1. Introduction

The increasing volume of wastewater generated globally poses significant environmental and public health challenges, particularly in developing countries where conventional treatment methods often prove impractical due to high costs and energy demands. Constructed wetland systems (CWSs) have emerged as a viable nature-based solution for wastewater treatment, utilizing natural processes involving soil, plants, and microorganisms to effectively remove contaminants [

1]. These systems consist of treatment cells filled with various bedding materials (BMs) and planted with hydrophytes, which play a crucial role in pollutant degradation [

2]. However, the application of CWSs in regions like Pakistan remains limited, primarily due to substantial land requirements and insufficient research on the influence of hydraulic parameters on their performance [

1]. To address these challenges, this study introduced a novel hybrid CWS design that integrated both horizontal and vertical surface flow configurations, aiming to enhance treatment efficiency for complex wastewaters, particularly from the textile industry and municipal sewage.

The emergence of hybrid constructed wetland systems, which integrate both horizontal and vertical surface flow configurations, represents a significant advancement in wastewater treatment technology. These hybrid systems leverage the strengths of both designs, enhancing pollutant removal efficiencies, particularly for heavy metals and organic matter [

1,

2]. By maintaining optimal oxygen levels and promoting diverse microbial communities, hybrid CWSs can adapt to varying flow rates and pollutant loads, making them a robust solution for urban wastewater challenges [

2,

3]. The optimization of hydraulic retention time (HRT) within these systems further contributes to their effectiveness, underscoring the need for site-specific designs tailored to local wastewater characteristics [

4].

A sustainable and operational model of a CWS encompasses appropriate types of BM and hydrophytes to proficiently remove contaminants [

1,

2]. Typically, wastewater is introduced into the treatment cells, permitted to percolate through the BM, and subsequently discharged through the outlet [

3,

4]. The fundamental components of a CWS include the treatment cells, BM, plants, and hydrological processes [

5,

6]. Numerous variables, such as the selection and combinations of hydrophytic species, hydrological conditions, landscape configuration, site-specific design considerations pertaining to the dimensions and form of the wetland system, characteristics of the BM, and operational methodologies, influence the treatment efficacy and optimization of a CWS concerning its treatment performance [

7,

8,

9].

Hydraulic dynamics within CWSs, specifically hydraulic loading rates (HLRs) and hydraulic retention time (HRT), are critical determinants of their treatment efficacy [

9]. Additionally, factors such as the surface area of constructed wetlands, flow rates, and porosity of BMs play a pivotal role in defining the HRT [

9,

10,

11]. A reduction in the HLR enhances the overall treatment efficiency, while an increased HRT facilitates superior contaminant removal [

7,

11,

12,

13,

14]. Consequently, the optimization of HRT duration emerges as an essential component for maximizing pollutant removal performance in constructed wetlands, effectively targeting infectious microorganisms as well [

15,

16,

17].

Despite the recognition of CWSs as an advanced alternative for wastewater treatment, their application in Pakistan remains constrained. While the nation possesses notable expertise in treating various wastewater types using CWSs, this is predominantly on a minor scale. The widespread adoption of CWSs faces a major hurdle due to their substantial land requirements. This issue is aggravated by limited research on the influence of specific hydraulic parameters of the CWS performance across varying climates, coupled with a lack of comprehensive evaluations on the pollutant removal efficiency of different hydrophytic species.

Hydrophytes exhibit a heightened vulnerability to water loss via evapotranspiration (ET), particularly under elevated temperature and wind conditions [

18,

19]. This loss can significantly affect the wastewater volume processed, thereby compromising the efficiency of CWSs in wastewater treatment [

20,

21,

22]. Unlike traditional treatment facilities that account for evaporation in their efficiency calculations, CWSs primarily focus on pollutant concentrations at the intake and outflow stages [

23,

24]. Contaminants such as biochemical oxygen demand (BOD), chemical oxygen demand (COD), total suspended solids (TSS), N, and P are examples of such pollutants [

25,

26]. In CWSs, where ET is often significant, determining pollutant removal efficiency based on concentration measurements can be inaccurate. This is because ET reduces the water content in treatment cells, resulting in higher concentrations of dissolved substances [

18,

27].

By sedimentation, filtration, and adsorption, BMs and constructed wetland hydrophytes filter pollutants out of wastewater. The BMs promote the development of biofilms and maintain the bacteria and plants in CWSs [

3,

17,

28]. For effective treatment efficiency in CWSs, the selection of BMs is essential, for instance, gravel, limestone, coal ash, demolished concrete, clay minerals, and industrial wastes [

29,

30]. The overall treatment efficiency of CWSs is greatly influenced by the physical and chemical characteristics of the BM. The ability of CWSs to eliminate pollutants is enhanced by the high specific surface area of the BM. This enhances the hydrodynamic and mechanical attributes of the CWS and offers microorganisms extra surface area. As a result, the efficacy of CWSs relies on their BMs [

3,

17,

31]. When the hydrophytes establish roots in the BM, they assist gas exchange of the microbial biofilm, accelerating the process of contaminant degradation.

With 280,000 tons of textile dyes emitted yearly into the world’s textile industrial effluent [

32,

33], this industry is among the most important and major sectors globally. The global economy has been affected negatively by the growing environmental degradation brought on by this industry [

34]. Significant volumes of effluents are produced by the various dyeing and finishing procedures employed in the textile dyeing industry. The majority of chemicals, including dyes, only undergo partial treatment, and untreated textile effluent wastewater is released into rivers, rendering the water unfit for human use, agriculture, and aquatic life [

11,

35,

36,

37]. Moreover, numerous dyes prevalent in the textile industry exhibit carcinogenic and toxic properties [

8,

38].

In developing countries like Pakistan, rapid urbanization and industrialization have caused a surge in wastewater volume, threatening both the environment and public health. Although effective, conventional wastewater treatment methods demand high capital, skilled operation, and energy-intensive processes, making them impractical for many resource-limited communities.

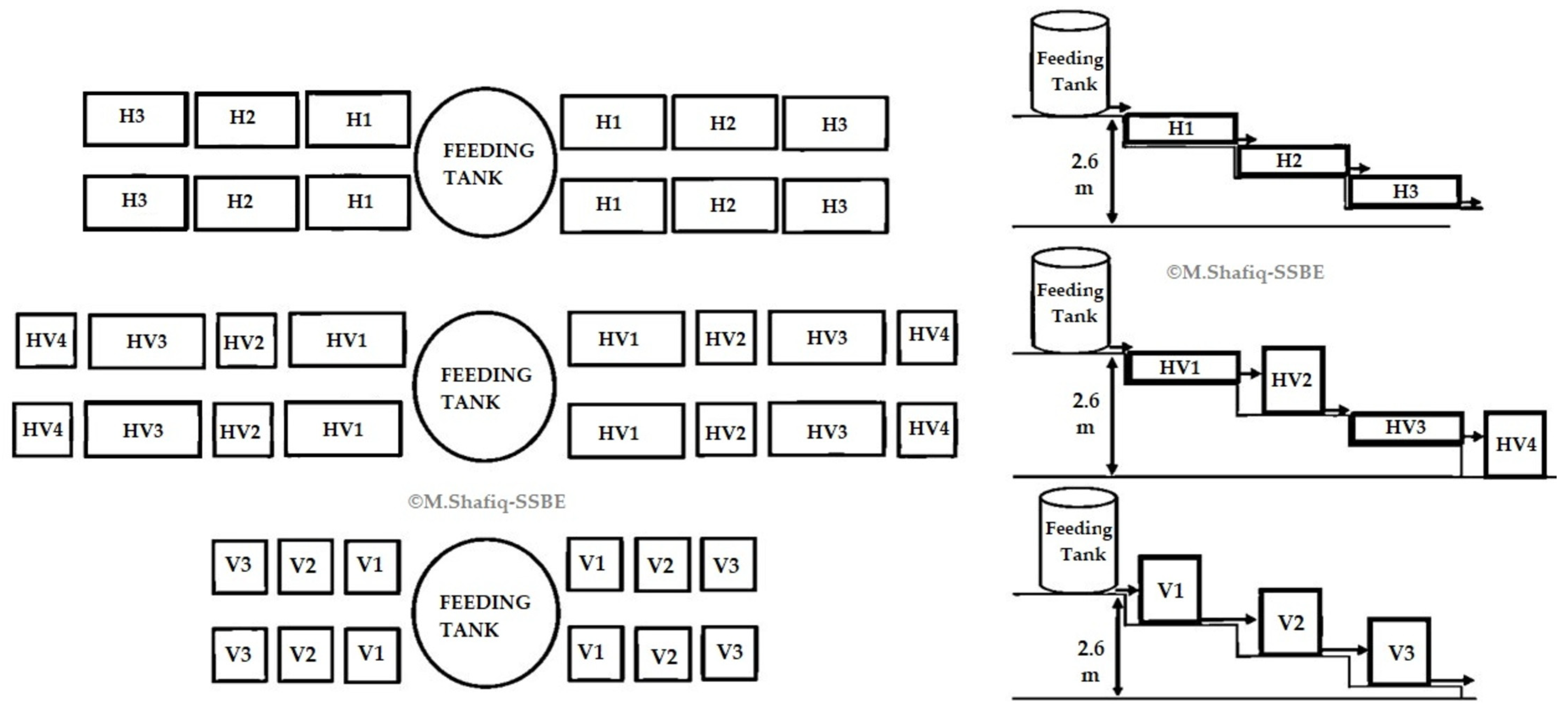

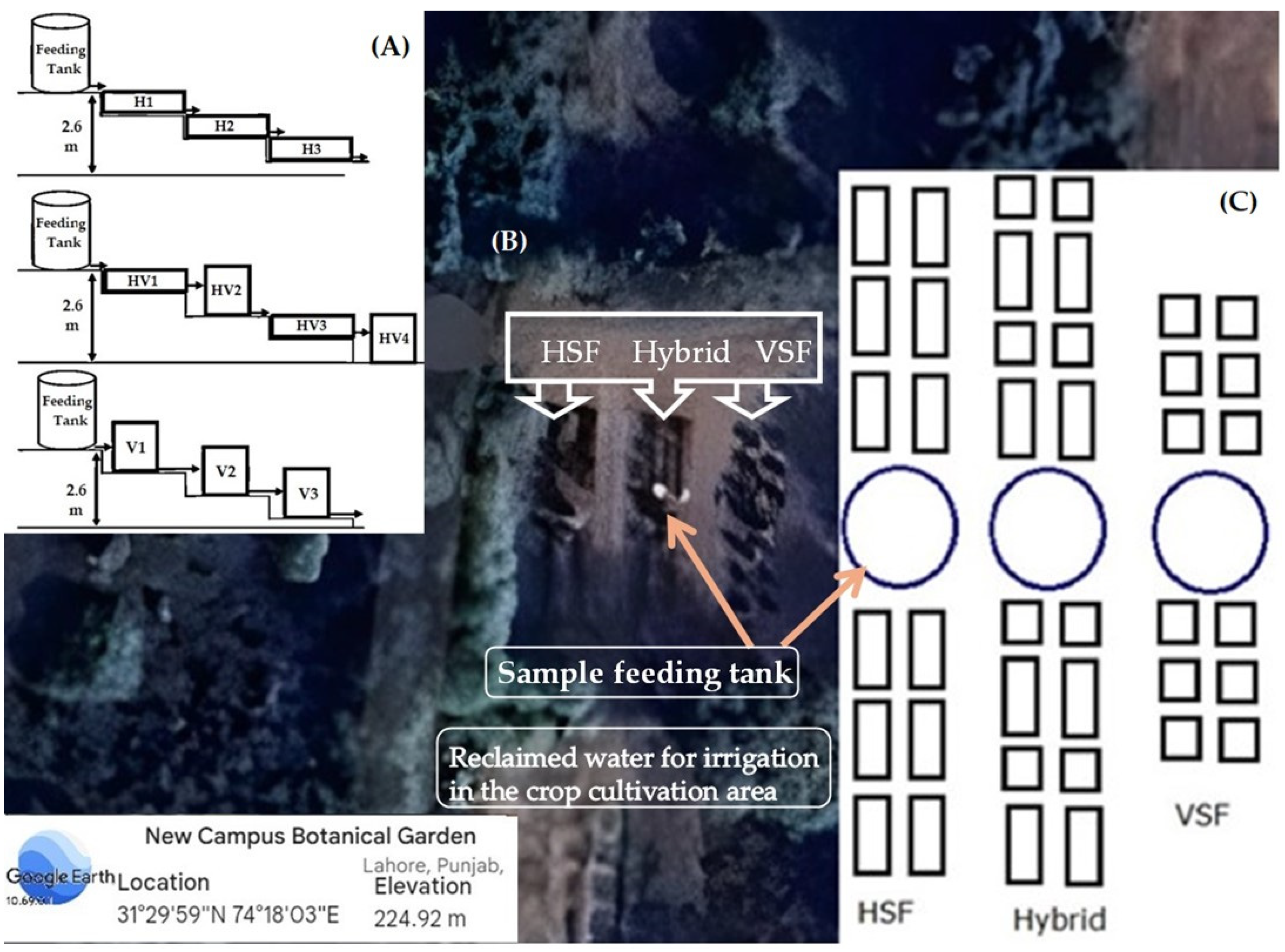

This study addressed the pressing need for sustainable and cost-effective wastewater treatment solutions in developing countries by investigating the performance of different CWS configurations (HSF, VSF, and hybrid) for treating both domestic sewage and textile effluents. The research specifically focuses on optimizing key design and operational parameters, including hydrophyte species selection, bedding material type, hydraulic retention time, and flow configuration, to maximize the pollutant removal efficiency and minimize the environmental impact.

By identifying the most effective CWS configuration and optimizing its performance, this research aims to provide valuable insights for the development and implementation of sustainable and affordable wastewater treatment solutions in resource-limited settings, contributing to improved environmental quality and public health in developing countries.

The objectives of this study were designed to enhance the understanding and effectiveness of CWS for wastewater treatment. First, the study aimed to evaluate the physicochemical characteristics of sewage and textile effluents, focusing on parameters such as pH, COD, total suspended solids (TSS), and heavy metal concentrations to establish baseline data for treatment performance. Second, it compared the pollutant removal efficiencies of hybrid CWSs against horizontal surface flow (HSF) and vertical surface flow (VSF) systems, specifically analyzing the removal rates of organic matter and heavy metals. The research also determined the optimal HRT for maximum removal efficiency of specific pollutants in hybrid CWSs, identifying conditions that led to enhanced treatment outcomes. Additionally, the study investigated the influence of different bedding materials on the performance of hybrid CWSs, aiming to identify the most effective combinations for pollutant removal. By refining these objectives, the study aimed to provide clearer guidance for its methodology and enhance its relevance to real-world applications.

This study introduced a novel hybrid CWS design, which is an innovative approach to enhance the treatment efficiency for heavy metals and organic matter. The research demonstrated significant improvements in contaminant removal addressing the challenges posed by complex wastewaters from textile industries and sewage. Furthermore, the study investigated hydraulic retention time in optimizing pollutant removal, revealing an optimal range for specific effluents. The findings emphasized the need for site-specific designs tailored to local conditions and the potential for scaling up hybrid CWS designs in resource-limited settings, providing environmental sustainability in wastewater management.

4. Discussion

The study provided valuable insights into the optimization of constructed wetlands, emphasizing the interplay between design factors, operational parameters, and the selection of materials and plant species in achieving effective wastewater treatment. The hybrid CWS demonstrated a significant reduction in various pollutants, including TSS, TKN, and NaCl concentrations, and heavy metals. This highlighted the CWS ability to address multiple wastewater contaminants.

The presence of a diverse microbial community within the hybrid CWS, when compared with HSF or VSF systems likely contributed to the corresponding enhanced treatment efficiency. Previous research has indicated that the strategic combination of CWS configurations, such as integrating a vertical flow unit followed by a horizontal flow unit, can yield improved nutrient removal, particularly in terms of nitrogen [

43]. Through rigorous experimentation, valuable insights into the factors influencing the performance of these systems showed a decline in removal efficiency during the later stages of treatment.

The observed reduction in BOD and COD concentrations in hybrid CWSs was significant, particularly at lower pollutant levels. This finding aligned with previous research that indicated constructed wetlands were effective in treating wastewater due to their ability to utilize microbial processes for organic matter degradation [

44,

45,

46]. However, as concentrations increased, the correlation shifted, suggesting a saturation effect where microbial activity became less efficient. This phenomenon has been documented in other studies, which noted that high pollutant loads can inhibit microbial growth and activity, leading to diminished treatment performance [

47,

48].

The majority of pollutants are typically removed during the initial stages of treatment within the CWS. This is due to the rapid adsorption, precipitation, and biodegradation of readily available contaminants by the diverse microbial communities and the high surface area provided by the CWS. Second, the performance of the hydrophytes in pollutant removal can diminish over time due to various factors [

49]. The wetland plants may experience stress, nutrient deficiencies, or the accumulation of toxins in their tissues over the course of the treatment process. These physiological changes can negatively impact on the plants’ ability to uptake and sequester pollutants, leading to a gradual decline in the overall pollutant removal efficiency of the CWS. Additionally, the gradual clogging and fouling of the CWS media can also contribute to the reduced performance observed in the later stages of treatment. This pattern is consistent with findings from other studies that have reported a gradual reduction in pollutant removal over time due to factors such as clogging, fouling, and accumulation of organic matter [

9,

50].

Previous studies have shown that pollutant removal from wastewater generally increases with increasing hydraulic retention time up to an optimal point, after which it gradually declines. This trend is often observed due to factors such as the saturation of treatment mechanisms, potential clogging or fouling of the system, and the limited capacity of the wetland plants and microorganisms to continue removing pollutants at a high rate over extended periods [

17,

51,

52,

53].

The superior performance of hybrid CWS in removing metals like Cu and Cd compared with HSF and VSF systems can be attributed to several factors. This system utilizes a combination of treatment mechanisms, including adsorption onto the wetland media, precipitation through chemical reactions, and uptake by the wetland plants [

51,

54].

The hybrid CWS features a surface water zone that promotes the establishment of diverse microbial communities. These microorganisms actively engage in bioaccumulation and biodegradation processes, significantly contributing to the removal of metals. The increased surface area of the hybrid CWS creates a more favourable habitat for these microbial populations, enhancing their activity and, consequently, improving the metal removal efficiency compared with the HSF and VSF systems, which have limited surface water interactions [

55,

56]. Direct uptake of metals by plant roots further contributes to their extraction from the wastewater. The synergistic relationship between plants and microbes is more pronounced in the hybrid CWS, leading to improved metal removal [

23,

57].

However, chromium (Cr) removal exhibited a different pattern. While the hybrid flow CWS demonstrated significantly better Cr removal overall compared with the HSF system, the mechanisms effective for Cu and Cd removal in the hybrid CWS might not be as efficient for Cr. This suggests that specific mechanisms or adaptations may be required for optimal Cr removal within the hybrid CWS design [

58].

Mixed-cultured treatment cells within the hybrid CWS design achieved superior RE for almost all pollutants in both effluents. This aligns with the understanding that diverse microbial communities in the rhizosphere of hydrophytes can break down a wider range of pollutants compared with monocultures. This finding emphasizes the critical importance of developing a rich microbial environment within the hybrid CWS for effective treatment of both sewage and textile effluents [

16,

57,

59,

60].

This trend was observed in the current study. Organic pollution and TKN exhibited relatively high removal across all hydraulic retention times, suggesting a strong degrading capability within the constructed wetland system. Notably, the TSS RE was highest at short HRTs and declined at longer HRTs [

61]. This decrease in TSS removal at longer HRTs may be attributed to optimized ET loss during shorter retention periods. While longer HRTs allow for more complete treatment, they also provide more time for the settlement of suspended solids, potentially leading to their resuspension in the water column at longer retention times [

55,

62]. Optimizing the HRT is crucial for balancing pollutant degradation with solids management within the CWS [

21,

30].

Glass beads, owing to their uniform size, create more space for the development of a robust biofilm. This enables intimate contact between the wastewater and the entire biofilm surface, leading to significant degradation of organic waste and maximizing the reduction in BOD and COD. Glass beads offer several advantages: they represent a one-time investment, provide an inert surface that is easy to clean and maintain, and foster the formation of better and thicker biofilms, facilitating rapid degradation of organic load. These characteristics contribute to more efficient metal removal, likely due to adsorption on the biofilm. Consequently, this study advocates for the use of glass beads to improve metal removal within CWS systems. The working of a CWS depends on the type of bedding material and the health of biofilms formed [

17]. It is the bedding material that keeps the plants and microbes alive in constructed wetlands [

3].

The biofilm causes a pronounced degradation of organic waste, causing more than 70% of reduction in BOD and COD in the cells. Even the cost of glass beads is not much in terms of the fact that it is a single-time investment. Glass beads provide inert surfaces, are easy to clean and wash, and form better and thicker biofilms, which facilitate a quick degradation of organic load. Even the metals are removed at a faster pace due to adsorption on the biofilm. So, this study proposes the use of glass beads for better removal efficiency in all types of wastewaters. Previous studies have shown biofilm formation on the surface of the wetland media to be instrumental in the degradation of organic matter and other pollutants making it a crucial factor in the performance of constructed wetlands [

63,

64].

This study presented a comprehensive examination of the factors influencing the successful performance of the hybrid CWS. It delved into the pivotal role of the impact of HRT and the advantages of utilizing glass beads as a BM. Additionally, the research highlighted the significance of considering the unique characteristics of target pollutants and optimizing design parameters to achieve optimal treatment efficiency. This work contributes to a deeper understanding of the hybrid CWS and its potential for effective wastewater treatment.

The correlations between organic, inorganic and metal contaminants in textile and sewage effluents can be understood through various mechanisms that govern their removal in CWSs. Organic contaminants, measured as BOD, are primarily broken down by microorganisms (bacteria and fungi) in CWSs [

62]. Hydrophytes enhance this process by providing surfaces for microbial colonization and facilitating oxygen transfer through their roots, which is essential for aerobic degradation. Previous studies showed hydrophytes and microbial degradation work symbiotically in constructed wetlands to improve wastewater treatment efficiency [

65,

66].

Inorganic contaminants, such as N and P are removed through biological uptake and chemical precipitation. Nitrifying bacteria assist in the removal of N, while P precipitates with metal ions in the bedding materials, removing it from the wastewater. Heavy metals like Cd, Cu, and Pb are removed via adsorption, precipitation and plant uptake. Bedding materials with high surface area and specific chemical properties enhance adsorption, while hydrophytes uptake metals through their roots, accumulating them in plant tissues and reducing their concentration in the water. Organic matter breakdown releases nutrients (N and P), which promote the growth of hydrophytes and microbial communities, improving the removal of contaminants [

52,

53,

55,

62]. However, heavy metals can inhibit microbial activity, slowing organic matter degradation. Phosphorus precipitation with metal ions can be influenced by the presence of organic matter, which alters the pH and ionic strength of the effluent, affecting metal solubility and adsorption. The removal of organic, inorganic, and metal contaminants in CWSs involves interconnected biological, chemical, and physical mechanisms. A holistic approach is essential for optimizing wastewater treatment processes [

50,

57,

58].

In summary, the current study provided insights into optimizing wastewater treatment systems by highlighting the effectiveness of a hybrid CWS design, the importance of HRT, the role of BM and the selection of hydrophytes. The research offered valuable guidance for enhancing CWS performance. The implications for developing countries underscore the potential of CWS to address urgent wastewater management challenges, promoting environmental sustainability and public health. Future research directions identified in the study can pave the way for continued advancements in this vital field.