Spray Characteristics and Parameter Optimization of Orifice Arrangement for Micro-Sprinkling Hoses

Abstract

:1. Introduction

2. Materials and Methods

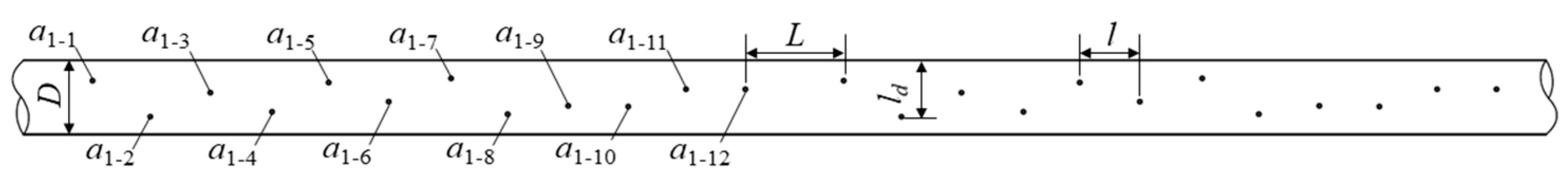

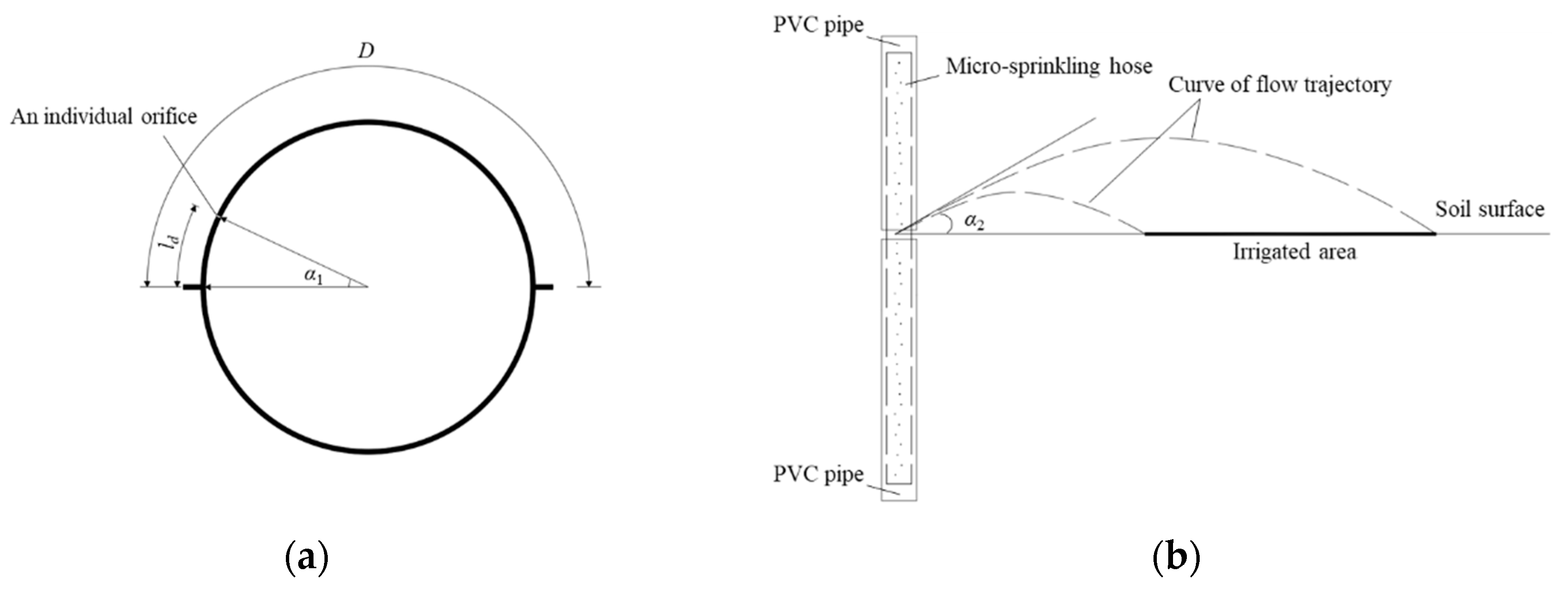

2.1. Micro-Sprinkling Hoses

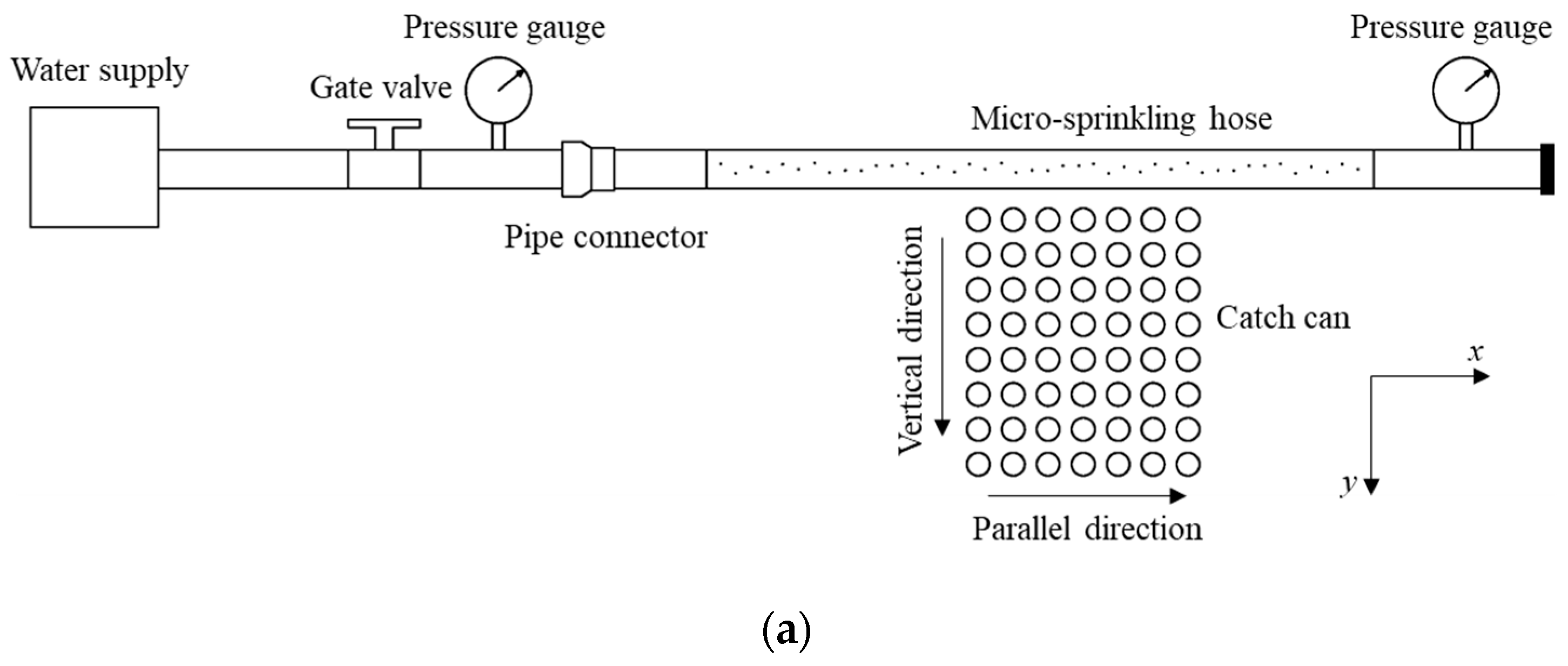

2.2. Experimental Design

2.3. Bimodal Two-Dimensional Gaussian Distribution Model

2.4. Optimization Method

3. Results

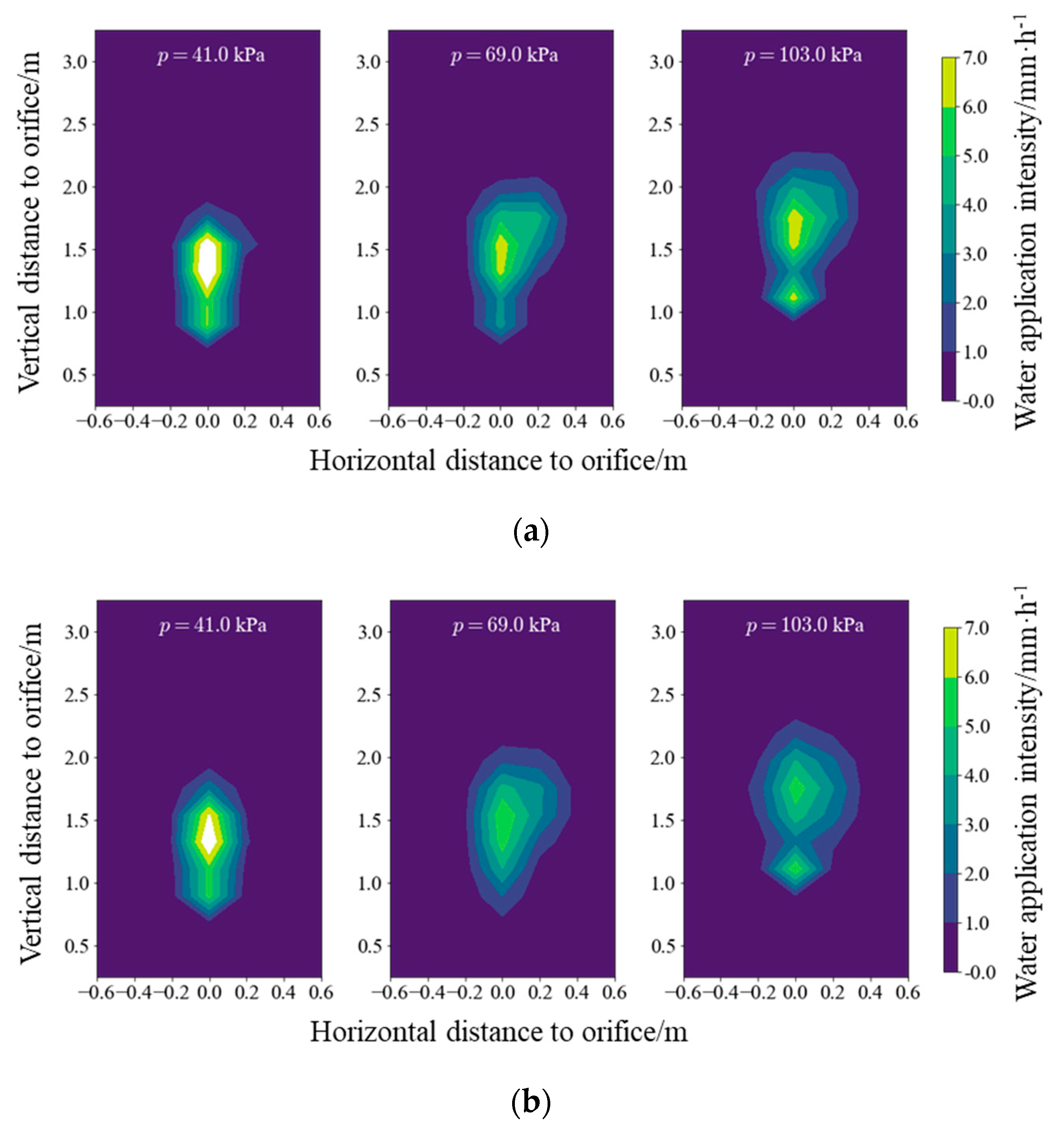

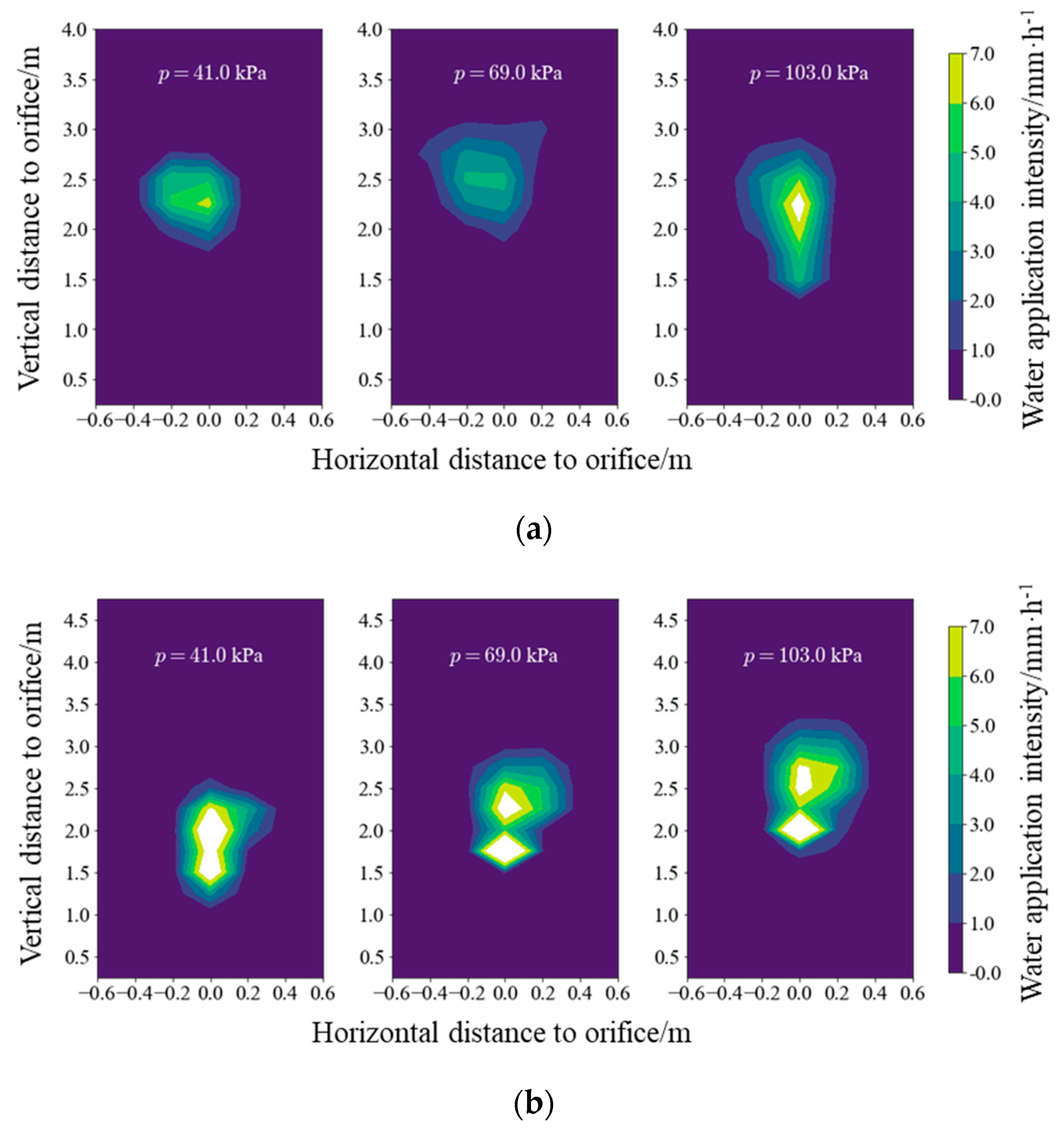

3.1. Model Validation

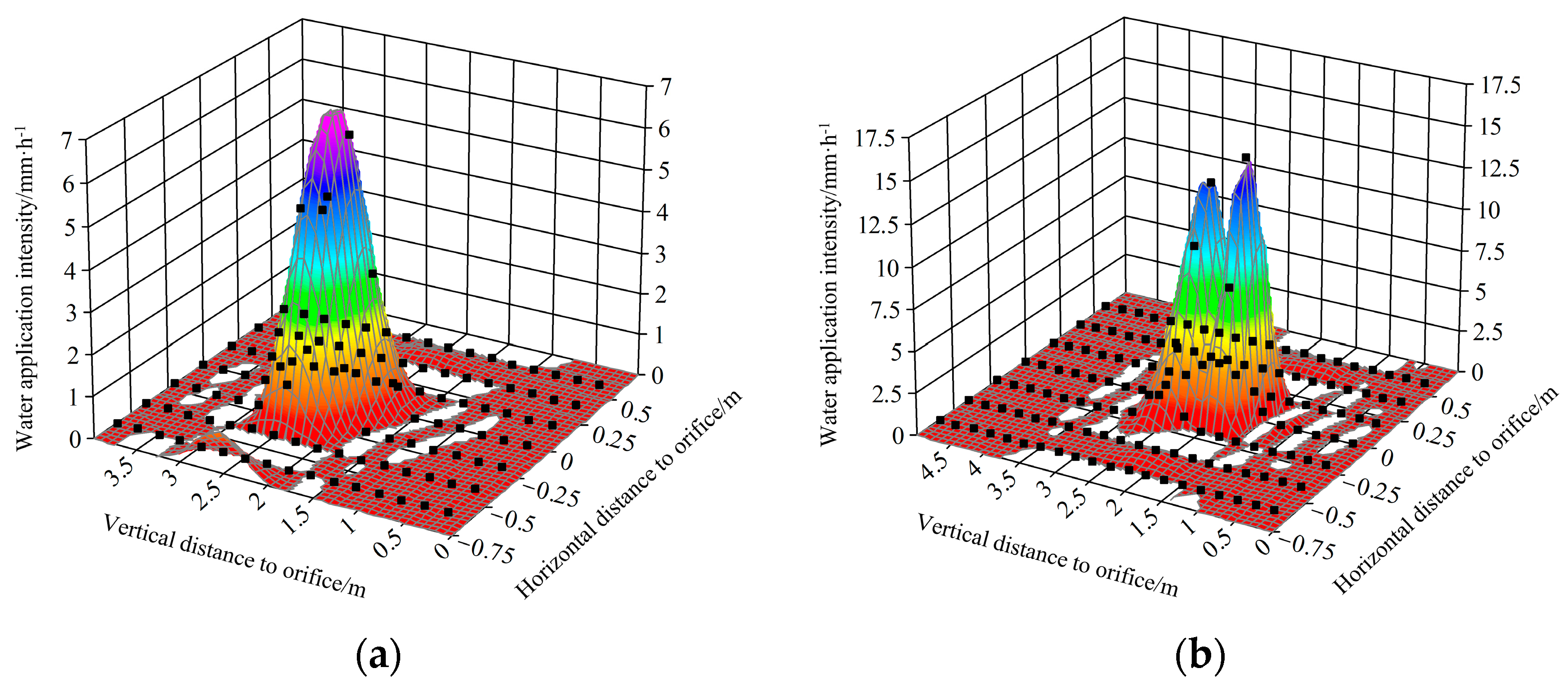

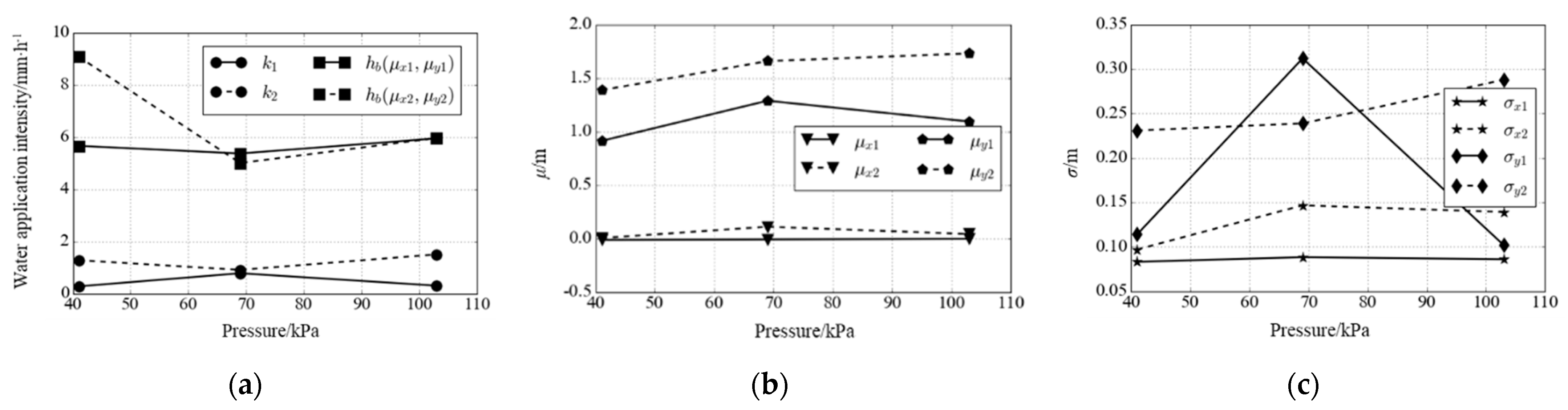

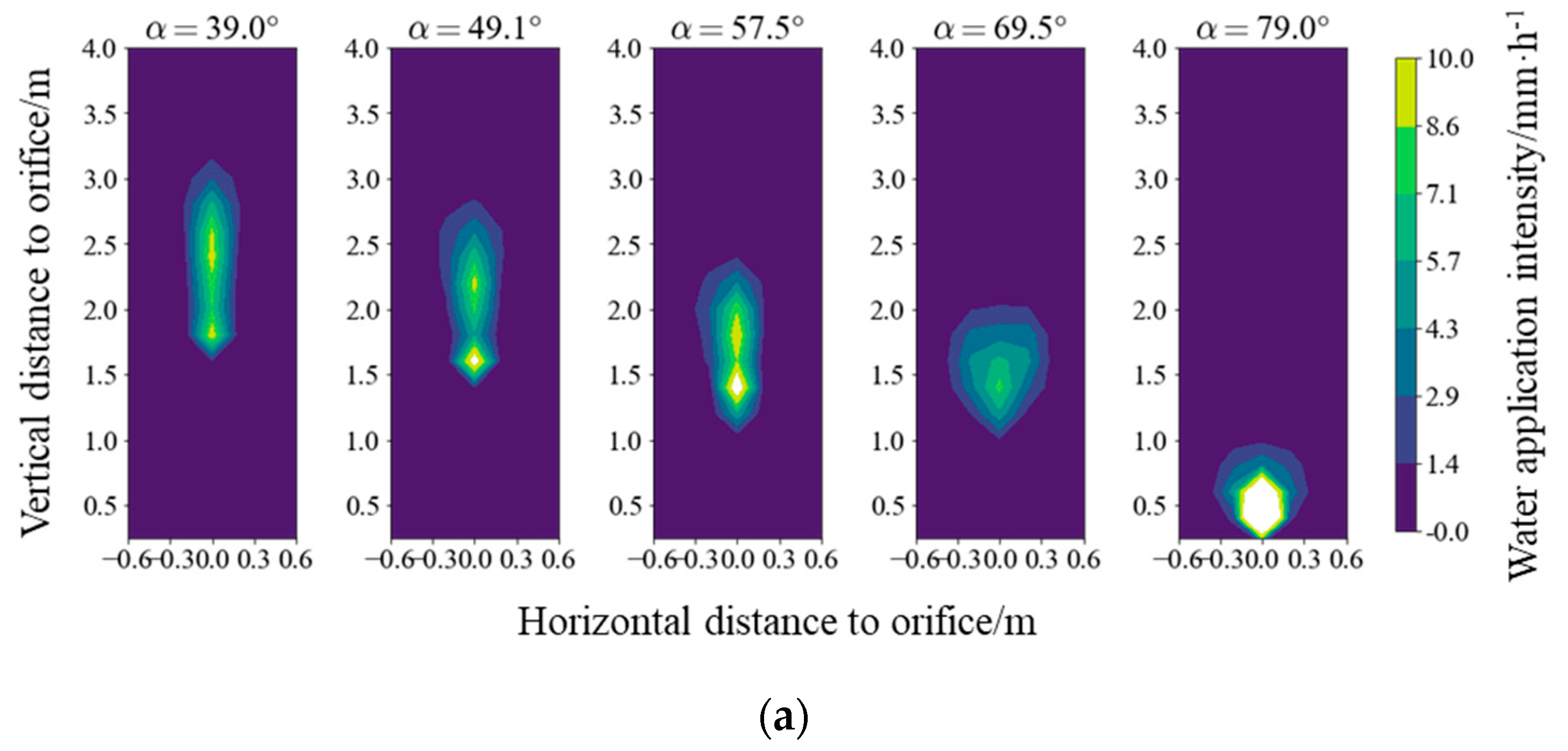

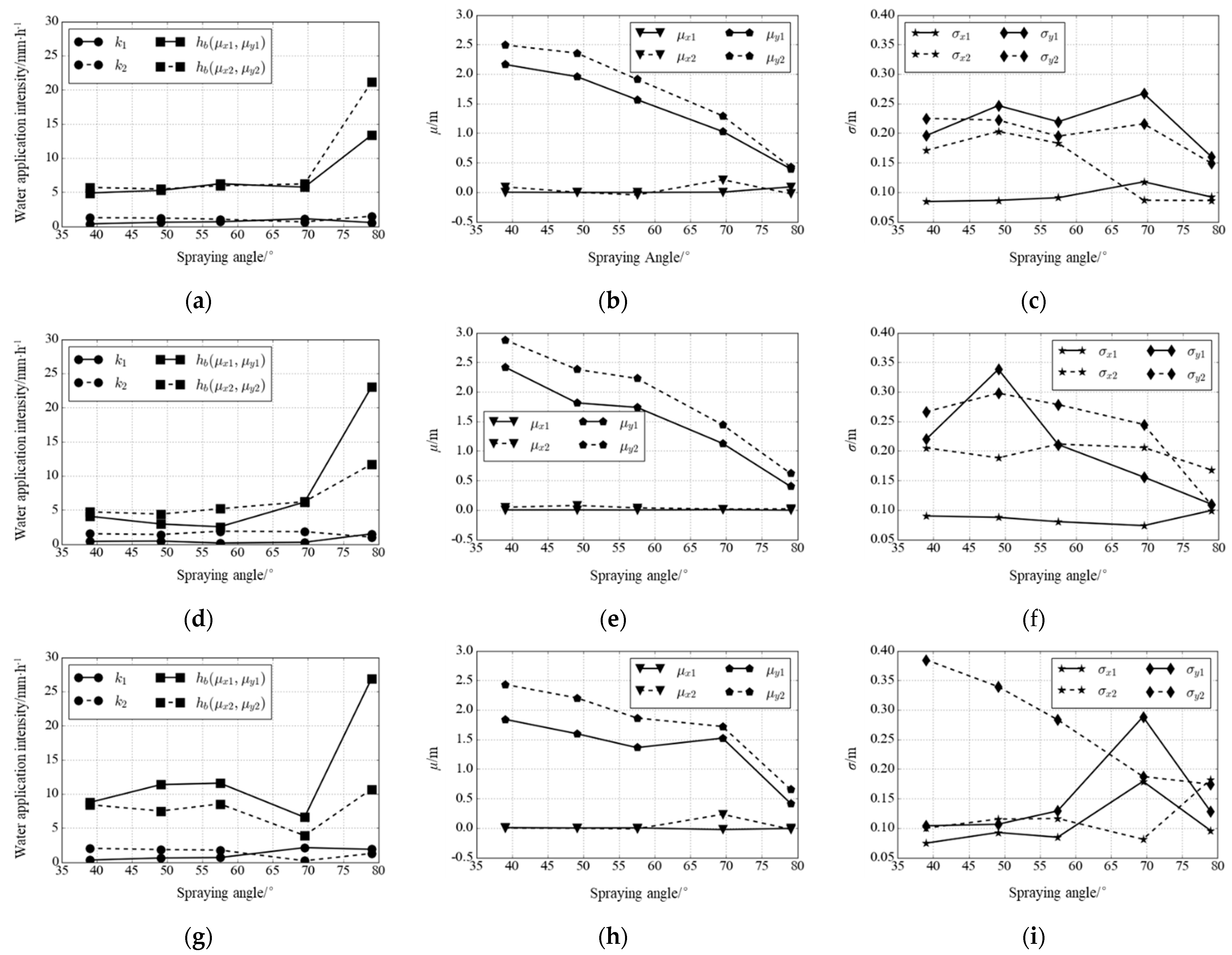

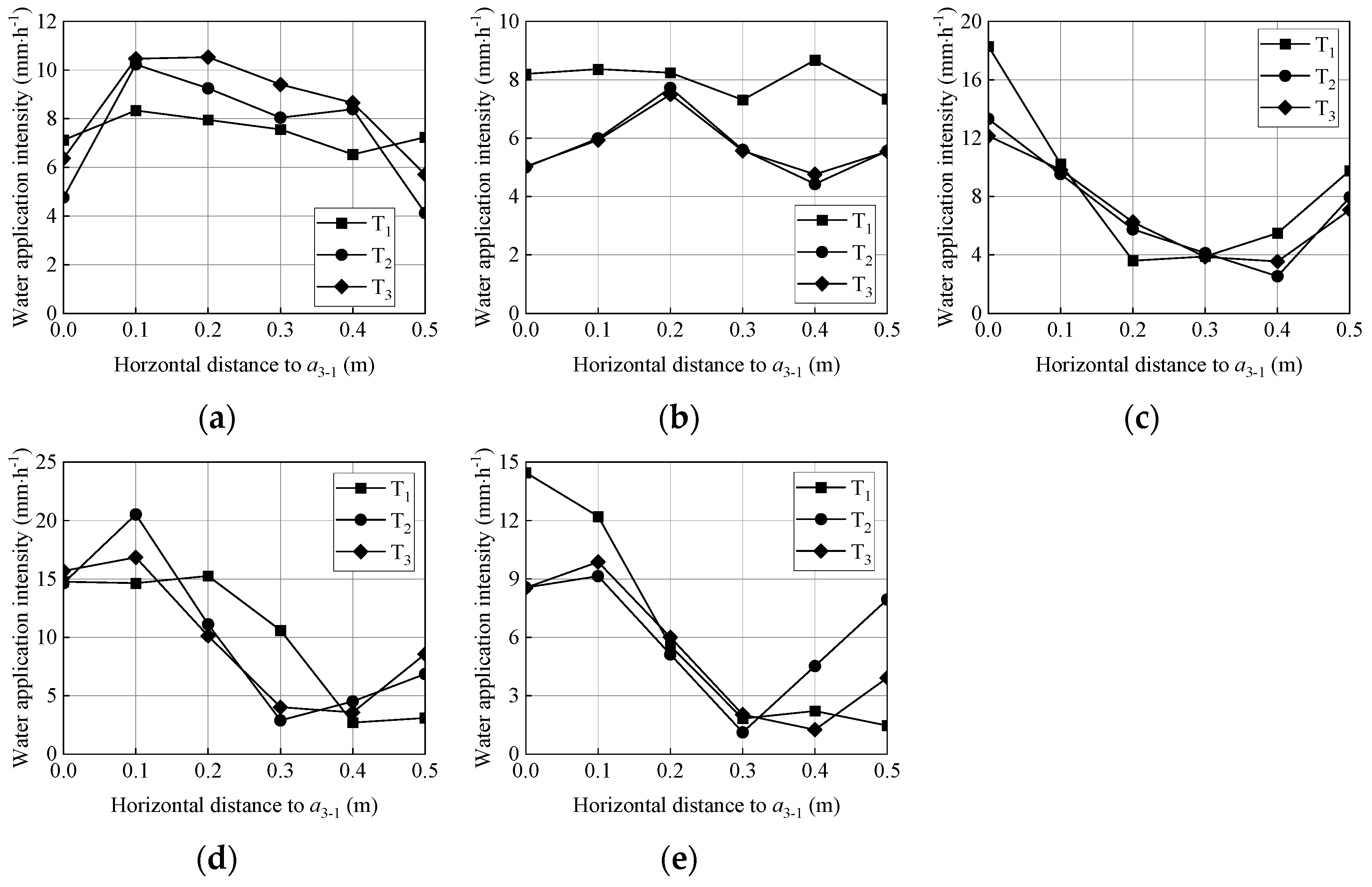

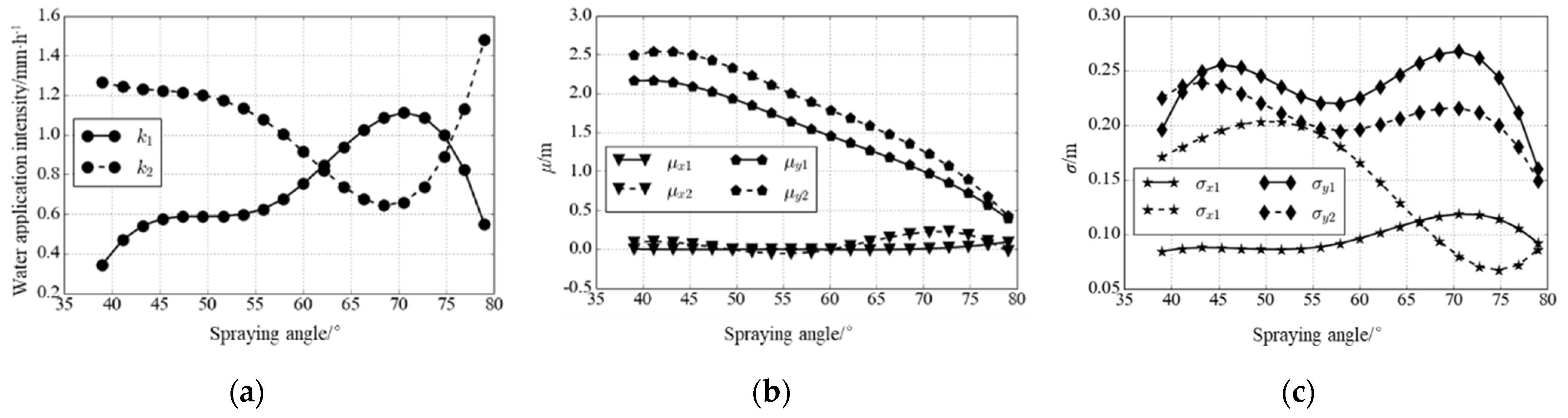

3.2. Influencing Factor of Water Application Intensity Distribution of an Individual Orifice

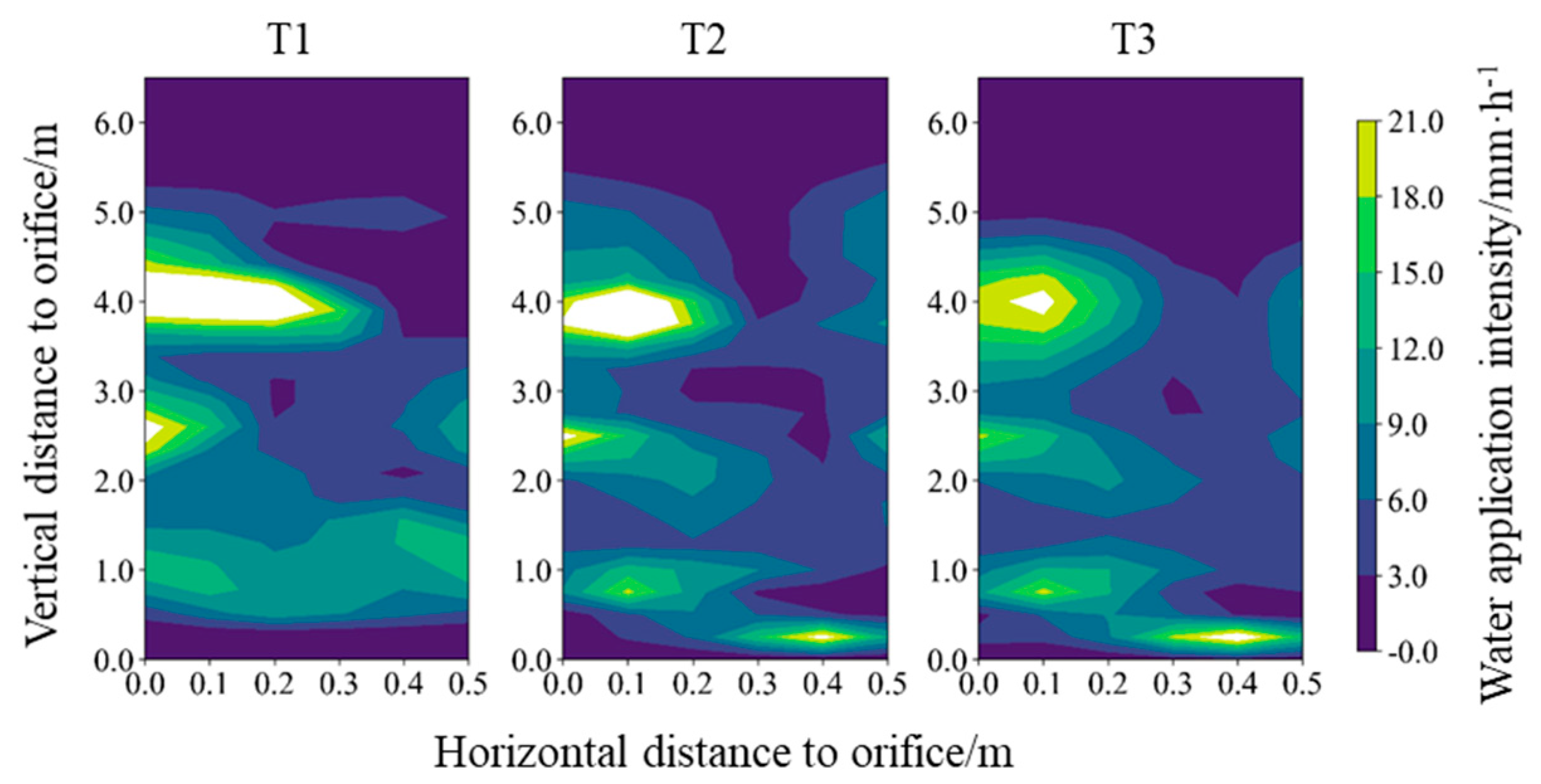

3.3. Superposition of Water Application Intensity Distribution

- Determine the spraying region of single-sided orifice groups;

- Divide the spraying region using evenly distributed grid nodes;

- Use coordinate transformation in the treatment of the measured values;

- Apply linear interpolation to calculate the water application intensity of six individual orifices on the spraying region of single-sided orifice groups;

- A summation of the water application intensity on six individual orifices in the same grid nodes is given to calculate the fitted value of single-sided orifice groups;

- Determine the spraying region of the single-sided micro-sprinkling hose;

- Divide the spraying region using evenly distributed grid nodes;

- Use coordinate transformation in the treatment of the calculated values on single-sided orifice groups;

- Apply linear interpolation to calculate the water application intensity of four single-sided orifice groups on the spraying region of the single-sided micro-sprinkling hose;

- A summation of water application intensity on four single-sided orifice groups in the same grid nodes is given to calculate the value of the single-sided micro-sprinkling hose;

- Determine the spraying region of the single-sided micro-sprinkling hose;

- Based on above-mentioned stages, the calculated value of the water application intensity on the other-sided micro-sprinkling hose is calculated in the same way.

- T3 was processed in the following steps:

- Determine the spraying region of the single-sided micro-sprinkling hose;

- Fit the water application intensity of all individual orifices on the single-sided micro-sprinkling hose with the bimodal two-dimensional Gaussian distribution model;

- Use coordinate transformation in the treatment of the fitting formula on each orifice along x-axis, and move the origin of the coordinate system to the first individual orifice in the third group;

- A summation of the fitting formula on all individual orifices is given to calculate the water application intensity with the coordinates on the spraying region of the single-sided micro-sprinkling hose.

- Based on above-mentioned stages, the fitted value of the water application intensity on the other-sided micro-sprinkling hose is calculated in the same way.

3.4. Optimization Results

4. Conclusions

- The difference between the orifice angles and spraying angles was small. The bimodal Gaussian distribution model performed well on tracking the two-dimensional features of the water application intensity distribution, where R2 > 0.90 and NRMSE < 30%.

- The water application intensity distribution of an individual orifice was affected by the pressure, spraying angle and orifice area, of which the spraying angle was the most sensitive factor. The influence of pressure on the peak value, peak location and the dispersion of the water application intensity distribution was relatively complicated. When the spraying angle exceeded 69.5°, the peak value began to increase, and μy1 and μy2 decreased with increasing angles.

- The water application intensity distribution of multiple groups of orifices could be calculated by overlapping the water application intensity distribution of each orifice. The Monte Carlo method was used for the optimization investigation of the orifice arrangement. An optimized orifice arrangement of the micro-sprinkling hose was obtained with a uniformity coefficient up to 58.5%. When the working pressure is 41 kPa, it is recommended that the spraying angles of the 12 individual orifices are 62.5°, 62.5°, 46.0°, 46.0°, 76.8°, 76.8°, 68.5°, 68.5°, 49.1°, 49.1°, 76.0° and 76.0°. Correspondingly, the distance from the orifice center to the edge of the 12 individual orifices are 21.5, 32.5, 15.9, 38.1, 26.5, 27.5, 23.6, 30.4, 16.9, 37.1, 26.2 and 27.8 mm. This study involved the same orifice diameter with a different orifice arrangement in the optimization method, and further research is therefore required.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jägermeyr, J.; Gerten, D.; Heinke, J.; Schaphoff, S.; Kummu, M.; Lucht, W. Water savings potentials of irrigation systems: Global simulation of processes and linkages. Hydrol. Earth Syst. Sci. 2015, 19, 3073–3091. [Google Scholar] [CrossRef] [Green Version]

- Ministry of Water Resource. People’s Republic of China 2021 Statistic Bulletin on China Water Activities; China Water Power Press: Beijing, China, 2022.

- Hui, X.; Zheng, Y.D.; Yan, H.J. Water distributions of low-pressure sprinklers as affected by the maize canopy under a centre pivot irrigation system. Agric. Water Manag. 2021, 245, 106646. [Google Scholar] [CrossRef]

- Reyes-Cabrera, J.; Zotarelli, L.; Dukes, M.D.; Rowland, D.L.; Sargent, S.A. Soil moisture distribution under drip irrigation and seepage for potato production. Agric. Water Manag. 2016, 169, 183–192. [Google Scholar] [CrossRef] [Green Version]

- Koumanov, K.S.; Hopmans, J.W.; Schwankl, L.J.; Andreu, L.; Tuli, A. Application efficiency of micro-sprinkler irrigation of almond trees. Agric. Water Manag. 1997, 34, 247–263. [Google Scholar] [CrossRef]

- De Almeida, C.D.G.C.; Botrel, T.A.; Smith, R.J. Characterization of the microtube emitters used in a novel micro-sprinkler. Irrig. Sci. 2009, 27, 209–214. [Google Scholar] [CrossRef]

- Home, P.G.; Panda, R.K.; Kar, S. Effect of method and scheduling of irrigation on water and nitrogen use efficiencies of Okra (Abelmoschus esculentus). Agric. Water Manag. 2002, 55, 159–170. [Google Scholar] [CrossRef]

- Liu, H.F. Study on Hydraulic Characteristics of Micro-Pressure Perforated Flexible Hose. Ph.D. Thesis, Northwest Agriculture and Forestry University, Yangling, China, July 2008. (In Chinese). [Google Scholar]

- Shi, H.Z.; Gao, W.K.; Chang, S.M.; Di, H.H.; Wang, T.X.; Yang, S.Q.; Wang, T.Y.; Wang, G.S. Effect of irrigating water quota with micro-irrigation on soil physical properties and nutrient transport in different layers of tobacco soil. J. Henan Agric. Univ. 2009, 43, 485–490. (In Chinese) [Google Scholar]

- Man, J.G.; Yu, J.S.; White, P.J.; Gu, S.B.; Zhang, Y.L.; Guo, Q.F.; Shi, Y.; Wang, D. Effects of supplemental irrigation with micro-sprinkling hoses on water distribution in soil and grain yield of winter wheat. Field Crops Res. 2014, 161, 26–37. [Google Scholar] [CrossRef]

- Man, J.G.; Wang, D.; White, P.J.; Yu, Z.W. The length of micro-sprinkling hoses delivering supplemental irrigation affects photosynthesis and dry matter production of winter wheat. Field Crop Res. 2014, 168, 65–74. [Google Scholar] [CrossRef]

- Ghidiu, G.; Kuhar, T.; Palumbo, J.; Schuster, D. Drip chemigation of insecticides as a pest management tool in vegetable production. J. Integr. Pest Manag. 2012, 3, E1–E5. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Liu, H.; Wang, S.S.; Guo, X.; Gong, X.W.; Sun, J.S. Modelling the soil water dynamics under micro-sprinkling hose irrigation for distorted roots of transplanted cotton. Int. J. Agric. Biol. 2019, 21, 191–200. [Google Scholar]

- Zhang, X.J.; Wu, Z.W.; Ding, X.M.; Li, X. Experimental analysis of water distribution characteristics of micro-sprinkling hose. Trans. Chin. Soc. Agric. Eng. 2009, 25, 66–69. (In Chinese) [Google Scholar]

- Dou, C.Y.; Meng, W.Z.; Zhang, L.K.; Yu, H.D.; Guo, M. Effects of hole arrangement on irrigation uniformity under micro-spraying hose irrigation. J. Irrig. Drain. 2015, 34, 42–46. (In Chinese) [Google Scholar]

- Wang, W.J.; Wang, W.E.; Hu, X.T.; Dai, D.K. Effects of spraying angle and pressure on the droplet distribution of micro-sprinkling hose. Trans. Chin. Soc. Agric. Eng. 2021, 37, 73–81. (In Chinese) [Google Scholar]

- Wang, J.J.; Yang, Y.Q.; Cai, J.M.; Zhai, G.L. Experimental study on the influence of working pressure and spraying angle on the single-hole spray characteristics of micro-sprinkling hose. Water Sav. Irrig. 2018, 4, 35–38. (In Chinese) [Google Scholar]

- Zhou, B.; Feng, J.; Zhang, X.J.; Wu, Z.W.; Shen, X.M. Characteristics and indexes of water distribution of punched thin-soft tape for spray. Trans. Chin. Soc. Agric. Eng. 2003, 19, 101–103. (In Chinese) [Google Scholar]

- Zhang, L.D.; Feng, J.; Zeng, A.J.; Zhou, B. Mathematical model of distribution of water application rate with punched thin-soft spray tape. J. China Agric. Univ. 2002, 7, 30–33. (In Chinese) [Google Scholar]

- Di, Z.G.; Yang, L.H.; Gou, W.L.; Wang, J.Y. Model establishment of spraying width of thin-walled micro-sprinkling hose. Trans. Chin. Soc. Agric. Eng. 2019, 35, 28–34. (In Chinese) [Google Scholar]

- Li, Y.C.; Bai, G.; Yan, H.J. Development and validation of a modified model to simulate the sprinkler water distribution. Comput. Electron. Agric. 2015, 111, 38–47. [Google Scholar] [CrossRef]

- Sadeghi, H.; Peters, T.R.; Amini, M.Z.; Malone, L.S. Novel approach to evaluate the dynamic variation of wind drift and evaporation losses under moving irrigation systems. Biosyst. Eng. 2015, 135, 44–53. [Google Scholar] [CrossRef] [Green Version]

- Zhou, B. Study on the Water Application Rate Distribution of Punched Thin-Soft Spray Tape. Master’s Thesis, China Agricultural University, Beijing, China, 2001. (In Chinese). [Google Scholar]

- Xu, R.; Wang, W.E.; Hu, X.T. Experimental study on the influence of working pressure on water distribution uniformity of micro-sprinkler belt. Water Sav. Irrig. 2020, 9, 88–93. (In Chinese) [Google Scholar]

- Wang, J.Y.; Yang, L.H.; Gou, W.L.; Di, Z.G.; Dong, Y.H. Optimization analysis of laying length of thin wall micro-spray belt under different slope conditions. Water Sav. Irrig. 2020, 183, 56–60. (In Chinese) [Google Scholar]

- Wang, J.Y.; Yang, L.H.; Gou, W.L.; Di, Z.G. Experimental study on uniformity of combination and the paving spacing for thin wall micro spray belt. J. Irrig. Drain. 2020, 39, 72–77+83. (In Chinese) [Google Scholar]

- Tang, P.; Li, H.; Chen, C.; Sun, C.Z. Optimization and experiment of adjustable structural parameters for vertical impact sprinkler with working pressure. Trans. Chin. Soc. Agric. Eng. 2016, 32, 99–107. (In Chinese) [Google Scholar]

- Chen, D.D.; Wallender, W.W. Economic sprinkler selection, spacing, and orientation. Trans. ASAE 1984, 27, 734–743. [Google Scholar]

- Li, S. The Study on Spray Nozzle Random Performance Test and Its Mathematical Simulation. Master’s Thesis, Hebei Agricultural University, Baoding, China, June 2011. (In Chinese). [Google Scholar]

- Cohen, A.C. Estimation in mixtures of two normal distributions. Technometrics 1967, 9, 15–28. [Google Scholar] [CrossRef]

- Christiansen, J.E. Irrigation by Sprinkler; California Agricultural Experimental Station Research Bulletin: Berkeley, CA, USA, 1942. [Google Scholar]

- Wang, X.S.; Xu, Y.C.; Yan, H.J.; Zhou, L.J.; Tan, H.B. Development of water distribution model of single orifice on micro-sprinkling hose. Trans. Chin. Soc. Agric. Eng. 2022, 38, 93–101. (In Chinese) [Google Scholar]

| Parameters | Number of the Individual Orifice | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a3-1 | a3-2 | a3-3 | a3-4 | a3-5 | a3-6 | a3-7 | a3-8 | a3-9 | a3-10 | a3-11 | a3-12 | |

| α1 (°) | 40.0 | 38.3 | 76.7 | 50.0 | 48.3 | 80.0 | 36.7 | 45.0 | 68.3 | 68.3 | 66.7 | 66.7 |

| α2 (°) | 40.7 | 41.2 | 74.8 | 54.1 | 47.8 | 82.0 | 34.3 | 47.7 | 73.8 | 70.5 | 63.7 | 74.6 |

| Relative error (%) | 1.8 | 7.6 | −2.5 | 8.2 | 1.0 | 2.5 | −7.0 | 5.7 | 8.1 | 3.2 | −4.5 | 11.8 |

| Working Pressure (kPa) | Parameters | Number of the Individual Orifice | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a3-1 | a3-2 | a3-3 | a3-4 | a3-5 | a3-6 | a3-7 | a3-8 | a3-9 | a3-10 | a3-11 | a3-12 | ||

| 41 | R2 | 0.96 | 0.87 | 0.97 | 0.96 | 0.97 | 0.98 | 0.95 | 0.94 | 0.94 | 0.96 | 0.96 | 0.97 |

| NRMSE(%) | 26.1 | 20.2 | 20.8 | 23.6 | 28.0 | 12.3 | 20.9 | 25.3 | 18.7 | 24.8 | 28.9 | 17.8 | |

| 69 | R2 | 0.94 | 0.95 | 0.98 | 0.92 | 0.91 | 0.96 | 0.96 | 0.94 | 0.97 | 0.94 | 0.92 | 0.97 |

| NRMSE(%) | 30.4 | 23.1 | 20.9 | 32.6 | 44.4 | 26.8 | 21.1 | 32.0 | 10.8 | 31.4 | 33.8 | 18.7 | |

| 103 | R2 | 0.94 | 0.94 | 0.95 | 0.90 | 0.95 | 0.97 | 0.72 | 0.96 | 0.95 | 0.96 | 0.96 | 0.96 |

| NRMSE(%) | 35.9 | 28.3 | 29.1 | 38.2 | 34.3 | 26.4 | 39.1 | 29.5 | 13.3 | 28.7 | 32.5 | 18.5 | |

| Sample Number | max{wi} | CUi/% | Bi/m |

|---|---|---|---|

| 50 | 2.01 | 49.9 | 3.04 |

| 100 | 2.04 | 52.1 | 2.99 |

| 500 | 2.04 | 52.1 | 2.99 |

| 1000 | 2.06 | 54.2 | 2.94 |

| 5000 | 2.12 | 55.4 | 3.04 |

| 10,000 | 2.15 | 58.3 | 2.94 |

| 50,000 | 2.16 | 58.5 | 2.99 |

| 100,000 | 2.16 | 58.5 | 2.99 |

| Parameters | Number of the Individual Orifice | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| α2/° | 62.5 | 62.5 | 46.0 | 46.0 | 76.8 | 76.8 | 68.5 | 68.5 | 49.1 | 49.1 | 76.0 | 76.0 |

| ld/mm | 21.5 | 32.5 | 15.9 | 38.1 | 26.5 | 27.5 | 23.6 | 30.4 | 16.9 | 37.1 | 26.2 | 27.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Xu, Y.; Yan, H.; Tan, H.; Zhou, L. Spray Characteristics and Parameter Optimization of Orifice Arrangement for Micro-Sprinkling Hoses. Water 2022, 14, 3260. https://doi.org/10.3390/w14203260

Wang X, Xu Y, Yan H, Tan H, Zhou L. Spray Characteristics and Parameter Optimization of Orifice Arrangement for Micro-Sprinkling Hoses. Water. 2022; 14(20):3260. https://doi.org/10.3390/w14203260

Chicago/Turabian StyleWang, Xiaoshan, Yuncheng Xu, Haijun Yan, Haibin Tan, and Lingjiu Zhou. 2022. "Spray Characteristics and Parameter Optimization of Orifice Arrangement for Micro-Sprinkling Hoses" Water 14, no. 20: 3260. https://doi.org/10.3390/w14203260

APA StyleWang, X., Xu, Y., Yan, H., Tan, H., & Zhou, L. (2022). Spray Characteristics and Parameter Optimization of Orifice Arrangement for Micro-Sprinkling Hoses. Water, 14(20), 3260. https://doi.org/10.3390/w14203260