1. Introduction

With the gradual improvement of China’s comprehensive transportation system, tunnel engineering construction is in a phase of rapid development. However, complex geological conditions and operational environments can affect the structural performance of tunnels, disrupt normal traffic flow, and even jeopardize tunnel stability and road safety [

1,

2,

3]. Extensive research has been conducted on tunnel structural safety evaluations, with both domestic and international researchers employing qualitative and quantitative methods to analyze them, achieving notable results [

4,

5,

6].

Hamidi et al. [

7] conducted a safety assessment based on the analytic hierarchy process for uncertain factors such as geological and geotechnical activities during tunnel construction. Hyun et al. [

8] applied fault tree analysis to categorize risk factors into geological, design, construction, and management aspects, combining this with AHP to evaluate and analyze shield tunnel risks. Park et al. [

9] evaluated the safety of common tunnel defects, categorizing tunnel lining structure conditions into five levels based on defined defect indicators. However, given the intricate and dynamic geological conditions in tunnels and underground engineering, waterproofing measures are influenced by construction conditions and external factors, thereby making leakage a critical factor impacting the safety of underground engineering.

In recent years, significant progress has been made in the research on tunnel leakage. Gong et al. [

10] analyzed the types and causes of leakage in tunnels and underground engineering and proposed a concept of leakage prevention throughout the life cycle from the design and construction stages to the service period. The researchers discussed methods for detecting leakage, treatment measures, and innovative grouting materials, establishing a solid foundation for practical implementation and further research on leakage prevention in tunnel and underground engineering. Yang et al. [

11] analyzed the interaction mechanisms between groundwater and surrounding rock using experimental and numerical simulation methods and investigated the disaster evolution process and patterns of karst cave water bursts in deep high-pressure tunnels. Li et al. [

12] studied a risk assessment system for karst tunnel water inrush by combining geographic information systems (GIS) with the analytic hierarchy process (AHP), enabling real-time assessment of karst tunnel water inrush. Jiang et al. [

13] employed matter element analysis and AHP to determine evaluation indicators, which are based on geological and hydrological conditions, to construct a predictive model for tunnel water inrush disasters. Based on distance discriminant analysis theory, Pan [

14] established a classification prediction and analysis model for tunnel seepage water diseases, conducting evaluations of seepage water disease levels using fuzzy comprehensive evaluation and BP neural network methods and developing a visualization program, laying a theoretical foundation for preventing tunnel seepage water. Based on an improved generative adversarial network (GAN) and Swin Transformer model, Wu et al. [

15] established a Swin Transformer model to visualize and reconstruct the 3D coordinates of the leakage area and realized the quantitative evaluation of the leakage area. The segmentation results achieves mAcc, mIoU, mF score, mPrecision, and mRecall metrics of 93.1%, 91.5%, 82.83%, 85.62%, and 80.3%, respectively. Feng et al. [

16] constructed forty U-shaped semantic segmentation models by deep learning, a leakage detection scheme with the best efficiency and accuracy was proposed, and a quantitative comparison was made with the existing dominant approaches, which can quickly and accurately assess the health status of subway tunnels. Lai et al. [

17] focused on lining concrete with two types of defects, namely, holes and cracks, and used TOUGH2 (V2.0) software to assess the impact of different seepage conditions on tunnel water leakage. The results indicated that fernal water pressure and defect size have a significant effect on water leakage. Sun et al. [

18] analyzed the interaction between tunnel structures and different soils, such as sandy soil and clay, during the process of water level changes through model experiments. It was found that the structures exhibited periodic sinking and floating behavior, with significant subsidence occurring in the final stage of water level decline. These achievements provided significant understanding of tunnel seepage water diseases, detection methods, and safety assessments. However, there is limited research on the types of tunnel seepage water diseases near reservoir tunnels and their impact on structures.

Currently, several scholars are investigating the stress characteristics and drainage technologies of tunnels near reservoirs. Li et al. [

19], focusing on subsea tunnels, discovered that both external water pressure and water inflow in the grouting area increase linearly with rising groundwater levels by comparing analytical and numerical solutions of pore pressure distribution and water inflow. Zhang et al. [

20] examined the impact of different water storage conditions at the Longsheng Reservoir on the seepage and stress fields of tunnels near reservoirs during construction and operation, proposing potential risks and improvement measures. Shen [

21] researched drainage schemes for tunnels near reservoirs, analyzed the effects of various schemes on water pressure distribution and lining stress, and evaluated the applicability of drainage and water-blocking schemes. Chen [

22], through on-site observation tests and three-dimensional numerical simulations, analyzed the stress and displacement changes in metro tunnel linings and surrounding rocks near reservoirs during water level fluctuations, guiding effective deformation and displacement control during operation.

In conclusion, existing research has not adequately considered the effects of external factors such as water level variations and water erosion on the safety assessment of leakage in tunnels near reservoirs. Addressing this gap, this paper analyzes the causes and influencing factors of tunnel leakage, investigates the effects of different reservoir water levels on tunnel structural stability, and establishes a hierarchical evaluation system for leakage in tunnels near reservoirs. Using the Tiebeishan Tunnel as a case study, a risk assessment of tunnel leakage diseases was conducted, and the preliminary discussion focused on the impact of factors such as changes in water pressure and water erosion on tunnel structure leakage.

5. Leakage Evaluation of Tiebeishan Tunnel

5.1. Surrounding Rock Classification Project Overview

Tiebeishan Tunnel, located within the Gaoliyingzi region on the Heida line in Fushun City, Liaoning Province, China, was built in 1989. The tunnel has a total length of 178 m, a clear width of 7 m, and a vertical clearance height of 5 m. The geological conditions at the tunnel site are complex, with a maximum tunnel depth of 48 m. The surrounding rock is composed of relatively stable granite gneiss. There is a fault zone trending from northwest to southeast passing 1 km to the southeast. The joint fractures in the surrounding rock are well developed, causing varying degrees of surface water infiltration at the tunnel’s entrance and exit sections, leading to the emergence of a certain amount of groundwater. Over the years, regular inspections have found serious water leakage problems in the tunnel, as shown in

Figure 7. Consequently, major repairs have been undertaken on the drainage system to address these issues.

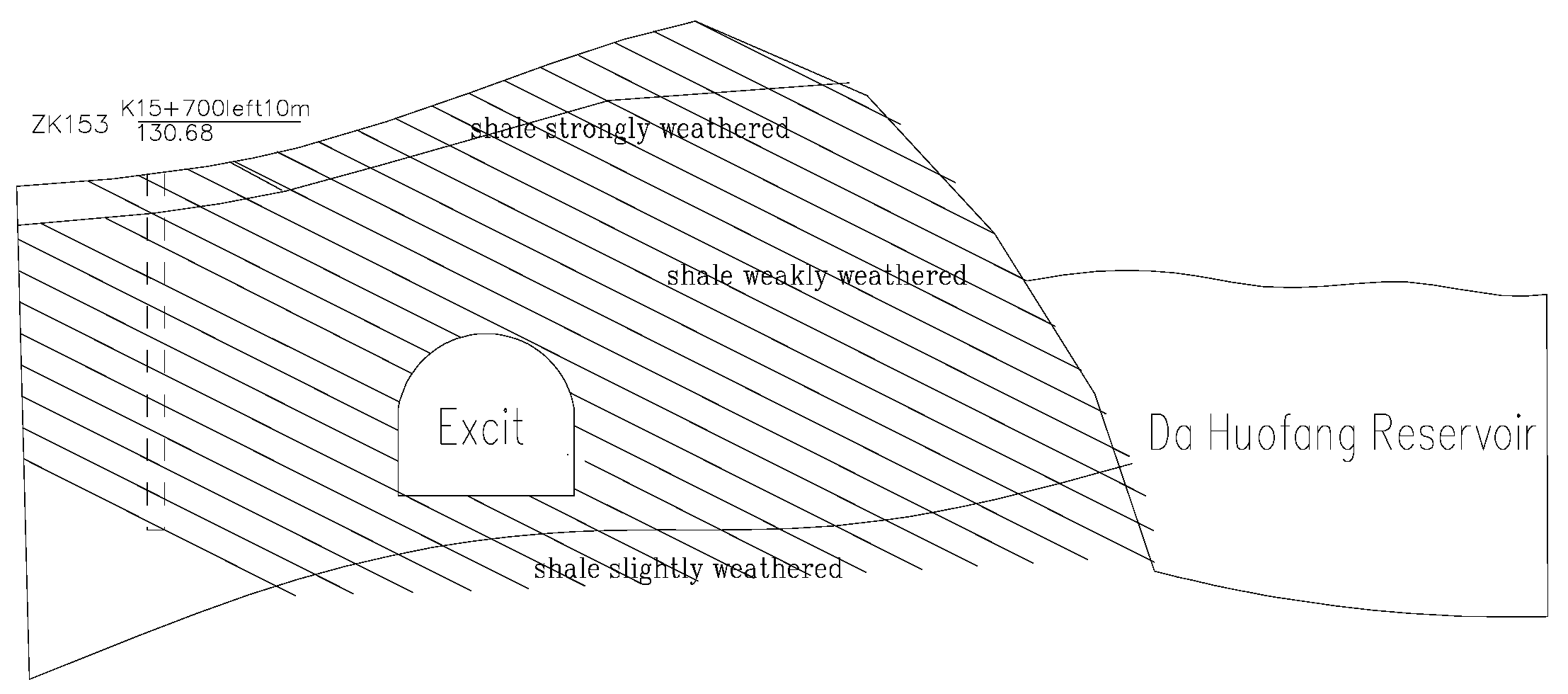

The spatial relationship between the tunnel and the reservoir is illustrated in

Figure 8. The average distance between the tunnel and the reservoir is 128 m, with the closest point being 8 m from the water source. The Dahuofang Reservoir, which holds water year-round, has a controlled catchment area of 5437 square kilometers and a total storage capacity of 21.81 billion cubic meters.

The proximity of the tunnel to the reservoir, combined with the well-developed fractures in the surrounding rock, creates a water seepage pathway on the side of the tunnel nearest to the reservoir. Changes in the reservoir water level can affect the stress on the tunnel lining structure. Inspections have confirmed severe leakage problems in the tunnel, which, at their worst, can compromise the structural stability of the tunnel and traffic safety.

5.2. Determination of the Matter Element Model

The classification of tunnel water leakage damage is divided into four categories:

P1 for intact condition,

P2 for minor leakage,

P3 for moderate leakage, and

P4 for severe leakage. After determining the classical domain and section domain of the matter element model, the matter element to be evaluated is determined based on the actual engineering situation of the Tiebeishan Tunnel.

5.3. Determination of Evaluation Indicator Weights and Consistency Tests

Based on the criterion of relative importance, a judgment matrix for the nine evaluation indicators in the matter element evaluation model is formed, as shown in

Table 13.

After establishing the judgment matrix, the weight for each indicator and the maximum eigenvalue of the judgment matrix are calculated by Equation (4), based on the square root method.

After calculation, the values for A1, A2, A3, A4, A5, A6, A7, A8, and A9 are 2.579, 2.579, 0.416, 0.717, 1.730, 0.728, 0.364, 0.373, and 2.819, respectively. The normalized weight vector for each evaluation indicator is

The maximum eigenvalue

λ is 9.81. Therefore, the value of the consistency indicator can be derived from the following equation:

By calculating the stochastic consistency index

RI as 1.46, followed by the following equation, the consistency ratio can be found.

The result proves that the weight set meets the consistency test requirement. A is the calculated weight set of each matter element, representing the weight accounted for by each evaluation indicator.

5.4. Correlation Calculation and Determination of Disease Levels

Based on the four levels of the tunnel disease degree classified in

Section 4.2, combined with Equations (8)–(10), the correlation of each index is calculated. The specific process is as follows:

where

kji represents the relevance of evaluation indicator

i to evaluation level

j.

μji denotes the value range of the classical domain, and

μpi denotes the value range of the section domain.

ρ(

μi,μji) is the distance from point

μi to the interval (

μjimin,μjimax), and

ρ(

μi,μpi) is the distance from point

μi to the interval (

μpimin,μpimax). The relevance matrix, which summarizes the relevance of each evaluation indicator to the different evaluation levels, is presented in

Table 14.

After calculating the correlation of each evaluation indicator regarding the four classes, based on Equation (11), the combined correlation of the disease classes of the evaluation model can be calculated as follows:

Calculation yields

k1,

k2,

k3,

k4 as −0.439, −0.191, −0.032, −0.228; according to the rating rules, the tunnel disease level is

The evaluation grade of water leakage in the tunnel is Grade III, indicating moderate water leakage.

5.5. Analysis of Evaluation Results

Based on the theories of extenics and the analytic hierarchy process, each evaluation indicator was quantified and its importance and weight were calculated. Ultimately, the comprehensive correlation degree was determined, concluding that the leakage evaluation level of Tiebeishan Tunnel reached Grade 3, indicating leakage. The evaluation model was found to align with the actual situation based on on-site inspection results and water leakage statistics. During inspections, severe cracks were observed in the tunnel lining structure, and issues like water leakage and efflorescence were noted during the rainy season, impacting traffic safety. This demonstrates that the established tunnel leakage evaluation model accurately reflects engineering realities and can serve as a valuable reference for similar projects.

6. Conclusions

(1) Based on the existing methods for evaluating tunnel water leakage, the impact of external environmental changes on tunnels near reservoirs was considered. It is proposed that the leakage evaluation index should be divided into geological conditions, hydrological conditions, and tunnel engineering aspects. Various factors influencing tunnel water leakage were analyzed, and a hierarchical evaluation index system for tunnel water leakage was proposed.

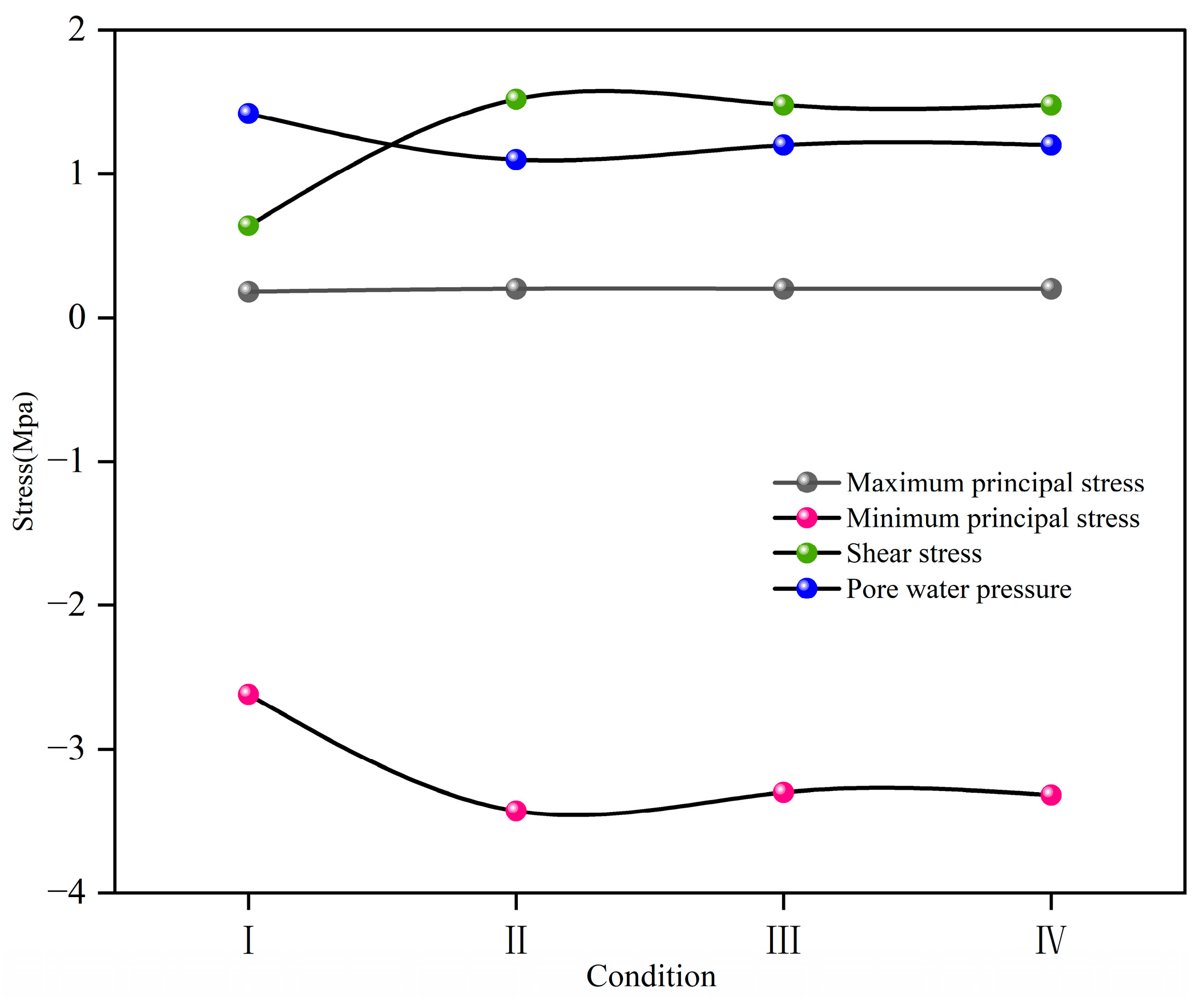

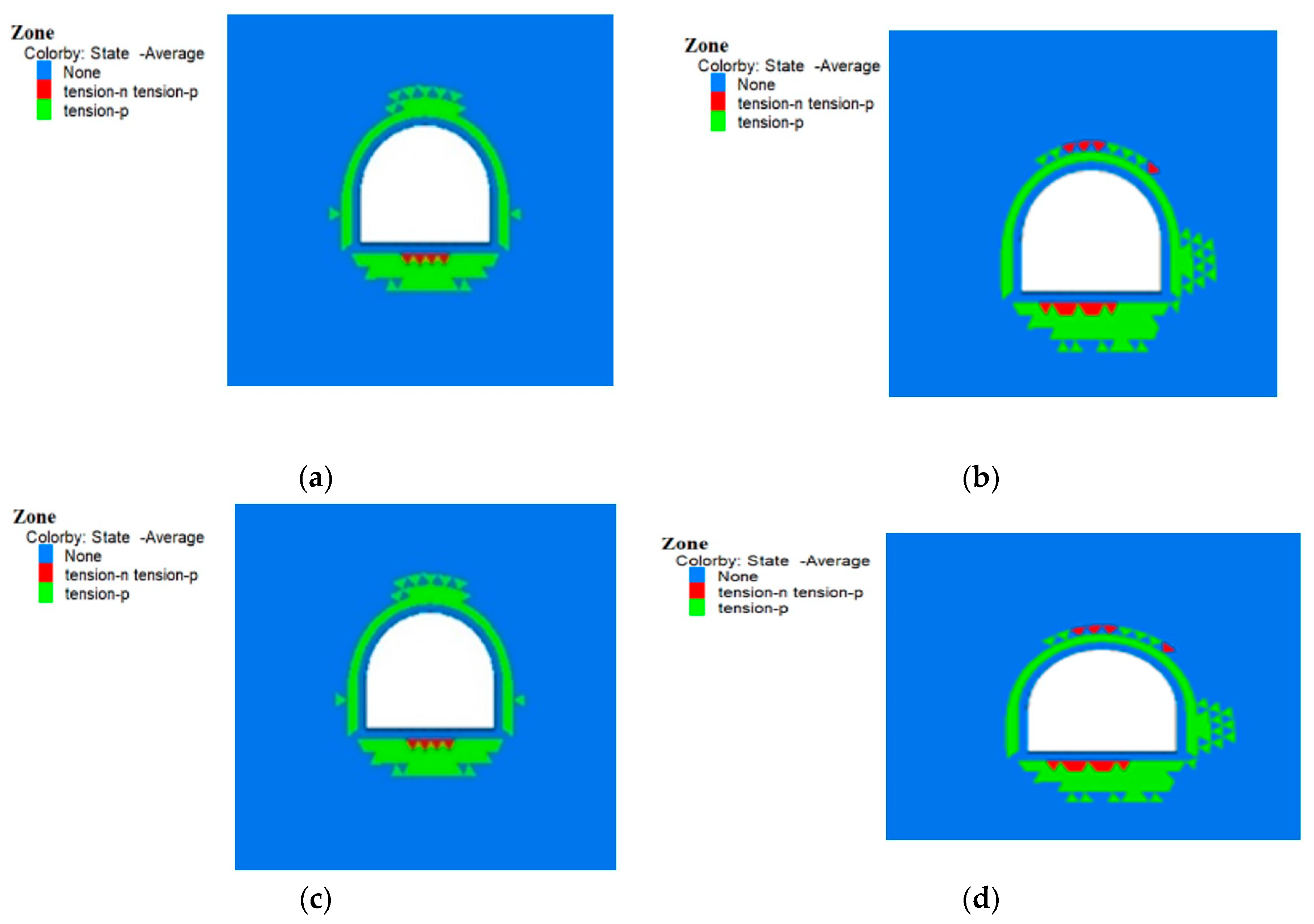

(2) The changes in reservoir water level significantly affect the stability of tunnels. With increasing water levels, the displacements and stresses of the tunnel structure gradually increase, with the inner side of the water level experiencing significantly greater effects than the outer side. The plastic zone undergoes notable changes, and structural damage progresses from the inner side to the entire cross section. Tunnels near reservoirs should receive focus on water level changes and have targeted reinforcement measures implemented to improve the stress state of tunnels.

(3) Combining the qualitative and quantitative descriptions of leakage conditions, the evaluation indicators and value standards for water leakage were specified based on the analytic hierarchy process (AHP) and the theory of extension. A hierarchical evaluation model for the leakage of tunnels near reservoirs was constructed.

(4) The proposed leakage evaluation model was applied to the Tiebeishan Tunnel project. A judgment matrix was constructed, and the comprehensive relevance degree of the leakage grade was determined. The leakage level of the Tiebeishan Tunnel is Grade 3 indicating moderate leakage. This application verified the rationality and applicability of the evaluation model.