Dual Fuzzy Energy Control Study of Automotive Fuel Cell Hybrid Power System with Three Energy Sources

Abstract

:1. Introduction

2. Hybrid Power System Modeling for Fuel Cell Vehicles

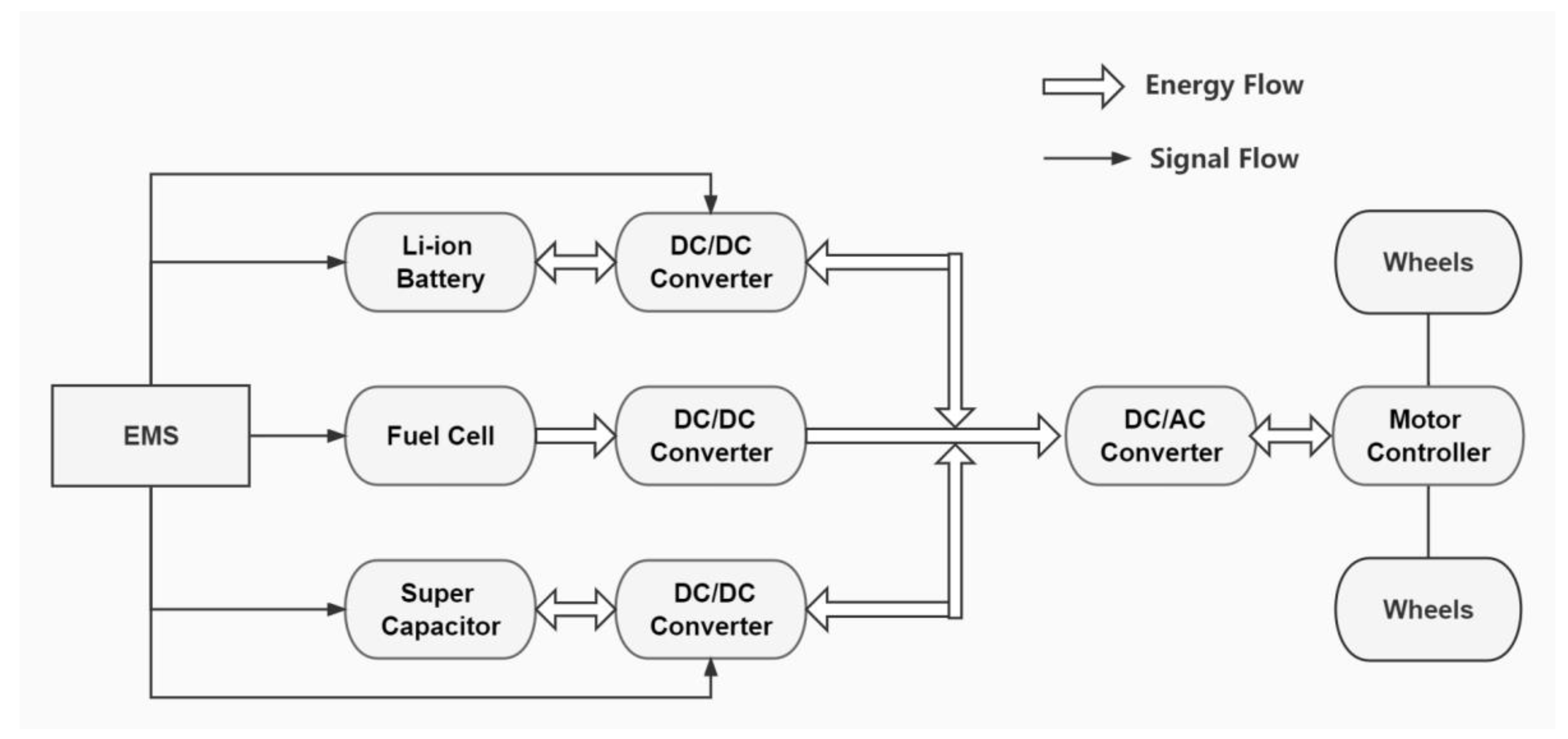

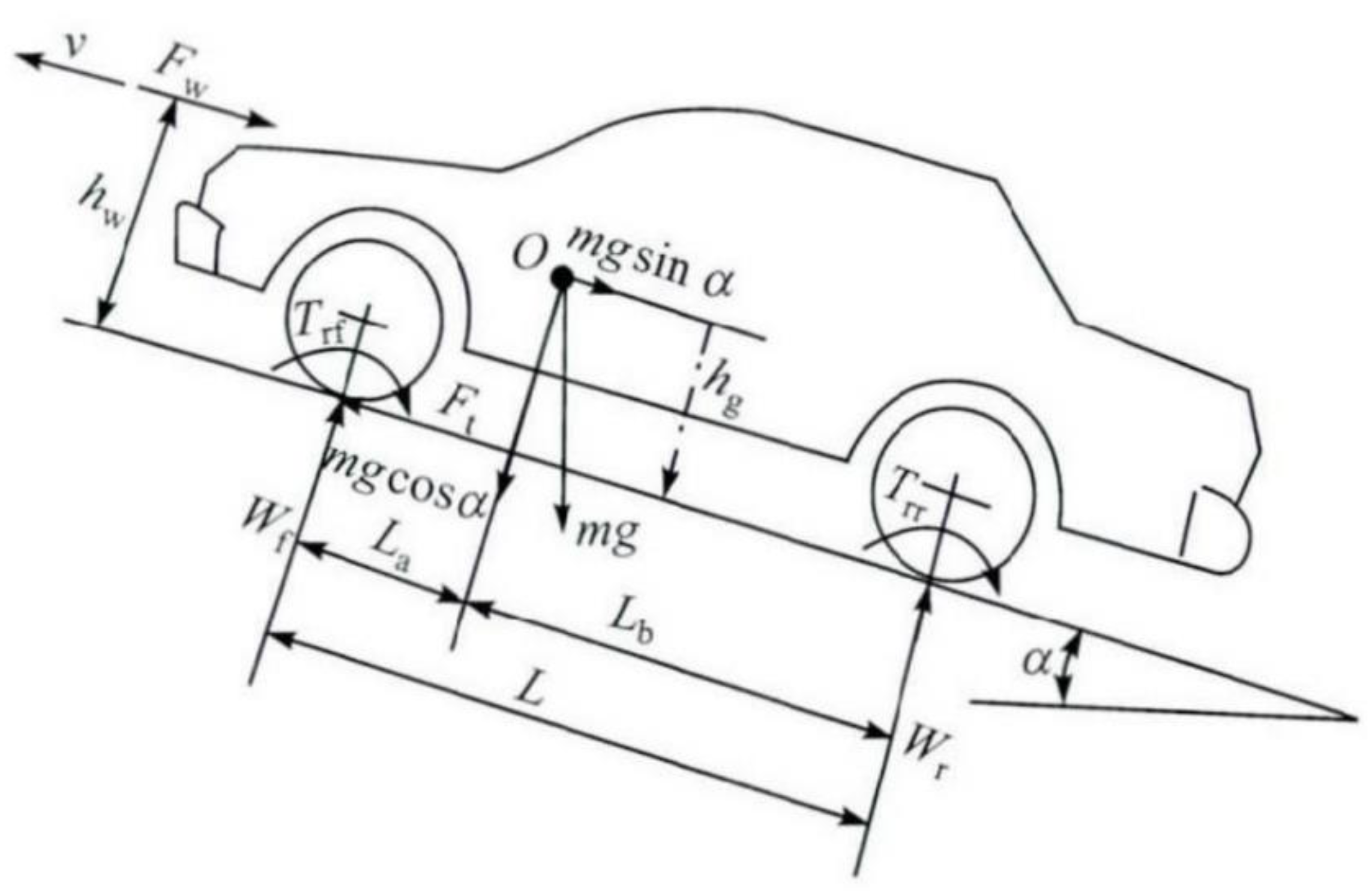

2.1. Whole-Vehicle Power System Model

2.2. Fuel Cell Model

2.3. Power Cell Model

2.4. Super Capacitor Model

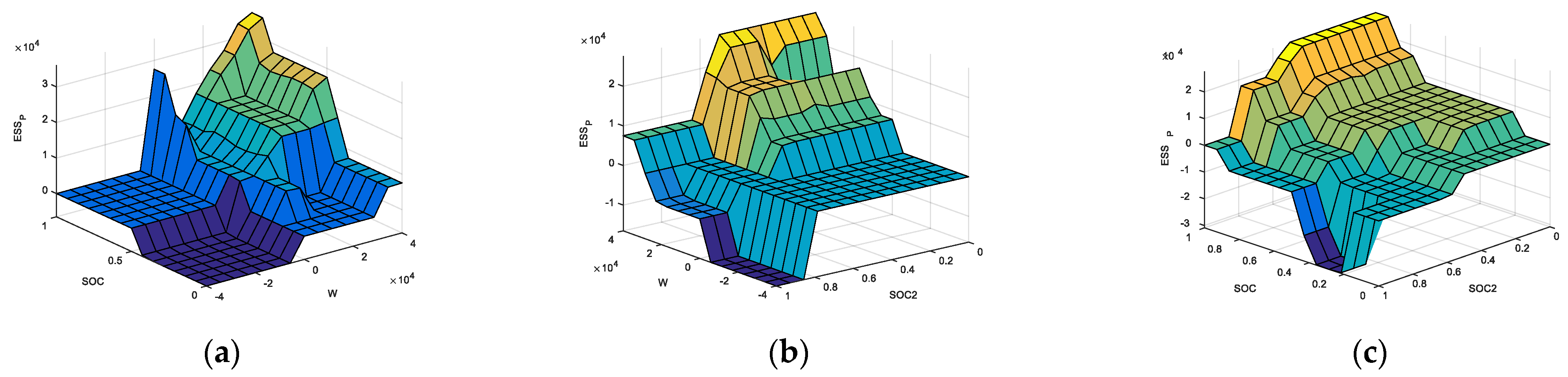

3. Dual Fuzzy Energy Control Strategy

3.1. Overall Program

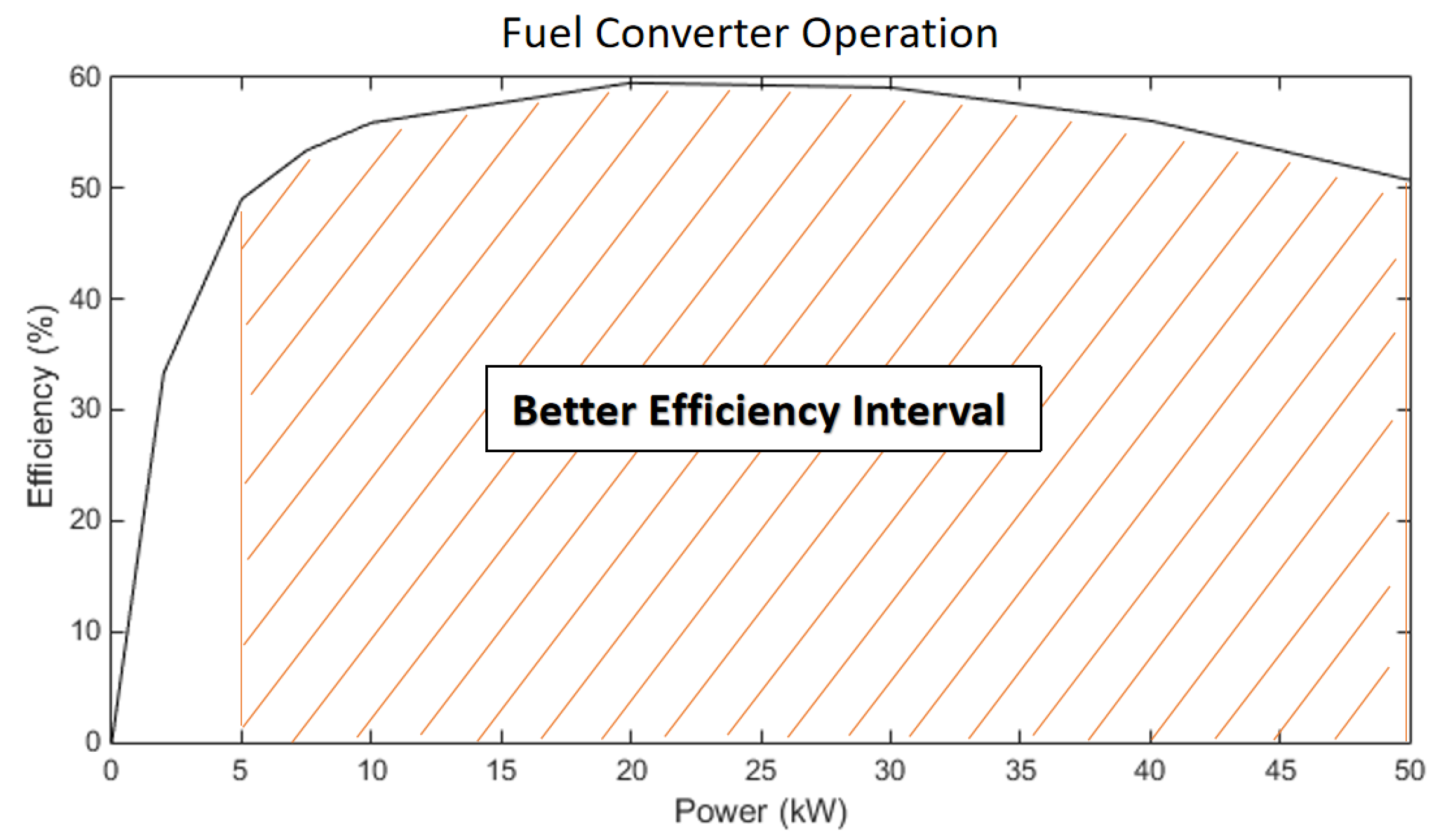

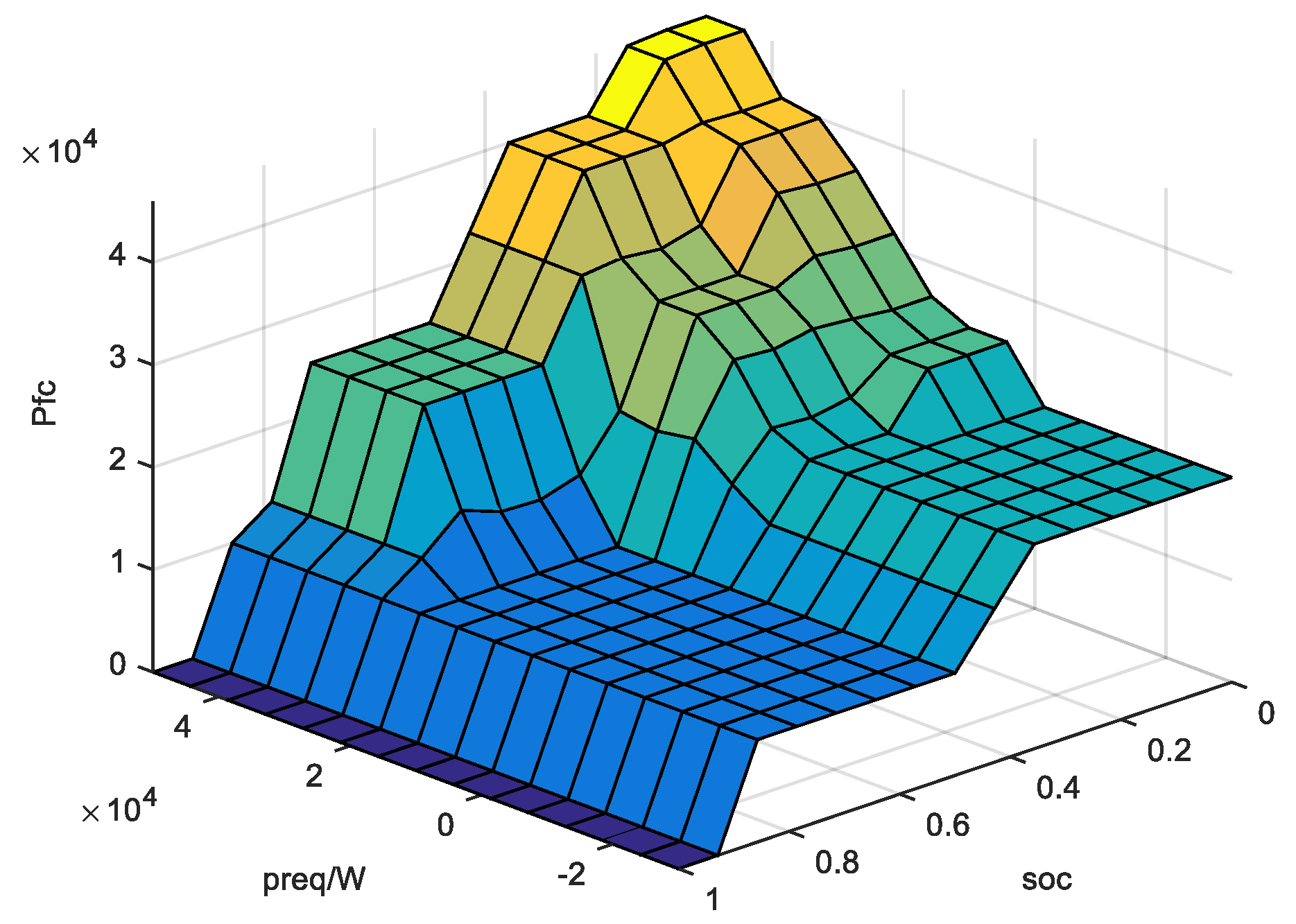

3.2. Main Fuzzy Controller

- FCHPS braking energy recovery is controlled at this time by the sub-fuzzy controller introduced below when the demand power of the FCHPS is zero (Z) and the output power of the fuel cell is zero (Z). The total power expression is:where , , , , and are fuel cell, lithium battery, super capacitor, motor output power, and overall vehicle demand power, respectively, and , , and are DC/DC conversion efficiency of motor efficiency, lithium battery, and super capacitor, respectively.

- When the FCHPS demand power is small (SSS, SS, MS) and the Li-ion battery SOC is very low or low (XL, L), the energy is provided by the fuel cell and the total power expression is:

- Fuel cell is turned off when the lithium battery SOC reaches medium and above (M, H, XH) and the following sub-fuzzy controller controls the Li-ion battery and super capacitor energy outputs. The total power expression is:

- When the FCHPS demand power is medium (HS, M, SH), when the fuel cell provides the main power and keeps the hydrogen combustion in a good range (SS, MS, HS, M), the remaining energy is obtained by the sub-fuzzy controller control and the total power expression is:

- When FCHPS demand power is high (MH, HH), then fuel cell, Li-ion battery, and super capacitor need to work together. The fuel cell output is kept at medium and above (M, SH, MH, HH, H) and charging and discharging of Li-ion battery and super capacitor are controlled by sub-fuzzy controller and the total power expression is:

3.3. Sub-Fuzzy Controller

- 6.

- When the brake energy recovered by FCHPS is larger (ZZZ), the super capacitor SOC is smaller than the Li-ion battery SOC. The super capacitor can withstand the high-current shock, so the super capacitor recovers most of the energy and the Li-ion battery recovers energy as Z1. The total power expression is:where is the difference between the FCHPS demand power and the main fuzzy controller output.

- 7.

- When the FCHPS recovers braking energy as ZZ and the super capacitor SOC is smaller than the Li-ion battery SOC, the super capacitor recovers most of the energy and the Li-ion battery does not recover energy. The total power expression is:

- 8.

- When the input power of the sub-fuzzy controller is small (L) and the super capacitor SOC is smaller than the Li-ion battery SOC, the output power of the super capacitor is Z. The remaining power is provided by the Li-ion battery. The total power expression is:

- 9.

- When the input power of the sub-fuzzy controller is medium (M) and the super capacitor SOC is smaller than the Li-ion battery SOC, the output power of the Li-ion battery is M. The total power expression is:

- 10.

- The sub-fuzzy controller that has a large input power (H, HH) turns on three energy sources simultaneously to supply energy to the whole vehicle when the input power is large and great. To ensure high charging and discharging efficiency in Li-ion batteries and super capacitors, the SOC of both batteries and super capacitors should be kept between 0.4 and 0.8. The total power expression is:

4. Experiments and Analysis

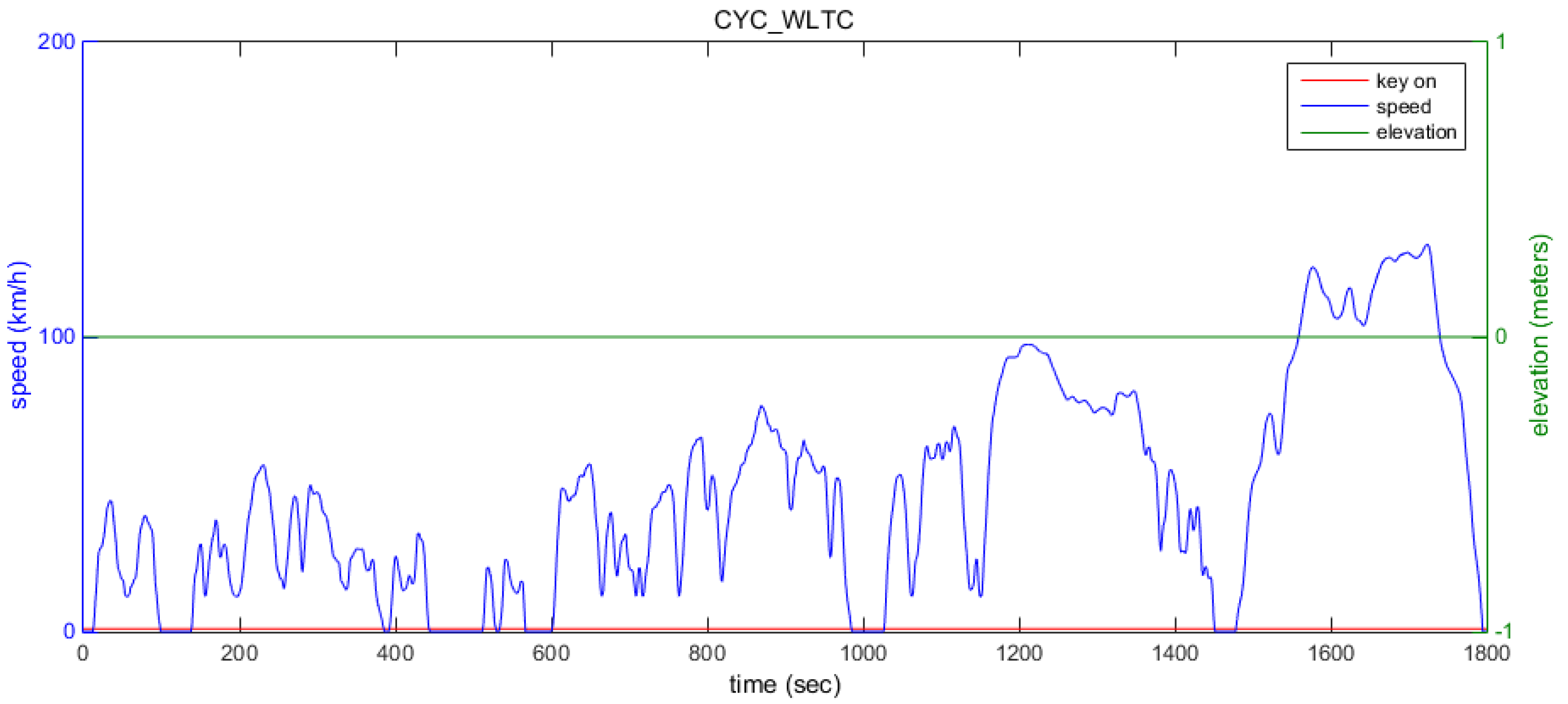

4.1. Simulation Conditions

Selection

4.2. Simulation Model Building

- Change the whole vehicle M file, add the super capacitor model, and rename it.

- Light up the second energy source in ADVISOR input interface and add super capacitor configuration information through the vehicle configuration data file “all menus. mat”.

- Modify multiple M files related to the main page and add the modified model data.

- Modify the super capacitor model parameters. Modify the names of all output variables in the model with the prefix ess2 to avoid data errors when using a super capacitor and Li-ion battery.

- Associate the modified model file with the whole vehicle configuration file.

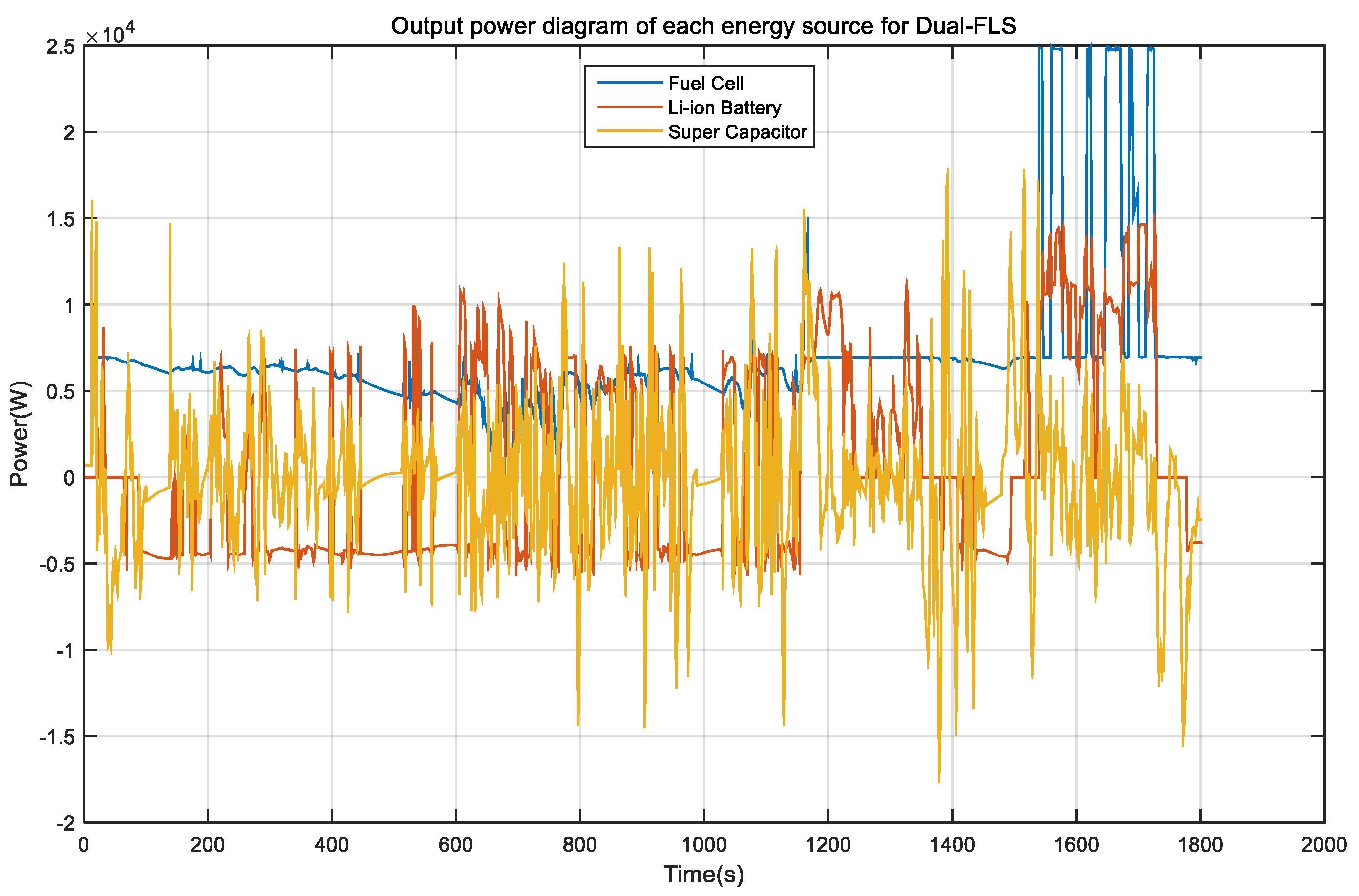

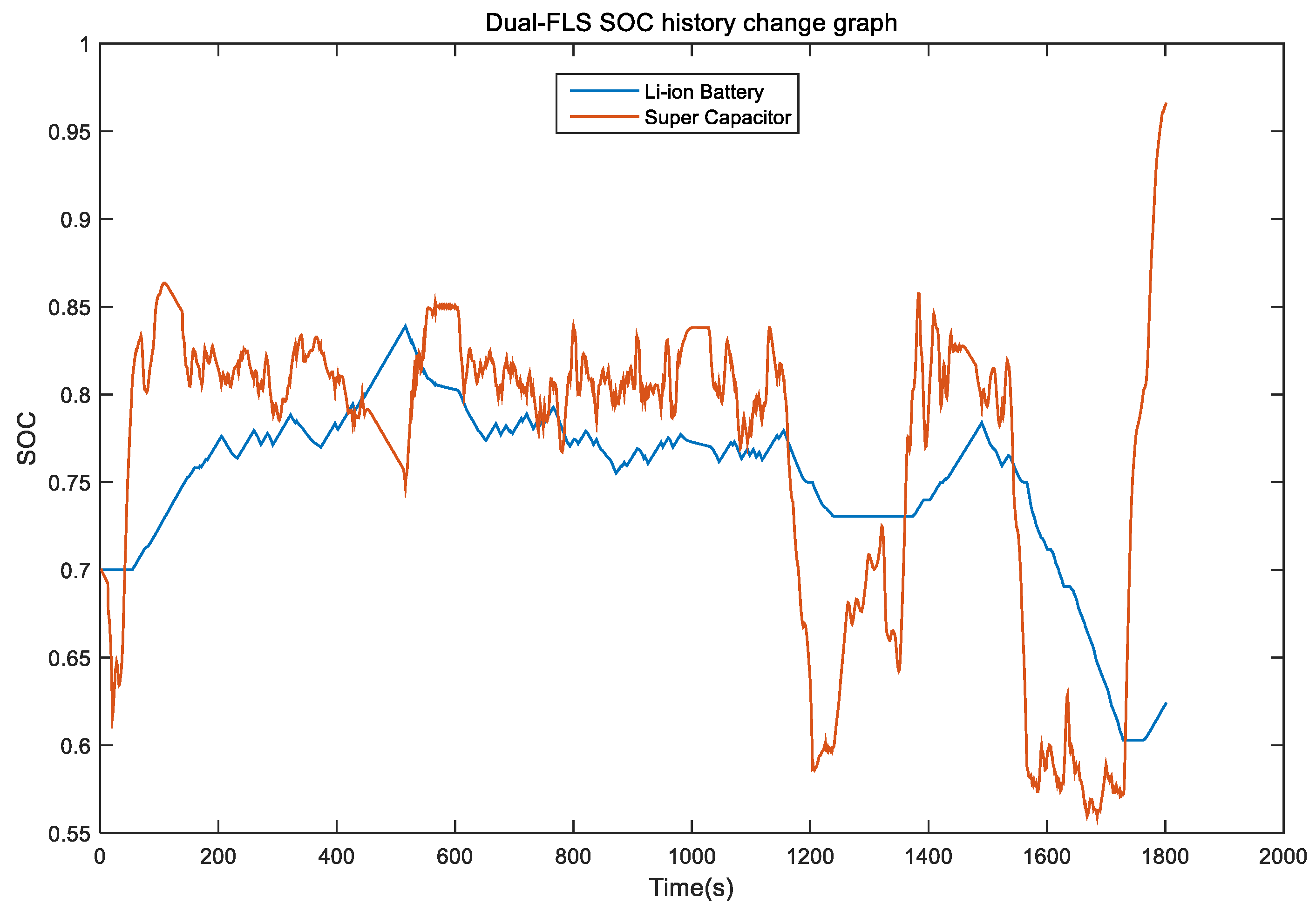

4.3. Simulation Analysis of Dual Control Strategy

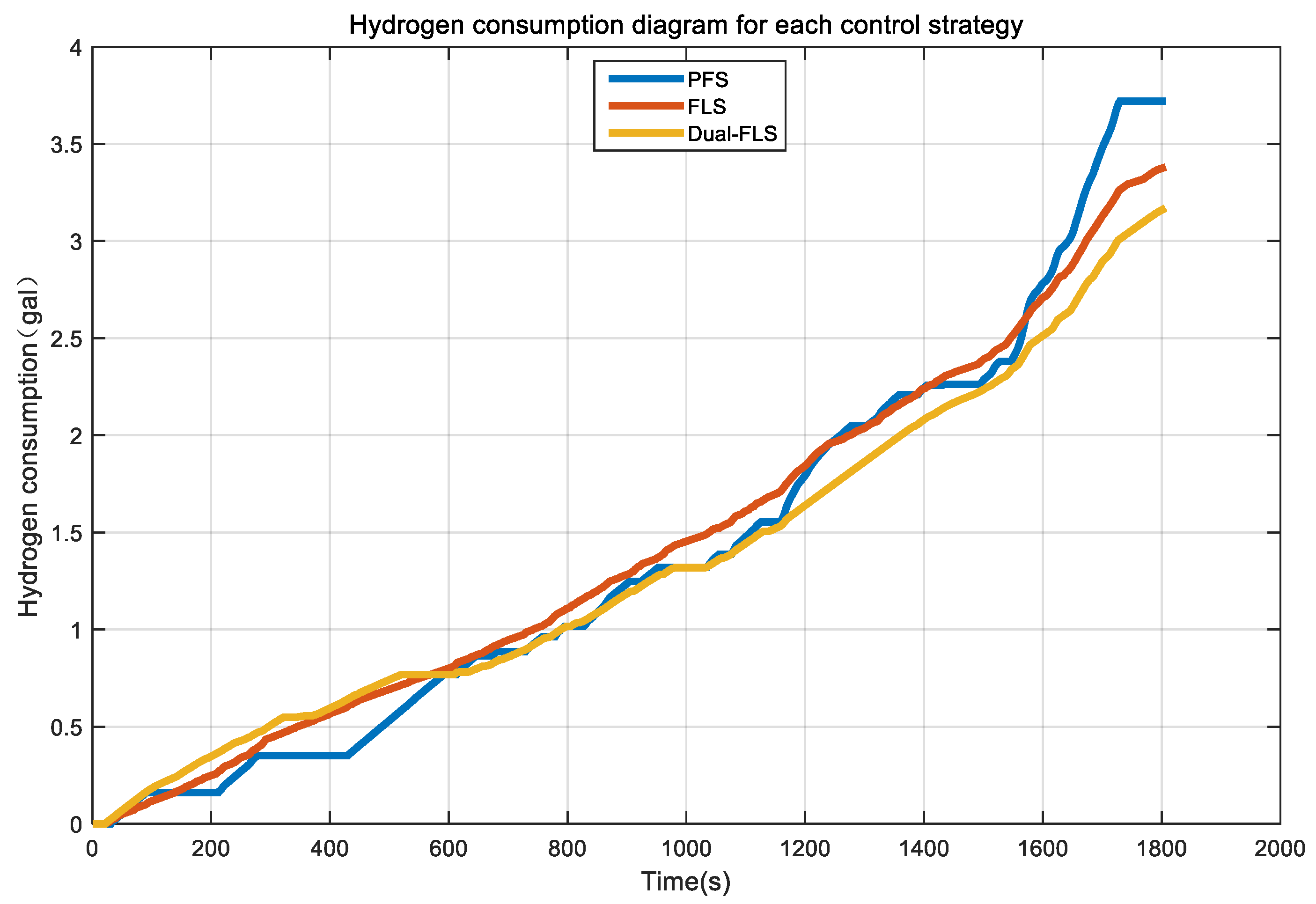

4.4. Control Strategy Simulation Comparison Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Miranda, M.; Banakar, P.; Gunnal, G.; Kumar, V.K.K. Robust Voltage Control of Improved Floating Interleaved Boost Converter for Photovoltaic Systems. In Proceedings of the 2020 5th International Conference on Computing, Communication and Security (ICCCS), Patna, India, 14–16 October 2020. [Google Scholar]

- Editorial Department of China Journal of Highway and Transport. Review on China’s Automotive Engineering Research Progress: 2017. China J. Highw. Transp. 2017, 30, 1–197. [Google Scholar] [CrossRef]

- Sykes, M.; Axsen, J. No free ride to zero-emissions: Simulating a region’s need to implement its own zero-emissions vehicle (ZEV) mandate to achieve 2050 GHG targets. Energy Policy 2017, 110, 447–460. [Google Scholar] [CrossRef]

- Chen, M.; Hua, Q.; Zhang, H.; Sui, Z.; Li, L. Research on Energy Management System of Fuel Cell/Battery Hybrid Electric Vehicle. J. Qingdao Univ. (Eng. Technol. Ed.) 2018, 33, 21–27. [Google Scholar] [CrossRef]

- Bauman, J.; Kazerani, M. A Comparative Study of Fuel-Cell–Battery, Fuel-Cell–Ultracapacitor, and Fuel-Cell–Battery–Ultracapacitor Vehicles. IEEE Trans. Veh. Technol. 2008, 57, 760–769. [Google Scholar] [CrossRef]

- Wang, H. Study on Energy Management Strategy of Medium Fuel Truck Power System. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2021. [Google Scholar] [CrossRef]

- Sun, Y.; Xia, C.; Yin, B.; Han, J.; Gao, H.; Liu, J. Energy Management Strategy of Fuel Cell Electric Vehicle. J. Jilin Univ. (Eng. Technol. Ed.) 2022, 9, 59244–59254. [Google Scholar] [CrossRef]

- Fu, Z.; Li, Z.; Si, P.; Tao, F. A Hierarchical Energy Management Strategy for Fuel Cell/Battery/Supercapacitor Hybrid Electric Vehicles. Int. J. Hydrog. Energy 2019, 44, 22146–22159. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, Y.; Luo, Y.; Li, L. Fuel Cell Vehicle Energy Management Strategy Based on Fuzzy Logic. Electr. Autom. 2020, 42, 50–53. [Google Scholar]

- Gao, D.; Jin, Z.; Lu, Q. Energy Management Strategy Based on Fuzzy Logic for A Fuel Cell Hybrid Bus. J. Power Sources 2008, 185, 311–317. [Google Scholar] [CrossRef]

- Koteswararao, K.V.; Srinivasulu, G.N.; Venkateswarlu, V. A Review on Energy Allocation of Fuel Cell/Battery/Ultracapacitor for Hybrid Electric Vehicles. Int. J. Energy Res. 2018, 42, 4263–4283. [Google Scholar]

- Wu, Y. Research on Energy Management and Optimal Control of Fuel Cell Hybrid Power Vehicle. Master’s Thesis, North University of China, Taiyuan, China, 2021. [Google Scholar] [CrossRef]

- Erdinc, O.; Vural, B.; Uzunoglu, M. A Wavelet-fuzzy Logic Based Energy Management Strategy for A Fuel Cell/Battery/Ultra-capacitor Hybrid Vehicular Power System. J. Power Sources 2009, 194, 369–380. [Google Scholar] [CrossRef]

- Zhang, W.; Wan, W.; Zhang, Z.; Liu, Q.; Ouyang, N. Analysis of Hybrid Energy Management Strategy forFuel Cell Vehicle. J. Foshan Univ. (Nat. Sci. Ed.) 2021, 39, 1–8. [Google Scholar] [CrossRef]

- Zhang, J. Study on Energy Management Strategy of Fuelcell-Battery-Supercapacitor Hybrid Bus. Master’s Thesis, Jilin University, Zhuhai, China, 2018. [Google Scholar]

- Li, X.; Wang, Y.; Yang, D.; Chen, Z. Adaptive Energy Management Strategy for Fuel Cell/Battery Hybrid Vehicles using Pontryagin’s Minimal Principle. J. Power Sources 2019, 440, 227105. [Google Scholar] [CrossRef]

- Fletcher, T.; Thring, R.; Watkinson, M. An Energy Management Strategy to concurrently optimise fuel consumption & PEM fuel cell lifetime in a hybrid vehicle. Int. J. Hydrog. Energy 2016, 41, 21503–21515. [Google Scholar]

- Wang, Y.; Yu, Q.; Wang, X.; Sun, F. Adaptive Optimal Energy Management Strategy of FuelCell Vehicle by Considering Fuel Cell Performance Degradation. J. Traffic Transp. Eng. 2022, 22, 190–204. [Google Scholar] [CrossRef]

- Li, W.; Zheng, C.H.; Xu, D.Z. Research on Energy Management Strategy of Fuel Cell Hybrid Vehicles Based on Deep Reinforcement Learning. J. Integr. Technol. 2021, 10, 47–60. [Google Scholar] [CrossRef]

- Yu, Z. Elementary Vehicle Dynamics, 5th ed.; Machine Press: Beijing, China, 2009; pp. 19–20. [Google Scholar]

- Ruan, Y.; Zhan, Y. Research on Optimization of Hierarchical Energy Management Strategy for Fuel Cell Vehicles. Electron. Meas. Technol. 2021, 44, 1–7. [Google Scholar] [CrossRef]

- Zeng, X.; Gong, W.; Li, X. ADVISOR 2002 Electric Vehicle Simulation and Redevelopment Application; Machine Press: Beijing, China, 2014; pp. 44–49. [Google Scholar]

- Tang, S. A Research on Optimization Theory of MAMDANI Fuzzy Systems. Master’s Thesis, Central South University, Changsha, China, 2005. Available online: https://kns.cnki.net/KCMS/detail/detail.aspx?dbname=CDFD9908&filename=2006037248.nh (accessed on 16 May 2006).

- Wang, W.; Shi, H.; Li, Y. Weighted Centroid Localization Algorithm Based on Mamdani Fuzzy Theory. Comput. Sci. 2015, 42, 101–105+121. [Google Scholar]

| Parts | Parameters | Parameter Value |

|---|---|---|

| Whole car | Quality/ | 1196 |

| Windward area/ | 2 | |

| Air resistance coefficient | 0.335 | |

| Tire rolling radius / | 478 | |

| Motor | Peak power/ | 83 |

| Fuel Cell | Maximum power/ | 50 |

| Power Rating/ | 30 | |

| Li-Ion Battery | Monomer capacity/ | 80 |

| Number of tandem | 30 | |

| Number of parallel connections | 3 | |

| Super Capacitor | Monomer capacity/ | 9500 |

| Number of tandem | 80 | |

| Number of parallel connections | 1 | |

| Monomer capacity/ | 9500 |

| Preq | ||||||||||

| Z | SSS | SS | MS | HS | M | SH | MH | HH | ||

| SOC | XL | HS | M | M | M | SH | MH | HH | HH | H |

| L | HS | HS | HS | M | SH | SH | SH | HH | HH | |

| M | SS | SS | SS | SS | SS | SS | SS | SS | SS | |

| H | SS | SS | SS | SS | SS | SS | M | M | M | |

| XH | Z | Z | Z | Z | Z | Z | Z | Z | Z | |

| Soc1 | XL | XL | XL | XL | L | L | L | L | M | M | M | M | H | H | H | H | XH | XH | XH | XH | |

| Soc2 | XL | L | M | H | XL | L | M | H | XL | L | M | H | XL | L | M | H | XL | L | M | H | |

| w | ZZZ | Z1 | Z1 | Z1 | ZZZ | Z1 | Z1 | Z1 | ZZZ | Z | Z | Z | ZZ | Z | Z | Z | ZZ | Z | Z | Z | Z |

| ZZ | Z1 | Z1 | Z1 | Z1 | Z1 | Z1 | Z1 | Z1 | Z | Z | Z | ZZ | Z | Z | Z1 | ZZ | Z | Z | Z | Z | |

| Z | Z | Z | Z1 | Z1 | L | Z | Z1 | ZZZ | L | L | Z | Z1 | M | M | L | Z1 | H | H | M | Z | |

| L | L | Z | Z | Z1 | L | L | L | Z1 | L | L | Z | Z1 | L | L | L | L | L | L | L | L | |

| M | M | Z | Z | Z1 | M | Z | Z | Z1 | M | M | Z | Z1 | M | M | M | Z | M | M | M | M | |

| H | Z | Z | Z | Z1 | Z | Z | Z | Z | L | M | Z | Z | M | M | M | Z | H | H | H | M | |

| HH | L | L | Z | Z | L | L | L | Z | H | H | L | L | HH | H | H | L | HH | HH | M | L |

| EMS | Fuel Cell Switching Times | Li-ion Battery Average Current | |

|---|---|---|---|

| PFS | 55.2 | 18 | 14.8 |

| FLS | 54.9 | 9 | 13.4 |

| Dual-FLS | 51.4 | 1 | 12.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, J.; Luo, W.; Huang, D.; Lan, H. Dual Fuzzy Energy Control Study of Automotive Fuel Cell Hybrid Power System with Three Energy Sources. Machines 2022, 10, 880. https://doi.org/10.3390/machines10100880

Lei J, Luo W, Huang D, Lan H. Dual Fuzzy Energy Control Study of Automotive Fuel Cell Hybrid Power System with Three Energy Sources. Machines. 2022; 10(10):880. https://doi.org/10.3390/machines10100880

Chicago/Turabian StyleLei, Jingxiang, Wenguang Luo, Dan Huang, and Hongli Lan. 2022. "Dual Fuzzy Energy Control Study of Automotive Fuel Cell Hybrid Power System with Three Energy Sources" Machines 10, no. 10: 880. https://doi.org/10.3390/machines10100880

APA StyleLei, J., Luo, W., Huang, D., & Lan, H. (2022). Dual Fuzzy Energy Control Study of Automotive Fuel Cell Hybrid Power System with Three Energy Sources. Machines, 10(10), 880. https://doi.org/10.3390/machines10100880