Carbon Footprint Analyses of Mainstream Wastewater Treatment Technologies under Different Sludge Treatment Scenarios in China

Abstract

:1. Introduction

2. Materials and Methods

2.1. Definition of Carbon Footprint

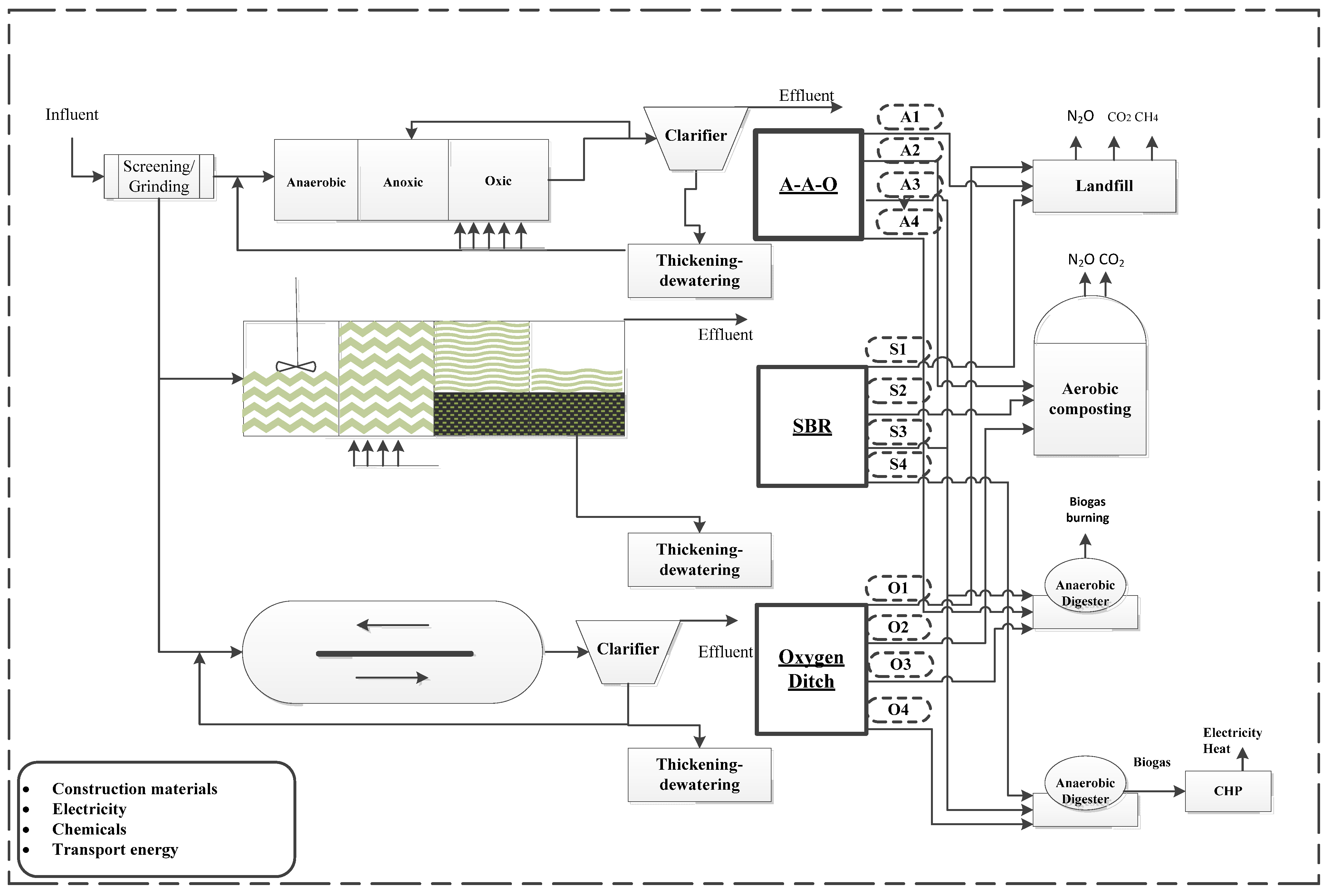

2.2. Scenarios Studied

2.3. Data and Assessment Model

| Wastewater Treatment Alternatives | A–A–O | SBR | OD | |

|---|---|---|---|---|

| Sludge Treatment and Disposal Alternatives | Flow rate: 20,000 m3/day; CODin = 480 mg/L; CODeff = 50 mg/L; BODin = 216 mg/L; BODeff = 10 mg/L; TNin = 45 mg/L; TNeff = 15 mg/L; SRT = 15 days; MLR Rate = 200; Electricity Demand = 0.305 kWh/m3; Raw Sludge Production = 5.2 t DS/day; PAC Demand = 138 t/year; PAM Demand = 5.6 t/year. | Flow Rate: 20,000 m3/day; CODin = 360 mg/L; CODeff = 50 mg/L; BODin = 180 mg/L; BODeff = 10 mg/L; TNin = 48 mg/L; TNeff = 15 mg/L; SRT = 15 days; MLR rate = 150; Electricity Demand = 0.249 kWh/m3; Raw sludge Production = 4.3 t DS/day; PAM demand = 4.69 t/year. | Flow Rate: 20,000 m3/day; CODin = 500 mg/L; CODeff = 50 mg/L; BODin = 300 mg/L; BODeff =10 mg/L; TNin = 40 mg/L; TNeff = 15 mg/L; SRT = 15 days; MLR Rate = 200; Electricity Demand = 0.343 kWh/m3; Raw Sludge Production = 3.7 t DS/day; PAM demand = 4.04 t/year. | |

| Direct Landfill: Direct landfill after dewatering and thickening by truck transport; Transport distance =20 km; CO2, CH4 and N2O emissions under anaerobic conditions during landfill were taken into account. | A1 | S1 | O1 | |

| Anaerobic digestion + biogas combustion: Mesophilic digester at 35 ± 2 °C; Assuming biogas, containing 65% (v/v) CH4 and 32% (v/v) CO2, was completely combusted and converted to CO2; Electricity demand for heating and mixing = 40 kWh/t biosolids (80% water content). | A3: Biogas production = 1,517 m3/day | S3: Biogas production = 1,270 m3/day | O3: Biogas production = 1,094 m3/day | |

| Anaerobic digestion + CHP: Mesophilic digester at 35 ± 2 °C; Electricity demand for heating and mixing = 40 kWh/t biosolids (80% water content); Biogas CHP unit to recover 70% energy, 30% for electricity and 40% for heat. | A4: Electricity production by CHP = 2,904 kWh/day; Heat production by CHP = 13,956 MJ/day. | S4: Electricity production by CHP=2,430 kWh/day; Heat production by CHP=11,681 MJ/day. | O4: Electricity production by CHP = 2,094 kWh/day; Heat production by CHP = 10,064 MJ/day. | |

| Parameters | Value | Unit | Reference |

|---|---|---|---|

| Wastewater Treatment | |||

| CO2 from OM oxidation | 1.375 | kg CO2/kg BODremoved | [23] |

| N2O from denitrification | 0.035 | kg N2O-N/kg Ndenitrified | [24] |

| Sludge Treatment and Disposal | |||

| N2O from composting | 0.700 | g N2O-N/kg DS | [25] |

| N2O from landfill | 8.200 | g N2O/kg Napplied | [9] |

| CH4 from landfill | 13.400 | g CH4/kg sludge | [20] |

| CO2 from landfill | 35.120 | g CO2/kg sludge | [20] |

| N2O from biogas combustion | 0.004 | g N2O/kg CH4 burned | [26] |

| Chemicals | |||

| Polymers (PAM) for dewatering | 1.500 | kg CO2e/kg | [27] |

| Polyaluminium chloride (PAC) | 22.700 | g CO2e/kg | [28] |

| Energy | |||

| Electricity | 0.681 | kg CO2e/kWh | [22] |

| Diesel | 72.600 | kg CO2e/GJ | [6] |

| Coal | 90.800 | kg CO2e/GJ | [6] |

| Construction Materials | |||

| Cement | 0.405 | kg CO2e/kg | Estimated |

| Steel | 2.196 | kg CO2e/kg | Estimated |

| Timber | 0.706 | kg CO2e/kg | Estimated |

| Sand | 0.009 | kg CO2e/kg | Estimated |

| Gravel | 0.009 | kg CO2e/kg | Estimated |

| Cast iron pipe | 3.096 | kg CO2e/kg | Estimated |

| Steel pipe and fittings | 3.096 | kg CO2e/kg | Estimated |

| Reinforced concrete pipe | 0.095 | kg CO2e/kg | Estimated |

3. Results and Discussion

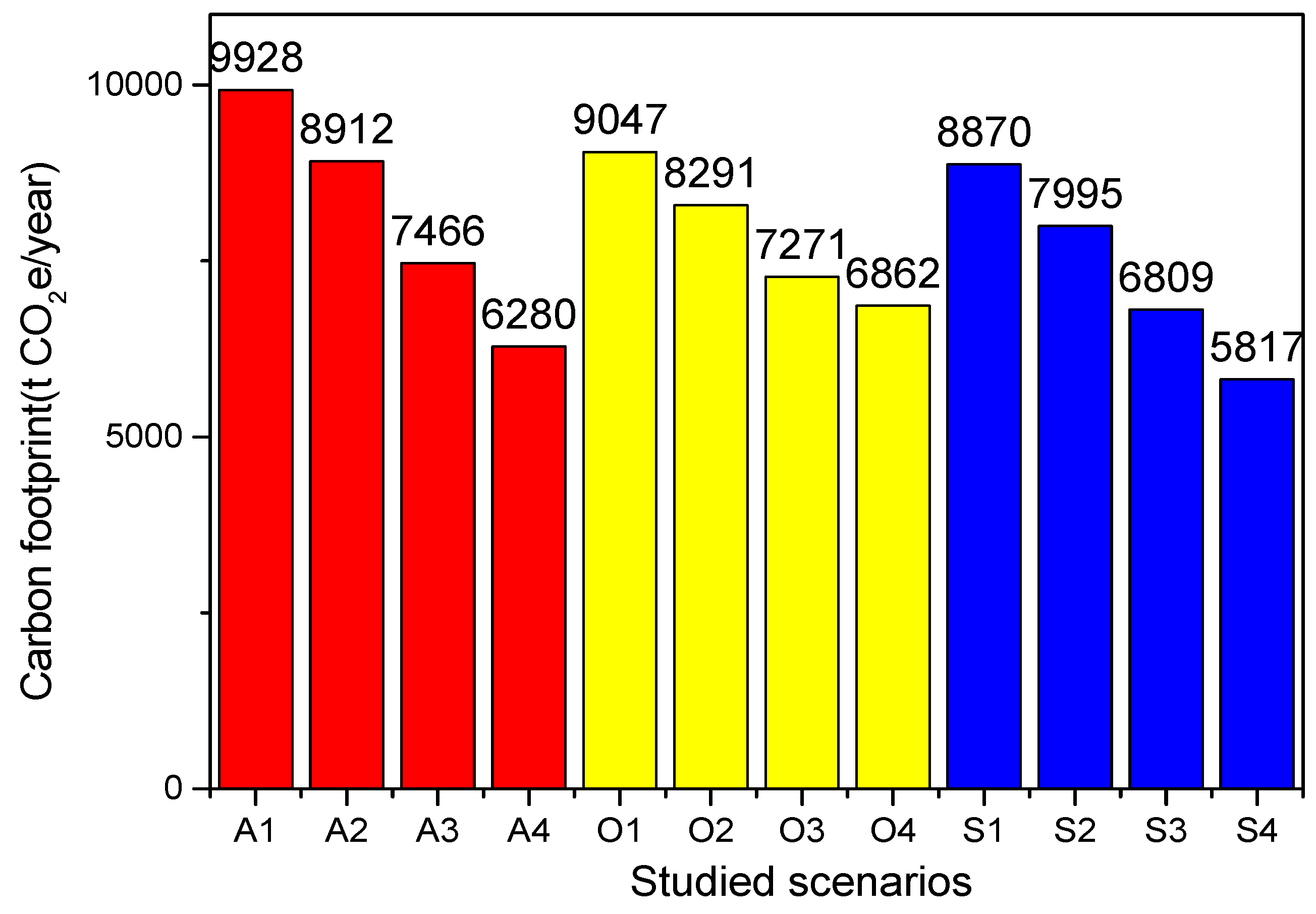

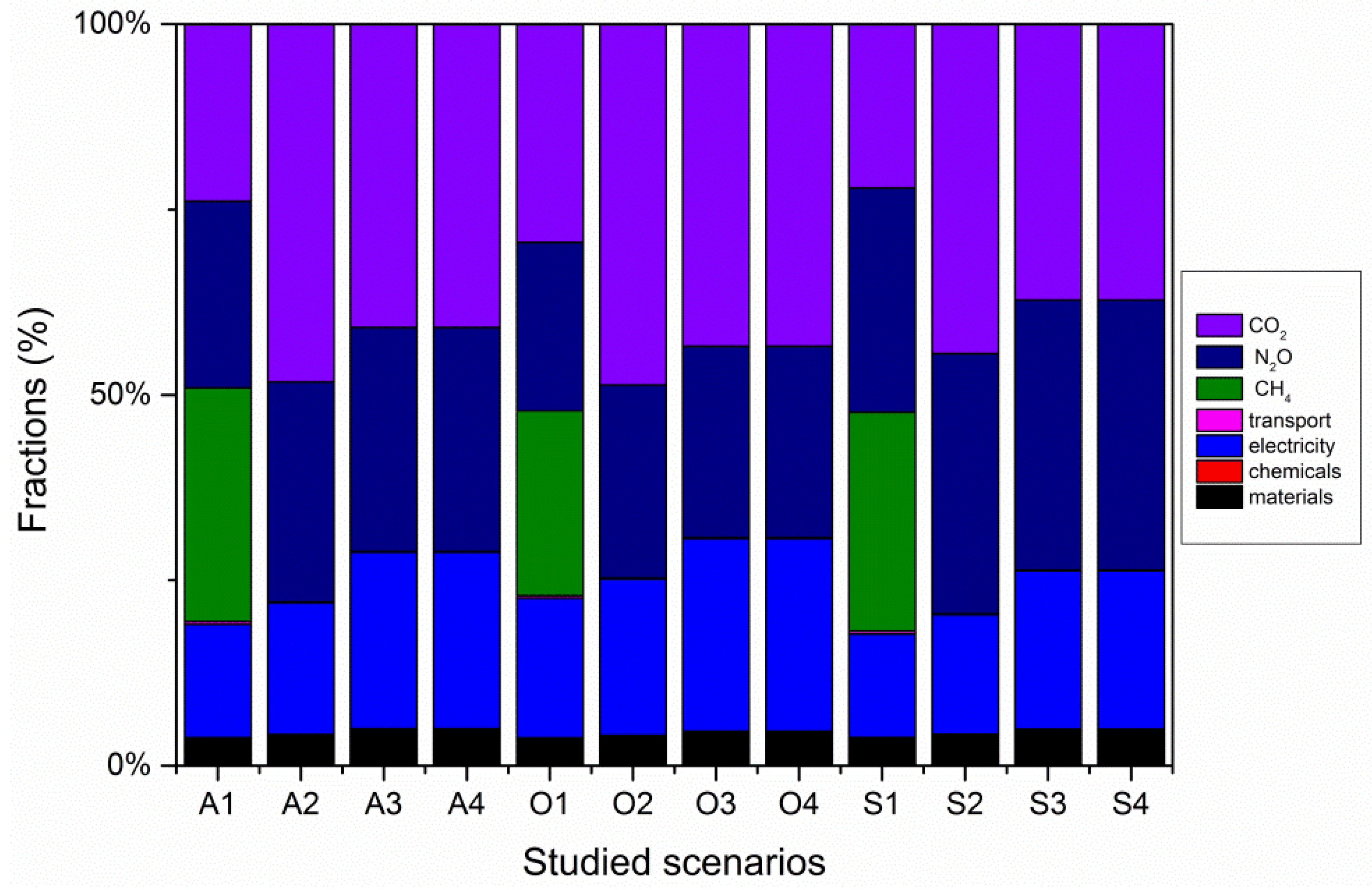

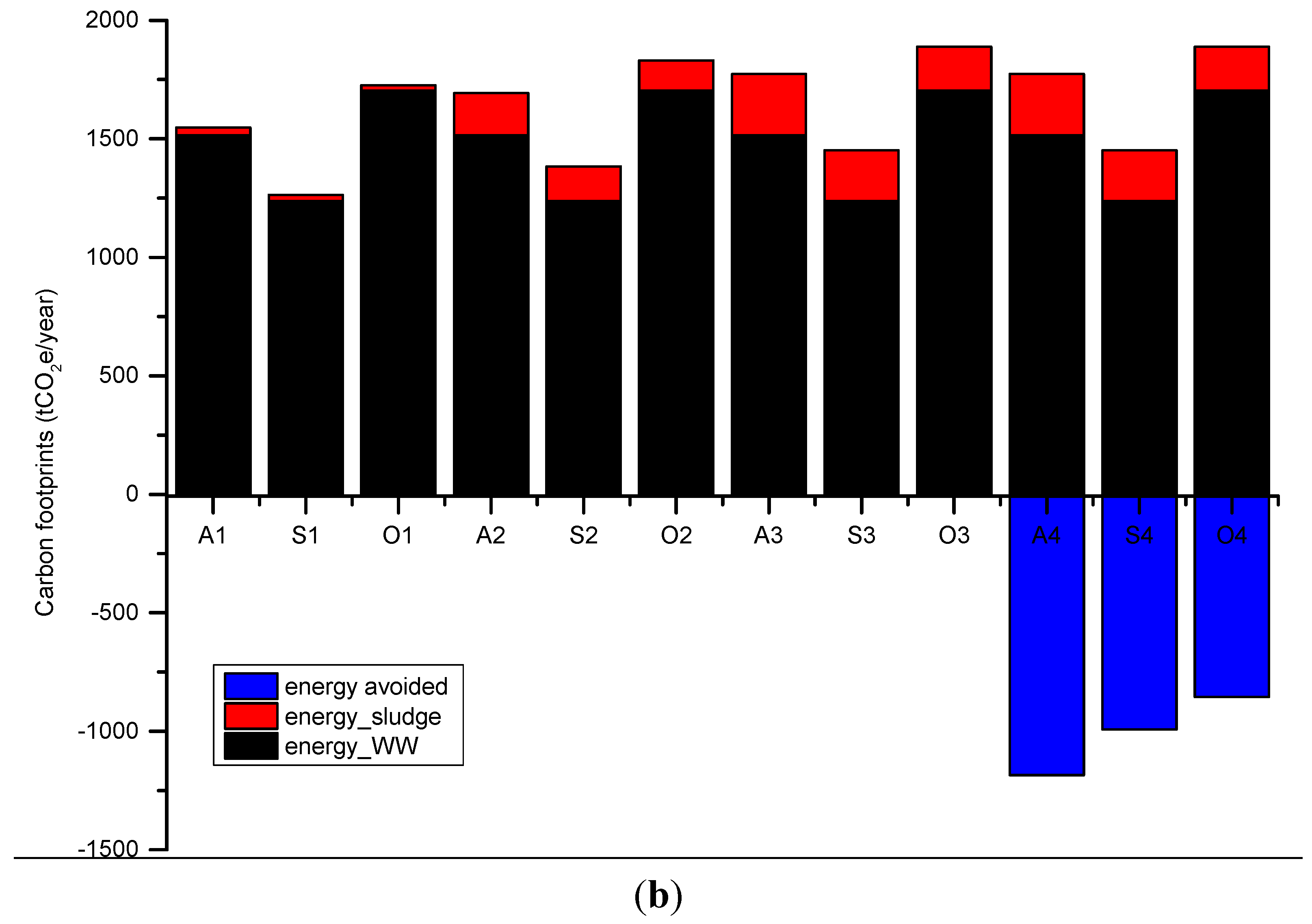

3.1. Carbon Footprint

| Scenarios | Total GHG Emissions (t CO2e/year) | GHG Emissions from Construction (t CO2e/year) | GHG Emissions from Chemicals (t CO2e/year) | GHG Emissions from Electricity Use (t CO2e/year) | GHG Emissions from Transport (t CO2e/year) | CH4 Emissions (t CO2e/year) | N2O Emissions (t CO2e/year) | CO2 Emissions (t CO2e/year) | GHG Offsets (t CO2e/year) |

|---|---|---|---|---|---|---|---|---|---|

| A1 | 9928 | 364 | 11 | 1516 | 41 | 3127 | 2501 | 2367 | n/a |

| A2 | 8870 | 332 | 7 | 1237 | 34.5 | 0 | 2683 | 1957 | n/a |

| A3 | 9047 | 333 | 6.1 | 1705 | 31.3 | 0 | 2054 | 2662 | n/a |

| A4 | 8912 | 364 | 11.4 | 1693 | 9.2 | 0 | 2649 | 4298 | −1186 |

| S1 | 7995 | 332 | 7 | 1384 | 8.4 | 2618 | 2806 | 3551 | n/a |

| S2 | 8291 | 333 | 6.1 | 1831 | 8.8 | 0 | 2159 | 4033 | n/a |

| S3 | 7466 | 364 | 11.4 | 1774 | 9.2 | 0 | 2253 | 3054 | n/a |

| S4 | 6809 | 332 | 7 | 1451 | 8.4 | 0 | 2478 | 2532 | −992 |

| O1 | 7271 | 333 | 6.1 | 1889 | 8.8 | 2255 | 1878 | 3157 | n/a |

| O2 | 6280 | 364 | 11.4 | 1774 | 9.2 | 0 | 2253 | 3054 | n/a |

| O3 | 5817 | 332 | 7 | 1451 | 8.4 | 0 | 2478 | 2532 | n/a |

| O4 | 6862 | 333 | 6.1 | 1889 | 8.8 | 0 | 1878 | 3157 | −855 |

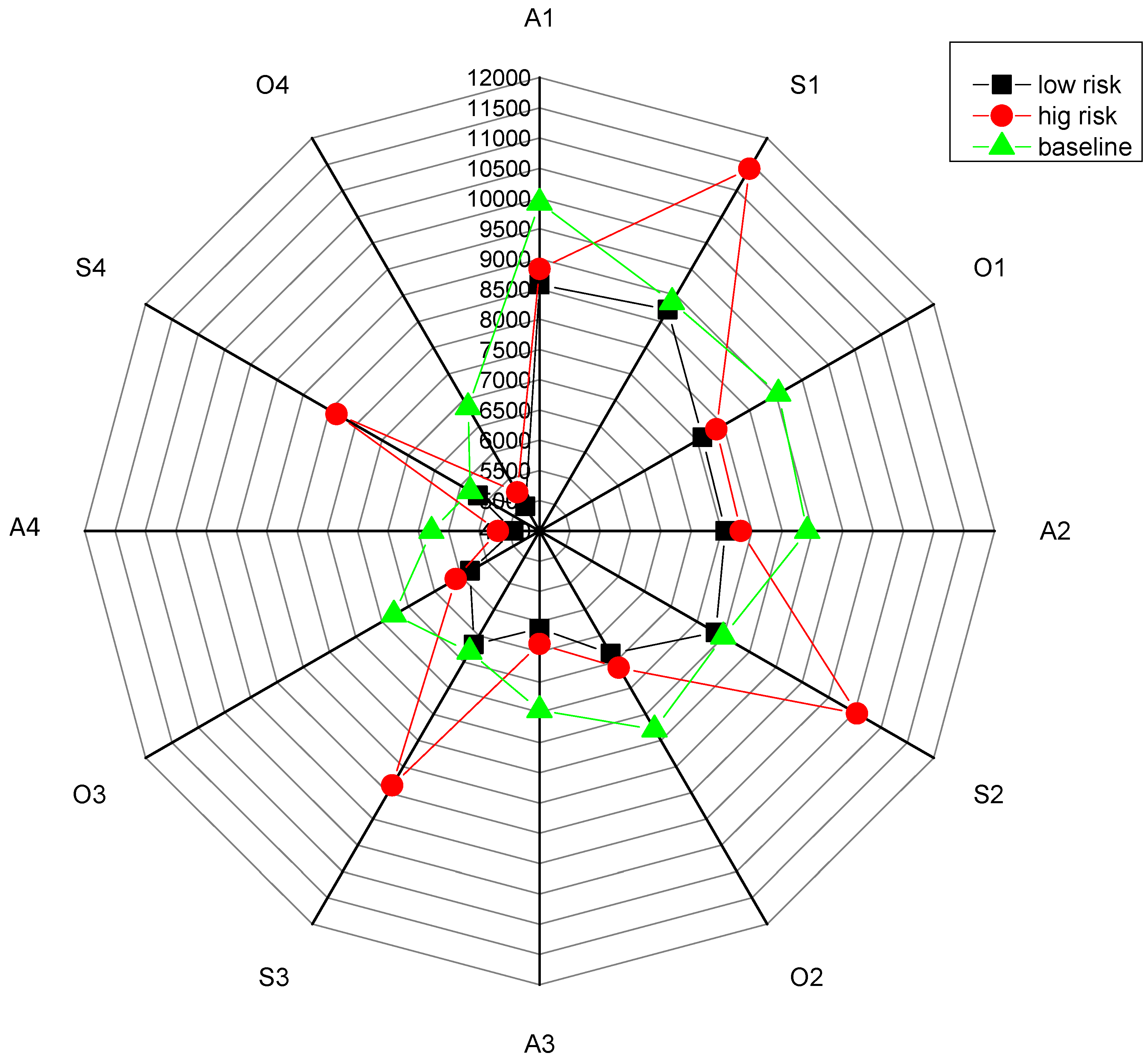

3.2. Emission Factors of N2O

| Treatment Technology | Effluent TN (mg/L) | MLR Rate (%) | SRT (days) | N2O Emission Factor (kg N2O-N/kg Ndenitrified) [24] | N2O Emission Factor (kg N2O-N/kg Ndenitrified) Baseline | N2O Emission Factor (kg N2O-N/kg Ndenitrified) High Risk | N2O Emission Factor (kg N2O-N/kg Ndenitrified) Low Risk |

|---|---|---|---|---|---|---|---|

| A–A–O | 15 | 200 | 18 | 0.010–0.018 (ave. 0.014) | 0.035 | 0.018 | 0.014 |

| SBR | 15 | 150 | 20 | 0.010–0.071 (ave. 0.033) | 0.035 | 0.071 | 0.033 |

| Oxygen Ditch | 15 | 300 | 22 | 0.006–0.013 (ave. 0.008) | 0.035 | 0.013 | 0.008 |

3.3. Measures to be Taken for Reducing Carbon Footprint

3.4. Limitations

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- OECD Economic Surveys: China 2013; OECD Publishing: Paris, France, 2013.

- Corominas, L.; Foley, J.; Guest, J.S.; Hospido, A.; Larsen, H.F.; Morera, S.; Shaw, A. Life cycle assessment applied to wastewater treatment: State of the art. Water Res. 2013, 47, 5480–5492. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.Z.; Zhang, D.Q.; Le, M.T.; Puah, A.N.; Ng, W.J. Energy utilization in sewage treatment—A review with comparisons. J. Water Clim. Chang. 2013, 4, 1. [Google Scholar] [CrossRef]

- Sahely, H.R.; Monteith, H.D.; MacLean, H.L.; Bagley, D.M. Comparison of on-site and upstream greenhouse gas emissions from canadian municipal wastewater treatment facilities. J. Environ. Eng. Sci. 2006, 5, 405–415. [Google Scholar] [CrossRef]

- Technical Speification for Management of Municipal Wastewater Treatment Plant Operaion (HJ 2038–2014); Ministry of Environmental Protection of the People’s Republic of China, China Environmental Science Press: Beijing, China, 2014. (In Chinese)

- Second National Communication on Climate Change of the People’s Republic of China; Climate Change Division of National Development and Reform Commission of the People’s Republic of China, China Economic Press: Beijing, China, 2013. (In Chinese)

- Yu, J.; Tian, N.; Wang, K.; Ren, Y. Analysis and discussion of sludge disposal and treatment of sewage treatment plants in China. Chin. J. Environ. Eng. 2007, 1, 5. (In Chinese) [Google Scholar]

- Wang, X.; Liu, J.; Ren, N.Q.; Yu, H.Q.; Lee, D.J.; Guo, X. Assessment of multiple sustainability demands for wastewater treatment alternatives: A refined evaluation scheme and case study. Environ. Sci. Technol. 2012, 46, 5542–5549. [Google Scholar] [CrossRef] [PubMed]

- De Haas, D.; Foley, J.; Barr, K. Greenhouse gas inventories from WWTPs—The trade-off with nutrient removal. In Sustainability 2008 Green Practices for the Water Environment; Water Environment Federation: National Harbor, MD, USA, 2008. [Google Scholar]

- Gustavsson, D.J.; Tumlin, S. Carbon footprints of scandinavian wastewater treatment plants. Water Sci. Technol. 2013, 68, 887–893. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.H.; Wang, X.C.; Xiong, J.Q.; Chen, R.; Cao, B. Application of life cycle assessment for an evaluation of wastewater treatment and reuse project—Case study of Xi’an, China. Bioresour. Technol. 2010, 101, 1421–1425. [Google Scholar] [CrossRef] [PubMed]

- Mo, W.; Zhang, Q. Can municipal wastewater treatment systems be carbon neutral? J. Environ. Manag. 2012, 112, 360–367. [Google Scholar] [CrossRef]

- De Haas, D.W.; Pepperell, C.; Foley, J. Perspective on greenhouse gas emission estimates based on australian wastewater treatment plant operating data. Water Sci. Technol. 2014, 69, 451–463. [Google Scholar]

- Suh, Y.-J.; Rousseaux, R. An lca of alternative wastewater sludge treatment scenarios. Resour. Conserv. Recycl. 2002, 35, 10. [Google Scholar]

- Liu, B.; Wei, Q.; Zhang, B.; Bi, J. Life cycle ghg emissions of sewage sludge treatment and disposal options in tai lake watershed, china. Sci. Total Environ. 2013, 447, 361–369. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Pawlowski, A. Life cycle assessment of two emerging sewage sludge-to-energy systems: Evaluating energy and greenhouse gas emissions implications. Bioresour. Technol. 2013, 127, 81–91. [Google Scholar] [CrossRef] [PubMed]

- Griffith, D.R.; Barnes, R.T.; Raymond, P.A. Inputs of fossil carbon from wastewater treatment plants to U.S. rivers and oceans. Environ. Sci. Technol. 2009, 43, 5. [Google Scholar] [CrossRef]

- Law, Y.; Jacobsen, G.E.; Smith, A.M.; Yuan, Z.; Lant, P. Fossil organic carbon in wastewater and its fate in treatment plants. Water Res. 2013, 47, 5270–5281. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Garcia, G.; Hospido, A.; Bagley, D.M.; Moreira, M.T.; Feijoo, G. A methodology to estimate greenhouse gases emissions in life cycle inventories of wastewater treatment plants. Environ. Impact Assess. Rev. 2012, 37, 37–46. [Google Scholar] [CrossRef]

- Chen, S.; Chen, B. Net energy production and emissions mitigation of domestic wastewater treatment system: A comparison of different biogas-sludge use alternatives. Bioresour. Technol. 2013, 144, 296–303. [Google Scholar] [CrossRef] [PubMed]

- Doorn, M.R.J.; Towprayoon, S.; Vieira, S.M.M.; Irving, W.; Palmer, C.; Pipatti, R.; Wang, C. Chapter 6 Wastewater Treatment and Emissions; Intergovernmental Panel on Climate Change: New York, NY, USA, 2006. [Google Scholar]

- Average CO2 Emission Factors of Regional Electric Grids in China during 2011 and 2012; National Development and Reform Commission of People’s Republic of China, Climate Change Division: Beijing, China, 2014. (In Chinese)

- Cakir, F.Y.; Stenstrom, M.K. Greenhouse gas production: A comparison between aerobic and anaerobic wastewater treatment technology. Water Res. 2005, 39, 4197–4203. [Google Scholar] [CrossRef] [PubMed]

- Foley, J.; de Haas, D.; Yuan, Z.; Lant, P. Nitrous oxide generation in full-scale biological nutrient removal wastewater treatment plants. Water Res. 2010, 44, 831–844. [Google Scholar] [CrossRef] [PubMed]

- Foley, J.; Lant, P. Fugitive greenhouse gas emissions from wastewater treatment. Water J. Aust. Water Assoc. 2008, 38, 6. [Google Scholar]

- Brown, S.; Beecher, N.; Carpenter, A. Calculator tool for determining greenhouse gas emissions for biosolids processing and end use. Environ. Sci. Technol. 2010, 44, 7. [Google Scholar] [CrossRef]

- Carr, M. Reducing Greenhouse Gas Emissions Industrial Biotechnology And Biorefining. In 2007 Taiwan International Chemical Industry Forum; Taiwan Chemical Industry Association: Taipei, Taiwan, 2007. [Google Scholar]

- Sharaai, A.H.; Mahmood, N.Z.; Sulaiman, A.H. Life cycle impact assessment (LCIA) using the ecological scaricity (ecopoints) method: A potential impact analysis to potable water production. World Applied Sci. J. 2010, 11, 12. [Google Scholar]

- MOHUD. Municipal Projects Investment Estimation Index Book IV Drainage Project; China Planning Press: Beijing, China, 2008. [Google Scholar]

- Hammond, G.; Jones, C. Inventory of Carbon and Energy (ICE) Version 1.6a; University of Bath: Bath, UK, 2008. Available online: www.bath.ac.uk/mech-eng/sert/embodied/ (accessed on 13 November 2014).

- Lu, H.; Price, L. China’s industrial carbon dioxide emissions in manufacturing subsectors and in selected provinces. Proceeedings of ECEEE Industrial Summer Study; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2013. Available online: http://escholarship.org/uc/item/917755dp (accessed on 15 November 2014).

- China Energy Statistical Yearbook 2013; National Bureau of Statistics of the People’s Republic of China, China Statistics Press: Beijing, China, 2013.

- Revised 1996 IPCC Guidelines for National Greenhouse Gas Inventories: Energy Workbook (Volume 2); Intergovernmental Panel on Climate Change (IPCC): New York, NY, USA, 1997.

- Revised 1996 IPCC Guidelines for National Greenhouse Gas Inventories: Reference Manual (Volume 3); Intergovernmental Panel on Climate Change (IPCC): New York, NY, USA, 1997.

- Monteith, H.D.; Sahely, H.R.; MacLean, H.L.; Bagley, D.M. A rational procedure for estimation of greenhouse-gas emissions from municipal wastewater treatment plants. Water Environ. Res. 2005, 77, 390–403. [Google Scholar] [CrossRef] [PubMed]

- Kampschreur, M.J.; Temmink, H.; Kleerebezem, R.; Jetten, M.S.; van Loosdrecht, M.C. Nitrous oxide emission during wastewater treatment. Water Res. 2009, 43, 4093–4103. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, C.; Zhang, D.; Yu, Y.; Feng, Y.; Wong, M.S. Carbon Footprint Analyses of Mainstream Wastewater Treatment Technologies under Different Sludge Treatment Scenarios in China. Water 2015, 7, 918-938. https://doi.org/10.3390/w7030918

Chai C, Zhang D, Yu Y, Feng Y, Wong MS. Carbon Footprint Analyses of Mainstream Wastewater Treatment Technologies under Different Sludge Treatment Scenarios in China. Water. 2015; 7(3):918-938. https://doi.org/10.3390/w7030918

Chicago/Turabian StyleChai, Chunyan, Dawei Zhang, Yanling Yu, Yujie Feng, and Man Sing Wong. 2015. "Carbon Footprint Analyses of Mainstream Wastewater Treatment Technologies under Different Sludge Treatment Scenarios in China" Water 7, no. 3: 918-938. https://doi.org/10.3390/w7030918

APA StyleChai, C., Zhang, D., Yu, Y., Feng, Y., & Wong, M. S. (2015). Carbon Footprint Analyses of Mainstream Wastewater Treatment Technologies under Different Sludge Treatment Scenarios in China. Water, 7(3), 918-938. https://doi.org/10.3390/w7030918