A Simulation-Optimization Approach of Geothermal Well-Doublet Placement in North China Using Back Propagation Neural Network and Genetic Algorithm

Abstract

1. Introduction

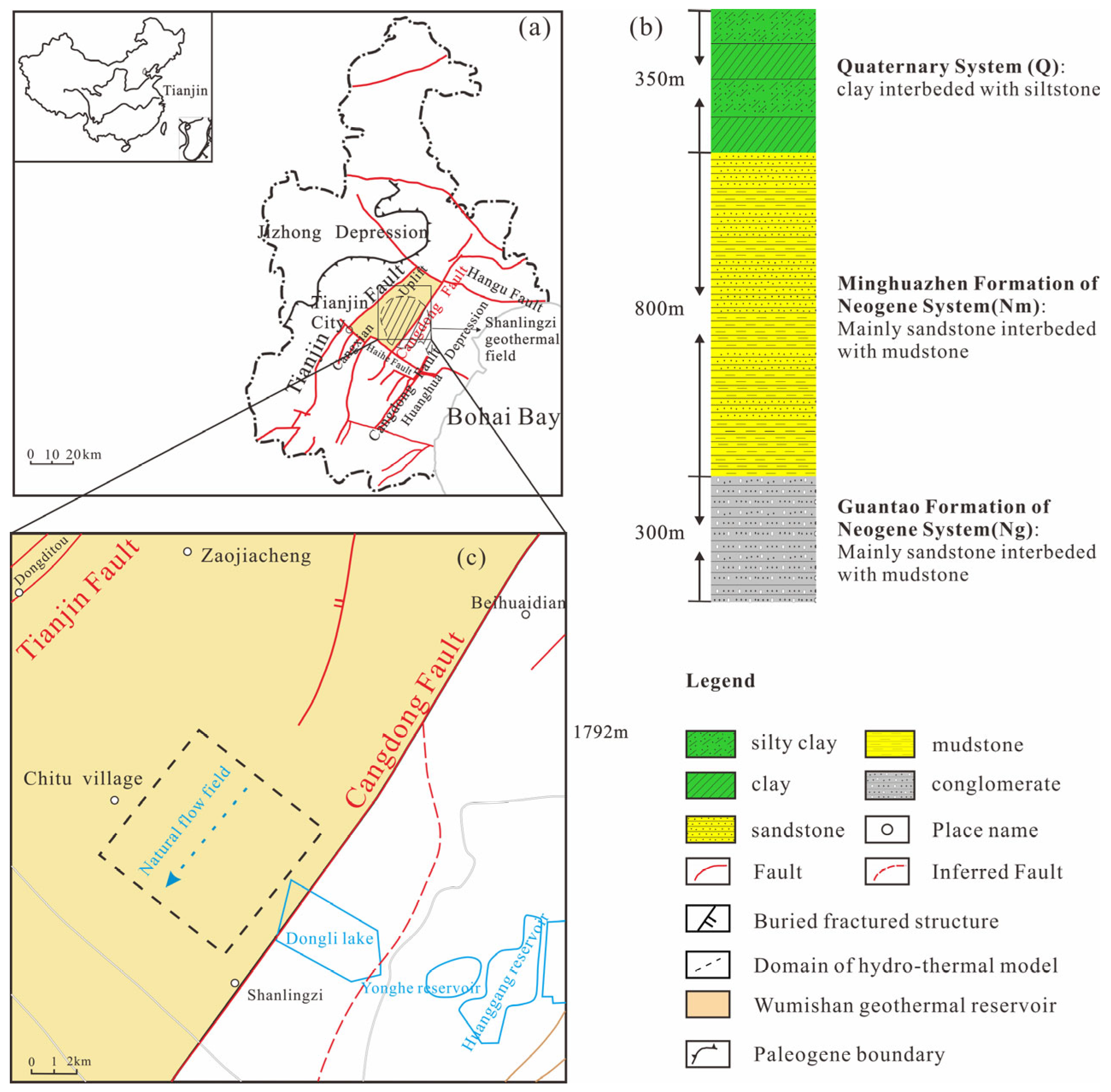

2. Study Area

3. Methodology

3.1. Numerical Simulation Algorithm

- (1)

- Model setup

- (a)

- AssumptionsThe aquifer is homogeneous, horizontal, equal thickness, and isotropic.The pores of the rock are full of fluid and all of them are water, which conforms to Darcy’s law of fluid and does not occur in a phase transition.The heat transfer mode between fluid and rock skeleton consists of convection and conduction.

- (b)

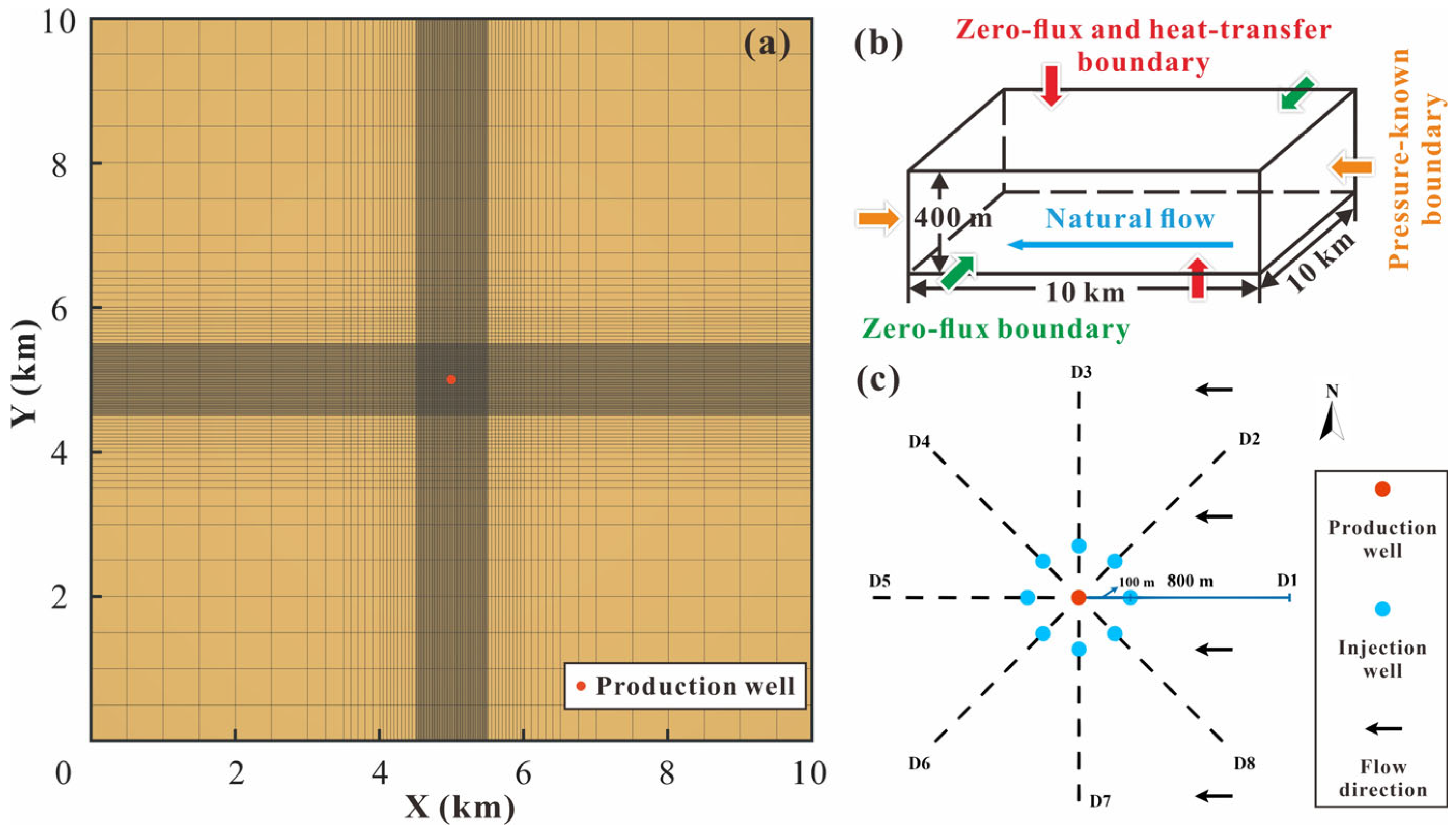

- Conception modelThe site conceptual model of the target reservoir constructed in this study is shown in Figure 2a. The lengths of the model in the X, Y, and Z directions are 10 km, 10 km, and 400 m, respectively. The geometric center of the X-Y plane is taken as the location of the production well (ignoring the well diameter). The site is spatially discretized according to the principle of ‘far sparse and close density’, relative to the production well [38]. The discrete scale is transferred from 500 m at the far-well area to 10 m at the near-well area in the X and Y direction, and the monolayer grid discretization is carried out in the Z direction (reservoir thickness 400 m). There are 16,900 discrete units in total.

- (c)

- Initial conditionThe target reservoir of this study is the Minghuazhen Formation reservoir in the Panzhuang Uplift area of Tianjin. The reasons are as follows: first, the buried depth is shallow, the production cost is low, and it is easy to realize geothermal well-doublet production; second, the data of geotechnical thermophysical parameters are abundant after years of exploitation and research. Based on previous site tests and numerical simulations [36], the main hydrogeological and thermophysical parameters of the Minghuazhen Formation of Neogene System in the study area are shown in Table 1.The well-doublet geothermal production system is mainly used for building heating in winter. The heating period starts in mid-November each year and lasts until mid-March of the following year.

- (d)

- Boundary conditionThe reservoir of the Minghuazhen Formation in the study area is a confined aquifer, and the heat transfer between the target reservoir and the surrounding rock is calculated by the semi-analytical solution to improve the calculation efficiency.The natural groundwater flows from northeast to southwest, the corresponding lateral boundaries (X= 10 km and X = 0 m) are set as constant pressure, and because the range of the numerical simulation area is large enough, the production and injection well cannot cause the change in temperature and pressure at the boundary of the target reservoir. The boundaries (Y = 10 km and Y = 0 m) along the northwest to southeast direction are considered impermeable, resulting in no groundwater flow across them. The boundary conditions of this study area are shown in Figure 2b.

- (2)

- Well placement scheme

3.2. Economic Analysis Method

3.3. Back Propagation Neural Network

- (1)

- The data output of hidden layer is expressed by Equation (2):where is the -th node in the hidden layer, is the -th node in the input layer, is the weight between the -th node of the input layer and -th node of the hidden layer, and is the i-th threshold value in the hidden layer.

- (2)

- The data output of output layer is expressed by Equation (3):where is the -th node in the output layer, is the weight between the -th node of input layer and -th node of hidden layer, and is the -th threshold value in the hidden layer.

- (3)

- The error calculation function of output node is according to Equation (4):where is the error of the output node, and is the expected value of the output node.

4. Results

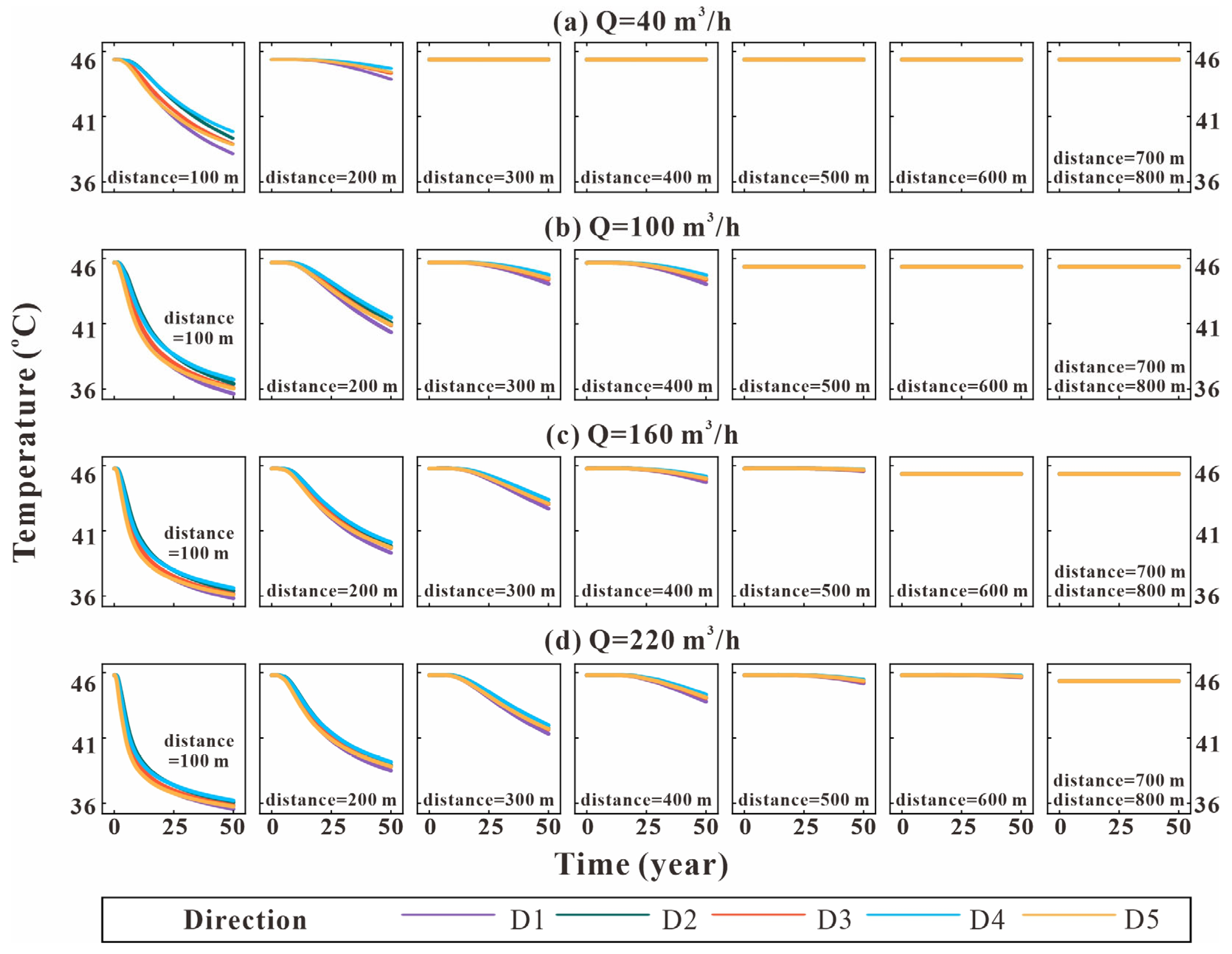

4.1. Temperature

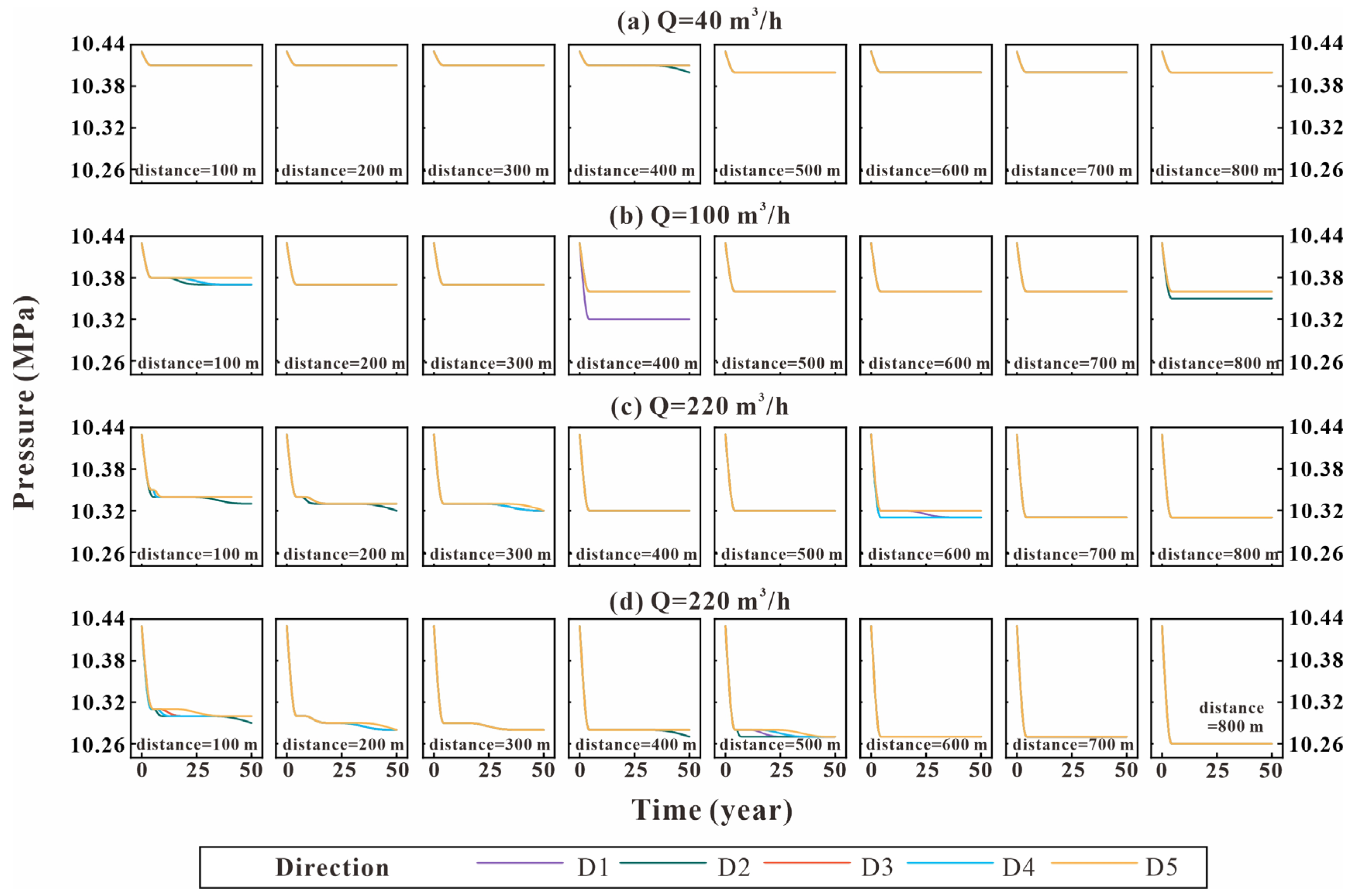

4.2. Pressure

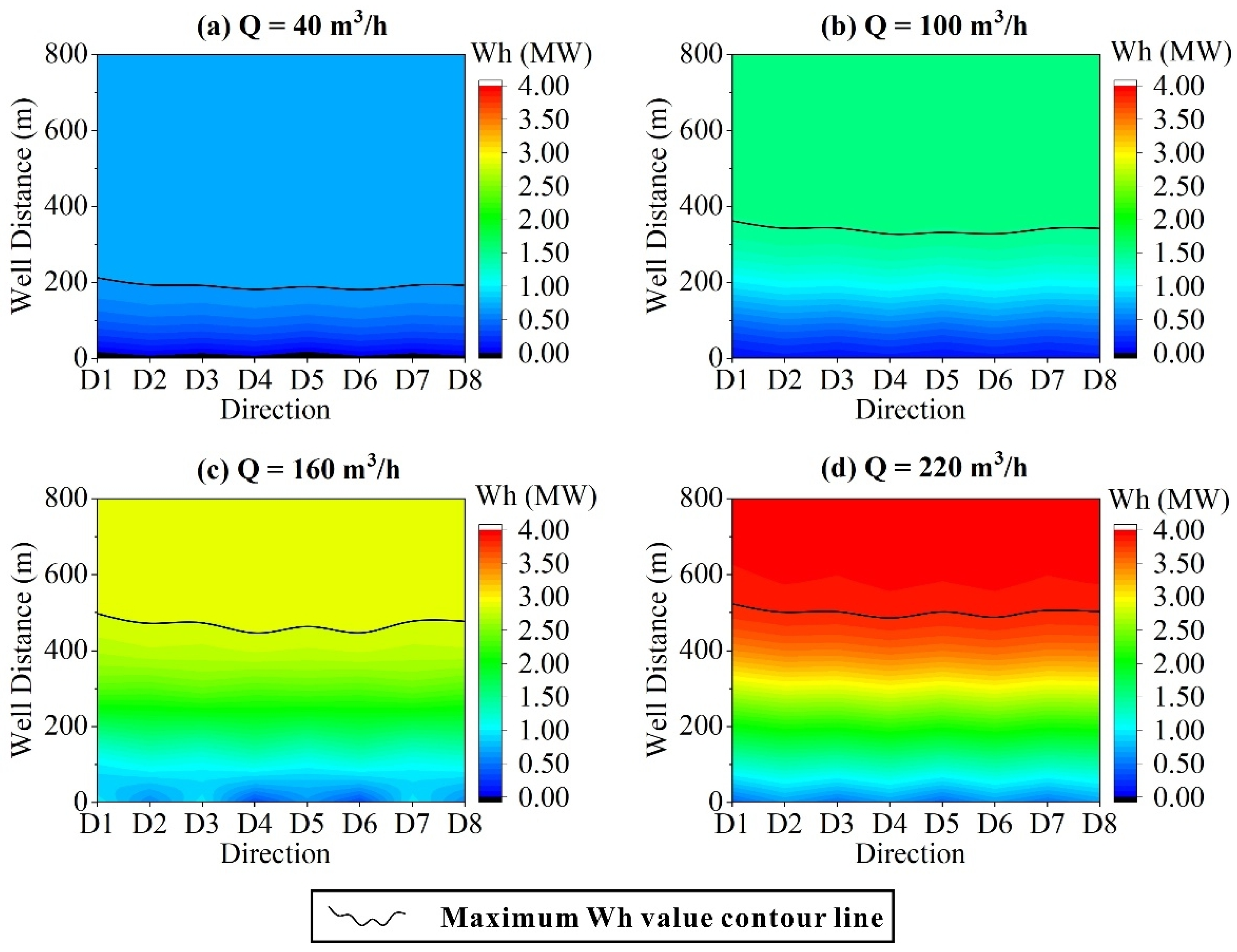

4.3. Heat Extraction Rate

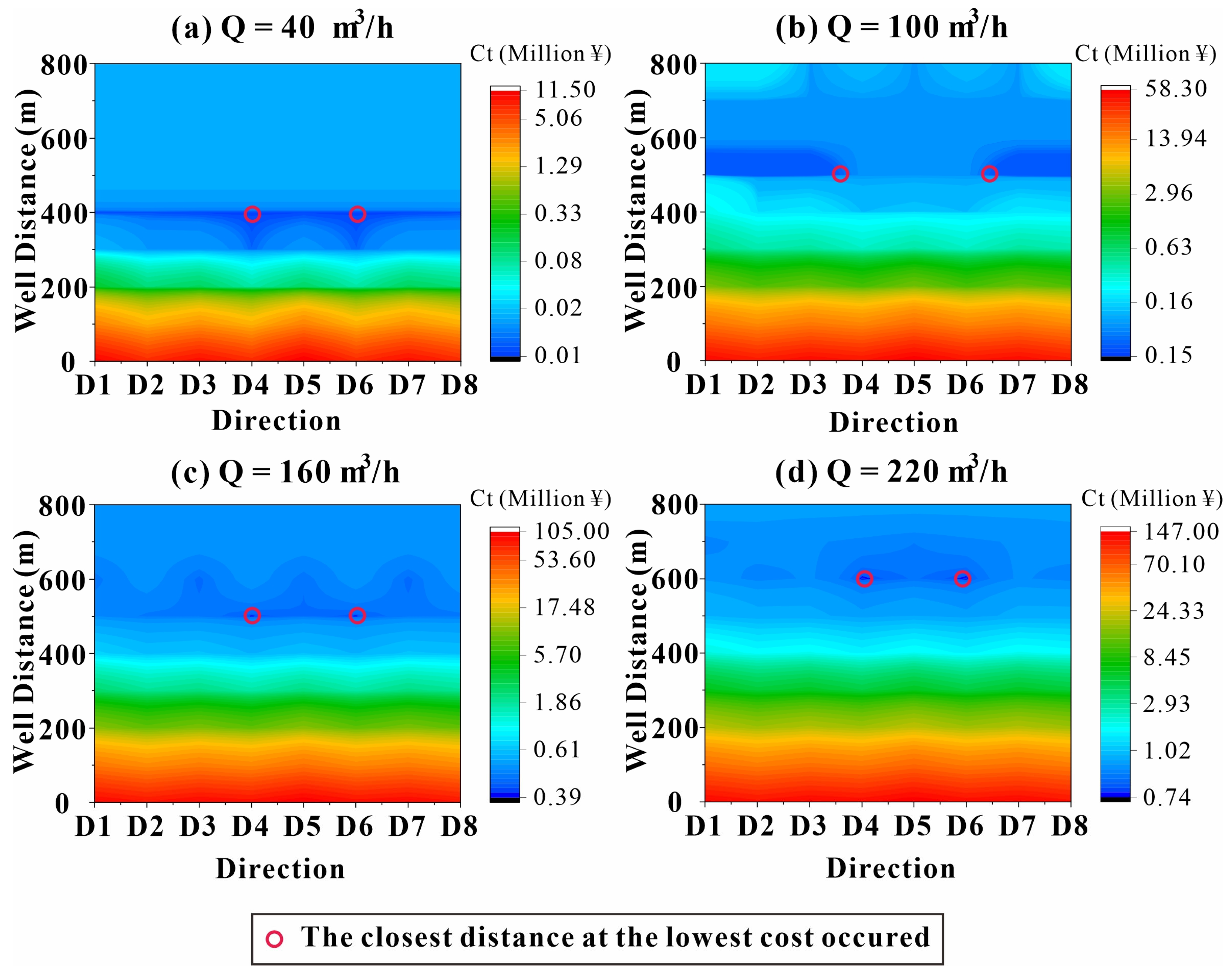

4.4. Analysis of Total Cost

4.5. Optimal Well Placement

- (1)

- There is no thermal breakthrough effect in the reservoir, and the temperature change threshold is 0.1 °C over 50 years;

- (2)

- Under the condition of satisfying (1), the pressure reduction of the reservoir is as small as possible;

- (3)

- Under the condition of satisfying (1) and (2), the heat extraction rate is as high as possible;

- (4)

- Under the condition of satisfying (1), (2), and (3), the operating cost is as low as possible.

5. Discussion

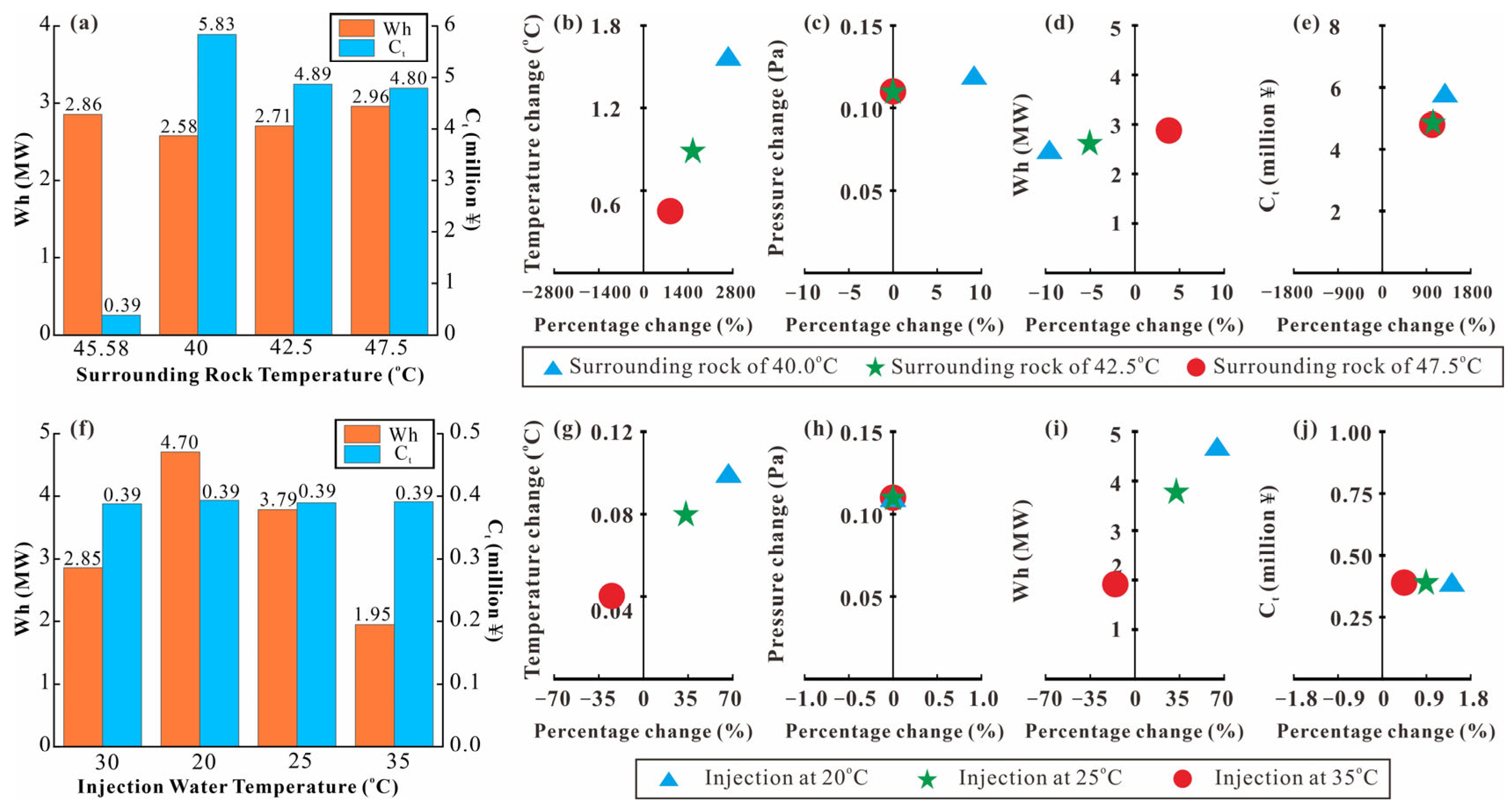

5.1. Sensitivity Analysis

- (1)

- Surrounding rock temperature

- (2)

- Injection water temperature

5.2. Setup and Structure of BPNN

- (1)

- Input series: angle (°), well distance (m), injection temperature (°C), and injection flow rate (m3/h);

- (2)

- Target series: the stable temperature at the production well (°C), stable pressure at the production well (Pa), heat extraction rate (MW), and total operating cost (million ¥).

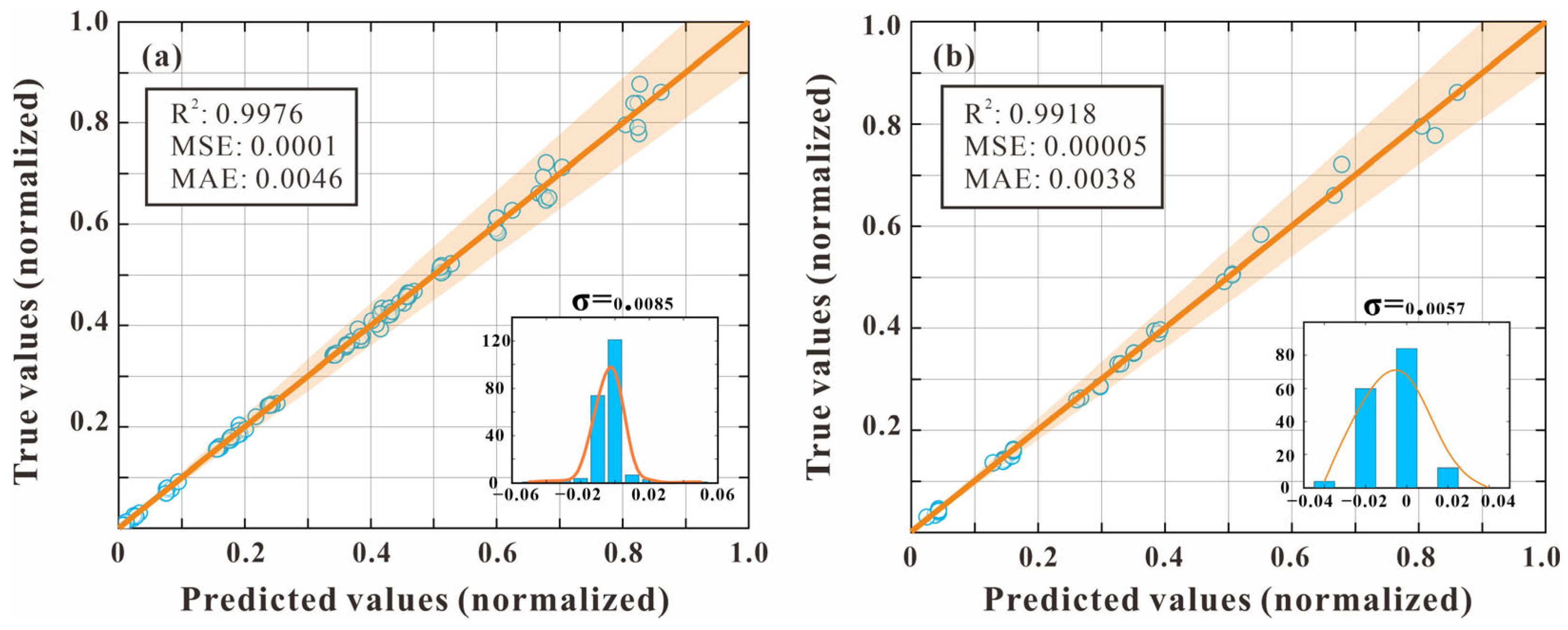

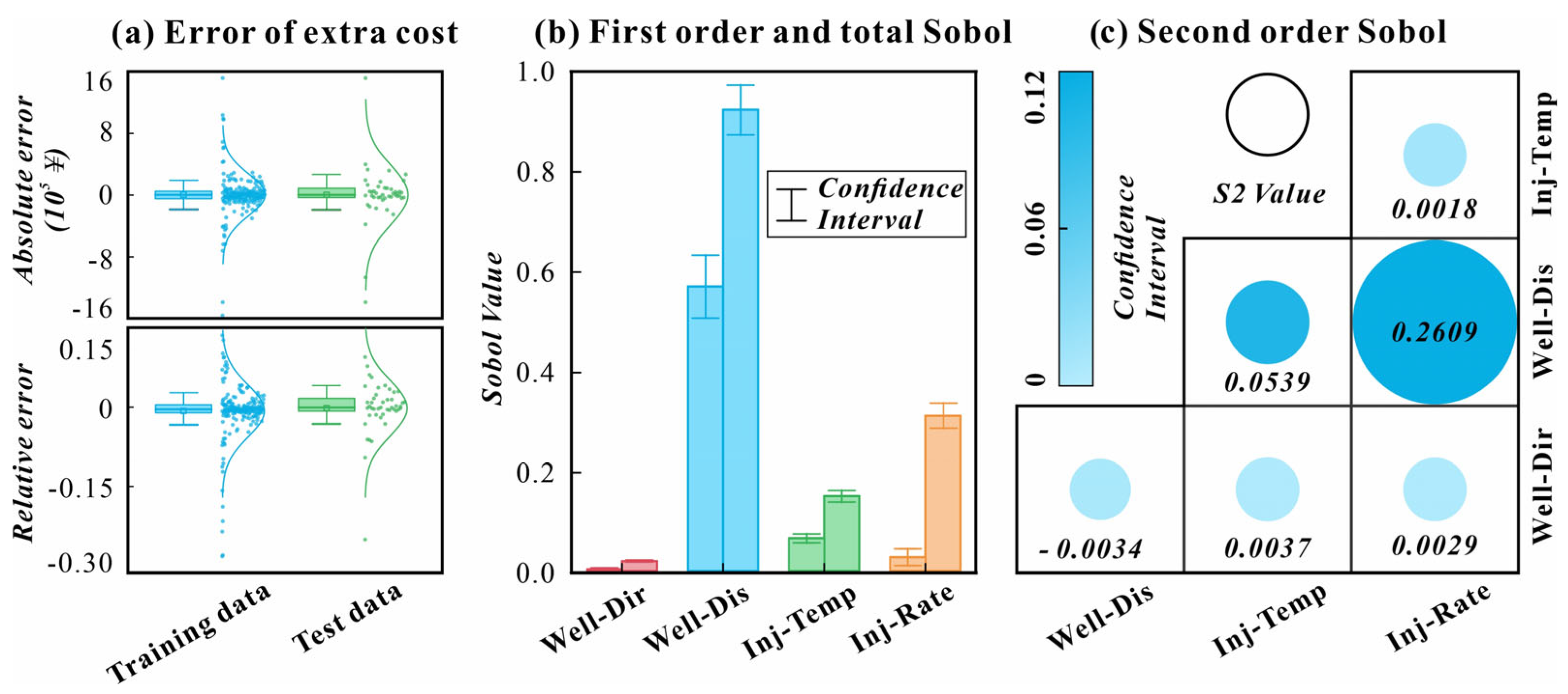

5.3. BPNN Learning Process and Results

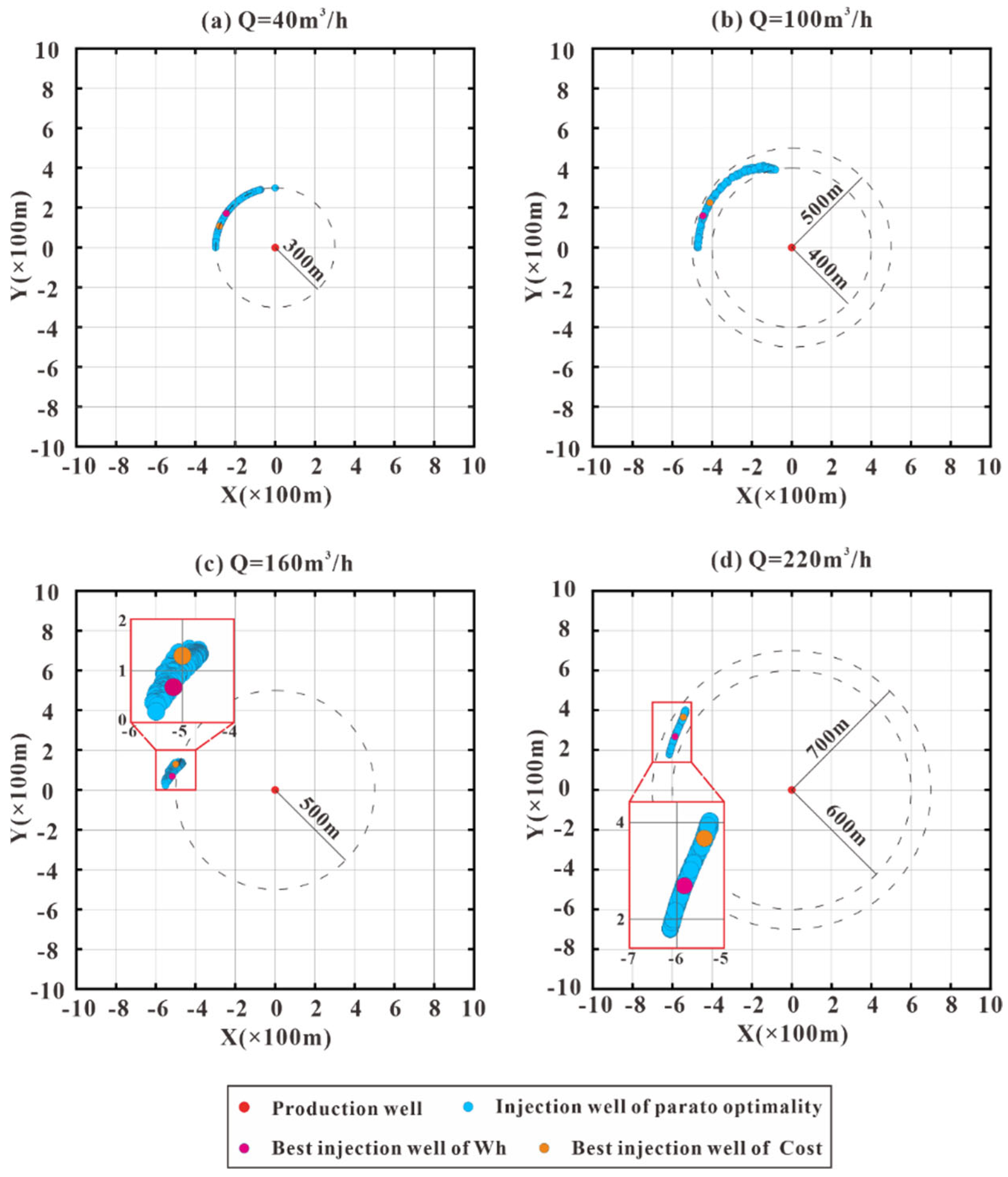

5.4. Optimization by Genetic Algorithm

5.5. Limitations of the Study

- (1)

- Samples are critical for training surrogate models. Training samples of high quality and adequate capacity can facilitate the training process, increase flexibility and prediction accuracy, and minimize the problem of difficult convergence and over-fitting [48,49] of the model. In the selection of sample points, various random selection methods, such as Latin hypercube sampling [49,50], may increase the sample quality when compared to the project’s uniform division and selection. Simultaneously, the project has the potential to further minimize the change gradient and enhance sample capacity in terms of production (injection) flow rate, well distance, and injection angle setting;

- (2)

- In this study, a set of Pareto optimal solutions is obtained by GA optimization. Theoretically, every solution in this set is the optimal solution under the goal equation [51]. However, in engineering applications, this set of solutions must be further optimized based on individual conditions, which increases the difficulty in decision-making. There are two solutions: (a) in future work, the possible situations are written into the constraints of the GA algorithm before optimization; and (b) other more advanced and flexible multi-objective optimization algorithms, such as the wolf pack algorithm [52] and simulated annealing algorithm [53,54,55], are chosen for optimization;

- (3)

- In this study, the work area is chosen from the Panzhuang Uplift area in Tianjin, and the assumption of strata homogeneity is applied. Specifically, the assumption of reservoir homogeneity is not based solely on the averaging of actual site parameters, but rather an equivalent porous medium approach is used to construct the conceptual model of the experimental site. This method utilizes real pumping test results and, based on the concept of reservoir homogenization, derives the overall effect of the reservoir on the water production capacity of the production wells, which is reflected in the porosity and permeability. This approach has been widely applied in both practical engineering and research. However, as the production time increases, particularly with the injection of low-temperature tail water through injection wells, the temperature at the production well may be affected, leading to thermal breakthrough. Due to the homogenized reservoir assumption overly idealizing the diffusion process of the low-temperature tailwater plume, it neglects the impact of permeability heterogeneity on the diffusion process. As a result, there are limitations in determining the timing of thermal breakthrough. Future research will explore the effects of different pore-permeability configurations on the model, considering homogeneous, heterogeneous, and fault-affected scenarios, in order to further enhance the adaptability and accuracy of the model;

- (4)

- In this study, the economic calculations were based on an exit equation, which focuses on the contribution of changes in temperature and head within the reservoir to operating costs, while simplifying the impact of societal depreciation rates on the extra cost calculations. This approach is reasonable and feasible in practical engineering and economic calculations. However, since this study is primarily concerned with prediction, forecasting fluctuations in energy prices and environmental changes presents significant challenges. Due to these limitations, future research will seek to introduce alternative methods to more comprehensively consider the impacts of energy price fluctuations and environmental changes on the extra costs of well exploitation.

6. Conclusions

- (1)

- An optimization strategy for the well system layout is proposed based on changes in reservoir temperature, pressure, and project operation cost. The optimal well placement for the geothermal reservoir well-doublet production system in North China is determined: the injection well should be positioned downstream of the production well, with a well distance of 500 m, and staggered relative to the natural flow field;

- (2)

- The simulation results from the hydro–thermal coupling model show that the production (injection) flow rate and surrounding rock temperature significantly influence the optimal well placement. When the production (injection) flow rate is high, the optimal well distance increases notably. For a production (reinjection) flow rate of 220 m3/h, the well distance can reach up to 600 m. Small changes in the surrounding rock temperature have a large impact on the geothermal fluid temperature in the production well. Therefore, it is crucial to minimize potential interference from adjacent thermal reservoir temperatures during production;

- (3)

- The substitution model trained by BPNN demonstrates a prediction accuracy of over 99%, with a normalized error of no more than 0.06. This model significantly reduces the calculation load and enhances portability, while providing guidance for optimizing the placement of geothermal well-doublets in geothermal reservoir production.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | |

| specific heat capacity of geothermal fluid, J·kg−1·K−1 | |

| total economic cost, million ¥ | |

| well distance between the production well and injection well, m | |

| counterclockwise Radian relative to east, o | |

| error of the output node of BPNN | |

| circulation variable | |

| MSE | mean squared error |

| MAE | mean absolute error |

| capacity of scheme | |

| N | simulated production time, year |

| -th node in the output layer of BPNN | |

| market electricity price, ¥ | |

| market heat price, ¥ | |

| pressure at the bottom of the production well, Pa | |

| initial pressure at the bottom of the production well, Pa | |

| sinks and sources, kg·m−3·s−1 | |

| flow rate of production and injection well, m3·s−1 | |

| flow rate of the production well, kg·s−1 | |

| depreciation rate | |

| R2 | R-Square |

| time, s | |

| expected value of the output node of BPNN | |

| temperature, °C | |

| initial temperature at the bottom of the production well, °C | |

| weight between the l-th node of input layer and i-th node of hidden layer of BPNN | |

| heat extract rate, MW | |

| -th node in the input layer of BPNN | |

| -th node in the input layer of BPNN | |

| observed value | |

| predicted value | |

| average value | |

| Greek symbol | |

| heat utilization efficiency | |

| -th threshold value in the hidden layer | |

| -th threshold value in the hidden layer | |

| fluid density, kg·m−3 | |

| geothermal fluid density, kg·m−3 | |

| weight between the i-th node of the input layer and j-th node of the hidden | |

| Others | |

| change in water head, m | |

| pressure change, Pa | |

| temperature change, K | |

References

- Huenges, E.; Ledru, P. Reservoir Definition. In Geothermal Energy Systems: Exploration, Development, and Utilization; Huenges, E., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011; Volume 1, pp. 1–2. [Google Scholar]

- Song, G.; Song, X.; Li, G.; Shi, Y.; Wang, G.; Ji, J.; Xu, F.; Song, Z. An integrated multi-objective optimization method to improve the performance of multilateral-well geothermal system. Renew. Energy 2021, 172, 1233–1249. [Google Scholar] [CrossRef]

- Limberger, J.; Boxem, T.; Pluymaekers, M.; Bruhn, D.; Manzella, A.; Calcagno, P.; Beekman, F.; Cloetingh, S.; van Wees, J.-D. Geothermal energy in deep aquifers: A global assessment of the resource base for direct heat utilization. Renew. Sustain. Energy Rev. 2018, 82, 961–975. [Google Scholar] [CrossRef]

- Bu, X.; Ran, Y.; Zhang, D. Experimental and simulation studies of geothermal single well for building heating. Renew. Energy 2019, 143, 1902–1909. [Google Scholar] [CrossRef]

- Li, F.; Guo, X.; Qi, X.; Feng, B.; Liu, J.; Xie, Y.; Gu, Y. A Surrogate Model-Based Optimization Approach for Geothermal Well-Doublet Placement Using a Regularized LSTM-CNN Model and Grey Wolf Optimizer. Sustainability 2025, 17, 266. [Google Scholar] [CrossRef]

- Lei, H.; Zhu, J. Numerical modeling of exploitation and reinjection of the Guantao geothermal reservoir in Tanggu District, Tianjin, China. Geothermics 2013, 48, 60–68. [Google Scholar] [CrossRef]

- Li, S.; Wen, D.; Feng, B.; Li, F.; Yue, D.; Zhang, Q.; Wang, J.; Feng, Z. Numerical optimization of geothermal energy extraction from deep karst reservoir in North China. Renew. Energy 2023, 202, 1071–1085. [Google Scholar] [CrossRef]

- An, Q.; Wang, Y.; Zhao, J.; Luo, C.; Wang, Y. Direct utilization status and power generation potential of low-medium temperature hydrothermal geothermal resources in Tianjin, China: A review. Geothermics 2016, 64, 426–438. [Google Scholar] [CrossRef]

- Akin, S. Geothermal re-injection performance evaluation using surveillance analysis methods. Renew. Energy 2019, 139, 635–642. [Google Scholar] [CrossRef]

- Ding, J.; Wang, S. 2D modeling of well array operating enhanced geothermal system. Energy 2018, 162, 918–932. [Google Scholar] [CrossRef]

- Cheng, W.; Wang, C.; Nian, Y.; Han, B.; Liu, J. Analysis of influencing factors of heat extraction from enhanced geothermal systems considering water losses. Energy 2016, 115, 274–288. [Google Scholar] [CrossRef]

- Murphy, H.; Brown, D.; Jung, R.; Matsunaga, I.; Parker, R. Hydraulics and well testing of engineered geothermal reservoirs. Geothermics 1999, 28, 491–506. [Google Scholar] [CrossRef]

- McDermott, C.I.; Randriamanjatosoa, A.R.L.; Tenzer, H.; Kolditz, O. Simulation of heat extraction from crystalline rocks: The influence of coupled processes on differential reservoir cooling. Geothermics 2006, 35, 321–344. [Google Scholar] [CrossRef]

- Jiang, P.; Li, X.; Xu, R.; Zhang, F. Heat extraction of novel underground well pattern systems for geothermal energy exploitation. Renew. Energy 2016, 90, 83–94. [Google Scholar] [CrossRef]

- Zeng, Y.C.; Tang, L.S.; Wu, N.Y.; Cao, Y.F. Analysis of influencing factors of production performance of enhanced geothermal system: A case study at Yangbajing geothermal field. Energy 2017, 127, 218–235. [Google Scholar] [CrossRef]

- Shaik, A.R.; Rahman, S.S.; Tran, N.H.; Tran, T. Numerical simulation of Fluid-Rock coupling heat transfer in naturally fractured geothermal system. Appl. Therm. Eng. 2011, 31, 1600–1606. [Google Scholar] [CrossRef]

- Liu, G.; Pu, H.; Zhao, Z.; Liu, Y. Coupled thermo-hydro-mechanical modeling on well pairs in heterogeneous porous geothermal reservoirs. Energy 2019, 171, 631–653. [Google Scholar] [CrossRef]

- Zhou, X.; Gao, Q.; Chen, X.; Yu, M.; Zhao, X. Numerically simulating the thermal behaviors in groundwater wells of groundwater heat pump. Energy 2013, 61, 240–247. [Google Scholar] [CrossRef]

- Asai, P.; Panja, P.; McLennan, J.; Deo, M. Effect of different flow schemes on heat recovery from Enhanced Geothermal Systems (EGS). Energy 2019, 175, 667–676. [Google Scholar] [CrossRef]

- Schulte, D.O.; Arnold, D.; Geiger, S.; Demyanov, V.; Sass, I. Multi-objective optimization under uncertainty of geothermal reservoirs using experimental design-based proxy models. Geothermics 2020, 86, 101792. [Google Scholar] [CrossRef]

- Zhang, C.; Jiang, G.; Jia, X.; Li, S.; Zhang, S.; Hu, D.; Hu, S.; Wang, Y. Parametric study of the production performance of an enhanced geothermal system: A case study at the Qiabuqia geothermal area, northeast Tibetan plateau. Renew. Energy 2019, 132, 959–978. [Google Scholar] [CrossRef]

- Blank, L.; Meneses Rioseco, E.; Caiazzo, A.; Wilbrandt, U. Modeling, simulation, and optimization of geothermal energy production from hot sedimentary aquifers. Comput. Geosci. 2020, 25, 67–104. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Jiang, Z.; Zhang, S.S.; Zhang, Q.; Feng, G. Well placement optimization for large-scale geothermal energy exploitation considering nature hydro-thermal processes in the Gonghe Basin, China. J. Clean. Prod. 2021, 317, 128391. [Google Scholar] [CrossRef]

- Helgason, D. Algorithm for Optimal Well Placement in Geothermal Systems Based on TOUGH2 Models. Ph.D. Thesis, Reykjavík University, Reykjavik, Iceland, 2017. [Google Scholar]

- Rajabi, M.M.; Chen, M. Simulation-optimization with machine learning for geothermal reservoir recovery: Current status and future prospects. Adv. Geo-Energy Res. 2022, 6, 451–453. [Google Scholar] [CrossRef]

- Akın, S.; Kok, M.V.; Uraz, I. Optimization of well placement geothermal reservoirs using artificial intelligence. Comput. Geosci. 2010, 36, 776–785. [Google Scholar] [CrossRef]

- Tselepidou, K.; Katsifarakis, K.L. Optimization of the exploitation system of a low enthalpy geothermal aquifer with zones of different transmissivities and temperatures. Renew. Energy 2010, 35, 1408–1413. [Google Scholar] [CrossRef]

- Zhang, L.; Deng, Z.; Zhang, K.; Long, T.; Desbordes, J.; Sun, H.; Yang, Y. Well-Placement Optimization in an Enhanced Geothermal System Based on the Fracture Continuum Method and 0-1 Programming. Energies 2019, 12, 709. [Google Scholar] [CrossRef]

- Chen, H.; Feng, Q.; Zhang, X.; Wang, S.; Zhou, W.; Geng, Y. Well placement optimization using an analytical formula-based objective function and cat swarm optimization algorithm. J. Pet. Sci. Eng. 2017, 157, 1067–1083. [Google Scholar] [CrossRef]

- Saffari, H.; Sadeghi, S.; Khoshzat, M.; Mehregan, P. Thermodynamic analysis and optimization of a geothermal Kalina cycle system using Artificial Bee Colony algorithm. Renew. Energy 2016, 89, 154–167. [Google Scholar] [CrossRef]

- Buster, G.; Siratovich, P.; Taverna, N.; Rossol, M.; Weers, J.; Blair, A.; Huggins, J.; Siega, C.; Mannington, W.; Urgel, A.; et al. A New Modeling Framework for Geothermal Operational Optimization with Machine Learning (GOOML). Energies 2021, 14, 6852. [Google Scholar] [CrossRef]

- Gudala, M.; Govindarajan, S.K. Numerical investigations on a geothermal reservoir using fully coupled thermo-hydro-geomechanics with integrated RSM-machine learning and ARIMA models. Geothermics 2021, 96, 102174. [Google Scholar] [CrossRef]

- Yu, F.; Xu, X. A short-term load forecasting model of natural gas based on optimized genetic algorithm and improved BP neural network. Appl. Energy 2014, 134, 102–113. [Google Scholar] [CrossRef]

- Zhang, B.; Guo, S.; Jin, H. Production forecast analysis of BP neural network based on Yimin lignite supercritical water gasification experiment results. Energy 2022, 246, 123306. [Google Scholar] [CrossRef]

- Zhang, J.-R.; Zhang, J.; Lok, T.-M.; Lyu, M.R. A hybrid particle swarm optimization–back-propagation algorithm for feedforward neural network training. Appl. Math. Comput. 2007, 185, 1026–1037. [Google Scholar] [CrossRef]

- Chen, M. Study on Hydro-Thermo-Mechanical Coupling Numerical Simulation of Sand-Stone Thermal Reservoir in Panzhuang Uplift Area, Tianjin City. Ph.D. Thesis, Jilin University, Changchun, China, 2020. [Google Scholar]

- Pruess, K.; Oldenburg, C.; Moridis, G. TOUGH2 User’s Guide Version 2; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 1999. [Google Scholar]

- Li, F.; Xu, T.; Feng, G.; Yuan, Y.; Zhu, H.; Feng, B. Simulation for water-heat coupling process of single well ground source heat pump systems implemented by T2well. Acta Energiae Solaris Sin. 2020, 41, 9. [Google Scholar]

- Kong, Y.; Pang, Z.; Shao, H.; Kolditz, O. Optimization of well-doublet placement in geothermal reservoirs using numerical simulation and economic analysis. Environ. Earth Sci. 2017, 76, 118. [Google Scholar] [CrossRef]

- Liu, C.; Ling, J.; Kou, L. Performance Comparison between GA-BP Neural Network and BP Neural Network. Chin. J. Health Stat. 2013, 30, 173. [Google Scholar]

- Fu, Q. Water Resources System Analysis; China Water & Power Press: Beijing, China, 2012. [Google Scholar]

- Liang, X.; Xu, T.F.; Feng, B.; Jiang, Z.J. Optimization of heat extraction strategies in fault-controlled hydro-geothermal reservoirs. Energy 2018, 164, 853–870. [Google Scholar] [CrossRef]

- National Development and Reform Commission & Ministry of Construction. Methods and Parameters for Economic Evaluation of Construction Projects, 3rd ed.; China Planning Press: Beijing, China, 2008.

- Tianjin Development and Reform Commission. Tianjin Residential and Agricultural Electricity Sales Price Meter. Available online: https://fzgg.tj.gov.cn/zmhd/gzcx/syjgcx/gd/202202/t20220217_5806380.html (accessed on 11 March 2025).

- Tianjin Development and Reform Commission. Heating Price. Available online: https://fzgg.tj.gov.cn/zmhd/gzcx/syjgcx/gr/202009/t20200923_3807284.html (accessed on 11 March 2025).

- Lund, J.W.; Freeston, D.H. World-wide direct uses of geothermal energy 2000. Geothermics 2001, 30, 29–68. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, Z.; Liu, G.; Xu, H. A robust optimization approach of well placement for doublet in heterogeneous geothermal reservoirs using random forest technique and genetic algorithm. Energy 2022, 254, 124427. [Google Scholar] [CrossRef]

- Shorten, C.; Khoshgoftaar, T.M. A survey on Image Data Augmentation for Deep Learning. J. Big Data 2019, 6, 48. [Google Scholar] [CrossRef]

- Helton, J.C.; Johnson, J.D.; Sallaberry, C.J.; Storlie, C.B. Survey of sampling-based methods for uncertainty and sensitivity analysis. Reliab. Eng. Syst. Saf. 2006, 91, 1175–1209. [Google Scholar]

- Helton, J.C.; Davis, F.J. Latin hypercube sampling and the propagation of uncertainty in analyses of complex systems. Reliab. Eng. Syst. Saf. 2003, 81, 23–69. [Google Scholar]

- Zhou, A.M.; Qu, B.Y.; Li, H.; Zhao, S.Z.; Suganthan, P.N.; Zhang, Q.F. Multiobjective evolutionary algorithms: A survey of the state of the art. Swarm Evol. Comput. 2011, 1, 32–49. [Google Scholar] [CrossRef]

- Dhargupta, S.; Ghosh, M.; Mirjalili, S.; Sarkar, R. Selective Opposition based Grey Wolf Optimization. Expert Syst. Appl. 2020, 151, 13. [Google Scholar]

- He, C.L.; Yan, J.W.; Wang, S.Q.; Zhang, S.; Chen, G.; Ren, C.Z. A theoretical and deep learning hybrid model for predicting surface roughness of diamond-turned polycrystalline materials. Int. J. Extrem. Manuf. 2023, 5, 25. [Google Scholar]

- Long, F.; Liu, H. An integration of machine learning models and life cycle assessment for lignocellulosic bioethanol platforms. Energy Convers. Manag. 2023, 292, 11. [Google Scholar]

- Vijay, D.; Jayashree, R. Sliding Mode Controller Based on Genetic Algorithm and Simulated Annealing for Assured Crew Reentry Vehicle. J. Aerosp. Eng. 2023, 36, 23. [Google Scholar]

| Parameters | Values | Unit |

|---|---|---|

| Aquifer buried depth | 1000 | m |

| Aquifer hydraulic slope | 0.001532 | |

| Aquifer thickness | 400 | m |

| Injection temperature | 30.00 | °C |

| Permeability | 3.385 × 10−13 | m2 |

| Porosity | 0.25 | |

| Skeleton density | 2600 | kg/(m3) |

| Specific heat of rock skeleton | 958 | J/(kg·K) |

| Thermal conductivity of rock skeleton | 2.5 | W/(m·K) |

| Thermal reservoir temperature | 45.58 | °C |

| Parameters/Unit | Values | Unit |

|---|---|---|

| Depreciation rate | 0.08 | |

| Electricity price | 0.515 | ¥/kwh |

| Heat price | 70 | ¥/GJ |

| Thermal utilization ratio | 0.7 |

| Phrase | Models | (×10−7) | ||||

|---|---|---|---|---|---|---|

| Training | BPNN | 0.0046 | 0.00010 | 4.19 | 0.9976 | 0.9991 |

| RF | 0.0211 | 0.00131 | 21.08 | 0.9702 | 0.9851 | |

| SVG | 0.0926 | 0.02249 | 92.63 | 0.4887 | 0.7567 | |

| Test | BPNN | 0.0038 | 0.00005 | 5.76 | 0.9918 | 0.9987 |

| RF | 0.0228 | 0.00189 | 22.82 | 0.8269 | 0.9443 | |

| SVG | 0.0681 | 0.00660 | 68.10 | 0.3935 | 0.6838 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, H.; Guo, X.; Zhang, H.; Feng, B.; Yuan, Y.; Li, F.; Liu, J. A Simulation-Optimization Approach of Geothermal Well-Doublet Placement in North China Using Back Propagation Neural Network and Genetic Algorithm. Water 2025, 17, 911. https://doi.org/10.3390/w17070911

Wei H, Guo X, Zhang H, Feng B, Yuan Y, Li F, Liu J. A Simulation-Optimization Approach of Geothermal Well-Doublet Placement in North China Using Back Propagation Neural Network and Genetic Algorithm. Water. 2025; 17(7):911. https://doi.org/10.3390/w17070911

Chicago/Turabian StyleWei, Hai, Xia Guo, Hongkai Zhang, Bo Feng, Yilong Yuan, Fengyu Li, and Jie Liu. 2025. "A Simulation-Optimization Approach of Geothermal Well-Doublet Placement in North China Using Back Propagation Neural Network and Genetic Algorithm" Water 17, no. 7: 911. https://doi.org/10.3390/w17070911

APA StyleWei, H., Guo, X., Zhang, H., Feng, B., Yuan, Y., Li, F., & Liu, J. (2025). A Simulation-Optimization Approach of Geothermal Well-Doublet Placement in North China Using Back Propagation Neural Network and Genetic Algorithm. Water, 17(7), 911. https://doi.org/10.3390/w17070911