Optimization of Efficient Development Modes of Offshore Heavy Oil and Development Planning of Potential Reserves in China

Abstract

:1. Introduction

2. Experiment

2.1. Experimental Purpose

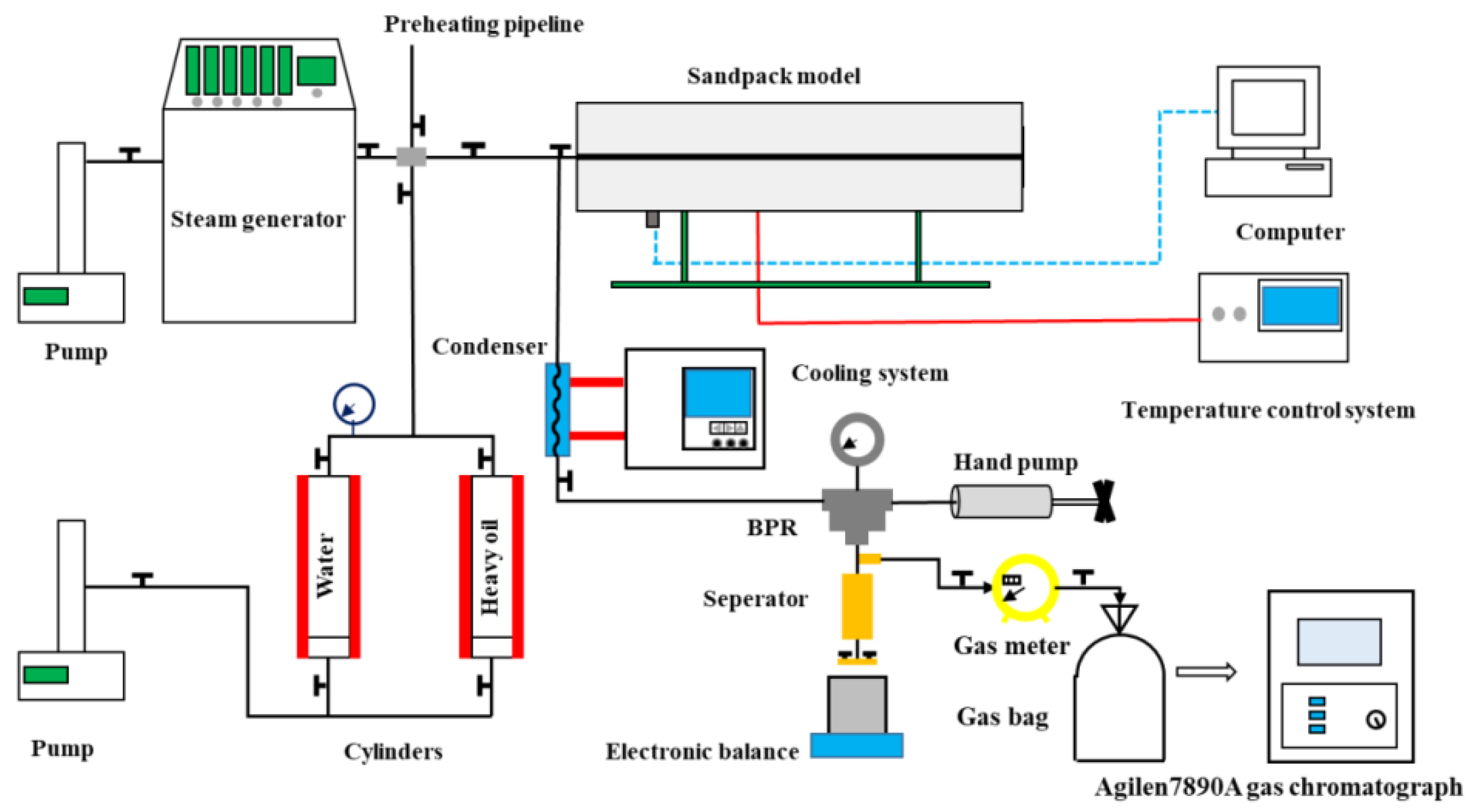

2.2. Experiment Apparatus

2.3. Experiment Procedures

2.4. Experimental Results and Discussion

3. Numerical Simulation

3.1. Matching of the Experimental Data

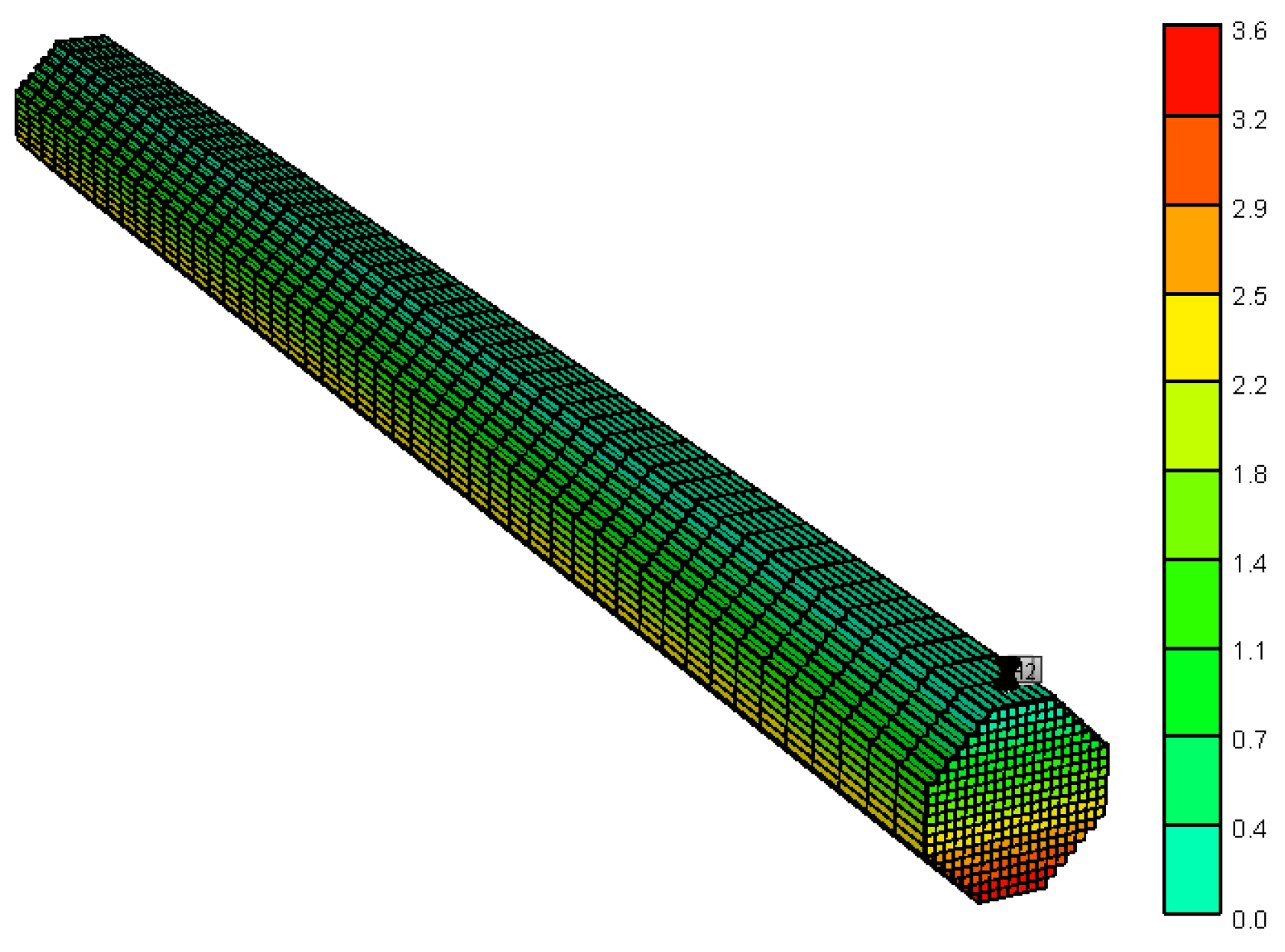

3.1.1. Building the One-Dimensional Numerical Simulation Model

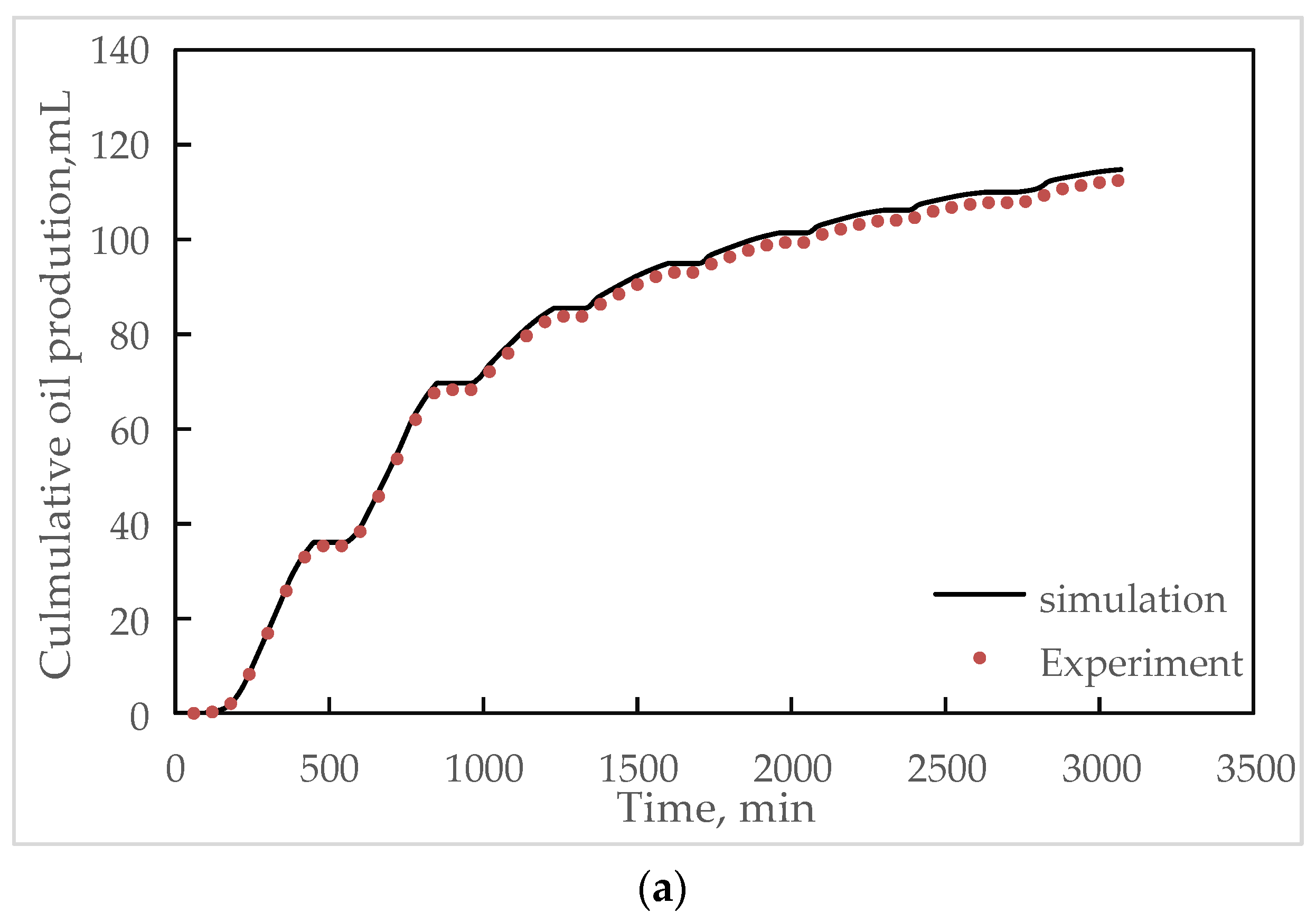

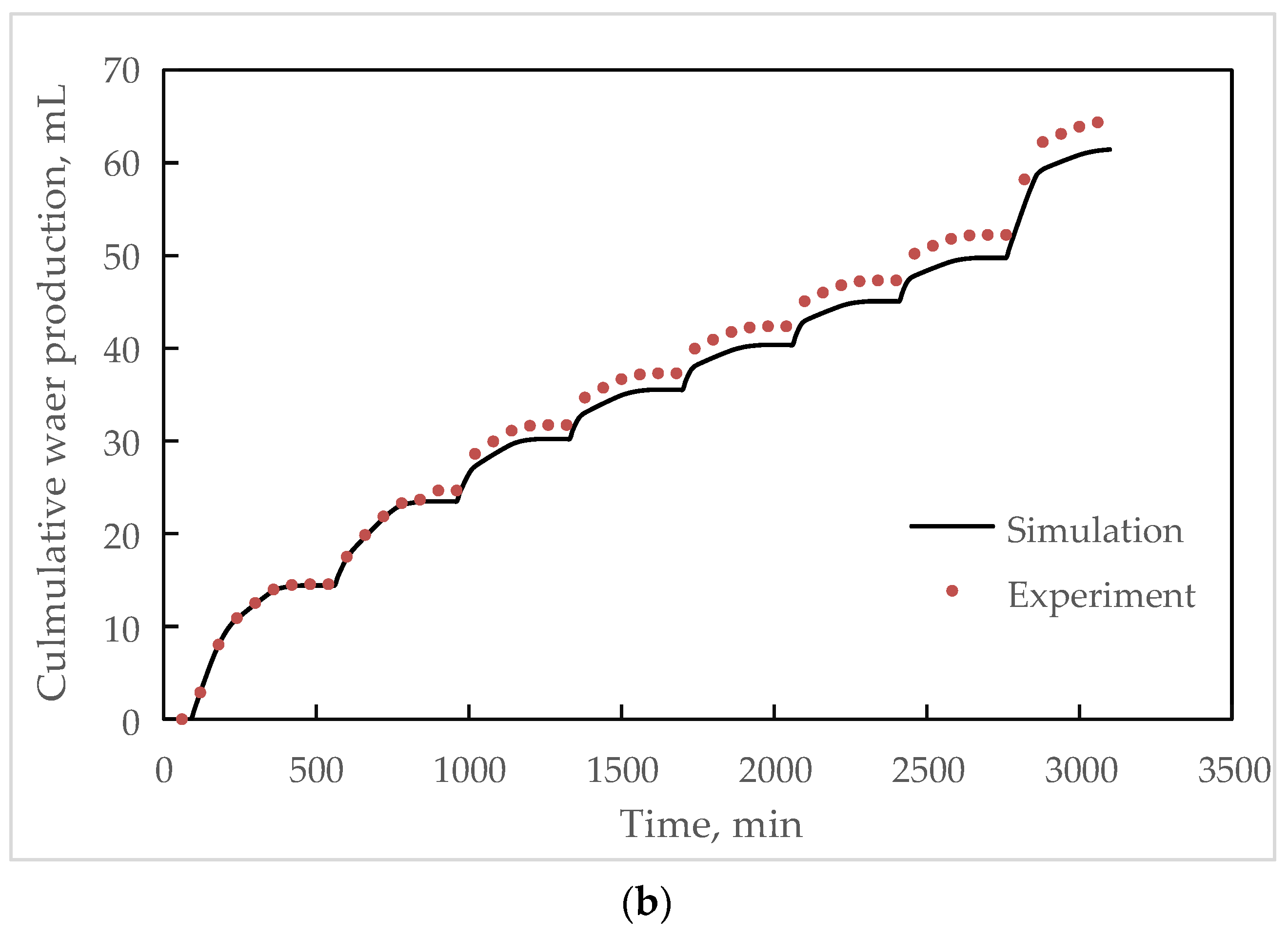

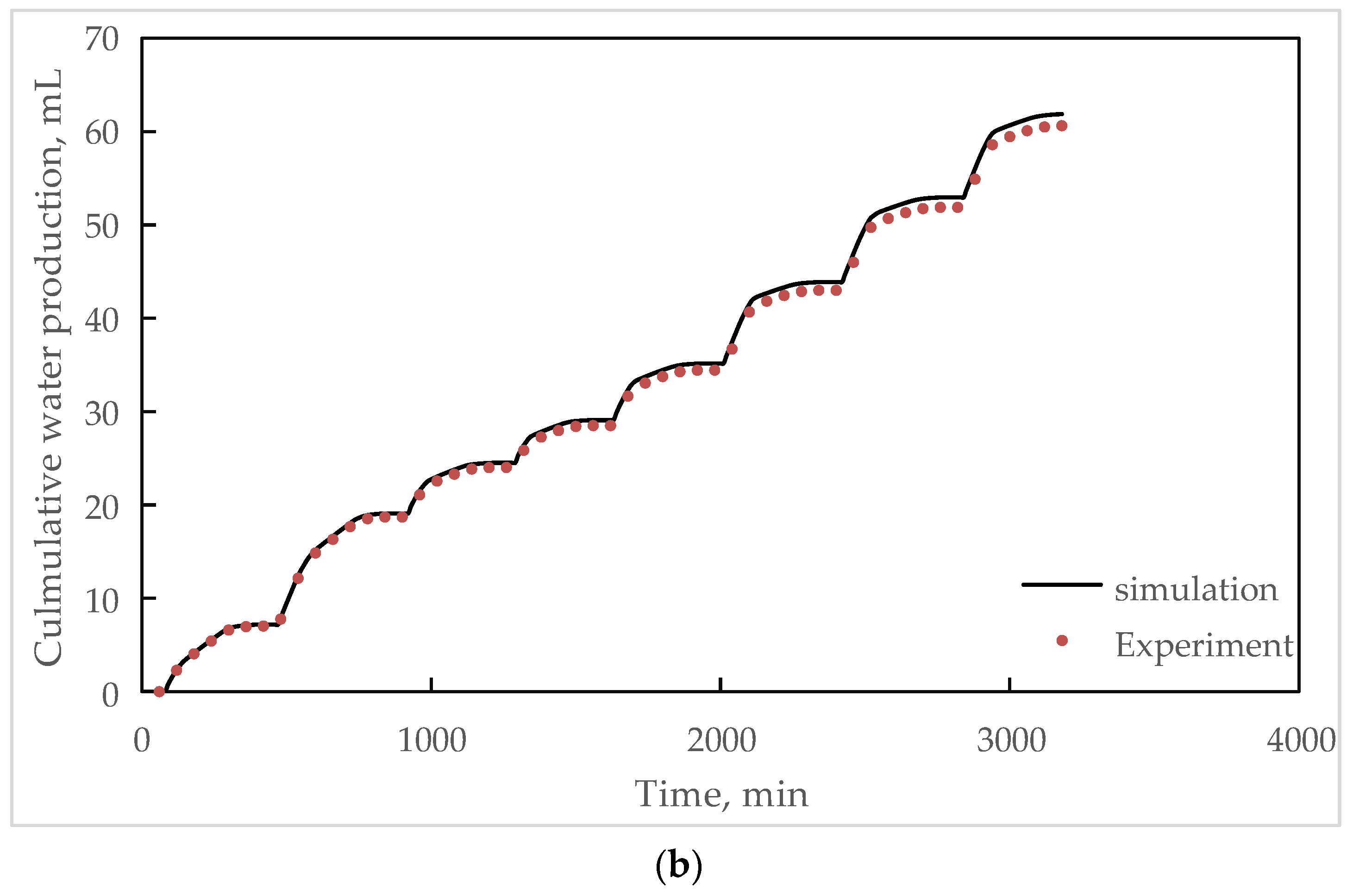

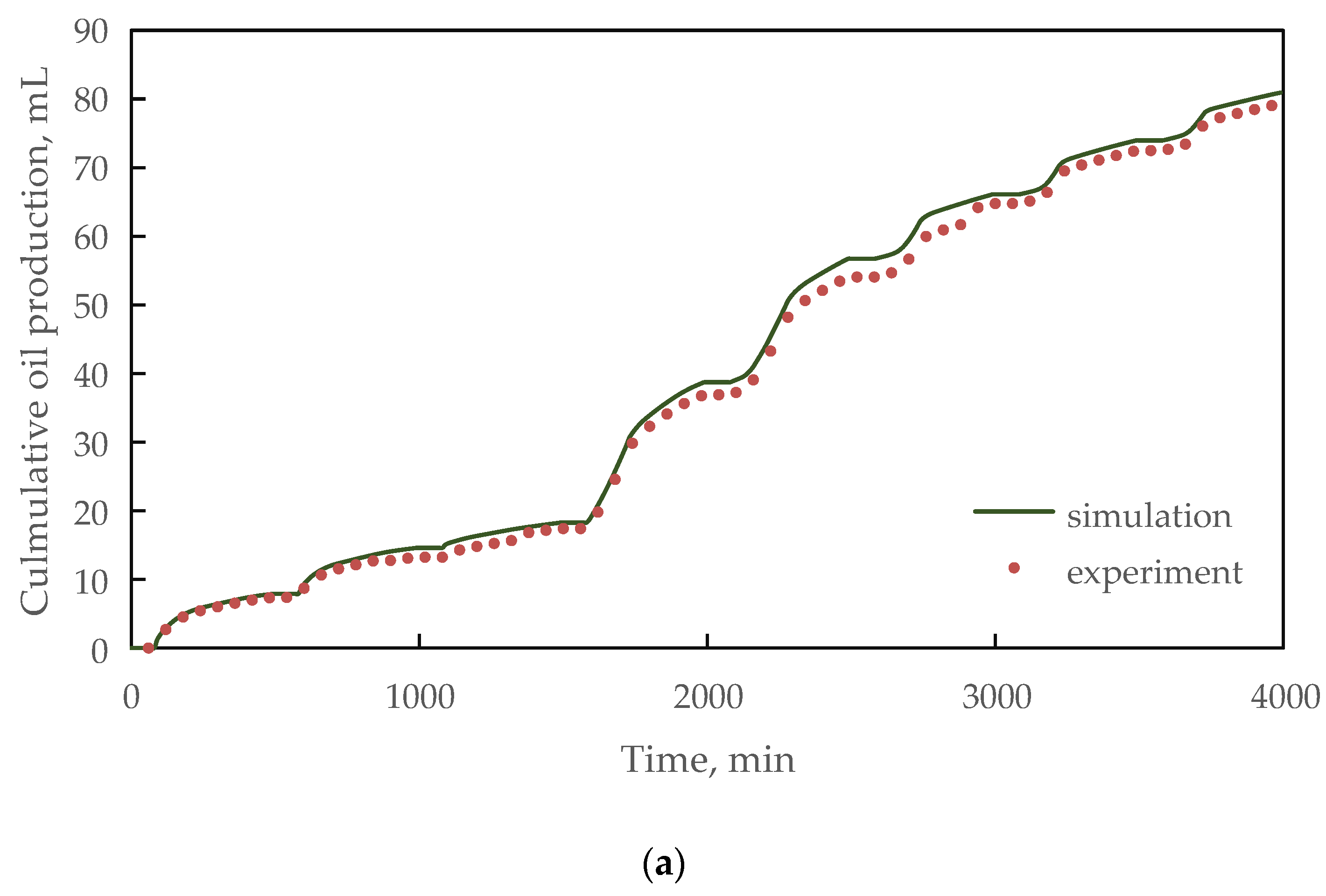

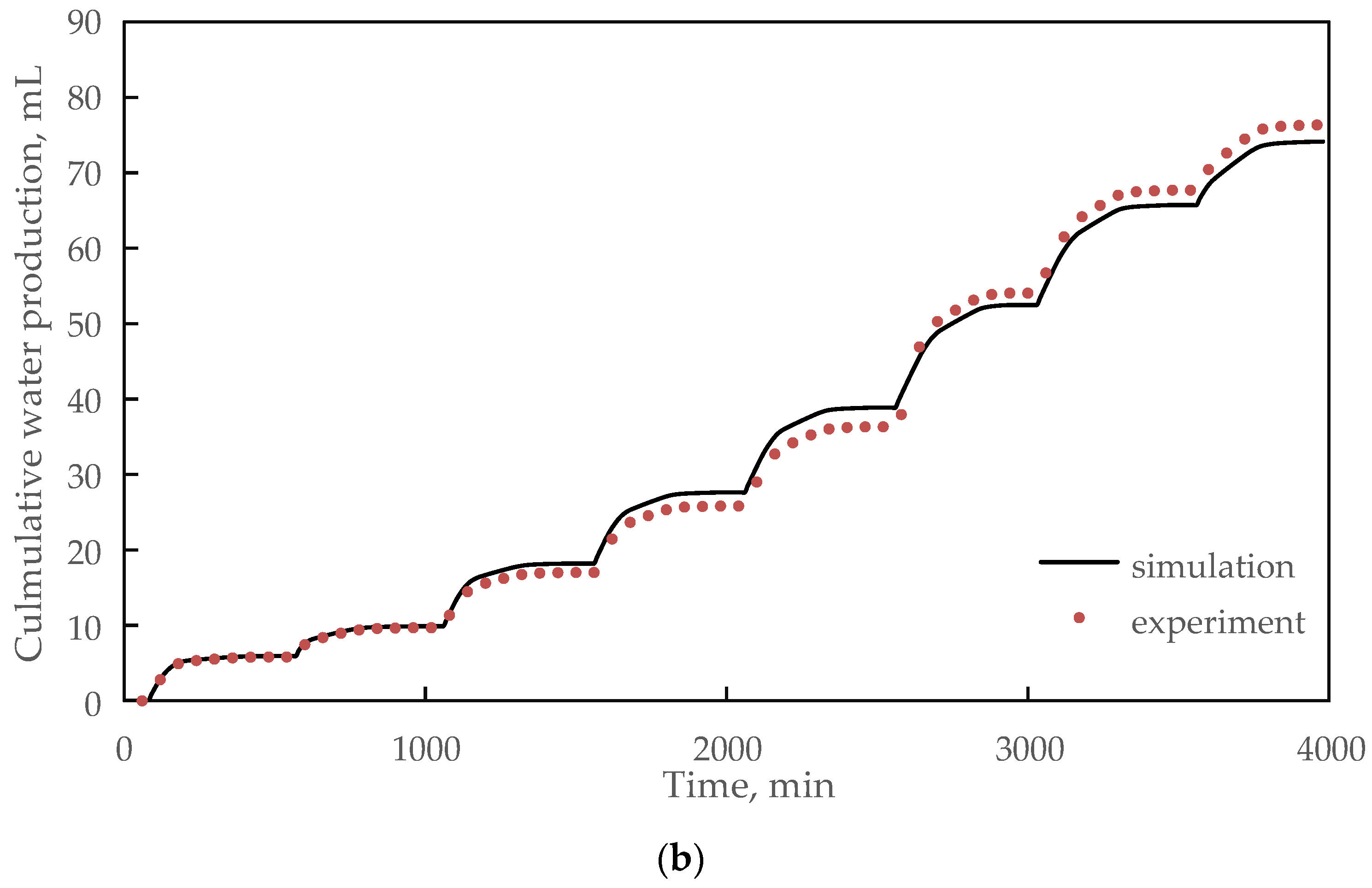

3.1.2. History Matching

3.2. Development Mode Optimization

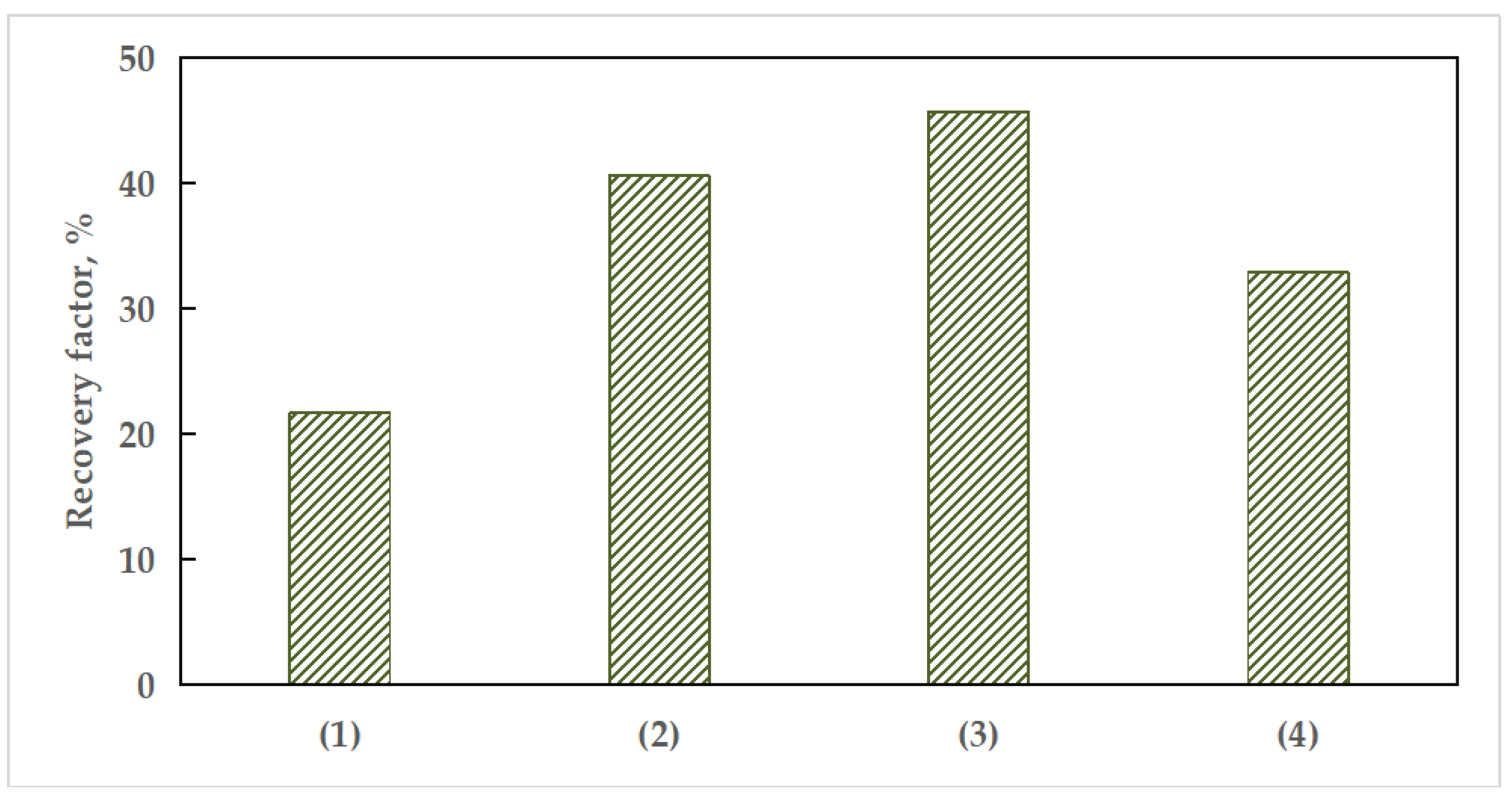

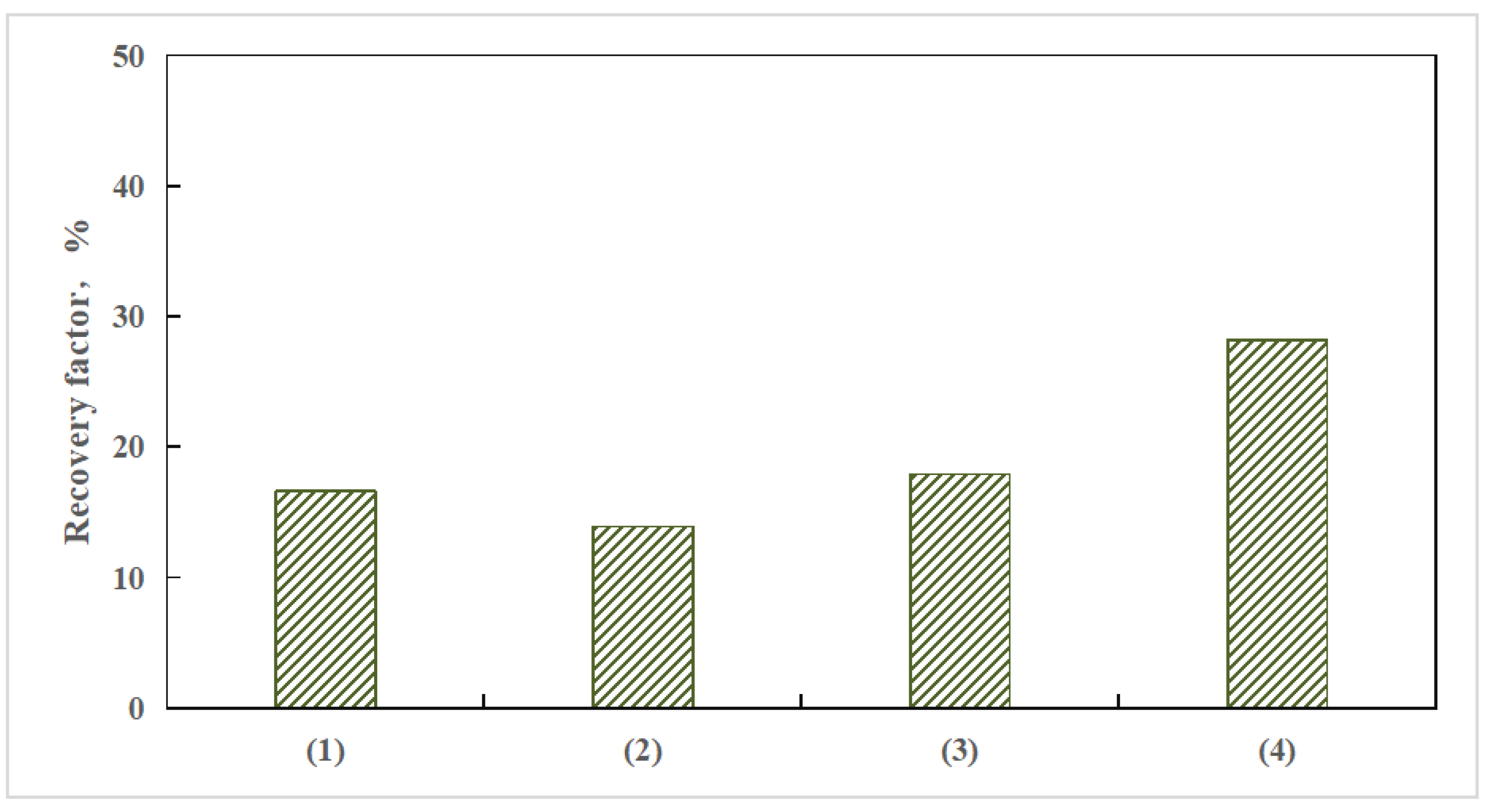

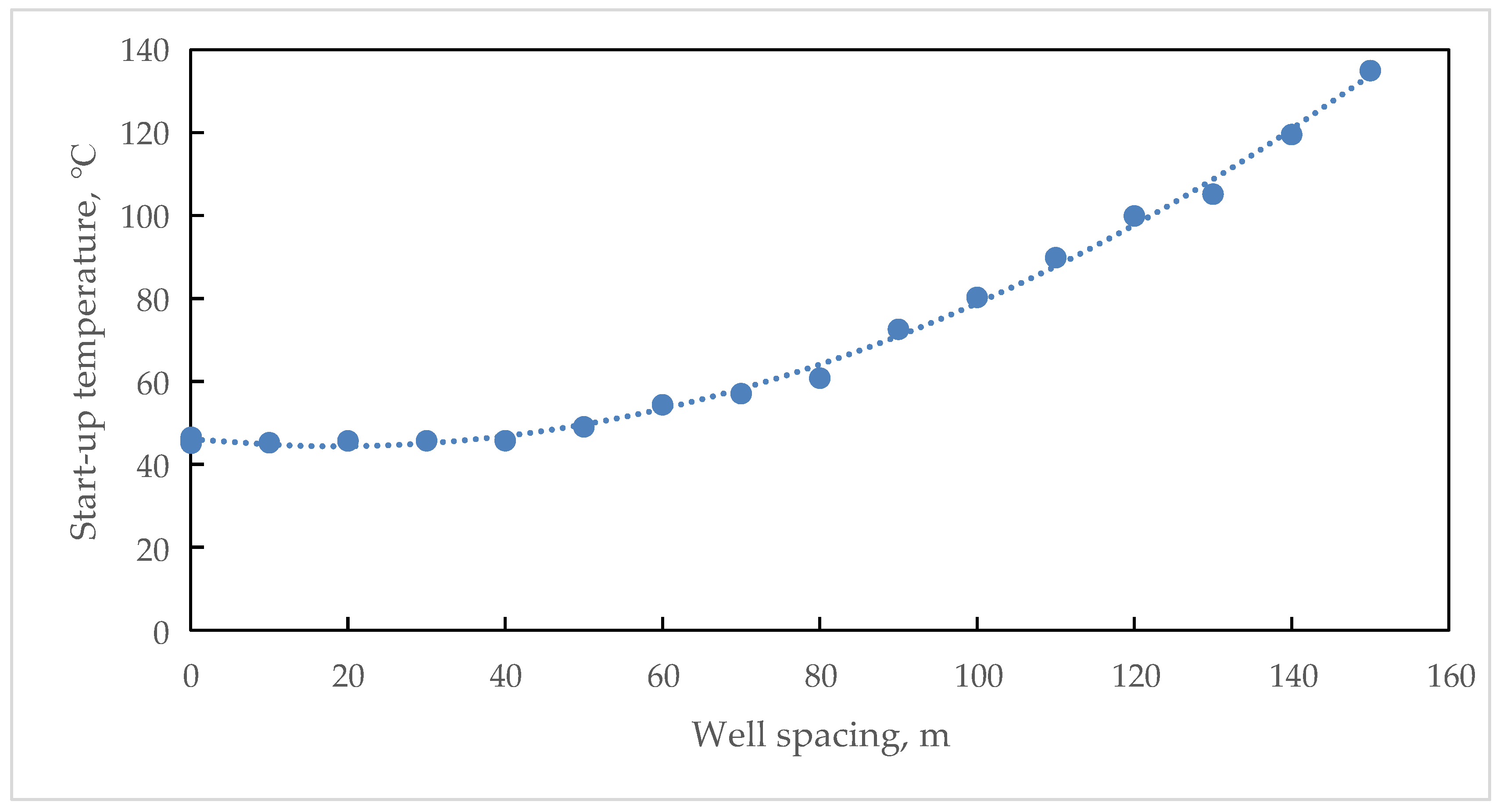

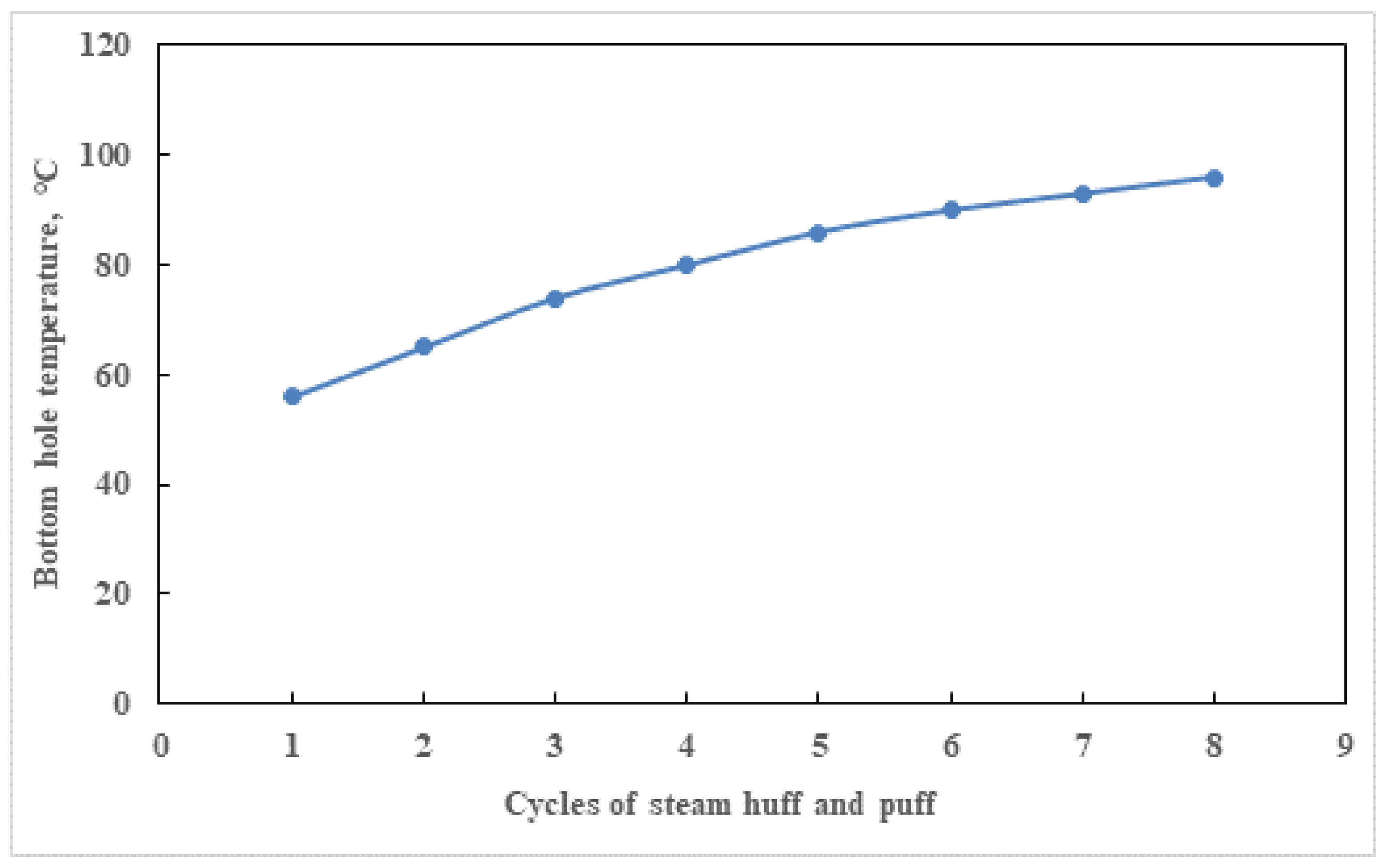

3.2.1. Single Sand Body Reservoir

3.2.2. Layered Reservoir

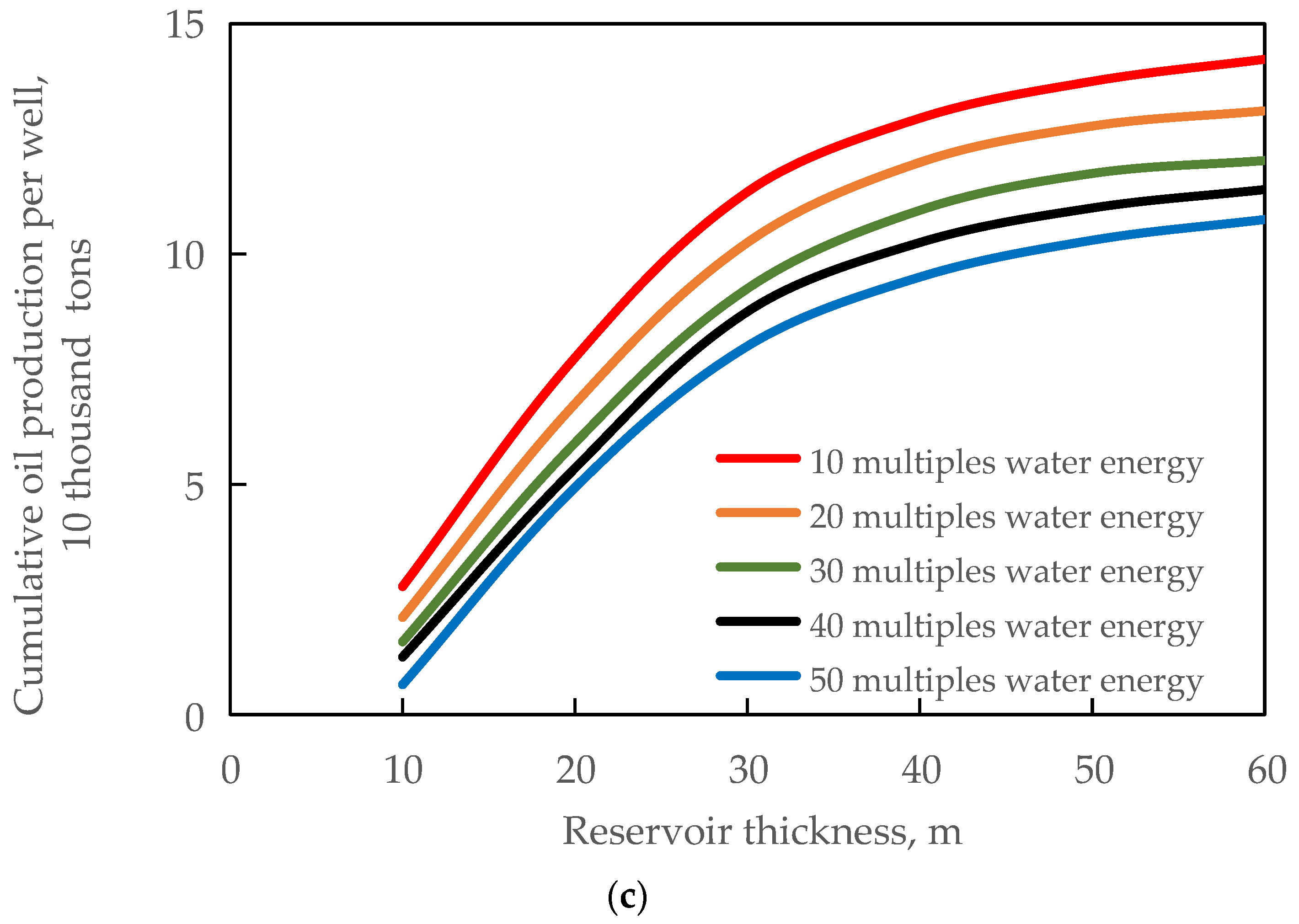

3.2.3. Thick Layer of Super Heavy Oil Reservoir

3.3. Sensitivity Analysis

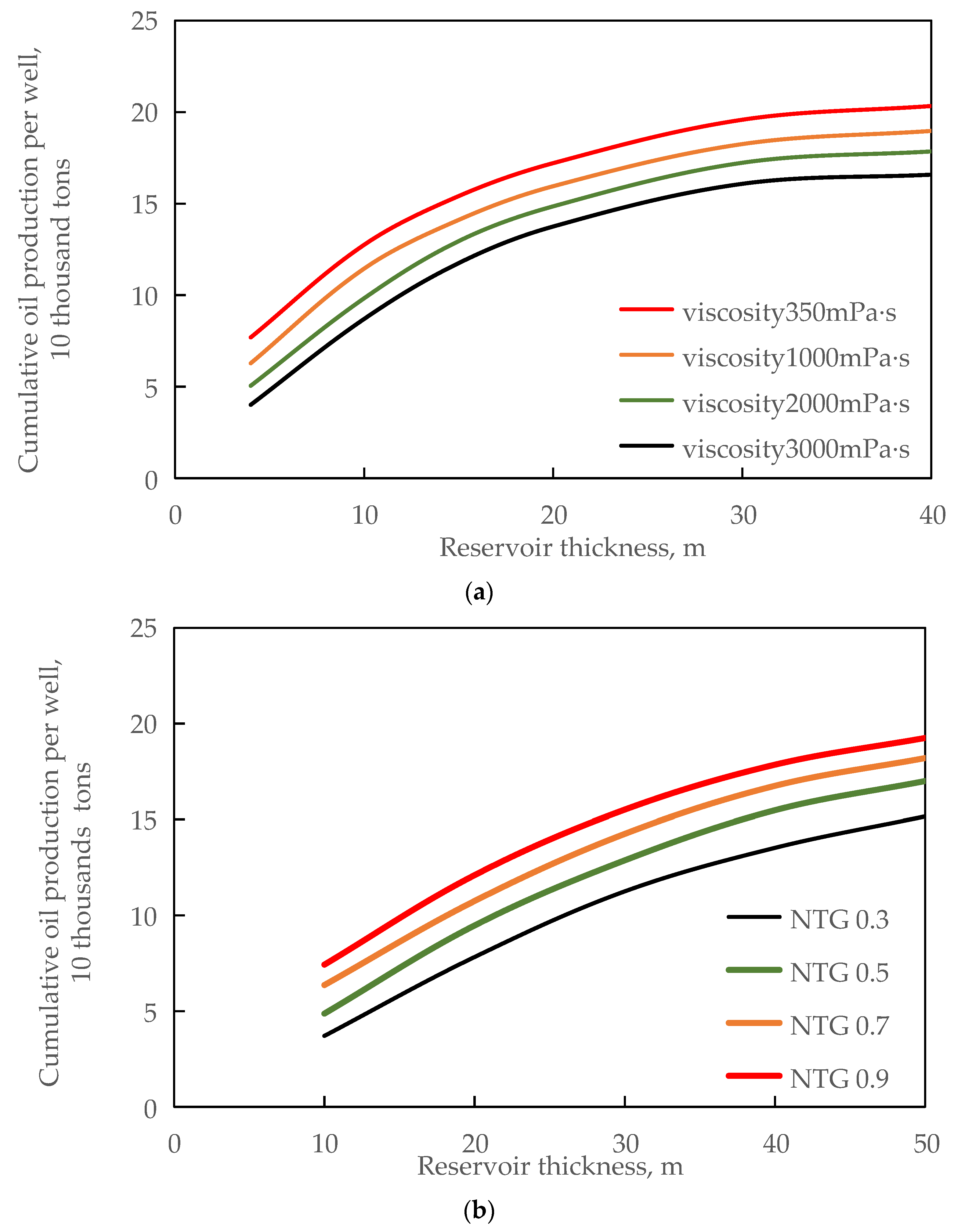

3.4. Establishment of Cumulative Oil Production per Well

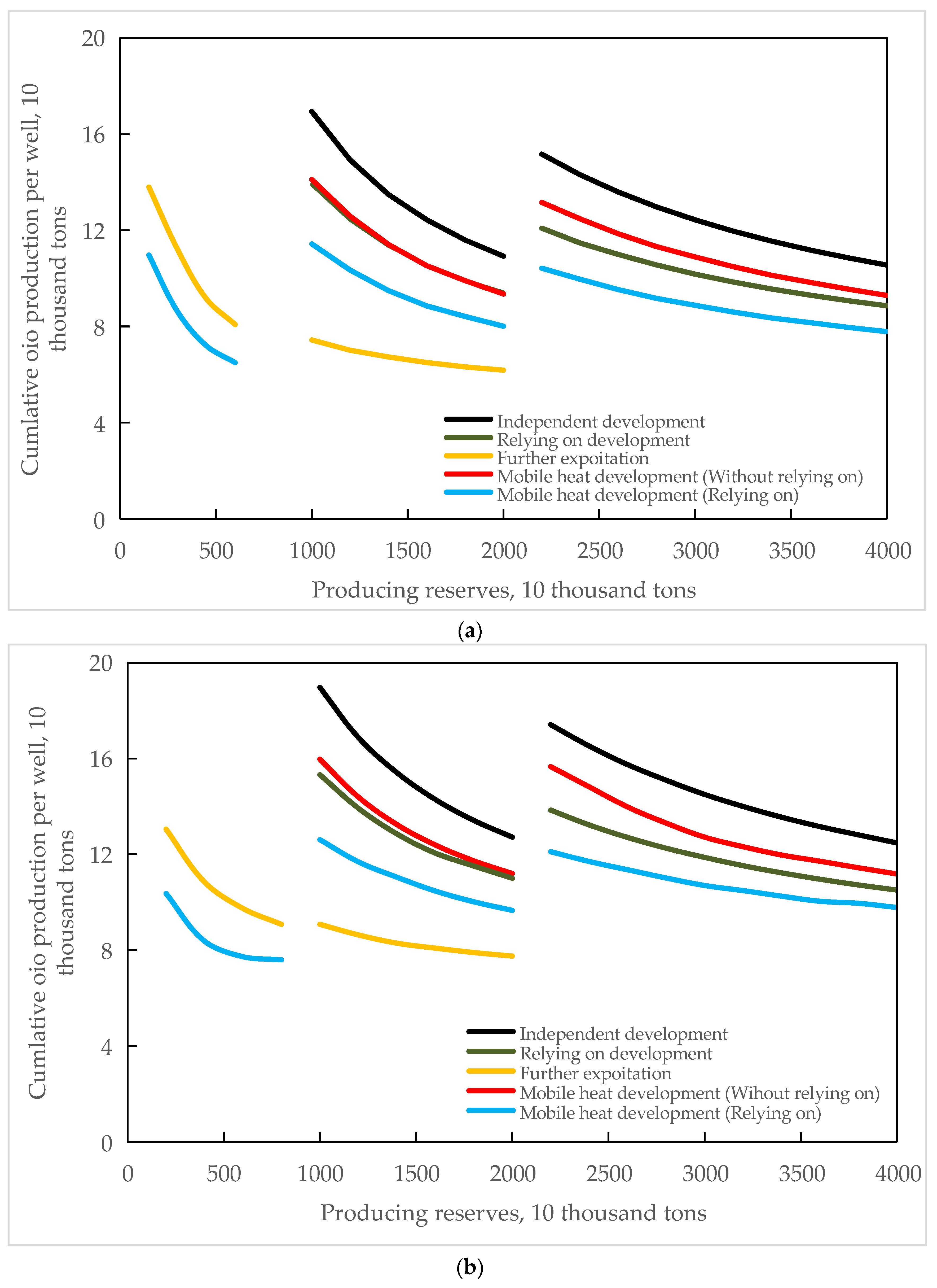

4. Economic Evaluation

4.1. Method of Economic Evaluation

4.2. Basic Mode of Evaluation

4.3. Application Boundary Study

5. Discussion and Application

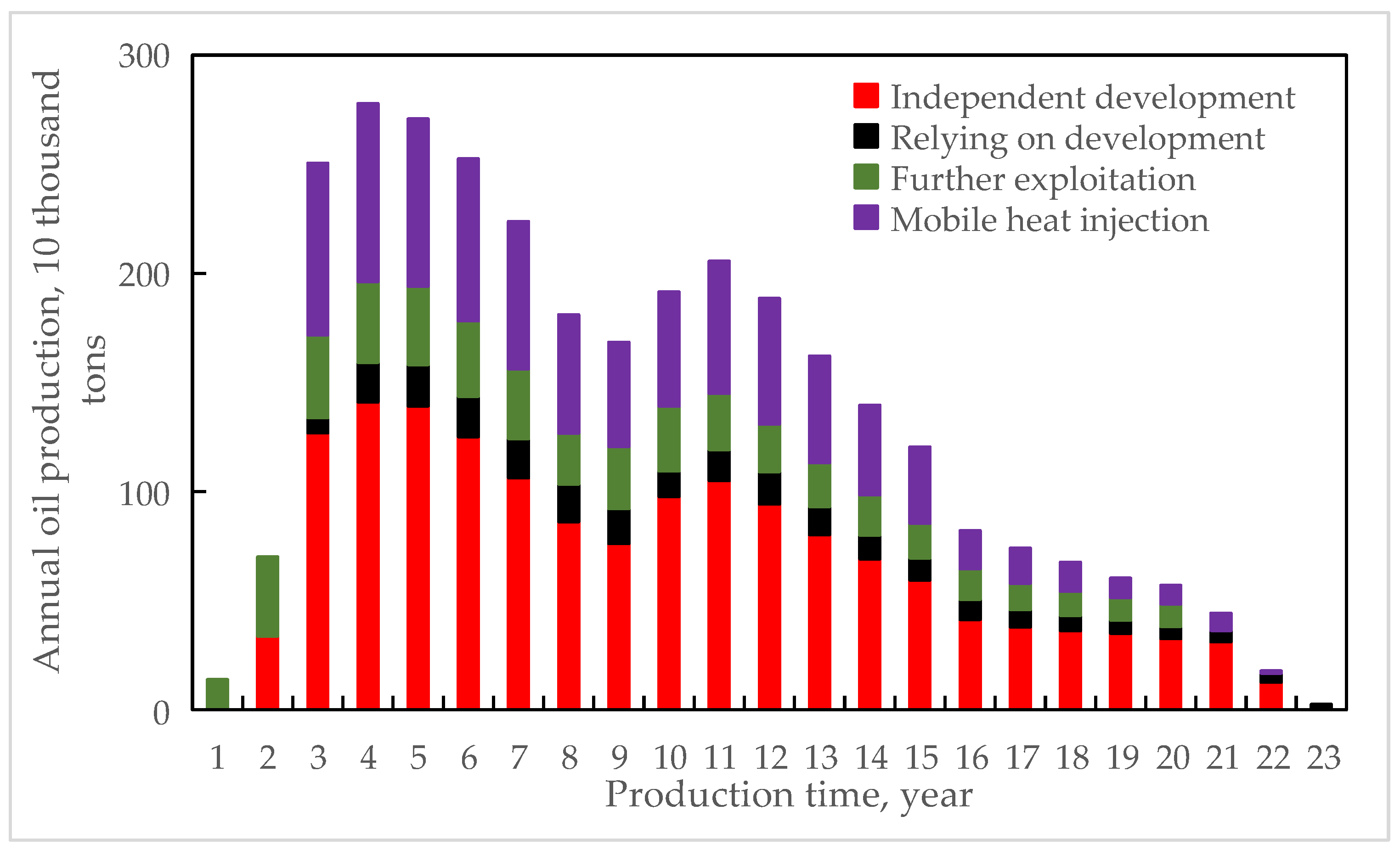

Development Strategy of Proved Reserves

- (1)

- Combined with the reservoir type and main control factor parameters of proved heavy oil reserves, the cumulative oil production per well can be predicted using the chart of cumulative oil production per well in Figure 12.

- (2)

- Combined with the development status and offshore development environment around the proved reserves, we can determine the engineering mode that can be adopted in the sea area where the heavy oil reserve is located.

- (3)

- According to the predicted oil production and the selected engineering mode, the economic production limit under the optimal engineering mode can be inversely deduced by using the economic limit chart in Figure 13. If the economic oil production limit is not higher than the predicted cumulative oil production per well, the oilfield can realize economic development. On the contrary, it is difficult to realize economic development.

6. Conclusions

- (1)

- Based on the laboratory physical simulation experimental method, the potential of superheated steam development in offshore reservoirs was identified. The numerical simulation equations for heavy oil steam injection development were established, and the matching error of the experimental results was under 10%.

- (2)

- From the numerical simulation comparison, superheated steam flooding after superheated steam huff and puff in single sand body reservoir and layered reservoir, and sidetrack after superheated steam huff and puff in extra and super heavy oil reservoirs were identified as the optimum development modes. The main factors influencing cumulative oil production of steam injection development in different reservoir types were screened by the numerical simulation method and grey correlation method, and prediction charts of cumulative oil production per well were established.

- (3)

- According to the discussion of reserve classification, the economic oil production limit charts for a single well of the different engineering models by the offshore economic evaluation method were established. Compared with other engineering modes, further exploitation and mobile heat injection were lower. At the end of the paper, the economic development mode of proved heavy oil reserves was planned. A total of 18 oilfields or blocks can achieve economic development in different modes, with a cumulative developed reserves of 259 million tons and a peak capacity of 2.78 million tons, which provides a decision for the construction of steam injection capacity of the Bohai heavy oil fields.

- (4)

- Under the current development strategy and engineering modes of offshore heavy oil, it is still difficult to achieve economic development for more than half of the heavy oil reserves. In order to reduce the threshold of economic development, offshore heavy oil should improve quality and efficiency in terms of development mode, cost reduction of drilling and production engineering, and optimization of thermal recovery processes.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, H. Thermal Recovery Principle and Method; Petroleum Industry Press: Beijing, China, 2013. [Google Scholar]

- Li, X.; Zhang, F.; Liu, G. Review on new heavy oil viscosity reduction technologies. IOP Conf. Ser. Earth Environ. Sci. 2022, 983, 012059. [Google Scholar] [CrossRef]

- Hong, K.C. Steamflood, Reservoir Management Thermal Enhanced Oil Recovery; Petroleum Industry Press: Beijing, China, 1996. [Google Scholar]

- Zhang, F.; Jiang, Y.; Liu, P. Laboratory Experimental Study on Polymer Flooding in High-Temperature and High-Salinity Heavy Oil Reservoir. Appl. Sci. 2022, 12, 11872. [Google Scholar] [CrossRef]

- Wang, T.; Yang, R.; Zhang, L.; Zheng, W.; Sun, Y.; Bai, Y. Experimental Measurements and Numerical Simulation of H2S Generation during Cyclic Steam Stimulation Process of Offshore Heavy Oil from Bohai Bay, China. Appl. Sci. 2022, 12, 7488. [Google Scholar] [CrossRef]

- Zhou, Z.; Wen, Z.; Yang, W.; Chen, Y.; Zhu, Q. Experimental research on recovery improved by polymer flooding after low salinity water flooding. Fault Block Oil Gas Field 2019, 26, 771–774. [Google Scholar]

- Pan, G.; Wu, J.; Zhang, C.; Li, H.; Liu, D. Oil Enhancement Analysis of Weak-Gel-Assisted Soak in Offshore Heavy Oil Reservoir. Spec. Oil Gas Reserv. 2017, 24, 134–138. [Google Scholar]

- Cheng, D. Recovery Countermeasures and Potential Indicators of Horizontal Well in Commination Well Pattern. Spec. Oil Gas Reserv. 2019, 26, 88–92. [Google Scholar]

- Jiang, Q.; You, H.; Pan, J.; Wang, Z.; Ge, P.; Ian, G.; Liu, J. Preliminary Discussion on Current Status and Development Direction of Heavy Oil Recovery Technologies. Spec. Oil Gas Reserv. 2020, 27, 30–38. [Google Scholar]

- Liu, Y.; Wang, L.; Shang, Y. Eor in Middle East: Current, Potential and Future Development Trend. Pet. Geol. Oilfield Dev. Daqing 2018, 37, 113–117. [Google Scholar]

- Xie, X.; Feng, G.; Liu, L.; Li, Y.; Yi, R. Study on Enhanced Oil Recovery Technology after Polymer Flooding in Offshore Oilfield. Pet. Geol. Recovery Effic. 2015, 22, 93–97. [Google Scholar]

- Tan, X.; Zheng, W.; Wang, T.; Zhu, G.; Sun, X.; Li, X. The Supercritical Multithermal Fluid Flooding Investigation: Experiments and Numerical Simulation for Deep Offshore Heavy Oil Reservoirs. Geofluids 2021, 15, 35–45. [Google Scholar] [CrossRef]

- Tian, J. Design Method and Application of Thermal Recovery in Offshore Heavy Oil; China Petrochemical Press: Beijing, China, 2019. [Google Scholar]

- Dong, X.; Jiang, X.; Zheng, W.; Liu, H.; Liu, R.; Wang, W.; Zeng, D.; Wang, T. Discussion on the Sweep Efficiency of Hybrid Steam-Chemical Process in Heavy Oil Reservoirs: An Experimental Study. Pet. Sci. 2022, 6, 18. [Google Scholar] [CrossRef]

- Carpenter, C. Offshore Heavy Oil Polymer Flooding Pilot Reveals Alternative Paths. Pet. Sci. 2009, 6, 194–200. [Google Scholar]

- Bai, J.; Liu, Y.; Wang, T.; Jiang, Z.; Ma, Z.; Zhao, Y.; Zhen, B. Research on Injection-Production Integrated Technology for Offshore Concentric-Tube Jet Pump. China Offshore Oil Gas 2021, 33, 148–155. [Google Scholar]

- Jia, L.; Han, Y.; Chen, Y.; Chen, B.; Xu, T. Failure Mechanism and Integrity of Sand Control Screen in Heavy Oil Thermal Production Well. Equip. Environ. Eng. 2021, 18, 77–82. [Google Scholar]

- Liu, X.; Tian, J.; Li, N.; Wang, L.; Cai, L. Study on Economic Boundaries of Offshore Heavy Oil Thermal Recovery Development. Spec. Oil Gas Reserv. 2016, 23, 106–109. [Google Scholar]

- Hyne, J.B.; Clark, P.D.; Clarke, R.A. Aquathermolysis of Heavy Oil. In Proceedings of the 2nd International Conference on Heavy Crudes and Tar Sands, Caracas, Venezuela, 7 February 1982. [Google Scholar]

- Jia, N.; Zhao, H.; Yang, T.; Ibatullin, T.; Gao, J. Experimental measurements of bitumen–water aquathermolysis during a steam-injection process. Energy Fuels 2016, 30, 5291–5299. [Google Scholar] [CrossRef]

- Ilyushin, Y.V.; Fetisov, V. Experience of virtual commissioning of a process control system for the production of high-paraffin oil. Sci. Rep. 2022, 12, 18415. [Google Scholar] [CrossRef]

- Sitnov, S.; Mukhamatdinov, I.; Aliev, F.; Khelkhal, M.A.; Slavkina, O.; Bugaev, K. Heavy oil aquathermolysis in the presence of rock-forming minerals and iron oxide (II, III) nanoparticles. Pet. Sci. Technol. 2020, 38, 574–579. [Google Scholar] [CrossRef]

- Zheng, W.; Fan, T.G.; Tan, X.H.; Jiang, W.D.; Wang, T.C.; Xie, H.J. Numerical simulations of chemical-assisted steam flooding in offshore heavy Oil reservoirs after water flooding. Geofluids 2021, 2021, 8794022. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, H.; Sun, X.; Duan, X.; Hu, W.; Zhang, X. Optimization of thermal recovery strategies for offshore heavy oil reservoirs in Bohai Bay, China. Pet. Sci. Technol. 2016, 34, 139–144. [Google Scholar] [CrossRef]

- Zhao, H.; Ge, M.; Zhang, H. Research an Application of Steam Flooding Technical Limit for Heavy Oil in Liaoe Oilfield. Spec. Oil Gas Reserv. 2022, 29, 98–103. [Google Scholar]

- Yin, X. Countermeasures to Improve the Quality and Efficiency of Heavy Oil Steam Huff and Puff Development in Shengli Oilfield. Pet. Geol. Eng. 2018, 32, 98–100. [Google Scholar]

- Cui, X. Application of Grey Related Degree Analysis in the Breeding of Mung Bean. Rain Fed. Crop. 2005, 25, 238–239. [Google Scholar]

- Tian, M.; Liu, S.; Bu, Z. Summary of Research on Grey Relational Degree Algorithmic Model. Stat. Decis. 2008, 24, 24–27. [Google Scholar]

- Feng, Q.; Chen, C.; Yang, G. Determination of inter-well Connectivity in Cha 15 Oilfield using Injection-production Data. Spec. Oil Gas Reserv. 2014, 21, 87–89. [Google Scholar]

- Li, X.; Tan, Y. Discussion on Development Engineering Modes for Offshore Oil and Gas Field. Pet. Eng. Constr. 2015, 41, 1–4. [Google Scholar]

- Huang, X.; Zhang, B. Basic Mode of the Marine Engineering System of Beach Oil field Development. Pet. Plan. Eng. 2011, 22, 1–6. [Google Scholar]

- Qin, W. Economic Evaluation Method of Oilfield and Gas Field Adjustment and Reconstruction Project. Nat. Gas Ind. 2007, 27, 363–364. [Google Scholar]

- Tan, Y. Economic Analysis of Offshore Oilfield Development Engineering Mode. Mod. Econ. Inf. 2015, 30, 426–430. [Google Scholar]

- Guo, T.; Su, Y. Current Status and Technical Development Direction in Heavy Oil Reservoir Development in Bohai Oilfields. China Offshore Oil Gas 2013, 25, 26–30. [Google Scholar]

- Ilyushin, Y.V. Development of a process control system for the production of high-paraffin oil. Energies 2022, 15, 6462. [Google Scholar] [CrossRef]

- Li, Q.; Wang, F.; Wang, Y.; Bai, B.; Zhang, J.; Lili, C.; Sun, Q.; Wang, Y.; Forson, K. Adsorption behavior and mechanism analysis of siloxane thickener for CO2 fracturing fluid on shallow shale oil. J. Mol. Liguids 2023, 376, 121394. [Google Scholar] [CrossRef]

- Dong, X.; Liu, H.; Chen, Z.; Wu, K.; Lu, N.; Zhang, Q. Enhanced oil recovery techniques for heavy oil and oilsands reservoirs after steam injection. Appl. Energy 2019, 239, 1190–1211. [Google Scholar] [CrossRef]

- Li, Q.; Han, Y.; Liu, X.; Ansari, U.; Cheng, Y.; Yan, C. Hydrate as a by-product in CO2 leakage during the long-term sub-seabed sequestration and its role in preventing further leakage. Environ. Sci. Pollut. Res. 2022, 29, 77737–77754. [Google Scholar] [CrossRef]

| Oil Sample | Type of Oil Sample | Oil Viscosity at 50 °C, mPa·s | Porosity, % | Permeability, mD | Oil Saturation, % | Initial Pressure, MPa |

|---|---|---|---|---|---|---|

| JZ23-2 | Common heavy oil | 350 | 29.0 | 668 | 68.1 | 11.1 |

| LD21-2 | Common heavy oil | 2980 | 32.1 | 2480 | 68.0 | 15.1 |

| LD5-2N | Super heavy oil | 50,154 | 35.0 | 2894 | 75.2 | 12.0 |

| Injection Medium | Experimental Method | Residual Oil Saturation, % | Recovery Factor, % |

|---|---|---|---|

| atmospheric temperature water (25 °C) | Huff and puff for 8 cycles | 33.2 | 21.2 |

| hot water (120 °C) | 23.0 | 33.2 | |

| saturated hot water (250 °C) | 14.4 | 43.4 | |

| saturated steam (250 °C) | 8.4 | 52.6 | |

| superheated steam (300 °C) | 6.8 | 58.5 |

| Injection Medium | Experimental Method | Residual Oil Saturation, % | Recovery Factor, % |

|---|---|---|---|

| atmospheric temperature water (25 °C) | Huff and puff for 8 cycles | 39.3 | 18.5 |

| hot water (120 °C) | 25.4 | 27.3 | |

| saturated hot water (250 °C) | 16.4 | 38.4 | |

| saturated steam (250 °C) | 11.5 | 42.0 | |

| superheated steam (300 °C) | 7.1 | 51.8 |

| Injection Medium | Experimental Method | Residual Oil Saturation, % | Recovery Factor, % |

|---|---|---|---|

| atmospheric temperature water (25 °C) | Huff and puff for 8 cycles | 57.5 | 3.3 |

| hot water (120 °C) | 46.5 | 9.9 | |

| saturated hot water (250 °C) | 27.9 | 16.9 | |

| saturated steam (250 °C) | 19.9 | 21.5 | |

| superheated steam (300 °C) | 13.8 | 29.9 |

| Oilfield | JZ23-2 | LD21-2 | LD5-2N |

|---|---|---|---|

| Grid size (X·Y·Z), m | 20 × 23 × 1 | 15 × 18 × 1 | 20 × 21 × 1 |

| Number of grid (X·Y·Z), number | 112 × 253 × 48 | 162 × 42 × 52 | 202 × 139 × 55 |

| Designed number of wells, number | 56 | 16 | 28 |

| Reservoir types | Layered reservoir | Single sand body reservoir | Thick layer of super heavy oil reservoir |

| Well types | Directional well | Horizontal well | Horizontal well |

| Reservoir thickness, m | 38 | 20 | 40 |

| Depth of burial, m | 998 | 1396 | 897 |

| Reserve volume, 104 m3 | 2824 | 1025 | 2801 |

| Designed well spacing, m | 200~220 | 180~200 | 125~150 |

| Comparison scheme | Superheated steam huff and puff for 16 cycles (1), switching to superheated steam flooding after superheated steam huff and puff for 4 cycles (2), switching to superheated steam flooding after superheated steam huff and puff for 8 cycles (3), sidetracking after superheated steam huff and puff for 8 cycles (4). Corresponding to the coordinate axis in the following figures. | ||

| Reservoir Types | Reference Pressure, MPa | Reservoir Thickness, m | Oil Saturation | Oil Viscosity, mPa·s | Permeability, mD | Water Energy (times) | Net-to-Gross Ratio (NTG) |

|---|---|---|---|---|---|---|---|

| Single sand body reservoir | 6.5~16.0 | 4~40 | 0.5~0.68 | 350~3000 | 300~5000 | 0.1~7 | |

| Layered reservoir | 6.5~16.0 | 10~50 | 0.5~0.68 | 350~5000 | 300~3000 | 0.1~10 | 0.3~0.9 |

| Thick layer of extra and super heavy oil reservoir | 6.5~14.0 | 20~60 | 0.5~0.9 | 10,000~50,000 | 2000~5000 | 10~50 |

| Reservoir Types | Reservoir Pressure MPa | Reservoir Thickness m | Oil Saturation | Oil Viscosity mPa·s | Permeability mD | Water Energy | NTG | Cumulative Oil Production 10 Thousand Tons |

|---|---|---|---|---|---|---|---|---|

| Single sand body reservoir | 6.5 | 4 | 0.50 | 350 | 300 | 0.1 | 7.7 | |

| 8 | 8 | 0.54 | 500 | 1000 | 1.0 | 10.2 | ||

| 10 | 10 | 0.57 | 750 | 2000 | 2.0 | 12.9 | ||

| 12 | 20 | 0.61 | 1000 | 3000 | 3.0 | 16.0 | ||

| 14 | 30 | 0.64 | 2000 | 4000 | 5.0 | 17.2 | ||

| 16 | 40 | 0.68 | 3000 | 5000 | 7.0 | 19.5 | ||

| Layered reservoir | 6.5 | 4 | 0.50 | 350 | 300 | 0.1 | 0.3 | 5.0 |

| 8 | 8 | 0.54 | 750 | 1000 | 1.0 | 0.5 | 5.2 | |

| 10 | 10 | 0.57 | 1000 | 1500 | 2.0 | 0.6 | 6.0 | |

| 12 | 20 | 0.61 | 2000 | 2000 | 3.0 | 0.7 | 10.8 | |

| 14 | 30 | 0.64 | 3000 | 2500 | 5.0 | 0.8 | 15.2 | |

| 16 | 40 | 0.68 | 5000 | 3000 | 10.0 | 0.9 | 17.9 | |

| Thick layer of extra and super heavy oil reservoir | 6.5 | 20 | 0.50 | 10,000 | 2000 | 10.0 | 7.8 | |

| 8 | 30 | 0.60 | 20,000 | 3000 | 20.0 | 10.3 | ||

| 10 | 40 | 0.70 | 30,000 | 4000 | 30.0 | 11.0 | ||

| 12 | 50 | 0.80 | 40,000 | 5000 | 40.0 | 11.0 | ||

| 14 | 60 | 0.90 | 50,000 | 6000 | 50.0 | 10.8 |

| Reservoir Types | Reservoir Pressure f | Reservoir Thickness f | Oil Saturation f | Oil Viscosity f | Permeability f | Water Energy f | NTG f | Cumulative Oil Production f |

|---|---|---|---|---|---|---|---|---|

| Single sand body reservoir | 0.59 | 0.21 | 0.85 | 0.28 | 0.12 | 0.03 | 0.57 | |

| 0.72 | 0.43 | 0.91 | 0.39 | 0.39 | 0.33 | 0.76 | ||

| 0.90 | 0.54 | 0.97 | 0.59 | 0.78 | 0.66 | 0.96 | ||

| 1.08 | 1.07 | 1.03 | 0.79 | 1.18 | 0.99 | 1.19 | ||

| 1.26 | 1.61 | 1.09 | 1.58 | 1.57 | 1.66 | 1.28 | ||

| 1.44 | 2.14 | 1.15 | 2.37 | 1.96 | 2.32 | 1.24 | ||

| Layered reservoir | 0.59 | 0.21 | 0.85 | 0.17 | 0.17 | 0.03 | 0.50 | 0.47 |

| 0.72 | 0.43 | 0.91 | 0.37 | 0.58 | 0.28 | 0.52 | 0.79 | |

| 0.90 | 0.54 | 0.97 | 0.50 | 0.87 | 0.57 | 0.60 | 0.95 | |

| 1.08 | 1.07 | 1.03 | 0.99 | 1.17 | 0.85 | 1.07 | 1.11 | |

| 1.26 | 1.61 | 1.09 | 1.49 | 1.46 | 1.42 | 1.52 | 1.26 | |

| 1.44 | 2.14 | 1.15 | 2.48 | 1.75 | 2.84 | 1.79 | 1.42 | |

| Thick layer of extra and super heavy oil reservoir | 0.64 | 0.50 | 0.71 | 0.33 | 0.50 | 0.33 | 0.76 | |

| 0.79 | 0.75 | 0.86 | 0.67 | 0.75 | 0.67 | 1.01 | ||

| 0.99 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.08 | ||

| 1.19 | 1.25 | 1.14 | 1.33 | 1.25 | 1.33 | 1.08 | ||

| 1.39 | 1.50 | 1.29 | 1.67 | 1.50 | 1.67 | 1.06 |

| Reservoir Types | Reservoir Pressure | Reservoir Thickness | Oil Saturation | Oil Viscosity | Permeability | Water Energy | NTG |

|---|---|---|---|---|---|---|---|

| Single sand body reservoir | 0.5691 | 0.8491 | 0.7294 | 0.8494 | 0.7572 | 0.7741 | |

| Layered reservoir | 0.6062 | 0.8735 | 0.7732 | 0.8503 | 0.6908 | 0.8203 | 0.8730 |

| Thick layer of extra and super heavy oil reservoir | 0.6832 | 0.8502 | 0.7897 | 0.7232 | 0.7071 | 0.8323 |

| Development Mode | Utilization Reserves (Million Tons) | Standardized Platform | Small Wellhead Platform | Center Processing Platform | Steam Injection Facilities |

|---|---|---|---|---|---|

| Independent development | >20 | Newly build | Newly build | Newly build | |

| 10~20 | Newly build | Newly build | Newly build | ||

| Relying on development | >20 | Newly build | Newly build | ||

| 10~20 | Newly build | Newly build | |||

| Further development | <10 | Newly build | |||

| Mobile heat injection | Dependent on reserve scale and supporting conditions | ||||

| Producing Reserves, 10 Thousand Tons | Development Modes | Economic Cumulative Production per Well, 10 Thousand Tons | ||||

|---|---|---|---|---|---|---|

| Independent Development | Relying on Development | Further Exploitation | Mobile Heat Injection (Without Relying on) | Mobile Heat Injection (Relying on) | ||

| 800 | Steam flooding after steam huff and puff | 8.1 | 6.5 | |||

| 2000 | 10.9 | 9.4 | 6.2 | 9.4 | 8.0 | |

| 4000 | 10.6 | 8.9 | 9.3 | 7.8 | ||

| 1000 | Sidetracking after steam huff and puff | 9.7 | 7.6 | |||

| 2000 | 12.7 | 11.2 | 7.8 | 11.0 | 9.7 | |

| 4000 | 12.5 | 10.5 | 11.2 | 9.8 | ||

| Development Mode | Producing Reserves Million Tons | Number of Oilfield Involved | Oilfield Involved |

|---|---|---|---|

| Independent development | 82 | 2 | JZ23-2, LD5-2N |

| Relying on development | 25 | 1 | KL9-6 |

| Further exploitation | 55 | 4 | LD27-2, LD16-3, etc. |

| Mobile heat injection | 97 | 11 | PL19-3, QHD33-1S, etc. |

| Difficult to realize economic development at present | 383 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Liu, F.; Li, X. Optimization of Efficient Development Modes of Offshore Heavy Oil and Development Planning of Potential Reserves in China. Water 2023, 15, 1897. https://doi.org/10.3390/w15101897

Wang T, Liu F, Li X. Optimization of Efficient Development Modes of Offshore Heavy Oil and Development Planning of Potential Reserves in China. Water. 2023; 15(10):1897. https://doi.org/10.3390/w15101897

Chicago/Turabian StyleWang, Taichao, Fengming Liu, and Xin Li. 2023. "Optimization of Efficient Development Modes of Offshore Heavy Oil and Development Planning of Potential Reserves in China" Water 15, no. 10: 1897. https://doi.org/10.3390/w15101897