Orthogonal Experiments and Neural Networks Analysis of Concrete Performance

Abstract

:1. Introduction

2. Design of Experiments for Concrete Mixture

3. Introduction to Orthogonal Experimental Design

4. About Neural Networks

5. Response Surfaces of Strength

- The water/binder ratio (w/b) is 0.5.

- The fly ash/binder ratio (fa/b) refers to the content of fly ash calculated by the weight of the binder, with a variation range of 10–30%.

- The age of concrete is different on the 3rd and 28th days. All other raw materials or their proportions remain unchanged.

5.1. Effects of fa/b

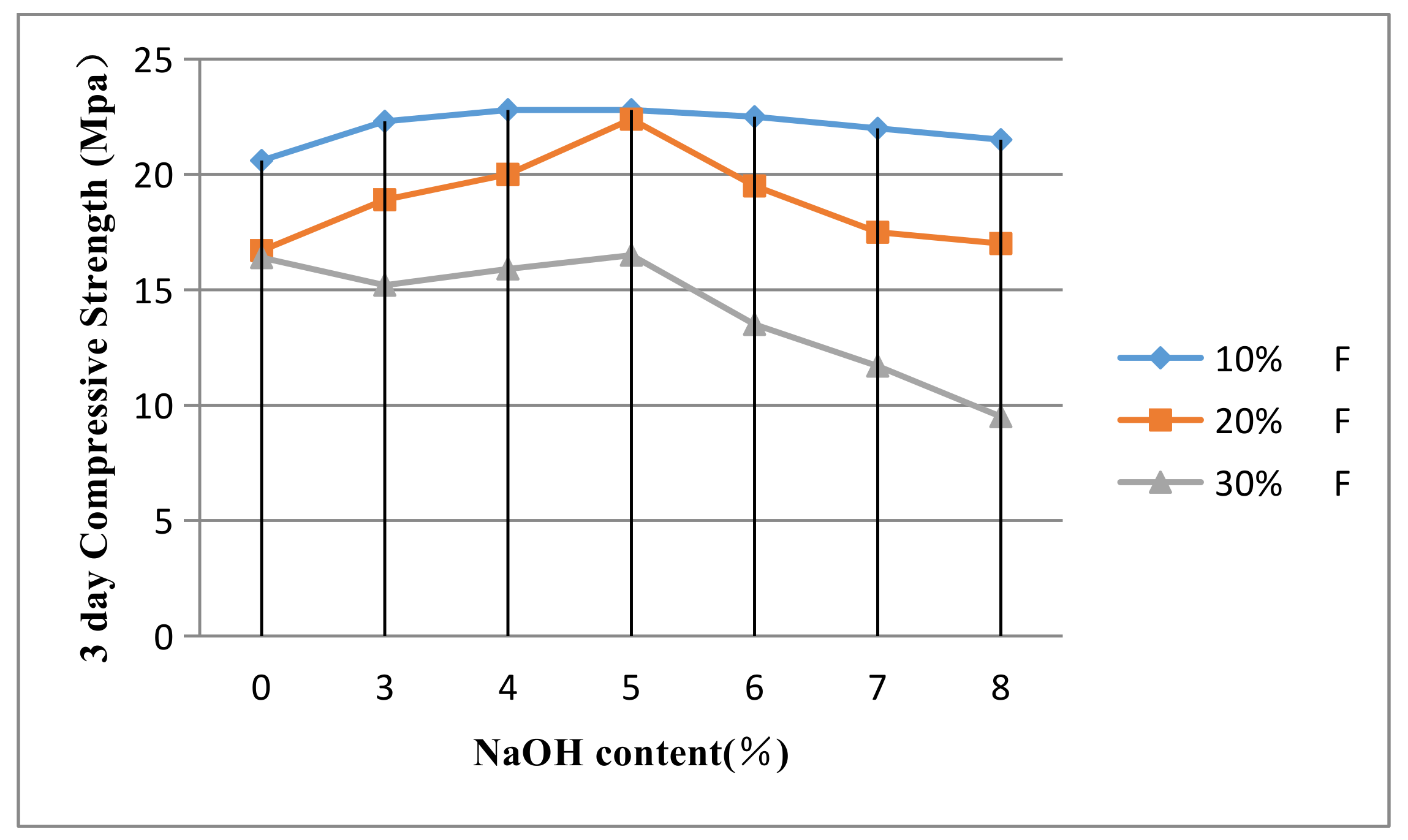

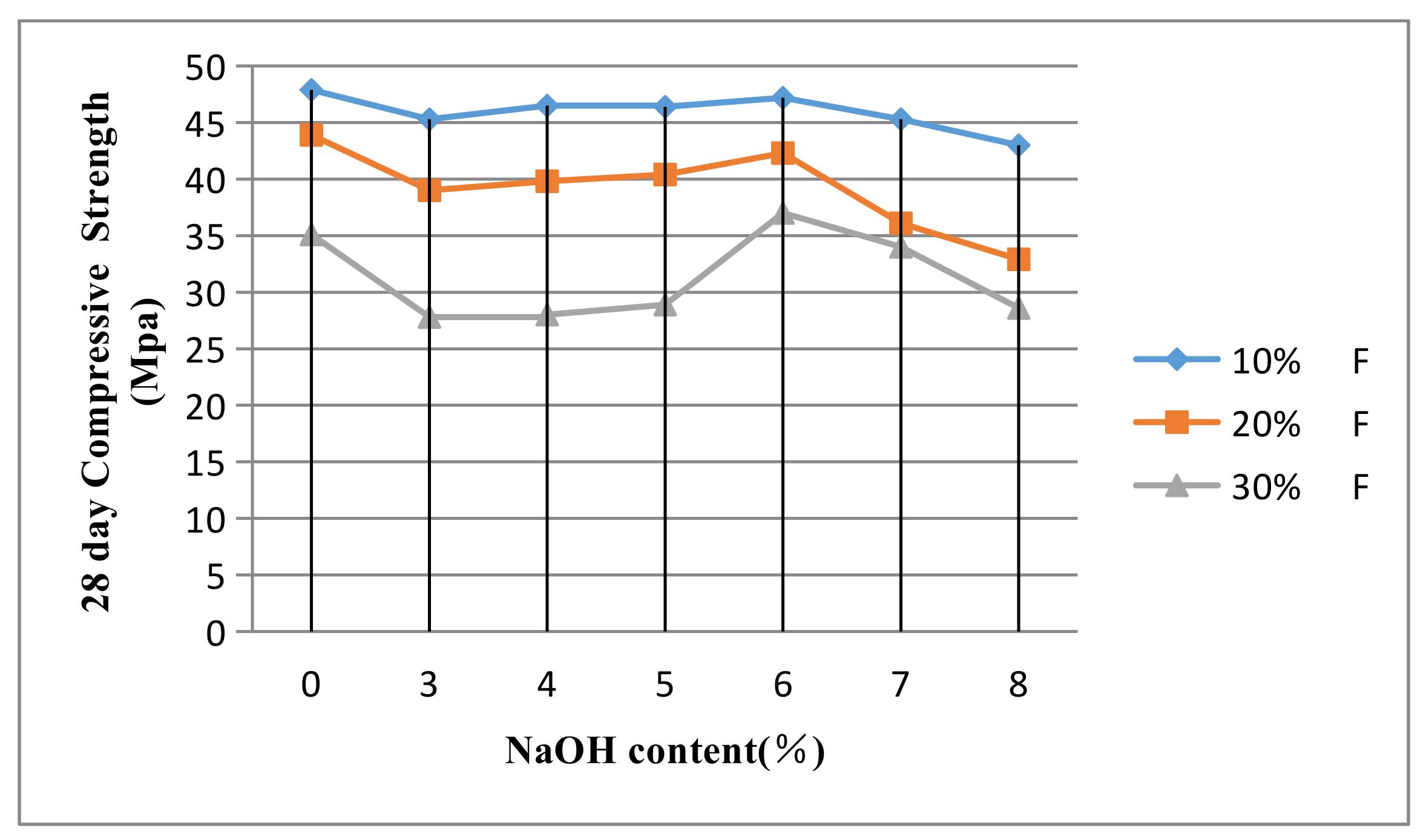

5.2. Effects of NaOH

5.3. Effects of Age

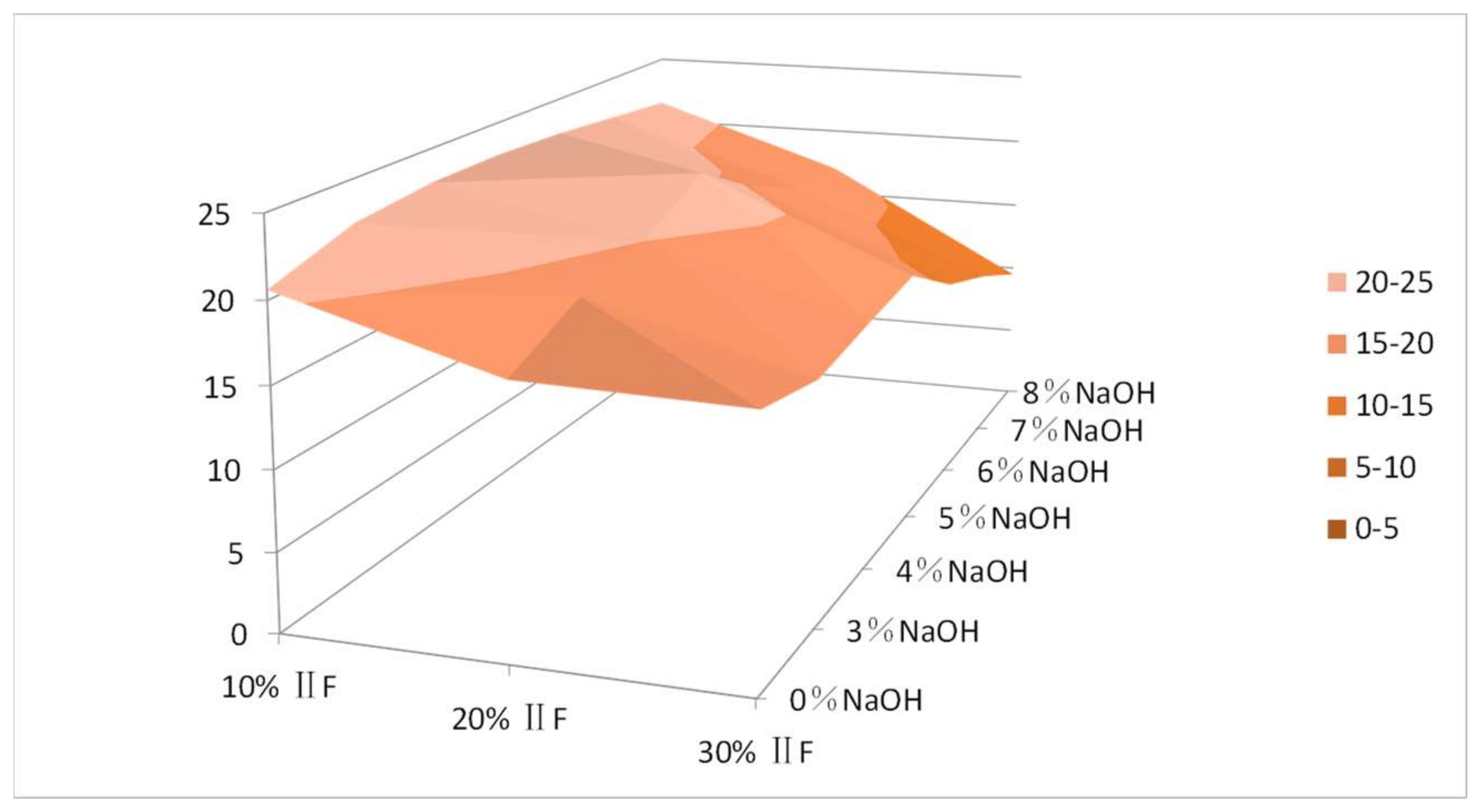

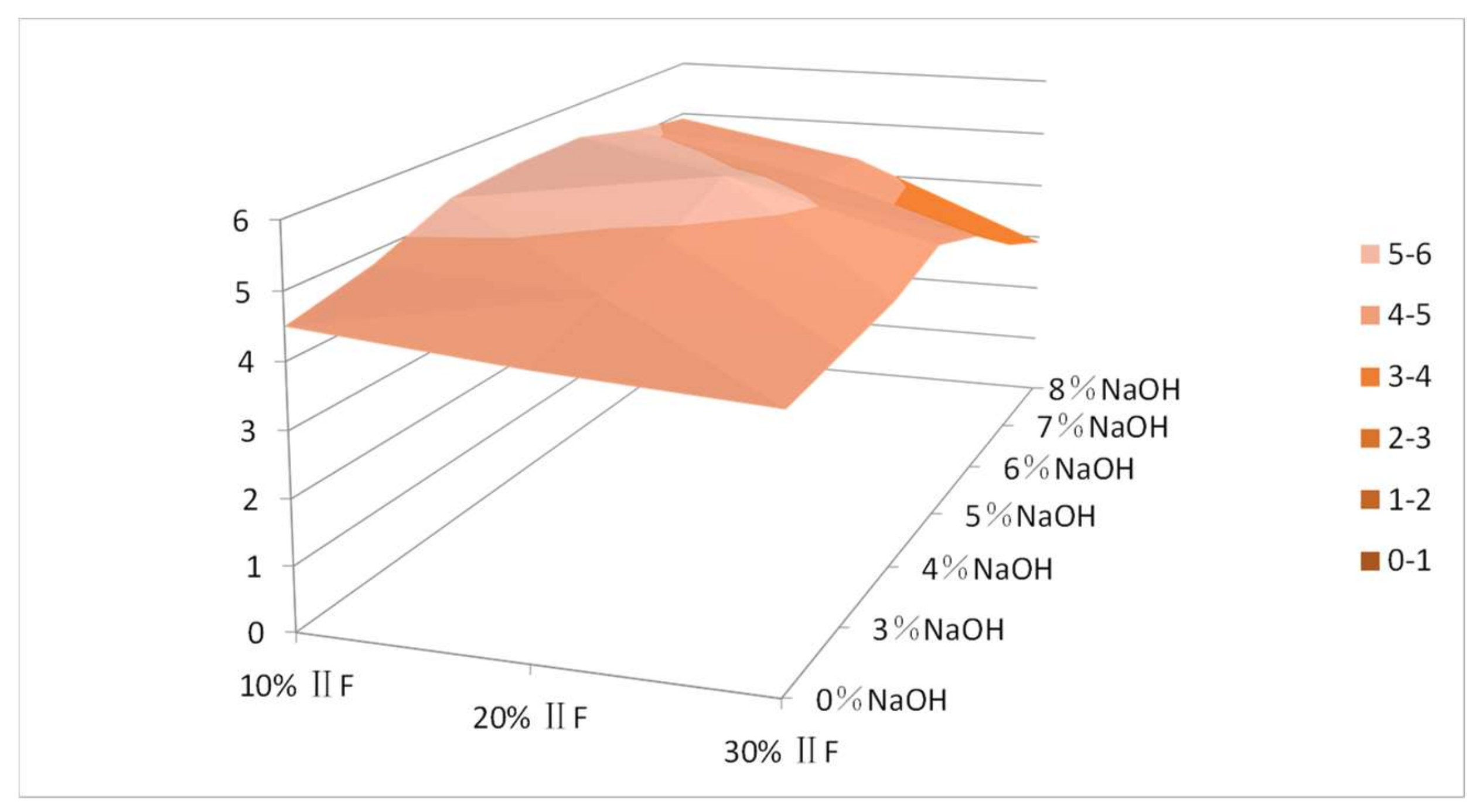

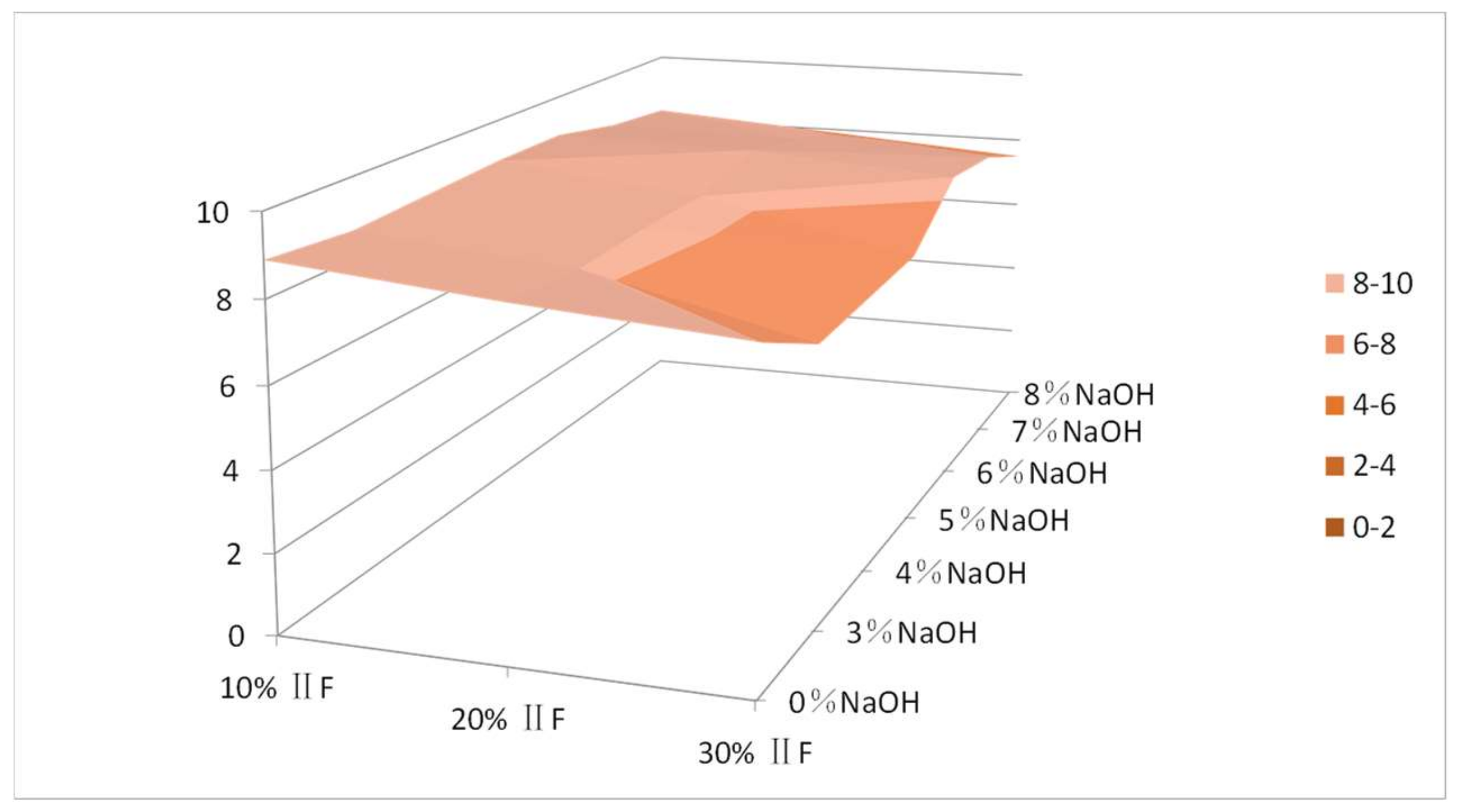

5.4. Interactions of fa/b and NaOH

- The effect of low and high content of fly ash replacement on the strength ratio had optimum strength and was roughly the same at 5% or 6% of NaOH. As shown in Figure 1 and Figure 2, at 3 days of age, the flexural strength of concrete with 10% fly ash at 5% or 6% of NaOH was the highest, and the compressive strength was the highest at 5% of NaOH. At 28 days, the flexural strength of concrete with 10% fly ash at 5% or 6% of NaOH was the highest, and compressive strength was the highest at 5% of NaOH.

- With the increase of fly ash, the strength decreased significantly at a high content of NaOH and decreased slightly lower at a low content of NaOH. For example, with NaOH contents of 0% and 8%, the compressive strength with 30% fly ash at 28 days of age was 74 and 66%, respectively, of concrete with 10% fly ash. At 28 days, the mortar strength reached the maximum when the fly ash accounted for 10% of the mixture, and the sodium hydroxide accounted for 6%.

5.5. Interactions of fa/b and Age

- In the early stage, fly ash contributed little to strength. As shown in Figure 1 and Figure 5, when the amount of NaOH was 5%, the compressive strength of concrete replaced with 10% fly ash decreased by 8% compared with that of concrete without fly ash, and the strength ratio of concrete replaced with 30% fly ash decreased by 40%.

5.6. Interactions of NaOH and Age

6. Analysis of Mechanical Properties Based on Orthogonal Test

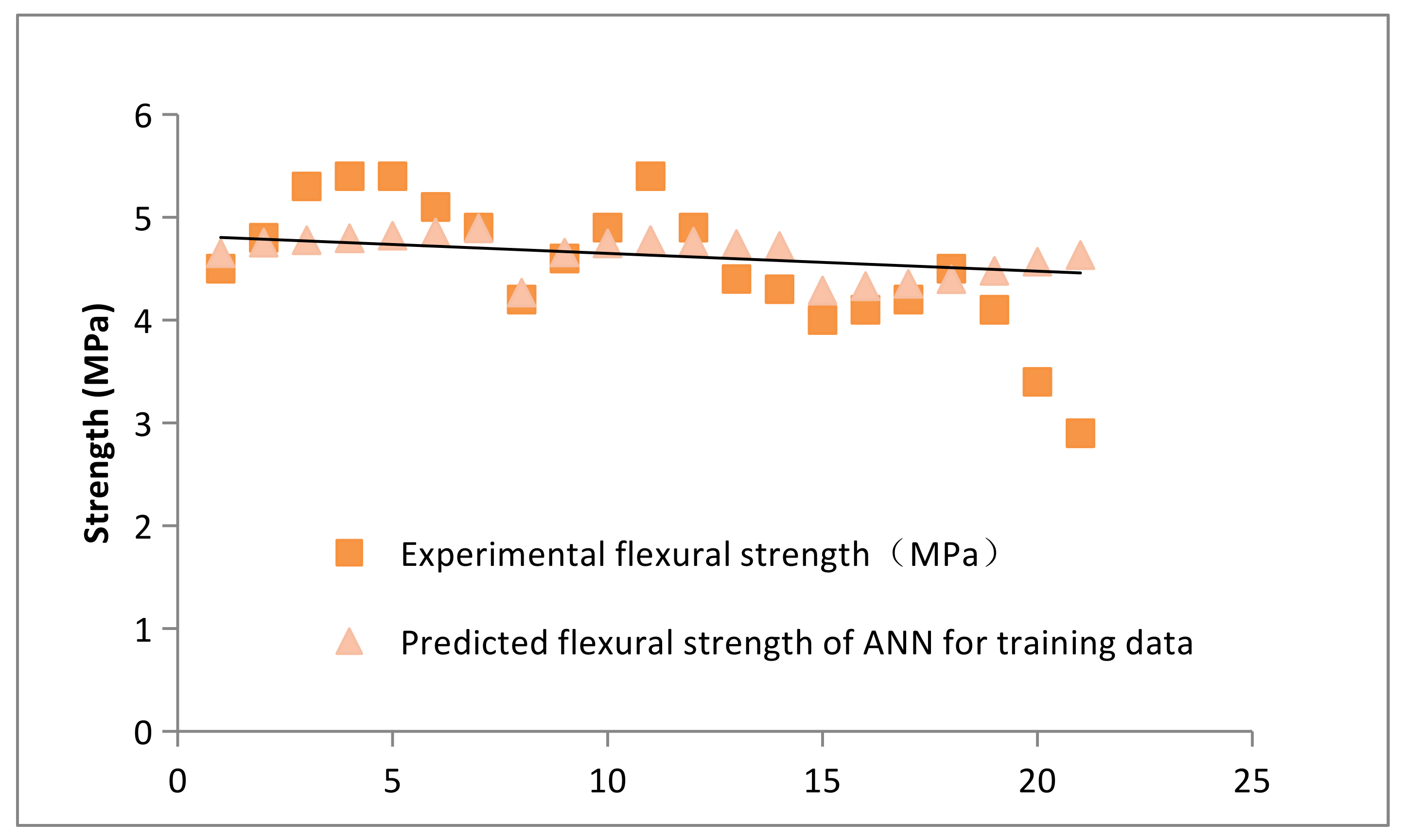

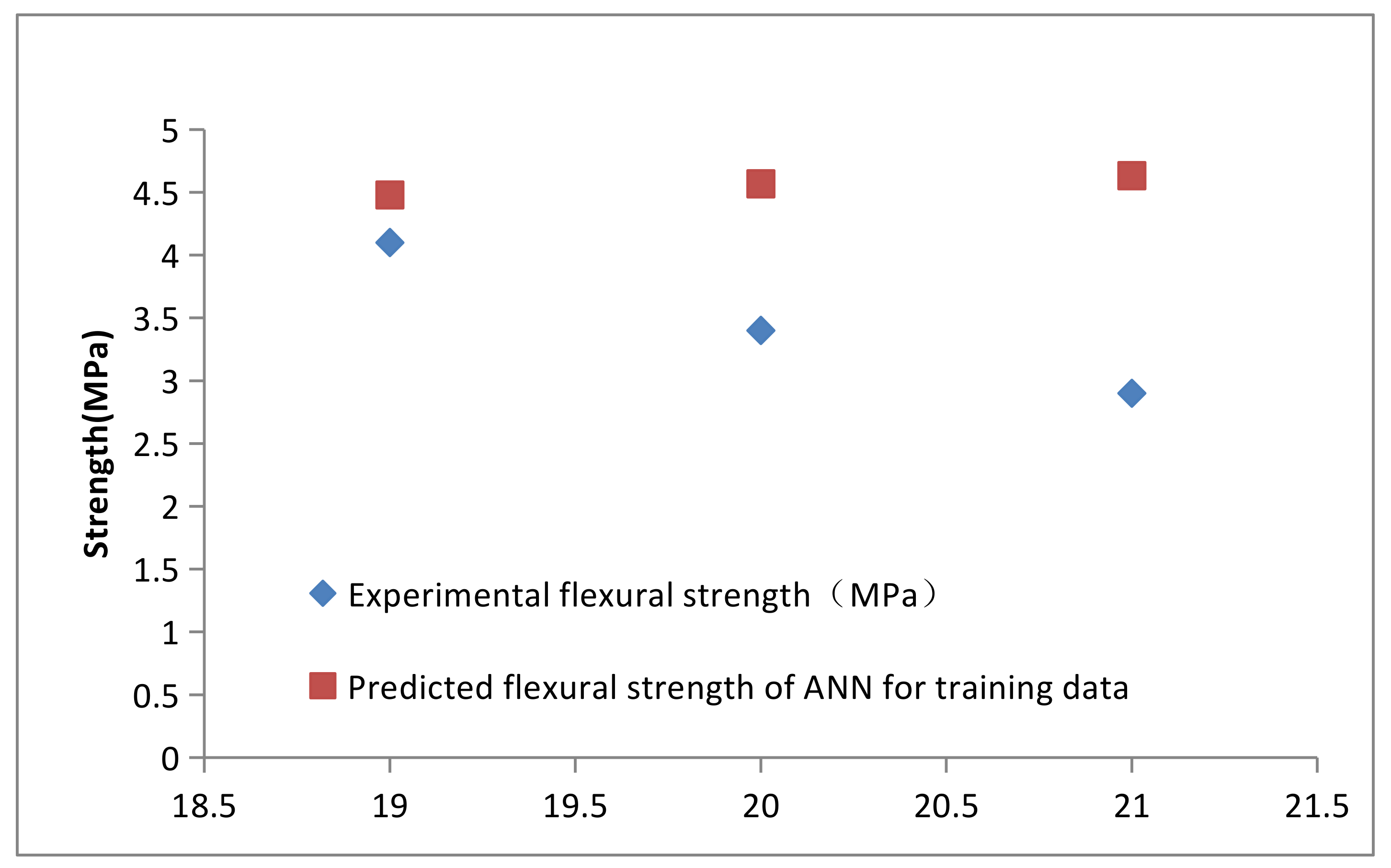

7. Neural Networks for Modeling Strength Behavior

8. Conclusions

- On the basis of laboratory tests, the concrete strength analysis is conducted to test the influence of various variables and their interaction on strength. This information can be used to elicit some interesting findings about the role and interaction of factors.

- At the same NaOH and the same age, the strength ratio (the strength ratio of concrete with fly ash and concrete without (pure cement concrete)) decreases significantly with the increase of fly ash, and it decreases significantly with age. Strength is the highest roughly when the NaOH content is 6% or 5%.

- The higher the fly ash content, the lower the overall strength ratio of the mixture, the greater the early age strength reduction, and the same optimal amount of NaOH.

- When high fly ash is substituted, the strength ratio is higher than others at 5% or 6% NaOH. However, under the condition of low fly ash content, in the concrete mixture with a certain w/b content, the strength ratio reduction caused by NaOH dosage for cement is basically the same as that caused by high fly ash concrete.

- As the age decreases, the strength ratio decreases significantly, and the strength ratio decreases more when the fly ash replacement rate is high and the content of NaOH is constant.

- For concrete compressive strength, an orthogonal experimental design can analyze the primary and secondary factors and the best combination of them (cement, fly ash, NaOH, standard, water, etc.). The optimal combination of 3-day intensity was A1B4, and the optimal combination of flexural strength at 28 days was A1B5. The optimal combination of 28 days compressive strength was A1B5 or A1B1. The OED can effectively determine the importance of each factor.

- Based on the mixture data obtained from the mix design test results and orthogonal tests, using the generalization ability of the neural network, a high correlation between the strength and composition of concrete can be developed. The model can effectively simulate the compressive strength behavior of concrete. Therefore, the neural network is much more economical.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, S.; Zhang, Y.; Zhou, D.; Wang, W.; Li, D.; Ke, Z. Experimental Study on Mechanical Properties of Fly Ash Stabilized with Cement. Adv. Civ. Eng. 2020, 2020, 6410246. [Google Scholar] [CrossRef]

- Onyari, E.K.; Ikotun, B.D. Prediction of compressive and flexural strengths of a modified zeolite additive mortar using artificial neural network. Constr. Build. Mater. 2018, 187, 1232–1241. [Google Scholar] [CrossRef]

- Herath, C.; Gunasekara, C.; Law, D.W.; Setunge, S. Performance of high volume fly ash concrete incorporating additives: A systematic literature review. Constr. Build. Mater. 2020, 258, 120606. [Google Scholar] [CrossRef]

- Jun, X.; Ding, Y.; Cao, M. Research progress on the design of self-compacting concrete ratio. Concrete 2013, 8, 105–109. (In Chinese) [Google Scholar]

- Medina, A.L.N.; García, J.A.; Castellanos, N.T. Flexural behavior of environmentally friendly ultra-high-performance concrete with locally available low-cost synthetic fibers. Eur. J. Environ. Civ. Eng. 2021, 1–24. [Google Scholar] [CrossRef]

- Prasad, V.D.; Prakash, E.L.; Abishek, M.; Dev, K.U.; Kiran, C.K.S. Study on concrete containing waste foundry sand, fly ash and polypropylene fibre using Taguchi method. Mater. Today Proc. 2018, 5, 23964–23973. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, Y.; Ge, X.; Cai, J.; Han, Y.; Zhang, H.; Wang, J.; Zhang, L.; Chen, D.; Hua, H.; et al. Research on Multiobjective Optimization of Bulb Tubular Turbine Based on Orthogonal Test. Shock Vib. 2021, 2021, 5581455. [Google Scholar] [CrossRef]

- Yeh, I.-C. Analysis of Strength of Concrete Using Design of Experiments and Neural Networks. J. Mater. Civ. Eng. 2006, 18, 597–604. [Google Scholar] [CrossRef]

- Gao, S.; Liu, Q.; Han, F.; Fu, Y. Mix Design of Recycled Coarse Aggregate Self-Compacting Concrete Based on Orthogonal Test and Analysis of Mercury Intrusion Porosimetry. Adv. Mater. Sci. Eng. 2021, 2021, 4829673. [Google Scholar] [CrossRef]

- Hosein, N.; Amir, H.R.; Pouyan, F. Compressive strength prediction of environmentally friendly concrete using artificial neural networks. J. Build. Eng. 2018, 16, 213–219. [Google Scholar]

- Shahmansouri, A.A.; Yazdani, M.; Ghanbari, S.; Bengar, H.A.; Jafari, A.; Ghatte, H.F. Artificial neural network model to predict the compressive strength of eco-friendly geopolymer concrete incorporating silica fume and natural zeolite. J. Clean. Prod. 2021, 279, 123697. [Google Scholar] [CrossRef]

- Khambra, G.; Shukla, P. Novel machine learning applications on fly ash based concrete: An overview. Mater. Today Proc. 2021; in press. ISSN 2214-7853. [Google Scholar] [CrossRef]

- Ly, H.-B.; Nguyen, T.-A.; Mai, H.-V.T.; Tran, V.Q. Development of deep neural network model to predict the compressive strength of rubber concrete. Constr. Build. Mater. 2021, 301, 124081. [Google Scholar] [CrossRef]

- Mohammed, S.I.; Najim, K.B. Mechanical strength, flexural behavior and fracture energy of recycled concrete aggregate self-compacting concrete. Structure 2020, 23, 34–43. [Google Scholar] [CrossRef]

- Liu, Q.; Han, F.; Yu, G.; Xu, P. Basic mechanical properties of recycled coarse aggregate self-compacting concrete. J. Build. Mater. 2020, 23, 65–72. (In Chinese) [Google Scholar]

- Asteris, P.G.; Mokos, V.G. Concrete compressive strength using artificial neural networks. Neural Comput. Appl. 2020, 32, 11807–11826. [Google Scholar] [CrossRef]

- Liu, Q.; Iqbal, M.F.; Yang, J.; Lu, X.; Zhang, P.; Rauf, M. Prediction of chloride diffusivity in concrete using artificial neural network: Modelling and performance evaluation. Constr. Build. Mater. 2021, 268, 121082. [Google Scholar] [CrossRef]

- Cao, X. Study on the Variation Rule of Pore Structure of Natural Pumice Concrete Based on NMR Technology; Inner Mongolia University of Technology: Hohhot, China, 2020. [Google Scholar]

- Kapoor, K.; Singh, S.P.; Singh, B.; Singh, P. Effect of recycled aggregates on fresh and hardened properties of self compacting concrete. Mater. Today Proc. 2020, 32, 600–607. [Google Scholar] [CrossRef]

- Singh, A.; Mohapatra, P.K.; Kalyanasundaram, D.; Kumar, S. Self-functionalized ultrastable water suspension of luminescent carbon quantum dots. Mater. Chem. Phys. 2019, 225, 23–27. [Google Scholar] [CrossRef]

- Tang, W.C. Fresh properties of self-compacting concrete with coarse recycled aggregate. Adv. Mater. Res. 2012, 602–604, 938–942. [Google Scholar] [CrossRef]

- Kim, Y.; Hanif, A.; Usman, M.; Park, W. Influence of bonded mortar of recycled concrete aggregates on interfacial characteristics-porosity assessment based on pore segmentation from backscattered electron image analysis. Constr. Build. Mater. 2019, 212, 149–163. [Google Scholar] [CrossRef]

- Ge, Z.; Liu, X.; Li, Q. Study on properties of selfcompacting concrete with recycled fine aggregate. J. Build. Struct. 2019, 49, 672–676. (In Chinese) [Google Scholar]

- Xiang, X.; Zhao, R.; Li, F.; Liao, P. Experimental investigation of basic mechanical properties of self-compacting recycled aggregate concrete. J. Southwest Jiaotong Univ. 2019, 54, 359–365. (In Chinese) [Google Scholar]

- Hanif, A.; Kim, Y.; Lu, Z.; Park, C. Early-age behavior of recycled aggregate concrete under steam curing regime. J. Clean. Prod. 2017, 152, 103–114. [Google Scholar] [CrossRef]

- Zine-el-abidine, T.; Tien-Tung, N.; El Hadj, K.; Adrien, B.; Farid, D.; Salima, A. Effect of cement and admixture on the utilization of recycled aggregates in concrete. Constr. Build. Mater. 2017, 149, 91–102. [Google Scholar]

- Lavado, J.; Bogas, J.; De Brito, J.; Hawreen, A. Fresh properties of recycled aggregate concrete. Constr. Build. Mater. 2020, 233, 117322. [Google Scholar] [CrossRef]

- Barnhouse, P.W.; Srubar, W.V. Material characterization and hydraulic conductivity modeling of macroporous recycled-aggregate pervious concrete. Constr. Build. Mater. 2016, 110, 89–97. [Google Scholar] [CrossRef]

- Huo, J.; Cao, X.; Wang, X.; Ji, Y.; Li, H. Influence of natural pumice concrete pore structure on its compressive strength. Bull. Chin. Ceram. Soc. 2020, 39, 84–89. (In Chinese) [Google Scholar]

- Golewski, G.L. Effect of curing time on the fracture toughness of fly ash concrete composites. Compos. Struct. 2018, 185, 105–112. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, Y.; Zhou, D.; Wang, W.; Li, D.; Ke, Z. Hydration characteristic of low heat Portland cement mixtures with fly ash or slag. Port Waterw. Eng. 2019, 599, 63–69. [Google Scholar]

- Liu, F.; Gong, A.; Wang, L.; Yang, Y. Experimental study on mechanical properties of fly ash—Cement concrete with alkali-admixture. S. N. Water Divers. Water Conserv. Technol. 2014, 12, 134–137. (In Chinese) [Google Scholar]

- Liu, F.; Gong, A.; Peng, Y.; Long, L.; Wang, X. Experimental study on strength performance of fly ash—Cement rubber sand with alkali—Adding activator. Hydraul. Electrogener. 2014, 40, 100–102. (In Chinese) [Google Scholar]

- Liu, F.; Xu, J.; Gong, A.; Chen, C.; Xie, F.; Luo, C. Application of THREE-DIMENSIONAL numerical simulation in strength test of fly ash and cement mortar with alkali addition. Jiangxi Sci. 2020, 38, 388–393. (In Chinese) [Google Scholar]

- Liu, F.; Yang, R.; Xu, J.; Gong, A.; Xie, F.; Luo, C. Experimental study on the strength performance of fly ash cement doped with sodium hydroxide activator. Fly Ash Compr. Util. 2019, 6, 3–6+50. (In Chinese) [Google Scholar]

- Chen, Q.; Zhu, H.; Ju, J.; Yan, Z.; Wang, C.; Jiang, Z. A stochastic micromechanical model for fiber-reinforced concrete using maximum entropy principle. Acta Mech. 2018, 229, 2719–2735. [Google Scholar] [CrossRef]

- Chen, Q.; Zhu, H.; Ju, J.W.; Jiang, Z.; Yan, Z.; Li, H. Stochastic micromechanical predictions for the effective properties of concrete considering the interfacial transition zone effects. Int. J. Damage Mech. 2018, 27, 1252–1271. [Google Scholar] [CrossRef]

- Chen, Q.; Zhu, H.H.; Ju, J.W.; Guo, F.; Wang, L.B.; Yan, Z.G.; Deng, T.; Zhou, S. A Stochastic Micromechanical model for Multiphase Composite Containing Spherical Inhomogeneities. Acta Mech. 2015, 226, 1861–1880. [Google Scholar] [CrossRef]

| Cementitious Material/g | Standard Sand/g | Mixing Water/mL |

|---|---|---|

| 450 ± 2 | 1350 ± 5 | 225 ± 1 |

| 3 Days Flexural | 3 Days Compression | 28 Days Flexural | 28 Days Compression | |||||

|---|---|---|---|---|---|---|---|---|

| A (Fly Ash) | B (NaOH) | A (Fly Ash) | B (NaOH) | A (Fly Ash) | B (NaOH) | A (Fly Ash) | B (NaOH) | |

| 5.06 | 4.23 | 22.07 | 17.9 | 8.71 | 8.43 | 45.94 | 42.3 | |

| 4.67 | 4.5 | 18.86 | 18.8 | 8.33 | 7.93 | 39.2 | 37.37 | |

| 3.89 | 4.8 | 14.1 | 19.57 | 7.59 | 8.03 | 31.34 | 38.1 | |

| 5.1 | 20.57 | 8.1 | 38.57 | |||||

| 4.8 | 18.5 | 8.7 | 42.17 | |||||

| 4.3 | 17.07 | 8.37 | 38.47 | |||||

| 4.03 | 16 | 7.9 | 34.83 | |||||

| R (the average poor) | 1.17 | 1.07 | 7.97 | 4.57 | 1.12 | 0.8 | 14.6 | 7.47 |

| Primary and secondary factors | A > B | A > B | A > B | A > B | ||||

| Optimal combination | A1B4 | A1B4 | A1B5 | A1B1 or A1B5 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Xu, J.; Tan, S.; Gong, A.; Li, H. Orthogonal Experiments and Neural Networks Analysis of Concrete Performance. Water 2022, 14, 2520. https://doi.org/10.3390/w14162520

Liu F, Xu J, Tan S, Gong A, Li H. Orthogonal Experiments and Neural Networks Analysis of Concrete Performance. Water. 2022; 14(16):2520. https://doi.org/10.3390/w14162520

Chicago/Turabian StyleLiu, Feipeng, Jing Xu, Shucheng Tan, Aimin Gong, and Huimei Li. 2022. "Orthogonal Experiments and Neural Networks Analysis of Concrete Performance" Water 14, no. 16: 2520. https://doi.org/10.3390/w14162520