Steady-State Reactive Power Capability Analysis of Doubly-Fed Variable Speed Pumped Storage Unit Considering the Unit’s Operating Characteristics

Abstract

1. Introduction

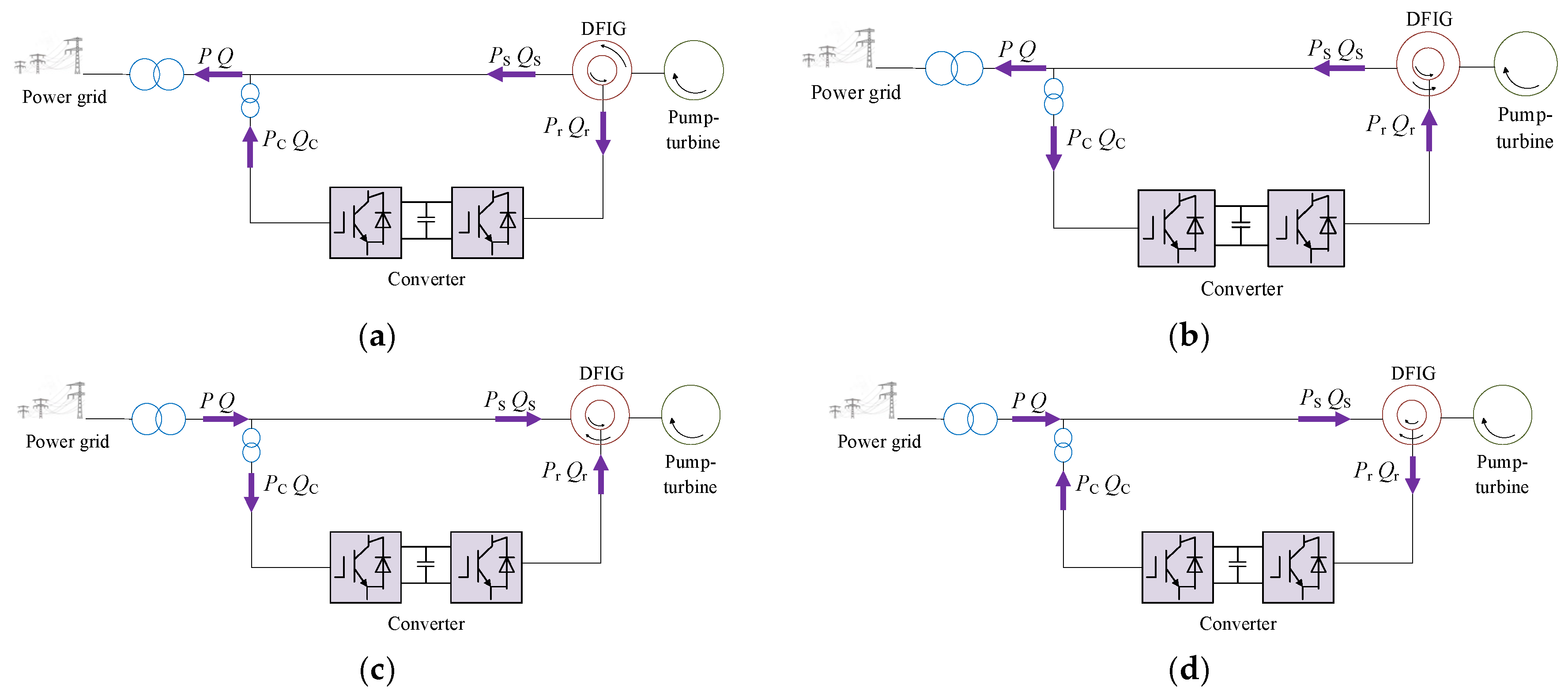

2. Power Coupling Analysis of the Doubly-Fed Variable Speed Pumped Storage Unit

2.1. Operating Principle of the DFVSPSU

2.2. Power Coupling Relationship of the DFVSPSU

3. Reactive Power Characteristic Analysis of the Stator Side of the Doubly-Fed Variable Speed Pumped Storage Unit

3.1. Stator Side Power Operating Constraints of the DFVSPSU

- Prime Mover Power Limitation (Pm):

- 2.

- Stator Current Limitation (Ismax):

- 3.

- Rotor Current Limitation (Irmax):

- 4.

- Rotor Voltage Limitation (Urmax):

3.2. Determination of the DFIG Capacity

3.3. Voltage and Current Limitations on the Stator Side of the DFVSPSU

3.4. Reactive Power-Regulation Capability of the Stator Side of the DFVSPSU

4. Reactive Power Characteristic Analysis of the Grid-Side Converter

4.1. Determining the Real Power on the Rotor Side of the DFVSPSU

4.2. Reactive Power Characteristic Analysis of the Grid-Side Converter in the DFVSPSU

5. Total Reactive Power Characteristics of the Doubly-Fed Variable Speed Pumped Storage Unit

6. Comparison of Reactive Power-Regulation Capabilities Between Fixed-Speed Pumped Storage Unit and Doubly-Fed Variable Speed Pumped Storage Unit

6.1. Power Operating Constraints of the FSPSU

- P-Q Power Operating Constraints of the FSPSU:

- Stator winding temperature rise constraint: The stator winding temperature rise depends on the stator current, which is influenced by the generator’s apparent power. The unit’s rated capacity is limited by the thermal capacity of the stator winding and core, ensuring safe operation, represented as a blue circle in the P-Q diagram;

- Prime mover power constraint: The rated power of the prime mover of a pumped storage unit is usually equal to the rated real power of the generator it is paired with. Therefore, the prime mover power constraint is shown in the P-Q diagram by four horizontal lines. With a rated power factor of cosφ = 0.9, the minimum output constraint for turbine operation is 50%, and the minimum input constraint for pump operation is 75% [34];

- Excitation winding temperature rise constraint: The excitation winding temperature rise constraint limits the temperature increase during operation, primarily dependent on the excitation current. Due to iron losses, the power circle’s center shifts from the origin to the negative reactive power axis, forming a purple circle;

- Other constraints: When the excitation electromotive force is constant, the maximum achievable real power and its corresponding power angle represent the static stability constraint. In practice, there is an additional 10–15% margin for the static stability constraint. When the excitation current is zero, the unit is in an excitation loss state, at which point the unit is subject to excitation loss constraints.

- 2.

- Reactive Power Regulation Range of the FSPSU:

6.2. Comparison of Reactive Power-Regulation Capabilities Between FSPSU and DFVSPSU

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DFVSPSUs | Doubly-fed variable speed pumped storage units |

| DFIG | Doubly-fed induction generator |

| PSUs | Pumped storage units |

| FSPSUs | Fixed-speed pumped storage units |

References

- Du, E.; Zhang, N.; Hodge, B.-M.; Wang, Q.; Kang, C.; Kroposki, B.; Xia, Q. The Role of Concentrating Solar Power Toward High Renewable Energy Penetrated Power Systems. IEEE Trans. Power Syst. 2018, 33, 6630–6641. [Google Scholar] [CrossRef]

- Wang, Y.; Qiu, D.; Sun, X.; Bie, Z.; Strbac, G. Coordinating Multi-Energy Microgrids for Integrated Energy System Resilience: A Multi-Task Learning Approach. IEEE Trans. Sustain. Energy 2024, 15, 920–937. [Google Scholar] [CrossRef]

- Ye, J.; Tan, L.; Shi, W.; Chen, C.; Francis, E.M. Numerical Simulation of Axial-Flow Pump Cavitation Based on Variable Frequency Speed Regulation. Water 2022, 14, 2757. [Google Scholar] [CrossRef]

- Li, H.; Sun, D.; Li, B.; Wang, X.; Zhao, Y.; Wei, M.; Dang, X. Collaborative Optimization of VRB-PS Hybrid Energy Storage System for Large-Scale Wind Power Grid Integration. Energy 2023, 265, 126292. [Google Scholar] [CrossRef]

- Qin, Y.; Li, D.; Wang, H.; Liu, Z.; Wei, X.; Wang, X.; Yang, W. Comprehensive Hydraulic Performance Improvement in a Pump-Turbine: An Experimental Investigation. Energy 2023, 284, 128550. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, R.; Cao, Y.; Zou, S.; Li, C. Quantitative Assessment of Static Voltage Stability for Power System with High-Penetration Wind Power Based on Energy Function. Energy Rep. 2024, 12, 699–707. [Google Scholar] [CrossRef]

- Coban, H.H.; Rehman, A.; Mousa, M. Load Frequency Control of Microgrid System by Battery and Pumped-Hydro Energy Storage. Water 2022, 14, 1818. [Google Scholar] [CrossRef]

- Atallah, M.; Mezouar, A.; Fernández–Ramírez, L.M.; Belgacem, K.; Saidi, Y.; Benmahdjoub, M.A.; Brahmi, B. Supervisory Control of Reactive Power in Wind Farms with Doubly Fed Induction Generator-Based Wind Turbines for Voltage Regulation and Power Losses Reduction. Electr. Power Syst. Res. 2024, 228, 110059. [Google Scholar] [CrossRef]

- Kougias, I.; Aggidis, G.; Avellan, F.; Deniz, S.; Lundin, U.; Moro, A.; Muntean, S.; Novara, D.; Pérez-Díaz, J.I.; Quaranta, E.; et al. Analysis of Emerging Technologies in the Hydropower Sector. Renew. Sustain. Energy Rev. 2019, 113, 109257. [Google Scholar] [CrossRef]

- Wang, R.; Yang, W.; Ji, L.; Li, X.; Zhang, S.; Jing, X. Regulation Intensity Assessment of Pumped Storage Units in Daily Scheduling for Renewable Energy Consumption. Sustain. Energy Technol. Assess. 2023, 56, 103027. [Google Scholar] [CrossRef]

- Pugliese, F.; Giugni, M. An Operative Framework for the Optimal Selection of Centrifugal Pumps As Turbines (PATs) in Water Distribution Networks (WDNs). Water 2022, 14, 1785. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, J.; Egusquiza, M.; Chen, D.; Li, F.; Behrens, P.; Egusquiza, E. A Review of Dynamic Models and Stability Analysis for a Hydro-Turbine Governing System. Renew. Sustain. Energy Rev. 2021, 144, 110880. [Google Scholar] [CrossRef]

- Fu, J.; Yu, X.; Gao, C.; Cui, J.; Li, Y. Nonsingular Fast Terminal Control for the DFIG-Based Variable-Speed Hydro-Unit. Energy 2022, 244, 122672. [Google Scholar] [CrossRef]

- Jukić, D.-K.; Kugi, A.; Kemmetmüller, W. Optimal Operation of Pumped Storage Power Plants with Fixed- and Variable-Speed Generators in Multiple Electricity Markets Considering Overload Operation. J. Energy Storage 2024, 88, 111601. [Google Scholar] [CrossRef]

- Kadri, A.; Marzougui, H.; Aouiti, A.; Bacha, F. Energy Management and Control Strategy for a DFIG Wind Turbine/Fuel Cell Hybrid System with Super Capacitor Storage System. Energy 2020, 192, 116518. [Google Scholar] [CrossRef]

- Ge, X.; Qian, J.; Fu, Y.; Lee, W.-J.; Mi, Y. Transient Stability Evaluation Criterion of Multi-Wind Farms Integrated Power System. IEEE Trans. Power Syst. 2022, 37, 3137–3140. [Google Scholar] [CrossRef]

- Tavoosi, J.; Mohammadzadeh, A.; Pahlevanzadeh, B.; Kasmani, M.B.; Band, S.S.; Safdar, R.; Mosavi, A.H. A Machine Learning Approach for Active/Reactive Power Control of Grid-Connected Doubly-Fed Induction Generators. Ain Shams Eng. J. 2022, 13, 101564. [Google Scholar] [CrossRef]

- Lei, L.; Li, F.; Kheav, K.; Jiang, W.; Luo, X.; Patelli, E.; Xu, B.; Chen, D. A Start-up Optimization Strategy of a Hydroelectric Generating System: From a Symmetrical Structure to Asymmetric Structure on Diversion Pipes. Renew. Energy 2021, 180, 1148–1165. [Google Scholar] [CrossRef]

- Kan, K.; Xu, Z.; Chen, H.; Xu, H.; Zheng, Y.; Zhou, D.; Muhirwa, A.; Maxime, B. Energy Loss Mechanisms of Transition from Pump Mode to Turbine Mode of an Axial-Flow Pump under Bidirectional Conditions. Energy 2022, 257, 124630. [Google Scholar] [CrossRef]

- Tang, W.; Hu, J.; Chang, Y.; Liu, F. Modeling of DFIG-Based Wind Turbine for Power System Transient Response Analysis in Rotor Speed Control Timescale. IEEE Trans. Power Syst. 2018, 33, 6795–6805. [Google Scholar] [CrossRef]

- Trivedi, T.; Jadeja, R.; Bhatt, P.; Long, C.; Sanjeevikumar, P.; Ved, A. Sliding Mode-Based Direct Power Control of Unified Power Quality Conditioner. Heliyon 2024, 10, e39597. [Google Scholar] [CrossRef] [PubMed]

- Jadhav, H.T.; Roy, R. A Comprehensive Review on the Grid Integration of Doubly Fed Induction Generator. Int. J. Electr. Power Energy Syst. 2013, 49, 8–18. [Google Scholar] [CrossRef]

- Parida, A.; Chatterjee, D. An Improved Control Scheme for Grid Connected Doubly Fed Induction Generator Considering Wind-Solar Hybrid System. Int. J. Electr. Power Energy Syst. 2016, 77, 112–122. [Google Scholar] [CrossRef]

- Schmidt, J.; Kemmetmüller, W.; Kugi, A. Modeling and Static Optimization of a Variable Speed Pumped Storage Power Plant. Renew. Energy 2017, 111, 38–51. [Google Scholar] [CrossRef]

- Siniscalchi-Minna, S.; Bianchi, F.D.; Ocampo-Martinez, C.; Domínguez-García, J.L.; De Schutter, B. A Non-Centralized Predictive Control Strategy for Wind Farm Active Power Control: A Wake-Based Partitioning Approach. Renew. Energy 2020, 150, 656–669. [Google Scholar] [CrossRef]

- Kadi, S.; Benbouhenni, H.; Abdelkarim, E.; Imarazene, K.; Berkouk, E.M. Implementation of Third-Order Sliding Mode for Power Control and Maximum Power Point Tracking in DFIG-Based Wind Energy Systems. Energy Rep. 2023, 10, 3561–3579. [Google Scholar] [CrossRef]

- Singh, R.R.; Baranidharan, M.; Subramaniam, U.; Bhaskar, M.S.; Rangarajan, S.S.; Abdelsalam, H.A.; Collins, E.R.; Senjyu, T. An Energy-Efficient Start-Up Strategy for Large Variable Speed Hydro Pump Turbine Equipped with Doubly Fed Asynchronous Machine. Energies 2022, 15, 3138. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, W.; Zhao, Z.; Han, W.; Li, Y.; Yang, J. Dynamic Modeling and Favorable Speed Command of Variable-Speed Pumped-Storage Unit during Power Regulation. Renew. Energy 2023, 206, 769–783. [Google Scholar] [CrossRef]

- Gayen, P.K.; Chatterjee, D.; Goswami, S.K. Stator Side Active and Reactive Power Control with Improved Rotor Position and Speed Estimator of a Grid Connected DFIG (Doubly-Fed Induction Generator). Energy 2015, 89, 461–472. [Google Scholar] [CrossRef]

- Ghosh, S.; Isbeih, Y.J.; Bhattarai, R.; Moursi, M.S.E.; El-Saadany, E.F.; Kamalasadan, S. A Dynamic Coordination Control Architecture for Reactive Power Capability Enhancement of the DFIG-Based Wind Power Generation. IEEE Trans. Power Syst. 2020, 35, 3051–3064. [Google Scholar] [CrossRef]

- Yin, J. Influence of Reactive Power Support Control Strategy on Short-Circuit Current Calculation and Fault Analysis Method of DFIG. Energy Rep. 2021, 7, 5933–5942. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, W.; Liu, Y.; Bao, Z.; Mao, Z.; Rashad, E.M. Modeling and Transient Response Analysis of Doubly-Fed Variable Speed Pumped Storage Unit in Pumping Mode. IEEE Trans. Ind. Electron. 2023, 70, 9935–9947. [Google Scholar] [CrossRef]

- Li, J.; Guo, W. Optimization of Shafting and Excitation Dual Damping Controller for Combined Pumped Storage and Wind Power System. Energy 2024, 313, 133894. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Pang, J.; Xu, L. Review on Cavitation Performance of Pump-turbine. Hydropower Pumped Storage 2025, 11, 88–101. [Google Scholar]

| Q | Qs | Qc | (Q − Qs)/Qs |

|---|---|---|---|

| 308.2 | 267.16 | 41.04 | 15.36% |

| 186.7 | 147.74 | 38.98 | 26.37% |

| 365.83 | 324.79 | 41.04 | 12.54% |

| 192.28 | 153.3 | 38.98 | 25.43% |

| Turbine Mode | Pump Mode | |||

|---|---|---|---|---|

| The Maximum Reactive Power Output | The Maximum Reactive Power Absorption | The Maximum Reactive Power Output | The Maximum Reactive Power Absorption | |

| DFVSPSU | 308.2 | 365.83 | 283.24 | 334.48 |

| FSPSU | 209.4 | 300.66 | 173 | 224.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, B.; Zhang, Z.; Dong, C.; Gao, C.; Sun, S.; Gu, J.; Yan, Q. Steady-State Reactive Power Capability Analysis of Doubly-Fed Variable Speed Pumped Storage Unit Considering the Unit’s Operating Characteristics. Water 2025, 17, 2519. https://doi.org/10.3390/w17172519

Yi B, Zhang Z, Dong C, Gao C, Sun S, Gu J, Yan Q. Steady-State Reactive Power Capability Analysis of Doubly-Fed Variable Speed Pumped Storage Unit Considering the Unit’s Operating Characteristics. Water. 2025; 17(17):2519. https://doi.org/10.3390/w17172519

Chicago/Turabian StyleYi, Bo, Zheyuan Zhang, Chuang Dong, Chunyang Gao, Sijia Sun, Jiawei Gu, and Qiming Yan. 2025. "Steady-State Reactive Power Capability Analysis of Doubly-Fed Variable Speed Pumped Storage Unit Considering the Unit’s Operating Characteristics" Water 17, no. 17: 2519. https://doi.org/10.3390/w17172519

APA StyleYi, B., Zhang, Z., Dong, C., Gao, C., Sun, S., Gu, J., & Yan, Q. (2025). Steady-State Reactive Power Capability Analysis of Doubly-Fed Variable Speed Pumped Storage Unit Considering the Unit’s Operating Characteristics. Water, 17(17), 2519. https://doi.org/10.3390/w17172519