Abstract

The necessity of mining valuable metals must be balanced with the safe and effective disposal or remediation of the resulting waste. Water, one of our most valuable resources, is a major component of the mining process, and its post-operation storage often results in acid mine drainage. While many remediation methods have been studied, they have low economic feasibility, as minimally active methods alone were inadequate, and thus required additional, costly active methods for effective neutralization. This study looks to neutralize acid mine drainage with only minimally passive methods, through an optimized dosage of lime, fly ash, and aluminum hydroxide. Wastewater samples of pH 3.62 and 5.03, containing 1.36 and 2.21 percent sulfides, respectively, were experimentally treated, with the utilized dosage parameters generated using the Monte Carlo method for neutralizing acidity. The remediated water samples presented 0.01% and 0.16% sulfur content values, which corresponds to 99.3% and 92.8% reductions, respectively. These results present, for the first time, that minimally active methods could achieve a pH of 8.5 without active methods. While future studies should validate these results and provide a more complete characterization of the water samples, the major challenge of neutralization was addressed, and, thus, these results contribute process incentives for mining companies to economically remediate their waste water in order to safeguard their surrounding communities and return valuable water back to the water cycle.

1. Introduction

The economic and technical benefits of metal mining should never preclude the search for a sustainable balance among resource usage, waste disposal, and, in many cases, waste recycling. Sustainability is strained during extraction mining, as great quantities of water are required throughout the entire process, from exploration, to drilling, to extraction, and finally, at the waste disposal and storage stages.

In the waste storage of heavily processed water specifically, there is a significant risk to the environment and to local communities. Waste water stored in ponds or dams, due to various chemical reactions, leeches contaminants from the surrounding rock, increases acidity, and generates what is known as acid mine drainage (AMD), one of the largest environmental problems that the mining sector faces on a global scale [].

The primary AMD characteristics in polymetallic mines are the low pH values and high concentrations of sulfate and metal ions (Fe2+, Al3+, and Zn2+), leading to the occurrence of AMD among mining operations in countries as diverse as Italy, South Africa, India, and Peru, and predominantly where mining operations expose sulfide minerals (pyrite, sphalerite, galena, and chalcopyrite) and oxidation leeches the sulfur into the waste water [,,,,,].

This waste water poses two sustainability challenges: the first in the risk of accidental discharge of the contaminated water from the storage pond; and the second in the water being permanently removed from the water cycle. Treatment can help with both challenges.

Although there is discussion on the terminology, active water treatment, usually defined as requiring electrical power for operation, is quite varied and effective, but costly. Passive options, which include limestone drains and anaerobic wetlands, have lower ongoing costs, but still require a significant upfront investment. As such, mining operations often choose not to treat the waste water, and store it in ponds instead. At times, this option has proven disastrous, due to the accidental discharge of the AMD and the resulting contamination consequences for the surrounding communities and ecosystem. Even if the pond would never experience accidental discharge, the valuable and increasingly scarce water contained within is removed from the water cycle.

Other water treatment options exist, so mining companies can mitigate the risk of waste water storage and AMD leakage, and recycle water back into the water cycle, in more cost effective ways. While they are, at times, considered active [], this study defines the use of neutralization agents as minimally active techniques, to distinguish them from other active techniques that require separate mechanical equipment and power, often rendering them cost-prohibitive. As such, these agents can offer more cost-justifiable methods for mining operations, as they raise the alkalinity of the water, while often precipitating out the harmful contaminants in the process. Examples include hydrated lime (Ca(OH)2), dolomite lime (CaMg(CO3)2), limestone (CaCO3), sodium hydroxide (NaOH), magnesium hydroxide (Mg(OH)2), and calcium oxide (CaO), as well as others.

CaO is a traditional, and quite effective, neutralizing agent [], but recent studies have sought to find more sustainable substitutions that are also waste products, such as waste concrete or basic oven furnace slag [,]. Another industrial byproduct, fly ash (FA), generated from coal mines, has proven an effective substitute, with [], finding that FA increased the pH and reduced the concentrations of Fe, Al, Mn, and sulphate significantly. Another additive for the neutralization process, aluminum hydroxide (Al(OH)3), has been added to mixtures to more efficiently neutralize acidity and precipitate contaminants, as Al(OH)3 is known to slow the increase in pH by increasing the content of CaO solutions [,,].

While these and other studies show that neutralizing agents are effective at reducing mineral contamination through precipitation [,], with [], listing the corresponding pH levels for twelve contaminating metals, of which eleven are below pH 8.5 [], previous work also shows that controlling neutralization is difficult. Some studies could not effectively neutralize the acidity with other agents [], while many overshot neutralization [,,,,]. Likewise, studies show that achieving a 6.5–8.0 pH range does not remove another major contaminant, sulfur, in its many forms [,]. Thus, additional active methods, such as using a jet loop reactor [], in situ and ex situ carbonization bubbling [], or reverse osmosis [], were required to further remediate the AMD for pH and sulfur content and to bring the treated water into compliance with international water reuse standards.

As these methods increase the cost of treatment, the search for optimized mixtures of these agents continues, as the most formidable challenge in terms of reducing the cost of remediation is in the neutralization of acidity, with the reduction of sulfurs seen as a secondary challenge.

In such optimization situations, statistical simulations have helped to theoretically discover a combination of inputs that can deliver a desired output in order to reduce extensive experimentation. One such method is the Monte Carlo method, which has been successful across many disciplines, specifically used to understand uncertainty in waste water treatment for improved quality [], reduce sulfides, and plan the long-term management of acidic water quality [,].

The procedure begins with selecting simulations; input parameters based on probability distributions are identified, and random values are given until a stable state is reached. The intention is to generate synthetic data sequences that maintain the key statistics (mean and standard deviation) of a true data series. This modeling approach is used to evaluate the minimum or maximum results of models across multiple runs of the same model with randomly selected values [,,].

AMD is a continual problem for various mining operations and the local and regional communities that surround them, and previous studies presented results that reduce acidity but do not adequately neutralize the contaminated waters to reuse standards without incurring the high costs of active methods. Therefore, this study seeks to use the Monte Carlo method to determine an optimized dosage of combined CaO, FA, and Al(OH)3 that does not require subsequent active techniques to bring the pH of the resulting water into a neutralized, reusable range. It also seeks to present a partial, but informative, characterization of the resulting water through a reduction in the most prevalent AMD contaminant, sulfur, to contribute methods that would economically mitigate AMD and allow the treated water to be returned to the water cycle.

2. Materials and Methods

For AMD treatments, it is first required to perform geological, geochemical and mineralogical characterization of mineral samples. These characterizations help in the development of a treatment plan for acidic waters as it characterizes the samples in terms of pH, metals concentration, and sulfur content [,].

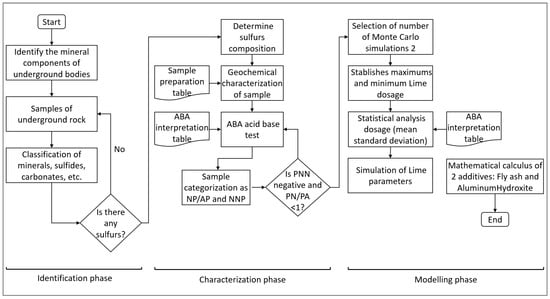

For the acidic water treatment method proposed in this study (Figure 1), the use of the three additives discussed above will allow us to comply with the regulatory parameters for the discharge of remediated water.

Figure 1.

Proposed methodology process.

First, we assess the mineralogy and geochemical records, as well as progress reports and the parameter control records of the mine: flows, pH levels, turbidity, conductivity, and oxygen reports. Based on the mineralogy reports for the mine, the types of mineralization present in the oxides and sulfides of the studied field can be determined.

Then, the quantity of mineralogical species will be confirmed from the geochemistry reports. The sampling should be conducted with a field specialist and taken from representative areas of the extraction operations and considering the current progress within the mine.

The representative samples will be extracted, following the Peruvian standard Soil Sampling Guide []. Using the analysis conducted on the technical reports of the mining unit and on samples taken, the mineral composition and sulfides, carbonates, sulfates, and oxides quantities in the samples will be determined. All sulfides will be analyzed in the laboratory.

After the chemical and mineralogical analyses, characterization of sulfide minerals using Acid-Base Accounting (ABA) parameters as well as the Net Acid Generation (NAG) tests provide analytical procedures to evaluate the acid-producing and acid-neutralizing potential of soils, sediments, and rocks. The pH values from the NAG test are indicators that can be used to sort the samples as acid-generating or non-acid-generating. Moreover, they assess the balance between the acid generation potential and the acid neutralization capacity [,,].

When ABA results suggest that the samples could be acid generating, they represent a detailed temporal observation of pH and metal concentrations and confirm that metal mobility is pH dependent [,]. These theoretical tests characterize the potential for chemical production after sulfide weathering, aiding in mining and recovery plans to minimize or completely eliminate potential acidic waters.

The acid-base accounting (ABA) test is comprised of two different measurements: the determination of the Neutralization Potential (NP) and the calculation of Acidic Potential (AP) of the samples. The difference between the two values classifies the sample as potentially consuming or producing acid [].

The geochemical characterization of samples will be conducted once the type of sulfide minerals and their percentages have been determined. Acidity generation potential tests will be conducted on the rock samples from the mine by SGS laboratories to identify the total potential generation and neutralization of rock acid.

The preparation of the samples will follow a three-step protocol: (i) drying, which will take place between 60 °C and 105 °C; (ii) crushing of 1 kg of sample until 75% has passed through a 2 mm sieve and 250 g of crushed sample is obtained; and, finally, (iii) pulverization (in a hardened steel disc and ring mill) until 85% passes through a 75 µm-sized sieve.

In the laboratory, the modified acid-base accounting will be performed by the PM-ABA method. The test will analyze the total sulfur and carbon concentrations (total sulfides and carbons) after pyrolysis (without O2) in the LECO-analyzer machine (combustion elemental analysis machine).

The residual concentrations (residual sulfides and carbon) will be assessed after the pyrolysis of sulfides to SO2 and of organic carbons to CO2 at 550–600 °C for one hour.

With these assessments, the acid generation potential (AP) and the neutralization potential (NP) of a given sample will be identified to ultimately, based on both AP and NP values, determine its net neutralization potential (NNP), and the NP/AP ratio. Once these tests are conducted, the pH level of the acid rock drainage will be determined.

Moreover, the neutralization potential and, especially, the sulfur and sulfate species that generate acidity in the sample, will be assessed through the PM-ABA test.

The simulation will be conducted using the Monte Carlo method that is used to perform multiple sequenced data simulations that maintain the key statistics (mean and standard deviation) of the true data series. This probabilistic tool will produce the necessary dosage standards for the alkaline additives to be established from two CaO dosage simulations, the maximum and minimum values, based on the actual data analyzed in the laboratory.

In the planning mode, a cumulative frequency curve and distribution histogram are generated to determine the model using different input data selected as per the probability distributions defined for each input variable []. The model equations are run using random numbers as input values until reaching a stable condition []. Overall, 1000 iterations will be conducted for each simulation, thus recording and plotting the mean and standard deviation for each iteration in a chart. From each of these simulations, five values of >80% effectiveness will be selected from the value table. Finally, using these five effective CaO values, the dosages for FA and aluminum hydroxide will be mathematically calculated.

This test determines the acidity potential (AP) and the neutralization potential (NP), both expressed in CaCO3 kg/ton. From these calculations, the net neutralization potential (NNP = NP−AP) and the NP/AP ratio are obtained and will determine acid generation potential of the sample (Table 1).

Table 1.

ABA test interpretation.

The data analysis was conducted through Macros in Microsoft Excel 2019 obtaining descriptive statistics for the two samples.

3. Results

This study seeks to help mining operations find efficient, minimally active methods to treat AMD so the treated water can be returned to the water cycle. The mining unit study area is located in the central coast of Peru, Lima, in the province of Huaral, districts of Chancay. Moreover, the zone presents disseminated mineralization and veinlets in sericitized volcanic breccia in the basal section, and massive mineralization in its upper zone.

The polymetallic deposit from which the samples were extracted contains zones of sulfide and oxide (Table 2), with pyrite and chalcopyrite containing the highest composition of sulfur and iron disulfide (FeS2) contaminants (Table 3).

Table 2.

Zone mineralization.

Table 3.

Composition of pollutants from mineralogical species.

Two samples, S-1 and S-2 were collected from the mine from two different tailings ponds, and tested with the ABA Test and the test for sulfur concentrations (Table 4), and present a high acid generation potential and a high sulfur contamination.

Table 4.

ABA test results.

For validation, the maximum and minimum values in Kg CaCO3/ton required to mitigate the acidic waters of the mine were considered as per the ABA test (Table 5). Similarly, the maximum and minimum equivalence necessary in terms of CaO are shown.

Table 5.

Maximum and minimum neutralization values.

The maximum and minimum density parameters were assigned for samples with purity indices of 0.95, 1.0 and 0.96 for CaO, FA and aluminum hydroxide, respectively. Based on these parameters, one thousand (1000) iterations were conducted using the Monte Carlo simulation for the theoretical dosage of CaO in (g/L) for 80 L of both samples. Then, the sample dosages for S-1 and S-2 were used for assessing the iterated data, wherein the mean standard deviation, minimum value, and maximum value were calculated. For the dosing of each sample (S-1, S-2), an analysis of the iterated data was made (Table 6 and Table 7).

Table 6.

Descriptive statistics of S-1.

Table 7.

Descriptive statistics of S-2.

These indicators are used to calculate the confidence level and establish in which parameter presents an effective dosage (Table 8 and Table 9). The minimum and maximum value determines the scale of values and then establish confidence value (z) using the following formula:

Table 8.

Confidence level scale S-1.

Table 9.

Confidence level scale of S-2.

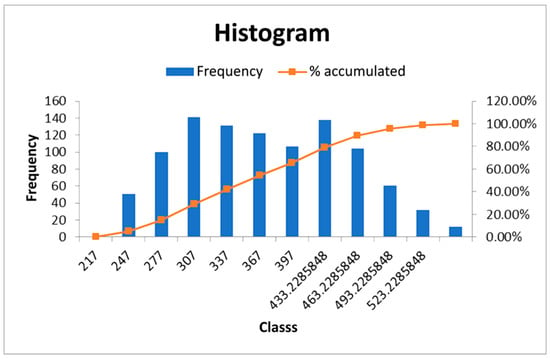

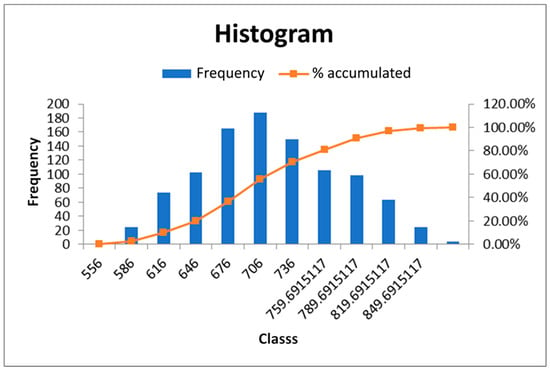

A dosage value for S-1 of 433.229 g/80 L was found for the CaO at a 95% confidence level (Table 8), and a dosage value for S-2 of 759.692 g/80 L for the CaO with a 95% confidence level (Table 9), exhibited in their corresponding histograms (Figure 2 and Figure 3).

Figure 2.

Monte Carlo histogram for S-1.

Figure 3.

Monte Carlo histogram for S-2.

Finally, the ideal dosage was found at a confidence level of 95% for the FA and Al(OH)3 additives through the algorithm for equivalence:

This generated the optimized dosage for both S-1 and S-2 (Table 10).

Table 10.

Sample dosage results at a 95% level of confidence.

These results bring the pH into irrigation standards for most areas of the world, and present a reduction of over 92% of sulfurs (Table 11).

Table 11.

Pre- and post-treatment % sulfur content.

4. Discussion

In a novel demonstration, this study was able to develop dosages of CaO, FA and Al(OH)3, optimized by the Monte Carlo method, that successfully neutralized AMD samples of initial pH of 5.03 and 3.62 and final pH of 8.5 and 8.5, while at the same time demonstrating >93% reductions in sulfur content.

This is relevant as much previous work has shown that while low acidity or neutralization functions quite well to precipitate out contaminating metals, the control of neutralization to reduce sulfur content and not require additional active methods has been difficult.

While fully remediated water must have a pH between 6.5 and 8.5, in the case of AMD, this must be balanced by controlling the alkalizing process, as [], using lignite FA and coal mine waste rocks, could not raise the pH from 3.3 to more than 5.1. Ref. [], looked to neutralize artificial AMD solutions of pH 3.1 and 2.7, with regular lignite and modified FA across different solids dosages of <1.0 g/50 mL, 1.0 g/50 mL, 5 g/50 mL and 10 g/50 mL. Demonstrating the difficulty of neutralization, only the treatment of 1.0 g/50 mL with the modified FA was able to achieve a pH of 6.7, with lower dosages remaining acidic and the higher dosages presenting pH values over 11.5 [].

In Ref. [], looking predominantly to desalinate and produce drinking water quality, achieved a pH of around 8.0 with the first treatment with BOF slag. However, in order to produce drinking water, they required additional reagents and processes, ultimately bringing the pH over 12.5 and then back to neutralization for full remediation [].

In Ref. [], used a tree-step process chain of laterite mine and concrete waste with CaO reagents, with four of their six samples achieving neutralization with pH vales of 7.01–8.08, while samples five and six overshot neutralization at 11.025 and 9.16, respectively [].

Using two of the same reagents as this study, but adding them in two stages, [], overshot neutralization to arrive at a pH of 10. Ref. [], went back to the reagents of their previous studies, adding CaO and FA first, then Al(OH)3 when the pH stabilized at 9.8, and then moved into active methods of carbonation to finally neutralize the samples.

As much previous work has shown that reductions in acidity, neutralization and moderate alkalinity help significantly in the decontamination of AMD through precipitation [], it stands to reason that recent work might alter focus to finding different sustainable reagents that decontaminate AMD from heavy metals, even if they do not achieve neutralization or sulfur content reduction [,,].

In Ref. [], while initially achieving a pH of around 8.0 with the first treatment with BOF slag, could not effectively reduce sulfurs and actually increased other contaminating metals. They required multiple additional reagents, such as CaO and Na2CO3, and additional processes, including reverse osmosis, to bring the pH over 12.5 and then back to neutralization for successful reduction of sulfurs, decontamination of metals, and full remediation [].

While [], were successful using concrete and literate mine waste to neutralize four of their six samples, the average sulfur reduction was only 57%. However, when solids were almost doubled to 66.0 g/50 mL in their last two samples, the pH values moved over 9.0, and the sulfurs were reduced by 85%.

Although [], had one of ten samples achieving a pH of 6.7, it was not enough to precipitate out all of the contaminating metals, and they concluded that it would be better to use the two highest solids concentrations of 10 g/50 mL that brought the pH over 9.0 for that objective. They did not test for sulfur content.

Refs. [,], had successful sulfur reductions, 84% and 94%, respectively, as well as successful reductions in all other contaminating metals after bringing their samples to pH levels over 9. As successful as they have been in decontamination, the additional active methods they applied suggest that without neutralization, there is little economic incentive for mining companies to discontinue long-term catchment policies.

Given the successes of previous work in the removal of contaminating metals from AMD, often through overshooting neutralization [], it seems the predominant challenge presented is the control of neutralization, with sulfur reduction following. A couple reasons could explain how this study surmounted these challenges and achieved a pH of 8.5 with over 92% reduction of sulfurs without active techniques.

One is the combination of CaO and Al(OH)3 to help control neutralization when added to the sustainable reagent of FA. While many studies are looking for new sustainable reagents, these three have a strong body of work supporting their efficacy.

Second, the Monte Carlo method helped lead us to different dosage proportions of these well-studied reagents. First, the investigation line of [,,], presented a trend of increasing the proportions of both CaO, from 0.25% to 1.21%, and Al(OH)3, from 0.61% to 2.0%. The Monte Carlo optimization produced a significant increase to 9.0% CaO and 16.0% Al(OH)3, with a corresponding reduction in FA to 75.0% instead of the 99.0% in those previous works.

Third and complementary to the second is the process change to add the CaO, FA and Al(OH)3 together at the start of treatment to take advantage of the Al(OH)3 not only for sulfur precipitation but also neutralization. Coupled with an increase in the percentage of Al(OH)3, it seems that the higher quantity of CaO and its dissolution was slowed, in effect slowing the entire neutralizing process, and yet still allowing the precipitation out of sulfurs. This could explain how this dosage avoided the high alkalinity that required previous studies to resort to active methods to neutralize the treated water to a reusable range.

5. Conclusions

The surrounding communities of metal mines face the constant threat of seepage and breeches of tailings dams that store acid mine drainage as active treatment processes are often too costly for mining operations. Likewise, water is a vital resource to those communities. Previous research had been able to precipitate out contaminating minerals, but not adequately neutralize the water without active methods.

Using the Monte Carlo method to determine an optimum dosage of lime, FA and aluminum hydroxide, this study effectively neutralized acid mine drainage of pH 5.03 and 3.62, as well as precipitated out the majority (99.3% and 92.8%) of sulfur contamination, a major contaminating mineral of AMD locations. This was the first study to demonstrate neutralization without active methods.

This contributes to the science by overcoming the most difficult step, neutralization, and opens the door to future studies to validate these results with a more complete characterization of the pre- and post-treatment samples. This also contributes to the science by offering another example of how Monte Carlo optimization can help break through difficult dosage optimizations.

The limitations of this study are due to its experimental nature and that it solely focused on neutralization and thus presents an incomplete characterization of the pre- and post-water samples.

6. Future Research

Future research should validate these results and provide a more complete characterization of the pre- and post-water samples through electrical conductivity, total dissolved solids and other physicochemical parameters, as well as for other major and minor contaminating minerals, apart from sulfur.

Should these prove positive, this will contribute to the practice by opening the door to economically viable options for mining companies to treat their waste water instead of storing it and carrying the risk of accidental discharge.

This treated water could then be returned to the water cycle, the sedimentations of sulfur and other contaminating metals could be removed for proper disposal, positively affecting sustainability while significantly reducing the threat of acid mine drainage contamination.

Author Contributions

Conceptualization, K.C.H. and Y.V.O.; data curation, K.C.H.; formal analysis, K.C.H. and C.R.I.; funding acquisition, C.R.I.; investigation, K.C.H. and Y.V.O.; methodology, V.A.R. and C.R.I.; resources, K.C.H. and C.R.I.; software, K.C.H. and Y.V.O.; supervision, L.A., C.R.I. and F.D.; validation, K.C.H., Y.V.O., C.R.I. and F.D.; visualization, V.A.R. and C.R.I.; writing—original draft, K.C.H.; writing—review and editing, K.C.H., L.A., C.R.I. and F.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding. The authors would like to thank the Research Department of the Peruvian University of Applied Sciences for the support provided to carry out this research work through the UPC-EXPOST-2023-2 incentive.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Instituto de Ingenieros de Minas del Peru. Available online: https://iimp.org.pe/pptjm/jm20151203_Avances_%20mineria_perunana.pdf (accessed on 6 December 2022).

- Acharya, B.S.; Kharel, G. Acid mine drainage from coal mining in the United States—An overview. J. Hydrol. 2020, 588, 125061. [Google Scholar] [CrossRef]

- Shoja, S.E.; Salari, M.M. Study of acid mine drainage production potential in flotation tailings of Sarcheshmeh porphyry copper mine. Arab. J. Geosci. 2015, 8, 8229–8236. [Google Scholar] [CrossRef]

- Clark, E.V.; Daniels, W.L.; Zipper, C.E.; Eriksson, K. Mineralogical influences on water quality from weathering of surface coal mine spoils. Appl. Geochem. 2018, 91, 97–106. [Google Scholar] [CrossRef]

- Çelebi, E.E.; Öncel, M.S. Determination of acid forming potential of massive sulfide minerals and the tailings situated in lead/zinc mining district of Balya (NW Turkey). J. Afr. Earth Sci. 2016, 124, 487–496. [Google Scholar] [CrossRef]

- Lawrence, R.W.; Scheske, M. A method to calculate the neutralization potential of mining wastes. Environ. Geol. 1997, 32, 100–106. [Google Scholar] [CrossRef]

- Paktunc, A.D. Mineralogical constraints on the determination of neutralization potential and prediction of acid mine drainage. Environ. Geol. 1999, 39, 103–112. [Google Scholar] [CrossRef]

- Brown, M.; Barley, B.; Wood, H. Minewater Treatment; IWA Publishing: London, UK, 2002. [Google Scholar]

- Masindi, V.; Osman, M.S.; Abu-Mahfouz, A.M. Integrated treatment of acid mine drainage using BOF slag, lime/soda ash and reverse osmosis (RO): Implication for the production of drinking water. Desalination 2017, 424, 45–52. [Google Scholar] [CrossRef]

- Turingan, C.O.A.; Cordero, K.S.; Santos, A.L.; Tan, G.S.L.; Tabelin, C.B.; Alorro, R.D.; Orbecido, A.H. Acid mine drainage treatment using a process train with laterite mine waste, concrete waste, and limestone as treatment media. Water 2022, 14, 1070. [Google Scholar] [CrossRef]

- Gitari, M.W.; Petrik, L.F.; Etchebers, O.; Key, D.L.; Iwuoha, E.; Okujeni, C. Treatment of acid mine drainage with fly ash: Removal of major contaminants and trace elements. J. Environ. Sci. Health Part A 2006, 41, 1729–1747. [Google Scholar] [CrossRef] [PubMed]

- Gilbert, C.; Ayanda, O.S.; Fatoba, O.O.; Madzivire, G.; Petrik, L.F. A novel method of using iron nanoparticles from coal fly ash or ferric chloride for acid mine drainage remediation. Mine Water Environ. 2019, 38, 617–631. [Google Scholar] [CrossRef]

- Madzivire, G.; Maleka, R.M.; Tekere, M.; Petrik, L.F. Cradle to cradle solution to problematic waste materials from mine and coal power station: Acid mine drainage, coal fly ash and carbon dioxide. J. Water Process Eng. 2019, 30, 100474. [Google Scholar] [CrossRef]

- Madzivire, G.; Maleka, P.P.; Vadapalli, V.R.K.; Gitari, W.M.; Lindsay, R.; Petrik, L.F. Fate of the naturally occurring radioactive materials during treatment of acid mine drainage with coal fly ash and aluminium hydroxide. J. Environ. Manag. 2014, 133, 12–17. [Google Scholar] [CrossRef] [PubMed]

- Roulia, M.; Alexopoulos, D.; Itskos, G.; Vasilatos, C. Lignite fly ash utilization for acid mine drainage neutralization and clean-up. Clean. Mater. 2022, 6, 100142. [Google Scholar] [CrossRef]

- Masindi, V.; Muedi, K.L. Environmental contamination by heavy metals. Heavy Met. 2018, 10, 115–132. [Google Scholar]

- Qureshi, A.; Maurice, C.; Öhlander, B. Effects of the co-disposal of lignite fly ash and coal mine waste rocks on AMD and leachate quality. Env. Sci. Pollut. Res. 2019, 26, 4104–4115. [Google Scholar] [CrossRef] [PubMed]

- Madzivire, G.; Gitari, W.M.; Vadapalli, V.R.K.; Ojumu, T.V.; Petrik, L.F. Fate of sulphate removed during the treatment of circumneutral mine water and acid mine drainage with coal fly ash: Modelling and experimental approach. Miner. Eng. 2011, 24, 1467–1477. [Google Scholar] [CrossRef]

- Madzivire, G.; Gitari, W.M.; Vadapalli, V.R.K.; Petrik, L.F. Jet loop reactor application for mine water treatment using fly ash, lime and aluminium hydroxide. Int. J. Environ. Sci. Technol. 2015, 12, 173–182. [Google Scholar] [CrossRef]

- Psarrou, E.; Tsoukalas, I.; Makropoulos, C. A Monte-Carlo-based method for the optimal placement and operation scheduling of sewer mining units in urban wastewater networks. Water 2018, 10, 200. [Google Scholar] [CrossRef]

- Wolkersdorfer, C. Water Management at Abandoned Flooded Underground Mines: Fundamentals, Tracer Tests, Modelling, Water Treatment; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Whitehead, P.; Jeffrey, H. Heavy metals from acid mine drainage—Impacts and modelling strategies. In International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts; Elsevier: Amsterdam, The Netherlands, 1995; pp. 55–66. [Google Scholar]

- Aubel, T.; Janneck, E.; Kalanchey, R. Process development for complex mine water treatment. In Mine Water Circular Economy (Vol II); Lappeenranta University of Technology: Lappeenranta, Finland, 2017; pp. 1147–1161. [Google Scholar]

- Anawar, H. Sustainable rehabilitation of mining waste and acid mine drainage using geochemistry, mine type, mineralogy, texture, ore extraction and climate knowledge. J. Environ. Manag. 2015, 158, 111–121. [Google Scholar] [CrossRef] [PubMed]

- Ministerio del Ambiente (MINAM). Guía para el Muestreo de Suelos, 1st ed.; Biblioteca Nacional del Perú: Lima, Perú, 2014; No. 2014-15792. [Google Scholar]

- Skousen, J. A methodology for geologic testing for land disturbance: Acid-Base Accounting for surface mines. Geoderma 2017, 308, 302–311. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).