Nitrate Removal and Woodchip Properties across a Paired Denitrifying Bioreactor Treating Centralized Agricultural Ditch Flows

Abstract

:1. Introduction

2. Materials and Methods

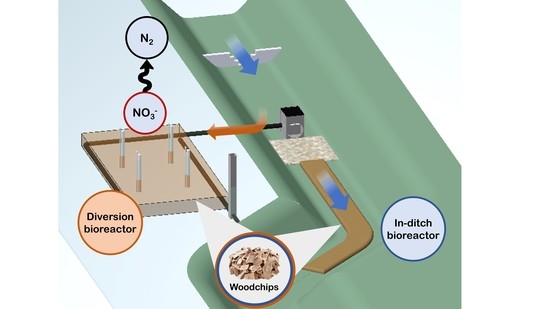

2.1. Bioreactor Design and Construction

2.2. Flow and Nitrate Monitoring

2.3. Media Physiochemical Analyses

2.4. Denitrification Potential

2.5. Statistical Analysis

3. Results and Discussion

3.1. Bioreactor Performance

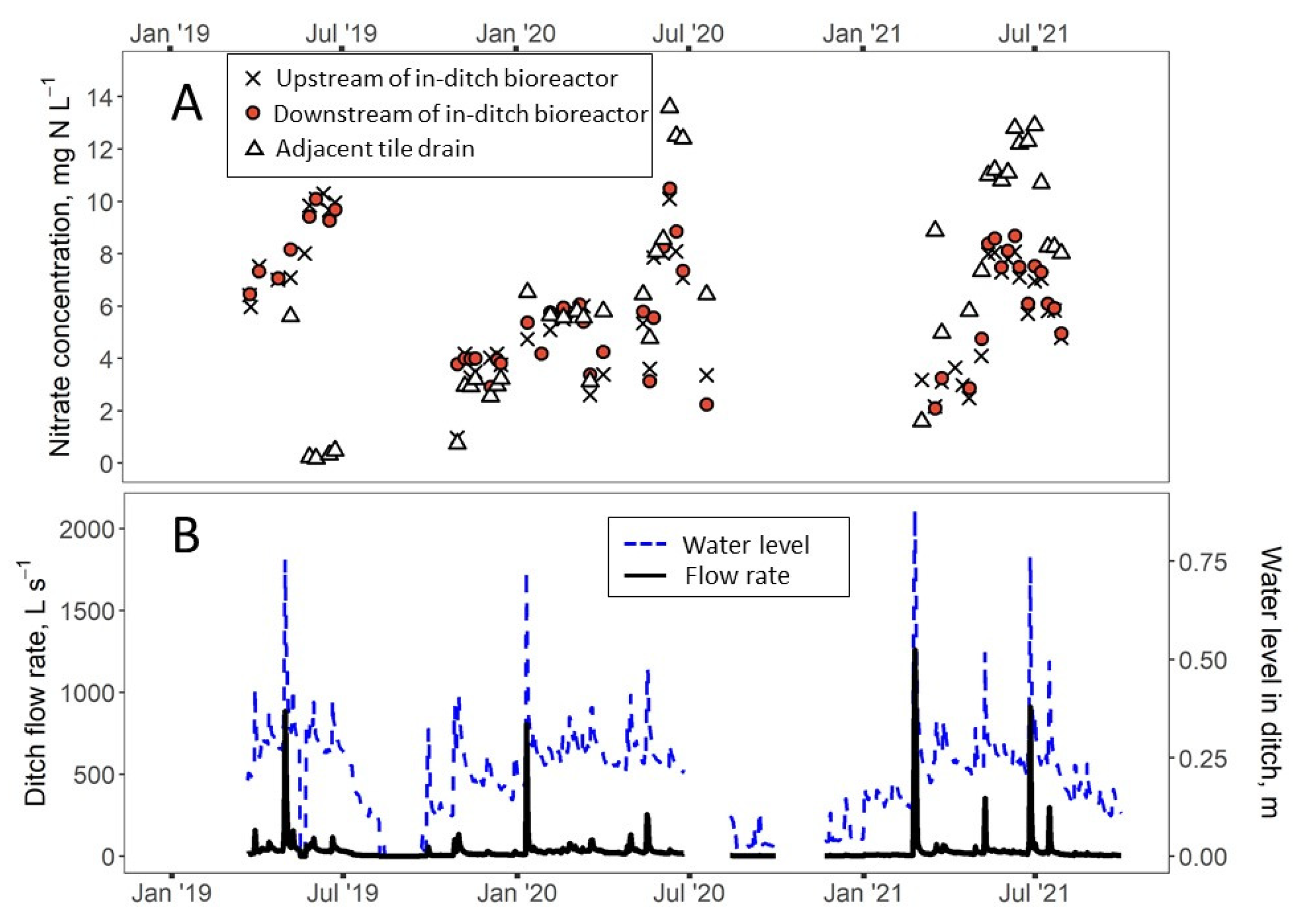

3.1.1. In-Ditch Bioreactor

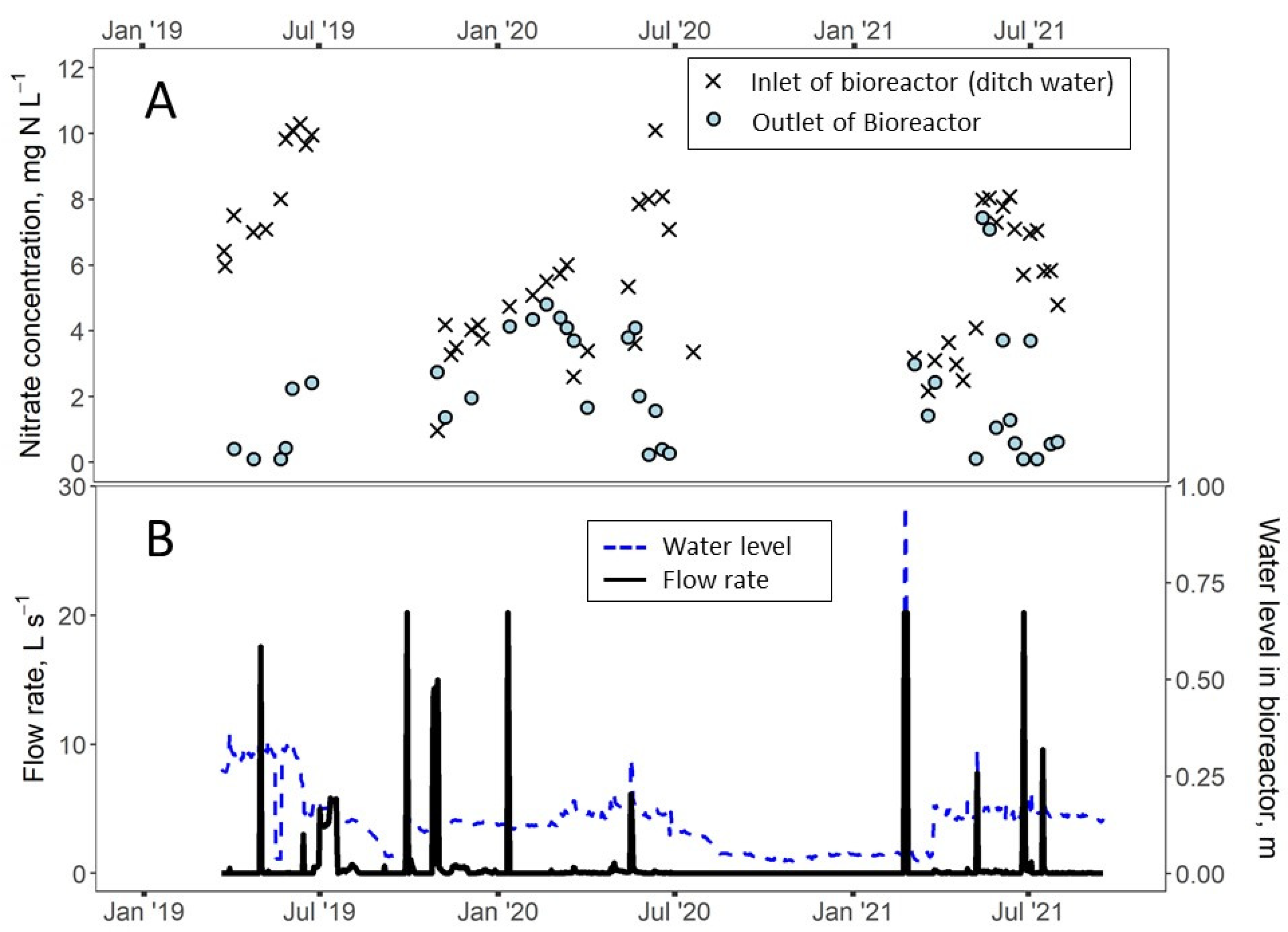

3.1.2. Ditch Diversion Bioreactor

3.1.3. Performance of Paired Bioreactor Design

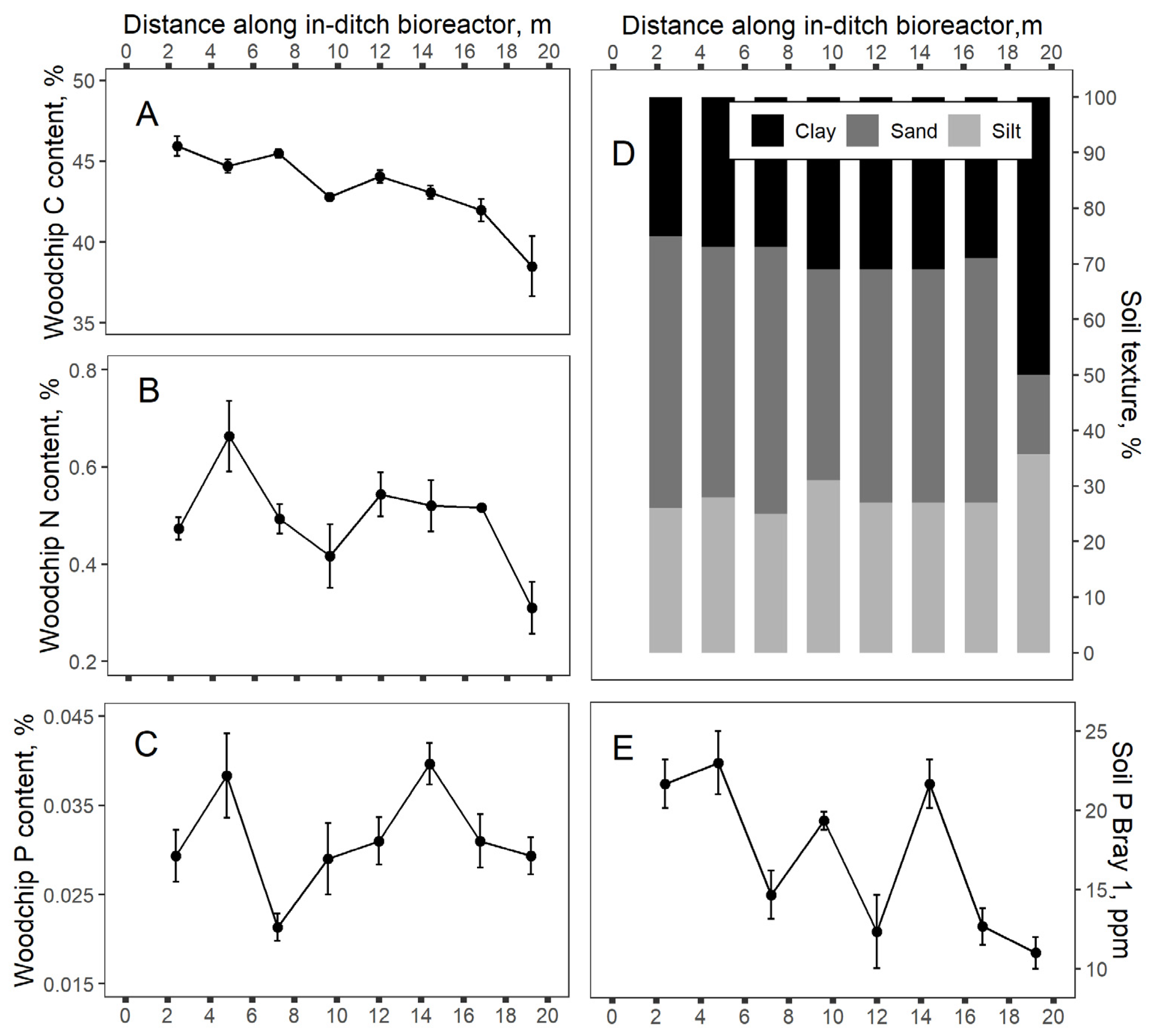

3.2. Microbial and Physiochemical Properties of Woodchips and Soil

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Schipper, L.A.; Robertson, W.D.; Gold, A.J.; Jaynes, D.B.; Cameron, S.C. Denitrifying bioreactors—An approach for reducing nitrate loads to receiving waters. Ecol. Eng. 2010, 36, 1532–1543. [Google Scholar] [CrossRef]

- Díaz-García, C.; Martínez-Sánchez, J.J.; Maxwell, B.M.; Franco, J.A.; Álvarez-Rogel, J. Woodchip bioreactors provide sustained denitrification of brine from groundwater desalination plants. J. Environ. Manag. 2021, 289, 112521. [Google Scholar] [CrossRef]

- Pulkkinen, J.T.; Ronkanen, A.; Pasanen, A.; Kiani, S.; Kiuru, T.; Koskela, J.; Lindholm-Lehto, P.; Lindroos, A.J.; Muniruzzaman, M.; Solismaa, L.; et al. Start-up of a “zero-discharge” recirculating aquaculture system using woodchip denitrification, constructed wetland, and sand infiltration. Aquacult. Eng. 2021, 93, 102161. [Google Scholar] [CrossRef]

- Robertson, W.D.; Merkley, L. In-stream bioreactor for agricultural nitrate treatment. J. Environ. Qual. 2009, 38, 230–237. [Google Scholar] [CrossRef] [Green Version]

- Christianson, L.E.; Collick, A.S.; Bryant, R.B.; Rosen, T.; Bock, E.M.; Allen, A.L.; Kleinman, P.J.A.; May, E.B.; Buda, A.R.; Robinson, J.; et al. Enhanced Denitrification Bioreactors Hold Promise for Mid-Atlantic Ditch Drainage. Agric. Environ. Lett. 2017, 2, 170032. [Google Scholar] [CrossRef] [Green Version]

- Pfannerstill, M.; Kühling, I.; Hugenschmidt, C.; Trepel, M.; Fohrer, N. Reactive ditches: A simple approach to implement denitrifying wood chip bioreactors to reduce nitrate exports into aquatic ecosystems? Environ. Earth Sci. 2016, 75, 1–10. [Google Scholar] [CrossRef]

- Chase, E.H.; Schneider, R.L.; Baker, N.J.; Dunn, S.J. Retrofitting the rural roadside ditch network to treat nitrogen from agricultural runoff using woodchip bioreactors. In Proceedings of the 12th International Conference on Low-Volume Roads, Kalispell, MT, USA, 15–18 September 2019; pp. 320–324. [Google Scholar]

- Addy, K.; Gold, A.J.; Christianson, L.E.; David, M.B.; Schipper, L.A.; Ratigan, N.A. Denitrifying bioreactors for nitrate removal: A meta-analysis. J. Environ. Qual. 2016, 45, 873–881. [Google Scholar] [CrossRef]

- Sarris, T.S.; Burbery, L.F. Stochastic multi-objective performance optimization of an in-stream woodchip denitrifying bioreactor. Ecol Eng. 2018, 124, 38–50. [Google Scholar] [CrossRef]

- USDA NRCS Illinois. Conservation Practice Standard Denitrifying Bioreactor Code 605 (605-CPS); United States Department of Agricultural Natural Resources Conservation Service: Champaign, IL, USA, 2020.

- Deutsch, B.; Kahle, P.; Voss, M. Assessing the source of nitrate pollution in water using stable N and O isotopes. Agron. Sustain. Dev. 2006, 26, 263–267. [Google Scholar] [CrossRef]

- Bernhardt, E.S.; Hall, R.O., Jr.; Likens, G.E. Whole-system estimates of nitrification and nitrate uptake in streams of the Hubbard Brook Experimental Forest. Ecosystems 2002, 5, 419–430. [Google Scholar] [CrossRef]

- Wickramarathne, N.M.; Cooke, R.A.; Book, R.; Christianson, L.E. Denitrifying woodchip bioreactor leachate tannic acid and true color: Lab and field studies. Trans. ASABE 2020, 63, 1747–1757. [Google Scholar] [CrossRef]

- Sanchez Bustamente-Bailon, A.P.; Margenot, A.; Cooke, R.A.; Christianson, L.E. Phosphorus removal in denitrifying woodchip bioreactors varies by wood type and water chemistry. Environ. Sci. Pollut. Res. 2021. [Google Scholar] [CrossRef]

- USEPA. Volunteer Stream Monitoring: A Methods Manual. 1997. Available online: https://www.epa.gov/sites/default/files/2015-06/documents/stream.pdf (accessed on 27 December 2021).

- Muste, M.; Lee, K.; Kim, D.; Bacotiu, C.; Oliveros, M.R.; Cheng, Z.; Quintero, F. Revisiting hysteresis of flow variables in monitoring unsteady streamflows. J. Hydraul. Res. 2020, 58, 867–887. [Google Scholar] [CrossRef]

- Christianson, L.; Christianson, R.; Lipka, A.; Bailey, S.; Chandrasoma, J.; McCoy, C.; Fontes, G.P.; Roh, J.; Bailon, A.P.; Wickramarathne, N.M.; et al. Calibration of stainless steel-edged V-notch weir stop logs for water level control structures. Appl. Eng. Agric. 2019, 35, 745–749. [Google Scholar] [CrossRef]

- Williams, M.R.; King, K.W.; Macrae, M.L.; Ford, W.; Van Esbroeck, C.; Brunke, R.I.; English, M.C.; Schiff, S.L. Uncertainty in nutrient loads from tile-drained landscapes: Effect of sampling frequency, calculation algorithm, and compositing strategy. J. Hydrol. 2015, 530, 306–316. [Google Scholar] [CrossRef]

- Tiedje, J.M.; Simkins, S.; Groffman, P.M. Perspectives on measurement of denitrification in the field including recommended protocols for acetylene based methods. Plant Soil 1989, 115, 261–284. [Google Scholar] [CrossRef]

- Wickramarathne, N.M.; Christianson, L.E.; Foltz, M.E.; Zilles, J.L.; Christianson, R.D.; Cooke, R.A. Biological Nitrate Removal with Emerald Ash Borer-Killed Ash and High-Tannin Oak Woodchips. Front. Environ. Sci. 2021, 9, 73. [Google Scholar] [CrossRef]

- Foltz, M.E.; Kent, A.D.; Koloutsou-Vakakis, S.; Zilles, J.L. Influence of rye cover cropping on denitrification potential and year-round field N2O emissions. Sci. Total Environ. 2021, 765, 144295. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2017; Available online: https://www.R-project.org/ (accessed on 1 December 2021).

- García-Gutiérrez, C.; Pachepsky, Y.; Martín, M.Á. Saturated hydraulic conductivity and textural heterogeneity of soils. Hydrol. Earth Syst. Sci. 2018, 22, 3923–3932. [Google Scholar] [CrossRef] [Green Version]

- Chun, J.; Cooke, R.; Eheart, J.; Kang, M. Estimation of flow and transport parameters for woodchip-based bioreactors: I. laboratory-scale bioreactor. Biosyst. Eng. 2009, 104, 384–395. [Google Scholar] [CrossRef]

- Cameron, S.G.; Schipper, L.A. Nitrate removal and hydraulic performance of organic carbon for use in denitrification beds. Ecol. Eng. 2010, 36, 1588–1595. [Google Scholar] [CrossRef]

- Hertzberger, A.; Pittelkow, C.; Harmel, R.; Christianson, L. The MANAGE Drain Concentration database: A new tool compiling North American drainage nutrient concentrations. Agric. Water Manag. 2019, 216, 113–117. [Google Scholar] [CrossRef]

- Maxwell, B.M.; Birgand, F.; Schipper, L.A.; Christianson, L.E.; Tian, S.; Helmers, M.J.; Williams, D.J.; Chescheir, G.M.; Youssef, M.A. Drying–rewetting cycles affect nitrate removal rates in woodchip bioreactors. J. Environ. Qual. 2019, 48, 93–101. [Google Scholar] [CrossRef]

- Christianson, L.E.; Bhandari, A.; Helmers, M.J.; Kult, K.J.; Sutphin, T.; Wolf, R. Performance evaluation of four field-scale agricultural drainage denitrification bioreactors in Iowa. Trans. ASABE 2012, 55, 2163. [Google Scholar] [CrossRef] [Green Version]

- Lepine, C.; Christianson, L.; Sharrer, K.; Summerfelt, S. Optimizing hydraulic retention times in denitrifying woodchip bioreactors treating recirculating aquaculture system wastewater. J. Environ. Qual. 2016, 45, 813–821. [Google Scholar] [CrossRef]

- Moorman, T.B.; Parkin, T.B.; Kaspar, T.C.; Jaynes, D.B. Denitrification activity, wood loss, and N2O emissions over 9 years from a wood chip bioreactor. Ecol. Eng. 2010, 36, 1567–1574. [Google Scholar] [CrossRef]

- Hathaway, S.K.; Bartolerio, N.A.; Rodríguez, L.F.; Kent, A.D.; Zilles, J.L. Denitrifying bioreactors resist disturbance from fluctuating water levels. Front. Environ. Sci. 2017, 5, 35. [Google Scholar] [CrossRef]

- Zhao, J.; Feng, C.; Tong, S.; Chen, N.; Dong, S.; Peng, T.; Jin, S. Denitrification behavior and microbial community spatial distribution inside woodchip-based solid-phase denitrification (W-SPD) bioreactor for nitrate-contaminated water treatment. Bioresour. Technol. 2018, 249, 869–879. [Google Scholar] [CrossRef] [PubMed]

- Fatehi-Pouladi, S.; Anderson, B.C.; Wootton, B.; Button, M.; Bissegger, S.; Rozema, L.; Weber, K.P. Interstitial water microbial communities as an indicator of microbial denitrifying capacity in wood-chip bioreactors. Sci. Total Environ. 2019, 655, 720–729. [Google Scholar] [CrossRef]

- Aalto, S.L.; Suurnäkki, S.; von Ahnen, M.; Tiirola, M.; Pedersen, P.B. Microbial communities in full-scale woodchip bioreactors treating aquaculture effluents. J. Environ. Manag. 2022, 301, 113852. [Google Scholar] [CrossRef]

- Hellman, M.; Hubalek, V.; Juhanson, J.; Almstrand, R.; Peura, S.; Hallin, S. Substrate type determines microbial activity and community composition in bioreactors for nitrate removal by denitrification at low temperature. Sci. Total Environ. 2021, 755, 143023. [Google Scholar] [CrossRef] [PubMed]

- Jéglot, A.; Sørensen, S.R.; Schnorr, K.M.; Plauborg, F.; Elsgaard, L. Temperature Sensitivity and Composition of Nitrate-Reducing Microbiomes from a Full-Scale Woodchip Bioreactor Treating Agricultural Drainage Water. Microorganisms 2021, 9, 1331. [Google Scholar] [CrossRef] [PubMed]

- Ghane, E.; Feyereisen, G.W.; Rosen, C.J.; Tschirner, U.W. Carbon quality of four-year-old woodchips in a denitrification bed treating agricultural drainage water. Trans. ASABE 2018, 61, 995–1000. [Google Scholar] [CrossRef]

- Schaefer, A.; Werning, K.; Hoover, N.; Tschirner, U.; Feyereisen, G.; Moorman, T.B.; Howe, A.C.; Soupir, M.L. Impact of flow on woodchip properties and subsidence in denitrifying bioreactors. Agrosyst. Geosci. Environ. 2021, 4, 20149. [Google Scholar] [CrossRef]

- Haan, C.T.; Barfield, B.J.; Hayes, J.C. Design Hydrology and Sedimentology for Small Catchments; Elsevier: Amsterdam, The Netherlands, 1994. [Google Scholar]

- Hua, G.; Salo, M.W.; Schmit, C.G.; Hay, C.H. Nitrate and phosphate removal from agricultural subsurface drainage using laboratory woodchip bioreactors and recycled steel byproduct filters. Water Res. 2016, 102, 180–189. [Google Scholar] [CrossRef]

- Husk, B.; Sanchez, J.; Anderson, B.; Whalen, J.; Wootton, B. Removal of phosphorus from agricultural subsurface drainage water with woodchip and mixed-media bioreactors. J. Soil Water Conserv. 2018, 73, 265–275. [Google Scholar] [CrossRef]

| Bioreactor and Sample Location | % Carbon | % Nitrogen | % Phosphorus | C:N Ratio |

|---|---|---|---|---|

| Initial woodchips used to construct both bioreactors | 47.8 ± 0.3 a | 0.30 ± 0.05 b | 0.011 ± 0.001 c | 161 ± 23 a |

| In-ditch bioreactor woodchips, unwashed † | 17.4 ± 0.5 c | 0.36 ± 0.02 ab | 0.051 ± 0.001 a | 48 ± 2 c |

| In-ditch bioreactor woodchips, washed ‡ | 43.3 ± 2.3 b | 0.49 ± 0.10 a | 0.031 ± 0.006 b | 92 ± 20 b |

| Diversion bioreactor, unwashed † | 46.9 ± 1.2 a | 0.36 ± 0.09 b | 0.010 ± 0.001 c | 137 ± 36 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maxwell, B.; Christianson, L.; Cooke, R.A.C.; Foltz, M.; Wickramarathne, N.; Chacon, R.; Christianson, R. Nitrate Removal and Woodchip Properties across a Paired Denitrifying Bioreactor Treating Centralized Agricultural Ditch Flows. Water 2022, 14, 56. https://doi.org/10.3390/w14010056

Maxwell B, Christianson L, Cooke RAC, Foltz M, Wickramarathne N, Chacon R, Christianson R. Nitrate Removal and Woodchip Properties across a Paired Denitrifying Bioreactor Treating Centralized Agricultural Ditch Flows. Water. 2022; 14(1):56. https://doi.org/10.3390/w14010056

Chicago/Turabian StyleMaxwell, Bryan, Laura Christianson, Richard A. C. Cooke, Mary Foltz, Niranga Wickramarathne, Ronnie Chacon, and Reid Christianson. 2022. "Nitrate Removal and Woodchip Properties across a Paired Denitrifying Bioreactor Treating Centralized Agricultural Ditch Flows" Water 14, no. 1: 56. https://doi.org/10.3390/w14010056

APA StyleMaxwell, B., Christianson, L., Cooke, R. A. C., Foltz, M., Wickramarathne, N., Chacon, R., & Christianson, R. (2022). Nitrate Removal and Woodchip Properties across a Paired Denitrifying Bioreactor Treating Centralized Agricultural Ditch Flows. Water, 14(1), 56. https://doi.org/10.3390/w14010056