Design and Investigation of an Effective Solar Still Applicable to Remote Islands

Abstract

:1. Introduction

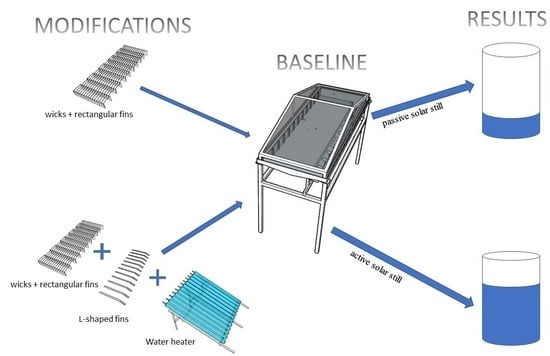

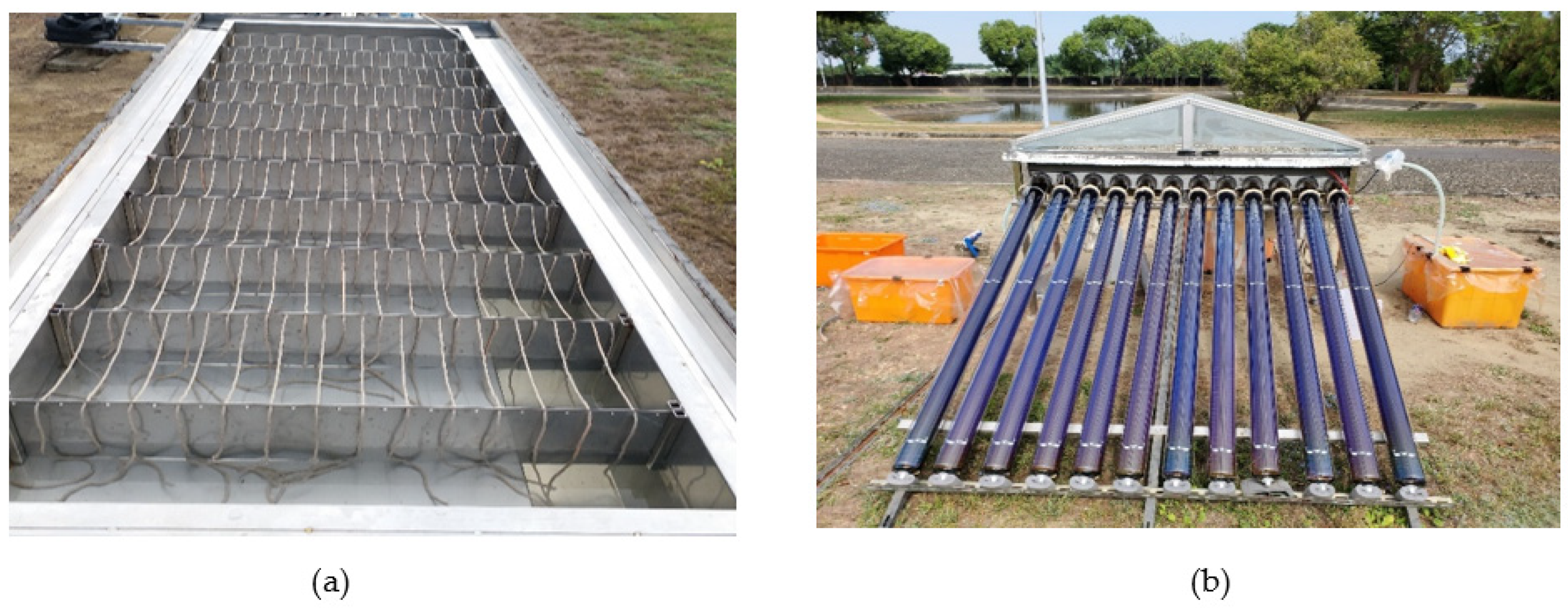

2. Solar Still Set-Up

2.1. Design and Fabrication Materials

2.2. Instrumentation

2.3. Experimental Procedure

2.4. Test Location and Solar Environment

3. Results and Discussion

3.1. Water Quality Analysis

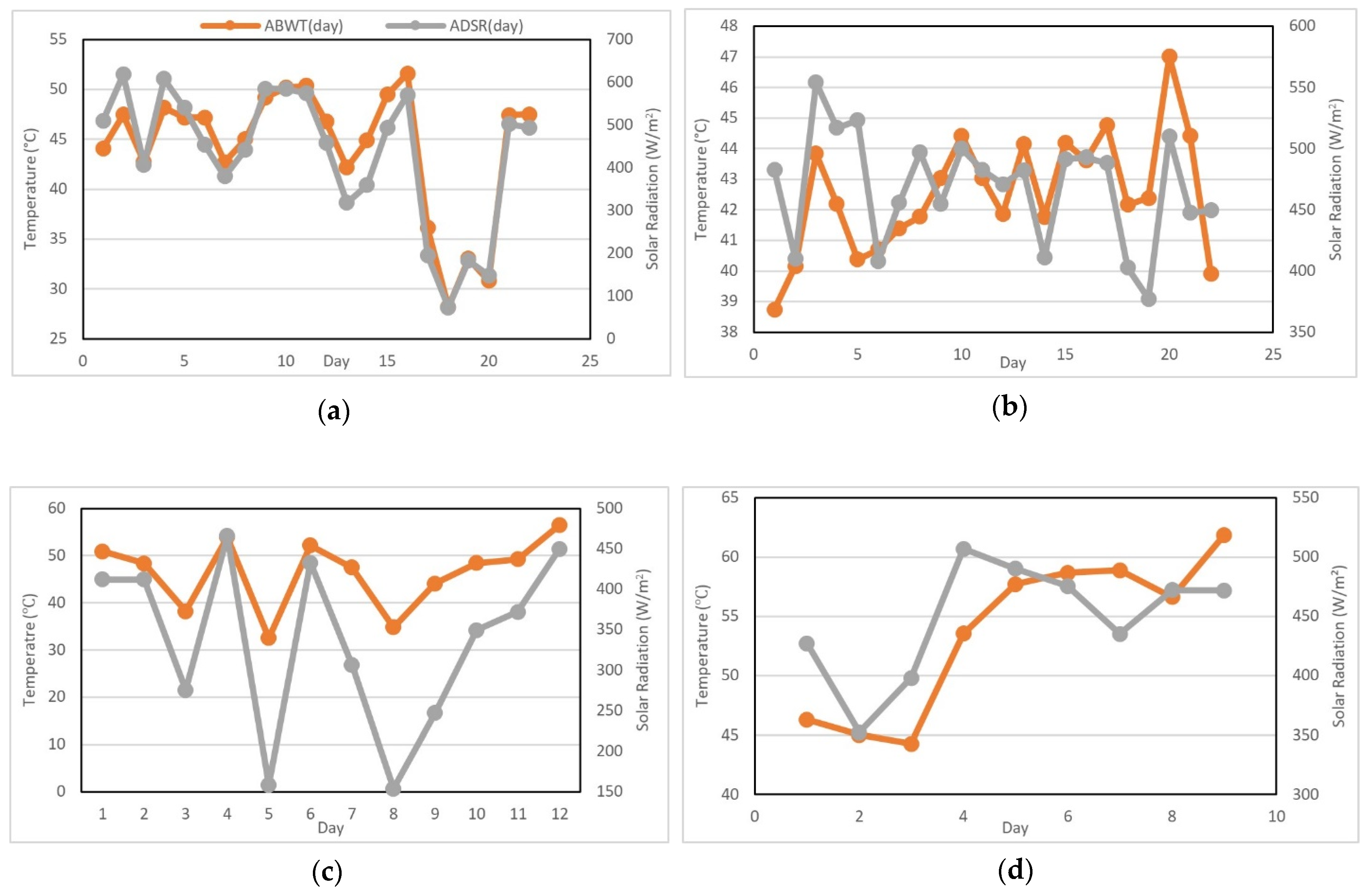

3.2. Variation in Averge Daytime Basin Water Temperature with Average Solar Irradiation

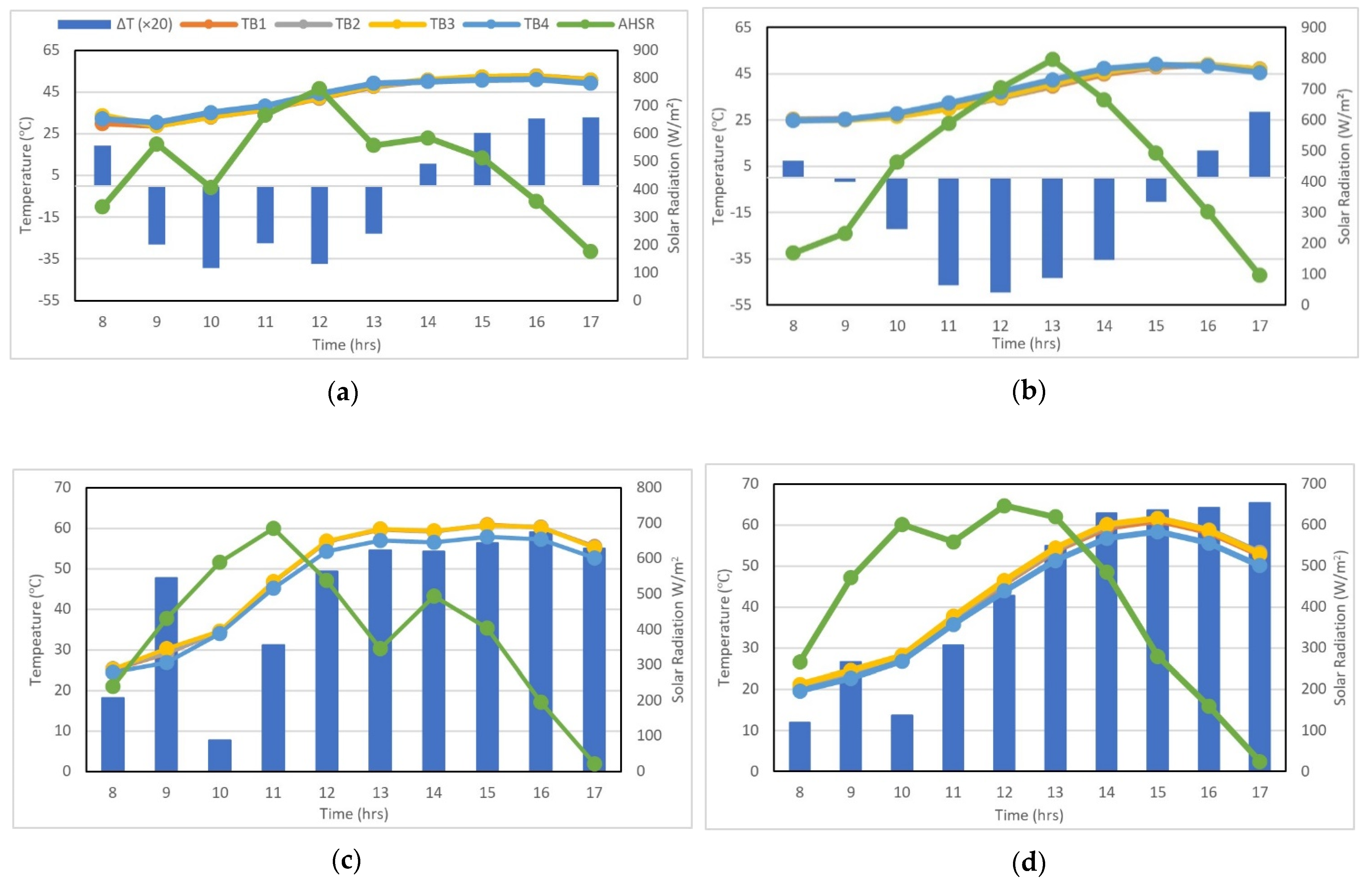

3.3. Effect of Adding Fins and Solar Water Heater on the Temperature Distribution within the Solar Stills

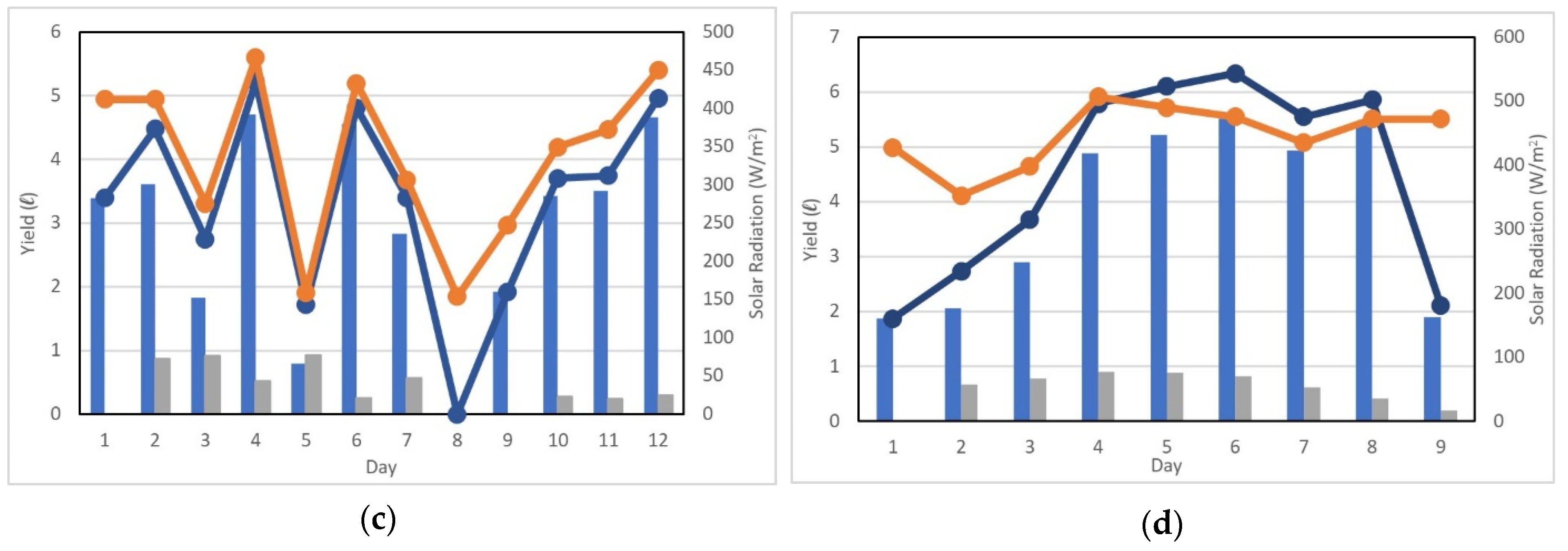

3.4. Variations in Daytime and Night-Time Yields with Avaerage Daily Solar Radiation

3.5. Productivity of the Solar Still

3.6. Estimated Cost per Liter of Distllate Peoduced by the Active (Modified) Solar Still

4. Conclusions

- The treatment of highly concentrated raw seawater using the solar still can be carried out with a large reduction in TDS and chloride concentrations, which met the WHO standard for potable water.

- The average daily productivity of the modified conventional passive solar still was reduced by 1.4% with the use of fins and wicks due to the bad solar condition in the testing period, whereas the average daytime hourly productivity increased by 28% compared to the unmodified conventional passive solar still under near equal solar radiation levels.

- The use of wicks and fins is more effective for increasing the distillate output when added to the active solar still compared to the passive solar still.

- The combined use of fins, wicks and a solar water heater increased the average daily productivity by 147% and the average daytime hourly productivity by 245% compared to the conventional passive solar still under near equal solar radiation levels.

- Using the present design, the active solar still under the solar environment of the testing site can provide 4.5 L of potable water per day. However, to achieve the minimum daily requirement of 7.5 L/day per person set by WHO, the present design should be modified by increasing the absorber area of the active solar still by 63%, to 1.34 m2, and increasing the number of evacuated tubes used in the solar water heater to 20 units. To apply this system in a different location, the required absorber area of the solar still and the number of evacuated tubes of the employed solar water heater can be recalculated in terms of the weather conditions, in particular, solar irradiance, in order to meet the minimum personal daily requirement set by WHO.

- The estimated unit cost of desalination of raw seawater from the active (modified) solar still used in this study was NTD 6 (USD 0.21) per liter.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Description |

| a | Amortization factor |

| ABWT | Average basin water temperature |

| ACcapital | Annual capital cost |

| ACO&M | Annual maintenance and operation cost |

| ACper liter | Annual cost per liter |

| ACtotal | Total annual cost |

| ADSR | Average daily solar radiation |

| Evaporative surface area | |

| AHSR | Average hourly solar radiation |

| Ccapital | Capital cost |

| Cequipment | Cost of equipment |

| Cinstallation | Installation cost |

| d | Diameter |

| i | Interest rate |

| I (t) | Solar radiation intensity |

| L | Length |

| Productivity per batch | |

| Condensation rate (production rate) | |

| M | Annual productivity |

| n | Lifetime |

| Number of batches | |

| NTD | New Taiwanese dollar |

| PRP | Production rate performance |

| Basin temperature | |

| TDS | Total dissolved solids |

| Glass temperature | |

| USD | United States dollar |

| Δt | Time interval |

| ∆T | Temperature difference |

References

- Shiklomanov, I. Assessment of Water Resources and Water Availability in the World: Scientific and Technical Report; State Hydrological Institute: St. Petersburg, Russia, 1996. [Google Scholar]

- Burns, W. Pacific Island Developing Country Water Resources and Climate Change. In The World’s Water 2002–2003; Island Press: Washington, DC, USA, 2002; pp. 113–131. [Google Scholar]

- Mirti, A.; Davies, S. Drinking Water Quality in the Pacific Island Countries: Situation Analysis and Needs Assessment; SOPAC Joint Contribution Report 181; Applied Geoscience and Technology Division, Secretariat of the Pacific Community: Suva, Fiji, 2005; Available online: http://www.pacificwater.org/userfiles/file/jc0181.pdf (accessed on 3 December 2021).

- Mcleod, E.; Bruton-Adams, M.; Förster, J.; Franco, C.; Gaines, G.; Gorong, B.; James, R.; Posing-Kulwaum, G.; Tara, M.; Terk, E. Lessons from the Pacific Islands—Adapting to Climate Change by Supporting Social and Ecological Resilience. Front. Mar. Sci. 2019, 6, 289. [Google Scholar] [CrossRef]

- Kucera, J. Desalination: Water from Water, 2nd ed.; John Wiley and Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- El-Dessouky, H.T.; Ettouney, H.M. Fundamentals of Saltwater Desalination, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Guidelines for Drinking-Water Quality, 4th ed.; Incorporating the 1st Addendum; World Health Organization; Available online: https://www.who.int/publications/i/item/9789241549950 (accessed on 3 December 2021).

- Prasad, S. An Overview of Renewable Energy Resources in the South Pacific Island Countries. RERIC Int. Energy J. 1991, 13, 131–138. [Google Scholar]

- Wibowo, A.I.; Chang, K.C. Solar Energy-Based Water Treatment System Applicable to the Remote Areas: Case of Indonesia. J. Water Sanit. Hyg. Dev. 2020, 10, 347–356. [Google Scholar] [CrossRef]

- Khadim, M.; Al-Awahid, W.; Hachim, D. Review on the Types of Solar Stills. IOP Conf. Ser. Mater. Sci. Eng. 2020, 928, 022046. [Google Scholar] [CrossRef]

- Sampathkumar, K.; Arjunan, T.V.; Pitchandi, P. Active Solar Distillation—A Detailed Review. Renew. Sustain. Energy Rev. 2010, 14, 1503–1526. [Google Scholar] [CrossRef]

- Manchanda, H.; Kumar, M. A Comprehensive Decade Review and Analysis on Designs and Performance Parameters of Passive Solar Still. Renew. Wind. Water Sol. 2015, 2, 17. [Google Scholar] [CrossRef]

- Dsilva Winfred Rufuss, D.; Iniyan, S.; Suganthi, L.; Davies, P.A. Solar Stills: A Comprehensive Review of Designs, Performance and Material Advances. Renew. Sustain. Energy Rev. 2016, 63, 464–496. [Google Scholar] [CrossRef] [Green Version]

- Muftah, F.; Alghoul, M.A.; Fudholi, A.; Abdul-Majeed, M.M.; Sopian, K. Factors Affecting Basin Type Solar Still Productivity: A Detailed Review. Renew. Sustain. Energy Rev. 2014, 32, 430–447. [Google Scholar] [CrossRef]

- Nguyen, B.T. Factors Affecting the Yield of Solar Distillation Systems and Measures to Improve Productivities. In Desalination and Water Treatment; Eyvaz, M., Yüksel, E., Eds.; Intechopen: London, UK, 2018; pp. 151–176. [Google Scholar]

- Chamsa-ard, W.; Fawcett, D.; Fung, C.C.; Poinern, G. Solar Thermal Energy Stills for Desalination: A Review of Designs, Operational Parameters and Material Advances. J. Energy Power Technol. 2020, 2, 48. [Google Scholar] [CrossRef]

- Tarawneh, M.S.K. Effect of Water Depth on the Performance Evaluation of Solar Still. Jordan J. Mech. Ind. Eng. 2007, 1, 23–29. [Google Scholar]

- Belessiotis, V.; Kalogirou, S.; Delyannis, E. Thermal Solar Desalination: Methods and Systems; Elsevier: London, UK, 2016; pp. 103–190. [Google Scholar]

- Sharma, M.; Tiwari, A.; Mishra, D. A Review on Desalination of Water Using Single Slope Passive Solar Still. Int. J. Dev. Res. 2016, 6, 10002–10012. [Google Scholar]

- El-Sebaii, A.A.; Ramadan, M.R.I.; Aboul-Enein, S.; El-Naggar, M. Effect of Fin Configuration Parameters on Single Basin Solar Still Performance. Desalination 2015, 365, 15–24. [Google Scholar] [CrossRef]

- Jain, P.; Kumar, H.; Anand, K.B. Performance Enhancement in Working of Double Slope Solar Still with Modifications. Int. J. Eng. Res. Gen. Sci. 2020, 8, 72–88. [Google Scholar]

- Dwivedi, V.K.; Tiwari, G.N. Annual Energy and Exergy Analysis of Single and Double Slope Passive Solar Stills. Trends Appl. Sci. Res. 2008, 3, 225–241. [Google Scholar]

- Al-Molhem, Y.A.; Eltawil, M.A. Enhancing the Double-Slope Solar Still Performance Using Simple Solar Collector and Floatable Black Wicks. Environ. Sci. Pollut. Res. 2020, 27, 35078–35098. [Google Scholar] [CrossRef]

- Patel, S.K.; Kumar, B.; Pal, P.; Dev, R.; Singh, D. Production of Potable Water from Gomti River by Using Modified Double Slope Solar Still with External Mounted Reflectors. Sol. Energy 2020, 209, 576–589. [Google Scholar] [CrossRef]

- Kamal, W. A Theoretical and Experimental Study of the Basin-Type Solar Still under the Arabian Gulf Climatic Conditions. Sol. Wind Technol. 1988, 5, 147–157. [Google Scholar] [CrossRef]

- Kandasamy, S.; Vellingiri, M.; Sengottain, S.; Balasundaram, J. Performance Correlation for Single-Basin Double-Slope Solar Still. Int. J. Energy Environ. Eng. 2013, 4, 4. [Google Scholar] [CrossRef] [Green Version]

- Tiwari, G.N.; Dimri, V.; Chel, A. Parametric Study of an Active and Passive Solar Distillation System: Energy and Exergy Analysis. Desalination 2009, 242, 1–18. [Google Scholar] [CrossRef]

- Kariuki, B.K. Solar Distillation; Design, Fabrication and Characterization of a Double Sloped Solar Still for Household Use along the Kenya Coast. Int. J. Recent Eng. Res. Dev. (IJRERD) 2018, 2, 87–97. [Google Scholar]

- Pal, P.; Dev, R.; Singh, D.; Ahsan, A. Energy Matrices, Exergoeconomic and Enviroeconomic Analysis of Modified Multi–Wick Basin Type Double Slope Solar Still. Desalination 2018, 447, 55–73. [Google Scholar] [CrossRef]

- Modi, K.; Jani, H. Experimental and Theoretical Assessment of Dual-Slope Single-Basin Solar Still with the Circular Cross-Sectional Hollow-Fins. Clean. Eng. Technol. 2021, 4, 100231. [Google Scholar] [CrossRef]

- Tuly, S.S.; Rahman, M.S.; Sarker, M.R.I.; Beg, R.A. Combined Influence of Fin, Phase Change Material, Wick, and External Condenser on the Thermal Performance of a Double Slope Solar Still. J. Clean. Prod. 2021, 287, 125458. [Google Scholar] [CrossRef]

- Al-Garni, A.Z.; Kassem, A.H.; Saeed, F.; Ahmed, F. Effect of Glass Slope Angle and Water Depth on Productivity of Double Slope Solar Still. J. Sci. Ind. Res. (JSIR) 2011, 70, 884–890. [Google Scholar]

- Babalola, T.A.; Boyo, A.O.; Kesinro, R.O. Effect of Water Depth and Temperature on the Productivity of a Double Slope Solar Still. J. Energy Nat. Resour. 2015, 4, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Zarzoum, K.; Zhani, K.; Bacha, H.B. Improving the Design, Modeling and Simulation in Dynamic Mode of a Solar Still. Desalination Water Treat. 2014, 52, 6304–6314. [Google Scholar] [CrossRef]

- CNS 15165-1; Test Methods for Solar Collectors—Part 1: Thermal Performance of Glazed Liquid Heating Collectors Including Pressure Drop. Central Bureau of Standard: Taibei, Taiwan, 2008.

- ISO 9806-1; Test Methods for Solar Collectors—Part 1: Thermal Performance of Glazed Liquid Heating Collectors Including Pressure Drop. International Standards Organization: Geneva, Switzerland, 1995.

- Halawa, E.; Chang, K.C.; Yoshinaga, M. Thermal Performance Evaluation of Solar Water Heating Systems in Australia, Taiwan and Japan—A Comparative Review. Renew. Energy 2015, 83, 1279–1286. [Google Scholar] [CrossRef]

- Ithape, P.K.; Barve, S.B.; Nadgire, A.R. Climatic and Design Parameters Effects on the Productivity of Solar Stills: A Review. Int. J. Curr. Eng. Sci. Res. 2017, 4, 17–23. [Google Scholar]

- Copper, J.C. Taiwan. Encyclopedia Britannica. Available online: https://www.britannica.com/place/Taiwan (accessed on 6 December 2021).

- Hsu, H.H.; Chen, C.T. Observed and Projected Climate Change in Taiwan. Meteorol. Atmos. Phys. 2002, 79, 87–104. [Google Scholar] [CrossRef]

- Salter, C.L.; Gritzner, C.F. Taiwan, 1st ed.; Infobase Publishing: Philadelphia, PA, USA, 2009; pp. 19–23. [Google Scholar]

- World Health Organization. Total Dissolved Solids in Drinking-Water. Available online: https://www.who.int/water_sanitation_health/dwq/chemicals/tds.pdf (accessed on 16 December 2021).

- Aybar, H.S. A Review of Desalination by Solar Still. In Solar Desalination for the 21st Century; Springer: Berlin/Heidelberg, Germany, 2007; pp. 207–214. [Google Scholar] [CrossRef]

- Nomor, E.; Islam, R.; Alim, M.A.; Rahman, A. Production of Fresh Water by a Solar Still: An Experimental Case Study in Australia. Water 2021, 13, 3373. [Google Scholar] [CrossRef]

- Gnanaraj, S.J.P.; Velmurugan, V. An Experimental Study on the Efficacy of Modifications in Enhancing the Performance of Single Basin Double Slope Solar Still. Desalination 2019, 467, 12–28. [Google Scholar] [CrossRef]

- Tiwari, G.N.; Dwivedi, V. K Experimental Validation of Thermal Model of a Double Slope Active Solar Still under Natural Circulation Mode. Desalination 2010, 250, 49–55. [Google Scholar]

- Kariuki, B.K.; Kamau, J.N.; Kinyua, R. Quality and Economic Analysis of a Double Sloped Solar Still for Household Use in Kilifi County, Kenya. Int. J. Adv. Res. Eng. Manag. 2017, 3, 70–78. [Google Scholar]

- Prajapati, U.K.; Gupta, B.; Bhalavi, J. Performance Improvement of Double Slope Solar Still Using Aluminum Fins and Phase Change Material. J. Emerg. Technol. Innov. Res. 2019, 6, 295–302. [Google Scholar]

- Howard, G.; Bartram, J. Domestic Water Quality, Service Level and Health; Technical Document, WHO/SDE/WSH/03.02; World Health Organization: Geneva, Switzerland, 2003. [Google Scholar]

| Species Concentration | Raw Seawater | Distilled Water | WHO Standard |

|---|---|---|---|

| Chloride (mg/L) | 20,100 | 0.20 | <250 [7] |

| TDS (mg/L) | 34,269 | Trace amount (<50) | <900 [42] |

| Solar Still Configuration | Percentage Contribution of Total Yield (%) | |

|---|---|---|

| Day-Time | Night-Time | |

| Conventional (unmodified) | 73.6 | 26.4 |

| Conventional (modified) | 78.7 | 21.3 |

| Active (unmodified) | 87.9 | 12.1 |

| Active (modified) | 86.7 | 13.3 |

| Configuration | Evaporative Surface Area | Average Daily Productivity 1 | Average Hourly Productivity (under Sunshine) | Daytime Productivity 6 | ||||

|---|---|---|---|---|---|---|---|---|

| Area (m2) | % Change | L/m2·day | % Change | L/m2·h | % Change | L/kJ·day × 10−5 | % Change | |

| Conventional (unmodified) | 0.820 | - | 2.20 (1.80 L/day) | - | 0.114 2 | - | 11.59 | - |

| Conventional (modified) | 0.866 | 5.61 | 2.17 (1.78 L/day) | −1.36 | 0.145 3 | 28.04 | 11.23 | −3.1 |

| Active (unmodified) | 0.820 | - | 4.07 3.34 L/day | 85 | 0.489 5 | 328.95 | 32.86 | 183.5 |

| Active (modified) | 0.866 | 5.61 | 5.43 (4.45 L/day) | 146.82 | 0.392 4 | 245.35 | 34.02 | 193.5 |

| References | Climatic Region | Latitude of Site | Testing Period | Productivity (L/m2·day) |

|---|---|---|---|---|

| Gnanaraj et al. [45] | India | 11.9° N | March–May | 1.880 |

| Tiwari et al. [46] | India | 28.6° N | January | 1.838 |

| Karanja et al. [47] | Kenya | 3.5° S | September–October | 1.652 |

| Prajapati et al. [48] | India | 22.7° N | November | 1.400 |

| Present | Taiwan | 22.9° N | September–October | 2.200 |

| Items | Quantity | Unit Cost (NTD) | Cost (NTD) | Cost (USD) 1 |

|---|---|---|---|---|

| Glass + glass frame | 1 | 18,000 | 18,000 | 640 |

| Basin + support structure + fins | 1 | 33,450 | 33,450 | 1189 |

| Evacuated tubes | 12 | 3000 | 36,000 | 1279 |

| Total cost | - | - | 87,450 | 3108 |

| Parameters | Values |

|---|---|

| a (Amortization) | 0.0837 |

| Ccapital (Present capital cost) | NTD 96,195 (USD 3418) |

| ACcapital (Annual capital cost) | NTD 8052 (USD 286) |

| ACO&M (Annual operation and maintenance cost) | NTD 0 |

| ACtotal (Total annual cost) | NTD 8052 (USD 286) |

| M (Annual productivity) | 1440 L |

| ACper liter (Annual cost per liter of distillate output) | NTD 6 (USD 0.21) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samuel, A.; Brizuela, J.; Chang, K.-C.; Lin, C.-T. Design and Investigation of an Effective Solar Still Applicable to Remote Islands. Water 2022, 14, 703. https://doi.org/10.3390/w14050703

Samuel A, Brizuela J, Chang K-C, Lin C-T. Design and Investigation of an Effective Solar Still Applicable to Remote Islands. Water. 2022; 14(5):703. https://doi.org/10.3390/w14050703

Chicago/Turabian StyleSamuel, Alinford, Josue Brizuela, Keh-Chin Chang, and Chun-Tin Lin. 2022. "Design and Investigation of an Effective Solar Still Applicable to Remote Islands" Water 14, no. 5: 703. https://doi.org/10.3390/w14050703

APA StyleSamuel, A., Brizuela, J., Chang, K.-C., & Lin, C.-T. (2022). Design and Investigation of an Effective Solar Still Applicable to Remote Islands. Water, 14(5), 703. https://doi.org/10.3390/w14050703