The Water Footprint of Heavy Oil Extraction in Colombia: A Case Study

Abstract

:1. Introduction

For oil production we used an averaged water consumption factor for primary and secondary extraction since we did not have data on the deployment of more advanced technologies, such as Enhanced Oil Recovery (EOR).

2. Literature Review

2.1. Water Scarcity and Water Footprint

- Establishment of objectives and scope: the decision to perform a study into one’s water footprint may be because of the particular goals of interested organizations, which are in turn defined by public or corporate policies. In terms of contextual scope, the study may consider an endless number of applications or entities, such as productive processes, goods or services. The value of the whole chain may be considered or it may be limited to a certain geographic area or a particular client etc. The organization should clearly state the scope of the water footprint itself i.e., if it will take into consideration all types (blue, green or grey or indirect and direct or only direct) or just one specifically. The spatial-temporal dimension of the study, as aforementioned, is essential.

- Accounting (inventory): This step takes into consideration the sum of all kinds of water consumption expressed in terms of unit production (e.g., m3/crude oil barrel). Both direct and indirect (e.g., raw materials provided by the supply chain) company processes could be included with exact details dependent on the objective of the study.

- Sustainability assessment: an approximation is made to analyze the degree of water stress relative to water availability, and for the determination of hotspots (e.g., especially vulnerable/sensitive areas).

- Response to water footprint (reduction strategy): Establishment of an action plan to mitigate or compensate any detrimental impacts caused by the organization’s significant direct and indirect activities. In this paper, as the authors do not belong to a company, we simply made suggestions based on our personal experience within and knowledge of the sector.

2.2. Hydrocarbon Sector: Water Scarcity and Footprint

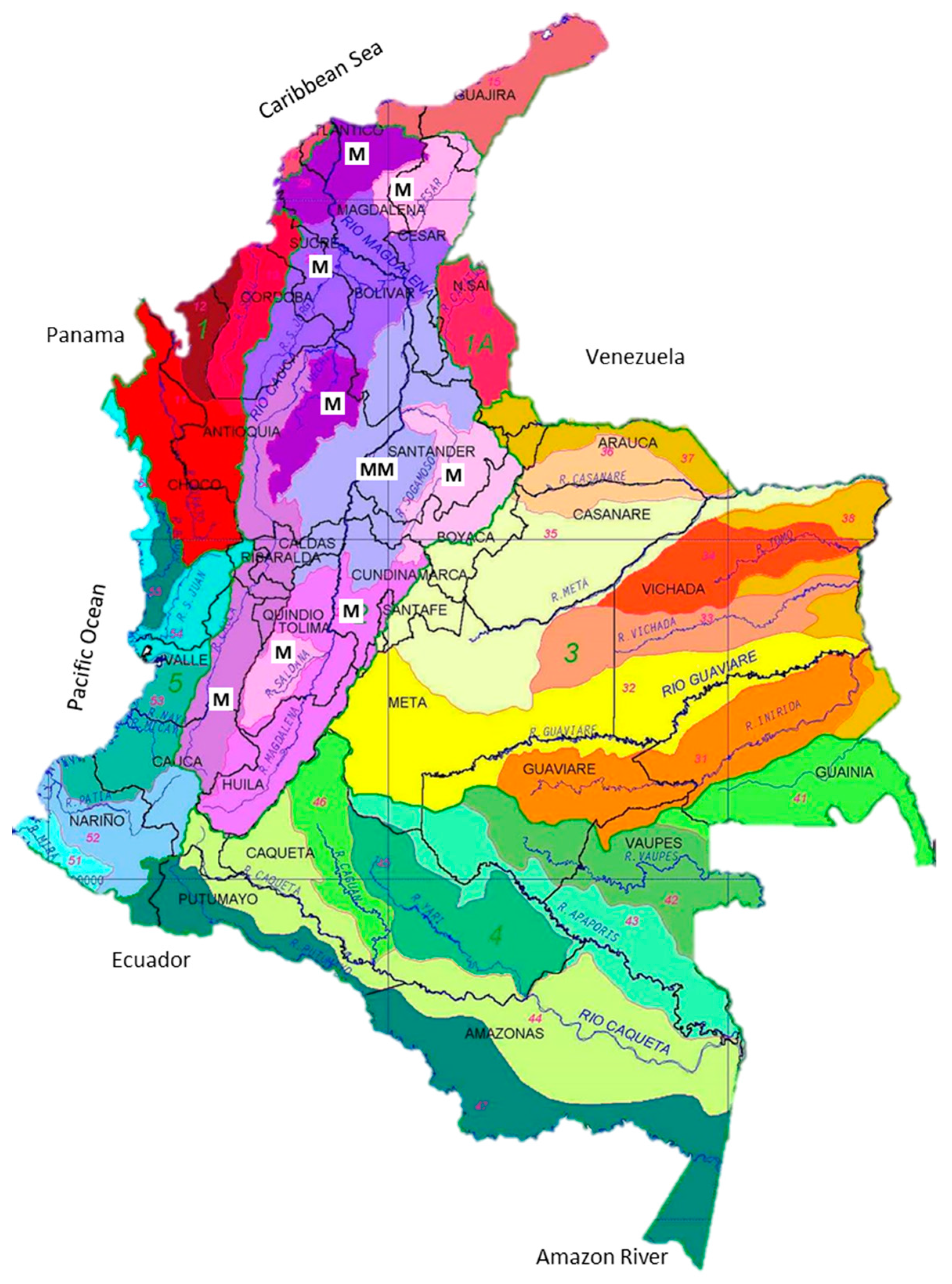

3. Colombian Case Study

3.1. Colombian Water Resources

3.2. Heavy Crude Oil Extraction

3.3. Company Specifics

4. Methodology

4.1. Project Objectives and Scope

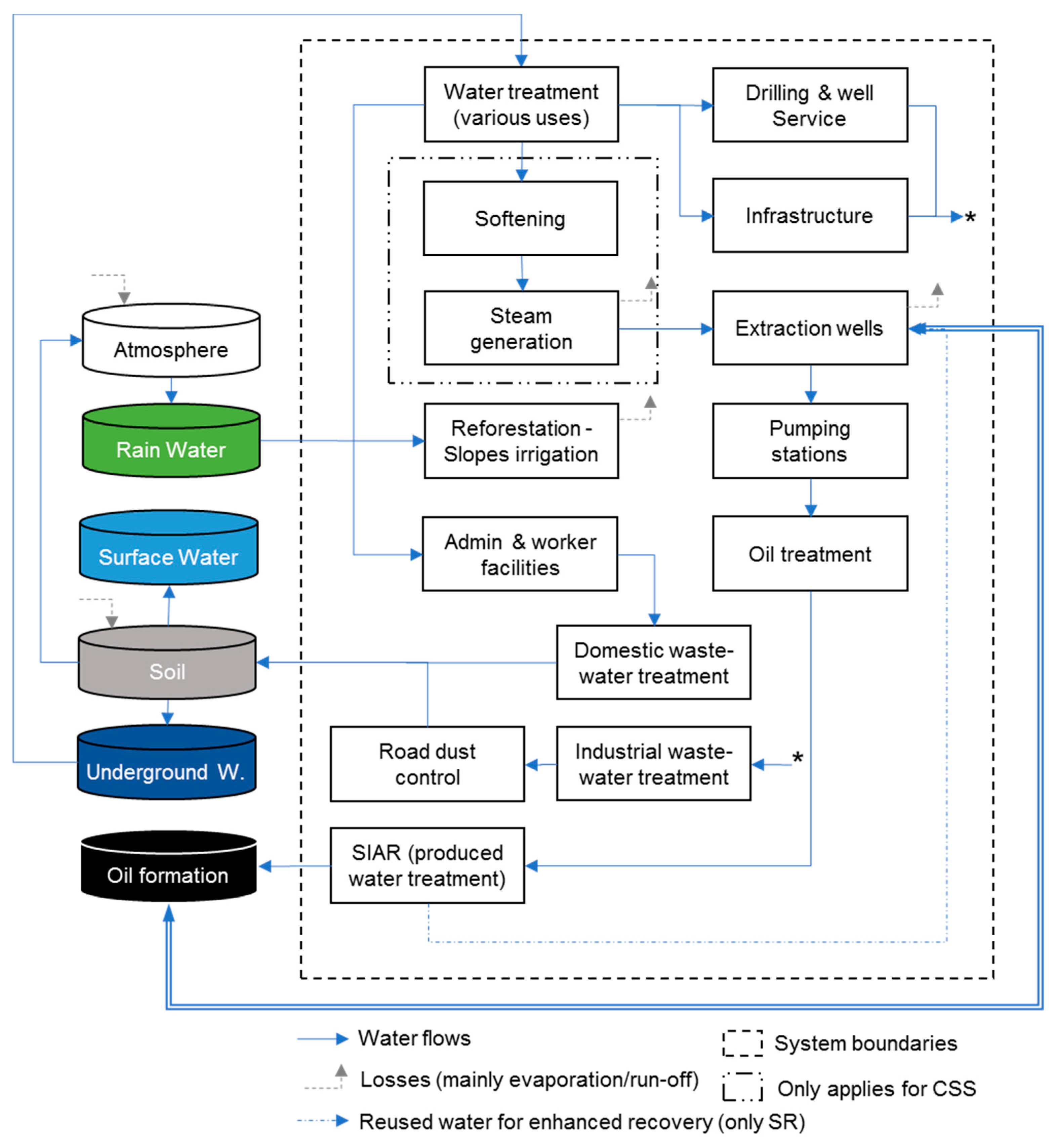

4.2. Water Inventory

4.2.1. Direct Blue

4.2.2. Green

4.2.3. Grey

4.2.4. Indirect Water Footprint

4.3. Sustainability Assessment

4.4. Response to Water Footprint

5. Results and Discussion

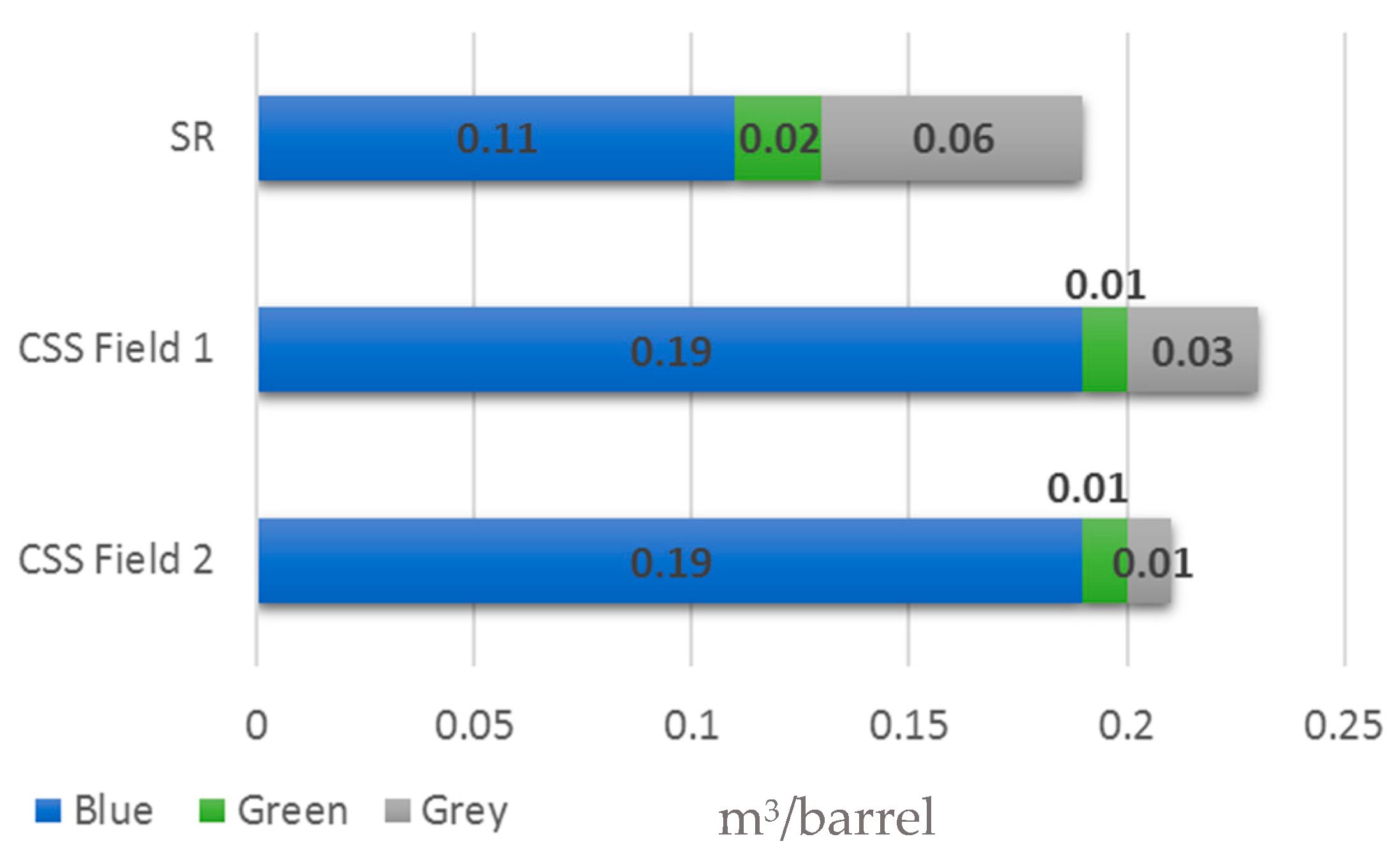

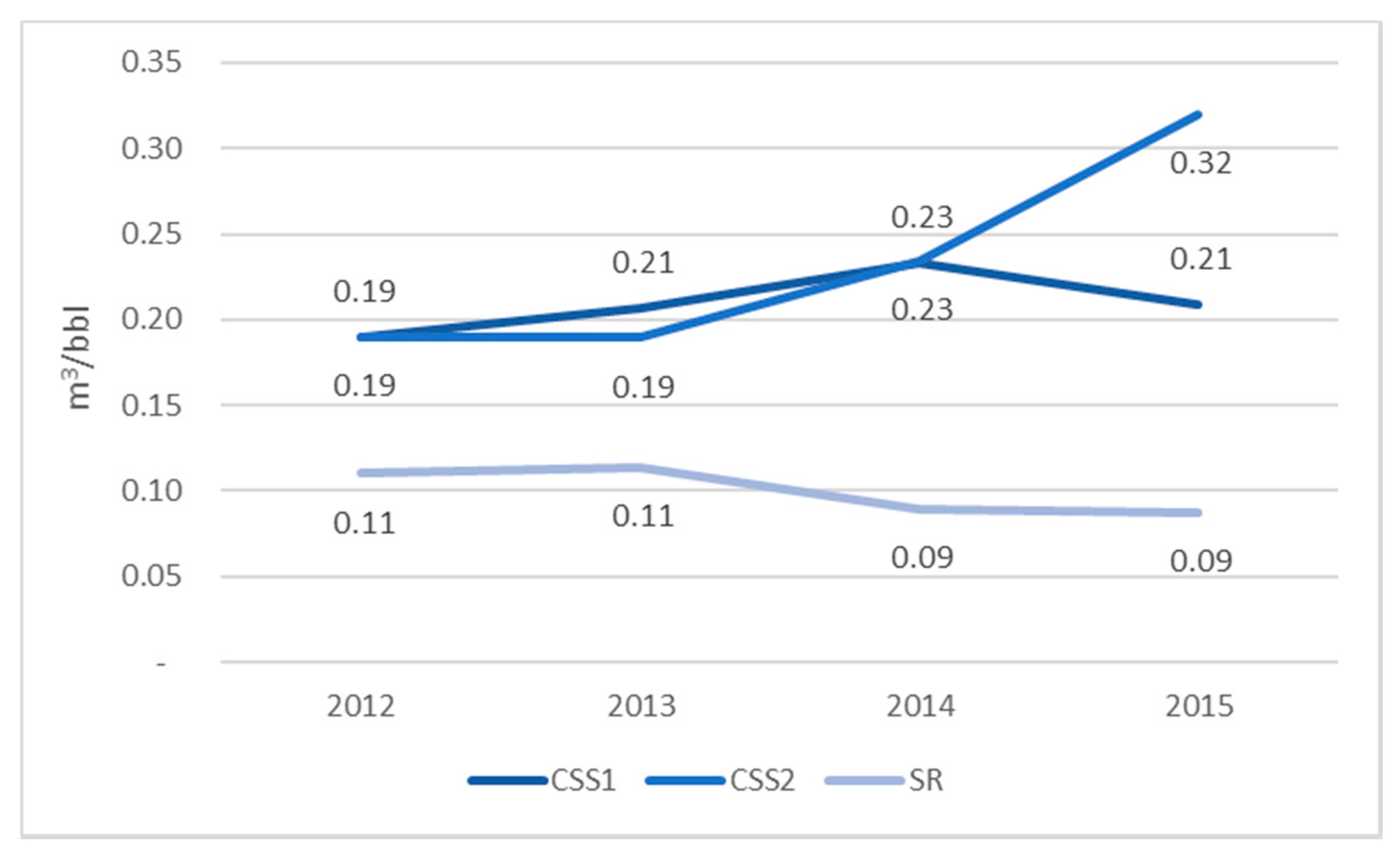

5.1. Direct Water Footprint

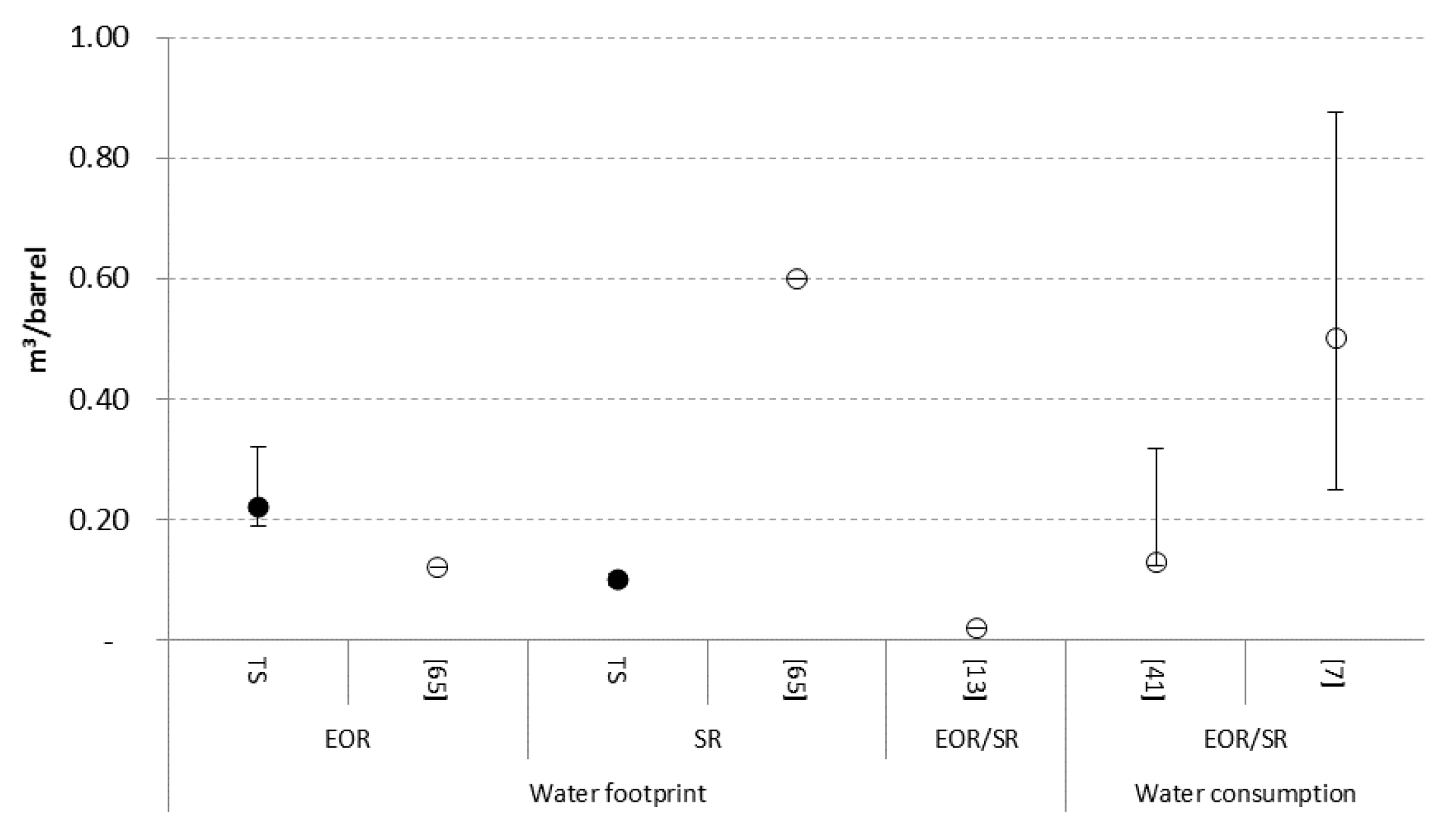

Comparison of the Direct Footprint with Other Studies

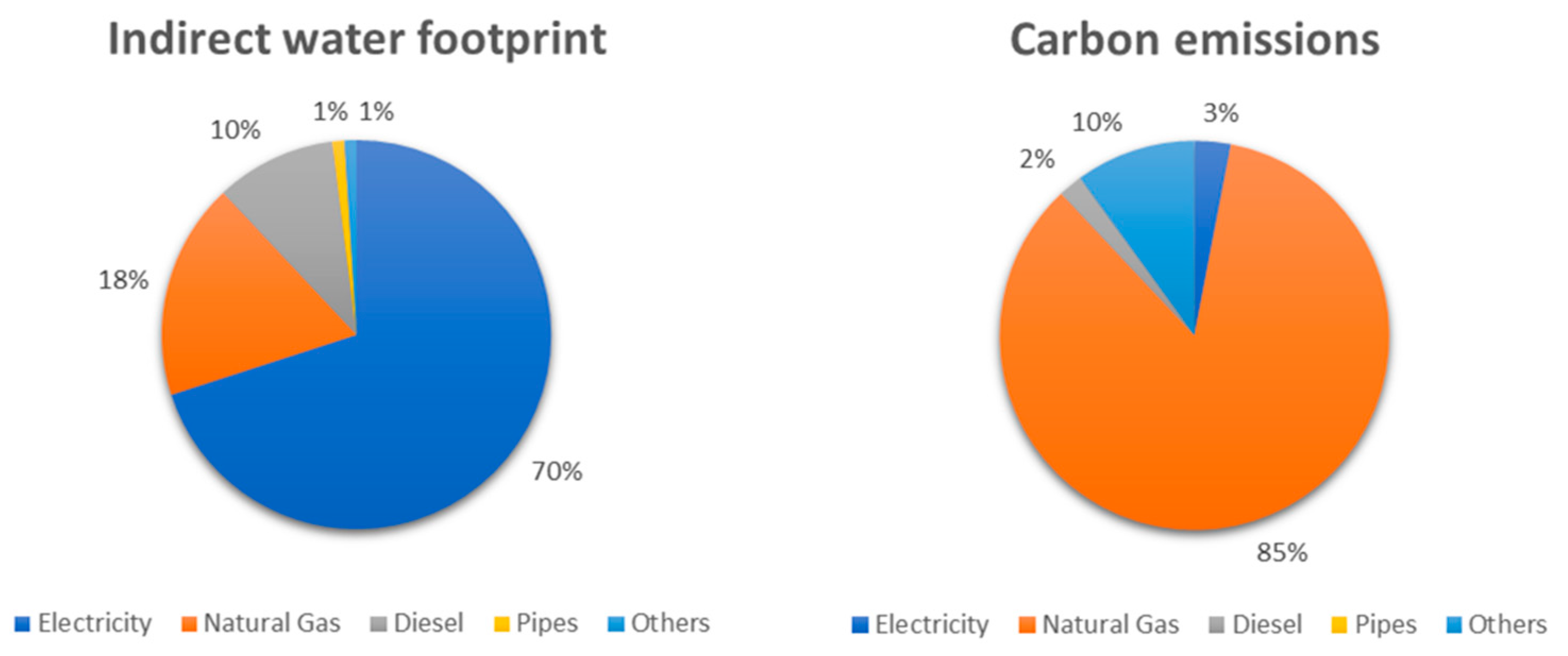

5.2. Calculation of Indirect Water Footprint

5.3. Sustainability Assessment and Response to the Water Footprint

6. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mancosu, N.; Snyder, R.L.; Kyriakakis, G.; Spano, D. Water scarcity and future challenges for food production. Water 2015, 7, 975–992. [Google Scholar] [CrossRef]

- Sohns, A.A.; Rodriguez, D.J.; Delgado, A. Thirsty Energy (ii): The Importance of Water for Oil and Gas Extraction, 2016. World Bank Group. Available online: https://openknowledge.worldbank.org/bitstream/handle/10986/23635/Thirsty0energy0l0and0gas0extraction.pdf?sequence=1 (accessed on 15 April 2017).

- Reig, P.; Luo, T.; Proctor, J.N. Global Shale Gas Development: Water Availability and Business Risks, 2014. World Resources Institute. Available online: http://www.wri.org/publication/global-shale-gas-development-water-availability-business-risks (accessed on 15 April 2017).

- CDP. Thirsty Business: Why Water is Vital to Climate Action. 2016 Annual Report of Corporate Water Disclosure. Available online: https://b8f65cb373b1b7b15feb-c70d8ead6ced550b4d987d7c03fcdd1d.ssl.cf3.rackcdn.com/cms/reports/documents/000/001/306/original/CDP-Global-Water-Report-2016.pdf?1479747926 (accessed on 15 April 2017).

- Rosa, L.; Davis, K.F.; Rulli, M.C.; D’Odorico, P. Environmental consequences of oil production from oil sands. Earth’s Future 2017, 5, 158–170. [Google Scholar] [CrossRef]

- Kondash, A.; Vengosh, A. Water footprint of hydraulic fracturing. Environ. Sci. Technol. Lett. 2015, 2, 276–280. [Google Scholar] [CrossRef]

- Spang, E.S.; Moomaw, W.R.; Gallagher, K.S.; Kirshen, P.H.; Marks, D.H. The water consumption of energy production: An international comparison. Environ. Res. Lett. 2014, 9, 105002. [Google Scholar] [CrossRef]

- Carmona, L.G. Water Footprint for Heavy Oil Extraction in Colombia: Relationship between Oil and Water. In Proceedings of the SPE E&P Health, Safety, Security and Environmental Conference-Americas, Denver, CO, USA, 16–18 March 2015; Society of Petroleum Engineers: Richardson, TX, USA, 2015. [Google Scholar]

- Dusseault, M.B. Comparing Venezuelan and Canadian heavy oil and tar sands. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 12–14 June 2001; Petroleum Society of Canada: Calgary, AB, Canada, 2001. [Google Scholar]

- CERI–Canadian Energy Research Institute. Canadian Oil Sands Supply Costs and Development Projects (2011–2045); Study No. 128; CERI: Calgary AB, Canada, 2012. [Google Scholar]

- Campetrol. El 55% del Petróleo que se Produce en Colombia es Crudo Pesado. 2015. Available online: http://campetrol.org/el-55-del-petroleo-que-se-produce-en-colombia-es-crudo-pesado/ (accessed on 15 April 2017).

- Hoekstra, A.; Chapagain, A.; Aldaya, M.; Mekonnen, M. The Water Footprint Assessment Manual. Setting the Global Standard; Earthscan: London, UK; Washington, DC, USA, 2011. [Google Scholar]

- IDEAM. Estudio Nacional del Agua 2014; Instituto de Hidrología, Meteorología y Estudios Ambientales—IDEAM: Bogotá, DC, Colombia, 2015.

- Hoekstra, A.Y. The global dimension of water governance: Why the river basin approach is no longer sufficient and why cooperative action at global level is needed. Water 2010, 3, 21–46. [Google Scholar] [CrossRef]

- Watkins, K. Human Development Report 2006-Beyond Scarcity: Power, Poverty and the Global Water Crisis; United Nations Development Programme: New York, NY, USA, 2006. [Google Scholar]

- United Nations. Water Scarcity Factsheet. 2013. Available online: http://www.un.org/waterforlifedecade/scarcity.shtml (accessed on 15 April 2017).

- FAO and WWC. Towards a Water and Food Secure Future: Critical Perspectives for Policy-Makers. Natural Resources and Environment Department, 2015. Available online: http://www.fao.org/3/a-i4560e.pdf (accessed on 15 April 2017).

- Water Foorpritn Network 2017. Available online: http://waterfootprint.org/en/water-footprint/frequently-asked-questions/ (accessed on 22 March 2017).

- Hoekstra, A.Y.; Mekonnen, M.M. The water footprint of humanity. Proc. Natl. Acad. Sci. USA 2012, 109, 3232–3237. [Google Scholar] [CrossRef] [PubMed]

- Hoekstra, A.Y.; Chapagain, A.K. Water footprints of nations: Water use by people as a function of their consumption pattern. Water Resour. Manag. 2007, 21, 35–48. [Google Scholar] [CrossRef]

- Hoekstra, A.Y. Human appropriation of natural capital: A comparison of ecological footprint and water footprint analysis. Ecol. Econ. 2009, 68, 1963–1974. [Google Scholar] [CrossRef]

- Čuček, L.; Klemeš, J.J.; Kravanja, Z. A review of footprint analysis tools for monitoring impacts on sustainability. J. Clean. Prod. 2012, 34, 9–20. [Google Scholar] [CrossRef]

- Fang, K.; Heijungs, R.; de Snoo, G.R. Theoretical exploration for the combination of the ecological, energy, carbon, and water footprints: Overview of a footprint family. Ecol. Indic. 2014, 36, 508–518. [Google Scholar] [CrossRef]

- Galli, A.; Wiedmann, T.; Ercin, E.; Knoblauch, D.; Ewing, B.; Giljum, S. Integrating ecological, carbon and water footprint into a “footprint family” of indicators: definition and role in tracking human pressure on the planet. Ecol. Indic. 2012, 16, 100–112. [Google Scholar] [CrossRef]

- Galli, A.; Weinzettel, J.; Cranston, G.; Ercin, E. A footprint family extended MRIO model to support Europe’s transition to a one planet economy. Sci. Total Environ. 2013, 461, 813–818. [Google Scholar] [CrossRef] [PubMed]

- Hoekstra, A.Y.; Chapagain, A.K.; Aldaya, M.M.; Mekonnen, M.M. Water Footprint Manual: State of the Art 2009; Water Footprint Network: Enschede, The Netherlands, 2009. [Google Scholar]

- Allan, J.A. Virtual water: A strategic resource. Ground Water 1998, 36, 545–547. [Google Scholar] [CrossRef]

- Hoekstra, A.Y.; Hung, P.Q. Virtual Water Trade. A Quantification of Virtual Water Flows between Nations in Relation to International Crop Trade; Value of Water Research Report Series, 11; UNESCO–IHE: Delft, The Netherlands, 2002. [Google Scholar]

- Hoekstra, A. Virtual Water Trade: Proceedings of the International Expert Meeting on Virtual Water Trade; Value of Water Research Report Series, 12; UNESCO–IHE: Delft, The Netherlands, 2002. [Google Scholar]

- Vanham, D.; Bidoglio, G. A review on the indicator water footprint for the EU28. Ecol. Indic. 2013, 26, 61–75. [Google Scholar] [CrossRef]

- CTA; GSI-LAC; COSUDE; IDEAM. Evaluación Multisectorial de la Huella Hídrica en Colombia. Resultados por Subzonas Hidrográficas en el Marco del Estudio Nacional del Agua 2014. Medellín, Colombia. 2015. Available online: http://documentacion.ideam.gov.co/openbiblio/bvirtual/023272/HH_ENA2014.pdf (accessed on 15 April 2017).

- Centro de Ciencia y Tecnología de Antioquia. Evaluación de la Huella Hídrica en la Cuenca del Río Porce. Resumen de Resultados. 2013. Available online: http://www.goodstuffinternational.com/images/PDF/LibroHuellahidrica.pdf (accessed on 15 April 2017).

- Arévalo, D.; Lozano, J.; Sabogal, J. Estudio nacional de huella hídrica Colombia sector agrícola. Revista Internacional de Sostenibilidad Tecnología y Humanismo 2011, 6, 101–126. [Google Scholar]

- Pérez, M.A.; Peña, M.R.; Álvarez, P. Agro-industria cañera y uso del agua: análisis crítico en el contexto de la política de agrocombustibles en Colombia. Ambiente Soc. 2011, 14, 153–178. [Google Scholar] [CrossRef]

- Swiss Agency for Development and Cooperation (SDC) in Colombia. Water Footprint Assessment Results for SuizAgua Colombia, Pilot Project Phase I and II; Swiss Agency for Development and Cooperation (SDC): Bogotá, Colombia, 2012. [Google Scholar]

- WWF. Huella hídrica en Bavaria: Identificando Riesgos para una Cadena de Custodia del Agua. 2014. Available online: http://d2ouvy59p0dg6k.cloudfront.net/downloads/huella_hidrica_bavaria_1.pdf (accessed on 15 April 2017).

- Vanegas, Y.; Ramírez, L. Evaluación de la Huella Hídrica para la Producción de Flores Lirio Japonés (Hemerocallis) en la Vereda Ricaurte del Municipio de Rondón–Boyacá. Bachelor’s Thesis, Trabajo de grado Ingeniera Ambiental y Sanitaria, Universidad de La Salle, Bogotá, Colombia, 2015. [Google Scholar]

- Rost, S.; Gerten, D.; Bondeau, A.; Lucht, W.; Rohwer, J.; Schaphoff, S. Agricultural green and blue water consumption and its influence on the global water system. Water Resour. Res. 2008, 44. [Google Scholar] [CrossRef]

- Calzadilla, A.; Rehdanz, K.; Tol, R.S. The economic impact of more sustainable water use in agriculture: A computable general equilibrium analysis. J. Hydrol. 2010, 384, 292–305. [Google Scholar] [CrossRef]

- Liu, J.; Yang, H. Spatially explicit assessment of global consumptive water uses in cropland: Green and blue water. J. Hydrol. 2010, 384, 187–197. [Google Scholar] [CrossRef]

- Williams, E.; Simmons, J.E. Water in the Energy Industry: An Introduction; BP Global: London, UK, 2013; Available online: http://www.bp.com/content/dam/bp/pdf/sustainability/group-reports/BP-ESC-water-handbook.pdf (accessed on 15 April 2017).

- World Bank. Will Water Constrain Our Energy Future? 2014. Available online: http://pubdocs.worldbank.org/en/905381435867523914/Thirsty-ENERGY-general-english.pdf (accessed on 15 April 2017).

- Gleick, P.H. Water and energy. Annu. Rev. Energy Environ. 1994, 19, 267–299. [Google Scholar] [CrossRef]

- Blok, K. Introduction to Energy Analysis; Techne Press: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Domínguez, E.; Moreno, J.; Ivanova, Y. Water scarcity in a tropical country? Revisiting the Colombian water resources. Int. Assoc. Hydrol. Sci. 2010, 340, 335–342. [Google Scholar]

- Bolivar Lobato, M.I.; Schneider, U.A. Managing water scarcity in the Magdalena river basin in Colombia. An economic assessment. In Proceedings of the European Geosciences Union General Assembly, Vienna, Austria, 27 April–2 May 2014; Volume 16, p. 2683. [Google Scholar]

- Calle, E.D.; Rivera, H.G.; Sarmiento, R.V.; Moreno, P. Relaciones demanda-oferta de agua y el índice de escasez de agua como herramientas de evaluación del recurso hídrico colombiano. Rev. Acad. Colomb. Cienc. 2008, 32, 195–212. [Google Scholar]

- Ministerio de Ambiente, Vivienda y Desarrollo Territorial. Política Nacional para la Gestión Integral del Recurso Hídrico; Ministerio de Ambiente, Vivienda y Desarrollo Territorial: Bogotá, DC, Colombia, 2010. [Google Scholar]

- Semana. ¿Qué tan Responsables son las Petroleras de la Tragedia Ambiental? 2014. Available online: http://www.semana.com/nacion/articulo/sequia-en-casanare-el-papel-de-las-petroleras/381584-3 (accessed on 15 April 2017).

- CGN. Informe de Actuación Especial de Fiscalización: Problemática Ambiental Presentada en el Municipio de paz de Ariporo, Departamento del Casanare—2014. CGR-CDMA No. 029. Contraloría General de la República; 2012. Available online: http://www.anh.gov.co/la-anh/Control-y-Rendicion/Informes%20de%20Auditora%20de%20Gestin/Informe%20Actuación%20Especial%20Problemática%20Ambiental%20Municipio%20de%20Paz%20de%20Ariporo%20(agosto%202014).pdf (accessed on 15 April 2017).

- IDEAM. Estudio Nacional del Agua 2010; Instituto de Hidrología, Meteorología y Estudios Ambientales: Bogotá, DC, Colombia, 2010.

- Dyoulgerov, M.; Bucher, A.; Zermoglio, F. Climate Risk and Adaptation Country Profile. Colombia; World Bank: Washington, DC, USA, 2011; Available online: http://sdwebx.worldbank.org/climateportalb/doc/GFDRRCountryProfiles/wb_gfdrr_climate_change_country_profile_for_COL.pdf (accessed on 15 April 2017).

- Restrepo, J.D. Los Sedimentos del Río Magdalena: Reflejo de la Crisis Ambiental; Fondo editorial Universidad de EAFIT: Medellín, Colombia, 2005. [Google Scholar]

- UPME. Escenarios de Oferta y Demanda de Hidrocarburos en Colombia; Ministerio de Minas y Energía: Bogota, Colombia, 2012. Available online: http://www.upme.gov.co/docs/publicaciones/2012/escenarios_oferta_demanda_hidrocarburos.pdf (accessed on 15 April 2017).

- Ecopetrol. Reporte Integrado de Gestión sostenible 2016. 2017. Available online: http://www.ecopetrol.com.co/documentos/reporte-integrado-gestion-sostenible-2016.pdf (accessed on 15 April 2017).

- Pareja-Carmona, M.I.; Jiménez-Segura, L.F.; Ochoa-Orrego, L.E. Variación espacio-temporal de las larvas de tres especies de peces migratorios en el cauce del río Magdalena (Colombia), durante el ciclo hidrológico 2006–2007. Actualidades Biológicas 2014, 36, 33. [Google Scholar]

- Carmona, L.G.; Cardenas, J.; Navarreta, M.; Cardenas, L.; Montenegro, P. Monitoring ad conservation program for umbrella species: The northern screamer as a strategic element for floodplain biodiversity in the middle Magdalena region, Colombia. In Proceedings of the 2015 SPE E&P Health, Safety, Security and Environmental Conference-Americas, Denver, CO, USA, 16–18 March 2015. [Google Scholar]

- Carmona, L.G.; Correa, F.; Perdomo, K. A Joint Strategy between the Hydrocarbon Sector and Colombian Environmental Authorities for the Conservation of a Regional Natural Park. In Proceedings of the SPE International Conference and Exhibition on Health, Safety, Security, Environment, and Social Responsibility, Stavanger, Norway, 11–13 April 2016; Society of Petroleum Engineers: Richardson, TX, USA. [Google Scholar]

- Veil, J.; Quinn, J. Water Issues Associated with Heavy Oil Production; US Department of Energy, National Energy Technology Laboratory. Environmental Science Division, Argonne National Laboratory: Lemont, IL, USA, 2008. Available online: http://www.perf.org/images/Archive_HeavyOilReport.pdf (accessed on 15 April 2017).

- Speight, J.G. Natural bitumen (tar sands) and heavy oil. G. Jinsheng, Coal, Oil Shale, Natural Bitumen, Heavy Oil and Peat. In Encyclopedia of Life Support Systems (EOLSS); UNESCO, EOLSS: Oxford, UK, 2005. [Google Scholar]

- Alagorni, A.H.; Yaacob, Z.B.; Nour, A.H. An Overview of Oil Production Stages: Enhanced Oil Recovery Techniques and Nitrogen Injection. Int. J. Environ. Sci. Dev. 2015, 6, 693. [Google Scholar] [CrossRef]

- IEA. Resources to. Reserves. Oil, Gas and Coal Technologies for the Energy Markets of the Future; International Energy Agency: Paris, France, 2013; Available online: https://www.iea.org/publications/freepublications/publication/Resources2013.pdf (accessed on 15 April 2017).

- Arévalo, D. Huella Hídrica y Energía. Medellín. April 2014. Available online: http://cta.org.co/images/PDF/HH.pdf (accessed on 15 April 2017).

- Wilson, W.; Leipzig, T.; Griffiths-Sattenspiel, B. Burning Our Rivers: The Water Footprint of Electricity; River Network (Austin, TX: Comptroller of Public Accounts, Data Division Services) Publication, (96-1704); River Network: Portland, OR, USA, 2012; p. 62. [Google Scholar]

- Gerbens-Leenes, P.W.; Hoekstra, A.Y.; Meer, T.H. Water Footprint of Bio-Energy and Other Primary Energy Carriers; UNESCO–IHE: Delft, The Netherlands, 2008. [Google Scholar]

- Wiles, L.; Portillo, L.; Nichols, E. Produced Water Treatment for Reuse in Cyclic Steam Boilers and Crop Irrigation. In Proceedings of the 2015 International Water Conference, Orlando, FL, USA, 15–19 November 2015; IWC 15-29. Available online: http://www.originclear.com/wp-content/uploads/2016/03/iwc-15-29-final.pdf (accessed on 15 April 2017).

- Heins, W.; Peterson, D. Use of Evaporation for Heavy Oil Produced Water Treatment; GE Water & Process Technologies RCC: Washington, DC, USA, 2005; Available online: https://www.gewater.com/kcpguest/salesedge/documents/Technical%20Papers_Cust/Americas/English/TP1042EN.pdf (accessed on 15 April 2017).

- Law, D.H.-S. A New Heavy Oil Recovery Technology to Maximize Performance and Minimize Environmental Impact; SPE International, 2011. Available online: http://www.spe.org/dl/docs/2011/Law.pdf (accessed on 15 April 2017).

| Parameter | Unit | Natural State of Aquifer | Produced Wastewater Treatment * | Domestic Wastewater Treatment | Industrial Wastewater Treatment | Legal Max 2015 ** |

|---|---|---|---|---|---|---|

| Total acidity | mg/L | 1 | NE | 37 | NE | - |

| Total alkalinity | mg/L | 190 | 583 | 412 | 222 | - |

| Chlorine (Cl-) | mg/L | 26.55 | 827 | 92 | 588 | 1200 |

| Conductivity | uS/cm | 527 | 2800 | 1529 | 2991 | - |

| BOD5 | mg/L | 15 | 345 | 193 | 59 | 60 |

| COD | mg/L | 5 | 645 | 246 | 80 | 180 |

| Total hardness | mg/L | 22 | 249 | 55 | 117 | - |

| Phenols | mg/L | <0.001 | 0.9 | <0.001 | 0.2 | 0.2 |

| Fats and oils | mg/L | <0.5 | 99 | 8 | 1055 | 15 |

| Total hydrocarbons | mg/L | <0.5 | 46 | 0.3 | 2249 | 10 |

| Total suspended solids | mg/L | 25 | 75.3 | 147 | 104 | 50 |

| Total solids | mg/L | 497 | 2380 | NE | 2405 | - |

| NWS-2014 Flow Categories (m3/barrel) | This Study | NWS-2014 | NWS-2014 Assumptions | ||

|---|---|---|---|---|---|

| CSS 1 | CSS 2 | SR | |||

| Industrial water consumption | 0.194 | 0.186 | 0.075 | 0.106 | |

| Domestic water consumption | 0.004 | 0.004 | 0.034 | 0.004 | |

| Industrial wastewater | 0.003 | 0.002 | 0.0005 | 0.095 | |

| Domestic wastewater | 0.002 | 0.0009 | 0.030 | 0.002 | |

| Partial indicator NWS-2014 | - | - | - | 0.013 | This is difference between water consumption and wastewater discharge. |

| Production water | 0.148 | 0.282 | 1.04 | 1.56 | |

| Re-injected water into the production well to enhance oil recovery | 0.000 | 0.000 | 0.167 | 0.184 | Water returned to catchment area |

| Re-injected into geological formation for final disposal | 0.144 | 0.282 | 0.868 | 0.719 | Water returned to catchment area |

| Wastewater discarded into natural water bodies | 0.0004 | 0.000 | 0.000 | 0.651 | Water returned to catchment area |

| Watering roads for dust and suspended matter reduction | 0.005 | 0.0003 | 0.000 | 0.003 | Evaporated |

| Sprinkling | 0.001 | 0.002 | 0.03 | 0.002 | Evaporated |

| Wastewater sent to third parties | 0.00003 | 0.000 | 0.000 | 0.001 | Water returned to catchment area |

| Losses | NE | NE | NE | 0.0007 | Evaporated |

| Partial indicator of production waters (NWS-2014) | - | - | - | 0.006 | The water footprint of NWA-2014 corresponds to the evaporated water in either sprinkling or road cleaning operations. They calculate that this constitutes 0.34 percent of the water used in crude production. |

| Total crude production water footprint | 0.230 | 0.211 | 0.190 | 0.019 | The water footprint of NWA-2014 corresponds to the sum of the two partial indicators |

| Field | Direct Blue Water Footprint | Indirect Blue Water Footprint * |

|---|---|---|

| SR | 0.11 | 0.12 |

| CSS Field 1 | 0.19 | 0.22 |

| CSS Field 2 | 0.19 | 0.23 |

| Sustainability of the WF in the Basin—Hotspots in Catchment | Non-Sustainable Fraction | Priority Response | ||||

|---|---|---|---|---|---|---|

| IARC * | IPHE ** | IACAL *** | ||||

| Very Low | Very High | Low | ||||

| WF | Blue | Green | Grey | |||

| Product | ||||||

| SR | No | Yes | No | 37% | Yes | |

| CSS 1 | No | Yes | No | 71% | Yes | |

| CSS 2 | No | Yes | No | 68% | Yes | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carmona, L.G.; Whiting, K.; Carrasco, A. The Water Footprint of Heavy Oil Extraction in Colombia: A Case Study. Water 2017, 9, 340. https://doi.org/10.3390/w9050340

Carmona LG, Whiting K, Carrasco A. The Water Footprint of Heavy Oil Extraction in Colombia: A Case Study. Water. 2017; 9(5):340. https://doi.org/10.3390/w9050340

Chicago/Turabian StyleCarmona, Luis Gabriel, Kai Whiting, and Angeles Carrasco. 2017. "The Water Footprint of Heavy Oil Extraction in Colombia: A Case Study" Water 9, no. 5: 340. https://doi.org/10.3390/w9050340

APA StyleCarmona, L. G., Whiting, K., & Carrasco, A. (2017). The Water Footprint of Heavy Oil Extraction in Colombia: A Case Study. Water, 9(5), 340. https://doi.org/10.3390/w9050340