State-of-the-Art Decarbonization in Sludge Thermal Treatments for Electrical Power Generation Considering Sensors and the Application of Artificial Intelligence

Abstract

1. Introduction

1.1. Problem Statement

1.2. Justification

1.3. Research Gaps

1.4. Objectives

- Provide a comprehensive overview of decarbonization strategies in sludge thermal treatments for electrical power generation, situating sludge-to-energy within broader climate change mitigation efforts.

- Explore and critically assess innovative thermal technologies, including pyrolysis, gasification, and co-combustion, focusing on their potential to enhance energy recovery while minimizing CO2 emissions during sludge conversion.

- Evaluate the impact of process parameters, feedstock characteristics, and operational conditions on the efficacy of each decarbonization route, thereby identifying key levers for optimization.

- Examine the integration of advanced sensor networks and artificial intelligence-based control to enable real-time monitoring, dynamic optimization, and enhanced safety in sludge thermal treatment processes.

- Identify existing research gaps and propose future directions, guiding the development of next-generation decarbonization technologies and supportive policy frameworks for sustainable sludge management and power generation.

1.5. Novelty

- Evaluate state-of-the-art thermal conversion technologies (pyrolysis, gasification, co-combustion);

- Propose novel performance indicators that jointly consider global warming potential and exergy efficiency losses;

- Outline a roadmap for embedding real-time sensor feedback with machine learning models to dynamically optimize reactor conditions. By explicitly charting research gaps and future directions, particularly the coupling of AI forecasting with adaptive control, this paper forges a clear path toward more sustainable, resilient sludge-to-energy systems.

1.6. Methods for Literature Search

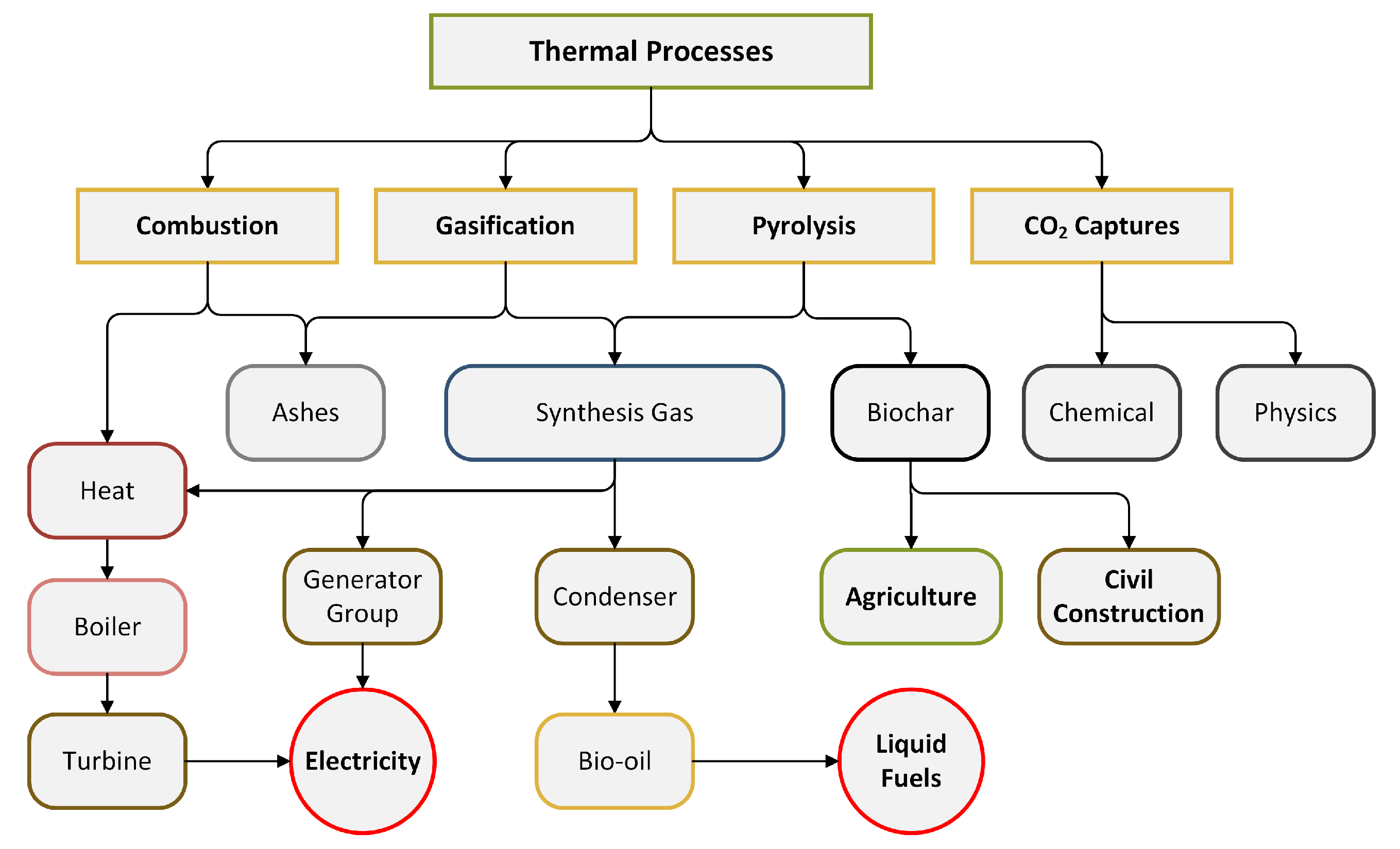

2. Decarbonization Techniques

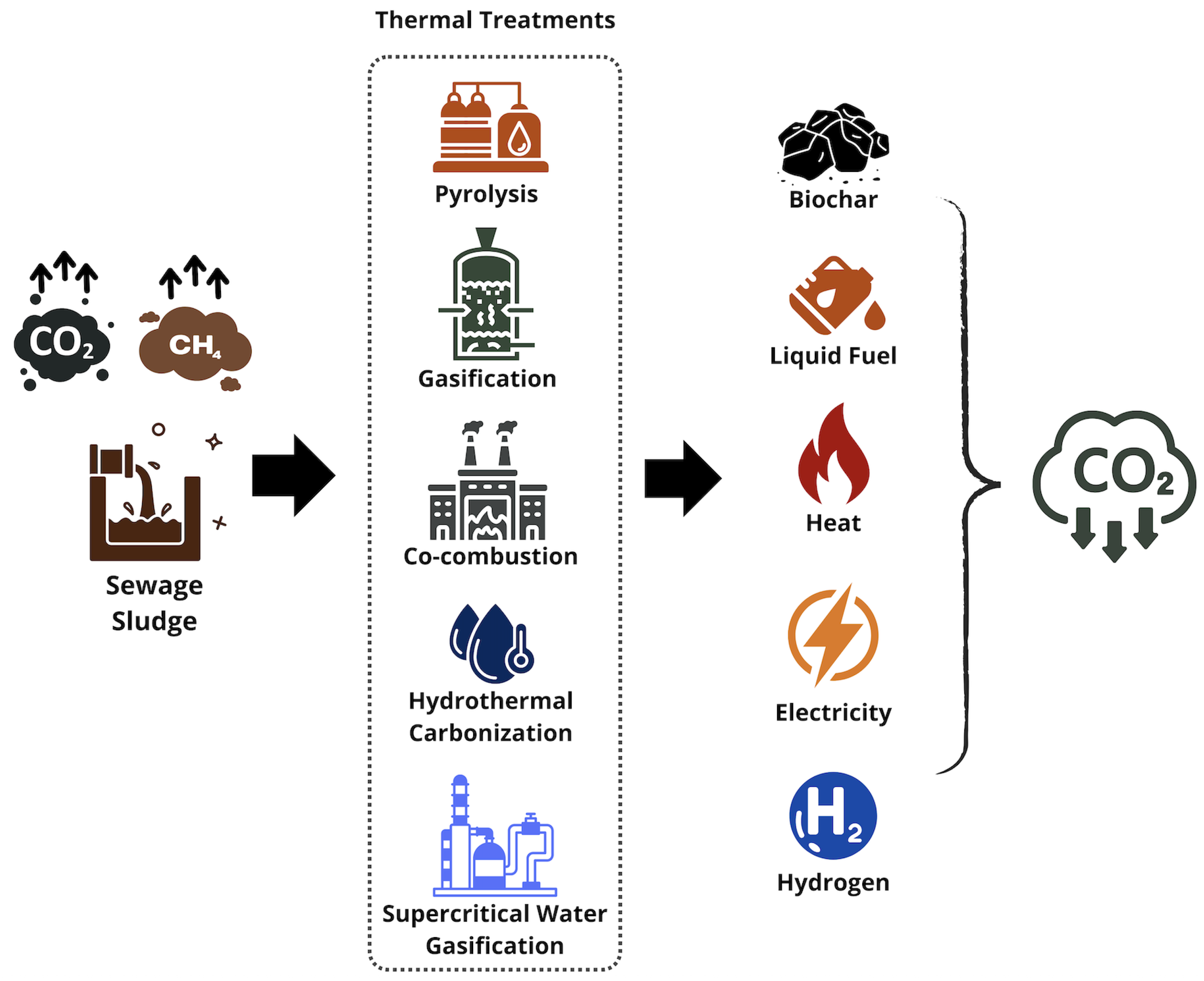

3. Thermal Treatment of Sludge

| Authors | Thermal Treatment/Challenge |

|---|---|

| Sikarwar et al. [88] | Thermal plasma with carbon capture, utilization, and storage/It needs considerable energy for plasma torch and a better pathway in innovations to reduce greenhouse gas emissions and phosphorous recovery. |

| Kossińska et al. [130] | Hydrothermal carbonization/Limited research about degradation, effects of moisture contents and changes in pH of sewage sludge, and its influence in the yield as improvements of mass-energy balance. |

| Hu et al. [131] | Supercritical water gasification/It needs a supply heat to reach the reaction temperature, especially with municipal sewage sludge, without drying with high water content. Increase in the volume concentration of sewage sludge in this process and collaboration with hydrogen production is required. |

| Luo et al. [132] | Microwave pyrolysis/High maintenance and operation costs, easy corrosion, and elevated costs of investments for the reactor. |

| Jadlovec et al. [133] | Co-Incineration/It has the greatest impact on terrestrial ecotoxicity, climate change, and human toxicity, as the challenge evaluated is to find the right blend ratio to maximize cost savings with power plant performance and emission limits. |

| Salimbeni et al. [134] | Slow pyrolysis and post-chemical leaching/Maximization of the phosphorous recovery and extraction of inorganic compounds separating magnesium, silicon, and aluminum are needed. Chemical extraction of silica requires high equipment and operational costs. |

| Zou et al. [135] | Co-pyrolysis of sewage sludge with corn stalks/Hard to integrate in the same industrial plant. However, carbon and nitrogen content is increased in biochars, the heavy metal contents present in sewage sludge are diluted, and it can be used to promote corn growth, improving the pore structure and germination rates as the potential to sequester carbon. |

AI Applications

4. Important Factors for Sustainable Implementation

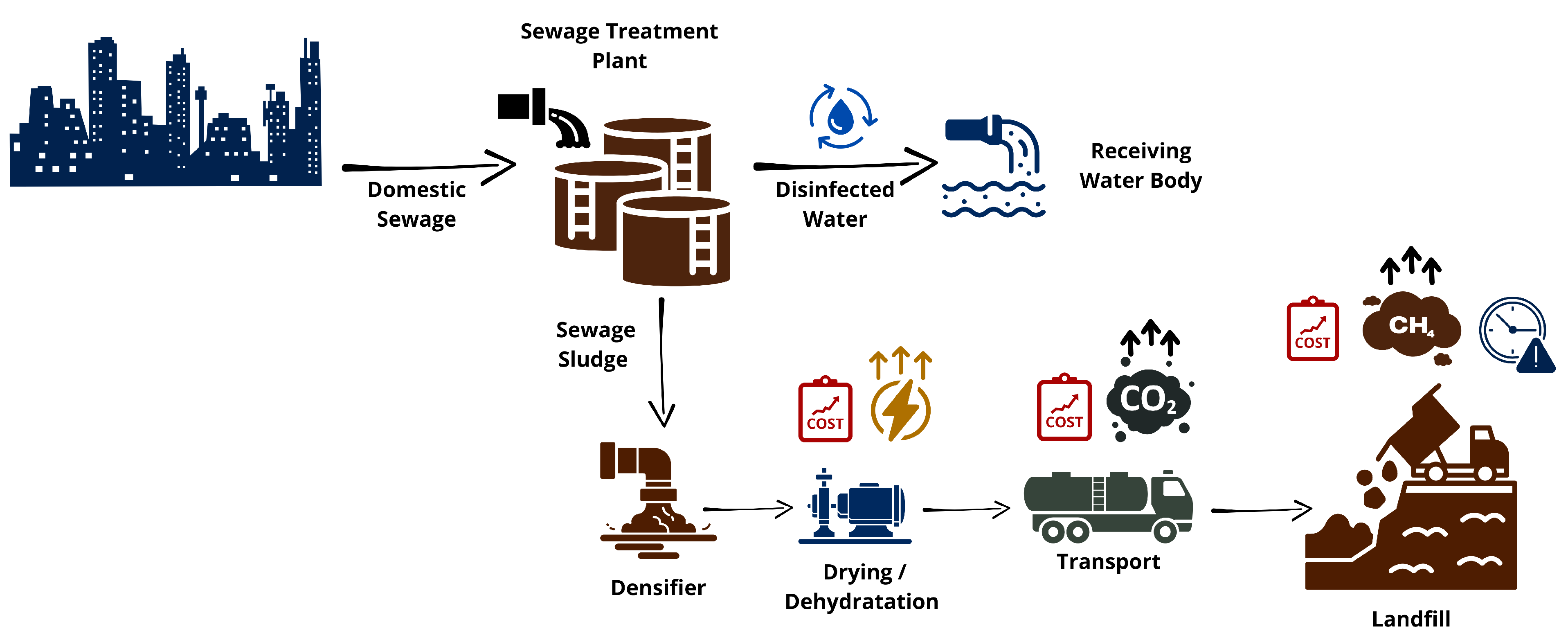

5. Wastewater Treatment Plant Necessary Changes for Reducing CO2

6. Final Remarks and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chai, Y.; Packham, N.; Wang, M. Process improvement analysis of pyrolysis/gasification of biomass and waste plastics with carbon capture and utilisation through process simulation. Fuel 2022, 324, 124571. [Google Scholar] [CrossRef]

- Cloete, S.; Melone, F.; del Pozo, C.A.; Dhoke, C.; Farmen, Ø.; Zaabout, A. Zero-cost partial decarbonization of natural gas via molten salt pyrolysis. Int. J. Hydrogen Energy 2023, 55, 164–176. [Google Scholar] [CrossRef]

- Xie, S.; Yang, Q.; Wang, Q.; Zhou, H.; Bartocci, P.; Fantozzi, F. Coal power decarbonization via biomass co-firing with carbon capture and storage: Tradeoff between exergy loss and GHG reduction. Energy Convers. Manag. 2023, 288, 117155. [Google Scholar] [CrossRef]

- Gomes e Souza, H.; Finardi, E.C.; Brito, B.H.; Takigawa, F.Y.K. Partitioning approach based on convex hull and multiple choice for solving hydro unit-commitment problems. Electr. Power Syst. Res. 2022, 211, 108285. [Google Scholar] [CrossRef]

- Larroyd, P.V.; Pedrini, R.; Beltrán, F.; Teixeira, G.; Finardi, E.C.; Picarelli, L.B. Dealing with Negative Inflows in the Long-Term Hydrothermal Scheduling Problem. Energies 2022, 15, 1115. [Google Scholar] [CrossRef]

- Colonetti, B.; Finardi, E.; Brito, S.; Zavala, V. Parallel Dual Dynamic Integer Programming for Large-Scale Hydrothermal Unit-Commitment. IEEE Trans. Power Syst. 2023, 38, 2926–2938. [Google Scholar] [CrossRef]

- Starke, L.; Hoppe, A.F.; Sartori, A.; Stefenon, S.F.; Santana, J.F.D.P.; Leithardt, V.R.Q. Interference recommendation for the pump sizing process in progressive cavity pumps using graph neural networks. Sci. Rep. 2023, 13, 16884. [Google Scholar] [CrossRef]

- Itajiba, J.A.; Varnier, C.A.C.; Cabral, S.H.L.; Stefenon, S.F.; Leithardt, V.R.Q.; Ovejero, R.G.; Nied, A.; Yow, K.C. Experimental Comparison of preferential vs. common delta connections for the star-delta starting of induction motors. Energies 2021, 14, 1318. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Nied, A. FEM applied to evaluation of the influence of electric field on design of the stator slots in PMSM. IEEE Lat. Am. Trans. 2019, 17, 590–596. [Google Scholar] [CrossRef]

- Liu, J.; Chen, H.; Zhao, S.; Pan, P.; Wu, L.; Xu, G. Evaluation and improvements on the flexibility and economic performance of a thermal power plant while applying carbon capture, utilization & storage. Energy Convers. Manag. 2023, 290, 117219. [Google Scholar] [CrossRef]

- Buratto, W.G.; Muniz, R.N.; Nied, A.; Barros, C.F.d.O.; Cardoso, R.; Gonzalez, G.V. A Review of Automation and Sensors: Parameter Control of Thermal Treatments for Electrical Power Generation. Sensors 2024, 24, 967. [Google Scholar] [CrossRef] [PubMed]

- Muniz, R.N.; da Costa Júnior, C.T.; Buratto, W.G.; Nied, A.; González, G.V. The Sustainability Concept: A Review Focusing on Energy. Sustainability 2023, 15, 14049. [Google Scholar] [CrossRef]

- Michaga, M.F.R.; Michailos, S.; Akram, M.; Cardozo, E.; Hughes, K.J.; Ingham, D.; Pourkashanian, M. Bioenergy with carbon capture and storage (BECCS) potential in jet fuel production from forestry residues: A combined Techno-Economic and Life Cycle Assessment approach. Energy Convers. Manag. 2022, 255, 115346. [Google Scholar] [CrossRef]

- Nandhini, R.; Sivaprakash, B.; Rajamohan, N.; Vo, D.V.N. Carbon-free hydrogen and bioenergy production through integrated carbon capture and storage technology for achieving sustainable and circular economy—A review. Fuel 2023, 342, 126984. [Google Scholar] [CrossRef]

- Chu, X.; Fei, Z.; Chu, Z.; Huang, W.c. Decarbonizing the sludge treatment industry: Assessing the feasibility of achieving carbon reduction from carbon peaking to carbon neutrality. J. Clean. Prod. 2024, 434, 140023. [Google Scholar] [CrossRef]

- Maktabifard, M.; Al-Hazmi, H.E.; Szulc, P.; Mousavizadegan, M.; Xu, X.; Zaborowska, E.; Li, X.; Mąkinia, J. Net-zero carbon condition in wastewater treatment plants: A systematic review of mitigation strategies and challenges. Renew. Sustain. Energy Rev. 2023, 185, 113638. [Google Scholar] [CrossRef]

- Khan, M.Z.A.; Khan, H.A.; Ravi, S.S.; Turner, J.W.; Aziz, M. Potential of clean liquid fuels in decarbonizing transportation–An overlooked net-zero pathway? Renew. Sustain. Energy Rev. 2023, 183, 113483. [Google Scholar] [CrossRef]

- Yang, M.; Peng, M.; Wu, D.; Feng, H.; Wang, Y.; Lv, Y.; Sun, F.; Sharma, S.; Che, Y.; Yang, K. Greenhouse gas emissions from wastewater treatment plants in China: Historical emissions and future mitigation potentials. Resour. Conserv. Recycl. 2023, 190, 106794. [Google Scholar] [CrossRef]

- Wang, K.; Nakakubo, T. Design of a sewage sludge energy conversion technology introduction scenario for large city sewage treatment plants in Japan: Focusing on zero fuel consumption. J. Clean. Prod. 2022, 379, 134794. [Google Scholar] [CrossRef]

- Dhoke, C.; Zaabout, A.; Cloete, S.; Amini, S. Review on reactor configurations for adsorption-based CO2 capture. Ind. Eng. Chem. Res. 2021, 60, 3779–3798. [Google Scholar] [CrossRef]

- Sun, Y.; Dong, B.; Wang, L.; Li, H.; Thorin, E. Technology selection for capturing CO2 from wood pyrolysis. Energy Convers. Manag. 2022, 266, 115835. [Google Scholar] [CrossRef]

- Li, M.; Zhao, W. Environmental impact of anaerobic digestion of sludge. J. Clean. Prod. 2020, 245, 118857. [Google Scholar] [CrossRef]

- Smith, J.; Kumar, R. Composting as a sustainable method for sludge management. Waste Manag. 2021, 122, 145–153. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, L. CO2 emissions from incineration of sewage sludge in China. Environ. Sci. Technol. 2022, 56, 7030–7037. [Google Scholar]

- Wang, Y.; Lee, S. Lifecycle GHG emissions from landfilling sludge: A case study. Resour. Conserv. Recycl. 2019, 149, 667–674. [Google Scholar] [CrossRef]

- Singh, H.; Li, C.; Cheng, P.; Wang, X.; Liu, Q. A critical review of technologies, costs, and projects for production of carbon-neutral liquid e-fuels from hydrogen and captured CO2. Energy Adv. 2022, 1, 580–605. [Google Scholar] [CrossRef]

- Yaashikaa, P.; Kumar, P.S.; Saravanan, A.; Karishma, S.; Rangasamy, G. A biotechnological roadmap for decarbonization systems combined into bioenergy production: Prelude of environmental life-cycle assessment. Chemosphere 2023, 329, 138670. [Google Scholar] [CrossRef]

- Papadis, E.; Tsatsaronis, G. Challenges in the decarbonization of the energy sector. Energy 2020, 205, 118025. [Google Scholar] [CrossRef]

- Bora, R.R.; Richardson, R.E.; You, F. Resource recovery and waste-to-energy from wastewater sludge via thermochemical conversion technologies in support of circular economy: A comprehensive review. BMC Chem. Eng. 2020, 2, 8. [Google Scholar] [CrossRef]

- Bertasini, D.; Battista, F.; Rizzioli, F.; Frison, N.; Bolzonella, D. Decarbonization of the European natural gas grid using hydrogen and methane biologically produced from organic waste: A critical overview. Renew. Energy 2023, 206, 386–396. [Google Scholar] [CrossRef]

- Helal, M.A.; Anderson, N.; Wei, Y.; Thompson, M. A Review of Biomass-to-Bioenergy Supply Chain Research Using Bibliometric Analysis and Visualization. Energies 2023, 16, 1187. [Google Scholar] [CrossRef]

- Yin, C.; Zhao, W.; Ye, J.; Muroki, M.; Pereira, P. Ecosystem carbon sequestration service supports the Sustainable Development Goals progress. J. Environ. Manag. 2023, 330, 117155. [Google Scholar] [CrossRef]

- Phuphuakrat, T.; Namioka, T.; Yoshikawa, K. Tar removal from biomass pyrolysis gas in two-step function of decomposition and adsorption. Appl. Energy 2010, 87, 2203–2211. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhai, Y.; Li, S.; Liu, X.; Wang, B.; Liu, X.; Fan, Y.; Shi, H.; Li, C.; Zhu, Y. Thermal treatment of sewage sludge: A comparative review of the conversion principle, recovery methods and bioavailability-predicting of phosphorus. Chemosphere 2022, 291, 133053. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Kibria, M.; Bhattacharya, S. Evaluation of high-temperature pyrolysis and CO2 gasification performance of bituminous coal in an entrained flow gasifier. J. Energy Inst. 2021, 94, 294–309. [Google Scholar] [CrossRef]

- Variny, M.; Varga, A.; Rimár, M.; Janošovskỳ, J.; Kizek, J.; Lukáč, L.; Jablonskỳ, G.; Mierka, O. Advances in biomass co-combustion with fossil fuels in the European context: A review. Processes 2021, 9, 100. [Google Scholar] [CrossRef]

- González-Arias, J.; Sánchez, M.E.; Cara-Jiménez, J.; Baena-Moreno, F.M.; Zhang, Z. Hydrothermal carbonization of biomass and waste: A review. Environ. Chem. Lett. 2022, 20, 211–221. [Google Scholar] [CrossRef]

- Hu, Y.; Gong, M.; Xing, X.; Wang, H.; Zeng, Y.; Xu, C.C. Supercritical water gasification of biomass model compounds: A review. Renew. Sustain. Energy Rev. 2020, 118, 109529. [Google Scholar] [CrossRef]

- Shaw, R.; Mukherjee, S. The development of carbon capture and storage (CCS) in India: A critical review. Carbon Capture Sci. Technol. 2022, 2, 100036. [Google Scholar] [CrossRef]

- Jiang, G.; Xu, D.; Hao, B.; Liu, L.; Wang, S.; Wu, Z. Thermochemical methods for the treatment of municipal sludge. J. Clean. Prod. 2021, 311, 127811. [Google Scholar] [CrossRef]

- Noussan, M.; Negro, V.; Prussi, M.; Chiaramonti, D. The potential role of biomethane for the decarbonization of transport: An analysis of 2030 scenarios in Italy. Appl. Energy 2024, 355, 122322. [Google Scholar] [CrossRef]

- Davoodi, S.; Al-Shargabi, M.; Wood, D.A.; Rukavishnikov, V.S.; Minaev, K.M. Review of technological progress in carbon dioxide capture, storage, and utilization. Gas Sci. Eng. 2023, 117, 205070. [Google Scholar] [CrossRef]

- Pleshivtseva, Y.; Derevyanov, M.; Pimenov, A.; Rapoport, A. Comparative analysis of global trends in low carbon hydrogen production towards the decarbonization pathway. Int. J. Hydrogen Energy 2023, 48, 32191–32240. [Google Scholar] [CrossRef]

- Cormos, C.C. Green hydrogen production from decarbonized biomass gasification: An integrated techno-economic and environmental analysis. Energy 2023, 270, 126926. [Google Scholar] [CrossRef]

- Ketov, A.; Sliusar, N.; Tsybina, A.; Ketov, I.; Chudinov, S.; Krasnovskikh, M.; Bosnic, V. Plant Biomass Conversion to Vehicle Liquid Fuel as a Path to Sustainability. Resources 2022, 11, 75. [Google Scholar] [CrossRef]

- Das, A.; Peu, S.D. A comprehensive review on recent advancements in thermochemical processes for clean hydrogen production to decarbonize the energy sector. Sustainability 2022, 14, 11206. [Google Scholar] [CrossRef]

- Li, L.; Du, G.; Yan, B.; Wang, Y.; Zhao, Y.; Su, J.; Li, H.; Du, Y.; Sun, Y.; Chen, G.; et al. Carbon footprint analysis of sewage sludge thermochemical conversion technologies. Sustainability 2023, 15, 4170. [Google Scholar] [CrossRef]

- Liu, J.; Liu, G.; Zhang, W.; Li, Z.; Jin, H.; Xing, F. A new approach to CO2 capture and sequestration: A novel carbon capture artificial aggregates made from biochar and municipal waste incineration bottom ash. Constr. Build. Mater. 2023, 398, 132472. [Google Scholar] [CrossRef]

- Francis, J.C.; Nighojkar, A.; Kandasubramanian, B. Relevance of wood biochar on CO2 adsorption: A review. Hybrid Advances 2023, 3, 100056. [Google Scholar] [CrossRef]

- Wang, L.; Deng, J.; Yang, X.; Hou, R.; Hou, D. Role of biochar toward carbon neutrality. Carbon Res. 2023, 2, 2. [Google Scholar] [CrossRef]

- Quan, C.; Zhou, Y.; Gao, N.; Yang, T.; Wang, J.; Wu, C. Direct CO2 capture from air using char from pyrolysis of digestate solid. Biomass Bioenergy 2023, 175, 106891. [Google Scholar] [CrossRef]

- Sudalaimuthu, P.; Sathyamurthy, R. Forecast sustainable and renewable hydrogen production via circular bio-economy of agro waste. Int. J. Hydrogen Energy 2024, 75, 179–199. [Google Scholar] [CrossRef]

- Liu, H.; Lu, H.; Hu, H. CO2 capture and mineral storage: State of the art and future challenges. Renew. Sustain. Energy Rev. 2024, 189, 113908. [Google Scholar] [CrossRef]

- Liu, E.; Lu, X.; Wang, D. A systematic review of carbon capture, utilization and storage: Status, progress and challenges. Energies 2023, 16, 2865. [Google Scholar] [CrossRef]

- Krishnan, A.; Nighojkar, A.; Kandasubramanian, B. Emerging towards zero carbon footprint via carbon dioxide capturing and sequestration. Carbon Capture Sci. Technol. 2023, 9, 100137. [Google Scholar] [CrossRef]

- Peu, S.D.; Das, A.; Hossain, M.S.; Akanda, M.A.M.; Akanda, M.M.H.; Rahman, M.; Miah, M.N.; Das, B.K.; Islam, A.R.M.T.; Salah, M.M. A comprehensive review on recent advancements in absorption-based post combustion carbon capture technologies to obtain a sustainable energy sector with clean environment. Sustainability 2023, 15, 5827. [Google Scholar] [CrossRef]

- Dermühl, S.; Riedel, U. A comparison of the most promising low-carbon hydrogen production technologies. Fuel 2023, 340, 127478. [Google Scholar] [CrossRef]

- Bergman-Fonte, C.; da Silva, G.N.; Império, M.; Draeger, R.; Coutinho, L.; Cunha, B.S.; Rochedo, P.R.; Szklo, A.; Schaeffer, R. Repurposing, co-processing and greenhouse gas mitigation–The Brazilian refining sector under deep decarbonization scenarios: A case study using integrated assessment modeling. Energy 2023, 282, 128435. [Google Scholar] [CrossRef]

- Aniruddha, R.; Singh, S.A.; Reddy, B.M.; Sreedhar, I. Sorption enhanced reforming: A potential route to produce pure H2 with in-situ carbon capture. Fuel 2023, 351, 128925. [Google Scholar] [CrossRef]

- Zaker, A.; ben Hammouda, S.; Sun, J.; Wang, X.; Li, X.; Chen, Z. Carbon-based materials for CO2 capture: Their production, modification and performance. J. Environ. Chem. Eng. 2023, 11, 109741. [Google Scholar] [CrossRef]

- Corso, M.P.; Stefenon, S.F.; Singh, G.; Matsuo, M.V.; Perez, F.L.; Leithardt, V.R.Q. Evaluation of visible contamination on power grid insulators using convolutional neural networks. Electr. Eng. 2023, 105, 3881–3894. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Seman, L.O.; Schutel Furtado Neto, C.; Nied, A.; Seganfredo, D.M.; Garcia da Luz, F.; Sabino, P.H.; Torreblanca González, J.; Quietinho Leithardt, V.R. Electric field evaluation using the finite element method and proxy models for the design of stator slots in a permanent magnet synchronous motor. Electronics 2020, 9, 1975. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Singh, G.; Souza, B.J.; Freire, R.Z.; Yow, K.C. Optimized hybrid YOLOu-Quasi-ProtoPNet for insulators classification. IET Gener. Transm. Distrib. 2023, 17, 3501–3511. [Google Scholar] [CrossRef]

- Li, C.; Dong, Z.; Ding, L.; Petersen, H.; Qiu, Z.; Chen, G.; Prasad, D. Interpretable Memristive LSTM Network Design for Probabilistic Residential Load Forecasting. IEEE Trans. Circuits Syst. I Regul. Pap. 2022, 69, 2297–2310. [Google Scholar] [CrossRef]

- Martínez, F.; Frías, M.P.; Pérez-Godoy, M.D.; Rivera, A.J. Time Series Forecasting by Generalized Regression Neural Networks Trained With Multiple Series. IEEE Access 2022, 10, 3275–3283. [Google Scholar] [CrossRef]

- Iftikhar, H.; Mancha Gonzales, S.; Zywiołek, J.; López-Gonzales, J.L. Electricity Demand Forecasting Using a Novel Time Series Ensemble Technique. IEEE Access 2024, 12, 88963–88975. [Google Scholar] [CrossRef]

- Moreno, S.R.; Seman, L.O.; Stefenon, S.F.; dos Santos Coelho, L.; Mariani, V.C. Enhancing wind speed forecasting through synergy of machine learning, singular spectral analysis, and variational mode decomposition. Energy 2024, 292, 130493. [Google Scholar] [CrossRef]

- Zhu, C.; Ma, X.; Ding, W.; Zhan, J. Long-Term Time Series Forecasting With Multilinear Trend Fuzzy Information Granules for LSTM in a Periodic Framework. IEEE Trans. Fuzzy Syst. 2024, 32, 322–336. [Google Scholar] [CrossRef]

- Pranolo, A.; Mao, Y.; Wibawa, A.P.; Utama, A.B.P.; Dwiyanto, F.A. Robust LSTM With Tuned-PSO and Bifold-Attention Mechanism for Analyzing Multivariate Time-Series. IEEE Access 2022, 10, 78423–78434. [Google Scholar] [CrossRef]

- Li, W.; Law, K.L.E. Deep Learning Models for Time Series Forecasting: A Review. IEEE Access 2024, 12, 92306–92327. [Google Scholar] [CrossRef]

- Klaar, A.C.R.; Stefenon, S.F.; Seman, L.O.; Mariani, V.C.; Coelho, L.S. Optimized EWT-Seq2Seq-LSTM with attention mechanism to insulators fault prediction. Sensors 2023, 23, 3202. [Google Scholar] [CrossRef]

- Quan, C.; Zhou, Y.; Wang, J.; Wu, C.; Gao, N. Biomass-based carbon materials for CO2 capture: A review. J. CO2 Util. 2023, 68, 102373. [Google Scholar] [CrossRef]

- Shi, T.; Moktadir, M.A.; Ren, J.; Shen, W. Comparative economic, environmental and exergy analysis of power generation technologies from the waste sludge treatment. Energy Convers. Manag. 2023, 286, 117074. [Google Scholar] [CrossRef]

- Su, G.; Zulkifli, N.W.M.; Liu, L.; Ong, H.C.; Ibrahim, S.; Yu, K.L.; Wei, Y.; Bin, F. Carbon-negative co-production of methanol and activated carbon from bagasse pyrolysis, physical activation, chemical looping, and methanol synthesis. Energy Convers. Manag. 2023, 293, 117481. [Google Scholar] [CrossRef]

- Akbari, M.; Kumar, A. The development of data-intensive techno-economic models for the comparison of renewable natural gas production from six different biomass feedstocks for the decarbonization of energy demand sectors. Fuel 2024, 358, 130107. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y. Sorption-enhanced steam gasification of biomass for H2-rich gas production and in-situ CO2 capture by CaO-based sorbents: A critical review. Appl. Energy Combust. Sci. 2023, 14, 100124. [Google Scholar] [CrossRef]

- Wang, Q.; Li, S.; Li, R. Forecasting energy demand in China and India: Using single-linear, hybrid-linear, and non-linear time series forecast techniques. Energy 2018, 161, 821–831. [Google Scholar] [CrossRef]

- da Silva, E.C.; Finardi, E.C.; Stefenon, S.F. Enhancing hydroelectric inflow prediction in the Brazilian power system: A comparative analysis of machine learning models and hyperparameter optimization for decision support. Electr. Power Syst. Res. 2024, 230, 110275. [Google Scholar] [CrossRef]

- Yamasaki, M.; Freire, R.Z.; Seman, L.O.; Stefenon, S.F.; Mariani, V.C.; dos Santos Coelho, L. Optimized hybrid ensemble learning approaches applied to very short-term load forecasting. Int. J. Electr. Power Energy Syst. 2024, 155, 109579. [Google Scholar] [CrossRef]

- Deb, C.; Zhang, F.; Yang, J.; Lee, S.E.; Shah, K.W. A review on time series forecasting techniques for building energy consumption. Renew. Sustain. Energy Rev. 2017, 74, 902–924. [Google Scholar] [CrossRef]

- Shang, Y.; Yang, Q.; Pu, Y.; Taghizadeh-Hesary, F. Employing artificial intelligence and enhancing resource efficiency to achieve carbon neutrality. Resour. Policy 2024, 88, 104510. [Google Scholar] [CrossRef]

- Yu, L.; Wang, Y.; Wei, X.; Zeng, C. Towards low-carbon development: The role of industrial robots in decarbonization in Chinese cities. J. Environ. Manag. 2023, 330, 117216. [Google Scholar] [CrossRef]

- Okonkwo, E.C.; AlNouss, A.; Shahbaz, M.; Al-Ansari, T. Developing integrated direct air capture and bioenergy with carbon capture and storage systems: Progress towards 2 ∘C and 1.5 ∘C climate goals. Energy Convers. Manag. 2023, 296, 117687. [Google Scholar] [CrossRef]

- Slavin, B.; Wang, R.; Roy, D.; Ling-Chin, J.; Roskilly, A.P. Techno-economic analysis of direct air carbon capture and hydrogen production integrated with a small modular reactor. Appl. Energy 2024, 356, 122407. [Google Scholar] [CrossRef]

- Kostowski, W.; Tańczuk, M.; Majchrzyk, M.; Banasik, A.; Klimanek, A. Generation of renewable hydrogen from sewage sludge—Quantitative and energy-based technology evaluation. Int. J. Hydrogen Energy 2024, 52, 983–994. [Google Scholar] [CrossRef]

- Adibimanesh, B.; Polesek-Karczewska, S.; Bagherzadeh, F.; Szczuko, P.; Shafighfard, T. Energy consumption optimization in wastewater treatment plants: Machine learning for monitoring incineration of sewage sludge. Sustain. Energy Technol. Assess. 2023, 56, 103040. [Google Scholar] [CrossRef]

- Zhou, A.; Wang, X.; Yu, S.; Deng, S.; Tan, H.; Mikulčić, H. Process design and optimization on self-sustaining pyrolysis and carbonization of municipal sewage sludge. Waste Manag. 2023, 159, 125–133. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Mašláni, A.; Van Oost, G.; Fathi, J.; Hlína, M.; Mates, T.; Pohořelỳ, M.; Jeremiáš, M. Integration of thermal plasma with CCUS to valorize sewage sludge. Energy 2024, 288, 129896. [Google Scholar] [CrossRef]

- Huang, Y.; Zhen, Y.; Liu, L.; Ning, X.; Wang, C.; Li, K.; Zhao, L.; Lu, Q. Comprehensive competitiveness assessment of four typical municipal sludge treatment routes in China based on environmental and techno-economic analysis. Sci. Total Environ. 2023, 895, 165123. [Google Scholar] [CrossRef]

- Moles, S.; Martinez, I.; Callén, M.S.; Gómez, J.; López, J.M.; Murillo, R. Pilot-scale study of sorption-enhanced gasification of sewage sludge. Fuel 2024, 360, 130611. [Google Scholar] [CrossRef]

- Zhou, K.; Yang, Y.; Liu, B.; Tian, G.; Jiang, Z.; Bian, B. Waste to worth: A new approach to treat wastewater sludge. Sep. Purif. Technol. 2023, 305, 122412. [Google Scholar] [CrossRef]

- Bobadilla, L.F.; Azancot, L.; González-Castaño, M.; Ruíz-López, E.; Pastor-Pérez, L.; Durán-Olivencia, F.J.; Ye, R.; Chong, K.; Blanco-Sánchez, P.H.; Wu, Z.; et al. Biomass gasification, catalytic technologies and energy integration for production of circular methanol: New horizons for industry decarbonisation. J. Environ. Sci. 2024, 140, 306–318. [Google Scholar] [CrossRef]

- Wilk, M.; Śliz, M.; Czerwińska, K.; Śledź, M. The effect of an acid catalyst on the hydrothermal carbonization of sewage sludge. J. Environ. Manag. 2023, 345, 118820. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Cui, P.; Yang, S.; Zhou, Y.; Du, W.; Wang, Y.; Deng, C.; Wang, S. Thermodynamic analysis of SOFC–CCHP system based on municipal sludge plasma gasification with carbon capture. Appl. Energy 2023, 336, 120822. [Google Scholar] [CrossRef]

- Yang, X.; Tian, S.; Kan, T.; Zhu, Y.; Xu, H.; Strezov, V.; Nelson, P.; Jiang, Y. Sorption-enhanced thermochemical conversion of sewage sludge to syngas with intensified carbon utilization. Appl. Energy 2019, 254, 113663. [Google Scholar] [CrossRef]

- Morgano, M.T.; Zubani, A.; Rada, E.C.; Ragazzi, M.; Torretta, V.; Apostol, T.; Istrate, I.A. An Overview of the Thermochemical Valorization of Sewage Sludge: Principles and Current Challenges. Energies 2024, 17, 2417. [Google Scholar] [CrossRef]

- Carotenuto, A.; Di Fraia, S.; Massarotti, N.; Sobek, S.; Uddin, M.R.; Vanoli, L.; Werle, S. Sewage Sludge Gasification Process Optimization for Combined Heat and Power Generation. Energies 2023, 16, 4742. [Google Scholar] [CrossRef]

- Fleiß, B.; Priscak, J.; Hammerschmid, M.; Fuchs, J.; Müller, S.; Hofbauer, H. CO2 capture costs of chemical looping combustion of biomass: A comparison of natural and synthetic oxygen carrier. J. Energy Chem. 2024, 92, 296–310. [Google Scholar] [CrossRef]

- Peltola, P.; Ruottu, L.; Larkimo, M.; Laasonen, A.; Myöhänen, K. A novel dual circulating fluidized bed technology for thermal treatment of municipal sewage sludge with recovery of nutrients and energy. Waste Manag. 2023, 155, 329–337. [Google Scholar] [CrossRef]

- Subramanian, N.; Madejski, P. Analysis of CO2 capture process from flue-gases in combined cycle gas turbine power plant using post-combustion capture technology. Energy 2023, 282, 128311. [Google Scholar] [CrossRef]

- Khan, R.; Shukla, S.; Kumar, M.; Zuorro, A.; Pandey, A. Sewage sludge derived biochar and its potential for sustainable environment in circular economy: Advantages and challenges. Chem. Eng. J. 2023, 471, 144495. [Google Scholar] [CrossRef]

- Roychowdhury, S.; Ghosh, S. State-of-the-art of biochar amended dark fermentative hydrogen production: A sustainable coupling of decarbonization pathways towards low carbon future. J. Clean. Prod. 2024, 443, 141208. [Google Scholar] [CrossRef]

- Andooz, A.; Eqbalpour, M.; Kowsari, E.; Ramakrishna, S.; Cheshmeh, Z.A. A comprehensive review on pyrolysis from the circular economy point of view and its environmental and social effects. J. Clean. Prod. 2023, 388, 136021. [Google Scholar] [CrossRef]

- Sajdak, M.; Zajemska, M.; Ouadi, M.; Mucha, W.; Misztal, E.; Pieszko, C.; Gałko, G. Perspectives of Using Sewage Sludge Char in CO2 Sequestration on Degraded and Brownfield Sites. Energies 2023, 16, 3945. [Google Scholar] [CrossRef]

- Shen, J.; Wu, Y.; Lan, G.; Xia, Y.; Yan, B.; Li, Y.; Zhang, Y.; Yu, Y.; Fu, C.; Xu, A.; et al. Effect of co-pyrolysis of sewage sludge with different plastics on the nitrogen, sulfur, and chlorine releasing characteristics and the heavy metals ecological risk of biochar. J. Environ. Chem. Eng. 2023, 11, 110406. [Google Scholar] [CrossRef]

- Huang, C.; Mohamed, B.A.; Li, L.Y. Comparative life-cycle energy and environmental analysis of sewage sludge and biomass co-pyrolysis for biofuel and biochar production. Chem. Eng. J. 2023, 457, 141284. [Google Scholar] [CrossRef]

- Liu, C.; Fu, C.; Li, T.; Zhang, P.; Xia, Y.; Wu, Y.; Lan, Q.; Li, Y.; Zhang, Y.; Gui, J. CO2 capture using biochar derived from conditioned sludge via pyrolysis. Sep. Purif. Technol. 2023, 314, 123624. [Google Scholar] [CrossRef]

- Slezak, R.; Unyay, H.; Szufa, S.; Ledakowicz, S. An extensive review and comparison of modern biomass reactors torrefaction vs. biomass pyrolizers—Part 2. Energies 2023, 16, 2212. [Google Scholar] [CrossRef]

- Yu, D.; Li, Z.; Li, J.; He, J.; Li, B.; Wang, Y. Enhancement of H2 and light oil production and CO2 emission mitigation during co-pyrolysis of oily sludge and incineration fly ash. J. Hazard. Mater. 2024, 462, 132618. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhao, Q.; Li, D.; Li, J.; Guo, W. Enhanced recovery of phosphorus in sewage sludge-derived biochar with CaCO3: Phosphorus speciation and slow-release phosphorus behavior. Sep. Purif. Technol. 2023, 311, 123325. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Y.; Lan, G.; Ji, X.; Xia, Y.; Fu, C.; Shen, J.; Gui, J.; Liu, Y.; Qu, Y.; et al. CO2 capture performance of biochar prepared from sewage sludge after conditioning with different dewatering agents. J. Environ. Chem. Eng. 2022, 10, 108318. [Google Scholar] [CrossRef]

- Zhao, L.; Sun, Z.F.; Pan, X.W.; Tan, J.Y.; Yang, S.S.; Wu, J.T.; Chen, C.; Yuan, Y.; Ren, N.Q. Sewage sludge derived biochar for environmental improvement: Advances, challenges, and solutions. Water Res. X 2023, 18, 100167. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Liu, S.; Han, Z.; Ma, R.; Cui, C.; Sun, S. Scaled-up microwave pyrolysis of sludge for hydrogen-rich biogas and life cycle assessment: Parameters synergistic optimization, carbon footprint analysis and technology upgrade. Chem. Eng. J. 2023, 452, 139551. [Google Scholar] [CrossRef]

- Cai, Y.; Aihemaiti, A.; Su, Y.; Sun, Y.; Sun, X.; Li, H.; Chen, K.; Shen, X.; Yan, F.; Qu, F.; et al. CO2 assisted Ca-based additives on pyrolytic characteristics and products from the co-pyrolysis of sewage sludge and biomass. Sep. Purif. Technol. 2024, 330, 125470. [Google Scholar] [CrossRef]

- Farooq, A.; Ko, C.H.; Park, Y.K. Sewage sludge steam gasification over bimetallic mesoporous Al-MCM48 catalysts for efficient hydrogen generation. Environ. Res. 2023, 224, 115553. [Google Scholar] [CrossRef]

- Fang, L.; Huang, T.; Lu, H.; Wu, X.L.; Chen, Z.; Yang, H.; Wang, S.; Tang, Z.; Li, Z.; Hu, B.; et al. Biochar-based materials in environmental pollutant elimination, H2 production and CO2 capture applications. Biochar 2023, 5, 42. [Google Scholar] [CrossRef]

- Hu, M.; Hu, H.; Ye, Z.; Tan, S.; Yin, K.; Chen, Z.; Guo, D.; Rong, H.; Wang, J.; Pan, Z.; et al. A review on turning sewage sludge to value-added energy and materials via thermochemical conversion towards carbon neutrality. J. Clean. Prod. 2022, 379, 134657. [Google Scholar] [CrossRef]

- Nunes, L.J.; Matias, J.C. Biomass torrefaction as a key driver for the sustainable development and decarbonization of energy production. Sustainability 2020, 12, 922. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, W.; Jin, H.; Li, Z.; Liu, G.; Xing, F.; Tang, L. Exploring the carbon capture and sequestration performance of biochar-artificial aggregate using a new method. Sci. Total Environ. 2023, 859, 160423. [Google Scholar] [CrossRef]

- Martínez-Alvarenga, H.; Gutiérrez, M.; Gómez-Cámer, J.; Benítez, A.; Martín, M.; Caballero, A. Integral evaluation of effective conversion of sewage sludge from WWTP into highly porous activated carbon. J. Environ. Manag. 2024, 351, 119822. [Google Scholar] [CrossRef]

- Ayeleru, O.O.; Modekwe, H.U.; Onisuru, O.R.; Ohoro, C.R.; Akinnawo, C.A.; Olubambi, P.A. Adsorbent technologies and applications for carbon capture, and direct air capture in environmental perspective and sustainable climate action. Sustain. Chem. Clim. Action 2023, 3, 100029. [Google Scholar] [CrossRef]

- Raza, S.; Orooji, Y.; Ghasali, E.; Hayat, A.; Karimi-Maleh, H.; Lin, H. Engineering approaches for CO2 converting to biomass coupled with nanobiomaterials as biomediated towards circular bioeconomy. J. CO2 Util. 2023, 67, 102295. [Google Scholar] [CrossRef]

- Yang, Q.; Ke, J.; Li, H.; Guo, X.; Wang, D.; Liu, Y.; Chen, J.; Guo, R. Waste carbon conversion and utilization in chemical wastewater treatment process: Experimental approaches from lab-to pilot-scale. Sep. Purif. Technol. 2023, 308, 122884. [Google Scholar] [CrossRef]

- Culaba, A.B.; Mayol, A.P.; San Juan, J.L.G.; Ubando, A.T.; Bandala, A.A.; Concepcion II, R.S.; Alipio, M.; Chen, W.H.; Show, P.L.; Chang, J.S. Design of biorefineries towards carbon neutrality: A critical review. Bioresour. Technol. 2022, 369, 128256. [Google Scholar] [CrossRef]

- Muniz, R.N.; Stefenon, S.F.; Buratto, W.G.; Nied, A.; Meyer, L.H.; Finardi, E.C.; Kühl, R.M.; de Sa, J.A.S.; da Rocha, B.R.P. Tools for measuring energy sustainability: A comparative review. Energies 2020, 13, 2366. [Google Scholar] [CrossRef]

- Beik, F.; Williams, L.; Brown, T.; Wagland, S.T. Development and prototype testing of a novel small-scale pyrolysis system for the treatment of sanitary sludge. Energy Convers. Manag. 2023, 277, 116627. [Google Scholar] [CrossRef]

- Li, J.; Li, L.; Tong, Y.W.; Wang, X. Understanding and optimizing the gasification of biomass waste with machine learning. Green Chem. Eng. 2023, 4, 123–133. [Google Scholar] [CrossRef]

- Zheng, W.; Xu, Z.; Shao, Z.; Li, J.; Lei, K.; Li, J. Optimal dispatch of nearly-zero carbon integrated energy system considering waste incineration plant-carbon capture system and market mechanisms. Int. J. Hydrogen Energy 2023, 48, 27013–27031. [Google Scholar] [CrossRef]

- Velidandi, A.; Gandam, P.K.; Chinta, M.L.; Konakanchi, S.; Bhavanam, A.R.; Baadhe, R.R.; Sharma, M.; Gaffey, J.; Nguyen, Q.D.; Gupta, V.K. State-of-the-art and future directions of machine learning for biomass characterization and for sustainable biorefinery. J. Energy Chem. 2023, 81, 42–63. [Google Scholar] [CrossRef]

- Kossińska, N.; Krzyżyńska, R.; Ghazal, H.; Jouhara, H. Hydrothermal carbonisation of sewage sludge and resulting biofuels as a sustainable energy source. Energy 2023, 275, 127337. [Google Scholar] [CrossRef]

- Hu, D.; Ren, C.; Zhang, S.; Ma, M.; Chen, Y.; Chen, B.; Guo, L. Thermodynamic and environmental analysis of integrated supercritical water gasification of sewage sludge for power and hydrogen production. Energy 2024, 299, 131568. [Google Scholar] [CrossRef]

- Luo, J.; Ma, R.; Lin, J.; Sun, S.; Gong, G.; Sun, J.; Chen, Y.; Ma, N. Review of microwave pyrolysis of sludge to produce high quality biogas: Multi-perspectives process optimization and critical issues proposal. Renew. Sustain. Energy Rev. 2023, 173, 113107. [Google Scholar] [CrossRef]

- Jadlovec, M.; Vỳtisk, J.; Honus, S.; Pospišilík, V.; Bassel, N. Pollutants production, energy recovery and environmental impact of sewage sludge co-incineration with biomass pellets. Environ. Technol. Innov. 2023, 32, 103400. [Google Scholar] [CrossRef]

- Salimbeni, A.; Di Bianca, M.; Lombardi, G.; Rizzo, A.M.; Chiaramonti, D. Opportunities of Integrating Slow Pyrolysis and Chemical Leaching for Extraction of Critical Raw Materials from Sewage Sludge. Water 2023, 15, 1060. [Google Scholar] [CrossRef]

- Zou, Y.; Hu, J.; Zhang, S.; Shi, K.; Liu, X.; Zhao, S.; Yang, H.; Jia, J. Carbonization characteristics of co-pyrolysis of sewage sludge and corn stalks and its agricultural benefits. J. Soils Sediments 2023, 23, 1674–1686. [Google Scholar] [CrossRef]

- Nasir, A.S.M.; Mohamed, B.; Li, L.Y. Comparative life cycle assessment of co-pyrolysing sewage sludge and wastewater-grown microalgae for biofuel production. Resour. Conserv. Recycl. 2023, 190, 106780. [Google Scholar] [CrossRef]

- Huang, C.; Mohamed, B.A.; Li, L.Y. Comparative life-cycle assessment of pyrolysis processes for producing bio-oil, biochar, and activated carbon from sewage sludge. Resour. Conserv. Recycl. 2022, 181, 106273. [Google Scholar] [CrossRef]

- Fakoya, M.B.; Imuezerua, E.O. Identifying ‘True’ Water Loss Information through the MFCA Model for Improved Cost-Saving Decisions in a Water Utility: A Case Study of the Doorndraai Water Treatment Scheme in South Africa. Sustainability 2020, 12, 7824. [Google Scholar] [CrossRef]

- Barska, A.; Jędrzejczak-Gas, J.; Wyrwa, J.; Kononowicz, K. Multidimensional assessment of the social development of EU countries in the context of implementing the concept of sustainable development. Sustainability 2020, 12, 7821. [Google Scholar] [CrossRef]

- Martinho, V.D.; Mourão, P.R. Circular economy and economic development in the European Union: A review and bibliometric analysis. Sustainability 2020, 12, 7767. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, X.; Xiao, J.; Peng, X.; Wang, J.; Ma, J.; Liu, D.; Liang, C. Comparative study of different sewage sludge incineration treatments based on environmental and economic life cycle assessment. Waste Manag. Res. 2024, 42, 418–429. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.J.; Eom, J.Y.; Lee, M.J.; Hwang, D.H.; Park, W.B.; Wie, Y.M.; Lee, K.G.; Lee, K.H. Comparative environmental evaluation of sewage sludge treatment and aggregate production process by life cycle assessment. Sustainability 2023, 16, 226. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, N. Machine learning modeling of thermally assisted biodrying process for municipal sludge. Waste Manag. 2024, 188, 95–106. [Google Scholar] [CrossRef] [PubMed]

- Shao, S.; Fu, D.; Yang, T.; Mu, H.; Gao, Q.; Zhang, Y. Analysis of machine learning models for wastewater treatment plant sludge output prediction. Sustainability 2023, 15, 13380. [Google Scholar] [CrossRef]

- Li, H.; Li, C.; Zhou, K.; Ye, W.; Lu, Y.; Chai, X.; Dai, X.; Wu, B. Intelligent upgrade of waste-activated sludge dewatering process based on artificial neural network model: Core influential factor identification and non-experimental prediction of sludge dewatering performance. J. Environ. Manag. 2023, 346, 118968. [Google Scholar] [CrossRef]

- Sun, L.; Li, M.; Liu, B.; Li, R.; Deng, H.; Zhu, X.; Zhu, X.; Tsang, D.C. Machine learning for municipal sludge recycling by thermochemical conversion towards sustainability. Bioresour. Technol. 2024, 394, 130254. [Google Scholar] [CrossRef]

- Rutland, H.; You, J.; Liu, H.; Bull, L.; Reynolds, D. A systematic review of machine-learning solutions in anaerobic digestion. Bioengineering 2023, 10, 1410. [Google Scholar] [CrossRef]

- Wu, Y.; Huang, D.; Zhang, L.; Zhang, R.; Yu, P.; Gao, Y.; Wu, D.; Gao, Y. An analytic hierarchy process combined with artificial neural network model to evaluate sustainable sludge treatment scenarios. Waste Manag. 2025, 201, 114821. [Google Scholar] [CrossRef]

- Cecconet, D.; Capodaglio, A.G. Sewage sludge biorefinery for circular economy. Sustainability 2022, 14, 14841. [Google Scholar] [CrossRef]

- Keller, F.; Voss, R.L.; Lee, R.P.; Meyer, B. Life cycle assessment of global warming potential of feedstock recycling technologies: Case study of waste gasification and pyrolysis in an integrated inventory model for waste treatment and chemical production in Germany. Resour. Conserv. Recycl. 2022, 179, 106106. [Google Scholar] [CrossRef]

- Tarpani, R.R.Z.; Azapagic, A. Life cycle sustainability assessment of advanced treatment techniques for urban wastewater reuse and sewage sludge resource recovery. Sci. Total Environ. 2023, 869, 161771. [Google Scholar] [CrossRef] [PubMed]

- Marami, H.; He, L.; Rafiee, S.; Khoshnevisan, B.; Tsapekos, P.; Mobli, H.; Elyasi, S.N.; Liu, H.; Angelidaki, I. Bridging to circular bioeconomy through a novel biorefinery platform on a wastewater treatment plant. Renew. Sustain. Energy Rev. 2022, 154, 111895. [Google Scholar] [CrossRef]

- Akinpelu, A.; Alam, M.S.; Shafiullah, M.; Rahman, S.M.; Al-Ismail, F.S. Greenhouse Gas Emission Dynamics of Saudi Arabia: Potential of Hydrogen Fuel for Emission Footprint Reduction. Sustainability 2023, 15, 5639. [Google Scholar] [CrossRef]

- Olafasakin, O.; Chang, Y.; Passalacqua, A.; Subramaniam, S.; Brown, R.C.; Mba Wright, M. Machine learning reduced order model for cost and emission assessment of a pyrolysis system. Energy Fuels 2021, 35, 9950–9960. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Seman, L.O.; Aquino, L.S.; dos Santos Coelho, L. Wavelet-Seq2Seq-LSTM with attention for time series forecasting of level of dams in hydroelectric power plants. Energy 2023, 274, 127350. [Google Scholar] [CrossRef]

- Sirisha, U.M.; Belavagi, M.C.; Attigeri, G. Profit Prediction Using ARIMA, SARIMA and LSTM Models in Time Series Forecasting: A Comparison. IEEE Access 2022, 10, 124715–124727. [Google Scholar] [CrossRef]

- Wen, X.; Li, W. Time Series Prediction Based on LSTM-Attention-LSTM Model. IEEE Access 2023, 11, 48322–48331. [Google Scholar] [CrossRef]

- Wan, S. A Denoising Time Window Algorithm for Optimizing LSTM Prediction. IEEE Access 2024, 12, 74268–74290. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, K.; Yang, Y.R.; Bi, J. Prophet: Toward Fast, Error-Tolerant Model-Based Throughput Prediction for Reactive Flows in DC Networks. IEEE/ACM Trans. Netw. 2020, 28, 2475–2488. [Google Scholar] [CrossRef]

- Luo, D.; Cao, Z.; Zhao, D.; Lin, Z.; Wang, C.; Yuan, H.; Liu, L.; Ma, H. OD-Prophet: Toward Efficiently Predicting Individual Origin-Destination Travel Demand in Location-Based Services. IEEE Internet Things J. 2024, 11, 25010–25023. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Zhu, K.; Zhang, J. Clothing Sale Forecasting by a Composite GRU–Prophet Model With an Attention Mechanism. IEEE Trans. Ind. Inform. 2021, 17, 8335–8344. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Seman, L.O.; Yamaguchi, C.K.; Coelho, L.D.S.; Mariani, V.C.; Matos-Carvalho, J.P.; Leithardt, V.R.Q. Neural Hierarchical Interpolation Time Series (NHITS) for Reservoir Level Multi-Horizon Forecasting in Hydroelectric Power Plants. IEEE Access 2025, 13, 54853–54865. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Seman, L.O.; da Silva, E.C.; Finardi, E.C.; Coelho, L.d.S.; Mariani, V.C. Hypertuned wavelet convolutional neural network with long short-term memory for time series forecasting in hydroelectric power plants. Energy 2024, 313, 133918. [Google Scholar] [CrossRef]

- Larcher, J.H.K.; Stefenon, S.F.; dos Santos Coelho, L.; Mariani, V.C. Enhanced multi-step streamflow series forecasting using hybrid signal decomposition and optimized reservoir computing models. Expert Syst. Appl. 2024, 255, 124856. [Google Scholar] [CrossRef]

- Zuege, C.V.; Stefenon, S.F.; Yamaguchi, C.K.; Mariani, V.C.; Gonzalez, G.V.; dos Santos Coelho, L. Wind speed forecasting approach using conformal prediction and feature importance selection. Int. J. Electr. Power Energy Syst. 2025, 168, 110700. [Google Scholar] [CrossRef]

- Lim, B.; Arık, S.O.; Loeff, N.; Pfister, T. Temporal Fusion Transformers for interpretable multi-horizon time series forecasting. Int. J. Forecast. 2021, 37, 1748–1764. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Seman, L.O.; da Silva, L.S.A.; Mariani, V.C.; dos Santos Coelho, L. Hypertuned temporal fusion transformer for multi-horizon time series forecasting of dam level in hydroelectric power plants. Int. J. Electr. Power Energy Syst. 2024, 157, 109876. [Google Scholar] [CrossRef]

- Linardatos, P.; Papastefanopoulos, V.; Panagiotakopoulos, T.; Kotsiantis, S. CO2 concentration forecasting in smart cities using a hybrid ARIMA–TFT model on multivariate time series IoT data. Sci. Rep. 2023, 13, 17266. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Seman, L.O.; Sopelsa Neto, N.F.; Meyer, L.H.; Mariani, V.C.; Coelho, L.d.S. Group method of data handling using Christiano-Fitzgerald random walk filter for insulator fault prediction. Sensors 2023, 23, 6118. [Google Scholar] [CrossRef]

- Alba, E.L.; Oliveira, G.A.; Ribeiro, M.H.D.M.; Rodrigues, E.O. Electricity Consumption Forecasting: An Approach Using Cooperative Ensemble Learning with SHapley Additive exPlanations. Forecasting 2024, 6, 839–863. [Google Scholar] [CrossRef]

- Liu, X.; Miao, X.; Jiang, H.; Chen, J.; Chen, Z. Fault Diagnosis in Power Line Inspection Using Normalized Multihierarchy Embedding Matching. IEEE Trans. Instrum. Meas. 2023, 72, 3505810. [Google Scholar] [CrossRef]

- Ribeiro, M.H.D.M.; da Silva, R.G.; Moreno, S.R.; Canton, C.; Larcher, J.H.K.; Stefenon, S.F.; Mariani, V.C.; dos Santos Coelho, L. Variational mode decomposition and bagging extreme learning machine with multi-objective optimization for wind power forecasting. Appl. Intell. 2024, 54, 3119–3134. [Google Scholar] [CrossRef]

- Liu, Y.; Dong, J.; Li, Y.; Gong, X.; Wang, J. A UAV-Based Aircraft Surface Defect Inspection System via External Constraints and Deep Learning. IEEE Trans. Instrum. Meas. 2022, 71, 5019315. [Google Scholar] [CrossRef]

- Klaar, A.C.R.; Stefenon, S.F.; Seman, L.O.; Mariani, V.C.; Coelho, L.S. Structure optimization of ensemble learning methods and seasonal decomposition approaches to energy price forecasting in Latin America: A case study about Mexico. Energies 2023, 16, 3184. [Google Scholar] [CrossRef]

- Ren, R.; Hung, T.; Tan, K.C. A Generic Deep-Learning-Based Approach for Automated Surface Inspection. IEEE Trans. Cybern. 2018, 48, 929–940. [Google Scholar] [CrossRef]

- Branco, N.W.; Cavalca, M.S.M.; Stefenon, S.F.; Leithardt, V.R.Q. Wavelet LSTM for fault forecasting in electrical power grids. Sensors 2022, 22, 8323. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Kasburg, C.; Freire, R.Z.; Silva Ferreira, F.C.; Bertol, D.W.; Nied, A. Photovoltaic power forecasting using wavelet neuro-fuzzy for active solar trackers. J. Intell. Fuzzy Syst. 2021, 40, 1083–1096. [Google Scholar] [CrossRef]

- Di Fraia, S.; Massarotti, N.; Uddin, M.R.; Vanoli, L. Conversion of Sewage Sludge to combined heat and power: Modeling and optimization. Smart Energy 2022, 5, 100061. [Google Scholar] [CrossRef]

- Bąk, K.; Ziółkowski, P.; Frost, J.; Drosińska-Komor, M. Comparative study of a combined heat and power plant retrofitted by CO2 capture during the combustion of syngas from sewage sludge gasification versus zero-emission combustion of hydrogen produced using renewables. Int. J. Hydrogen Energy 2023, 48, 39625–39640. [Google Scholar] [CrossRef]

- Yang, S.G.; Hu, Z.; Zhou, X.Y.; Cai, Q.; Xie, J.H.; Wu, Y.W.; Lu, Q.; Zhou, J.L. Site selection decision framework for biomass pyrolysis project based on a mixed method under probabilistic linguistic environment and low carbon perspective: A case study in China. Energy 2023, 272, 127118. [Google Scholar] [CrossRef]

- Khan, U.; Bilal, M.; Adil, H.M.; Darlington, N.; Khan, A.; Khan, N.; Ihsanullah, I. Hydrogen from sewage sludge: Production methods, influencing factors, challenges, and prospects. Sci. Total Environ. 2024, 919, 170696. [Google Scholar] [CrossRef]

- Qamar, O.A.; Jamil, F.; Hussain, M.; Ala’a, H.; Inayat, A.; Waris, A.; Akhter, P.; Park, Y.K. Feasibility-to-applications of value-added products from biomass: Current trends, challenges, and prospects. Chem. Eng. J. 2023, 454, 140240. [Google Scholar] [CrossRef]

- Shahbeik, H.; Shafizadeh, A.; Gupta, V.K.; Lam, S.S.; Rastegari, H.; Peng, W.; Pan, J.; Tabatabaei, M.; Aghbashlo, M. Using nanocatalysts to upgrade pyrolysis bio-oil: A critical review. J. Clean. Prod. 2023, 413, 137473. [Google Scholar] [CrossRef]

- González, M.; García, J.; Pérez, L. Thermal Hydrolysis of Sewage Sludge: A Case Study of a WWTP in Burgos, Spain. Appl. Sci. 2021, 11, 964. [Google Scholar] [CrossRef]

- Liew, C.S.; Kiatkittipong, W.; Lim, J.W.; Lam, M.K.; Ho, Y.C.; Ho, C.D.; Ntwampe, S.K.; Mohamad, M.; Usman, A. Stabilization of heavy metals loaded sewage sludge: Reviewing conventional to state-of-the-art thermal treatments in achieving energy sustainability. Chemosphere 2021, 277, 130310. [Google Scholar] [CrossRef] [PubMed]

- Croll, H.C.; Ikuma, K.; Ong, S.K.; Sarkar, S. Reinforcement learning applied to wastewater treatment process control optimization: Approaches, challenges, and path forward. Crit. Rev. Environ. Sci. Technol. 2023, 53, 1775–1794. [Google Scholar] [CrossRef]

- Hernández-del Olmo, F.; Gaudioso, E.; Duro, N.; Dormido, R.; Gorrotxategi, M. Advanced Control by Reinforcement Learning for Wastewater Treatment Plants: A Comparison with Traditional Approaches. Appl. Sci. 2023, 13, 4752. [Google Scholar] [CrossRef]

- Zheng, X.; Lam, K.L. An overview of environmental co-benefits and trade-offs to reduce greenhouse gas emissions in municipal wastewater management. Sustain. Prod. Consum. 2024, 46, 1–10. [Google Scholar] [CrossRef]

- Deon, B.; Cotta, K.; Silva, R.; Batista, C.; Justino, G.; Freitas, G.; Cordeiro, A.; Barbosa, A.; Loução Jr, F.; Simioni, T.; et al. Digital twin and machine learning for decision support in thermal power plant with combustion engines. Knowl.-Based Syst. 2022, 253, 109578. [Google Scholar] [CrossRef]

- Reza, M.S.; Afroze, S.; Kuterbekov, K.; Kabyshev, A.; Zh. Bekmyrza, K.; Haque, M.N.; Islam, S.N.; Hossain, M.A.; Hassan, M.; Roy, H.; et al. Advanced applications of carbonaceous materials in sustainable water treatment, energy storage, and CO2 capture: A comprehensive review. Sustainability 2023, 15, 8815. [Google Scholar] [CrossRef]

- Zhou, X.; Yang, J.; Zhao, X.; Dong, Q.; Wang, X.; Wei, L.; Yang, S.S.; Sun, H.; Ren, N.Q.; Bai, S. Towards the carbon neutrality of sludge treatment and disposal in China: A nationwide analysis based on life cycle assessment and scenario discovery. Environ. Int. 2023, 174, 107927. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, T.V.; Germano, A.D.; da Costa, E.G. Ultrasound and Artificial Intelligence Applied to the Pollution Estimation in Insulations. IEEE Trans. Power Deliv. 2012, 27, 583–589. [Google Scholar] [CrossRef]

- Sundaram, K.M.; Hussain, A.; Sanjeevikumar, P.; Holm-Nielsen, J.B.; Kaliappan, V.K.; Santhoshi, B.K. Deep Learning for Fault Diagnostics in Bearings, Insulators, PV Panels, Power Lines, and Electric Vehicle Applications—The State-of-the-Art Approaches. IEEE Access 2021, 9, 41246–41260. [Google Scholar] [CrossRef]

- Haj, Y.E.; El-Hag, A.H.; Ghunem, R.A. Application of Deep-Learning via Transfer Learning to Evaluate Silicone Rubber Material Surface Erosion. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1465–1467. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Seman, L.O.; Klaar, A.C.R.; Ovejero, R.G.; Leithardt, V.R.Q. Hypertuned-YOLO for interpretable distribution power grid fault location based on EigenCAM. Ain Shams Eng. J. 2024, 15, 102722. [Google Scholar] [CrossRef]

- Souza, B.J.; Stefenon, S.F.; Singh, G.; Freire, R.Z. Hybrid-YOLO for classification of insulators defects in transmission lines based on UAV. Int. J. Electr. Power Energy Syst. 2023, 148, 108982. [Google Scholar] [CrossRef]

- Wang, Q.; Li, X.; Liu, W.; Zhai, S.; Xu, Q.; Nie, S.; Ouyang, Q.; Wang, H.; Wang, A.; Huang, C. Carbon source recovery from waste sludge reduces greenhouse gas emissions in a pilot-scale industrial wastewater treatment plant. Environ. Sci. Ecotechnology 2023, 14, 100235. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, Q.; Xie, Y.; Dzakpasu, M.; Zhang, J.; Wang, X.C. A novel carbon emission evaluation model for anaerobic-anoxic-oxic urban sewage treatment. J. Environ. Manag. 2024, 350, 119640. [Google Scholar] [CrossRef] [PubMed]

- Crawford, T.W. Urban form as a technological driver of carbon dioxide emission: A structural human ecology analysis of onroad and residential sectors in the conterminous US. Sustainability 2020, 12, 7801. [Google Scholar] [CrossRef]

- Nie, S.; Zhou, J.; Yang, F.; Lan, M.; Li, J.; Zhang, Z.; Chen, Z.; Xu, M.; Li, H.; Sanjayan, J.G. Analysis of theoretical carbon dioxide emissions from cement production: Methodology and application. J. Clean. Prod. 2022, 334, 130270. [Google Scholar] [CrossRef]

- Ahmed Ali, K.; Ahmad, M.I.; Yusup, Y. Issues, impacts, and mitigations of carbon dioxide emissions in the building sector. Sustainability 2020, 12, 7427. [Google Scholar] [CrossRef]

- Mostafaeipour, A.; Bidokhti, A.; Fakhrzad, M.B.; Sadegheih, A.; Mehrjerdi, Y.Z. A new model for the use of renewable electricity to reduce carbon dioxide emissions. Energy 2022, 238, 121602. [Google Scholar] [CrossRef]

- Han, Y.; Li, J.; Lou, X.; Fan, C.; Geng, Z. Energy saving of buildings for reducing carbon dioxide emissions using novel dendrite net integrated adaptive mean square gradient. Appl. Energy 2022, 309, 118409. [Google Scholar] [CrossRef]

- Han, B.; Jin, Y.; Chen, B.; Zhou, W.; Yu, B.; Wei, C.; Wang, H.; Wang, K.; Chen, Y.; Chen, B.; et al. Maximizing electroactive sites in a three-dimensional covalent organic framework for significantly improved carbon dioxide reduction electrocatalysis. Angew. Chem. Int. Ed. 2022, 61, e202114244. [Google Scholar] [CrossRef]

- Ringe, S.; Morales-Guio, C.G.; Chen, L.D.; Fields, M.; Jaramillo, T.F.; Hahn, C.; Chan, K. Double layer charging driven carbon dioxide adsorption limits the rate of electrochemical carbon dioxide reduction on Gold. Nat. Commun. 2020, 11, 33. [Google Scholar] [CrossRef]

- Hu, Q.; Han, Z.; Wang, X.; Li, G.; Wang, Z.; Huang, X.; Yang, H.; Ren, X.; Zhang, Q.; Liu, J.; et al. Facile synthesis of sub-nanometric copper clusters by double confinement enables selective reduction of carbon dioxide to methane. Angew. Chem. Int. Ed. 2020, 59, 19054–19059. [Google Scholar] [CrossRef]

- Banerjee, S.; Zhang, Z.Q.; Hall, A.S.; Thoi, V.S. Surfactant perturbation of cation interactions at the electrode–electrolyte interface in carbon dioxide reduction. ACS Catal. 2020, 10, 9907–9914. [Google Scholar] [CrossRef]

- Liu, A.; Gao, M.; Ren, X.; Meng, F.; Yang, Y.; Gao, L.; Yang, Q.; Ma, T. Current progress in electrocatalytic carbon dioxide reduction to fuels on heterogeneous catalysts. J. Mater. Chem. A 2020, 8, 3541–3562. [Google Scholar] [CrossRef]

- Prabhu, P.; Jose, V.; Lee, J.M. Heterostructured catalysts for electrocatalytic and photocatalytic carbon dioxide reduction. Adv. Funct. Mater. 2020, 30, 1910768. [Google Scholar] [CrossRef]

- Zhu, H.; Liou, S.R.; Chen, P.C.; He, X.Y.; Sui, M.L. Carbon Emissions Reduction of a Circular Architectural Practice: A Study on a Reversible Design Pavilion Using Recycled Materials. Sustainability 2024, 16, 1729. [Google Scholar] [CrossRef]

- Shi, X.; Kou, L.; Liang, H.; Wang, Y.; Li, W. Evaluating Carbon Emissions during Slurry Shield Tunneling for Sustainable Management Utilizing a Hybrid Life-Cycle Assessment Approach. Sustainability 2024, 16, 2702. [Google Scholar] [CrossRef]

| Treatment Method | Examples of CO2 Emissions (kg/ton) | Reference |

|---|---|---|

| Anaerobic Digestion | 120 | Li and Zhao [22] |

| Composting | 250 | Smith and Kumar [23] |

| Incineration | 950 | Zhang and Chen [24] |

| Landfilling | 600 | Wang and Lee [25] |

| Concept/Application | |

|---|---|

| Pyrolysis | Thermochemical conversion of sludge into bio-oil, pyrolysis syngas, and biochar in an oxygen-free environment. Energy generation; Biofuel production; Soil improvement; Materials production [33]. Production of biochar, a versatile material with potential for carbon sequestration, soil improvement, and application in various industries. Reduction in the volume of sludge. Production of synthesis gas from pyrolysis [34]. |

| Gasification | Thermochemical conversion of sludge into synthesis gas (syngas). Energy generation; Hydrogen and Chemical products production [35]. |

| Co-combustion | Burning sludge together with other fuels, such as coal or biomass. Energy generation; Reduction in the volume of waste [36]. |

| Hydrothermal carbonization | Treatment of sludge with water at high temperature and pressure to produce hydrocarbon [37]. |

| Supercritical water gasification | Sludge gasification using water in a supercritical state to produce hydrogen and other gases. Hydrogen production; Energy generation [38]. |

| Technique | Process Parameters | Feedstock Characteristics | Operation Conditions | AI/Software |

|---|---|---|---|---|

| Pyrolysis | Dewater to ≥60% solids. Heat to 400 °C (constant). Air coefficient 2.6–2.8 in incineration chamber. | Municipal sludge, pre-dried ≥ 60% solids. | Use part of produced oil/gas for self-heating. | Machine learning (ML) to predict product yields, simulate thermogravimetry, optimize routes. |

| Gasification | — | Sewage sludge dried in solar facility. | CaO bed; steam agent. Syngas: H2 70–73 vol%; CO 2–3 vol%; CO2 8 vol%. | Aspen Plus simulation (syngas mass-balances). |

| Co-combustion | — | Sludge blended in coal boilers. | Co-incineration in retrofit coal plants. Low-NOx burners; post-combustion amine capture. | — |

| Hydrothermal Carbonization | — | Dehydrated sludge (15% humidity). Acid catalyst (HCl) to lower Ni/Cr; ↑P in hydrochar. | Wet medium; pressure–temperature as per [85]. | — |

| Method | Advantages | Disadvantages |

|---|---|---|

| Pyrolysis | Produces bio-oil usable as fuel or for chemical refining; generates biochar for carbon sequestration and soil amendment; reduces sludge volume and yields synthesis gas. | High energy demand (especially for sludge drying); variable bio-oil quality; requires tar cleanup from syngas; needs market development for bio-products. |

| Gasification | Produces versatile syngas for heat, power, or hydrogen; can integrate carbon capture to lower emissions. | Tar formation can foul equipment; requires high temperature and pressure, raising capital and operating costs. |

| Co-combustion | Utilizes existing combustion infrastructure; lower investment compared to new plants; reduces reliance on fossil fuels. | Still emits significant GHGs without capture; potential NOx/SO2 pollution; ash handling issues. |

| Hydrothermal Carbonization | Efficient for high-moisture sludge (no drying needed); produces high-energy-density hydrochar. | Emerging technology with high operating costs; process optimization and product quality still under research. |

| Supercritical Water Gasification | Very high hydrogen yield; low atmospheric pollutant emissions. | Requires corrosion-resistant materials for extreme temperature and pressure; still at development scale with high capital cost. |

| Technology | Maturity | Emissions | Energy Efficiency | Cost (USD/ton) |

|---|---|---|---|---|

| Pyrolysis | Emerging | Medium to Low, depends on reactor design [35] | Medium to High (bio-oil, char, gas outputs) | Medium to High |

| Gasification | Emerging | Lower emissions with steam/CCS [40] | High H2 yield (70–73%) | Medium |

| Co-combustion | Mature | High GHGs unless post-treatment used [36] | Moderate, uses fossil fuel co-firing | Low |

| Hydrothermal Carbonization | Emerging | Low, works with wet sludge [37] | Moderate (hydrochar production) | High |

| Supercritical Water Gasification | Developmental | Very Low, minimal air pollutants [40] | Very High, efficient hydrogen production | High |

| Plasma Gasification | Developmental | Very Low with up to 97% CO2 capture [91] | High (∼50% efficiency) | Very High |

| Authors | Method/Application |

|---|---|

| Han et al. [203] | A dendrite network-integrated adaptive mean square gradient method for optimizing energy efficiency in buildings. |

| Han et al. [204] | Enhancing electroactive sites within a three-dimensional covalent organic framework. |

| Ringe et al. [205] | CO2 adsorption rate in electrochemical processes is constrained by double layer charging. |

| Hu et al. [206] | Sub-nanometric copper cluster synthesis through double confinement facilitates selective characteristics. |

| Banerjee et al. [207] | Waste sludge decreases greenhouse gas emissions in a pilot-scale industrial wastewater treatment facility. |

| Liu et al. [208] | Electrocatalytic carbon applied to fuels on heterogeneous catalysts. |

| Prabhu et al. [209] | Catalysts with heterostructures for both electrocatalytic and photocatalytic applications. |

| Zhu et al. [210] | Pavilion of reversible design crafted from recycled materials. |

| Shi et al. [211] | Sustainable management utilizing a life-cycle assessment. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muniz, R.N.; Buratto, W.G.; Cardoso, R.; Barros, C.F.d.O.; Nied, A.; Gonzalez, G.V. State-of-the-Art Decarbonization in Sludge Thermal Treatments for Electrical Power Generation Considering Sensors and the Application of Artificial Intelligence. Water 2025, 17, 1946. https://doi.org/10.3390/w17131946

Muniz RN, Buratto WG, Cardoso R, Barros CFdO, Nied A, Gonzalez GV. State-of-the-Art Decarbonization in Sludge Thermal Treatments for Electrical Power Generation Considering Sensors and the Application of Artificial Intelligence. Water. 2025; 17(13):1946. https://doi.org/10.3390/w17131946

Chicago/Turabian StyleMuniz, Rafael Ninno, William Gouvêa Buratto, Rodolfo Cardoso, Carlos Frederico de Oliveira Barros, Ademir Nied, and Gabriel Villarrubia Gonzalez. 2025. "State-of-the-Art Decarbonization in Sludge Thermal Treatments for Electrical Power Generation Considering Sensors and the Application of Artificial Intelligence" Water 17, no. 13: 1946. https://doi.org/10.3390/w17131946

APA StyleMuniz, R. N., Buratto, W. G., Cardoso, R., Barros, C. F. d. O., Nied, A., & Gonzalez, G. V. (2025). State-of-the-Art Decarbonization in Sludge Thermal Treatments for Electrical Power Generation Considering Sensors and the Application of Artificial Intelligence. Water, 17(13), 1946. https://doi.org/10.3390/w17131946