Managing Bisphenol A Contamination: Advances in Removal Technologies and Future Prospects

Abstract

:1. Introduction

2. BPA Application and Occurrence in Environment

3. Endocrine and Toxicological Effects of BPA

4. Treatment Technologies Available for BPA Removal

4.1. Physicochemical Treatments

4.1.1. Adsorption Processes

4.1.2. Membrane Technologies

4.1.3. Conventional Oxidation Processes

4.1.4. Advanced Oxidation Processes (AOPs)

Photocatalysis

Photooxidation with UV Radiation

Fenton-Related Processes

Ultrasound Treatment

Sonocatalytic Treatment

Plasma Treatment

4.2. Biological Treatments

4.2.1. Activated Sludge System

4.2.2. Biological Aerated Filter (BAF)

4.2.3. Membrane Bioreactor (MBR)

4.2.4. Granular Sequencing Batch Reactor (GSBR)

4.3. Emergence of Hybrid/Integrated Systems for BPA Removal

4.3.1. Technologies Combining Biological Treatments and Membrane Filtration

4.3.2. Technologies Combining Adsorption and AOPs

4.3.3. Technologies Combining AOPs and Membrane Filtrations

5. Discussion on Comparative Performance of BPA Removal

6. Future Directions

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sarma, H.; Nava, A.R.; Manriquez, A.M.E.; Dominguez, D.C.; Lee, W.-Y. Biodegradation of bisphenol A by bacterial consortia isolated directly from river sediments. Environ. Technol. Innov. 2019, 14, 100314. [Google Scholar] [CrossRef]

- Siddique, S.; Kubwabo, C.; Harris, S.A. A review of the role of emerging environmental contaminants in the development of breast cancer in women. Emerg. Contam. 2016, 2, 204–219. [Google Scholar] [CrossRef]

- Almeida, S.; Raposo, A.; Almeida-González, M.; Carrascosa, C. Bisphenol A: Food Exposure and Impact on Human Health. Compr. Rev. Food Sci. Food Saf. 2018, 17, 1503–1517. [Google Scholar] [CrossRef] [PubMed]

- Kurniawan, S.B.; Abdullah, S.R.S.; Imron, M.F.; Ismail, N. Current state of marine plastic pollution and its technology for more eminent evidence: A review. J. Clean. Prod. 2020, 278, 123537. [Google Scholar] [CrossRef]

- Moussavi, G.; Haddad, F.A. Bacterial peroxidase-mediated enhanced biodegradation and mineralization of bisphenol A in a batch bioreactor. Chemosphere 2019, 222, 549–555. [Google Scholar] [CrossRef]

- Im, J.; Löffer, F.E. Fate of bisphenol A in terrestrial and aquatic environments. Environ. Sci. Technol. 2016, 50, 8403–8416. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Pan, F.; Li, W.; Li, D.; Xu, H.; Xia, D.; Li, A. Enhanced Adsorption of Bisphenol A from Aqueous Solution with 2-Vinylpyridine Functionalized Magnetic Nanoparticles. Polymers 2018, 10, 1136. [Google Scholar] [CrossRef]

- Kadasala, N.R.; Narayanan, B.; Liu, Y. International Trade Regulations on BPA: Global Health and Economic Implications. Asian Dev. Policy Rev. 2016, 4, 134–142. [Google Scholar] [CrossRef]

- Tarafdar, A.; Sirohi, R.; Balakumaran, P.A.; Reshmy, R.; Madhavan, A.; Sindhu, R.; Binod, P.; Kumar, Y.; Kumar, D.; Sim, S.J. The hazardous threat of Bisphenol A: Toxicity, detection and remediation. J. Hazard. Mater. 2022, 423, 127097. [Google Scholar] [CrossRef]

- Gewurtz, S.B.; Tardif, G.; Power, M.; Backus, S.M.; Dove, A.; Dubé-Roberge, K.; Garron, C.; King, M.; Lalonde, B.; Letcher, R.J.; et al. Bisphenol A in the Canadian environment: A multimedia analysis. Sci. Total Environ. 2021, 755, 142472. [Google Scholar] [CrossRef]

- Lin, Z.; Wang, L.; Jia, Y.; Zhang, Y.; Dong, Q.; Huang, C. A Study on Environmental Bisphenol A Pollution in Plastics Industry Areas. Water Air Soil Pollut. 2017, 228, 98. [Google Scholar] [CrossRef]

- Zhang, W.; Xiong, B.; Sun, W.-F.; An, S.; Lin, K.-F.; Guo, M.-J.; Cui, X.-H. Acute and chronic toxic effects of bisphenol a on Chlorella pyrenoidosa and Scenedesmus obliquus. Environ. Toxicol. 2014, 29, 714–722. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Chen, M.; Shan, G.; Chen, P.; Cui, S.; Yi, S.; Zhu, L. Bioaccumulation and biomagnification of emerging bisphenol analogues in aquatic organisms from Taihu Lake, China. Sci. Total Environ. 2017, 598, 814–820. [Google Scholar] [CrossRef] [PubMed]

- Adeyi, A.A.; Babalola, B.A. Bisphenol-A (BPA) in Foods commonly consumed in Southwest Nigeria and its Human Health Risk. Sci. Rep. 2019, 9, 17458. [Google Scholar] [CrossRef] [PubMed]

- Cao, P.; Zhong, H.-N.; Qiu, K.; Li, D.; Wu, G.; Sui, H.-X.; Song, Y. Exposure to bisphenol A and its substitutes, bisphenol F and bisphenol S from canned foods and beverages on Chinese market. Food Control. 2021, 120, 107502. [Google Scholar] [CrossRef]

- Gys, C.; Bastiaensen, M.; Bruckers, L.; Colles, A.; Govarts, E.; Martin, L.R.; Verheyen, V.; Koppen, G.; Morrens, B.; Hond, E.D.; et al. Determinants of exposure levels of bisphenols in flemish adolescents. Environ. Res. 2020, 193, 110567. [Google Scholar] [CrossRef] [PubMed]

- Choong, C.E.; Ibrahim, S.; Basirun, W.J. Mesoporous silica from batik sludge impregnated with aluminum hydroxide for the removal of bisphenol A and ibuprofen. J. Colloid Interface Sci. 2019, 541, 12–17. [Google Scholar] [CrossRef]

- Zhou, N.; Liu, Y.; Cao, S.; Guo, R.; Ma, Y.; Chen, J. Biodegradation of bisphenol compounds in the surface water of Taihu Lake and the effect of humic acids. Sci. Total Environ. 2020, 723, 138164. [Google Scholar] [CrossRef]

- Aravind, P.; Devarajan, A.; Solaiappan, A.; Selvaraj, H.; Sundaram, M. Removal of BPA from thermal cash receipts via electro oxidation cum biodegradation: Evaluating its degradation mechanism and in silico toxicity analysis. J. Water Process. Eng. 2019, 31, 100849. [Google Scholar] [CrossRef]

- Mokhtar, A.; Nishioka, T.; Matsumoto, H.; Kitada, S.; Ryuno, N.; Okobira, T. Novel biodegradation system for bisphenol A using laccase-immobilized hollow fiber membranes. Int. J. Biol. Macromol. 2019, 130, 737–744. [Google Scholar] [CrossRef]

- Sharma, J.; Mishra, I.M.; Kumar, V. Degradation and mineralization of Bisphenol A (BPA) in aqueous solution using advanced oxidation processes: UV/H2O2 and UV/S2O82− oxidation systems. J. Environ. Manag. 2015, 156, 266–275. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Zhang, M. Adsorption Characteristics and Mechanism of Bisphenol A by Magnetic Biochar. Int. J. Environ. Res. Public Health 2020, 17, 1075. [Google Scholar] [CrossRef] [PubMed]

- Yüksel, S.; Kabay, N.; Yüksel, M. Removal of bisphenol A (BPA) from water by various nanofiltration (NF) and reverse osmosis (RO) membranes. J. Hazard. Mater. 2013, 263, 307–310. [Google Scholar] [CrossRef] [PubMed]

- Plahuta, M.; Tišler, T.; Toman, M.J.; Pintar, A. Efficiency of advanced oxidation processes in lowering bisphenol A toxicity and oestrogenic activity in aqueous samples. Arch. Ind. Hyg. Toxicol. 2014, 65, 77–87. [Google Scholar] [CrossRef]

- Imron, M.F.; Kurniawan, S.B.; Ismail, N.; Abdullah, S.R.S. Future challenges in diesel biodegradation by bacteria isolates: A review. J. Clean. Prod. 2019, 251, 119716. [Google Scholar] [CrossRef]

- Kurniawan, S.B.; Abdullah, S.R.S.; Imron, M.F.; Said, N.S.M.; Ismail, N.; Abu Hasan, H.; Othman, A.R.; Purwanti, I.F. Challenges and Opportunities of Biocoagulant/Bioflocculant Application for Drinking Water and Wastewater Treatment and Its Potential for Sludge Recovery. Int. J. Environ. Res. Public Health 2020, 17, 9312. [Google Scholar] [CrossRef]

- Yahya, M.N.; Gökçekuş, H.; Ozsahin, D.U. Comparative Analysis of Wastewater Treatment Technologies. J. Kejuruter. 2020, 32, 221–230. [Google Scholar] [CrossRef]

- Kurniawan, S.B.; Ahmad, A.; Imron, M.F.; Abdullah, S.R.S.; Othman, A.R.; Abu Hasan, H. Potential of microalgae cultivation using nutrient-rich wastewater and harvesting performance by biocoagulants/bioflocculants: Mechanism, multi-conversion of biomass into valuable products, and future challenges. J. Clean. Prod. 2022, 365, 132806. [Google Scholar] [CrossRef]

- Abu Hasan, H.; Shanmugam, D.S.A.; Abdullah, S.R.S.; Muhamad, M.H.; Kurniawan, S.B. Potential of Using Dual-Media Biofilm Reactors as a Real Coffee Industrial Effluent Pre-Treatment. Water 2022, 14, 2025. [Google Scholar] [CrossRef]

- Al-Ajalin, F.A.H.; Idris, M.; Abdullah, S.R.S.; Kurniawan, S.B.; Imron, M.F. Effect of wastewater depth to the performance of short-term batching-experiments horizontal flow constructed wetland system in treating domestic wastewater. Environ. Technol. Innov. 2020, 20, 101106. [Google Scholar] [CrossRef]

- Buhari, J.; Abu Hasan, H.; Rahim, N.F.M.; Kurniawan, S.B.; Abdullah, S.R.S.; Othman, A.R. Unveiling the optimal ammonia-oxidising bacterial consortium for polishing low ammonia-contaminated wastewater. J. Water Process. Eng. 2022, 47, 102753. [Google Scholar] [CrossRef]

- Ferro Orozco, A.M.; Lobo, C.; Contreras, E.; Zaritzky, N. Biodegradation of bisphenol-A (BPA) in activated sludge batch reactors: Analysis of the acclimation process. Int. Biodeterior. Biodegrad. 2013, 85, 392–399. [Google Scholar] [CrossRef]

- Gu, Y.; Sun, X.; Liu, Y. Biosorption and biodegradation of bisphenol A in an activated sludge system. Res. Chem. Intermed. 2016, 42, 4289–4301. [Google Scholar] [CrossRef]

- Mohammad, A.W.; Teow, Y.H.; Chong, W.C.; Ho, K.C. Hybrid processes: Membrane bioreactor. In Membrane Separation Principles and Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 401–470. [Google Scholar] [CrossRef]

- Hou, J.; Dong, G.; Luu, B.; Sengpiel, R.G.; Ye, Y.; Wessling, M.; Chen, V. Hybrid membrane with TiO 2 based bio-catalytic nanoparticle suspension system for the degradation of bisphenol-A. Bioresour. Technol. 2014, 169, 475–483. [Google Scholar] [CrossRef] [PubMed]

- Muhamad, M.H.; Abdullah, S.R.S.; Abu Hasan, H.; Abu Bakar, S.N.H.; Kurniawan, S.B.; Ismail, N. A hybrid treatment system for water contaminated with pentachlorophenol: Removal performance and bacterial community composition. J. Water Process. Eng. 2021, 43, 102243. [Google Scholar] [CrossRef]

- Zielińska, M.; Cydzik-Kwiatkowska, A.; Bułkowska, K.; Bernat, K.; Wojnowska-Baryła, I. Treatment of Bisphenol A-Containing Effluents from Aerobic Granular Sludge Reactors with the Use of Microfiltration and Ultrafiltration Ceramic Membranes. Water Air Soil Pollut. 2017, 228, 282. [Google Scholar] [CrossRef]

- Rochester, J.R. Bisphenol A and human health: A review of the literature. Reprod. Toxicol. 2013, 42, 132–155. [Google Scholar] [CrossRef]

- Li, G.; Zu, L.; Wong, P.-K.; Hui, X.; Lu, Y.; Xiong, J.; An, T. Biodegradation and detoxification of bisphenol A with one newly-isolated strain Bacillus sp. GZB: Kinetics, mechanism and estrogenic transition. Bioresour. Technol. 2012, 114, 224–230. [Google Scholar] [CrossRef]

- IHS Markit. Bisphenol A [WWW Document]. Chem. Econ. Handb. 2020. Available online: https://ihsmarkit.com/products/chemical-economics-handbooks.html (accessed on 25 December 2020).

- Careghini, A.; Mastorgio, A.F.; Saponaro, S.; Sezenna, E. Bisphenol A, nonylphenols, benzophenones, and benzotriazoles in soils, groundwater, surface water, sediments, and food: A review. Environ. Sci. Pollut. Res. 2014, 22, 5711–5741. [Google Scholar] [CrossRef]

- Shokoohi, R.; Zolghadrnasab, H.; Shanehsaz, S.; Leili, M.; Shaygan, M.; Azizi, F. Efficiency of the catalytic ozonation processes using nanoparticles deposited on pumice in the removal of bisphenol A. Int. J. Environ. Anal. Chem. 2021, 103, 3121–3137. [Google Scholar] [CrossRef]

- Rajasärkkä, J.; Pernica, M.; Kuta, J.; Lašňák, J.; Šimek, Z.; Bláha, L. Drinking water contaminants from epoxy resin-coated pipes: A field study. Water Res. 2016, 103, 133–140. [Google Scholar] [CrossRef] [PubMed]

- Graziani, N.S.; Carreras, H.; Wannaz, E. Atmospheric levels of BPA associated with particulate matter in an urban environment. Heliyon 2019, 5, e01419. [Google Scholar] [CrossRef] [PubMed]

- Jahromi, F.A.; Moore, F.; Keshavarzi, B.; Mohebbi-Nozar, S.L.; Mohammadi, Z.; Sorooshian, A.; Abbasi, S. Bisphenol A (BPA) and polycyclic aromatic hydrocarbons (PAHs) in the surface sediment and bivalves from Hormozgan Province coastline in the Northern Persian Gulf: A focus on source apportionment. Mar. Pollut. Bull. 2020, 152, 110941. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.; Huang, X.; Liang, P.; Xiao, K.; Zhou, Y.; Zhang, X.; Logan, B.E. A New Method for Water Desalination Using Microbial Desalination Cells. Environ. Sci. Technol. 2009, 43, 7148–7152. [Google Scholar] [CrossRef]

- Kang, J.-H.; Katayama, Y. Biodegradation or metabolism of bisphenol A in the environment. In Environmental Biodegradation Research Focus; Wang, B.Y., Ed.; Nova Publishers: New York, NY, USA, 2007; pp. 49–76. [Google Scholar]

- Predieri, B.; Iughetti, L.; Bernasconi, S.; Street, M.E. Endocrine disrupting chemicals’ effects in children: What we know and what we need to learn? Int. J. Mol. Sci. 2022, 23, 11899. [Google Scholar] [CrossRef]

- Wang, N.; Zhou, Y.; Fu, C.; Wang, H.; Huang, P.; Wang, B.; Su, M.; Jiang, F.; Fang, H.; Zhao, Q.; et al. Influence of Bisphenol A on Thyroid Volume and Structure Independent of Iodine in School Children. PLoS ONE 2015, 10, e0141248. [Google Scholar] [CrossRef]

- Michałowicz, J. Bisphenol A—Sources, toxicity and biotransformation. Environ. Toxicol. Pharmacol. 2014, 37, 738–758. [Google Scholar] [CrossRef]

- Ho, S.-M.; Rao, R.; To, S.; Schoch, E.; Tarapore, P. Bisphenol A and its analogues disrupt centrosome cycle and microtubule dynamics in prostate cancer. Endocr.-Relat. Cancer 2017, 24, 83–96. [Google Scholar] [CrossRef]

- Braun, J.M.; Yolton, K.; Dietrich, K.N.; Hornung, R.; Ye, X.; Calafat, A.M.; Lanphear, B.P. Prenatal Bisphenol A Exposure and Early Childhood Behavior. Environ. Health Perspect. 2009, 117, 1945–1952. [Google Scholar] [CrossRef]

- Ejaredar, M.; Lee, Y.; Roberts, D.J.; Sauve, R.; Dewey, D. Bisphenol A exposure and children’s behavior: A systematic review. J. Expo. Sci. Environ. Epidemiol. 2016, 27, 175–183. [Google Scholar] [CrossRef]

- Seachrist, D.D.; Bonk, K.W.; Ho, S.-M.; Prins, G.S.; Soto, A.M.; Keri, R.A. A review of the carcinogenic potential of bisphenol A. Reprod. Toxicol. 2016, 59, 167–182. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Zhu, Q.; Yan, X.; Liao, C.; Jiang, G. Occurrence, fate and risk assessment of BPA and its substituents in wastewater treatment plant: A review. Environ. Res. 2019, 178, 108732. [Google Scholar] [CrossRef] [PubMed]

- Guerra, P.; Kim, M.; Teslic, S.; Alaee, M.; Smyth, S.A. Bisphenol-A removal in various wastewater treatment processes: Operational conditions, mass balance, and optimization. J. Environ. Manag. 2015, 152, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Liang, L.; Zhang, J.; Feng, P.; Li, C.; Huang, Y.; Dong, B.; Li, L.; Guan, X. Occurrence of bisphenol A in surface and drinking waters and its physicochemical removal technologies. Front. Environ. Sci. Eng. 2015, 9, 16–38. [Google Scholar] [CrossRef]

- Zhou, A.; Wu, X.; Chen, W.; Liao, L.; Xie, P. Fabrication of hydrophobic/hydrophilic bifunctional adsorbent for the removal of sulfamethoxazole and bisphenol A in Water. J. Environ. Chem. Eng. 2020, 8, 104161. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Anastopoulos, I. Adsorptive removal of bisphenol A (BPA) from aqueous solution: A review. Chemosphere 2017, 168, 885–902. [Google Scholar] [CrossRef]

- Hernández-Abreu, A.; Álvarez-Torrellas, S.; Águeda, V.; Larriba, M.; Delgado, J.; Calvo, P.; García, J. Enhanced removal of the endocrine disruptor compound Bisphenol A by adsorption onto green-carbon materials. Effect of real effluents on the adsorption process. J. Environ. Manag. 2020, 266, 110604. [Google Scholar] [CrossRef]

- Alhokbany, N.S.; Naushad, M.; Kumar, V.; Al Hatim, S.; Alshehri, S.M.; Ahamad, T. Self-nitrogen doped carbons aerogel derived from waste cigarette butts (cellulose acetate) for the adsorption of BPA: Kinetics and adsorption mechanisms. J. King Saud Univ. Sci. 2020, 32, 3351–3358. [Google Scholar] [CrossRef]

- Supong, A.; Bhomick, P.C.; Baruah, M.; Pongener, C.; Sinha, U.B.; Sinha, D. Adsorptive removal of Bisphenol A by biomass activated carbon and insights into the adsorption mechanism through density functional theory calculations. Sustain. Chem. Pharm. 2019, 13, 100159. [Google Scholar] [CrossRef]

- Dong, S.; Rene, E.R.; Zhao, L.; Xiaoxiu, L.; Ma, W. Design and preparation of functional azo linked polymers for the adsorptive removal of bisphenol A from water: Performance and analysis of the mechanism. Environ. Res. 2022, 206, 112601. [Google Scholar] [CrossRef]

- Sun, Z.; Zhao, L.; Liu, C.; Zhen, Y.; Ma, J. Fast adsorption of BPA with high capacity based on π-π electron donor-acceptor and hydrophobicity mechanism using an in-situ sp2 C dominant N-doped carbon. Chem. Eng. J. 2020, 381, 122510. [Google Scholar] [CrossRef]

- Westerhoff, P.; Yoon, Y.; Snyder, S.; Wert, E. Fate of Endocrine-Disruptor, Pharmaceutical, and Personal Care Product Chemicals during Simulated Drinking Water Treatment Processes. Environ. Sci. Technol. 2005, 39, 6649–6663. [Google Scholar] [CrossRef] [PubMed]

- Dehghani, M.H.; Karri, R.R.; Alimohammadi, M.; Nazmara, S.; Zarei, A.; Saeedi, Z. Insights into endocrine-disrupting Bisphenol-A adsorption from pharmaceutical effluent by chitosan immobilized nanoscale zero-valent iron nanoparticles. J. Mol. Liq. 2020, 311, 113317. [Google Scholar] [CrossRef]

- Hacıosmanoğlu, G.G.; Doğruel, T.; Genç, S.; Oner, E.T.; Can, Z.S. Adsorptive removal of bisphenol A from aqueous solutions using phosphonated levan. J. Hazard. Mater. 2019, 374, 43–49. [Google Scholar] [CrossRef] [PubMed]

- Ahsan, A.; Islam, T.; Hernandez, C.; Kim, H.; Lin, Y.; Curry, M.L.; Gardea-Torresdey, J.; Noveron, J.C. Adsorptive Removal of Sulfamethoxazole and Bisphenol A from Contaminated Water using Functionalized Carbonaceous Material Derived from Tea Leaves. J. Environ. Chem. Eng. 2018, 6, 4215–4225. [Google Scholar] [CrossRef]

- Guo, X.; Huang, Y.; Yu, W.; Yu, X.; Han, X.; Zhai, H. Multi-walled carbon nanotubes modified with iron oxide and manganese dioxide (MWCNTs-Fe3O4−MnO2) as a novel adsorbent for the determination of BPA. Microchem. J. 2020, 157, 104867. [Google Scholar] [CrossRef]

- Noufel, K.; Djebri, N.; Boukhalfa, N.; Boutahala, M.; Dakhouche, A. Removal of bisphenol A and trichlorophenol from aqueous solutions by adsorption with organically modified bentonite, activated carbon composites: A comparative study in single and binary systems. Groundw. Sustain. Dev. 2020, 11, 100477. [Google Scholar] [CrossRef]

- Ahsan, M.A.; Jabbari, V.; Islam, M.T.; Turley, R.S.; Dominguez, N.; Kim, H.; Castro, E.; Hernandez-Viezcas, J.A.; Curry, M.L.; Lopez, J.; et al. Sustainable synthesis and remarkable adsorption capacity of MOF/graphene oxide and MOF/CNT based hybrid nanocomposites for the removal of Bisphenol A from water. Sci. Total Environ. 2019, 673, 306–317. [Google Scholar] [CrossRef]

- Saleh, T.A.; Tuzen, M.; Sarı, A. Magnetic vermiculite-modified by poly(trimesoyl chloride-melamine) as a sorbent for enhanced removal of bisphenol A. J. Environ. Chem. Eng. 2019, 7, 103436. [Google Scholar] [CrossRef]

- Hao, J.; Zhang, Q.; Liu, Y.; Chen, P.; Zheng, X.; Zhuang, X.; Fu, D.; Liu, H.; Liu, G.; Lv, W. A novel nitrogen-containing covalent organic framework adsorbent for the efficient removal of bisphenol A from aqueous solution. J. Taiwan Inst. Chem. Eng. 2020, 113, 204–213. [Google Scholar] [CrossRef]

- Cevallos-Mendoza, J.; Amorim, C.G.; Rodríguez-Díaz, J.M.; Montenegro, M.d.C.B.S.M. Removal of contaminants from water by membrane filtration: A review. Membranes 2022, 12, 570. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Niu, X.; Yang, J.; Wang, C.; Lu, M. Retentions of bisphenol A and norfloxacin by three different ultrafiltration membranes in regard to drinking water treatment. Chem. Eng. J. 2016, 294, 410–416. [Google Scholar] [CrossRef]

- Bolong, N.; Ismail, A.; Salim, M.; Rana, D.; Matsuura, T.; Tabe-Mohammadi, A. Negatively charged polyethersulfone hollow fiber nanofiltration membrane for the removal of bisphenol A from wastewater. Sep. Purif. Technol. 2010, 73, 92–99. [Google Scholar] [CrossRef]

- Kim, J.-H.; Park, P.-K.; Lee, C.-H.; Kwon, H.-H. Surface modification of nanofiltration membranes to improve the removal of organic micro-pollutants (EDCs and PhACs) in drinking water treatment: Graft polymerization and cross-linking followed by functional group substitution. J. Membr. Sci. 2008, 321, 190–198. [Google Scholar] [CrossRef]

- Chen, Z.-H.; Liu, Z.; Hu, J.-Q.; Cai, Q.-W.; Li, X.-Y.; Wang, W.; Faraj, Y.; Ju, X.-J.; Xie, R.; Chu, L.-Y. β-Cyclodextrin-modified graphene oxide membranes with large adsorption capacity and high flux for efficient removal of bisphenol A from water. J. Membr. Sci. 2020, 595, 117510. [Google Scholar] [CrossRef]

- Koyuncu, I.; Arikan, O.A.; Wiesner, M.R.; Rice, C. Removal of hormones and antibiotics by nanofiltration membranes. J. Membr. Sci. 2008, 309, 94–101. [Google Scholar] [CrossRef]

- Heo, J.; Flora, J.R.; Her, N.; Park, Y.-G.; Cho, J.; Son, A.; Yoon, Y. Removal of bisphenol A and 17β-estradiol in single walled carbon nanotubes–ultrafiltration (SWNTs–UF) membrane systems. Sep. Purif. Technol. 2012, 90, 39–52. [Google Scholar] [CrossRef]

- Li, X.; Xu, Y.; Goh, K.; Chong, T.H.; Wang, R. Layer-by-layer assembly based low pressure biocatalytic nanofiltration membranes for micropollutants removal. J. Membr. Sci. 2020, 615, 118514. [Google Scholar] [CrossRef]

- Pan, Z.; Yu, F.; Li, L.; Liu, M.; Song, C.; Yang, J.; Li, H.; Wang, C.; Pan, Y.; Wang, T. Low-cost electrochemical filtration carbon membrane prepared from coal via self-bonding. Chem. Eng. J. 2020, 385, 123928. [Google Scholar] [CrossRef]

- Wang, P.; Wang, F.; Jiang, H.; Zhang, Y.; Zhao, M.; Xiong, R.; Ma, J. Strong improvement of nanofiltration performance on micropollutant removal and reduction of membrane fouling by hydrolyzed-aluminum nanoparticles. Water Res. 2020, 175, 115649. [Google Scholar] [CrossRef]

- Li, C.; Feng, G.; Pan, Z.; Song, C.; Fan, X.; Tao, P.; Wang, T.; Shao, M.; Zhao, S. High-performance electrocatalytic microfiltration CuO/Carbon membrane by facile dynamic electrodeposition for small-sized organic pollutants removal. J. Membr. Sci. 2020, 601, 117913. [Google Scholar] [CrossRef]

- Lee, W.J.; Bao, Y.; Hu, X.; Lim, T.-T. Hybrid catalytic ozonation-membrane filtration process with CeOx and MnOx impregnated catalytic ceramic membranes for micropollutants degradation. Chem. Eng. J. 2019, 378, 121670. [Google Scholar] [CrossRef]

- Wang, S.; Tian, J.; Jia, L.; Jia, J.; Shan, S.; Wang, Q.; Cui, F. Removal of aqueous organic contaminants using submerged ceramic hollow fiber membrane coupled with peroxymonosulfate oxidation: Comparison of CuO catalyst dispersed in the feed water and immobilized on the membrane. J. Memb. Sci. 2021, 618, 118707. [Google Scholar] [CrossRef]

- Silva, L.L.; Abdelraheem, W.; Nadagouda, M.N.; Rocco, A.M.; Dionysiou, D.D.; Fonseca, F.V.; Borges, C.P. Novel microwave-driven synthesis of hydrophilic polyvinylidene fluoride/polyacrylic acid (PVDF/PAA) membranes and decoration with nano zero-valent-iron (nZVI) for water treatment applications. J. Membr. Sci. 2021, 620, 118817. [Google Scholar] [CrossRef]

- Linares, R.V.; Yangali-Quintanilla, V.; Li, Z.; Amy, G. Rejection of micropollutants by clean and fouled forward osmosis membrane. Water Res. 2011, 45, 6737–6744. [Google Scholar] [CrossRef]

- Bu, L.; Ding, J.; Zhu, N.; Kong, M.; Wu, Y.; Shi, Z.; Zhou, S.; Dionysiou, D.D. Unraveling different mechanisms of persulfate activation by graphite felt anode and cathode to destruct contaminants of emerging concern. Appl. Catal. B Environ. 2019, 253, 140–148. [Google Scholar] [CrossRef]

- Sorokhaibam, L.G.; Ahmaruzzaman, M. Phenolic Wastewater Treatment: Development and Applications of New Adsorbent Materials. In Industrial Wastewater Treatment, Recycling and Reuse; Butterworth-Heinemann: Oxford, UK, 2014; pp. 323–368. [Google Scholar] [CrossRef]

- Shi, Z.; Li, Z.; Gao, J.; Wu, Y.; Zhou, S.; Bu, L. Enhanced oxidation of bisphenol A by permanganate in the presence of epigallocatechin gallate: Kinetics and mechanism. Sep. Purif. Technol. 2020, 247, 117025. [Google Scholar] [CrossRef]

- Ibrahim, S.M.; Al-Hossainy, A.F. Kinetics and mechanism of oxidation of bromothymol blue by permanganate ion in acidic medium: Application to textile industrial wastewater treatment. J. Mol. Liq. 2020, 318, 114041. [Google Scholar] [CrossRef]

- Waldemer, R.H.; Tratnyek, P.G. Kinetics of Contaminant Degradation by Permanganate. Environ. Sci. Technol. 2006, 40, 1055–1061. [Google Scholar] [CrossRef]

- Guan, X.; He, D.; Ma, J.; Chen, G. Application of permanganate in the oxidation of micropollutants: A mini review. Front. Environ. Sci. Eng. China 2010, 4, 405–413. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, B.; Guan, X. Oxidative removal of bisphenol A by permanganate: Kinetics, pathways and influences of co-existing chemicals. Sep. Purif. Technol. 2013, 107, 48–53. [Google Scholar] [CrossRef]

- Jiang, J.; Pang, S.-Y.; Ma, J. Role of Ligands in Permanganate Oxidation of Organics. Environ. Sci. Technol. 2010, 44, 4270–4275. [Google Scholar] [CrossRef] [PubMed]

- Ohore, O.E.; Zhang, S. Endocrine disrupting effects of bisphenol A exposure and recent advances on its removal by water treatment systems. A review. Sci. Afr. 2019, 5, e00135. [Google Scholar] [CrossRef]

- Yang, J.; Zhao, J.; Ma, J.; Liu, Z.-Q. Simultaneous oxidation of phenol and bisphenol A by permanganate: Synergetic or competitive effect. Sep. Purif. Technol. 2013, 116, 271–276. [Google Scholar] [CrossRef]

- Bu, L.; Bi, C.; Shi, Z.; Zhou, S. Significant enhancement on ferrous/persulfate oxidation with epigallocatechin-3-gallate: Simultaneous chelating and reducing. Chem. Eng. J. 2017, 321, 642–650. [Google Scholar] [CrossRef]

- Liu, K.; Shi, Z.; Zhou, S. Reduction of hexavalent chromium using epigallocatechin gallate in aqueous solutions: Kinetics and mechanism. RSC Adv. 2016, 6, 67196–67203. [Google Scholar] [CrossRef]

- Gallard, H.; Leclercq, A.; Croué, J.-P. Chlorination of bisphenol A: Kinetics and by-products formation. Chemosphere 2004, 56, 465–473. [Google Scholar] [CrossRef]

- Gao, Y.; Jiang, J.; Zhou, Y.; Pang, S.-Y.; Ma, J.; Jiang, C.; Yang, Y.; Huang, Z.-S.; Gu, J.; Guo, Q.; et al. Chlorination of bisphenol S: Kinetics, products, and effect of humic acid. Water Res. 2018, 131, 208–217. [Google Scholar] [CrossRef]

- Xiang, W.; Qu, R.; Wang, X.; Wang, Z.; Bin-Jumah, M.; Allam, A.A.; Zhu, F.; Huo, Z. Removal of 4-chlorophenol, bisphenol A and nonylphenol mixtures by aqueous chlorination and formation of coupling products. Chem. Eng. J. 2020, 402, 126140. [Google Scholar] [CrossRef]

- Lane, R.F.; Adams, C.D.; Randtke, S.J.; Carter, R.E. Chlorination and chloramination of bisphenol A, bisphenol F, and bisphenol A diglycidyl ether in drinking water. Water Res. 2015, 79, 68–78. [Google Scholar] [CrossRef]

- Hu, J.-Y.; Aizawa, T.; Ookubo, S. Products of Aqueous Chlorination of Bisphenol A and Their Estrogenic Activity. Environ. Sci. Technol. 2002, 36, 1980–1987. [Google Scholar] [CrossRef] [PubMed]

- Han, Q.; Wang, H.J.; Dong, W.Y.; Liu, T.Z.; Yin, Y.L.; Fan, H.K. Degradation of bisphenol A by ferrate (VI) oxidation: Kinetics, products and toxicity assessment. Chem. Eng. J. 2015, 262, 34–40. [Google Scholar] [CrossRef]

- Yang, T.; Wang, L.; Liu, Y.-L.; Zhang, W.; Cheng, H.-J.; Liu, M.-C.; Ma, J. Ferrate oxidation of bisphenol F and removal of oxidation products with ferrate resulted particles. Chem. Eng. J. 2020, 383, 123167. [Google Scholar] [CrossRef]

- Wu, X.; Tang, A.; Bi, X.; Nguyen, T.H.; Yuan, B. Influence of algal organic matter of Microcystis aeruginosa on ferrate decay and MS2 bacteriophage inactivation. Chemosphere. 2019, 236, 124727. [Google Scholar] [CrossRef] [PubMed]

- Gombos, E.; Felföldi, T.; Barkács, K.; Vértes, C.; Vajna, B.; Záray, G. Ferrate treatment for inactivation of bacterial community in municipal secondary effluent. Bioresour. Technol. 2011, 107, 116–121. [Google Scholar] [CrossRef]

- Lee, Y.; Zimmermann, S.G.; Kieu, A.T.; von Gunten, U. Ferrate (Fe(VI)) Application for Municipal Wastewater Treatment: A Novel Process for Simultaneous Micropollutant Oxidation and Phosphate Removal. Environ. Sci. Technol. 2009, 43, 3831–3838. [Google Scholar] [CrossRef]

- Li, C.; Li, X.; Graham, N.; Gao, N. The aqueous degradation of bisphenol A and steroid estrogens by ferrate. Water Res. 2008, 42, 109–120. [Google Scholar] [CrossRef]

- Rai, P.K.; Lee, J.; Kailasa, S.K.; Kwon, E.E.; Tsang, Y.F.; Ok, Y.S.; Kim, K.-H. A critical review of ferrate(VI)-based remediation of soil and groundwater. Environ. Res. 2018, 160, 420–448. [Google Scholar] [CrossRef]

- Ahmad, N.; Yuzir, M.; Yong, E.; Abdullah, N.; Salim, M.R. Removal of Bisphenol A (BPA) in Surface Water by Ozone Oxidation Process. Appl. Mech. Mater. 2015, 735, 210–214. [Google Scholar] [CrossRef]

- Li, S.; Wu, Y.; Zheng, Y.; Jing, T.; Tian, J.; Zheng, H.; Wang, N.; Nan, J.; Ma, J. Free-radical and surface electron transfer dominated bisphenol A degradation in system of ozone and peroxydisulfate co-activated by CoFe2O4-biochar. Appl. Surf. Sci. 2021, 541, 147887. [Google Scholar] [CrossRef]

- Umar, M.; Roddick, F.; Fan, L.; Aziz, H.A. Application of ozone for the removal of bisphenol A from water and wastewater—A review. Chemosphere 2013, 90, 2197–2207. [Google Scholar] [CrossRef] [PubMed]

- Ikehata, K.; Li, Y. Ozone-Based Processes. In Advanced Oxidation Processes for Wastewater Treatment: Emerging Green Chemical Technology; Academic Press: Cambridge, MA, USA, 2018; pp. 115–134. [Google Scholar] [CrossRef]

- Zorzo, C.F.; Inticher, J.J.; Borba, F.H.; Cabrera, L.C.; Dugatto, J.S.; Baroni, S.; Kreutz, G.K.; Seibert, D.; Bergamasco, R. Oxidative degradation and mineralization of the endocrine disrupting chemical bisphenol-A by an eco-friendly system based on UV-solar/H2O2 with reduction of genotoxicity and cytotoxicity levels. Sci. Total Environ. 2021, 770, 145296. [Google Scholar] [CrossRef] [PubMed]

- Askenaizer, D. Drinking Water Quality and Treatment. In Encyclopedia of Physical Science and Technology; Academic Press: Cambridge, MA, USA, 2003; pp. 651–671. [Google Scholar] [CrossRef]

- Huang, Y.; Guo, J.; Yan, P.; Gong, H.; Fang, F. Sorption-desorption behavior of sulfamethoxazole, carbamazepine, bisphenol A and 17α-ethinylestradiol in sewage sludge. J. Hazard. Mater. 2019, 368, 739–745. [Google Scholar] [CrossRef] [PubMed]

- Kanakaraju, D.; Glass, B.D.; Oelgemöller, M. Advanced oxidation process-mediated removal of pharmaceuticals from water: A review. J. Environ. Manag. 2018, 219, 189–207. [Google Scholar] [CrossRef]

- Chavoshani, A.; Hashemi, M.; Amin, M.M.; Ameta, S.C. Pharmaceuticals as emerging micropollutants in aquatic environments. In Micropollutants and Challenges; Elsevier: Amsterdam, The Netherlands, 2020; pp. 35–90. [Google Scholar] [CrossRef]

- Kusvuran, E.; Yildirim, D. Degradation of bisphenol A by ozonation and determination of degradation intermediates by gas chromatography–mass spectrometry and liquid chromatography–mass spectrometry. Chem. Eng. J. 2013, 220, 6–14. [Google Scholar] [CrossRef]

- Gultekin, I.; Mavrov, V.; Ince, N.H. Degradation of Bisphenol-A by Ozonation. J. Adv. Oxid. Technol. 2009, 12, 242–248. [Google Scholar] [CrossRef]

- Porcar-Santos, O.; Cruz-Alcalde, A.; Sans, C. Aqueous oxidation of bisphenol analogues by ozone: Relevance of substituents on reactivity. J. Environ. Chem. Eng. 2023, 11, 110849. [Google Scholar] [CrossRef]

- Zielińska, M.; Wojnowska-Baryła, I.; Cydzik-Kwiatkowska, A. Bisphenol A Removal from Water and Wastewater; Springer International Publishing AG: Berlin, Germany, 2018. [Google Scholar] [CrossRef]

- Xu, L.; Yang, L.; Johansson, E.M.; Wang, Y.; Jin, P. Photocatalytic activity and mechanism of bisphenol a removal over TiO2−x/rGO nanocomposite driven by visible light. Chem. Eng. J. 2018, 350, 1043–1055. [Google Scholar] [CrossRef]

- Tang, Y.; Yin, X.; Mu, M.; Jiang, Y.; Li, X.; Zhang, H.; Ouyang, T. Anatase TiO2@MIL-101(Cr) nanocomposite for photocatalytic degradation of bisphenol A. Colloids Surf. A: Physicochem. Eng. Asp. 2020, 596, 124745. [Google Scholar] [CrossRef]

- Huang, Y.; Su, M.; Zhou, Y.; Chen, D.; Xu, Z.; Zhang, H.; Liao, C. LiCl–CN nanotubes ceramic films with highly efficient visible light—Driven photocatalytic active for bisphenol A degradation and efficient regeneration process. Ceram. Int. 2020, 46, 26492–26501. [Google Scholar] [CrossRef]

- Zhao, W.; Zhang, J.; Zhu, F.; Mu, F.; Zhang, L.; Dai, B.; Xu, J.; Zhu, A.; Sun, C.; Leung, D.Y. Study the photocatalytic mechanism of the novel Ag/p-Ag2O/n-BiVO4 plasmonic photocatalyst for the simultaneous removal of BPA and chromium(VI). Chem. Eng. J. 2019, 361, 1352–1362. [Google Scholar] [CrossRef]

- Hao, X.; Li, M.; Zhang, L.; Wang, K.; Liu, C. Photocatalyst TiO2/WO3/GO nano-composite with high efficient photocatalytic performance for BPA degradation under visible light and solar light illumination. J. Ind. Eng. Chem. 2017, 55, 140–148. [Google Scholar] [CrossRef]

- Sharma, J.; Mishra, I.; Kumar, V. Mechanistic study of photo-oxidation of Bisphenol-A (BPA) with hydrogen peroxide (H2O2) and sodium persulfate (SPS). J. Environ. Manag. 2016, 166, 12–22. [Google Scholar] [CrossRef]

- Wardenier, N.; Liu, Z.; Nikiforov, A.; Van Hulle, S.W.H.; Leys, C. Micropollutant elimination by O3, UV and plasma-based AOPs: An evaluation of treatment and energy costs. Chemosphere 2019, 234, 715–724. [Google Scholar] [CrossRef] [PubMed]

- Mehrabani-Zeinabad, M.; Langford, C.H.; Achari, G. Advanced oxidative degradation of bisphenol A and bisphenol S. J. Environ. Eng. Sci. 2016, 10, 92–102. [Google Scholar] [CrossRef]

- Olmez-Hanci, T.; Dursun, D.; Aydin, E.; Arslan-Alaton, I.; Girit, B.; Mita, L.; Diano, N.; Mita, D.G.; Guida, M. S2O82−/UV-C and H2O2/UV-C treatment of Bisphenol A: Assessment of toxicity, estrogenic activity, degradation products and results in real water. Chemosphere 2015, 119, S115–S123. [Google Scholar] [CrossRef]

- Sánchez-Polo, M.; Daiem, M.M.A.; Ocampo-Pérez, R.; Rivera-Utrilla, J.; Mota, A.J. Comparative study of the photodegradation of bisphenol A by HO, SO4− and CO3−/HCO3 radicals in aqueous phase. Sci. Total Environ. 2013, 463–464, 423–431. [Google Scholar] [CrossRef]

- Molkenthin, M.; Olmez-Hanci, T.; Jekel, M.R.; Arslan-Alaton, I. Photo-Fenton-like treatment of BPA: Effect of UV light source and water matrix on toxicity and transformation products. Water Res. 2013, 47, 5052–5064. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Y.; Zeng, D.; Zhang, B.; Hassan, M.; Li, P.; Qi, C.; He, Y. Enhanced catalytic activation of photo-Fenton process by Cu0.5Mn0.5Fe2O4 for effective removal of organic contaminants. Chemosphere 2020, 247, 125780. [Google Scholar] [CrossRef]

- Zhang, X.; Ding, Y.; Tang, H.; Han, X.; Zhu, L.; Wang, N. Degradation of bisphenol A by hydrogen peroxide activated with CuFeO2 microparticles as a heterogeneous Fenton-like catalyst: Efficiency, stability and mechanism. Chem. Eng. J. 2014, 236, 251–262. [Google Scholar] [CrossRef]

- Torres, R.A.; Pétrier, C.; Combet, E.; Carrier, M.; Pulgarin, C. Ultrasonic cavitation applied to the treatment of bisphenol A. Effect of sonochemical parameters and analysis of BPA by-products. Ultrason. Sonochem. 2008, 15, 605–611. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Feng, R. Ultrasonic irradiation-induced degradation of low-concentration bisphenol A in aqueous solution. J. Hazard. Mater. 2009, 163, 855–860. [Google Scholar] [CrossRef]

- Lim, M.; Son, Y.; Khim, J. The effects of hydrogen peroxide on the sonochemical degradation of phenol and bisphenol A. Ultrason. Sonochem. 2014, 21, 1976–1981. [Google Scholar] [CrossRef] [PubMed]

- Macwan, D.P.; Dave, P.N.; Chaturvedi, S. A review on nano-TiO2 sol–gel type syntheses and its applications. J. Mater. Sci. 2011, 46, 3669–3686. [Google Scholar] [CrossRef]

- Bechambi, O.; Sayadi, S.; Najjar, W. Photocatalytic degradation of bisphenol A in the presence of C-doped ZnO: Effect of operational parameters and photodegradation mechanism. J. Ind. Eng. Chem. 2015, 32, 201–210. [Google Scholar] [CrossRef]

- Mu, C.; Zhang, Y.; Cui, W.; Liang, Y.; Zhu, Y. Removal of bisphenol A over a separation free 3D Ag3PO4-graphene hydrogel via an adsorption-photocatalysis synergy. Appl. Catal. B: Environ. 2017, 212, 41–49. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, L.; Wei, M.; Chen, P.; Shan, G. Photolytic reaction mechanism and impacts of coexisting substances on photodegradation of bisphenol A by Bi2WO6 in water. Water Res. 2012, 46, 845–853. [Google Scholar] [CrossRef]

- Wang, C.-Y.; Zhang, Y.-J.; Wang, W.-K.; Pei, D.-N.; Huang, G.-X.; Chen, J.-J.; Zhang, X.; Yu, H.-Q. Enhanced photocatalytic degradation of bisphenol A by Co-doped BiOCl nanosheets under visible light irradiation. Appl. Catal. B: Environ. 2018, 221, 320–328. [Google Scholar] [CrossRef]

- Abdelraheem, W.H.; Patil, M.K.; Nadagouda, M.N.; Dionysiou, D.D. Hydrothermal synthesis of photoactive nitrogen- and boron-codoped TiO2 nanoparticles for the treatment of bisphenol A in wastewater: Synthesis, photocatalytic activity, degradation byproducts and reaction pathways. Appl. Catal. B Environ. 2019, 241, 598–611. [Google Scholar] [CrossRef]

- Hunge, Y.M.; Yadav, A.A.; Kang, S.-W.; Kim, H. Photocatalytic degradation of tetracycline antibiotics using hydrothermally synthesized two-dimensional molybdenum disulfide/titanium dioxide composites. J. Colloid Interface Sci. 2022, 606, 454–463. [Google Scholar] [CrossRef]

- Hunge, Y.; Yadav, A.; Kang, S.-W.; Lim, S.J.; Kim, H. Visible light activated MoS2/ZnO composites for photocatalytic degradation of ciprofloxacin antibiotic and hydrogen production. J. Photochem. Photobiol. A Chem. 2023, 434, 114250. [Google Scholar] [CrossRef]

- Nitoi, I.; Oancea, P.; Raileanu, M.; Crisan, M.; Constantin, L.; Cristea, I. UV–VIS photocatalytic degradation of nitrobenzene from water using heavy metal doped titania. J. Ind. Eng. Chem. 2015, 21, 677–682. [Google Scholar] [CrossRef]

- Shokri, M.; Jodat, A.; Modirshahla, N.; Behnajady, M.A. Photocatalytic degradation of chloramphenicol in an aqueous suspension of silver-doped TiO2 nanoparticles. Environ. Technol. 2013, 34, 1161–1166. [Google Scholar] [CrossRef] [PubMed]

- Faraldos, M.; Bahamonde, A. Environmental applications of titania-graphene photocatalysts. Catal. Today 2017, 285, 13–28. [Google Scholar] [CrossRef]

- Wang, G.; Dai, J.; Luo, Q.; Deng, N. Photocatalytic degradation of bisphenol A by TiO2@aspartic acid-β-cyclodextrin@reduced graphene oxide. Sep. Purif. Technol. 2021, 254, 117574. [Google Scholar] [CrossRef]

- Hunge, Y.; Yadav, A.; Khan, S.; Takagi, K.; Suzuki, N.; Teshima, K.; Terashima, C.; Fujishima, A. Photocatalytic degradation of bisphenol A using titanium dioxide@nanodiamond composites under UV light illumination. J. Colloid Interface Sci. 2021, 582, 1058–1066. [Google Scholar] [CrossRef]

- Chen, P.-J.; Linden, K.G.; Hinton, D.E.; Kashiwada, S.; Rosenfeldt, E.J.; Kullman, S.W. Biological assessment of bisphenol A degradation in water following direct photolysis and UV advanced oxidation. Chemosphere 2006, 65, 1094–1102. [Google Scholar] [CrossRef]

- Deborde, M.; Rabouan, S.; Mazellier, P.; Duguet, J.-P.; Legube, B. Oxidation of bisphenol A by ozone in aqueous solution. Water Res. 2008, 42, 4299–4308. [Google Scholar] [CrossRef]

- Buxton, G.V.; Greenstock, C.L.; Helman, W.P.; Ross, A.B. Critical Review of rate constants for reactions of hydrated electrons, hydrogen atoms and hydroxyl radicals (·OH/·O− in Aqueous Solution. J. Phys. Chem. Ref. Data 1988, 17, 513–886. [Google Scholar] [CrossRef]

- Méndez-Díaz, J.; Sánchez-Polo, M.; Rivera-Utrilla, J.; Canonica, S.; von Gunten, U. Advanced oxidation of the surfactant SDBS by means of hydroxyl and sulphate radicals. Chem. Eng. J. 2010, 163, 300–306. [Google Scholar] [CrossRef]

- Irmak, S.; Erbatur, O.; Akgerman, A. Degradation of 17β-estradiol and bisphenol A in aqueous medium by using ozone and ozone/UV techniques. J. Hazard. Mater. 2005, 126, 54–62. [Google Scholar] [CrossRef] [PubMed]

- Rivas, F.J.; Encinas, A.; Acedo, B.; Beltrán, F.J. Mineralization of bisphenol A by advanced oxidation processes. J. Chem. Technol. Biotechnol. 2009, 84, 589–594. [Google Scholar] [CrossRef]

- Wang, M.; Su, X.; Yang, S.; Li, L.; Li, C.; Sun, F.; Dong, J.; Rong, Y. Bisphenol A degradation by Fenton Advanced Oxidation Process and operation parameters optimization. E3S Web Conf. 2020, 144, 01014. [Google Scholar] [CrossRef]

- Georgi, A.; Schierz, A.; Trommler, U.; Horwitz, C.; Collins, T.; Kopinke, F.-D. Humic acid modified Fenton reagent for enhancement of the working pH range. Appl. Catal. B Environ. 2007, 72, 26–36. [Google Scholar] [CrossRef]

- Qian, K.; Chen, H.; Li, W.; Ao, Z.; Wu, Y.-N.; Guan, X. Single-Atom Fe Catalyst Outperforms Its Homogeneous Counterpart for Activating Peroxymonosulfate to Achieve Effective Degradation of Organic Contaminants. Environ. Sci. Technol. 2021, 55, 7034–7043. [Google Scholar] [CrossRef]

- Chen, L.; Ma, J.; Li, X.; Zhang, J.; Fang, J.; Guan, Y.; Xie, P. Strong Enhancement on Fenton Oxidation by Addition of Hydroxylamine to Accelerate the Ferric and Ferrous Iron Cycles. Environ. Sci. Technol. 2011, 45, 3925–3930. [Google Scholar] [CrossRef]

- Zhang, T.; Li, C.; Ma, J.; Tian, H.; Qiang, Z. Surface hydroxyl groups of synthetic α-FeOOH in promoting ·OH generation from aqueous ozone: Property and activity relationship. Appl. Catal. B Environ. 2008, 82, 131–137. [Google Scholar] [CrossRef]

- Gonçalves, N.P.; Minella, M.; Mailhot, G.; Brigante, M.; Prevot, A.B. Photo-activation of persulfate and hydrogen peroxide by humic acid coated magnetic particles for Bisphenol A degradation. Catal. Today 2019, 361, 43–49. [Google Scholar] [CrossRef]

- Torres, R.; Abdelmalek, F.; Combet, E.; Pétrier, C.; Pulgarin, C. A comparative study of ultrasonic cavitation and Fenton’s reagent for bisphenol A degradation in deionised and natural waters. J. Hazard. Mater. 2007, 146, 546–551. [Google Scholar] [CrossRef]

- Gültekin, I.; Ince, N.H. Ultrasonic destruction of bisphenol-A: The operating parameters. Ultrason. Sonochem. 2008, 15, 524–529. [Google Scholar] [CrossRef]

- Inoue, M.; Masuda, Y.; Okada, F.; Sakurai, A.; Takahashi, I.; Sakakibara, M. Degradation of bisphenol A using sonochemical reactions. Water Res. 2008, 42, 1379–1386. [Google Scholar] [CrossRef] [PubMed]

- Lee, G.; Ibrahim, S.; Kittappa, S.; Park, H.; Park, C.M. Sonocatalytic activity of a heterostructured β-Bi2O3/Bi2O2CO3 nanoplate in degradation of bisphenol A. Ultrason. Sonochem. 2018, 44, 64–72. [Google Scholar] [CrossRef] [PubMed]

- Sunasee, S.; Wong, K.T.; Lee, G.; Pichiah, S.; Ibrahim, S.; Park, C.; Kim, N.C.; Yoon, Y.; Jang, M. Titanium dioxide-based sonophotocatalytic mineralization of bisphenol A and its intermediates. Environ. Sci. Pollut. Res. 2017, 24, 15488–15499. [Google Scholar] [CrossRef] [PubMed]

- Qiu, P.; Li, W.; Thokchom, B.; Park, B.; Cui, M.; Zhao, D.; Khim, J. Uniform core–shell structured magnetic mesoporous TiO2 nanospheres as a highly efficient and stable sonocatalyst for the degradation of bisphenol-A. J. Mater. Chem. A 2015, 3, 6492–6500. [Google Scholar] [CrossRef]

- Park, J.-S.; Her, N.; Oh, J.; Yoon, Y. Sonocatalytic degradation of bisphenol A and 17α-ethinyl estradiol in the presence of stainless steel wire mesh catalyst in aqueous solution. Sep. Purif. Technol. 2011, 78, 228–236. [Google Scholar] [CrossRef]

- Dükkancı, M. Heterogeneous sonocatalytic degradation of Bisphenol-A and the influence of the reaction parameters and ultrasonic frequency. Water Sci. Technol. 2019, 79, 386–397. [Google Scholar] [CrossRef]

- Al-Hamadani, Y.A.; Chu, K.H.; Son, A.; Heo, J.; Her, N.; Jang, M.; Park, C.M.; Yoon, Y. Stabilization and dispersion of carbon nanomaterials in aqueous solutions: A review. Sep. Purif. Technol. 2015, 156, 861–874. [Google Scholar] [CrossRef]

- Her, N.; Park, J.-S.; Yoon, Y. Sonochemical enhancement of hydrogen peroxide production by inert glass beads and TiO2-coated glass beads in water. Chem. Eng. J. 2011, 166, 184–190. [Google Scholar] [CrossRef]

- Yang, J.; Zeng, D.; Hassan, M.; Ma, Z.; Dong, L.; Xie, Y.; He, Y. Efficient degradation of Bisphenol A by dielectric barrier discharge non-thermal plasma: Performance, degradation pathways and mechanistic consideration. Chemosphere 2022, 286, 131627. [Google Scholar] [CrossRef]

- Hijosa-Valsero, M.; Molina, R.; Bayona, J.M. Assessment of a dielectric barrier discharge plasma reactor at atmospheric pressure for the removal of bisphenol A and tributyltin. Environ. Technol. 2014, 35, 1418–1426. [Google Scholar] [CrossRef]

- Yan, X.; Yi, C.; Wang, Y.; Cao, W.; Mao, D.; Ou, Q.; Shen, P.; Wang, H. Multi-catalysis of nano-zinc oxide for bisphenol A degradation in a dielectric barrier discharge plasma system: Effect and mechanism. Sep. Purif. Technol. 2020, 231, 115897. [Google Scholar] [CrossRef]

- Mao, D.; Yan, X.; Wang, H.; Shen, Z.; Yi, C. Catalysis of rGO-WO3 nanocomposite for aqueous bisphenol A degradation in dielectric barrier discharge plasma oxidation process. Chemosphere 2021, 262, 128073. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Rodríguez, A.; Matamoros, V.; Fontàs, C.; Salvadó, V. The ability of biologically based wastewater treatment systems to remove emerging organic contaminants—A review. Environ. Sci. Pollut. Res. 2014, 21, 11708–11728. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.B.; Zhou, J.L.; Ngo, H.H.; Guo, W.; Thomaidis, N.S.; Xu, J. Progress in the biological and chemical treatment technologies for emerging contaminant removal from wastewater: A critical review. J. Hazard. Mater. 2017, 323, 274–298. [Google Scholar] [CrossRef]

- Xue, J.; Kannan, K. Mass flows and removal of eight bisphenol analogs, bisphenol A diglycidyl ether and its derivatives in two wastewater treatment plants in New York State, USA. Sci. Total Environ. 2019, 648, 442–449. [Google Scholar] [CrossRef]

- Sun, Q.; Wang, Y.; Li, Y.; Ashfaq, M.; Dai, L.; Xie, X.; Yu, C.-P. Fate and mass balance of bisphenol analogues in wastewater treatment plants in Xiamen City, China. Environ. Pollut. 2017, 225, 542–549. [Google Scholar] [CrossRef]

- Qian, Y.; Jia, X.; Ding, T.; Yang, M.; Yang, B.; Li, J. Occurrence and removal of bisphenol analogues in wastewater treatment plants and activated sludge bioreactor. Sci. Total Environ. 2021, 758, 143606. [Google Scholar] [CrossRef]

- Seyhi, B.; Drogui, P.; Buelna, G.; Blais, J.F. Removal of bisphenol-A from spiked synthetic effluents using an immersed membrane activated sludge process. Sep. Purif. Technol. 2012, 87, 101–109. [Google Scholar] [CrossRef]

- Cydzik-Kwiatkowska, A.; Bernat, K.; Zielińska, M.; Bułkowska, K.; Wojnowska-Baryła, I. Aerobic granular sludge for bisphenol A (BPA) removal from wastewater. Int. Biodeterior. Biodegrad. 2017, 122, 1–11. [Google Scholar] [CrossRef]

- Buttiglieri, G.; Knepper, T.P. Removal of Emerging Contaminants in Wastewater Treatment: Conventional Activated Sludge Treatment. Handb. Environ. Chem. 2007, 5, 1–35. [Google Scholar] [CrossRef]

- Luo, Y.L.; Guo, W.S.; Ngo, H.H.; Nghiem, L.D.; Hai, F.I.; Zhang, J.; Liang, S.; Wang, X.C. A review on the occurrence of micropollutants in the aquatic environment and their fate and removal during wastewater treatment. Sci. Total Environ. 2014, 473–474, 619–641. [Google Scholar] [CrossRef]

- Sreekanth, D.; Sivaramakrishna, D.; Himabindu, V.; Anjaneyulu, Y. Thermophilic treatment of bulk drug pharmaceutical industrial wastewaters by using hybrid up flow anaerobic sludge blanket reactor. Bioresour. Technol. 2009, 100, 2534–2539. [Google Scholar] [CrossRef] [PubMed]

- Ying, G.-G.; Kookana, R.S.; Kumar, A. Fate of estrogens and xenoestrogens in four sewage treatment plants with different technologies. Environ. Toxicol. Chem. 2008, 27, 87–94. [Google Scholar] [CrossRef] [PubMed]

- Kasprzyk-Hordern, B.; Dinsdale, R.M.; Guwy, A.J. The removal of pharmaceuticals, personal care products, endocrine disruptors and illicit drugs during wastewater treatment and its impact on the quality of receiving waters. Water Res. 2009, 43, 363–380. [Google Scholar] [CrossRef] [PubMed]

- Tran, N.H.; Reinhard, M.; Gin, K.Y.-H. Occurrence and fate of emerging contaminants in municipal wastewater treatment plants from different geographical regions-a review. Water Res. 2018, 133, 182–207. [Google Scholar] [CrossRef] [PubMed]

- Hashimoto, K.; Matsuda, M.; Inoue, D.; Ike, M. Bacterial community dynamics in a full-scale municipal wastewater treatment plant employing conventional activated sludge process. J. Biosci. Bioeng. 2014, 118, 64–71. [Google Scholar] [CrossRef]

- Roh, H.; Subramanya, N.; Zhao, F.; Yu, C.-P.; Sandt, J.; Chu, K.-H. Biodegradation potential of wastewater micropollutants by ammonia-oxidizing bacteria. Chemosphere 2009, 77, 1084–1089. [Google Scholar] [CrossRef]

- Yan, Z.-R.; Zhu, Y.-Y.; Meng, H.-S.; Wang, S.-Y.; Gan, L.-H.; Li, X.-Y.; Xu, J.; Zhang, W. Insights into thermodynamic mechanisms driving bisphenol A (BPA) binding to extracellular polymeric substances (EPS) of activated sludge. Sci. Total Environ. 2019, 677, 502–510. [Google Scholar] [CrossRef]

- Ferro Orozco, A.M.; Contreras, E.M.; Zaritzky, N.E. Monitoring the biodegradability of bisphenol A and its metabolic intermediates by manometric respirometry tests. Biodegradation 2016, 27, 209–221. [Google Scholar] [CrossRef]

- Zhao, J.G.; Chen, X.R.; Liu, F.K.; Yang, N.; Huang, H.; Zhao, J. Mechanism of toxicity formation and spatial distribution in activated sludge treating synthetic effluent containing bisphenol A (BPA). Chem. Eng. J. 2014, 250, 91–98. [Google Scholar] [CrossRef]

- Boonnorat, J.; Kanyatrakul, A.; Prakhongsak, A.; Honda, R.; Panichnumsin, P.; Boonapatcharoen, N. Effect of hydraulic retention time on micropollutant biodegradation in activated sludge system augmented with acclimatized sludge treating low-micropollutants wastewater. Chemosphere 2019, 230, 606–615. [Google Scholar] [CrossRef]

- Dong, J.; Wang, Y.; Wang, L.; Wang, S.; Li, S.; Ding, Y. The performance of porous ceramsites in a biological aerated filter for organic wastewater treatment and simulation analysis. J. Water Process. Eng. 2020, 34, 101134. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.-H.; Zhang, J.; Huang, R.-P.; Yin, H.; Dang, Z.; Wu, P.-X.; Liu, Y. Insights into removal mechanisms of bisphenol A and its analogues in municipal wastewater treatment plants. Sci. Total Environ. 2019, 692, 107–116. [Google Scholar] [CrossRef] [PubMed]

- Sun, Q.; Li, Y.; Chou, P.-H.; Peng, P.-Y.; Yu, C.-P. Transformation of Bisphenol A and Alkylphenols by Ammonia-Oxidizing Bacteria through Nitration. Environ. Sci. Technol. 2012, 46, 4442–4448. [Google Scholar] [CrossRef] [PubMed]

- Seyhi, B.; Drogui, P.; Buelna, G.; Azaïs, A.; Heran, M. Contribution of a submerged membrane bioreactor in the treatment of synthetic effluent contaminated by Bisphenol-A: Mechanism of BPA removal and membrane fouling. Environ. Pollut. 2013, 180, 229–235. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, X.; Zhou, H.; Chen, J.; Xue, W. Removal of typical endocrine disrupting chemicals by membrane bioreactor: In comparison with sequencing batch reactor. Water Sci. Technol. 2011, 64, 2096–2102. [Google Scholar] [CrossRef]

- Ouarda, Y.; Zolfaghari, M.; Drogui, P.; Seyhi, B.; Buelna, G.; Dubé, R. Performance of a membrane bioreactor in extreme concentrations of bisphenol A. Water Sci. Technol. 2018, 77, 1505–1513. [Google Scholar] [CrossRef]

- Vinardell, S.; Astals, S.; Peces, M.; Cardete, M.A.; Fernández, I.; Mata-Alvarez, J.; Dosta, J. Advances in anaerobic membrane bioreactor technology for municipal wastewater treatment: A 2020 updated review. Renew. Sustain. Energy Rev. 2020, 130, 109936. [Google Scholar] [CrossRef]

- Luo, Y.; Jiang, Q.; Ngo, H.H.; Nghiem, L.D.; Hai, F.I.; Price, W.E.; Wang, J.; Guo, W. Evaluation of micropollutant removal and fouling reduction in a hybrid moving bed biofilm reactor–membrane bioreactor system. Bioresour. Technol. 2015, 191, 355–359. [Google Scholar] [CrossRef]

- Cydzik-Kwiatkowska, A.; Zielińska, M.; Bernat, K.; Bułkowska, K.; Wojnowska-Baryła, I. Insights into mechanisms of bisphenol A biodegradation in aerobic granular sludge. Bioresour. Technol. 2020, 315, 123806. [Google Scholar] [CrossRef]

- Rusanowska, P.; Cydzik-Kwiatkowska, A.; Świątczak, P.; Wojnowska-Baryła, I. Changes in extracellular polymeric substances (EPS) content and composition in aerobic granule size-fractions during reactor cycles at different organic loads. Bioresour. Technol. 2018, 272, 188–193. [Google Scholar] [CrossRef] [PubMed]

- Nancharaiah, Y.V.; Sarvajith, M. Aerobic granular sludge process: A fast growing biological treatment for sustainable wastewater treatment. Curr. Opin. Environ. Sci. Health 2019, 12, 57–65. [Google Scholar] [CrossRef]

- Li, K.; Wei, D.; Zhang, G.; Shi, L.; Wang, Y.; Wang, B.; Wang, X.; Du, B.; Wei, Q. Toxicity of bisphenol A to aerobic granular sludge in sequencing batch reactors. J. Mol. Liq. 2015, 209, 284–288. [Google Scholar] [CrossRef]

- Dhangar, K.; Kumar, M. Tricks and tracks in removal of emerging contaminants from the wastewater through hybrid treatment systems: A review. Sci. Total Environ. 2020, 738, 140320. [Google Scholar] [CrossRef] [PubMed]

- Fudala-Ksiazek, S.; Pierpaoli, M.; Luczkiewicz, A. Efficiency of landfill leachate treatment in a MBR/UF system combined with NF, with a special focus on phthalates and bisphenol A removal. Waste Manag. 2018, 78, 94–103. [Google Scholar] [CrossRef]

- Sahar, E.; David, I.; Gelman, Y.; Chikurel, H.; Aharoni, A.; Messalem, R.; Brenner, A. The use of RO to remove emerging micropollutants following CAS/UF or MBR treatment of municipal wastewater. Desalination 2011, 273, 142–147. [Google Scholar] [CrossRef]

- Zhu, H.; Li, W. Bisphenol A removal from synthetic municipal wastewater by a bioreactor coupled with either a forward osmotic membrane or a microfiltration membrane unit. Front. Environ. Sci. Eng. 2013, 7, 294–300. [Google Scholar] [CrossRef]

- Chen, J.; Huang, X.; Lee, D. Bisphenol A removal by a membrane bioreactor. Process. Biochem. 2008, 43, 451–456. [Google Scholar] [CrossRef]

- Lee, J.; Lee, B.C.; Ra, J.S.; Cho, J.; Kim, I.S.; Chang, N.I.; Kim, H.K.; Kim, S.D. Comparison of the removal efficiency of endocrine disrupting compounds in pilot scale sewage treatment processes. Chemosphere 2008, 71, 1582–1592. [Google Scholar] [CrossRef]

- Racar, M.; Dolar, D.; Karadakić, K.; Čavarović, N.; Glumac, N.; Ašperger, D.; Košutić, K. Challenges of municipal wastewater reclamation for irrigation by MBR and NF/RO: Physico-chemical and microbiological parameters, and emerging contaminants. Sci. Total Environ. 2020, 722, 137959. [Google Scholar] [CrossRef]

- Huang, Y.; Xu, W.; Hu, L.; Zeng, J.; He, C.; Tan, X.; He, Z.; Zhang, Q.; Shu, D. Combined adsorption and catalytic ozonation for removal of endocrine disrupting compounds over MWCNTs/Fe3O4 composites. Catal. Today 2017, 297, 143–150. [Google Scholar] [CrossRef]

- Zhang, Y.; Cui, W.; An, W.; Liu, L.; Liang, Y.; Zhu, Y. Combination of photoelectrocatalysis and adsorption for removal of bisphenol A over TiO2-graphene hydrogel with 3D network structure. Appl. Catal. B Environ. 2018, 221, 36–46. [Google Scholar] [CrossRef]

- Mohanta, D.; Ahmaruzzaman, M. Biogenic synthesis of SnO2 quantum dots encapsulated carbon nanoflakes: An efficient integrated photocatalytic adsorbent for the removal of bisphenol A from aqueous solution. J. Alloys Compd. 2020, 828, 154093. [Google Scholar] [CrossRef]

- Chatterjee, A.; Jana, A.K.; Basu, J.K. A novel synthesis of MIL-53(Al)@SiO2: An integrated photocatalyst adsorbent to remove bisphenol a from wastewater. New J. Chem. 2020, 44, 18892–18905. [Google Scholar] [CrossRef]

- Xu, X.; Chen, W.; Zong, S.; Ren, X.; Liu, D. Magnetic clay as catalyst applied to organics degradation in a combined adsorption and Fenton-like process. Chem. Eng. J. 2019, 373, 140–149. [Google Scholar] [CrossRef]

- Escalona, I.; Fortuny, A.; Stüber, F.; Bengoa, C.; Fabregat, A.; Font, J. Fenton coupled with nanofiltration for elimination of Bisphenol A. Desalination 2014, 345, 77–84. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, X.; Yan, X.; Ng, J.; Wang, Y.; Sun, D.D. Removal of bisphenol A via a hybrid process combining oxidation on β-MnO2 nanowires with microfiltration. Colloids Surfaces A Physicochem. Eng. Asp. 2011, 392, 198–204. [Google Scholar] [CrossRef]

- Yin, R.; Shang, C. Removal of micropollutants in drinking water using UV-LED/chlorine advanced oxidation process followed by activated carbon adsorption. Water Res. 2020, 185, 116297. [Google Scholar] [CrossRef]

- Liang, P.; Zhang, C.; Duan, X.; Sun, H.; Liu, S.; Tade, M.O.; Wang, S. An insight into metal organic framework derived N-doped graphene for the oxidative degradation of persistent contaminants: Formation mechanism and generation of singlet oxygen from peroxymonosulfate. Environ. Sci. Nano 2017, 4, 315–324. [Google Scholar] [CrossRef]

- Tsai, W.-T.; Lee, M.-K.; Su, T.-Y.; Chang, Y.-M. Photodegradation of bisphenol-A in a batch TiO2 suspension reactor. J. Hazard. Mater. 2009, 168, 269–275. [Google Scholar] [CrossRef]

- Torres, R.A.; Pétrier, C.; Combet, E.; Moulet, F.; Pulgarin, C. Bisphenol A Mineralization by Integrated Ultrasound-UV-Iron (II) Treatment. Environ. Sci. Technol. 2007, 41, 297–302. [Google Scholar] [CrossRef] [PubMed]

- Kang, D.; Kim, T.W.; Kubota, S.R.; Cardiel, A.C.; Gil Cha, H.; Choi, K.-S. Electrochemical Synthesis of Photoelectrodes and Catalysts for Use in Solar Water Splitting. Chem. Rev. 2015, 115, 12839–12887. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Wang, C.; Li, Y.; Wang, W.; Wei, J. Treatment of phenolic wastewater by combined UF and NF/RO processes. Desalination 2015, 355, 68–74. [Google Scholar] [CrossRef]

- Kwon, Y.-N.; Leckie, J.O. Hypochlorite degradation of crosslinked polyamide membranes: II. Changes in hydrogen bonding behavior and performance. J. Membr. Sci. 2006, 282, 456–464. [Google Scholar] [CrossRef]

- Tyrovola, K.; Diamadopoulos, E. Bromate formation during ozonation of groundwater in coastal areas in Greece. Desalination 2005, 176, 201–209. [Google Scholar] [CrossRef]

- Oh, B.S.; Jang, H.Y.; Jung, Y.J.; Kang, J.-W. Microfiltration of MS2 bacteriophage: Effect of ozone on membrane fouling. J. Membr. Sci. 2007, 306, 244–252. [Google Scholar] [CrossRef]

- Sabogal-Paz, L.P.; Campos, L.C.; Bogush, A.; Canales, M. Household slow sand filters in intermittent and continuous flows to treat water containing low mineral ion concentrations and Bisphenol A. Sci. Total Environ. 2020, 702, 135078. [Google Scholar] [CrossRef]

- Zdarta, J.; Antecka, K.; Frankowski, R.; Zgoła-Grześkowiak, A.; Ehrlich, H.; Jesionowski, T. The effect of operational parameters on the biodegradation of bisphenols by Trametes versicolor laccase immobilized on Hippospongia communis spongin scaffolds. Sci. Total Environ. 2018, 615, 784–795. [Google Scholar] [CrossRef]

- Hernández-Maldonado, A.J.; Blaney, L. Contaminants of Emerging Concern in Water and Wastewater: Advanced Treatment Processes; Butterworth-Heinemann: Oxford, UK, 2020; pp. 1–418. [Google Scholar] [CrossRef]

- Takáčová, A.; Smolinská, M.; Semerád, M.; Matúš, P. Degradation of btex by microalgae Parachlorella kessleri. Pet. Coal. 2015, 57, 101–107. [Google Scholar]

- Uthayasooriyan, M.; Pathmanathan, S.; Ravimannan, N.; Sathyaruban, S. Formulation of alternative culture media for bacterial and fungal growth. Der Pharm. Lett. 2016, 8, 431–436. [Google Scholar]

- Jehawi, O.H.; Abdullah, S.R.S.; Idris, M.; Abu Hasan, H.; Sbania, N.H.A.; Ismail, N.I. Removal of Chemical Oxygen Demand (COD) from Domestic Wastewater Using Hybrid Reed Bed System. Appl. Mech. Mater. 2015, 773–774, 1226–1230. [Google Scholar] [CrossRef]

- Saeed, T.; Majed, N.; Khan, T.; Mallika, H. Two-stage constructed wetland systems for polluted surface water treatment. J. Environ. Manag. 2019, 249, 109379. [Google Scholar] [CrossRef] [PubMed]

- Ronen, Z.; Abeliovich, A. Anaerobic-Aerobic Process for Microbial Degradation of Tetrabromobisphenol A. Appl. Environ. Microbiol. 2000, 66, 2372–2377. [Google Scholar] [CrossRef] [PubMed]

- Fan, M.; Zhou, N.; Li, P.; Chen, L.; Chen, Y.; Shen, S.; Zhu, S. Anaerobic co-metabolic biodegradation of tetrabromobisphenol A using a bioelectrochemical system. J. Hazard. Mater. 2017, 321, 791–800. [Google Scholar] [CrossRef]

- Taghizadeh, T.; Talebian-Kiakalaieh, A.; Jahandar, H.; Amin, M.; Tarighi, S.; Faramarzi, M.A. Biodegradation of bisphenol A by the immobilized laccase on some synthesized and modified forms of zeolite Y. J. Hazard. Mater. 2019, 386, 121950. [Google Scholar] [CrossRef]

- Vijayalakshmi, V.; Senthilkumar, P.; Mophin-Kani, K.; Sivamani, S.; Sivarajasekar, N.; Vasantharaj, S. Bio-degradation of Bisphenol A by Pseudomonas aeruginosa PAb1 isolated from effluent of thermal paper industry: Kinetic modeling and process optimization. J. Radiat. Res. Appl. Sci. 2018, 11, 56–65. [Google Scholar] [CrossRef]

- Rawat, C.D.; Phian, S.; Gupta, R.; Verma, H.; Kumar, M.; Kaur, J.; Rawat, V.S. Microbial bioprocesses in remediation of contaminated environments and resource recovery. In Microbial Bioprocesses—Applications and Perspectives; Shukla, P., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2023; pp. 225–274. [Google Scholar] [CrossRef]

- Frontistis, Z.; Lykogiannis, G.; Sarmpanis, A. Machine Learning Implementation in Membrane Bioreactor Systems: Progress, Challenges, and Future Perspectives: A Review. Environments 2023, 10, 127. [Google Scholar] [CrossRef]

- Radwan, E.K.; Ghafar, H.H.A.; Ibrahim, M.; Moursy, A.S. Recent trends in treatment technologies of emerging contaminants. Environ. Qual. Manag. 2022, 32, 7–25. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Iacovidou, E.; Gerassimidou, S. An overview of the occurrence, fate, and human risks of the bisphenol-A present in plastic materials, components, and products. Integr. Environ. Assess. Manag. 2022, 19, 45–62. [Google Scholar] [CrossRef]

| No | Contaminated Medium/Organism | Location | Summary | Source |

|---|---|---|---|---|

| 1 | Air | Argentina | Although the transfer of BPA into air phase is considered to be low, it can still be detectable in the airborne. BPA concentration was associated with particulate matter in the air. A maximum concentration of 2454 pg/m3 was found in the air during spring season. Potential hazard from dermal exposure or inhalation of BPA has not been widely studied yet. | Graziani et al. [44] |

| 2 | Food commodity | China | BPA was found in consumable goods in local Chinese market. Among 151 canned food samples, >92% of it were contaminated with BPA. Canned congee was the major contributor of BPA in canned food sample. | Cao et al. [46] |

| 3 | Food commodity | Nigeria | Exposure of BPA to humans was highlighted after results found that BPA concentrations in food commodities were detected. Results showed that vegetable oil contains the highest BPA of 28.4 ng/g, followed by canned fish and beef with 26.3 ng/g and 21.3 ng/g, respectively. Canned food is considered to be major source of BPA exposure to humans, since it is used as a metal coating compound. | Adeyi and Babalola [14] |

| 4 | Human | Belgium | BPA was found in the human body, assessed via a urine test in adolescents. More than 80% of the tested participant showed positive of BPA in their urine sample. The observed BPA concentration was still below the allowable limit. Socio-economic status and food consumption were highly related to BPA concentration among the tested participants. | Gys et al. [16] |

| 5 | Soil and surface water | Canada | BPA was found in the Canadian environment, including soil and surface water. It was thought to originate from wastewater, biosolid waste, and leachate percolation. BPA concentrations in agricultural soil sample showed the potential harm of BPA exposure in field commodities. The surface water concentration of BPA was considered to increase with time, reaching up to 6.37 µg/L, with future increments needing to be monitored. | Gewurtz et al. [10] |

| 6 | Surface sediment and bivalves | Iran | High concentrations of BPA (787.01 ng/g) were found in surface sediments received from municipal wastewater disposal. BPA was also observed in bivalves nearby the sampling location, with concentrations reaching up to 340.16 ng/g. It was proven that anthropogenic activity contributed to the occurrence of BPA in the environment, especially the aquatic ecosystem. | Jahromi et al. [45] |

| 7 | Surface water, soil, and aquatic animal | China | A high concentration of BPA was observed surrounding the plastic industry in Southeast China. The observed concentrations were 240 ng–5.68 µg/L in surface water, 38.7 ng–2.96 µg/g in soil, and 116.1–477.4 ng/g in aquatic animals. These results found that internal industrial wastewater treatment plant still releases a considerable amount of BPA into the surrounding environment. | Lin et al. [11] |

| No | Adsorbent Materials | Initial BPA Concentration | Dosage | Adsorption Capacity (qm) | Summary | References |

|---|---|---|---|---|---|---|

| 1 | nZVI-chitosan | 6 mg/L | 1.5 g/L | 65.16 mg/g | The adsorption process achieved 93.8% BPA removal from real pharmaceutical wastewater, 95% removal from synthetic wastewater, with a short 1 h adsorption time, and the adsorbent could be reused for up to three cycles. | Dehghani et al. [66] |

| 2 | Phosphonated Halomonas Levan (PhHL) | 10 mg/L | 0.5 g/L | 126.6 mg/g | The adsorption process reached equilibrium after 360 min, and the adsorbent could be reused for three cycles, with a 28.6% decrease in adsorption percentage after the third cycle. | Hacıosmanoğlu et al. [67] |

| 3 | Sulfonic acid functionalized carbonaceous adsorbent (TW-SO3H) from tea leaves | 100–400 ppm | 5–20 mg/20 mL | 236.80 mg/g | The adsorbent can be used for three cycles, and increasing the adsorbent dosage enhances BPA removal until agglomeration occurs. | Ahsan et al. [68] |

| 4 | Polydopamine-carbon, PDA-C | 50 mg/L | 5 mg | 1351 mg/g | The adsorption capacity was 1.5 times higher than conventional carbon, and the process was completed in less than 5 min. | Sun et al. [64] |

| 5 | Modification of multi-walled carbon nanotube with iron oxide and manganese dioxide (MWCNTs-Fe3O4−MnO2) | 22.8 ng/mL | 50 mg | 132.9 mg/g | The adsorption process took 150 min, and the adsorbent could be reused at least six times, resulting in up to 99% BPA removal. | Guo et al. [69] |

| 6 | Calcium alginate/activated carbon (A-AC) | 30–300 mg/L | 1g/L | 368.3 mg/g | The adsorbent could be used for at least six cycles without reduced adsorption, and it took 50 h to reach adsorption equilibrium. | Noufel et al. [70] |

| 7 | Xerogel (RFX), a chemical-activated carbon from Kraft lignin (KLP), commercial activated carbon (F400) | 100 mg/L | 0.36 g/L | F400 = 407 mg/g KLP = 220 mg/g xerogel = 78 mg/g | The adsorption process reached equilibrium in 24 h, with KLP and RFX exhibiting higher kinetic adsorption compared to F400, while F400 and KLP showed the highest BPA recovery. | Hernández-Abreu et al. [60] |

| 8 | Biomass activated carbon (Tithonia diversifolia) | 40 mg/L | 0.2 g/L | 15.69 mg/g | 98.2% BPA removal was achieved in 80 min. | Supong et al. [62] |

| 9 | Cu-BDC MOFs Cu-BDC@GrO (graphene oxide) | 20 mg | 20 mL of 100 ppm | 182 mg/g | Maximum BPA removal occurred in 30 min with increased adsorbent dosage, and the adsorbent could be reused for up to five cycles with minimal efficiency loss. | Ahsan et al. [71] |

| 11 | Cellulose acetate (cigarettes butt) activated carbon | 60 mg/L | 0.2 g | 364.21 mg/g | After seven cycles of use, the adsorption capacity remained at 94.21%, and maximum adsorption was achieved with a 150 min contact time. | Alhokbany et al. [61] |

| 12 | Calcite sludge-aluminum hydroxide (CAl) | 200 mg/L | - | 83.53 mg/g | The adsorbent was recycled five times and ethanol was used as a desorbing agent. | Choong et al. [17] |

| 13 | Magnetic vermiculite-modified (MV) -poly(trimesoyl chloride- melamine) (MP) | 10 mg/L | 200 mg | 273.67 mg/g | The adsorbent demonstrated satisfactory adsorption–desorption ability over five cycles, with a 66% reduction in BPA after the seventh cycle of adsorption/desorption. | Saleh et al. [72] |

| 15 | Nitrogen-containing covalent organic framework (PyTTA-Dva-COF) | 100 mg/L | 10 mg | 285 mg/g | The regeneration study showed excellent performance up to the seventh cycle, with BPA sorption maintained at 39 mg/g. | Hao et al. [73] |

| No | Membrane | Type | Removal Efficiency | BPA Removal Process | Reference |

|---|---|---|---|---|---|

| 1 | Layer-by-layer (LBL) biocatalytic nanofiltration membrane | Nanofiltration | 92.5% |

| X. Li et al. [81] |

| 2 | Electrochemical filtration carbon membrane (ECM) | - | 97.73% |

| Pan et al. [82] |

| 3 | Polyamide nanofiltration membrane | Nanofiltration | 88.5% |

| P. Wang et al. [83] |

| 4 | Dynamic electrodeposited CuO/carbon membrane (DECuO/CM) | Microfiltration | 98.04% |

| C. Li et al. [84] |

| 5 | Catalytic ceramic membrane (CCMs) | - | 80% (Co = 3 mg/L) |

| Lee et al. [85] |

| 6 | Catalyst immobilized ceramic membrane (CIM) | - | 95% (Co = 10 mg/L) |

| S. Wang et al. [86] |

| 7 | PVDFMW catalytic-membrane | Microfiltration | 40% Co = 50 µm |

| Silva et al. [87] |

| 8 | PVC membrane | Ultrafiltration | 60% Co = 25–50 mg/L |

| Wu et al. [75] |

| 9 | Forward osmosis membrane | Forward Osmosis | 40% Co = 10 µg/L |

| Linares et al. [88] |

| Treatment | BPA Removal Efficiency | Summary | References |

|---|---|---|---|

| Photocatalysis | 91% |

| Xu et al. [126] |

| 99.4% |

| Tang et al. [127] | |

| 100% |

| Huang et al. [128] | |

| 91.9% |

| Zhao et al. [129] | |

| 93.2% |

| Hao et al. [130] | |

| Photochemical oxidation | 98.98% (SPS) 95.43% (H2O2) |

| Sharma et al. [131] |

| >80% |

| Wardenier et al. [132] | |

| 56% (H2O2) >95% (O3) |

| Mehrabani-Zeinabad et al. [133] | |

| 100% |

| Olmez-Hanci et al. [134] | |

| 100% |

| Sánchez-Polo et al. [135] | |

| Fenton-based process | 100% |

| Molkenthin et al. [136] |

| 92.5% |

| J. Yang et al. [137] | |

| 99.2% |

| X. Zhang et al. [138] | |

| Ultrasonic cavitation | 100% |

| Torres et al. [139] |

| 70% |

| Guo and Feng [140] | |

| 47% |

| Lim et al. [141] |

| Treatment System | Influent Concentration | BPA Removal Efficiency | Type of Wastewater | Reference |

|---|---|---|---|---|

| Activated Sludge | 100 µg/L | 79.3% | Synthetic wastewater | Huang et al. [119] |

| Activated Sludge | 90 ng/L | 52% | Wastewater | Xue and Kannan [183] |

| Activated Sludge | 1 mg/L | 80.7% | Domestic Wastewater | Sun et al. [184] |

| Activated Sludge | - | Approx. 100% | Municipal Wastewater | Y. Qian et al. [185] |

| BAF | 400 ng/L | 95% | Wastewater | Guerra et al. [56] |

| MBR | 1–15 mg/L | 98% | Synthetic WW | Seyhi et al. [186] |

| GSBR | 0–12 mg/L | 97% | Synthetic WW | Cydzik-Kwiatkowska et al. [187] |

| Treatment Processes | Hybrid/Integrated Systems | BPA Source | Influent (μg/L) | Removal (%) | Reference |

|---|---|---|---|---|---|

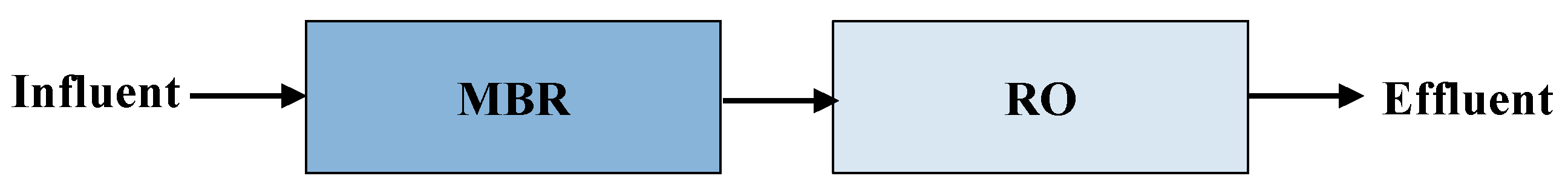

| Biological treatments + membrane filtrations | MBR + UF | Municipal solid waste | 606 | 100 | Fudala-Ksiazek et al. [213] |

| MBR + OF | Synthetic municipal wastewater | - | 98 | Zhu and Li [215] | |

| MBR + RO | Municipal wastewater | 3.7 | 99 | Sahar et al. [214] | |

| MBR + NF/RO | Sewage water | 0.09 | 95 (NF) 96 (RO) | Lee et al. [170] | |

| Adsorption + AOPs | Adsorption + catalytic ozonation | Synthetic wastewater | 50 mg/L | 98 | Huang et al. [219] |

| Adsorption + PEC | Synthetic wastewater | 20 mg/L | 100 | Zhang et al. [220] | |

| Adsorption + PC | Synthetic wastewater | 50 mg/L | 98 | Mohanta and Ahmaruzzaman [221] | |

| Adsorption + PC | Synthetic wastewater | 50 mg/L | 85 | Chatterjee et al. [222] | |

| Adsorption + Fenton | Synthetic wastewater | 50 mg/L | 87 | Xu et al. [223] | |

| AOPs + membrane filtrations | Fenton + NF | Synthetic wastewater | 300 mg/L | 100 | Escalona et al. [224] |

| β-MnO2 nanowires + MF | Synthetic wastewater | 10 mg/L | 99 | Zhang et al. [225] | |

| Catalytic ozonation + CM | Synthetic wastewater | 3 mg/L | 80 | Lee et al. [85] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abu Hasan, H.; Muhamad, M.H.; Budi Kurniawan, S.; Buhari, J.; Husain Abuzeyad, O. Managing Bisphenol A Contamination: Advances in Removal Technologies and Future Prospects. Water 2023, 15, 3573. https://doi.org/10.3390/w15203573

Abu Hasan H, Muhamad MH, Budi Kurniawan S, Buhari J, Husain Abuzeyad O. Managing Bisphenol A Contamination: Advances in Removal Technologies and Future Prospects. Water. 2023; 15(20):3573. https://doi.org/10.3390/w15203573

Chicago/Turabian StyleAbu Hasan, Hassimi, Mohd Hafizuddin Muhamad, Setyo Budi Kurniawan, Junaidah Buhari, and Osama Husain Abuzeyad. 2023. "Managing Bisphenol A Contamination: Advances in Removal Technologies and Future Prospects" Water 15, no. 20: 3573. https://doi.org/10.3390/w15203573