Study on the Transient Flow Characteristics of a Hump Water Pipeline Based on the Random Distribution of Bubbles

Abstract

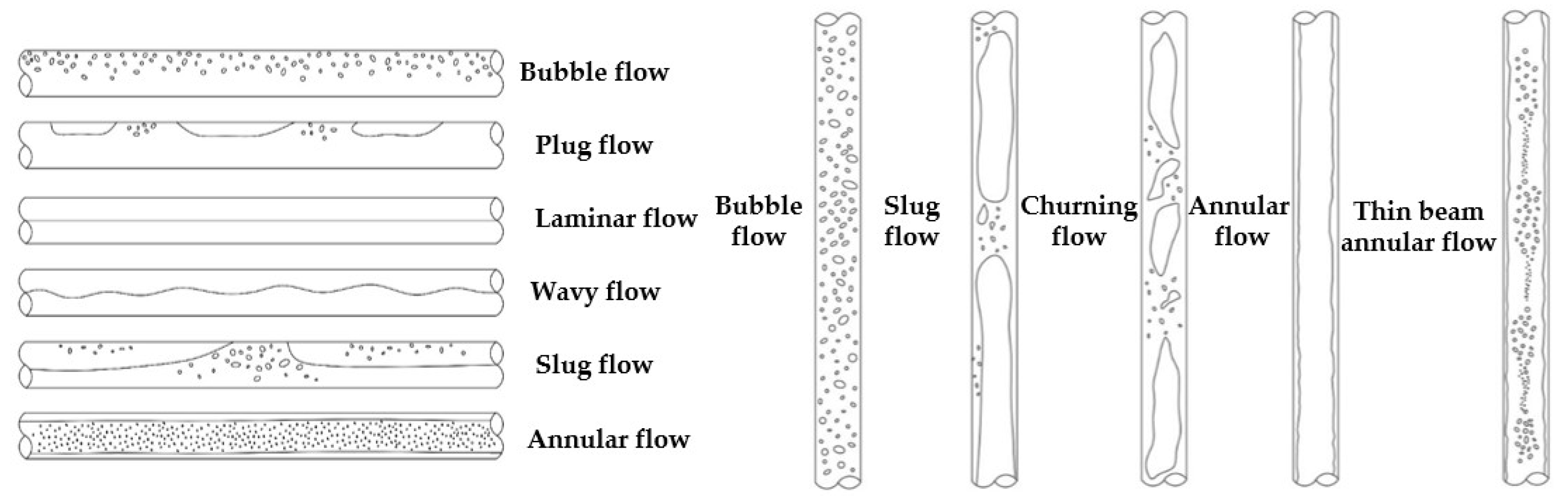

:1. Introduction

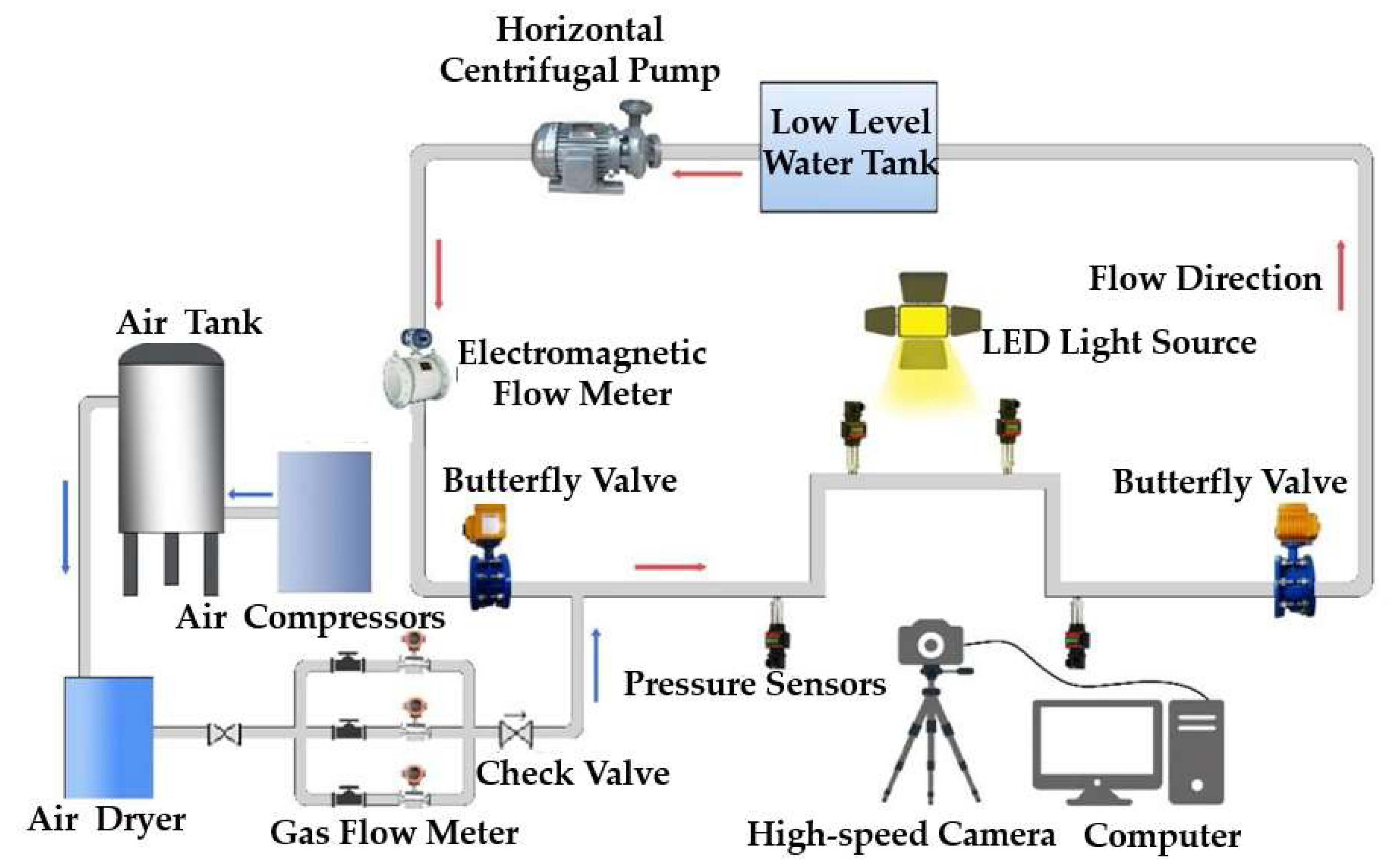

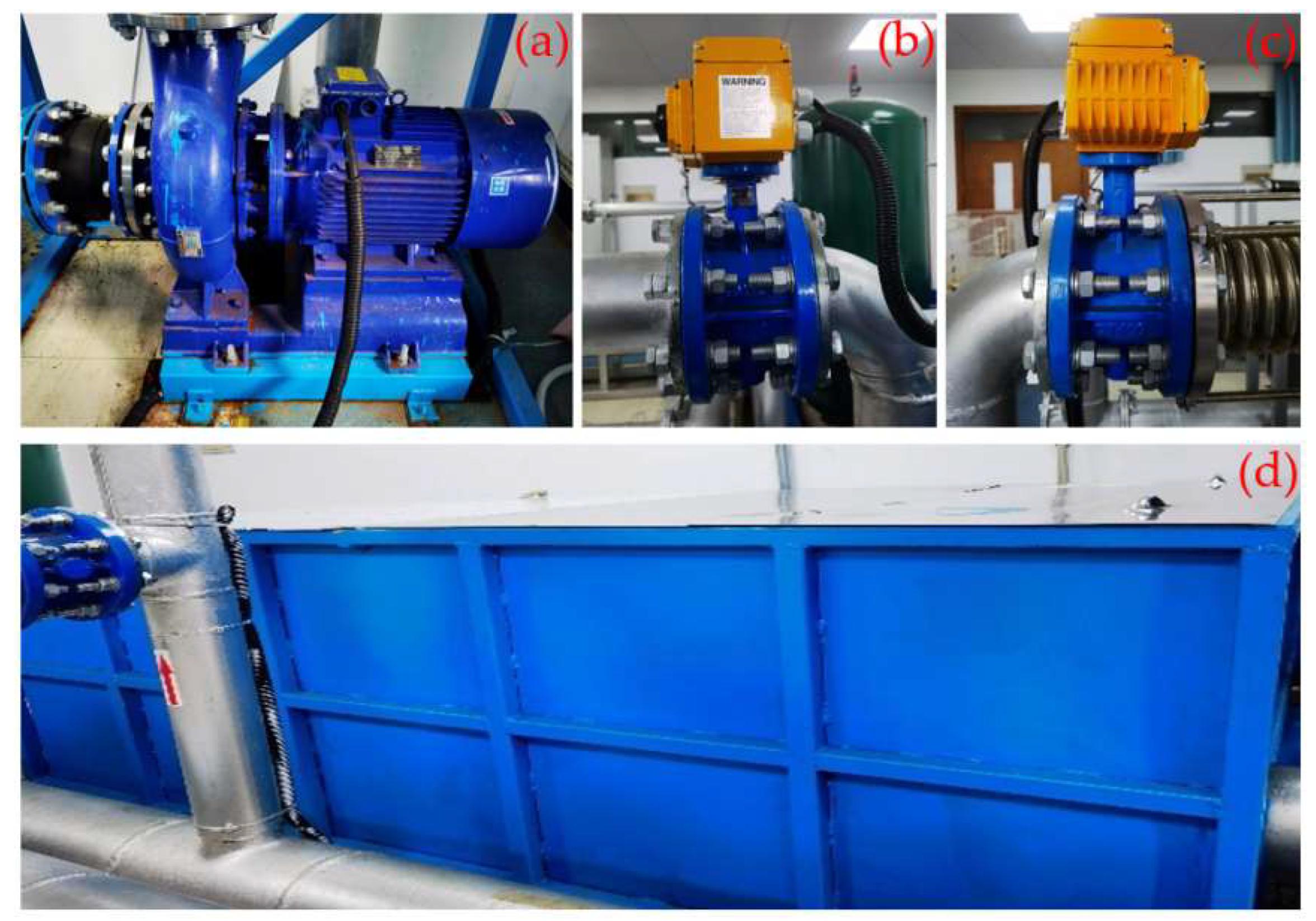

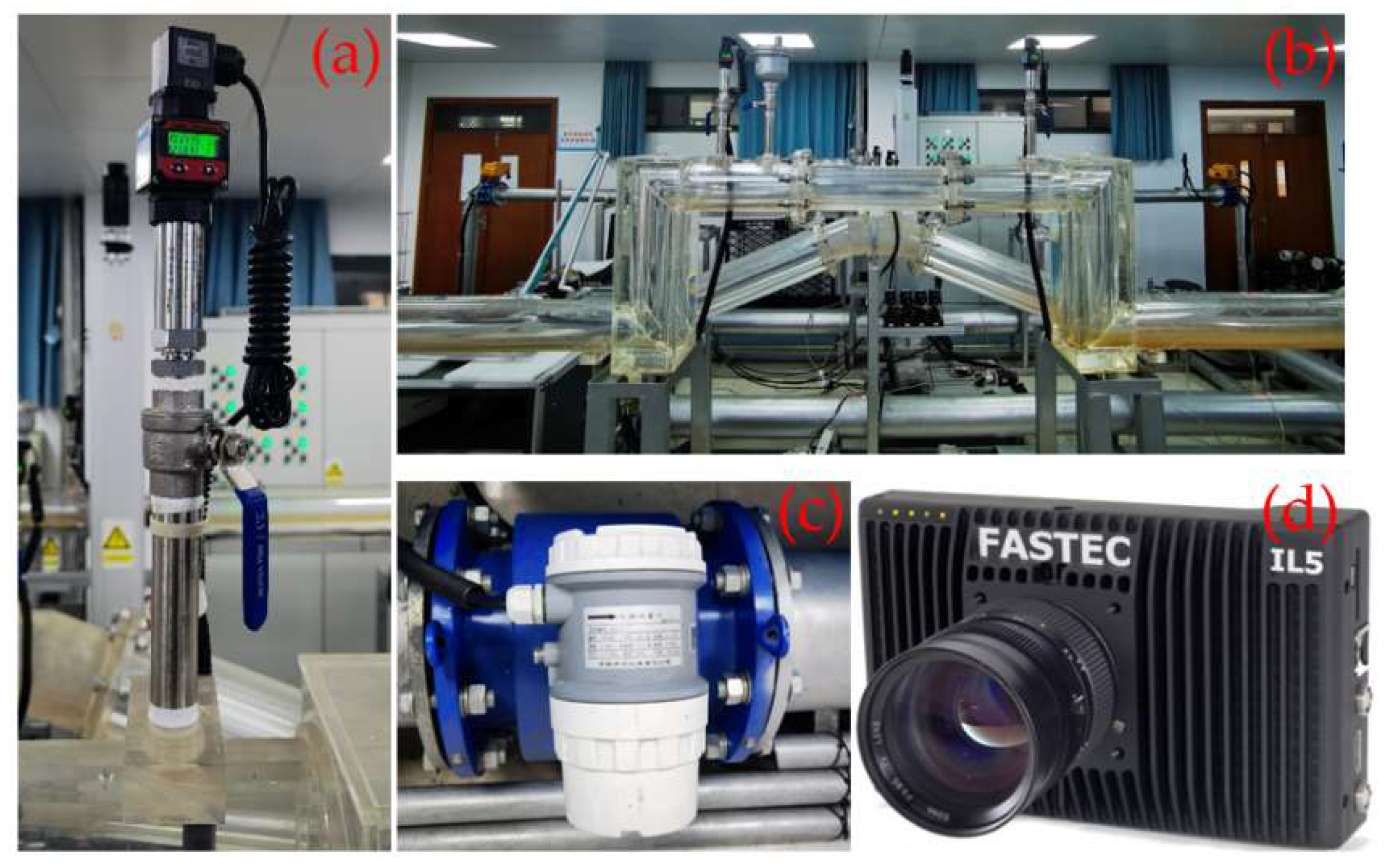

2. Physical Tests of Gas–Liquid Two-Phase Pipe Flow

2.1. Test Platform

2.2. Test Program

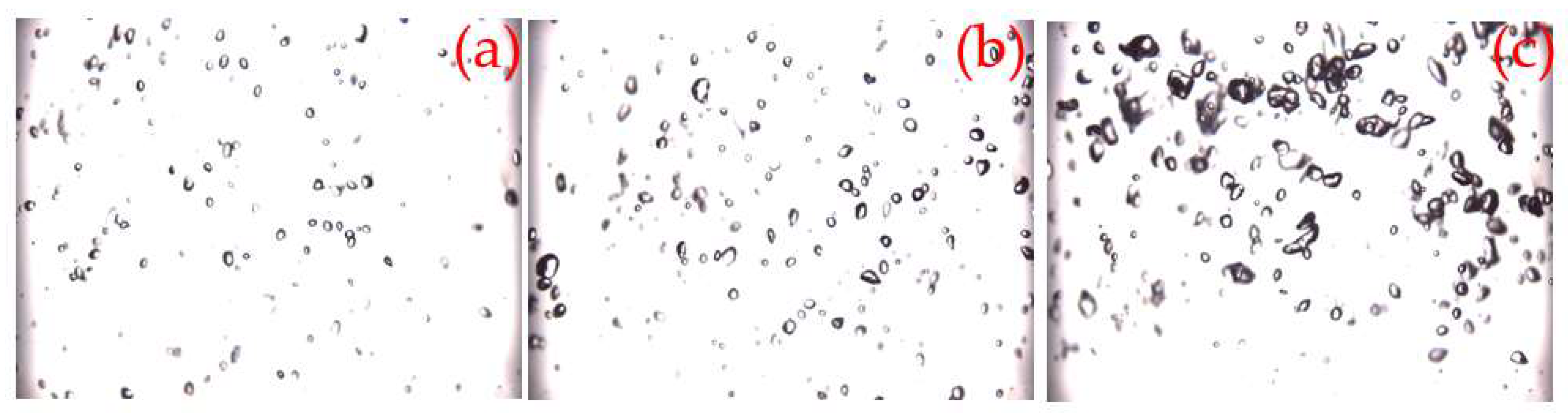

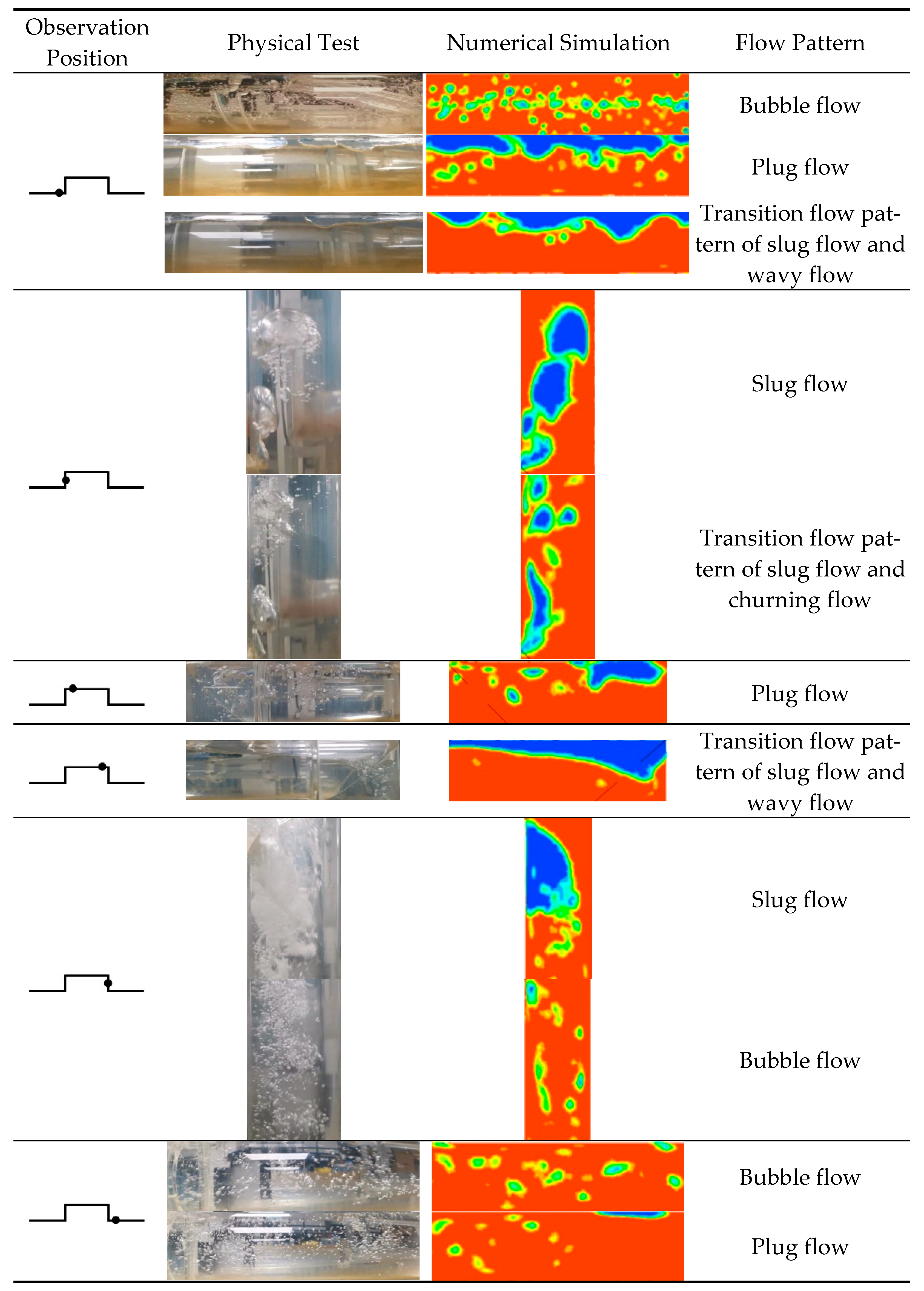

2.3. Image Analysis of the Random Distribution of Bubbles

3. CFD Numerical Simulation

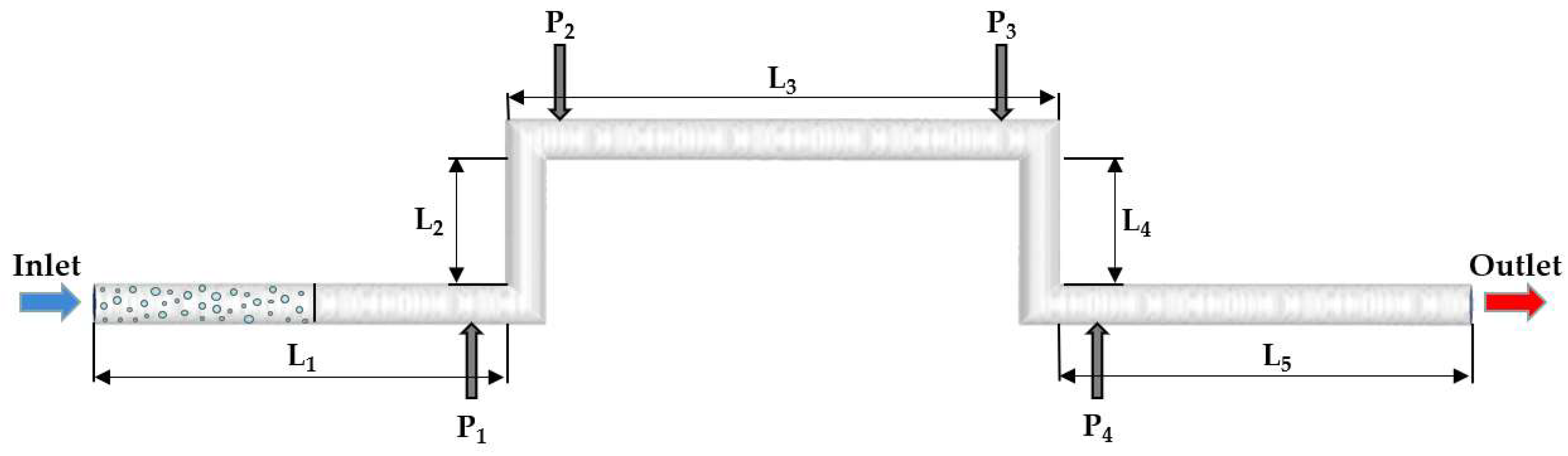

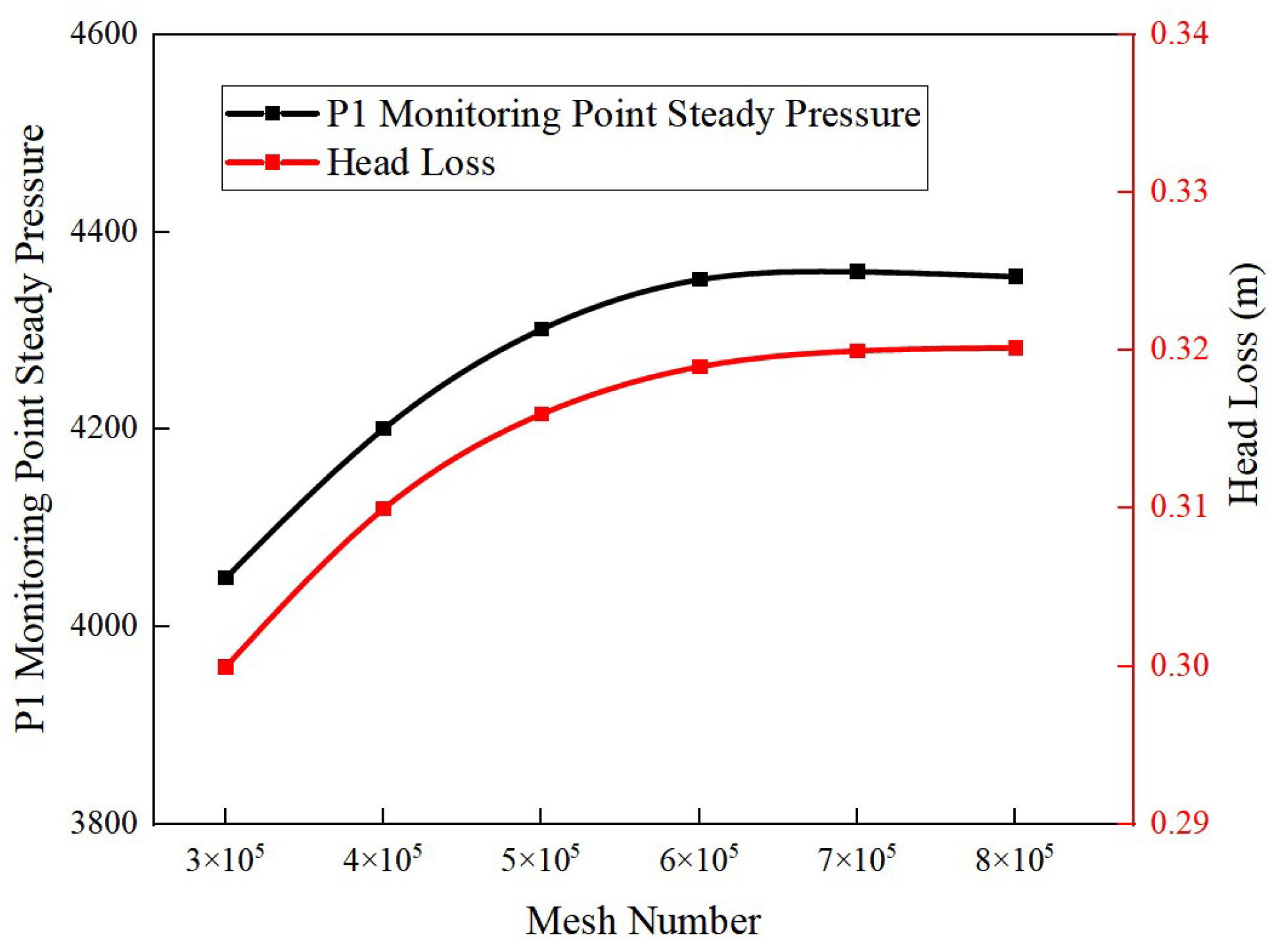

3.1. Hydraulic Model and Meshing

3.2. Numerical Simulation Methods

3.2.1. VOF Multiphase Flow Model

3.2.2. RNG k-ε Turbulence Model

3.3. Boundary Conditions and Solution Settings

3.3.1. Boundary Conditions

3.3.2. Solution Setup

4. Results and Analysis

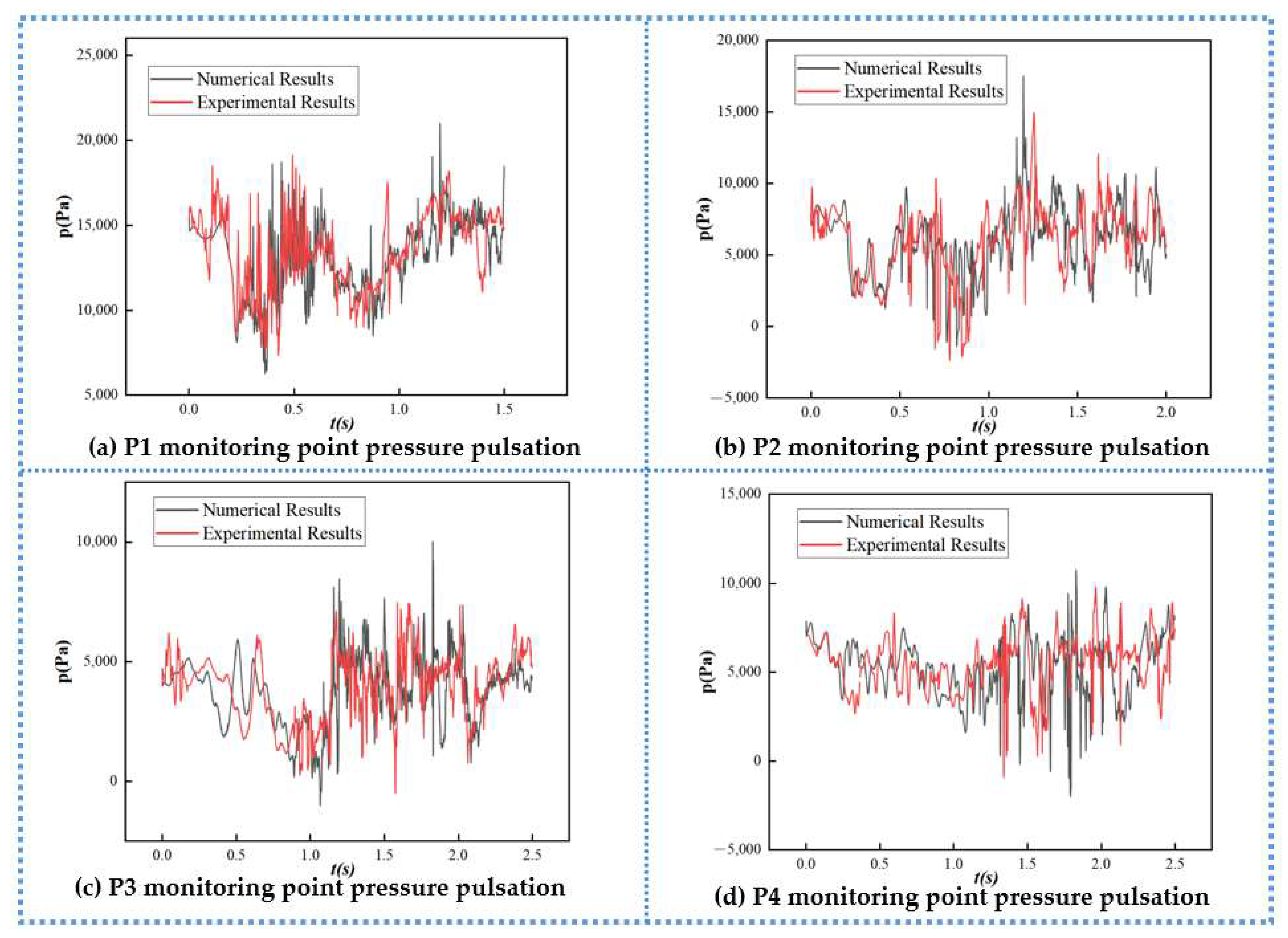

4.1. Validation of the Numerical Simulation Results

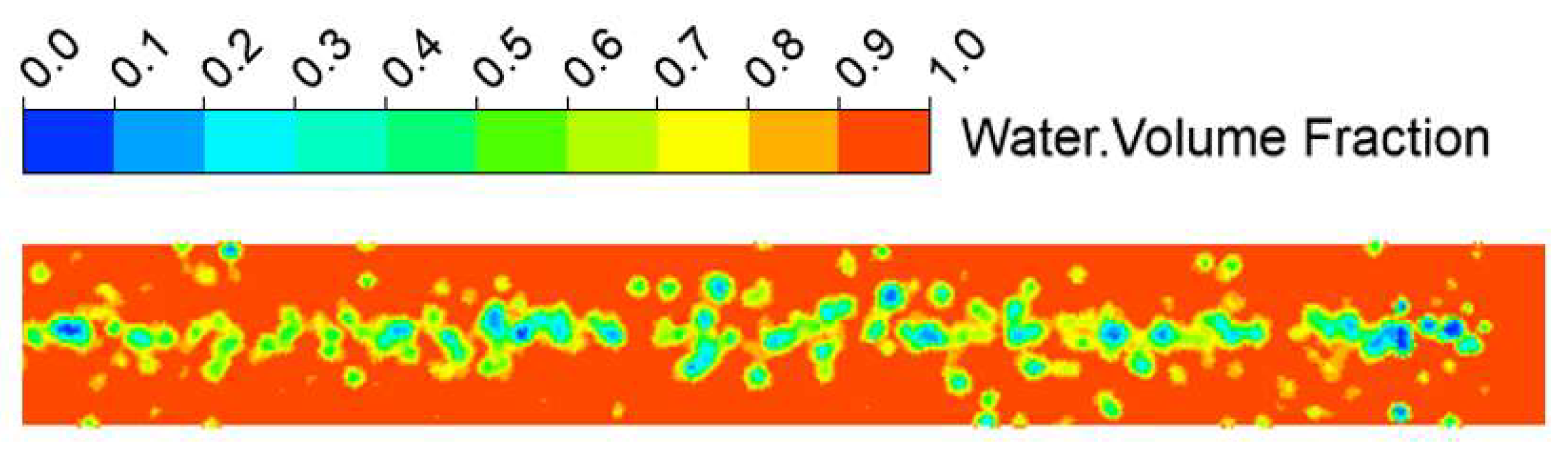

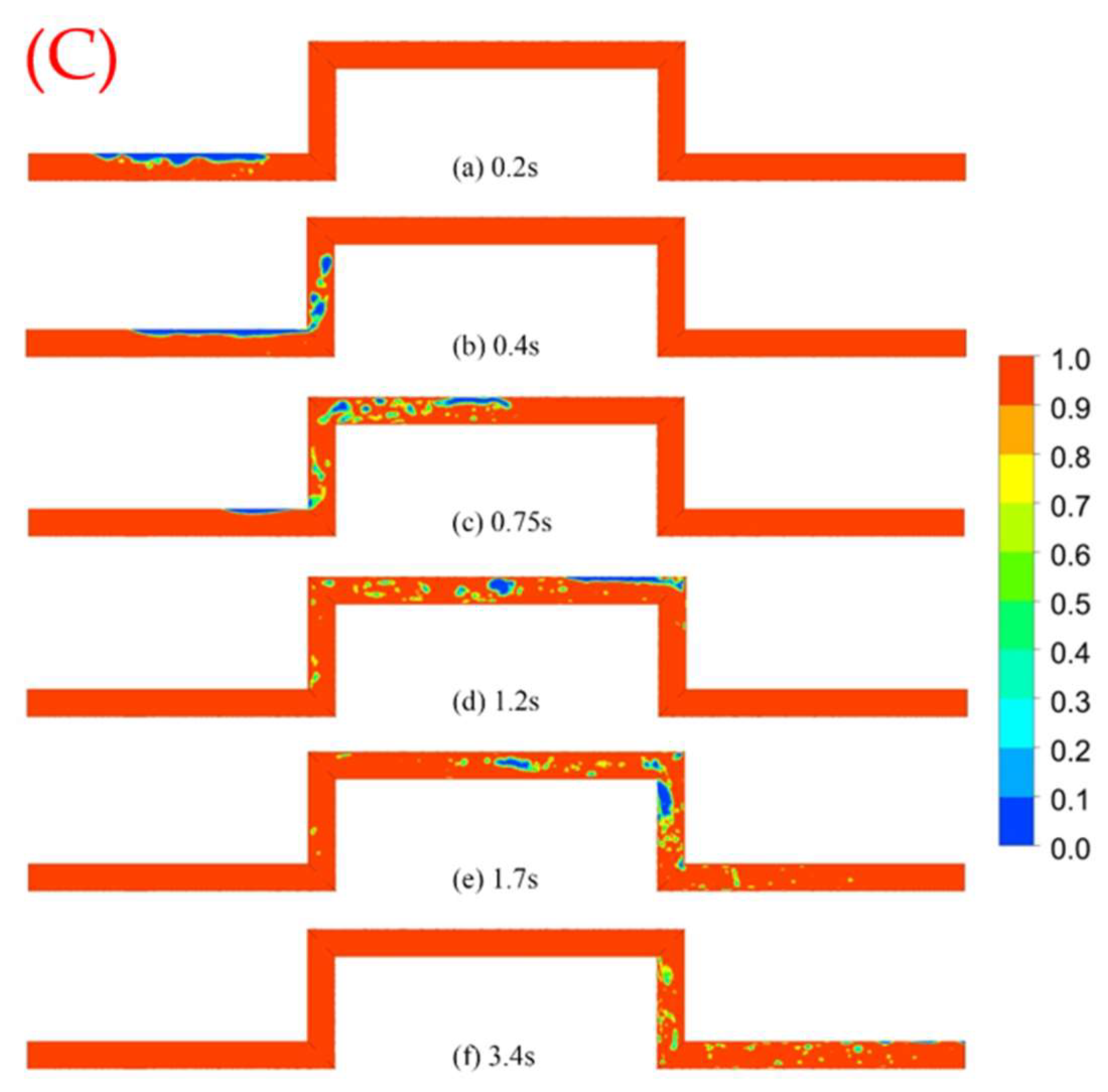

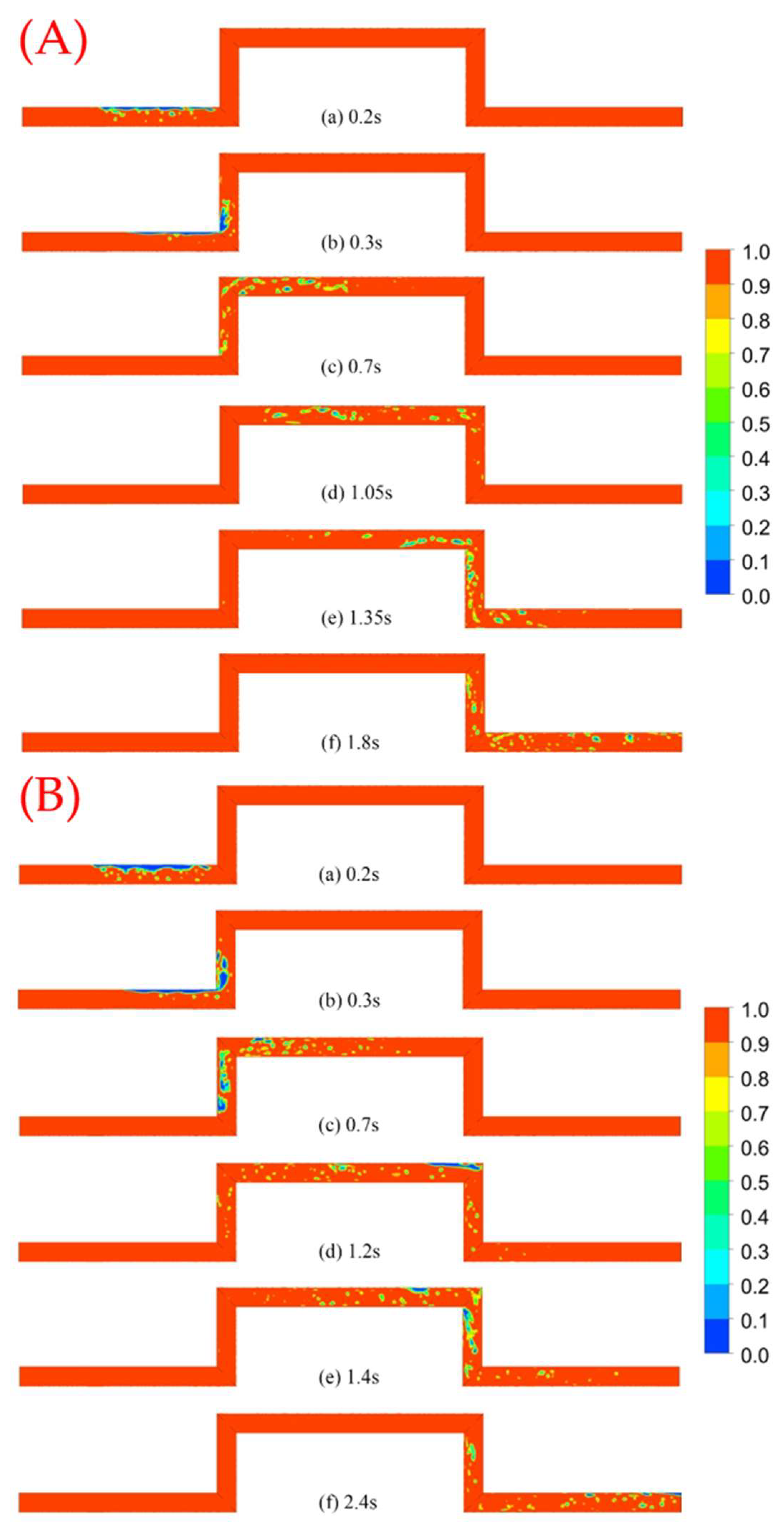

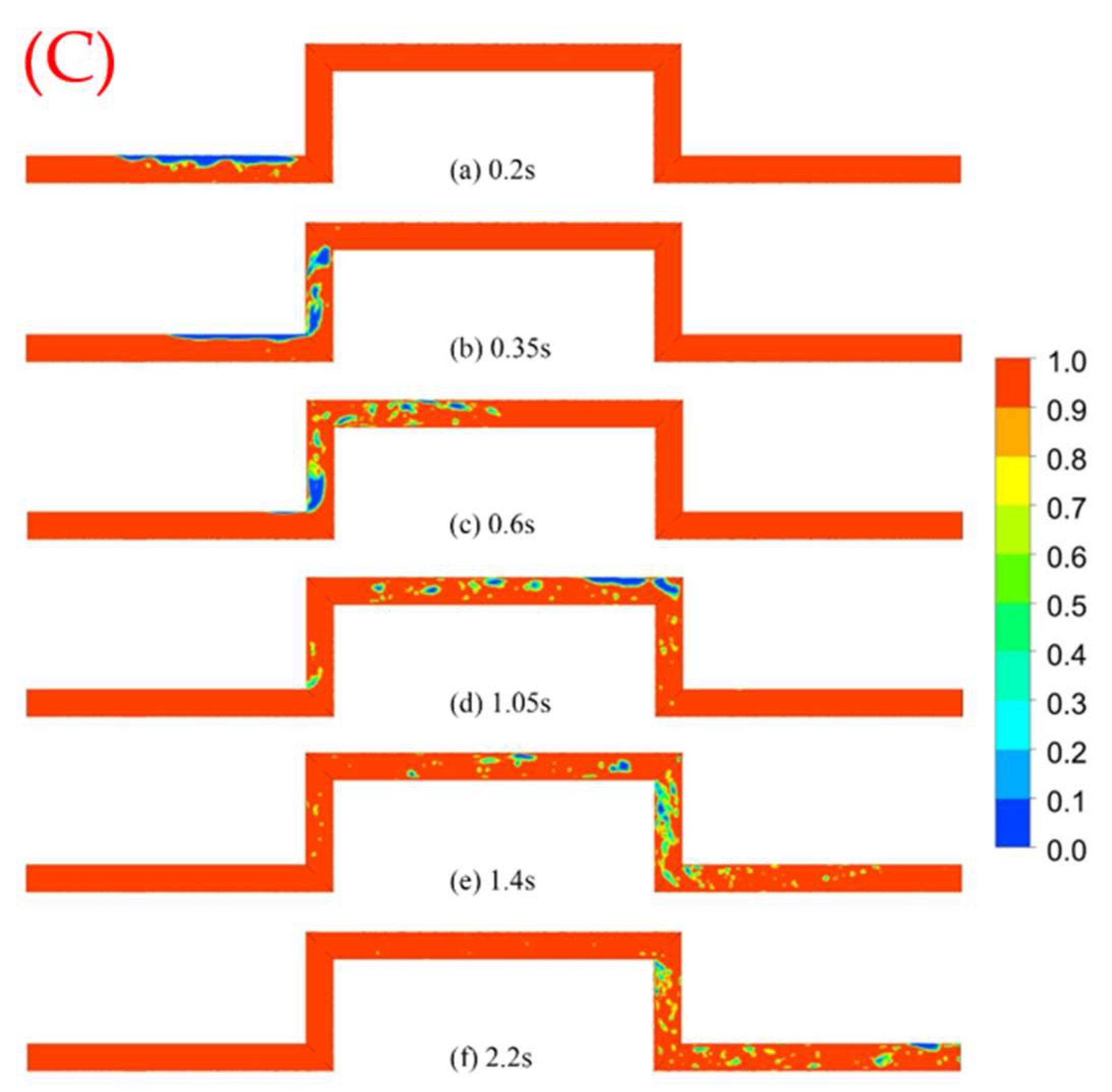

4.2. Flow Field Analysis

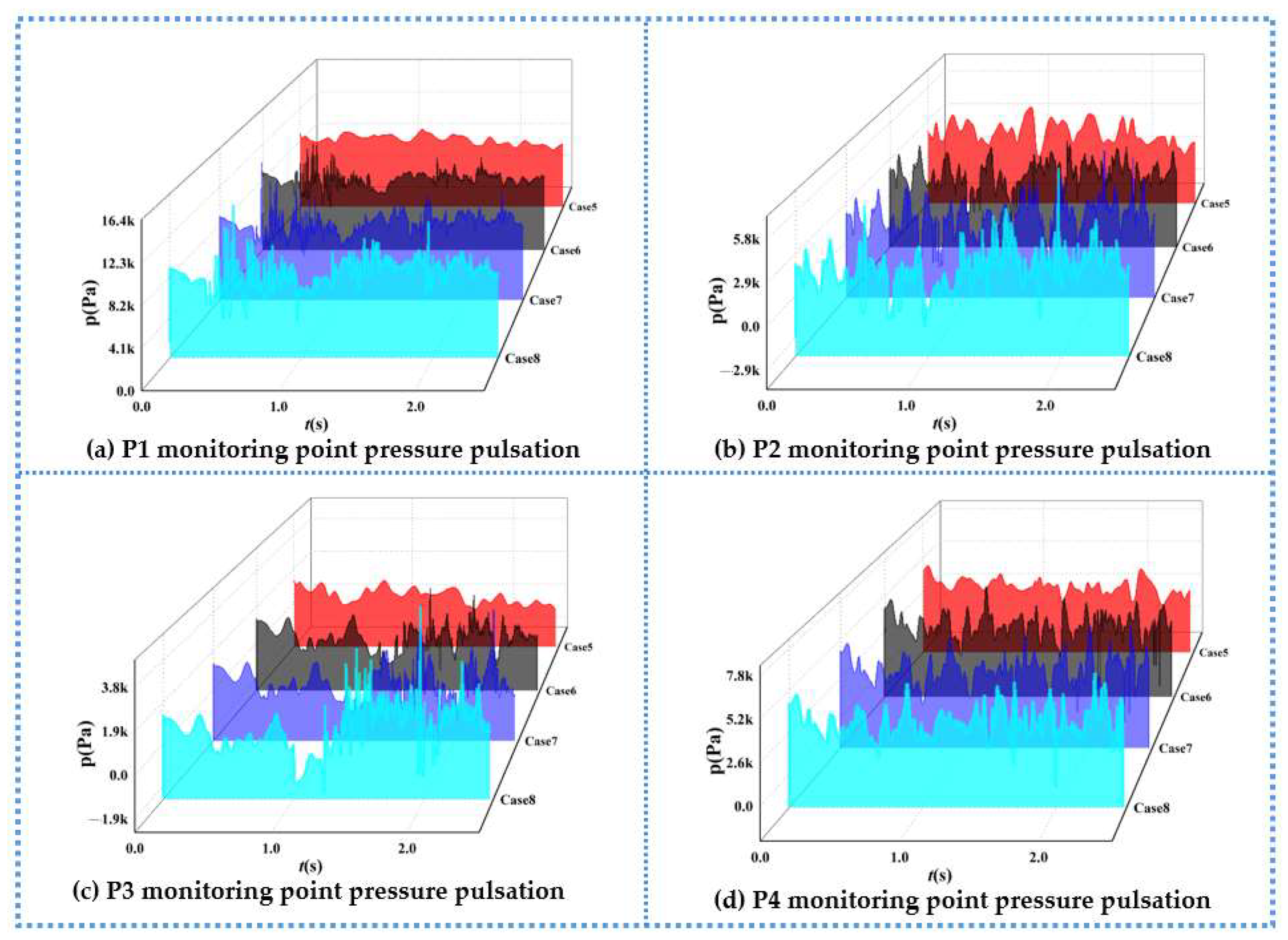

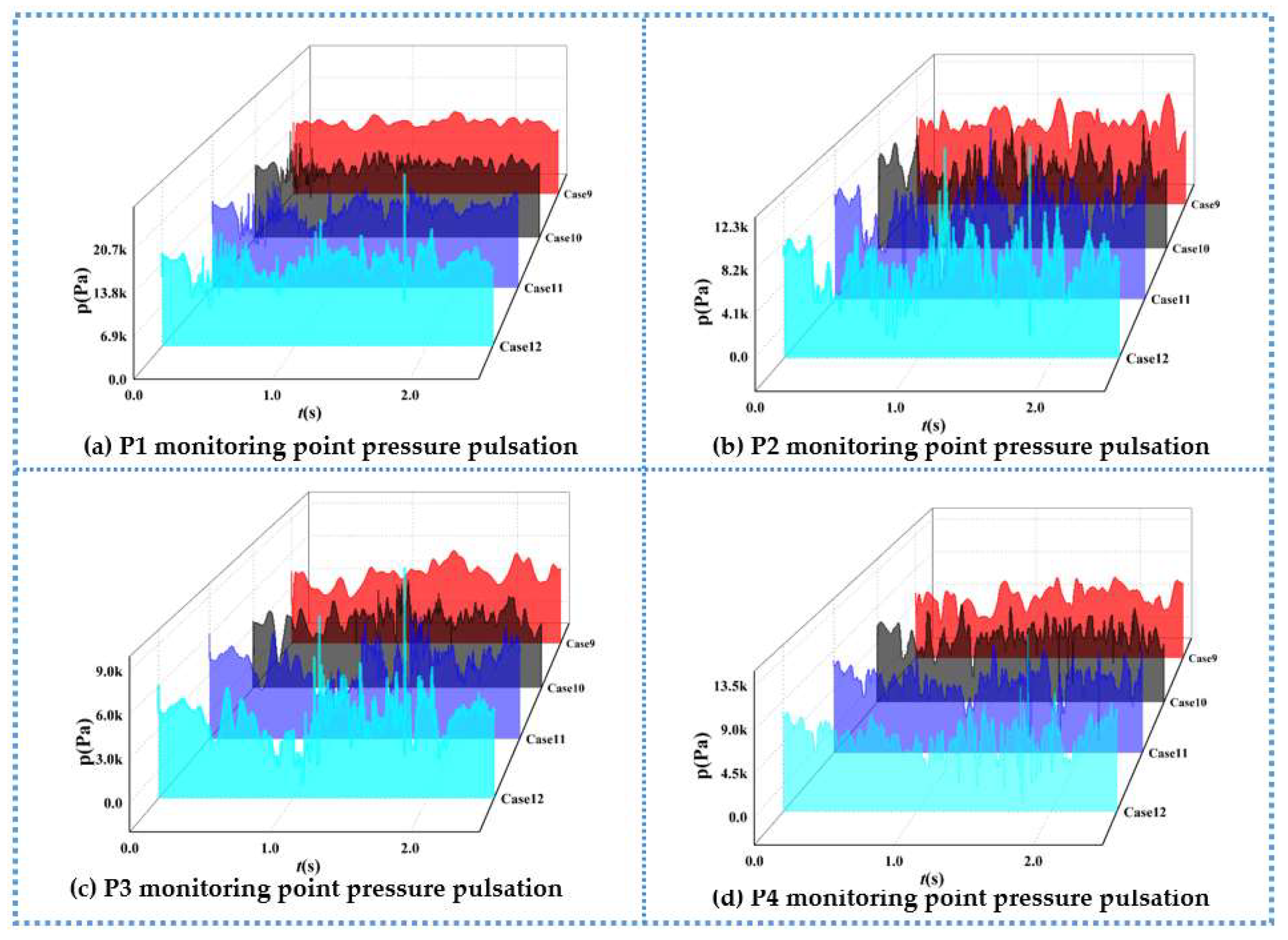

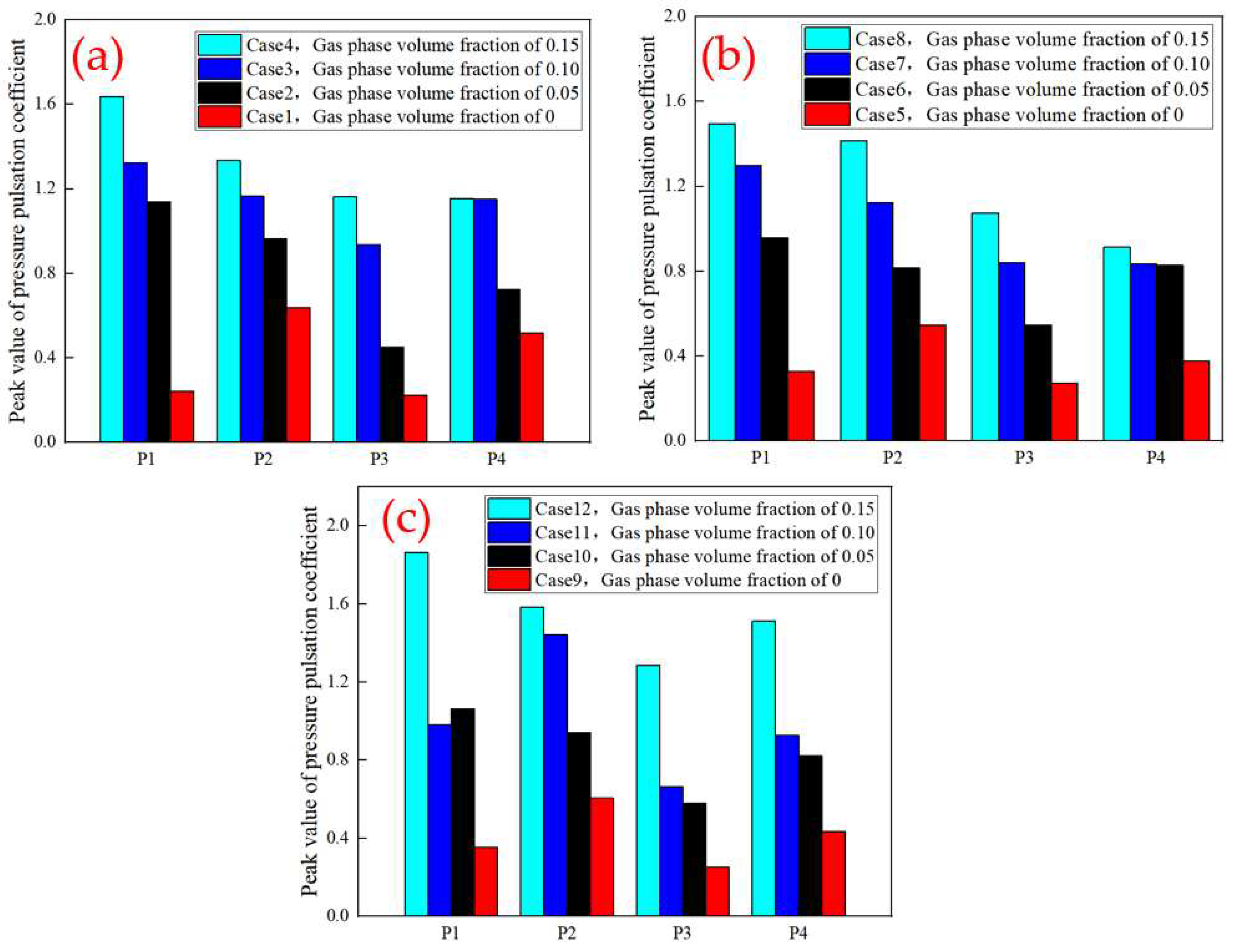

4.3. Pressure Pulsation Analysis

5. Conclusions

- (1)

- The random distribution of bubbles in the test tube section was analyzed, the random distribution of bubbles law was measured, the final bubble size was obtained as a lognormal distribution law, and the equivalent diameter was between 3 mm and 10 mm. The higher the air content, the more obvious the phenomenon of small bubbles aggregating to form large bubbles. However, the distribution position of bubbles is random, and the relationship between bubble size and bubble distribution position is also random.

- (2)

- The flow pattern in the hump pipe is rich and varied, and there are five main types of flow patterns. After the 90-degree bend, the flow pattern is rapidly transformed, experiencing a complex flow pattern transformation, such as bubble flow–wavy flow–slug flow–churning flow–slug flow–bubble flow. The higher the flow rate, the more intense the flow pattern evolution process, the more disordered the flow pattern and the higher the air content. In addition to the increase in the typical flow pattern, there are also many transitional flow patterns.

- (3)

- When pipeline bubbles or airbags flow through a region, due to gas–liquid two-phase disorder, they will cause the region pressure pulsation amplitude to steeply increase or decrease, and pressure fluctuations are extremely frequent, in which the flow rate mainly affects the pressure pulsation amplitude, and the air content has an effect on the pressure pulsation frequency and pressure pulsation amplitude. The relative pressure pulsation amplitude decreases as the air content decreases, and the air content is the main factor affecting the relative pressure pulsation amplitude compared to the flow rate.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Valve, V.M.; Corp, M. Protecting Drinking Water Pipelines with Inflow Prevention; American Society of Sanitary Engineering: Elmhurst, IL, USA, 2011. [Google Scholar]

- Pozos, O.; Gonzalez, C.A.; Pedrozo, A.; Sanchez, A.; Rodal, E. Boundary between air entrainment and air transport downstream of a hydraulic jump in circular conduits. In Proceedings of the 5th IAHR International Symposium on Hydraulic Structures, Brisbane, Australia, 25–27 June 2014. [Google Scholar] [CrossRef]

- Lu, K.M.; Zhou, L.; Cao, B.; Wang, H. Three-dimensional dynamic characteristics simulation of water flow impacting the trapped air mass in undulating pipeline. J. Irr. Dra. Mac. Eng. 2020, 38, 384–389+402. [Google Scholar]

- Guo, Y.X.; Yang, K.L.; Guo, X.L.; Fu, H. Influence of retained bubbles on water delivery capacity during water filling of large pipeline water delivery system. J. Hydraul. Eng. 2013, 44, 6. [Google Scholar] [CrossRef]

- Lu, K.M.; Zhou, L.; Liu, J. Three-dimensional numerical simulation of water impact on multi-stage stagnant air mass. J. Irr. Dra. Mac. Eng. 2021, 39, 6. [Google Scholar]

- Zheng, Y.; Liu, D.Y.; Zhang, J.; Suo, L.S. Summary of research on gas-liquid two-phase transient flow in pressurized water pipeline system. J. Hohai Univ. 2002, 30, 5. [Google Scholar] [CrossRef]

- Kranenburg, C. The Effects of free gas on cavitation in pipe tines. In 1st Inter Conference on Pressure Surges; British Hydromechanics Research Assoc: Cranfield, UK, 1972; pp. 41–52. [Google Scholar]

- Brown, R.J. Water column separation at to pumping pants. J. Basic. Eng. Trans. 1968, 90, 521–531. [Google Scholar] [CrossRef]

- Simpson, A.R.; Bergant, A. Numerical comparison of pipe-column-separation models. J. Hydraul. Eng. 1994, 120, 361–377. [Google Scholar] [CrossRef]

- Bergant, A.; Simpson, A.R. Pipeline column separation flow regimes. J. Hydraul. Eng. 1999, 125, 835–848. [Google Scholar] [CrossRef]

- Yang, K.L.; Dong, X.L. Study on dynamic characteristics of bubbles in long-distance water conveyance pipeline of hydropower station. J. Hydraul. Eng. 1998, 29, 6–16. [Google Scholar] [CrossRef]

- Yang, K.L. Research progress and frontier scientific problems of hydraulic control for long-distance water conveyance. J. Hydraul. Eng. 2016, 47, 424–435. [Google Scholar] [CrossRef]

- Tokuhiro, A.; Maekawa, M.; Iizuka, K. Turbulent flow past a bubble and an ellipsoid using shadow-image and PIV techniques. Int. J. Multiph. Flow 1998, 24, 1383–1406. [Google Scholar] [CrossRef]

- Rezapour, S.; Riasi, A. Experimental investigation of viscoelastic turbulent fluid hammer in helical tubes, considering column-separation. Int. J. Press. Ves. Piping 2021, 194, 104489. [Google Scholar] [CrossRef]

- Wan, W.; Li, C.; Yu, Y. Investigation on critical equilibrium of trapped air pocket in water supply pipeline system. J. Zhejiang Univ. 2017, 18, 167–178. [Google Scholar] [CrossRef]

- Jansson, M.; Andersson, M.; Karlsson, M. High-Speed Imaging of Water Hammer Cavitation in Oil–Hydraulic Pipe Flow. Fluids 2022, 7, 102. [Google Scholar] [CrossRef]

- Urbanowicz, K.; Bergant, A.; Kodura, A.; Kubrak, M.; Malesińska, A.; Bury, P.; Stosiak, M. Modeling Transient Pipe Flow in Plastic Pipes with Modified Discrete Bubble Cavitation Model. Energies 2021, 14, 6756. [Google Scholar] [CrossRef]

- He, J.; Liu, X.; Li, B.; Zhai, J.; Song, J. Cavitation Erosion Characteristics for Different Metal Surface and Influencing Factors in Water Flowing System. Appl. Sci. 2022, 12, 5840. [Google Scholar] [CrossRef]

- Veisi, A.; Shahsavari, M.H.; Roshani, G.H.; Eftekhari-Zadeh, E.; Nazemi, E. Experimental Study of Void Fraction Measurement Using a Capacitance-Based Sensor and ANN in Two-Phase Annular Regimes for Different Fluids. Axioms 2023, 12, 66. [Google Scholar] [CrossRef]

- Khan, U.; Pao, W.; Sallih, N. Numerical Gas–Liquid Two-Phase Flow Regime Identification in a Horizontal Pipe Using Dynamic Pressure Data. Appl. Sci. 2023, 13, 1225. [Google Scholar] [CrossRef]

- Zhao, L.; Song, Z.C.; Wu, R.C.; Wang, J.P. Theoretical Analysis of Gas Release during Transient Process of Hydraulic Transients. DEStech Trans. Soc. Sci. Educ. Hum. Sci. 2017. [Google Scholar] [CrossRef]

- Li, X.Q.; Meng, L.P.; Li, P.; Cai, Z.H.; Liu, J.W.; Wang, F.J. Influence of trapped gas on operation stability of diversion system of hydropower station. J. Hydroelectr. Eng. 2017, 43, 4. [Google Scholar]

- Zhou, L.; Liu, J.; Huang, K.; Liu, D.Y. Numerical simulation of transient flow with trapped air mass during start-up and filling of water pipeline Influence of trapped gas on operation stability of diversion system of hydropower station. Adv. Sci. Tech. Water Resour. 2021, 41, 1–7. [Google Scholar]

- Apollonio, C.; Balacco, G.; Fontana, N.; Giugni, M.; Marini, G.; Piccinni, A.F. Hydraulic Transients Caused by Air Expulsion during Rapid Filling of Undulating Pipelines. Water 2016, 8, 25. [Google Scholar] [CrossRef]

- Vasconcelos, J.G.; Wright, S.J. Rapid Flow Startup in Filled Horizontal Pipelines. J. Hydra. Eng. 2008, 134, 984–992. [Google Scholar] [CrossRef]

- Ramos, H.M.; Fuertes-Miquel, V.S.; Tasca, E.; Coronado-Hernández, O.E.; Besharat, M.; Zhou, L.; Karney, B. Concerning Dynamic Effects in Pipe Systems with Two-Phase Flows: Pressure Surges, Cavitation, and Ventilation. Water 2022, 14, 2376. [Google Scholar] [CrossRef]

- Feng, L.; Yao, Q.Y. Numerical simulation of gas-liquid two-phase flow in pressure pipeline of pumping station based on VOF model. China Rural. Water Hydropower 2012, 12, 124–126+130. [Google Scholar]

- Wang, Z.W.; He, Y.P.; Li, M.Z.; Qiu, M.; Huang, C.; Liu, Y.D. Numerical simulation and flow pattern evolution of gas-liquid two-phase flow in 90 elbow based on computational fluid dynamics. J. Shanghai Jiaotong Univ. 2022, 56, 1159–1167. [Google Scholar] [CrossRef]

- Yu, Q.Q.; Shi, H.H.; Dong, R.L.; Peng, S.S. Numerical simulation of flow pattern characteristics of gas-liquid two-phase flow in vertical upward circular tube. J. Zhejiang Sci.-Tech. Univ. 2022, 47, 397–404. [Google Scholar]

- Bourlioux, A. A coupled level-set volume-of-fluid algorithm for tracking material interfaces. In Proceedings of the 6th International Symposium on Computational Fluid Dynamics, Lake Tahoe, CA, USA, 4–8 September 1995; p. 15. [Google Scholar]

- Yang, C.Z. Study on Critical Velocity of Bubble Initiation in Long Water Pipeline Pressurized by Pump. Master’s Dissertation, North China Univ. Water Res. & Electric Power, Zhengzhou, China, 2021. [Google Scholar]

- Shang, Z.; Lou, J.; Li, H. Simulations of flow transitions in a vertical pipe using coupled level set and VOF method. Int. J. Comp. Meth. 2017, 14, 135–141. [Google Scholar] [CrossRef]

- Tang, X.; Duan, X.; Gao, H.; Li, X.; Shi, X. CFD Investigations of Transient Cavitation Flows in Pipeline Based on Weakly-Compressible Model. Water 2020, 12, 448. [Google Scholar] [CrossRef]

- Hu, J.; Wang, Q.; Zhang, Y. Numerical and Experimental Study on the Process of Filling Water in Pressurized Water Pipeline. Water 2023, 15, 2508. [Google Scholar] [CrossRef]

- Ling, P.; Ting, Z.; Jian, L. Three-Dimensional Numerical Study of Dam-Break Flood Impacting Problem with VOF Method and Different Turbulence Closures. Water Res. Manag. 2023, 37, 1–21. [Google Scholar] [CrossRef]

- Devade, K.D.; Pise, A.T.; Urade, A.R. Numerical Analysis of Flow Behavior in Vortex Tube for Different Gases. Mech. Eng. Res. 2017, 7, 18–39. [Google Scholar] [CrossRef]

- Xu, L.C.; Peng, Y.J.; Tang, W.; Liu, D.M.; Liu, X.B. Flow Characteristics and Pressure Pulsation in the S Characteristic Area of Model Pump Turbine. Chin. J. Hydro. 2022, 37, 213–225. [Google Scholar] [CrossRef]

| Model Number | Design Flow Rate (m3/h) | Design Head (m) | Rated Speed (r/min) | Motor Power (kW) | Cavitation Allowance (m) |

|---|---|---|---|---|---|

| QZHW200-250IA Pipeline centrifugal pump | 358 | 14 | 1450 | 22 | 4 |

| Operating Mode | Inlet Flow Rate (m/s) | Gas-Phase Volume Fraction | Outlet Absolute Pressure (Pa) |

|---|---|---|---|

| Case 1 | 1.0 | 0 | 101,325 |

| Case 2 | 1.0 | 0.05 | 101,325 |

| Case 3 | 1.0 | 0.10 | 101,325 |

| Case 4 | 1.0 | 0.15 | 101,325 |

| Case 5 | 1.5 | 0 | 101,325 |

| Case 6 | 1.5 | 0.05 | 101,325 |

| Case 7 | 1.5 | 0.10 | 101,325 |

| Case 8 | 1.5 | 0.15 | 101,325 |

| Case 9 | 2.0 | 0 | 101,325 |

| Case 10 | 2.0 | 0.05 | 101,325 |

| Case 11 | 2.0 | 0.10 | 101,325 |

| Case 12 | 2.0 | 0.15 | 101,325 |

| Medium | Density (kg/m3) | Dynamic Viscosity (Pa∙s) | Surface Tension (N/m) | Temp (°C) | Atmospheric Pressure (Pa) |

|---|---|---|---|---|---|

| Water | 998.2 | 1.003 × 10−3 | 0.072 | 20 | 101,325 |

| Air | 1.225 | 1.7894 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Hu, J.; Song, M.; Shen, H.; Zhou, Y.; Li, D.; Xie, F. Study on the Transient Flow Characteristics of a Hump Water Pipeline Based on the Random Distribution of Bubbles. Water 2023, 15, 3831. https://doi.org/10.3390/w15213831

Wang Q, Hu J, Song M, Shen H, Zhou Y, Li D, Xie F. Study on the Transient Flow Characteristics of a Hump Water Pipeline Based on the Random Distribution of Bubbles. Water. 2023; 15(21):3831. https://doi.org/10.3390/w15213831

Chicago/Turabian StyleWang, Qingbo, Jianyong Hu, Mingming Song, Hui Shen, Yu Zhou, Dongfeng Li, and Feng Xie. 2023. "Study on the Transient Flow Characteristics of a Hump Water Pipeline Based on the Random Distribution of Bubbles" Water 15, no. 21: 3831. https://doi.org/10.3390/w15213831

APA StyleWang, Q., Hu, J., Song, M., Shen, H., Zhou, Y., Li, D., & Xie, F. (2023). Study on the Transient Flow Characteristics of a Hump Water Pipeline Based on the Random Distribution of Bubbles. Water, 15(21), 3831. https://doi.org/10.3390/w15213831