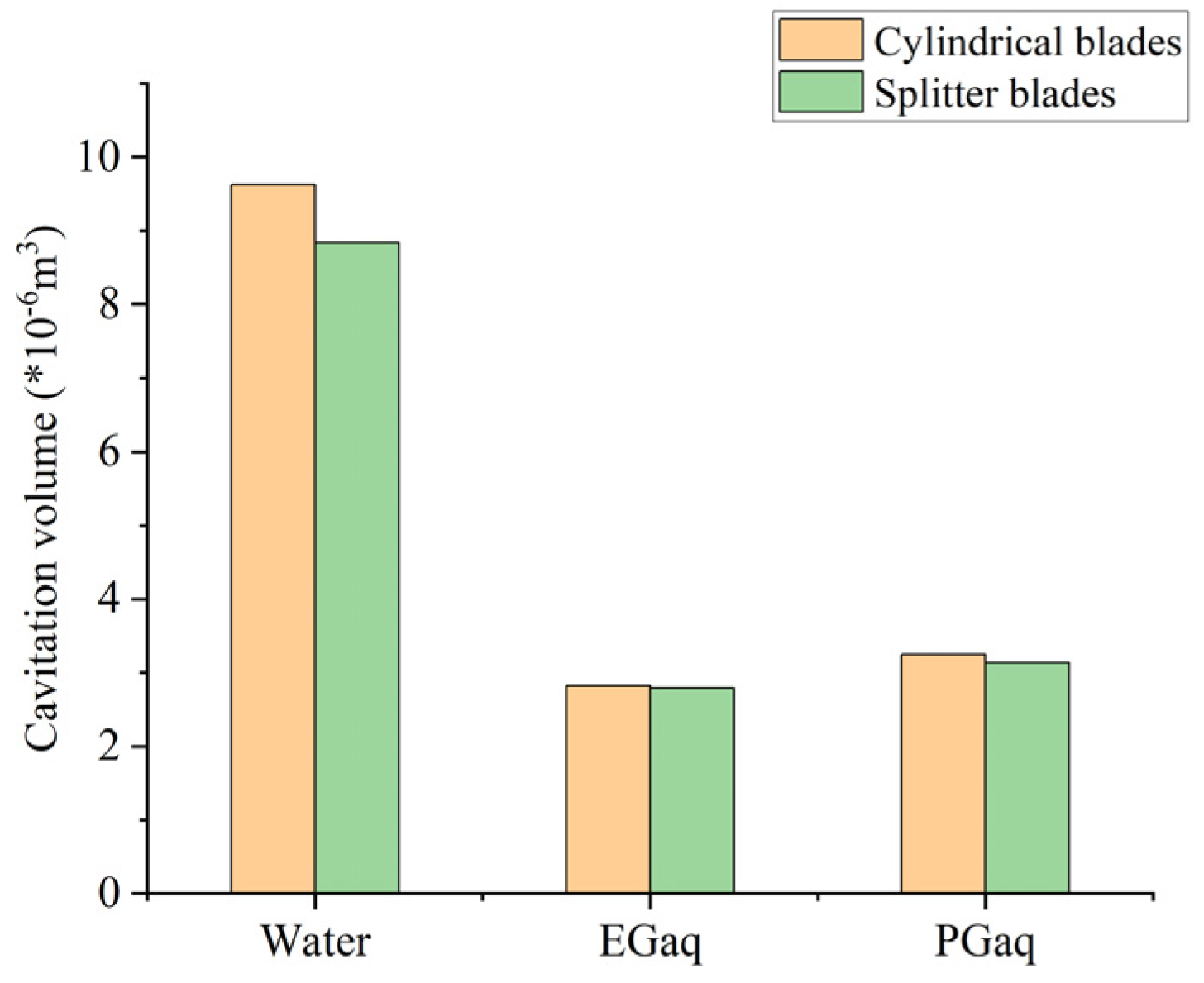

4.3. Characteristics of Pump Cavitation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guan, X.F. Modern Pump Theory and Design; China Aerospace Publishing House: Beijing, China, 2011. (In Chinese) [Google Scholar]

- Jin, J.; Fan, Y.; Han, W.; Hu, J. Design and Analysis on Hydraulic Model of The Ultra -Low Specific-Speed Centrifugal Pump. Procedia Eng. 2012, 31, 110–114. [Google Scholar] [CrossRef][Green Version]

- Zhu, Z.C. Experimental study on high-speed centrifugal pumps with different impellers. Chin. J. Mech. Eng. (Engl. Ed.) 2002, 15, 372–375. [Google Scholar] [CrossRef]

- Lindsay, R.B. On the Pressure Developed in a Liquid During the Collapse of a Spherical Cavity (1917). In Men of Physics Lord Rayleigh—The Man & His Work; Elsevier: Amsterdam, The Netherlands, 1970; pp. 221–226. [Google Scholar] [CrossRef]

- Plesset, M.S.; Devine, R.E. Effect of Exposure Time on Cavitation Damage. J. Basic Eng. Trans. ASME 1966, 88, 31. [Google Scholar] [CrossRef]

- Plessett, M.S.; Prosperetti, A. Bubble Dynamics and Cavitation. Annu. Rev. Fluid Mech. 1977, 9, 1945–1985. [Google Scholar] [CrossRef]

- Brennen, C.E.; Meissner, C.; Lo, E.Y.; Hoffman, G.S. Scale Effects in the Dynamic Transfer Functions for Cavitating Inducers. J. Fluids Eng. 1982, 104, 428–433. [Google Scholar] [CrossRef][Green Version]

- Katz, J. Cavitation Inception in Separated Flows. Ph.D. Thesis, California Institute of Technology, Pasadena, CA, USA, 1982. [Google Scholar] [CrossRef]

- Tanaka, T.; Tsukamoto, H. Transient Behavior of a Cavitating Centrifugal Pump at Rapid Change in Operating Condition (1st Report, Transient Phenomena at Opening/Closure of Discharge Valve). Trans. Jpn. Soc. Mech. Eng. Ser. B 1997, 63, 3976–3983. [Google Scholar] [CrossRef]

- Huang, B.; Wang, G.Y.; Zhang, B.; Yu, Z.Y. Evaluation of the Cavitation Models on the Numerical Simulation of Cloud Cavitating Flows around a Hydrofoil. Beijing Ligong Daxue Xuebao/Trans. Beijing Inst. Technol. 2009, 29, 785–789. [Google Scholar]

- Cheng, H.; Ji, B.; Long, X.; Huai, W.; Farhat, M. A Review of Cavitation in Tip-Leakage Flow and Its Control. J. Hydrodyn. 2021, 33, 226–242. [Google Scholar] [CrossRef]

- Singhal, A.K.; Athavale, M.M.; Li, H.; Jiang, Y. Mathematical Basis and Validation of the Full Cavitation Model. In Proceedings of the ASME FEDSM’01, 2001 ASME Fluids Engineering Division Summer Meeting, New Orleans, LA, USA, 29 May–1 June 2001; 2003; Volume 1, pp. 379–406. [Google Scholar]

- Shih, T.-H.; Liou, W.W.; Shabbir, A.; Yang, Z.; Zhu, J. A New K-ϵ Eddy Viscosity Model for High Reynolds Number Turbulent Flows. Computers & Fluids 1995, 24, 227–238. [Google Scholar] [CrossRef]

- Wang, G.; Ostoja-Starzewski, M. Large Eddy Simulation of a Sheet/Cloud Cavitation on a NACA0015 Hydrofoil. Applied Mathematical Modelling 2007, 31, 417–447. [Google Scholar] [CrossRef]

- Kral, L.D. Recent experience with different turbulence models applied to the calculation of flow over aircraft components. Prog. Aerosp. Sci. 1998, 34, 481–541. [Google Scholar] [CrossRef]

- Sun, H.; Xiao, R.; Wang, F.; Xiao, Y.; Liu, W. Analysis of the Pump-Turbine S Characteristics Using the Detached Eddy Simulation Method. Chin. J. Mech. Eng. Engl. Ed. 2015, 28, 115–122. [Google Scholar] [CrossRef]

- Feng, J.; Benra, F.K.; Dohmen, H.J. Application of Different Turbulence Models in Unsteady Flow Simulations of a Radial Diffuser Pump. Forsch. Ing. 2010, 74, 123–133. [Google Scholar] [CrossRef]

- Zhou, P.J.; Wang, F.J.; Yang, M. Internal Flow Numerical Simulation of Double-Suction Centrifugal Pump Using DES Model. IOP Conf. Ser.: Earth Environ. Sci. 2012, 15. [Google Scholar] [CrossRef]

- Zhang, J.; Li, G.; Mao, J.; Yuan, S.; Qu, Y.; Jia, J. Numerical Investigation of the Effects of Splitter Blade Deflection on the Pressure Pulsation in a Low Specific Speed Centrifugal Pump. Proc. Inst. Mech. Eng. Part A J. Power Energy 2019, 234, 420–432. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Y.X.; Zhang, J.Y.; Li, Z.W.; Xu, A. Comparative Research on Various Turbulence Closure Models for Unsteady Cavitation Flows in the Ultra-Low Specific Speed Centrifugal Pump. IOP Conf. Ser.: Earth Environ. Sci. 2019, 240, 062038. [Google Scholar] [CrossRef]

- Limbach, P.; Skoda, R. Numerical and Experimental Analysis of Cavitating Flow in a Low Specific Speed Centrifugal Pump with Different Surface Roughness. J. Fluids Eng. Trans. ASME 2017, 139, 101201. [Google Scholar] [CrossRef]

- Hindawi. Experimental Investigation on Cavitating Flow Induced Vibration Characteristics of a Low Specific Speed Centrifugal Pump. Available online: https://www.hindawi.com/journals/sv/2017/6568930/ (accessed on 11 September 2022).

- Zhang, Y.L.; Yuan, S.Q.; Zhang, J.F.; Feng, Y.N.; Lu, J.X. Numerical Investigation of the Effects of Splitter Blades on the Cavitation Performance of a Centrifugal Pump. IOP Conf. Ser. Earth Environ. Sci. 2014, 22, 052003. [Google Scholar] [CrossRef]

- Hu, Q.; Yang, Y.; Shi, W. Cavitation Simulation of Centrifugal Pump with Different Inlet Attack Angles. Int. J. Simul. Model. 2020, 19, 279–290. [Google Scholar] [CrossRef]

- Yang, Q.W.; Zhang, W.; Li, X.J. Numerical simulation of cavitation and analysis of flow characteristic of thermo-sensitive fluid. J. Drain. Irrig. Mach. Eng. (JDIME) 2021, 39, 699–705. (In Chinese) [Google Scholar]

- Sun, T.; Ma, X.; Wei, Y.; Wang, C. Computational modeling of cavitating flows in liquid nitrogen by an extended transport-based cavitation model. Sci. China Technol. Sci. 2016, 59, 337–346. [Google Scholar] [CrossRef]

- Yuan, S.Q. Theory and Design of Low Specific Speed Centrifugal Pump; China Machine Press: Beijing, China, 1997. (In Chinese) [Google Scholar]

- Zhang, D.; Liu, Y.; Kang, J.; Zhang, Y.; Meng, F. The Effect of Discharge Areas on the Operational Performance of a Liquid-Ring Vacuum Pump: Numerical Simulation and Experimental Verification. Vacuum 2022, 206, 111425. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Ji, L.; Zhao, X.; Shi, W.; Agarwal, R.K.; Awais, M.; Yang, Y. A Study on the Cavitation and Pressure Pulsation Characteristics in the Impeller of an LNG Submerged Pump. Machines 2022, 10, 14. [Google Scholar] [CrossRef]

- Menter, F.R. Two-Equation Eddy-Viscosity Turbulence Models for Engineering Applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Menter, F.R.; Kuntz, M.; Langtry, R. Ten Years of Industrial Experience with the SST Turbulence Model. Turbul. Heat Mass Transf. 2003, 4, 625–632. [Google Scholar]

- Menter, F.R. Zonal Two Equation Kappa-Omega Turbulence Models for Aerodynamic Flows. In Proceedings of the AIAA 24th Fluid Dynamic Conference, Orlando, FL, USA, 6–9 July 1993. [Google Scholar]

- Zwart, P.J.; Gerber, A.G.; Belamri, T. A Two-Phase Flow Model for Predicting Cavitation Dynamics. In Proceedings of the 5th International Conference on Multiphase Flow, Yokohama, Japan, May 30–June 3 2004; Volume 152. [Google Scholar]

- Zhang, D.; Shi, L.; Shi, W.; Zhao, R.; Wang, H.; Van Esch, B.B. Numerical Analysis of Unsteady Tip Leakage Vortex Cavitation Cloud and Unstable Suction-Side-Perpendicular Cavitating Vortices in an Axial Flow Pump. Int. J. Multiph. Flow 2015, 77, 244–259. [Google Scholar] [CrossRef]

- 2017 ASHRAE Handbook—Fundamentals (I-P Edition); American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2017; Volume 30, pp. 875–887.

| Flow Rate Qd (m3/h) | Pump Head H (m) | Speed n (r/min) | |

|---|---|---|---|

| Original design parameters | 13.2 | 132 | 11,000 |

| Modified design parameters | 15.84 | 120.91 | 11,000 |

| Parameters | Value |

|---|---|

| Rated speed | 11,000 r/min |

| Specific speed | 62 |

| Impeller inlet diameter | 32 mm |

| Impeller outlet diameter | 94 mm |

| Impeller Outlet Width | 4 mm |

| Volute outlet diameter | 20 mm |

| Saturation Pressure/P(bar) | |||||

|---|---|---|---|---|---|

| EGaq | 20 | 1582 | 5.38 | 1086.27 | 3084 |

| 60 | 13,600 | 1.69 | 1063.69 | 3258 | |

| PGaq | 20 | 1760 | 10.04 | 1048.25 | 3339 |

| 60 | 15,435 | 2.22 | 1020.66 | 3515 | |

| Water | 20 | 2330 | 1.005 | 998.2 | 4183 |

| 60 | 1582 | 5.38 | 1086.27 | 3084 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, A.; Zhao, R.; Wang, F.; Zhang, D.; Wang, X. Effects of Coolant and Working Temperature on the Cavitation in an Aeronautic Cooling Pump with High Rotation Speed. Machines 2022, 10, 904. https://doi.org/10.3390/machines10100904

Wu A, Zhao R, Wang F, Zhang D, Wang X. Effects of Coolant and Working Temperature on the Cavitation in an Aeronautic Cooling Pump with High Rotation Speed. Machines. 2022; 10(10):904. https://doi.org/10.3390/machines10100904

Chicago/Turabian StyleWu, Ao, Ruijie Zhao, Fei Wang, Desheng Zhang, and Xikun Wang. 2022. "Effects of Coolant and Working Temperature on the Cavitation in an Aeronautic Cooling Pump with High Rotation Speed" Machines 10, no. 10: 904. https://doi.org/10.3390/machines10100904

APA StyleWu, A., Zhao, R., Wang, F., Zhang, D., & Wang, X. (2022). Effects of Coolant and Working Temperature on the Cavitation in an Aeronautic Cooling Pump with High Rotation Speed. Machines, 10(10), 904. https://doi.org/10.3390/machines10100904