Groundwater Flow Impact in Complex Karst Regions Considering Tunnel Construction Conditions: A Case Study of the New Construction Project at XLS Tunnel

Abstract

1. Introduction

2. Methods

3. Case Analysis

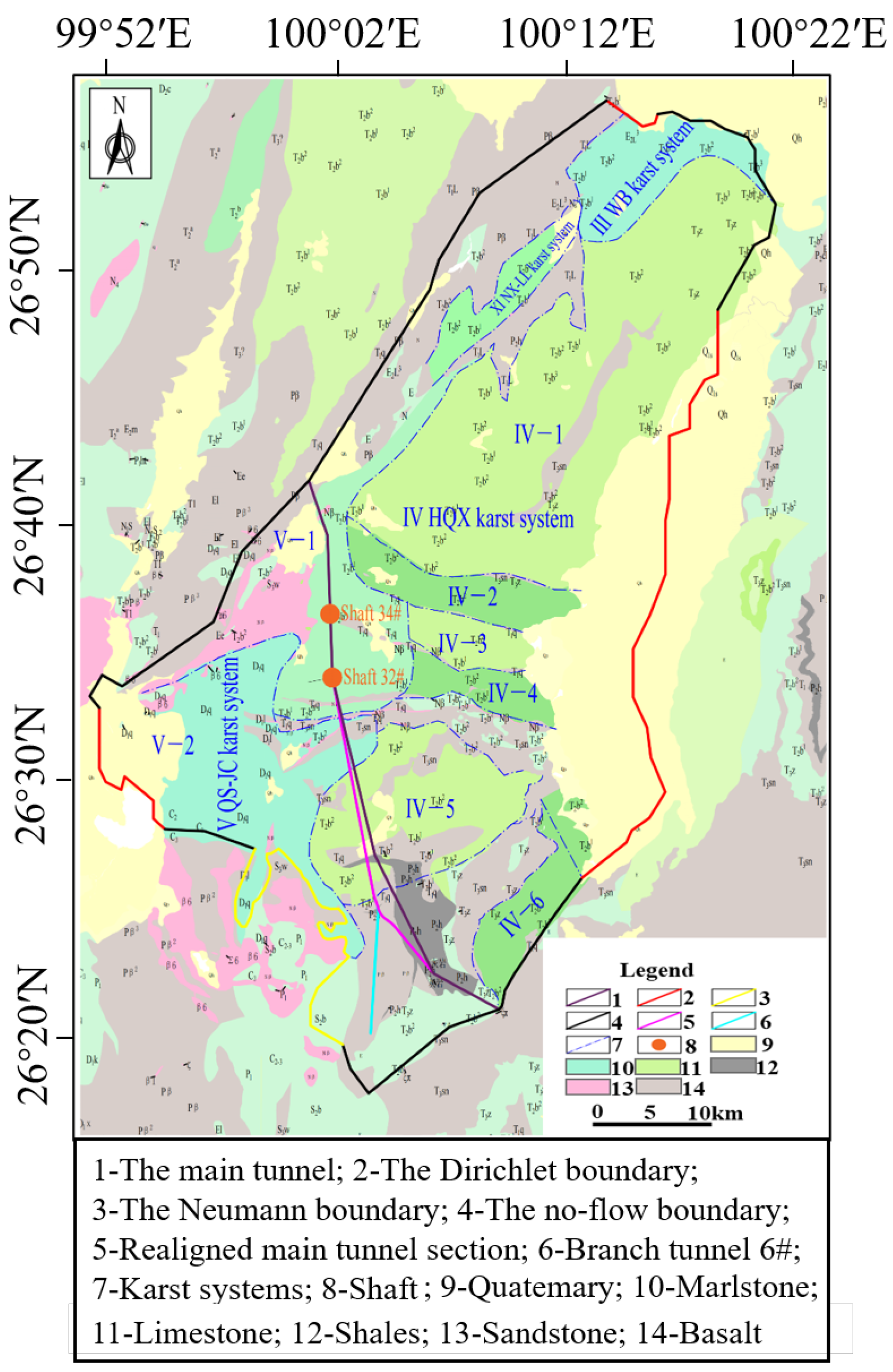

3.1. Site Description

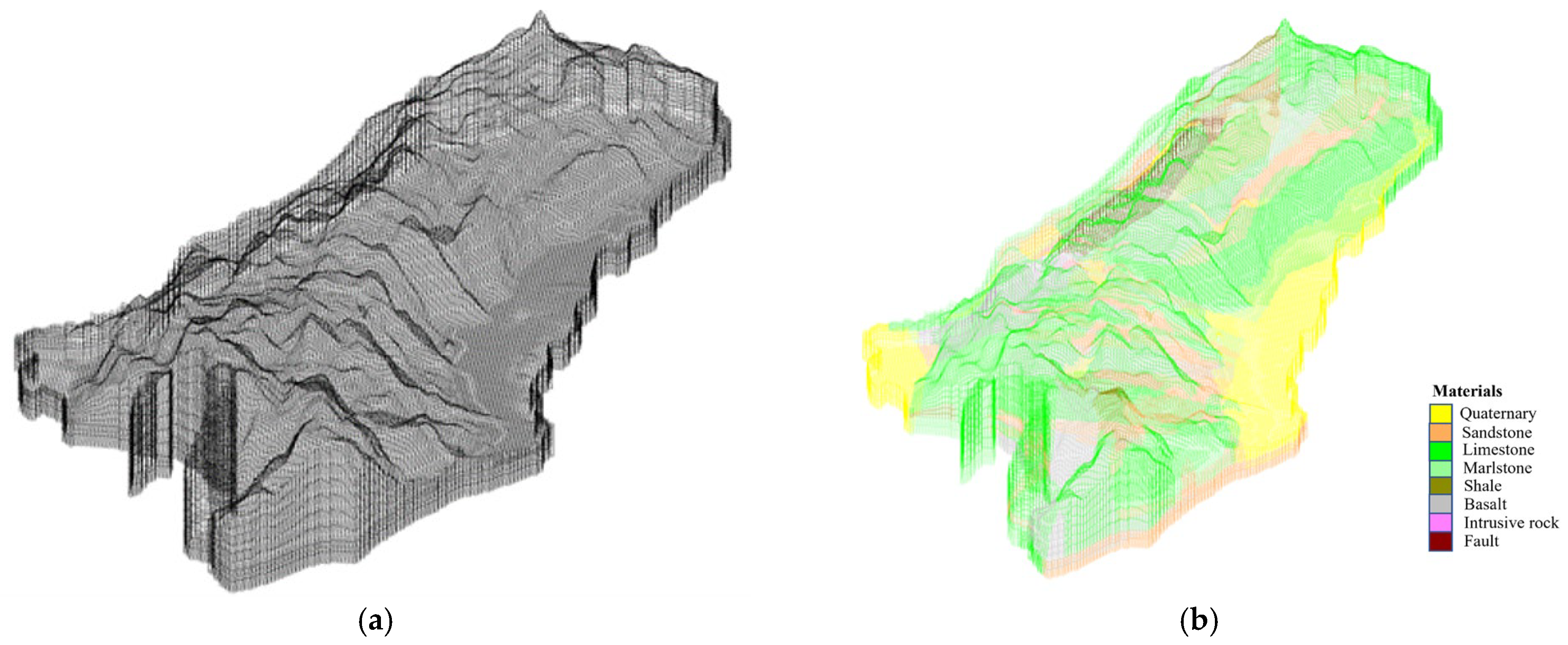

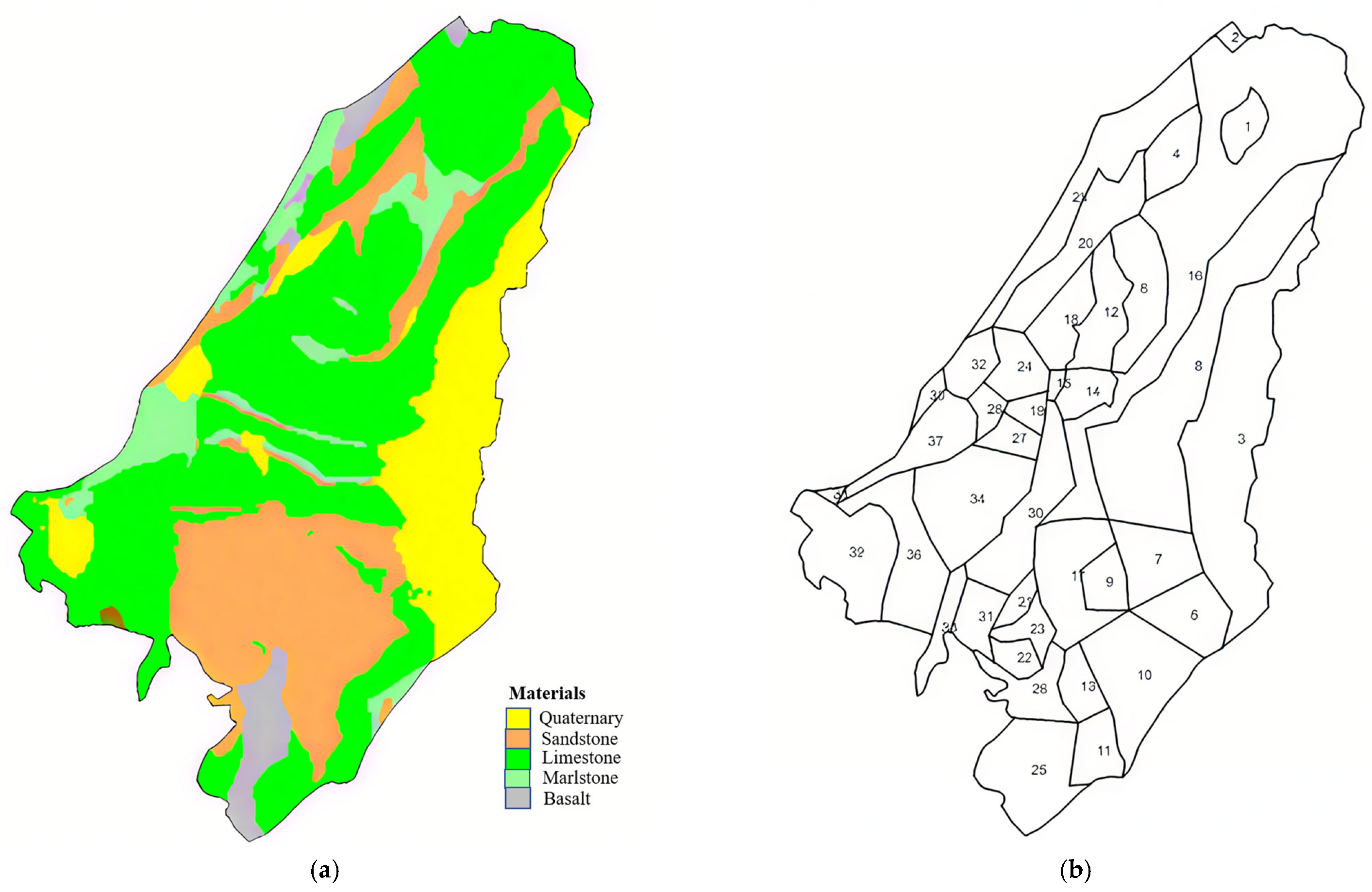

3.2. Model and Parameter Settings

3.3. Model Calibration

3.4. Simulation Results

4. Discussion

4.1. Geological Controls on Grouting Efficacy

4.2. Practical Implications and Cost–Benefit Trade-Offs

4.3. Model Advancements and Limitations

5. Conclusions

- (1)

- Under natural conditions (unlined tunnel scenario), tunnel construction would induce substantial perturbations in the groundwater flow field. Significant water inflows are predicted. Conventional grouting reduced inflows by 27–97% across sections, most effectively in shafts (>90% reduction at 20/24 segments). Microfine cement grouting enhanced mitigation to a 49–98% reduction, particularly in high-inflow zones.

- (2)

- Implementation of appropriate seepage control measures can also significantly mitigate these construction-related impacts on the local groundwater environment. Unlined excavation would desiccate two springs and reduce discharge at others. Conventional grouting prevents the drying up of spring points and effectively reduces the decrease in spring flow. Microfine cement grouting can further mitigate the impact of tunnel construction on the GEPTS.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Z.; He, C.; Zhang, Y.; Xu, Z.; Li, Z.; Yu, B. The impact of formation heterogeneity on water discharge and groundwater depletion of an excavated tunnel. J. Hydrol. 2023, 627, 130403. [Google Scholar] [CrossRef]

- Gokdemir, C.; Rui, Y.; Rubin, Y.; Li, X. A framework for assessing tunnel drainage-induced impact on terrestrial vegetation. Tunn. Undergr. Space Technol. 2023, 132, 104917. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, N.; Chen, K.; Ren, F. Study on drainage mode and anti-clogging performance of new waterproofing and drainage system in a tunnel. Sci. Rep. 2023, 13, 5354. [Google Scholar] [CrossRef] [PubMed]

- Teng, Z.; Liu, Y.; Zhou, Y.; Li, Y.; Mei, S.; Chen, Q.; Chen, L.; Du, B. Investigation of a new reverse drainage construction and the pressure-reducing effect of a tunnel in a water-rich karst location. Tunn. Undergr. Space Technol. 2024, 145, 105580. [Google Scholar] [CrossRef]

- Guo, F.; Jiang, G.; Yuan, D.; Polk, J.S. Evolution of major environmental geological problems in karst areas of Southwestern China. Environ. Earth Sci. 2012, 69, 2427–2435. [Google Scholar] [CrossRef]

- Liu, N.; Pei, J.; Cao, C.; Liu, X.; Huang, Y.; Mei, G. Geological investigation and treatment measures against water inrush hazard in karst tunnels: A case study in Guiyang, southwest China. Tunn. Undergr. Space Technol. 2022, 124, 104491. [Google Scholar] [CrossRef]

- Bi, J.; Jiang, H.; Ding, W. Analytical solution for calculating the flow rate in a lined tunnel with drainage systems. Tunn. Undergr. Space Technol. 2023, 138, 105132. [Google Scholar] [CrossRef]

- Zarei, H.R.; Uromeihy, A.; Sharifzadeh, M. A new tunnel inflow classification (TIC) system through sedimentary rock masses. Tunn. Undergr. Space Technol. 2013, 34, 1–12. [Google Scholar] [CrossRef]

- Hwang, J.-H.; Lu, C.-C. A semi-analytical method for analyzing the tunnel water inflow. Tunn. Undergr. Space Technol. 2007, 22, 39–46. [Google Scholar] [CrossRef]

- Perrochet, P. A simple solution to tunnel or well discharge under constant drawdown. Hydrogeol. J. 2004, 13, 886–888. [Google Scholar] [CrossRef]

- Cheng, P.; Zhao, L.; Luo, Z.; Li, L.; Li, Q.; Deng, X.; Peng, W. Analytical solution for the limiting drainage of a mountain tunnel based on area-well theory. Tunn. Undergr. Space Technol. 2019, 84, 22–30. [Google Scholar] [CrossRef]

- Farhadian, H.; Katibeh, H.; Huggenberger, P.; Butscher, C. Optimum model extent for numerical simulation of tunnel inflow in fractured rock. Tunn. Undergr. Space Technol. 2016, 60, 21–29. [Google Scholar] [CrossRef]

- Yang, Z.-M.; Wu, S.-C.; Gao, Y.-T.; Jin, A.-B.; Cong, Z.-J. Time and technique of rehabilitation for large deformation of tunnels in jointed rock masses based on FDM and DEM numerical modeling. Tunn. Undergr. Space Technol. 2018, 81, 669–681. [Google Scholar] [CrossRef]

- Long, Y.-Y.; Tan, Y. Soil arching due to leaking of tunnel buried in water-rich sand. Tunn. Undergr. Space Technol. 2020, 95, 103158. [Google Scholar] [CrossRef]

- Yin, Z.-Y.; Wang, P.; Zhang, F. Effect of particle shape on the progressive failure of shield tunnel face in granular soils by coupled FDM-DEM method. Tunn. Undergr. Space Technol. 2020, 100, 103158. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, Y.; Xu, L.; Zhou, S.; Zhou, J.; Su, N. Effects of cyclic loading on soil arching within pile-supported embankment with artificial crust: A coupled DEM-FDM approach. Transp. Geotech. 2023, 42, 101099. [Google Scholar] [CrossRef]

- Lv, Y.; Jiang, J.; Chen, L.; Hu, W.; Jiang, Y. Elaborate simulation and predication of the tunnel drainage effect on karst groundwater field and discharge based on Visual MODFLOW. J. Hydrol. 2022, 612, 128023. [Google Scholar] [CrossRef]

- Zheng, X.; Yang, Z.; Wang, S.; Chen, Y.-F.; Hu, R.; Zhao, X.-J.; Wu, X.-L.; Yang, X.-L. Evaluation of hydrogeological impact of tunnel engineering in a karst aquifer by coupled discrete-continuum numerical simulations. J. Hydrol. 2021, 597, 125765. [Google Scholar] [CrossRef]

- Tian, C.; Xiao, Z.; Ye, F.; Tong, Y.; Cao, X.; Sun, J.; Li, Z. The impact of extreme rainfall and drainage system failure on rock tunnels: A case study of deep-buried karst tunnel. Eng. Fail. Anal. 2025, 171, 109345. [Google Scholar] [CrossRef]

- Chen, Z.; Su, Z.; Li, M.; Shen, Q.; Fan, L.; Zhang, Y. Investigation of the Tunnel Water Inflow Prediction Method Based on the MODFLOW-DRAIN Module. Water 2024, 16, 1078. [Google Scholar] [CrossRef]

- Huang, Y.; Xu, Y.; Chen, Z.; Shen, Q.; Chen, Z. Three-Dimensional Simulation of Subsurface Flow Dynamics in Karst Conduits at the Jingxian Pumped Storage Hydropower Plant. Water 2025, 17, 533. [Google Scholar] [CrossRef]

- Li, Z.; Xiao, J.; Wan, J.; Cheng, J.; Feng, H.; Zhan, H.; Yuan, S.; Huang, K. A dynamic modeling approach to predict water inflow during tunnel excavation in relatively uniform rock masses. Tunn. Undergr. Space Technol. 2024, 146, 105668. [Google Scholar] [CrossRef]

- Li, J.; Hong, A.; Yuan, D.; Jiang, Y.; Deng, S.; Cao, C.; Liu, J. A new distributed karst-tunnel hydrological model and tunnel hydrological effect simulations. J. Hydrol. 2021, 593, 125639. [Google Scholar] [CrossRef]

- Xu, X.; Huang, G.; Zhan, H.; Qu, Z.; Huang, Q. Integration of SWAP and MODFLOW-2000 for modeling groundwater dynamics in shallow water table areas. J. Hydrol. 2012, 412–413, 170–181. [Google Scholar] [CrossRef]

- Xia, Q.; Xu, M.; Zhang, H.; Zhang, Q.; Xiao, X.-x. A dynamic modeling approach to simulate groundwater discharges into a tunnel from typical heterogenous geological media during continuing excavation. KSCE J. Civ. Eng. 2018, 22, 341–350. [Google Scholar] [CrossRef]

- Bai, Y.; Wu, Z.; Huang, T.; Peng, D. A Dynamic Modeling Approach to Predict Water Inflow during Karst Tunnel Excavation. Water 2022, 14, 2380. [Google Scholar] [CrossRef]

- Vilhelmsen, T.N.; Christensen, S.; Mehl, S.W. Evaluation of MODFLOW-LGR in Connection with a Synthetic Regional-Scale Model. Groundwater 2011, 50, 118–132. [Google Scholar] [CrossRef] [PubMed]

- Duran, L.; Gill, L. Modeling spring flow of an Irish karst catchment using Modflow-USG with CLN. J. Hydrol. 2021, 597, 125971. [Google Scholar] [CrossRef]

- Kresic, N.; Panday, S. Modeling of groundwater flow and transport in coastal karst aquifers. Hydrogeol. J. 2020, 29, 249–258. [Google Scholar] [CrossRef]

- Harbaugh, A.W. MODFLOW-2005, the US Geological Survey Modular Ground-Water Model: The Ground-Water Flow Process; US Department of the Interior, US Geological Survey: Reston, VA, USA, 2005; Volume 6. [Google Scholar]

- Prudic, D.E. Documentation of a Computer Program to Simulate Stream-Aquifer Relations Using a Modular, Finite-Difference, Ground-Water Flow Model; No. 88-729; US Geological Survey: Reston, VA, USA, 1989. [Google Scholar]

- Liu, J.; Gokdemir, C.; Li, X.; Xi, Y. Experimental and Analytical Study on the External Water Pressure of a Composite Lining Considering the Waterproofing and Drainage System. Rock Mech. Rock Eng. 2024, 58, 1099–1115. [Google Scholar] [CrossRef]

- Wang, P.; Li, S.; Li, J.; Zhou, H.; Ma, P.; Tian, Y.; Yuan, C.; Feng, X. Seepage behavior and mechanical properties of two kinds of polyurethane/water glass in combined grouting experiment. Tunn. Undergr. Space Technol. 2023, 136, 105092. [Google Scholar] [CrossRef]

- Moreno-Gómez, M.; Kavousi, A.; Martínez-Salvador, C.; Reimann, T. Evaluation of inferred conduit configurations in the Yucatan karst system (Mexico) from gravity and aeromagnetic anomalies, using MODFLOW-CFPv2. Hydrogeol. J. 2024, 32, 1363–1375. [Google Scholar] [CrossRef]

- Pham, Q.B.; Kumar, M.; Di Nunno, F.; Elbeltagi, A.; Granata, F.; Islam, A.R.M.T.; Talukdar, S.; Nguyen, X.C.; Ahmed, A.N.; Anh, D.T. Groundwater level prediction using machine learning algorithms in a drought-prone area. Neural Comput. Appl. 2022, 34, 10751–10773. [Google Scholar] [CrossRef]

| No. | Groundwater Environmental Protection Target | Spatial Relationship to Tunnel Alignment |

|---|---|---|

| GEPT 1 | Runan River 2 (Hongmai Village Spring) | 4 km northwest of Shaft 23# |

| GEPT 2 | Qingshuijiang Village Cluster Springs | 800 m west of Shaft 32# |

| GEPT 3 | Xideng Village Spring | 2.7 km southeast of Shaft 34# |

| GEPT 4 | Xiaomachang Spring | 570 m west of realigned main tunnel section |

| GEPT 5 | Damachang Spring | 1.3 km west of realigned main tunnel section |

| GEPT 6 | Heinishao Spring | 600 m east of realigned main tunnel section |

| GEPT 7 | Aqinggou Upstream Spring #1 | 160 m west of branch tunnel 6# |

| GEPT 8 | Aqinggou Spring #2 | 790 m west of branch tunnel 6# |

| GEPT 9 | Loushan River Irrigation Spring #1 | 1.3 km southeast of realigned main tunnel section |

| Lithology | Range of Permeability Coefficients K(cm/s) |

|---|---|

| Quatemary | 2.00 × 10−4–1.00 × 10−2 |

| Sandstone | 1.00 × 10−7–1.00 × 10−3 |

| Limestone | 1.00 × 10−5–5.00 × 10−3 |

| Mudstone | 3.00 × 10−8–6.00 × 10−4 |

| Shale | 1.00 × 10−8–1.00 × 10−6 |

| Basalt | 2.00 × 10−8–3.00 × 10−4 |

| Intrusive rock | 2.00 × 10−7–5.00 × 10−5 |

| Fault | 1.00 × 10−4–1.00 × 10−1 |

| Metric | Value | Unit |

|---|---|---|

| MAR | 3.06 | m |

| RMSE | 4.01 | m |

| RSS | 128.75 | m2 |

| Target Minimum | 2250 | m |

| Target Maximum | 2750 | m |

| Lithology | Permeability Coefficients in the x Direction—Kx (cm/s) | Kx/Ky | Kx/Kz |

|---|---|---|---|

| Quatemary | 8.64 × 10−4 | 1 | 10 |

| Sandstone | 7.76 × 10−6 | 1 | 1 |

| Limestone | 4.32 × 10−4 | 1 | 1 |

| Mudstone | 3.88 × 10−5 | 1 | 2 |

| Shale | 3.46 × 10−5 | 1 | 10 |

| Basalt | 1.78 × 10−6 | 1 | 2 |

| Intrusive rock | 2.16 × 10−6 | 1 | 2 |

| Fault | 1.39 × 10−3 | 1 | 10 |

| Tunnel | Lithology | Length of Tunnel Section (m) | Total Water Inflow (m3/d) | Percentage Reduction in Water Inflow Compared with Natural Condition | |||

|---|---|---|---|---|---|---|---|

| Natural Condition | Conventional Cement Grouting | Microfine Cement Grouting | Cement Grouting | Microfine Cement Grouting | |||

| Shaft 32# | Limestone | 44 | 1809.81 | 98.36 | 75.1 | 94.57% | 95.85% |

| Limestone | 140 | 4813.14 | 180.39 | 116.75 | 96.25% | 97.57% | |

| Limestone | 140 | 7798.37 | 219.73 | 137.2 | 97.18% | 98.24% | |

| Limestone | 140 | 7977.26 | 225.07 | 140.13 | 97.18% | 98.24% | |

| Limestone | 140 | 6061.65 | 196.97 | 126.87 | 96.75% | 97.91% | |

| Limestone | 50 | 1253.38 | 180.42 | 118.32 | 85.61% | 90.56% | |

| Limestone | 44 | 1809.81 | 98.36 | 75.1 | 94.57% | 95.85% | |

| Shaft 34# | Limestone | 110 | 1659.38 | 61.11 | 41.01 | 96.32% | 97.53% |

| Limestone | 271 | 6736 | 138.11 | 80.4 | 97.95% | 98.81% | |

| Sandstone | 236 | 8322.36 | 176.48 | 100.21 | 97.88% | 98.80% | |

| Sandstone | 135 | 8456.16 | 183.15 | 104.26 | 97.83% | 98.77% | |

| Basalt | 135 | 6260.35 | 158.77 | 92.56 | 97.46% | 98.52% | |

| Basalt | 50 | 1152.56 | 143.7 | 84.63 | 87.53% | 92.66% | |

| Basalt | 25 | 1024 | 134.88 | 79.85 | 86.83% | 92.20% | |

| Branch tunnel 6# | Basalt | 143 | 7599.41 | 5539.17 | 3854.28 | 27.11% | 49.28% |

| Basalt | 418 | 7602.00 | 5541.38 | 3902.25 | 27.11% | 48.67% | |

| Basalt | 805 | 7612.54 | 5548.44 | 3909.44 | 27.11% | 48.64% | |

| Basalt | 1867 | 8362.05 | 5572.88 | 3919.06 | 33.36% | 53.13% | |

| Basalt | 1011 | 8362.05 | 5813.89 | 4051.22 | 30.47% | 51.55% | |

| Basalt | 2164 | 11,178.46 | 6387.48 | 4308.41 | 42.86% | 61.46% | |

| Realigned main tunnel section | Basalt | 664 | 5175 | 2558 | 1352 | 50.57% | 73.87% |

| Fault | 47 | 892 | 464 | 206 | 47.98% | 76.91% | |

| Basalt | 514 | 2261 | 1052 | 256 | 53.47% | 88.68% | |

| Fault | 34 | 658 | 341 | 76 | 48.18% | 88.45% | |

| Limestone | 743 | 11,227 | 5622 | 1524 | 49.92% | 86.43% | |

| Fault | 39 | 609 | 316 | 94 | 48.11% | 84.56% | |

| Limestone | 892 | 20,602 | 12,662 | 962 | 38.54% | 95.33% | |

| Limestone | 1287 | 24,311 | 17,400 | 1366 | 28.43% | 94.38% | |

| Limestone | 2031 | 34,736 | 20,850 | 2142 | 39.98% | 93.83% | |

| Fault | 43 | 681 | 345 | 100 | 49.34% | 85.32% | |

| Limestone | 678 | 13,246 | 7147 | 499 | 46.04% | 96.23% | |

| Limestone | 223 | 966 | 514 | 103 | 46.79% | 89.34% | |

| Mudstone | 311 | 316 | 216 | 129 | 31.65% | 59.18% | |

| Fault | 59 | 638 | 382 | 100 | 40.13% | 84.33% | |

| Basalt | 460 | 1838 | 1190 | 518 | 35.26% | 71.82% | |

| Basalt | 481 | 1739 | 1572 | 759 | 9.60% | 56.35% | |

| Basalt | 4462 | 13,861 | 8800 | 4342 | 36.51% | 68.67% | |

| Fault | 53 | 346 | 260 | 180 | 24.86% | 47.98% | |

| Basalt | 1613 | 5940 | 3478 | 1308 | 41.45% | 77.98% | |

| Fault | 188 | 741 | 403 | 250 | 45.61% | 66.26% | |

| Basalt | 1566 | 4125 | 2716 | 1063 | 34.16% | 74.23% | |

| Fault | 87 | 701 | 413 | 198 | 41.08% | 71.75% | |

| Mudstone | 312 | 430 | 249 | 170 | 42.09% | 60.47% | |

| Groundwater Environmental Protection Targets | The Degree of Flow Reduction at the Spring Point Under Different Conditions (%) | ||

|---|---|---|---|

| Natural Condition | Conventional Cement Grouting | Microfine Cement Grouting | |

| GEPT 1 | 2.42 | 0.27 | 0.13 |

| GEPT 2 | 42.15 | 21.35 | 8.23 |

| GEPT 3 | 67.94 | 28.56 | 12.38 |

| GEPT 4 | 12.63 | 10.46 | 7.61 |

| GEPT 5 | 8.50 | 6.62 | 2.49 |

| GEPT 6 | Dry | 16.71 | 13.28 |

| GEPT 7 | Dry | 12.79 | 11.92 |

| GEPT 8 | 49.40 | 7.38 | 2.53 |

| GEPT 9 | 15.55 | 4.64 | 2.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Zhang, H.; Shen, Q.; Chen, Z.; Wang, K.; Chen, C. Groundwater Flow Impact in Complex Karst Regions Considering Tunnel Construction Conditions: A Case Study of the New Construction Project at XLS Tunnel. Water 2025, 17, 2383. https://doi.org/10.3390/w17162383

Chen Z, Zhang H, Shen Q, Chen Z, Wang K, Chen C. Groundwater Flow Impact in Complex Karst Regions Considering Tunnel Construction Conditions: A Case Study of the New Construction Project at XLS Tunnel. Water. 2025; 17(16):2383. https://doi.org/10.3390/w17162383

Chicago/Turabian StyleChen, Zhou, Hongtu Zhang, Qi Shen, Zihao Chen, Kai Wang, and Changsheng Chen. 2025. "Groundwater Flow Impact in Complex Karst Regions Considering Tunnel Construction Conditions: A Case Study of the New Construction Project at XLS Tunnel" Water 17, no. 16: 2383. https://doi.org/10.3390/w17162383

APA StyleChen, Z., Zhang, H., Shen, Q., Chen, Z., Wang, K., & Chen, C. (2025). Groundwater Flow Impact in Complex Karst Regions Considering Tunnel Construction Conditions: A Case Study of the New Construction Project at XLS Tunnel. Water, 17(16), 2383. https://doi.org/10.3390/w17162383