Laboratory Model Test and Field In Situ Test of Distributed Optical Fiber Monitoring of Seepage in a Karst Depression Reservoir Basin

Abstract

:1. Introduction

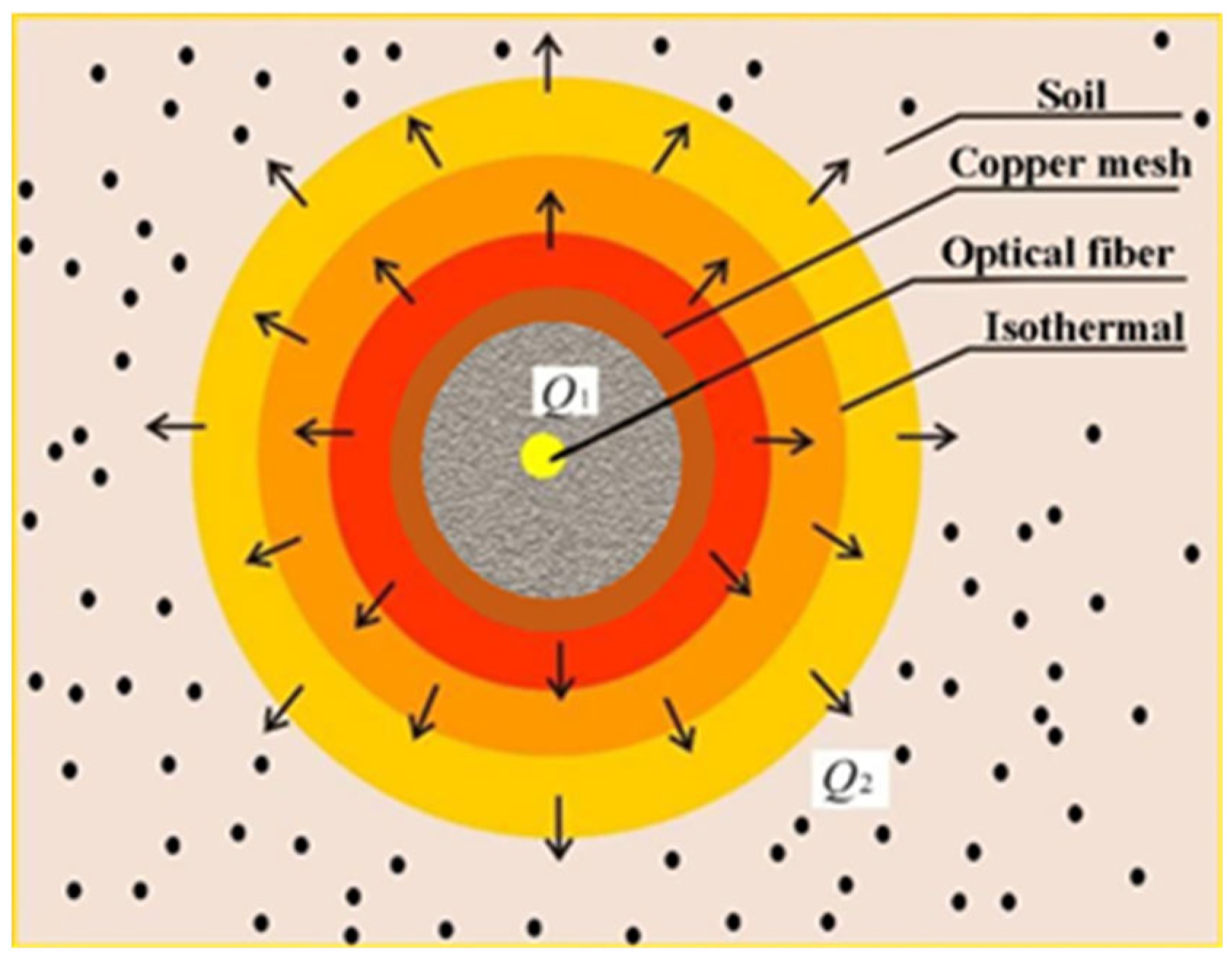

2. Principle of Distributed Optical Fiber Leakage Monitoring

3. Leakage Test of Heatable Temperature-Sensing Optical Cables under Different Moisture Content Media (Sand, Phosphorus Slag)

- (1)

- Build a test device, fill the acrylic box with the medium, and bury the optical cable in the box to straighten and fix it;

- (2)

- Before the official start of the test, check all equipment to ensure that it is operating normally and collecting data synchronously;

- (3)

- Use a hot air gun to heat the medium, observe the real-time temperature data of the DTS demodulator, and locate the part of the optical cable in the acrylic box. After the temperature of the heatable temperature-sensing optical cable has stabilized, a heating power of 5 w/m was applied to raise the temperature to a steady state. Then, the peristaltic pump was activated to start the leakage test. The speed of the peristaltic pump is controlled to 30 rpm, and the temperature curve is observed. After the temperature drops to a stable state, stop the test.

- (4)

- Process the test data, analyze the overall temperature change curve of the heatable temperature-sensing optical cable in the test section and the temperature change curve at the leakage point, and evaluate the identification effect of the heatable temperature-sensing cable under leakage conditions.

3.1. Comparison of the Temperature Measurement Results of Different Media in the Dry State

3.2. Comparison of the Temperature Measurement Results of Different Media in the Unsaturated State

4. Monitoring Test and Quantitative Analysis of the Leakage Velocity of the Heatable Temperature-Sensing Optical Cable

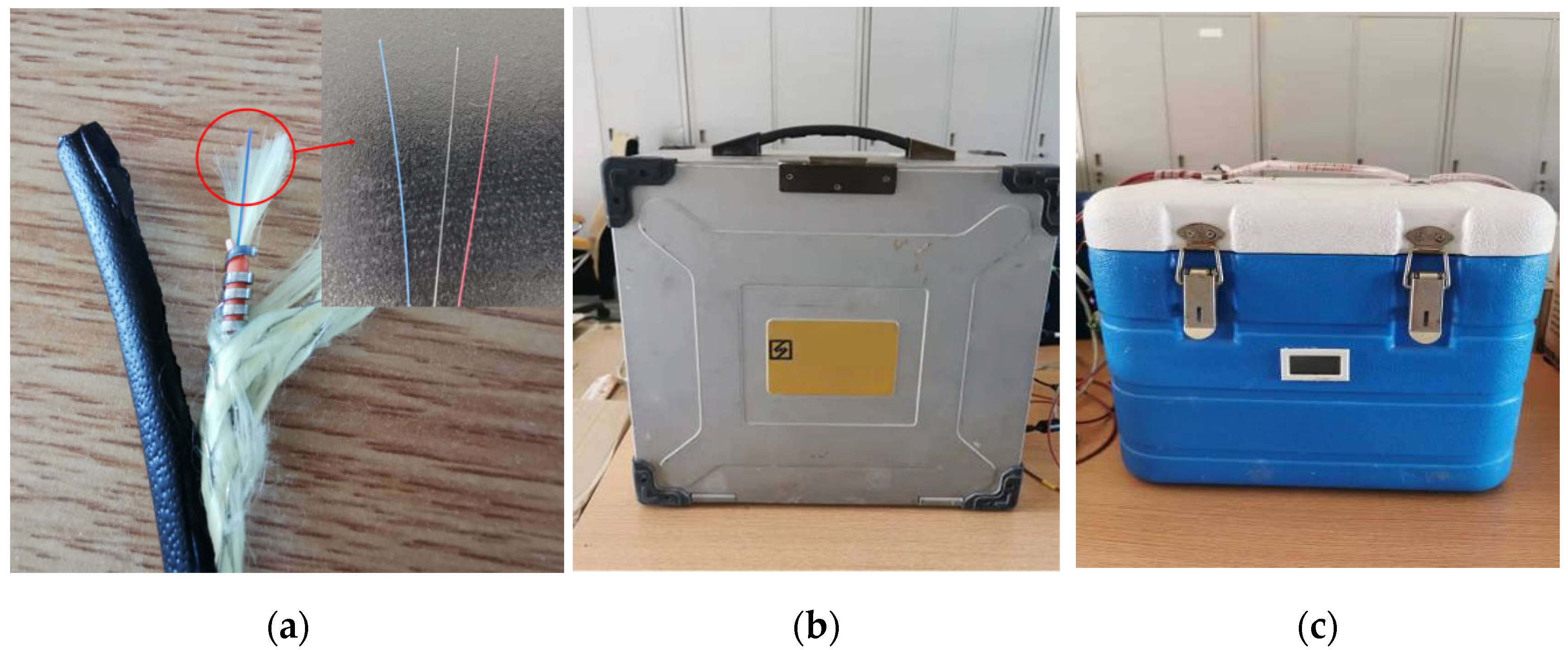

4.1. Test Arrangement and Test Procedure

- (1)

- Fill the saturated sand medium in the acrylic box, bury the temperature-sensing optical cable in the acrylic box, and straighten and fix it;

- (2)

- Connect one end of the optical cable and the jumper together through the fusion splicer, and connect the other end of the jumper to the port of the temperature calibrator. The other port of the temperature calibrator can be connected to the channel port of the DTS demodulator for data communication. Connect one end of the line to the temperature calibration box and the other end to the USB interface corresponding to the DTS host;

- (3)

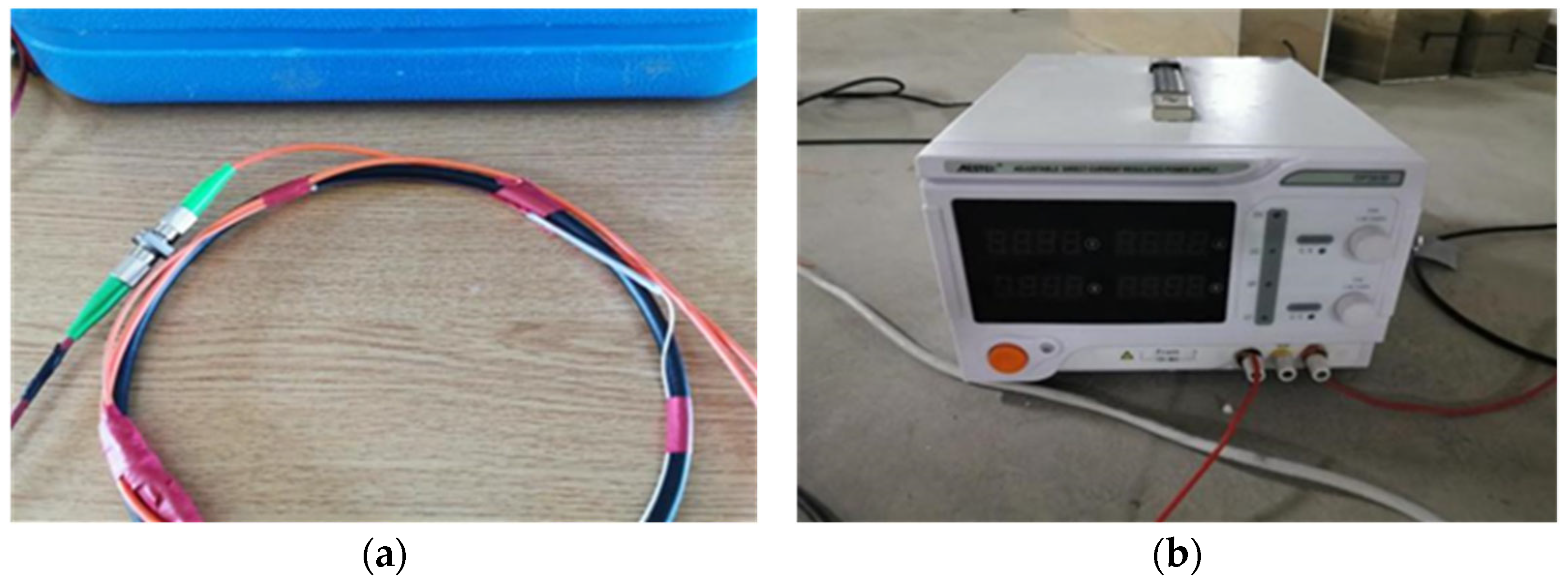

- Connect the copper wires at both ends of the heatable temperature-sensing optical cable to the DC power supply through external copper wires to form a heatable loop;

- (4)

- Before the simulated leakage starts, check all equipment to ensure that it is operating normally and collecting data synchronously;

- (5)

- Position the part of the optical cable in the acrylic box, which can be heated by a thermal drying gun; observe the real-time temperature data of the DTS demodulator and record the position data;

- (6)

- After the temperature drops to a stable level, turn on the water valve switch and calculate the flow rate through the volume of water in the measuring cylinder at the corresponding time. After the flow rate stabilizes, maintain the flow rate and apply different heating powers (5–10 w/m). Carry out heating, observe the real-time temperature data of the DTS demodulator, and stop heating after the temperature rises to a relatively stable level;

- (7)

- After the temperature drops and stabilizes, change the flow rate by adjusting the water valve, and repeat step (6);

- (8)

- Analyze the test data, compare and analyze the relationship between different flow velocities and temperature characteristic values, and establish a semiquantitative evaluation of leakage velocity.

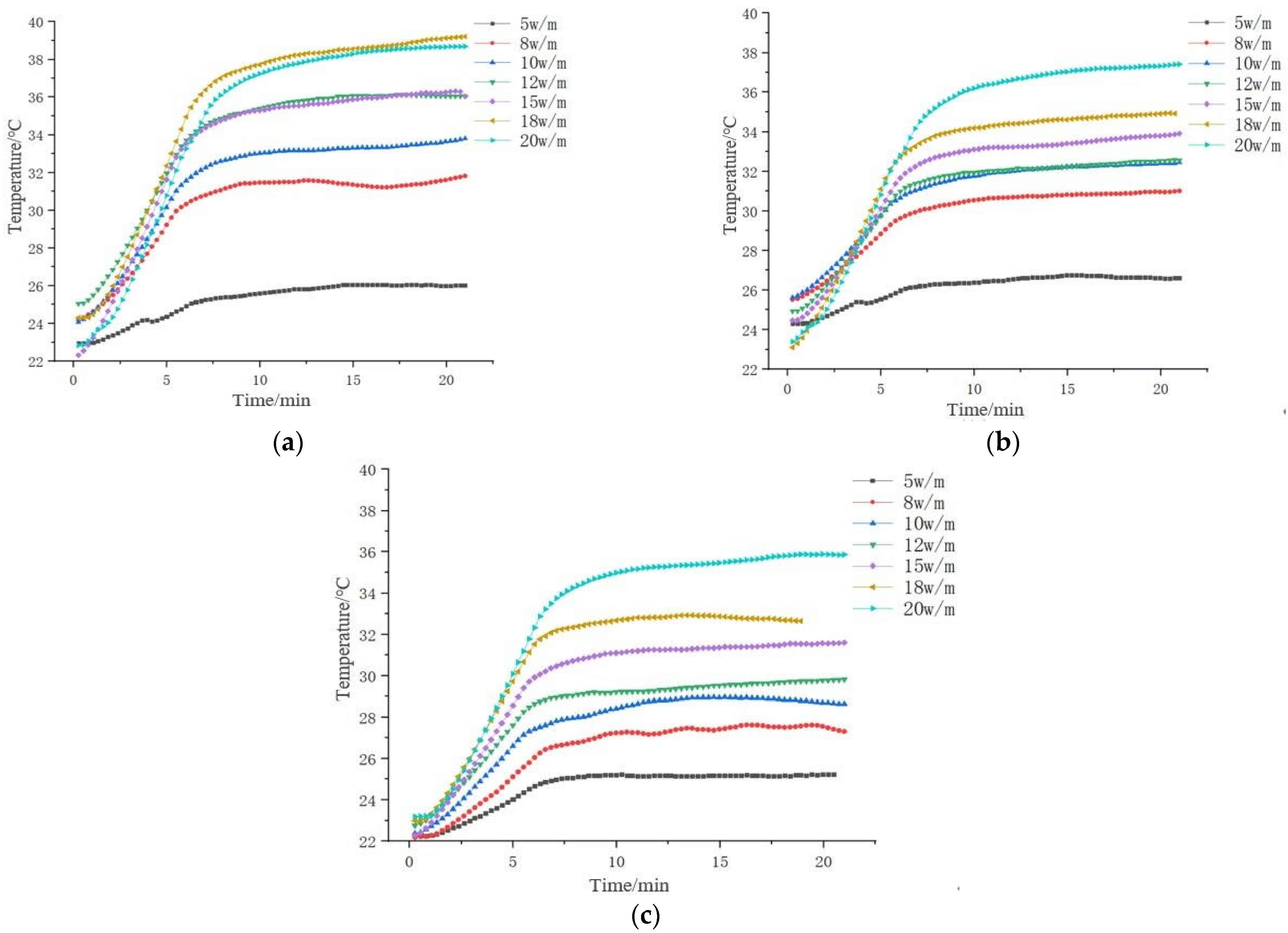

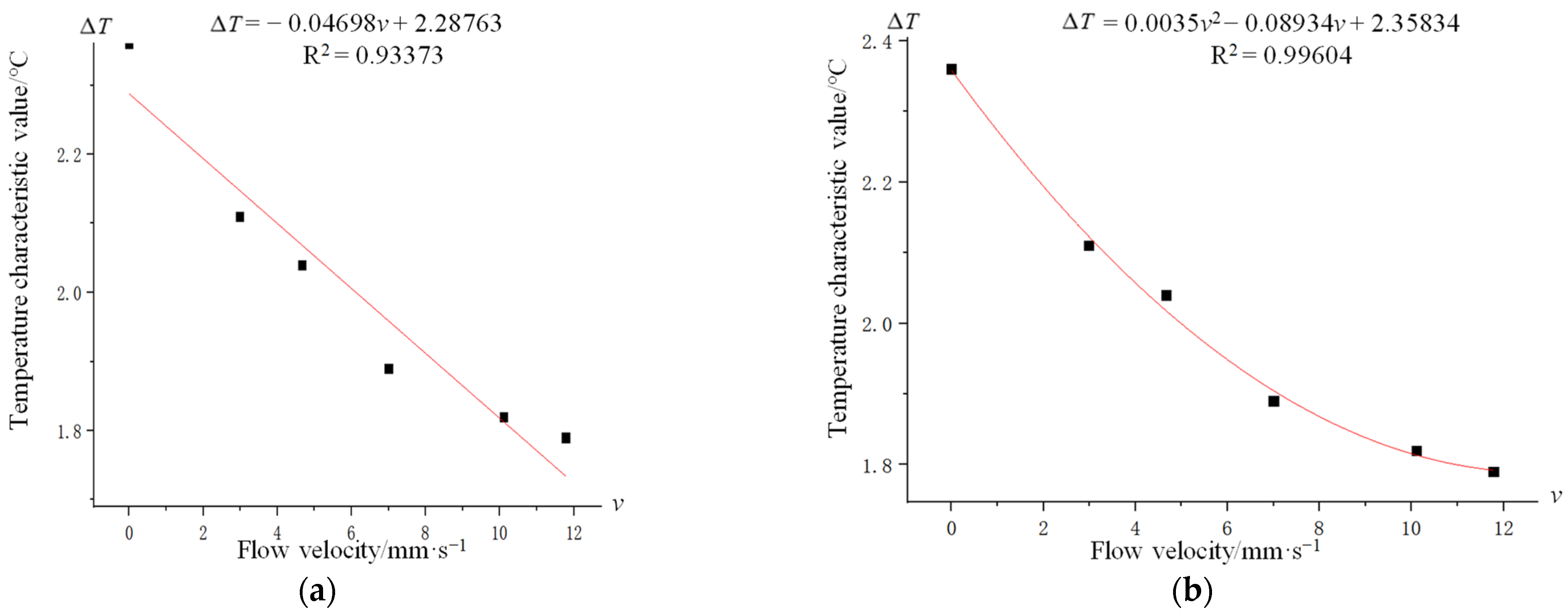

4.2. Analysis of Test Results

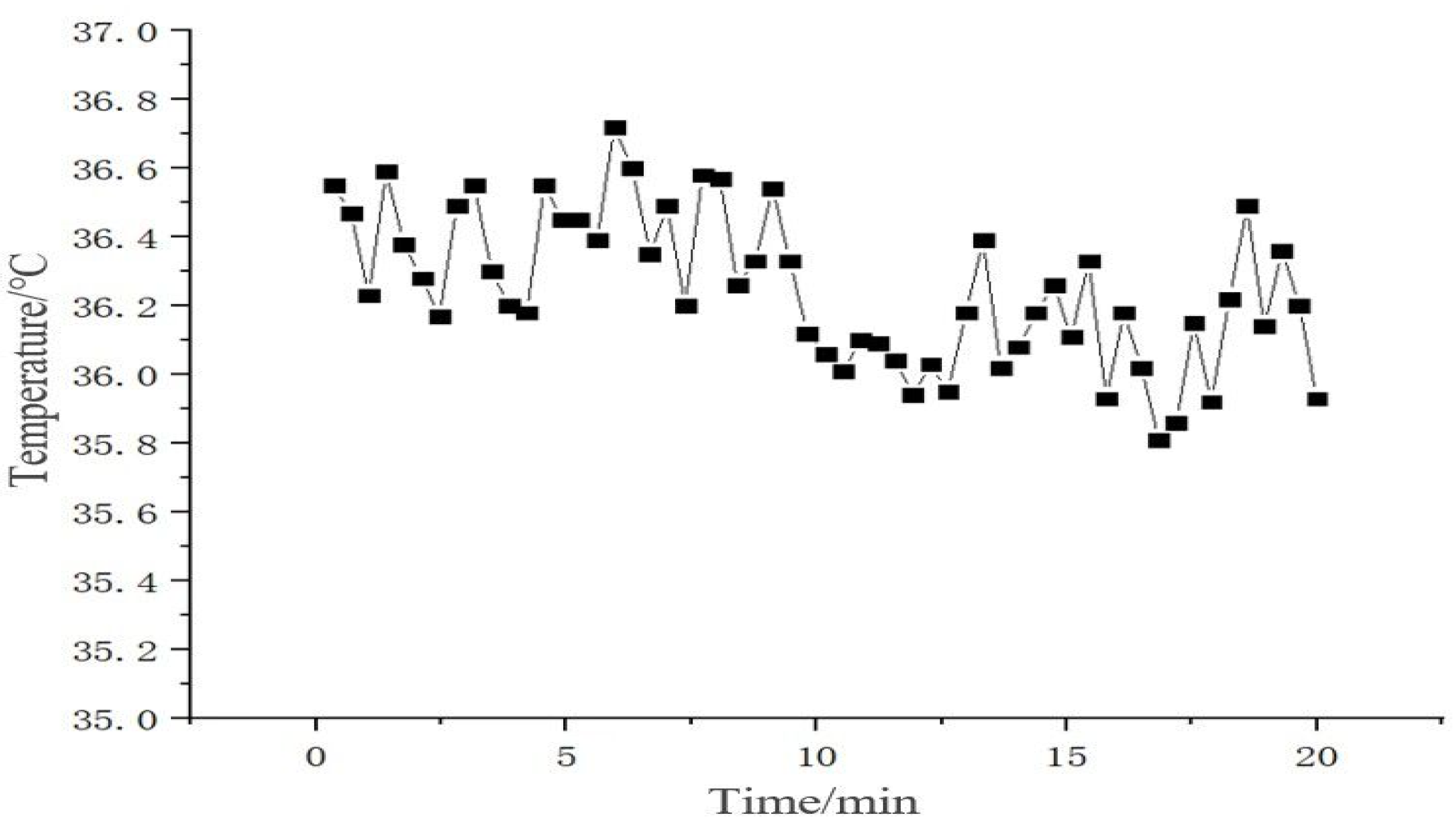

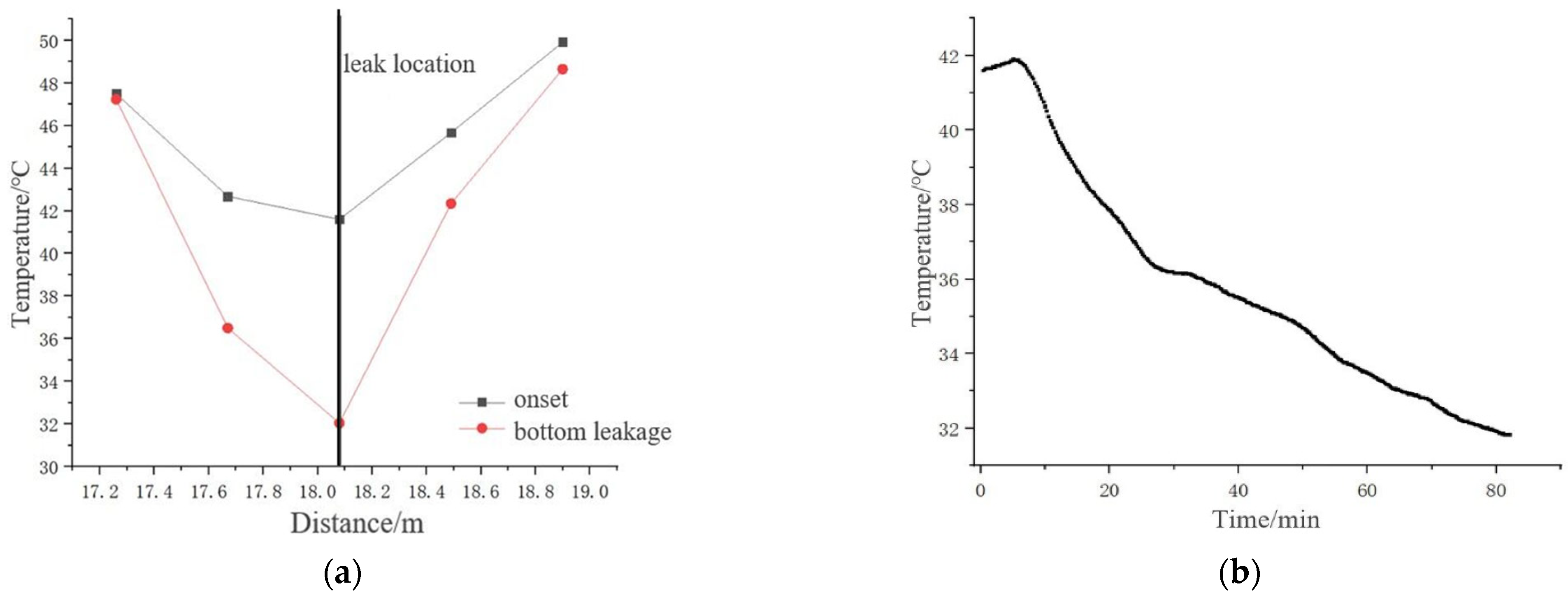

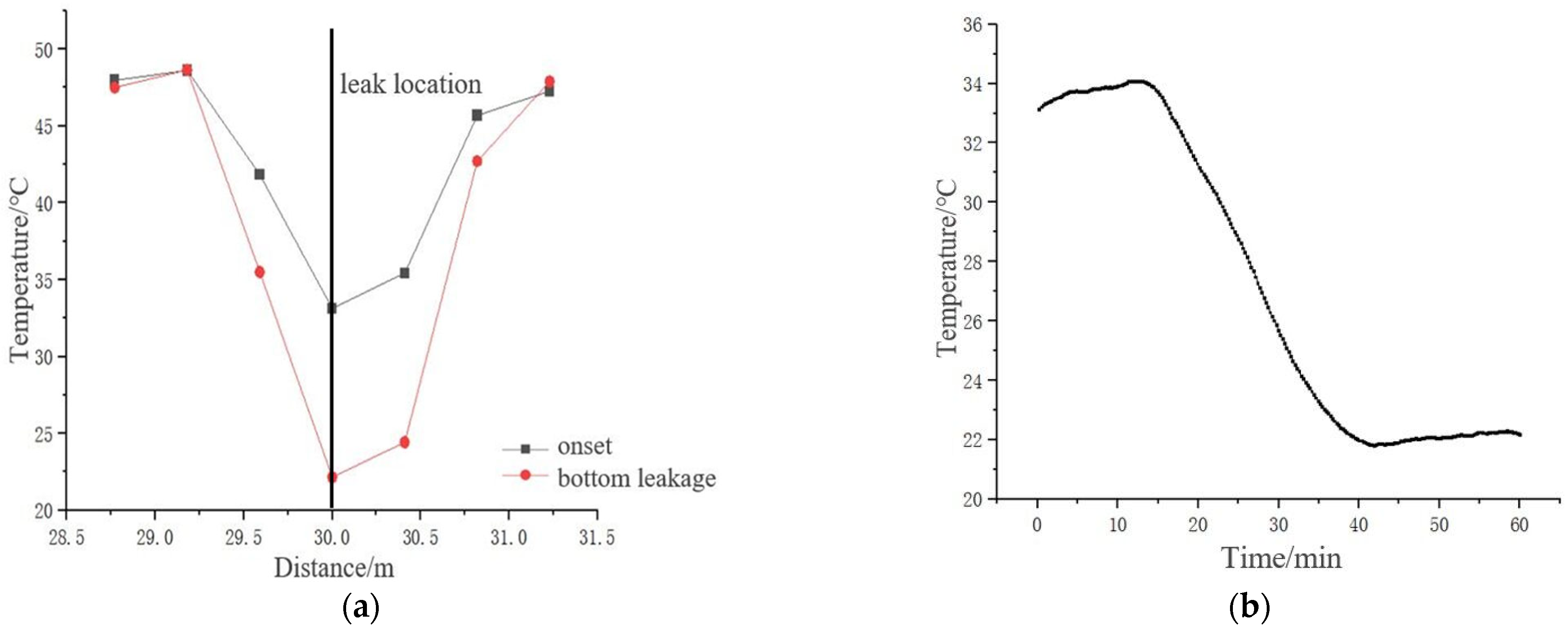

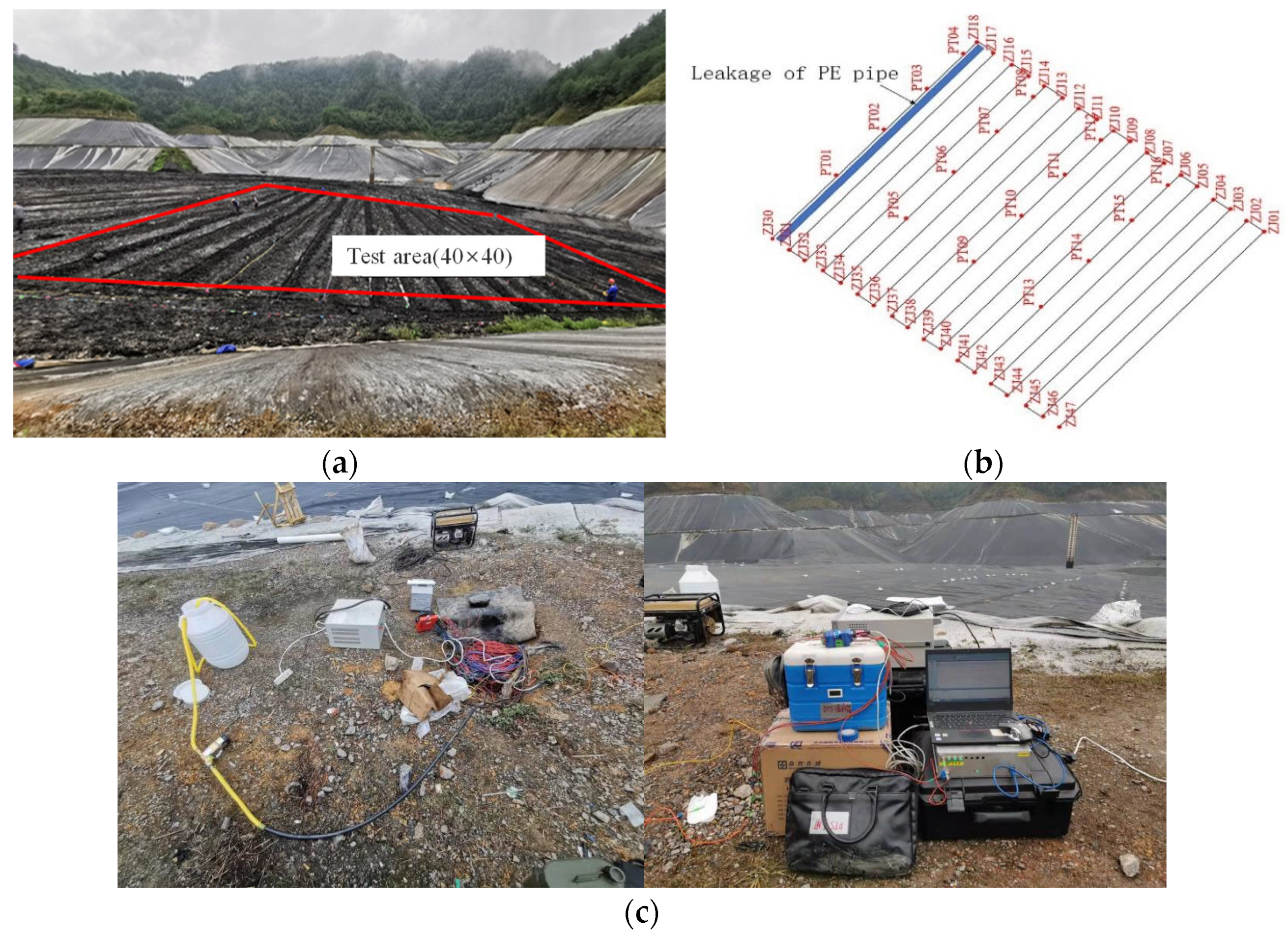

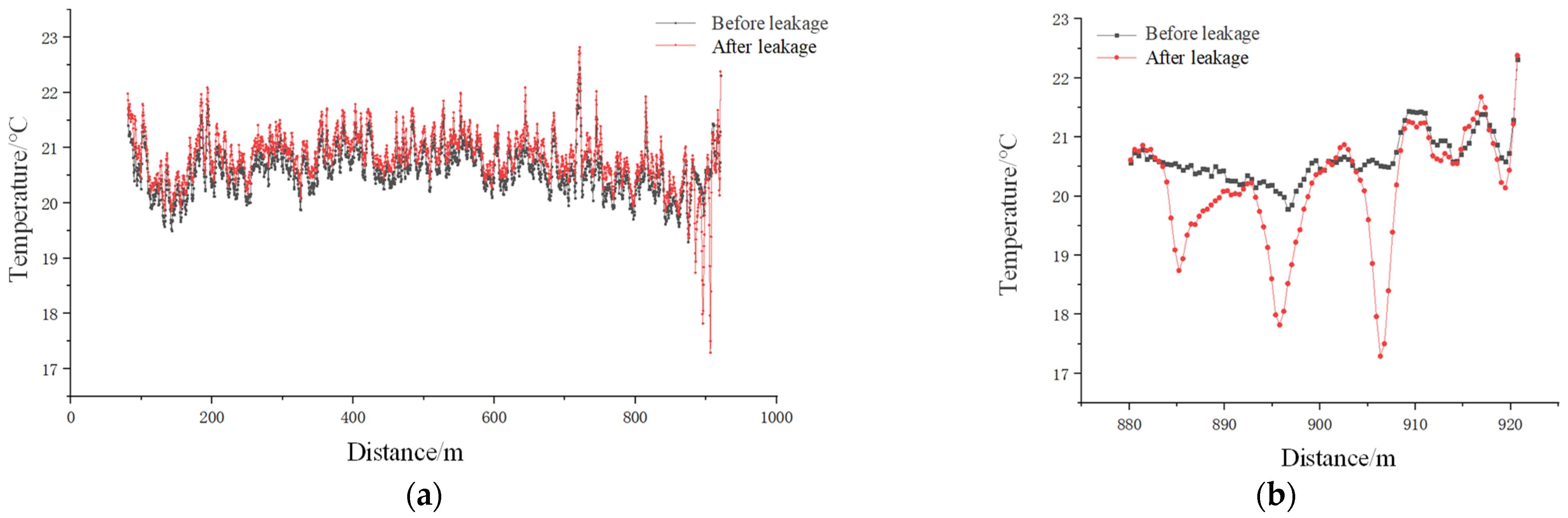

5. On-Site In Situ Test

6. Discussion

- (1)

- In the experiment described in this paper, the permeability of phosphorus slag was worse than that of sand, and its response to leakage events was slower. Therefore, when laying temperature measurement cables, placing the cables in soil layers with good permeability or setting permeable soil layers around the cables when burying them should be considered to enhance their detection accuracy and response speed to leakage events.

- (2)

- Through the experiments conducted in this study, it was found that the temperature characteristics of optical cables in sand and slag with different moisture contents increased with the increase in heating power. Moreover, the temperature increase in the optical cable at the same power level basically decreased with the increasing moisture content. Specifically, when the moisture content of the sand medium itself is less than 8%, leakage occurs, and the minimum heating power for effectively identifying leakage using the heated optical cable is 12 w/m. When the moisture content of the sand medium itself is greater than 14%, leakage occurs, and a heating power within 20 w/m cannot effectively identify the leakage. When the moisture content of the slag medium itself is less than 14%, leakage occurs, and the minimum heating power for effectively identifying leakage using the heated optical cable is 5 w/m. When the moisture content of the slag medium itself is between 14% and 24%, leakage occurs, and the minimum heating power for effectively identifying leakage using the heated optical cable is 12 w/m. The heating power of the heated optical cable is directly related to its heating effect. If the heating power is too low, it may not meet practical needs, and if the heating power is too high, it will result in energy waste and overheating, which may cause damage to the facility. Currently, scholars have paid little attention to this issue, and in practical engineering, reasonable heating power can be selected through indoor model experiments to provide a basis for actual engineering measurement.

- (3)

- The establishment of a quantitative relationship between seepage velocity and temperature characteristic values is the basis for the quantitative monitoring of seepage. Currently, research in this field involves conducting measurement experiments in indoor models and then applying the analysis results of the indoor experimental data to actual engineering. This paper also adopts a similar approach, and the analysis of experimental data shows that the quadratic polynomial fitting curve has high reliability.

7. Conclusions

- (1)

- The leakage test results of the heatable temperature-sensing optical cable in different dry and unsaturated media show that the leakage identification effect of the heatable temperature-sensing optical cable is very obvious, which verifies the feasibility and precise positioning function of leakage identification of optical cables in dry media. Because phosphorus slag has worse water permeability than sand, the response speed to leakage events is slower.

- (2)

- In the unsaturated medium test, the difference in moisture content of the medium can be identified by heating the optical cable, and increasing the heating power can increase the identification effect in the range of moisture content identified.

- (3)

- In the semiquantitative identification test of leakage velocity, the temperature characteristic value under different conditions was measured by controlling the flow rate and heating power. The results showed that there was a significant negative correlation between leakage velocity and temperature characteristic value. The greater the flow rate is, the higher the temperature. The smaller the eigenvalue is, the more stable it is. By comparing the data, the quadratic polynomial fitting curve has high reliability.

- (4)

- The temperature behavior of two types of temperature-sensing optical cables (conventional type and heating type) under the same leakage conditions was studied through in situ tests. The degree of response of the heatable fiber optic cable to leakage is very significant, and the result is accurately identifying the location of the leakage.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, Z.R.; Zhang, L.Z. Research on seepage safety monitoring technology for dams. Water Resour. Hydropower Eng. Des. 2001, 3, 44–48. [Google Scholar]

- Yan, W.J. Technical improvement of dam seepage observation by measuring weir method in Yantan Hydropower Station. Hongshui River 2016, 35, 76–79. [Google Scholar]

- Wang, H.B. Application of high density resistivity method in the detection of embankment hidden danger. J. Zhejiang Univ. Water Resour. Electr. Power 2010, 22, 31–34. [Google Scholar] [CrossRef]

- Duan, X. Research on dam leakage detection based on temperature tracer method. Sci. Technol. Eng. 2014, 14, 140–143. [Google Scholar]

- Fang, C.G.; Ge, H.G.; Jia, Y.M. Technical problems of transient electromagnetic method used in the detection of hidden dangers of dike leakage. Dam Obs. Geotech. Tests 2001, 5, 21–24. [Google Scholar]

- Ren, A.W.; Ke, B.R.; Cheng, J.S. Cause analysis and non-destructive testing verification of reservoir leakage in karst area. J. Hydraul. Eng. 2014, 45, 119–124. [Google Scholar]

- Aufleger, M.; Goltz, M.; Dornstadter, J. Distributed fiber optic temperature measurements in embankment dams with central core new benchmark for seepage monitoring. In Proceedings of the International Symposium on Dams and Reservoirs under Changing Challenges during the 79th Annual Meeting of the International Commission on Large Dams, Lucerne, Switzerland, 1–3 June 2011. [Google Scholar]

- Aufleger, M.; Conrad, M.; Goltz, M. Innovative dam monitoring tools based on distributed temperature measurement. Jordan J. Civ. Eng. 2007, 1, 29–37. [Google Scholar]

- Li, R.Y.; Chen, X.P.; Wang, Z.W. Application of temperature indication method in seepage monitoring of Yangtze River levee. J. Yangtze River Sci. Res. Inst. 2000, 17, 48–57. [Google Scholar]

- Li, Y.X. Study on Multiparameter Monitoring of Embankment Based on Distributed Fiber-Optic Sensing Technology. Master’s Thesis, Nanjing University, Nanjing, China, 2021. [Google Scholar] [CrossRef]

- Wang, Y.H.; Cai, D.S.; Xiao, H.L. Application of DTS in leakage monitoring of concrete face rockfill dam. China Rural Water Hydropower 2006, 8, 101–102. [Google Scholar] [CrossRef]

- Wei, D.R.; Zhao, H.C.; Qin, Y.T. Leakage monitoring technology based on optical fiber temperature measurement. Zhejiang Hydrotech. 2004, 2, 19–21. [Google Scholar] [CrossRef]

- Qin, L.T.; Liu, J.M.; Xia, X.P. Distributed optical fiber temperature monitoring system and its application. Dam Saf. 2004, 01, 45–48. [Google Scholar] [CrossRef]

- Tan, Z.W.; Hu, L.Z. Study on Optical Fiber Seepage Monitoring Technology of the Vertical Core Rockfill Dam. Water Power 2011, 37, 83–85. [Google Scholar] [CrossRef]

- Harvie, W.B.; Peppler, R.A. Sensor-Enabled Geosynthetics Monitoring Stability and Leak Detection in Earthen Construction Technical Paper #159. In Proceedings of the World of Coal Ash Conference, Lexington, KY, USA, 22–25 April 2013. [Google Scholar]

- Wang, Z.H. Study on Seepage Monitoring Method of Soil and Stone Dam Based on Distributed of Optical Fiber Temperature Measurement Technology. Ph.D. Thesis, Xi’an University of Technology, Xi’an, China, 2019. [Google Scholar]

- Thiele, E.; Helbig, R.; Krebber, K. Dike Monitoring. In Proceedings of the 4th International Symposium on Flood Defense, Managing flood Risk Reliability and Vulnerability, Toronto, ON, Canada, 6–8 May 2008. [Google Scholar]

- Artieres, O.; Galian, M.; Royet, P. Fiber optics monitoring solution for canal dykes. In Proceedings of the Planc Mmx Congress, Liverpool, UK, 10–14 May 2010. [Google Scholar]

- Vogt, T.; Schneider, P.; Woernle, L.H. Estimation of seepage rates in a losing stream by means of fiber-optic high-resolution vertical temperature profiling. J. Hydrol. 2010, 380, 154–164. [Google Scholar] [CrossRef]

- Beck, Y.L.; Cunat, P.; Reboud, M. Improvement of leakage monitoring in dikes by the use of distributed fiber optics sensors. In Proceedings of the 6th International Conference on Scour and Erosion, Paris, France, 27–31 August 2012. [Google Scholar]

- Deng, X.W. Model Test of Leakage Monitoring Based on Distributed Optical Fiber Temperature Sensing Technology. Master’s Thesis, Hubei University of Technology, Wuhan, China, 2011. [Google Scholar]

- Liu, T.; Sun, W.J.; Kou, H.L. Experimental Study of Leakage Monitoring of Diaphragm Walls Based on Distributed Optical Fiber Temperature Measurement Technology. Sensors 2019, 19, 2269. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Number | Media Type | Moisture Content |

|---|---|---|

| 1 | Sand | dry soil |

| 2 | 8% | |

| 3 | 14% | |

| 4 | 20% | |

| 5 | Phosphorus slag | dry soil |

| 6 | 14% | |

| 7 | 24% | |

| 8 | 34% (saturation) |

| Heating Power (w/m) | 8% Moisture Content Temperature Increase (°C) | 14% Moisture Content Temperature Increase (°C) | 20% Moisture Content Temperature Increase (°C) |

|---|---|---|---|

| 5 | 3.10 | 2.45 | 2.94 |

| 8 | 7.39 | 5.29 | 5.27 |

| 10 | 9.25 | 6.64 | 6.60 |

| 12 | 11.03 | 7.31 | 6.80 |

| 15 | 13.58 | 9.08 | 8.94 |

| 18 | 14.29 | 11.54 | 9.90 |

| 20 | 15.52 | 13.69 | 12.31 |

| Heating Power (w/m) | 14% Moisture Content Temperature Increase (°C) | 24% Moisture Content Temperature Increase (°C) | 34% Moisture Content Temperature Increase (°C) |

|---|---|---|---|

| 5 | 8.71 | 5.92 | 4.66 |

| 8 | 12.03 | 8.16 | 6.66 |

| 10 | 17.06 | 11.68 | 9.46 |

| 12 | 18.91 | 12.90 | 10.28 |

| 15 | 20.95 | 14.17 | 11.48 |

| 18 | 25.22 | 17.28 | 13.66 |

| 20 | 27.30 | 18.84 | 14.99 |

| Heating Power (w/m) | Flow Velocity v (mm/s) | |||||

|---|---|---|---|---|---|---|

| 0.00 | 2.90 | 4.60 | 7.00 | 10.10 | 11.78 | |

| 5 | 2.36 | 2.11 | 2.04 | 1.89 | 1.82 | 1.79 |

| 8 | 3.45 | 3.30 | 2.84 | 2.71 | 2.66 | 2.63 |

| 10 | 4.49 | 4.05 | 3.93 | 3.68 | 3.54 | 3.49 |

| Condition Number | Content |

|---|---|

| I | Heat the cable to a stable temperature with 2 w/m heating power (the maximum power that the field device can provide) |

| II | Heat the cable at 2 w/m until the temperature stabilizes to simulate leakage |

| III | Stop heating and wait for the temperature to drop and stabilize, then reheat the optical cable with 2 w/m heating power to stabilize |

| IV | Simulate leakage again after heating stabilizes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, B.; Shen, C.; Peng, H.; Guo, F. Laboratory Model Test and Field In Situ Test of Distributed Optical Fiber Monitoring of Seepage in a Karst Depression Reservoir Basin. Water 2023, 15, 1477. https://doi.org/10.3390/w15081477

Yu B, Shen C, Peng H, Guo F. Laboratory Model Test and Field In Situ Test of Distributed Optical Fiber Monitoring of Seepage in a Karst Depression Reservoir Basin. Water. 2023; 15(8):1477. https://doi.org/10.3390/w15081477

Chicago/Turabian StyleYu, Bo, Chunyong Shen, Hao Peng, and Fawang Guo. 2023. "Laboratory Model Test and Field In Situ Test of Distributed Optical Fiber Monitoring of Seepage in a Karst Depression Reservoir Basin" Water 15, no. 8: 1477. https://doi.org/10.3390/w15081477

APA StyleYu, B., Shen, C., Peng, H., & Guo, F. (2023). Laboratory Model Test and Field In Situ Test of Distributed Optical Fiber Monitoring of Seepage in a Karst Depression Reservoir Basin. Water, 15(8), 1477. https://doi.org/10.3390/w15081477