Mathematical Modeling of a Domestic Wastewater Treatment System Combining a Septic Tank, an Up Flow Anaerobic Filter, and a Constructed Wetland

Abstract

1. Introduction

2. Materials and Methods

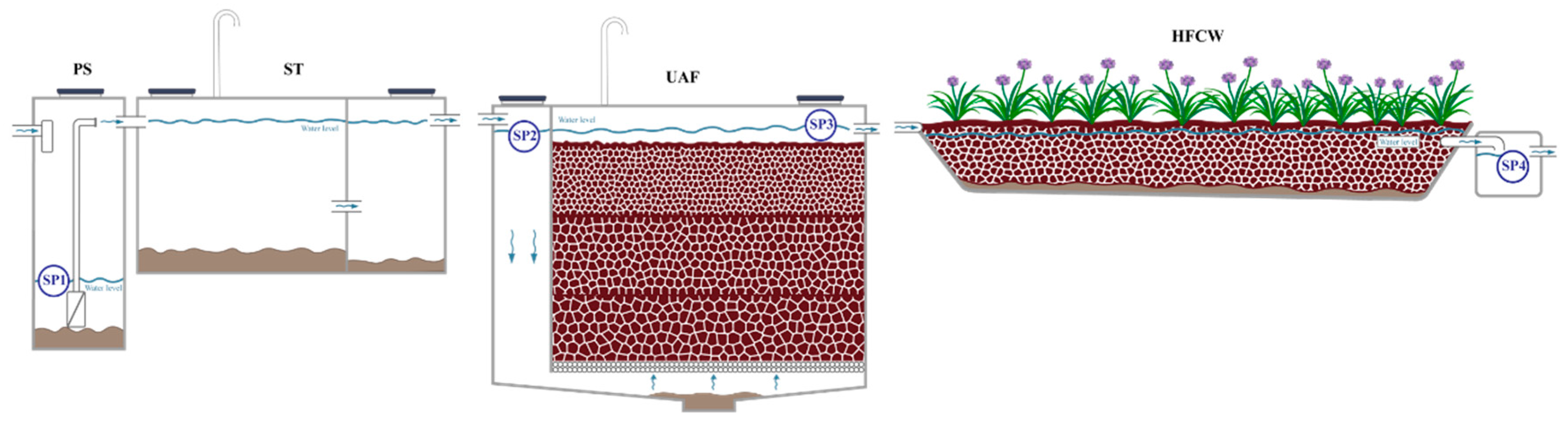

2.1. Site Description

2.2. Water Quality Sampling

2.3. Mathematical Modeling

2.3.1. First-Order Kinetic Model

2.3.2. Multiple Liner Regression Model

2.3.3. Mass Balance Model

3. Results and Discussion

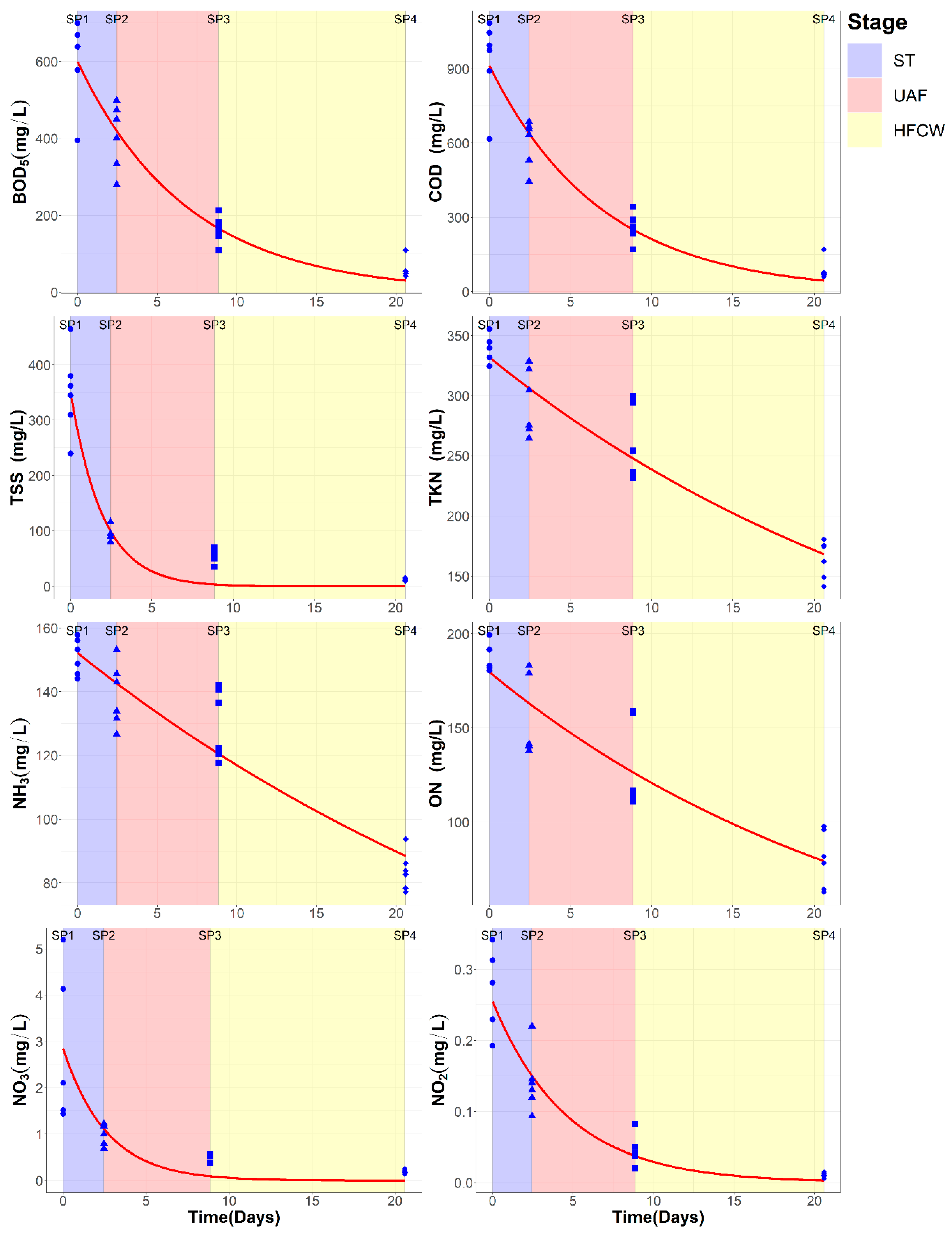

3.1. System Performance

3.2. Mathematical Models

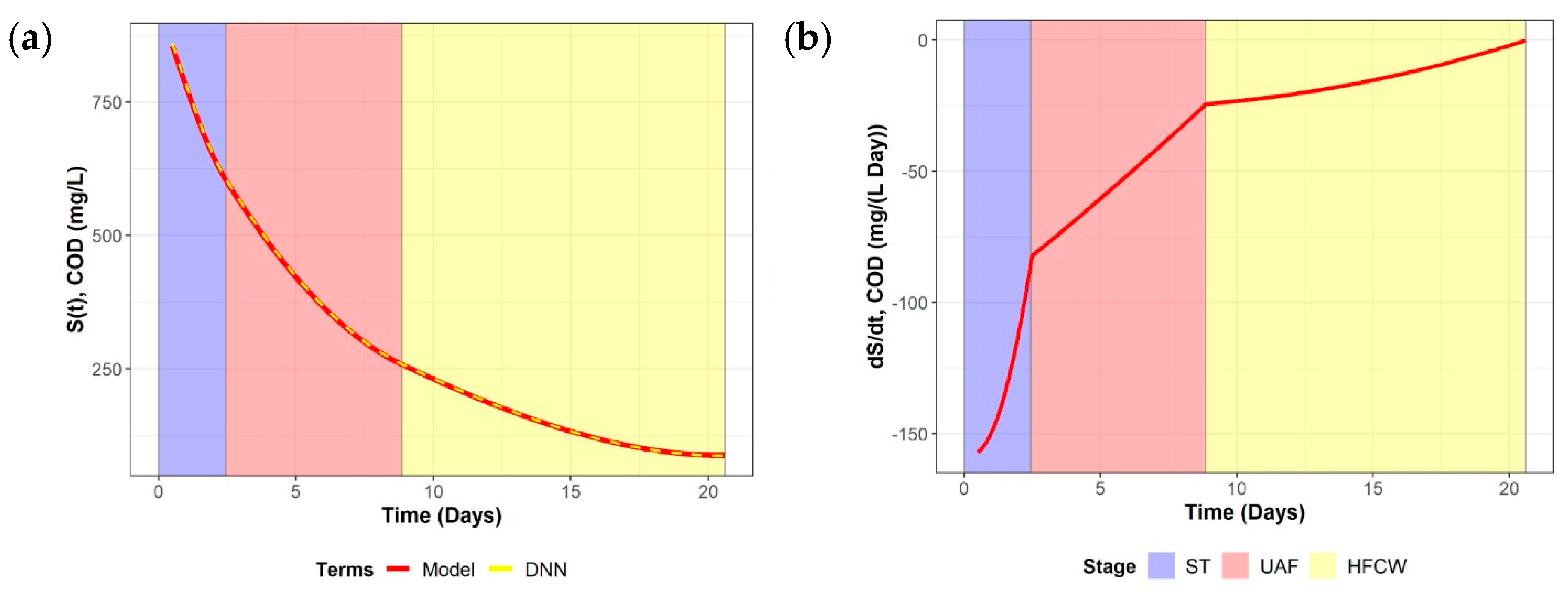

3.2.1. First-Order Models

3.2.2. Linear Regression Models

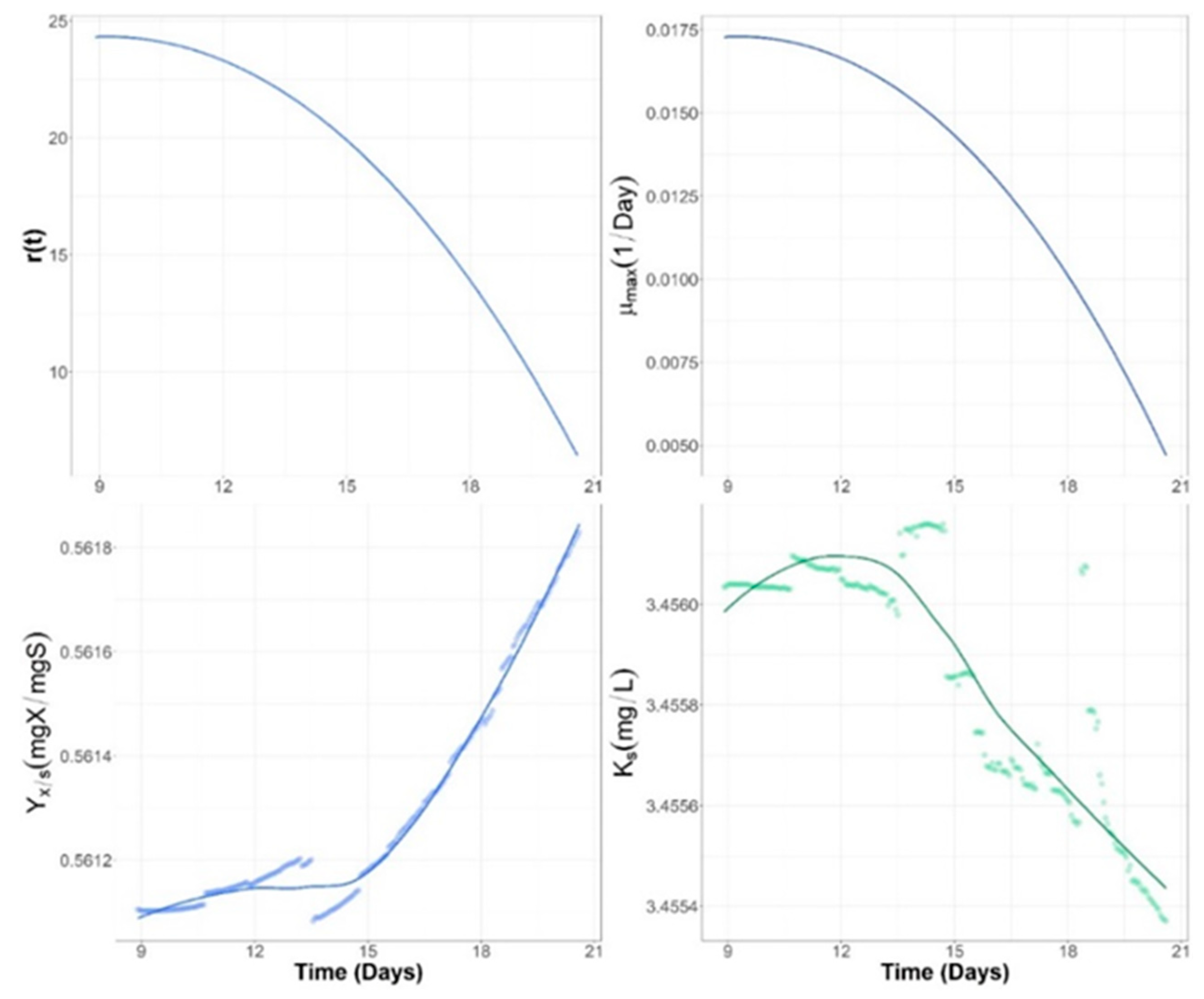

3.2.3. Mass Balance Models

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ujang, Z.; Buckley, C. Water and wastewater in developing countries: Present reality and strategy for the future. Water Sci. Technol. 2002, 46, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Water and the Sustainable Development Goals (SDGs)|2015 UN-Water Annual International Zaragoza Conference. Water and Sustainable Development: From Vision to Action. 15–17 January 2015. Available online: https://www.un.org/waterforlifedecade/waterandsustainabledevelopment2015/open_working_group_sdg.shtml (accessed on 21 October 2020).

- Tsegaye, S.; Missimer, T.M.; Kim, J.-Y.; Hock, J. A Clustered, Decentralized Approach to Urban Water Management. Water 2020, 12, 185. [Google Scholar] [CrossRef]

- Muga, H.E.; Mihelcic, J.R. Sustainability of wastewater treatment technologies. J. Environ. Manag. 2008, 88, 437–447. [Google Scholar] [CrossRef] [PubMed]

- Massoud, M.A.; Tarhini, A.; Nasr, J.A. Decentralized approaches to wastewater treatment and management: Applicability in developing countries. J. Environ. Manag. 2009, 90, 652–659. [Google Scholar] [CrossRef]

- Singh, N.K.; Kazmi, A.A.; Starkl, M. A review on full-scale decentralized wastewater treatment systems: Techno-economical approach. Water Sci. Technol. 2015, 71, 468–478. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, J.; Ngo, H.H.; Guo, W.; Hu, Z.; Liang, S.; Fan, J.; Liu, H. A review on the sustainability of constructed wetlands for wastewater treatment: Design and operation. Bioresour. Technol. 2015, 175, 594–601. [Google Scholar] [CrossRef]

- ElZein, Z.; Abdou, A.; ElGawad, I.A. Constructed Wetlands as a Sustainable Wastewater Treatment Method in Communities. Procedia Environ. Sci. 2016, 34, 605–617. [Google Scholar] [CrossRef]

- Sanchez, J.D.A.; Shear, H. Searching for a sustainable model to manage and treat wastewater in Jalisco, Mexico. Int. J. Dev. Sustain. 2016, 5, 278–294. [Google Scholar]

- Libralato, G.; Volpi Ghirardini, A.; Avezzù, F. To centralise or to decentralise: An overview of the most recent trends in wastewater treatment management. J. Environ. Manag. 2012, 94, 61–68. [Google Scholar] [CrossRef]

- Liu, R.; Zhao, Y.; Doherty, L.; Hu, Y.; Hao, X. A review of incorporation of constructed wetland with other treatment processes. Chem. Eng. J. 2015, 279, 220–230. [Google Scholar] [CrossRef]

- Vymazal, J.; Kröpfelová, L. Removal of organics in constructed wetlands with horizontal sub-surface flow: A review of the field experience. Sci. Total Environ. 2009, 407, 3911–3922. [Google Scholar] [CrossRef] [PubMed]

- Chan, Y.J.; Chong, M.F.; Law, C.L.; Hassell, D.G. A review on anaerobic–aerobic treatment of industrial and municipal wastewater. Chem. Eng. J. 2009, 155, 1–18. [Google Scholar] [CrossRef]

- Van Lier, J.B.; Mahmoud, N.; Zeeman, G. Anaerobic Wastewater Treatment; IWA Publishing: London, UK, 2008. [Google Scholar]

- Cakir, F.Y.; Stenstrom, M.K. Greenhouse gas production: A comparison between aerobic and anaerobic wastewater treatment technology. Water Res. 2005, 39, 4197–4203. [Google Scholar] [CrossRef] [PubMed]

- De Anda, J.; López-López, A.; Villegas-García, E.; Valdivia-Aviña, K. High-Strength Domestic Wastewater Treatment and Reuse with Onsite Passive Methods. Water 2018, 10, 99. [Google Scholar] [CrossRef]

- Álvarez, J.A.; Ruíz, I.; Soto, M. Anaerobic digesters as a pretreatment for constructed wetlands. Ecol. Eng. 2008, 33, 54–67. [Google Scholar] [CrossRef]

- Merino-Solís, M.L.; Villegas, E.; De Anda, J.; López-López, A. The Effect of the Hydraulic Retention Time on the Performance of an Ecological Wastewater Treatment System: An Anaerobic Filter with a Constructed Wetland. Water 2015, 7, 1149–1163. [Google Scholar] [CrossRef]

- Abdelhakeem, S.G.; Aboulroos, S.A.; Kamel, M.M. Performance of a vertical subsurface flow constructed wetland under different operational conditions. J. Adv. Res. 2016, 7, 803–814. [Google Scholar] [CrossRef]

- Kadlec, R.; Wallace, S. Treatment Wetlands, 2nd ed.; CRC Press: Cleveland, OH, USA, 2008; ISBN 1-56670-526-6. [Google Scholar]

- Chan, S.Y.; Tsang, Y.F.; Cui, L.H.; Chua, H. Domestic wastewater treatment using batch-fed constructed wetland and predictive model development for NH3-N removal. Process Biochem. 2008, 43, 297–305. [Google Scholar] [CrossRef]

- Trang, N.T.D.; Konnerup, D.; Schierup, H.-H.; Chiem, N.H.; Tuan, L.A.; Brix, H. Kinetics of pollutant removal from domestic wastewater in a tropical horizontal subsurface flow constructed wetland system: Effects of hydraulic loading rate. Ecol. Eng. 2010, 36, 527–535. [Google Scholar] [CrossRef]

- Sheridan, C.M.; Glasser, D.; Hildebrandt, D. Estimating rate constants of contaminant removal in constructed wetlands treating winery effluent: A comparison of three different methods. Process Saf. Environ. Prot. 2014, 92, 903–916. [Google Scholar] [CrossRef]

- Gholizadeh, A.; Gholami, M.; Davoudi, R.; Rastegar, A.; Miri, M. Efficiency and Kinetic Modeling of Removal of Nutrients and Organic Matter from a Full-Scale Constructed Wetland in Qasre-Shirin, Iran; Social Science Research Network: Rochester, NY, USA, 2015. [Google Scholar]

- Hu, W.C.; Thayanithy, K.; Forster, C.F. A kinetic study of the anaerobic digestion of ice-cream wastewater. Process Biochem. 2002, 37, 965–971. [Google Scholar] [CrossRef]

- Crites, G.; Tchobanoglous, G. Small and Decentralized Wastewater Management Systems; McGraw-Hill: New York, NY, USA, 1998. [Google Scholar]

- De Oliveira Cruz, L.M.; Gomes, B.G.L.A.; Tonetti, A.L.; Figueiredo, I.C.S. Using coconut husks in a full-scale decentralized wastewater treatment system: The influence of an anaerobic filter on maintenance and operational conditions of a sand filter. Ecol. Eng. 2019, 127, 454–459. [Google Scholar] [CrossRef]

- Fitch, M.W.; England, E. Biological Fixed Film Systems. Water Environ. Res. 2002, 74, 1–87. [Google Scholar] [CrossRef]

- Picanço, A.P.; Vallero, M.V.G.; Gianotti, E.P.; Zaiat, M.; Blundi, C.E. Influence of porosity and composition of supports on the methanogenic biofilm characteristics developed in a fixed bed anaerobic reactor. Water Sci. Technol. 2001, 44, 197–204. [Google Scholar] [CrossRef] [PubMed]

- Eaton, A.D.; Franson, M. Water Environment Federation. Stand. Methods Exam. Water Wastewater Wash. DC Am. Public Health Assoc. 2005. [Google Scholar]

- Kim, S.-J.; Hong, S.-W.; Choi, Y.-S.; Bae, W.-K.; Lee, S.-H. Performance evaluation of a newly developed flow diverted bed system for stream restoration. Process Biochem. 2007, 42, 199–209. [Google Scholar] [CrossRef]

- Darajeh, N.; Idris, A.; Fard Masoumi, H.R.; Nourani, A.; Truong, P.; Sairi, N.A. Modeling BOD and COD removal from Palm Oil Mill Secondary Effluent in floating wetland by Chrysopogon zizanioides (L.) using response surface methodology. J. Environ. Manag. 2016, 181, 343–352. [Google Scholar] [CrossRef]

- Tchobanoglous, G.; Burton, F.L.; Stensel, H.D. Wastewater Engineering: Treatment and Reuse, 4th ed.; McGraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Halling-Sørensen, B.; Nielsen, S.N. A model of nitrogen removal from waste water in a fixed bed reactor using simultaneous nitrification and denitrification (SND). Ecol. Model. 1996, 87, 131–141. [Google Scholar] [CrossRef]

- Gradilla-Hernández, M.S.; García-González, A.; Gschaedler, A.; Herrera-López, E.J.; González-Avila, M.; García-Gamboa, R.; Yebra Montes, C.; Fuentes-Aguilar, R.Q. Applying Differential Neural Networks to Characterize Microbial Interactions in an Ex Vivo Gastrointestinal Gut Simulator. Processes 2020, 8, 593. [Google Scholar] [CrossRef]

- Gradilla-Hernández, S.; Herrera-López, E.J.; Gschaedler, A.; González-Avila, M.; Fuentes-Aguilar, R.; Garcia-Gonzalez, A. Differential neural network identifier for parameter determination of a mixed microbial culture model⁎⁎Authors thank the support of the Metabolic Diseases research group at Tecnolgico de Monterrey in Guadalajara. IFAC Pap. 2018, 51, 479–484. [Google Scholar] [CrossRef]

- Dochain, D. Automatic Control of Bioprocesses; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Barati, R. Parameter Estimation of Nonlinear Muskingum Models Using Nelder-Mead Simplex Algorithm. J. Hydrol. Eng. 2011, 16, 946–954. [Google Scholar] [CrossRef]

- Zeikus, J.; Winfrey, M. Temperature limitation of methanogenesis in aquatic sediments. Appl. Environ. Microbiol. 1976, 31, 99–107. [Google Scholar] [CrossRef] [PubMed]

- Saeed, T.; Sun, G. A review on nitrogen and organics removal mechanisms in subsurface flow constructed wetlands: Dependency on environmental parameters, operating conditions and supporting media. J. Environ. Manag. 2012, 112, 429–448. [Google Scholar] [CrossRef] [PubMed]

- Knowles, P.; Dotro, G.; Nivala, J.; García, J. Clogging in subsurface-flow treatment wetlands: Occurrence and contributing factors. Ecol. Eng. 2011, 37, 99–112. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, J.; Jia, W.; Xie, H.; Gu, R.R.; Li, C.; Gao, B. Impact of COD/N ratio on nitrous oxide emission from microcosm wetlands and their performance in removing nitrogen from wastewater. Bioresour. Technol. 2009, 100, 2910–2917. [Google Scholar] [CrossRef]

- De la Varga, D.; Díaz, M.A.; Ruiz, I.; Soto, M. Avoiding clogging in constructed wetlands by using anaerobic digesters as pre-treatment. Ecol. Eng. 2013, 52, 262–269. [Google Scholar] [CrossRef]

- Van Haandel, A.; Van Der Lubbe, J. Handbook Biological Waste Water Treatment-Design and Optimisation of Activated Sludge Systems; Webshop Wastewater Handbook: London, UK, 2007. [Google Scholar]

- Wunderlin, P.; Mohn, J.; Joss, A.; Emmenegger, L.; Siegrist, H. Mechanisms of N2O production in biological wastewater treatment under nitrifying and denitrifying conditions. Water Res. 2012, 46, 1027–1037. [Google Scholar] [CrossRef]

- Melián, J.A.H.; Rodríguez, A.J.M.; Araña, J.; Díaz, O.G.; Henríquez, J.J.G. Hybrid constructed wetlands for wastewater treatment and reuse in the Canary Islands. Ecol. Eng. 2010, 36, 891–899. [Google Scholar] [CrossRef]

- Pehlivanoglu-Mantas, E.; Sedlak, D.L. Wastewater-Derived Dissolved Organic Nitrogen: Analytical Methods, Characterization, and Effects—A Review. Crit. Rev. Environ. Sci. Technol. 2006, 36, 261–285. [Google Scholar] [CrossRef]

- Bhunia, P.; Ghangrekar, M.M. Analysis, evaluation, and optimization of kinetic parameters for performance appraisal and design of UASB reactors. Bioresour. Technol. 2008, 99, 2132–2140. [Google Scholar] [CrossRef]

- Henze, M.; Harremoës, P. Anaerobic Treatment of Wastewater in Fixed Film Reactors—A Literature Review. Water Sci. Technol. 1983, 15, 1–101. [Google Scholar] [CrossRef]

- Pavlostathis, S.G.; Giraldo-Gomez, E. Kinetics of Anaerobic Treatment. Water Sci. Technol. 1991, 24, 35–59. [Google Scholar] [CrossRef]

- Zurita, F.; De Anda, J.; Belmont, M.A. Treatment of domestic wastewater and production of commercial flowers in vertical and horizontal subsurface-flow constructed wetlands. Ecol. Eng. 2009, 35, 861–869. [Google Scholar] [CrossRef]

- Peng, Y. Biological Nitrogen Removal with Nitrification and Denitrification via Nitrite Pathway. Appl. Microbiol. Biotechnol. 2006, 73, 15–26. [Google Scholar] [CrossRef]

- He, Y.; Tao, W.; Wang, Z.; Shayya, W. Effects of pH and seasonal temperature variation on simultaneous partial nitrification and anammox in free-water surface wetlands. J. Environ. Manag. 2012, 110, 103–109. [Google Scholar] [CrossRef]

- Dong, Y.; Scholz, M.; Harrington, R. Statistical Modeling of Contaminants Removal in Mature Integrated Constructed Wetland Sediments. J. Environ. Eng. 2012, 138, 1009–1017. [Google Scholar] [CrossRef]

- Nguyen, X.C.; Chang, S.W.; Nguyen, T.L.; Ngo, H.H.; Kumar, G.; Banu, J.R.; Vu, M.C.; Le, H.S.; Nguyen, D.D. A hybrid constructed wetland for organic-material and nutrient removal from sewage: Process performance and multi-kinetic models. J. Environ. Manag. 2018, 222, 378–384. [Google Scholar] [CrossRef]

- Bayley, M.L.; Davison, L.; Headley, T.R. Nitrogen removal from domestic effluent using subsurface flow constructed wetlands: Influence of depth, hydraulic residence time and pre-nitrification. Water Sci. Technol. 2003, 48, 175–182. [Google Scholar] [CrossRef]

- Galleguillos, M.; Vasel, J.-L. Landfill leachate characterization for simulation of biological treatment with Activated Sludge Model No. 1 and Activated Sludge Model No. 3. Environ. Technol. 2011, 32, 1259–1267. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.C.; Cheng, Z.; Li, Y.; Tang, J. Effect of fermentation liquid from food waste as a carbon source for enhancing denitrification in wastewater treatment. Chemosphere 2016, 144, 689–696. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, C.; Hong, S.; Hao, H.; Yang, Y. Behavior of solid carbon sources for biological denitrification in groundwater remediation. Water Sci. Technol. 2012, 65, 1696–1704. [Google Scholar] [CrossRef]

- Fernández-Nava, Y.; Marañón, E.; Soons, J.; Castrillón, L. Denitrification of high nitrate concentration wastewater using alternative carbon sources. J. Hazard. Mater. 2010, 173, 682–688. [Google Scholar] [CrossRef] [PubMed]

- Babatunde, A.O.; Zhao, Y.Q.; Doyle, R.J.; Rackard, S.M.; Kumar, J.L.G.; Hu, Y.S. On the fit of statistical and the k-C* models to projecting treatment performance in a constructed wetland system. J. Environ. Sci. Health Part A 2011, 46, 490–499. [Google Scholar] [CrossRef] [PubMed]

- Moussavi, G.; Kazembeigi, F.; Farzadkia, M. Performance of a pilot scale up-flow septic tank for on-site decentralized treatment of residential wastewater. Process Saf. Environ. Prot. 2010, 88, 47–52. [Google Scholar] [CrossRef]

- Song, M.; Shin, S.G.; Hwang, S. Methanogenic population dynamics assessed by real-time quantitative PCR in sludge granule in upflow anaerobic sludge blanket treating swine wastewater. Bioresour. Technol. 2010, 101, S23–S28. [Google Scholar] [CrossRef]

- Yi, X.-H.; Wan, J.; Ma, Y.; Wang, Y. Characteristics and dominant microbial community structure of granular sludge under the simultaneous denitrification and methanogenesis process. Biochem. Eng. J. 2016, 107, 66–74. [Google Scholar] [CrossRef]

- Zhou, H.; Xu, G. Integrated effects of temperature and COD/N on an up-flow anaerobic filter-biological aerated filter: Performance, biofilm characteristics and microbial community. Bioresour. Technol. 2019, 293, 122004. [Google Scholar] [CrossRef]

- Viraraghavan, T.; Kikkeri, S.R. Effect of Temperature on Anaerobic Filter Treatment of Dairy Wastewater. Water Sci. Technol. 1990, 22, 191–198. [Google Scholar] [CrossRef]

- Liu, H.; Hu, Z.; Zhang, J.; Ngo, H.H.; Guo, W.; Liang, S.; Fan, J.; Lu, S.; Wu, H. Optimizations on supply and distribution of dissolved oxygen in constructed wetlands: A review. Bioresour. Technol. 2016, 214, 797–805. [Google Scholar] [CrossRef]

- Wang, W.; Ding, Y.; Ullman, J.L.; Ambrose, R.F.; Wang, Y.; Song, X.; Zhao, Z. Nitrogen removal performance in planted and unplanted horizontal subsurface flow constructed wetlands treating different influent COD/N ratios. Environ. Sci. Pollut. Res. 2016, 23, 9012–9018. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Y.; Li, X.; Fu, C.; Shi, T.; Yan, P. Effects of influent nitrogen loads on nitrogen and COD removal in horizontal subsurface flow constructed wetlands during different growth periods of Phragmites australis. Sci. Total Environ. 2018, 635, 1360–1366. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Zhu, H.; Bañuelos, G.; Yan, B.; Zhou, Q.; Yu, X.; Cheng, X. Constructed wetlands for saline wastewater treatment: A review. Ecol. Eng. 2017, 98, 275–285. [Google Scholar] [CrossRef]

- Li, X.; Zhang, M.; Liu, F.; Chen, L.; Li, Y.; Li, Y.; Xiao, R.; Wu, J. Seasonality distribution of the abundance and activity of nitrification and denitrification microorganisms in sediments of surface flow constructed wetlands planted with Myriophyllum elatinoides during swine wastewater treatment. Bioresour. Technol. 2018, 248, 89–97. [Google Scholar] [CrossRef] [PubMed]

- Hua, G.; Cheng, Y.; Kong, J.; Li, M.; Zhao, Z. High-throughput sequencing analysis of bacterial community spatiotemporal distribution in response to clogging in vertical flow constructed wetlands. Bioresour. Technol. 2018, 248, 104–112. [Google Scholar] [CrossRef]

- Rodríguez, M.G. Dynamic model of secondary process of urban wastewater treatment plants. J. Environ. Sci. Health Part Environ. Sci. Eng. Toxicol. 1997, 32, 2057–2068. [Google Scholar] [CrossRef]

- Jijai, S.; Srisuwan, G.; Sompong, O.; Ismail, N.; Siripatana, C. Effect of Granule Sizes on the Performance of Upflow Anaerobic Sludge Blanket (UASB) Reactors for Cassava Wastewater Treatment. Energy Procedia 2015, 79, 90–97. [Google Scholar] [CrossRef]

- Abyar, H.; Younesi, H.; Bahramifar, N.; Zinatizadeh, A.A.; Amini, M. Kinetic evaluation and process analysis of COD and nitrogen removal in UAASB bioreactor. J. Taiwan Inst. Chem. Eng. 2017, 78, 272–281. [Google Scholar] [CrossRef]

| BOD5 (mg/L) | COD (mg/L) | TSS (mg/L) | TKN (mg/L) | NH3 (mg/L) | ON (mg/L) | NO2− (mg/L) | NO3− (mg/L) | |

|---|---|---|---|---|---|---|---|---|

| SP1 | 607.90 ± 112.09 | 934.50 ± 168.74 | 350.33 ± 74.82 | 336.92 ± 12.17 | 150.94 ± 5.62 | 186.46 ± 7.50 | 2.88 ± 1.69 | 0.26 ± 0.06 |

| SP2 | 406.28 ± 85.14 | 603.65 ± 94.72 | 92.67 ± 13.29 | 294.65 ± 27.50 | 139.00 ± 9.92 | 153.80 ± 21.23 | 0.98 ± 0.23 | 0.14 ± 0.04 |

| SP3 | 163.12 ± 34.90 | 258.41 ± 57.38 | 53.83 ± 11.89 | 258.49 ± 30.96 | 129.97 ± 10.99 | 128.52 ± 23.24 | 0.52 ± 0.08 | 0.05 ± 0.02 |

| SP4 | 59.78 ± 24.74 | 87.39 ± 41.51 | 11.33 ± 1.97 | 163.90 ± 15.80 | 83.67 ± 6.00 | 80.24 ± 14.97 | 0.19 ± 0.04 | 0.01 ± 0.00 |

| Removal Efficiency (%) | Mass Reduction (mg/L) | |||||||

|---|---|---|---|---|---|---|---|---|

| OS | ST | UAF | HFCW | OS | ST | UAF | HFCW | |

| BOD5 | 90 ± 05 | 33 ± 07 | 57 ± 17 | 64 ± 08 | 548.1 ± 117.0 | 201.6 ± 60.2 | 243.2 ± 105.1 | 103.3 ± 22.1 |

| COD | 90 ± 05 | 35 ± 05 | 55 ± 16 | 67 ± 10 | 847.1 ± 181.0 | 330.8 ± 92.8 | 345.2 ± 136.9 | 171.0 ± 37.0 |

| TSS | 97 ± 00 | 73 ± 04 | 41 ± 15 | 78 ± 05 | 339.0 ± 73.3 | 257.7 ± 65.2 | 38.8 ± 15.0 | 42.5 ± 11.4 |

| TKN | 51 ± 05 | 12 ± 11 | 12 ± 03 | 36 ± 07 | 173.0 ± 20.3 | 42.3 ± 37.7 | 36.2 ± 8.4 | 94.6 ± 25.9 |

| NH3 | 45 ± 04 | 07 ± 10 | 08 ± 04 | 35 ± 08 | 68.5 ± 7.2 | 11.4 ± 15.7 | 10.9 ± 6.9 | 46.3 ± 13.5 |

| ON | 57 ± 08 | 17 ± 13 | 17 ± 03 | 37 ± 07 | 106.2 ± 17.0 | 32.7 ± 25.6 | 25.3 ± 2.4 | 48.3 ± 12.8 |

| NO2− | 91 ± 05 | 53 ± 32 | 44 ± 15 | 63 ± 08 | 2.7 ± 1.7 | 1.90 ± 1.8 | 0.45 ± 0.2 | 0.33 ± 0.1 |

| NO3− | 95 ± 02 | 44 ± 15 | 67 ± 14 | 74 ± 13 | 0.2 ± 0.1 | 0.12 ± 0.1 | 0.10 ± 0.0 | 0.03 ± 0.0 |

| DO (mg/L) | CT (mS/cm) | pH | Temp (°C) | |

|---|---|---|---|---|

| OS | 0.51 ± 0.50 | 1.52 ± 0.24 | 7.43 ± 0.69 | 20.36 ± 2.25 |

| SP1 | 0.50 ± 0.54 | 1.36 ± 0.31 | 7.80 ± 0.92 | 21.04 ± 1.74 |

| SP2 | 0.26 ± 0.13 | 1.65 ± 0.24 | 7.23 ± 0.72 | 21.06 ± 1.97 |

| SP3 | 0.72 ± 0.53 | 1.62 ± 0.20 | 7.32 ± 0.67 | 20.91 ± 2.31 |

| SP4 | 0.58 ± 0.67 | 1.45 ± 0.09 | 7.36 ± 0.39 | 18.45 ± 2.27 |

| OS | ST | UAF | HFCW | ||||||

|---|---|---|---|---|---|---|---|---|---|

| BOD5 | C0 | 599 ± 27 | p = 1.5 × 10−16 | 608 ± 41 | p = 3.6 × 10−8 | 406 ± 27 | p = 2.9 × 10−8 | 163 ± 12 | p = 1.2 × 10−7 |

| k | 0.15 ± 0.02 | p = 4.4 × 10−8 | 0.17 ± 0.05 | p = 7.4 × 10−3 | 0.14 ± 0.03 | p = 4.0 × 10−4 | 0.09 ± 0.02 | p = 1.0 × 10−3 | |

| R2 | 0.90 | 0.55 | 0.81 | 0.78 | |||||

| COD | C0 | 913 ± 39 | p = 3.5 × 10−17 | 935 ± 56 | p = 1.2 × 10−8 | 604 ± 32 | p = 3.8 × 10−9 | 258 ± 20 | p = 1.8 × 10−7 |

| k | 0.15 ± 0.02 | p = 1.4 × 10−8 | 0.18 ± 0.05 | p = 2.7 × 10−3 | 0.13 ± 0.02 | p = 8.9 × 10−5 | 0.09 ± 0.02 | p = 1.4 × 10−3 | |

| R2 | 0.92 | 0.64 | 0.85 | 0.78 | |||||

| TSS | C0 | 349 ± 19 | p = 5.1 × 10−15 | 350 ± 22 | p = 1.9 × 10−8 | 93 ± 05 | p = 6.0 × 10−9 | 54 ± 04 | p = 2.6 × 10−8 |

| k | 0.51 ± 0.07 | p = 1.5 × 10−6 | 0.54 ± 0.10 | p = 2.9 × 10−4 | 0.09 ± 0.02 | p = 6.1 × 10−4 | 0.13 ± 0.03 | p = 5.6 × 10−4 | |

| R2 | 0.90 | 0.87 | 0.74 | 0.88 | |||||

| TKN | C0 | 332 ± 07 | p = 3.9 × 10−23 | 337 ± 09 | p = 3.1 × 10−12 | 295 ± 12 | p = 2.8 × 10−10 | 259 ± 10 | p = 1.8 × 10−10 |

| k | 0.03 ± 0.003 | p = 1.0 × 10−10 | 0.05 ± 0.02 | p = 6.5 × 10−3 | 0.02 ± 0.01 | p = 0.06 * | 0.04 ± 0.01 | p = 9.1 × 10−5 | |

| R2 | 0.89 | 0.54 | 0.31 | 0.82 | |||||

| NH3 | C0 | 152 ± 01 | p = 4.8 × 10−24 | 152 ± 03 | p = 3.0 × 10−11 | 139 ± 04 | p = 1.8 × 10−11 | 130 ± 04 | p = 6.6 × 10−12 |

| k | 0.03 ± 0.002 | p = 2.7 × 10−10 | 0.05 ± 0.01 | p = 6.5 × 10−3 | 0.01 ± 0.01 | p = 0.17 * | 0.04 ± 0.004 | p = 6.4 × 10−6 | |

| R2 | 0.87 | 0.63 | 0.18 | 0.89 | |||||

| ON | C0 | 180 ± 06 | p = 9.2 × 10−20 | 186 ± 07 | p = 6.2 × 10−11 | 154 ± 09 | p = 1.1 × 10−8 | 129 ± 08 | p = 1.8 × 10−5 |

| k | 0.04 ± 0.005 | p = 1.1 × 10−8 | 0.08 ± 0.02 | p = 5.6 × 10−3 | 0.03 ± 0.01 | p = 0.08 * | 0.04 ± 0.01 | p = 2.4 × 10−3 | |

| R2 | 0.83 | 0.56 | 0.28 | 0.65 | |||||

| NO2− | C0 | 0.26 ± 0.02 | p = 4.2 × 10−14 | 0.26 ± 0.02 | p = 3.6 × 10−7 | 0.14 ± 0.01 | p = 1.1 × 10−6 | 0.05 ± 0.01 | p = 1.8 × 10−5 |

| k | 0.22 ± 0.04 | p = 3.6 × 10−06 | 0.25 ± 0.07 | p = 6.8 × 10−3 | 0.18 ± 0.05 | p = 4.8 × 10−3 | 0.13 ± 0.05 | p = 3.0 × 10−2 | |

| R2 | 0.87 | 0.58 | 0.71 | 0.63 | |||||

| NO3− | C0 | 2.84 ± 0.4 | p = 5.8 × 10−7 | 2.88 ± 0.5 | p = 7.1 × 10−4 | 0.98 ± 0.08 | p = 1.5 × 10−6 | 0.52 ± 0.03 | p = 5.5 × 10−8 |

| k | 0.38 ± 0.14 | p = 1.5 × 10−2 | 0.44 ± 0.24 | p = 0.10 * | 0.10 ± 0.03 | p = 6.1 × 10−3 | 0.09 ± 0.01 | p = 1.6 × 10−4 | |

| R2 | 0.61 | 0.44 | 0.68 | 0.90 | |||||

| OS | HFCW | UAF | ST | |||||

|---|---|---|---|---|---|---|---|---|

| Model | TNout = 0.5TNin + 11.5DOin − 20.4DOout * | BODout = 0.2BODin + 36.1DOin * | BODout = BODin + 7.3NH3in − 6.7NH3out | BODout = 0.7BODin − 1.2TNin 1.2TNout | ||||

| R2 | 0.9972 | 0.9918 | 0.9910 | 0.9999 | ||||

| p-values | TNin | 0.0020 | BODin | 0.0059 | BODin | 0.7892 | BODin | 0.02400 |

| DOin | 0.3448 | DOin | 0.0081 | NH3in | 0.0561 | TNin | 0.0774 | |

| DOout | 0.0923 | NH3out | 0.0950 | TNout | 0.0710 | |||

| Model | TNout = 0.7TNin − 301NO2in − 742NO2out | BODout = 0.6BODin − 98.6CTin + 82.6CTout * | TNout = 1.4TNin − 1.5NH3in + 0.3NH3out | TSSout = −0.2TSSin + 28.9CTin − 11.6CTout * | ||||

| R2 | 0.9991 | 0.9907 | 1 | 0.9983 | ||||

| p-values | TNin | 0.0021 | BODin | 0.0247 | TNin | 0.0001 | TSSin | 0.0052 |

| NO2in | 0.0182 | CTin | 0.0395 | NH3in | 0.0020 | CTin | 0.0198 | |

| NO2out | 0.5478 | CTout | 0.0896 | NH3out | 0.2348 | CTout | 0.2377 | |

| Model | NH3out = 0.6NH3in − 3.3DOin − 7.9DOout * | TSSout = -TSSin − 1.3Tempin + 2.1Tempout * | NH3out = 0.7NH3in + 10.5 Tempin − 8.6Tempout * | TSSout = 0.1TSSin + 0.1BODin − BODout | ||||

| R2 | 0.9986 | 0.9990 | 0.9999 | 0.9995 | ||||

| p-values | NH3in | 8.54 × 10−5 | TSSin | 0.4727 | NH3in | 0.0029 | TSSin | 0.0036 |

| DOin | 0.4415 | TEMPin | 0.0672 | Tempin | 0.0168 | BODin | 0.0181 | |

| DOout | 0.0827 | TEMPout | 0.0292 | Tempout | 0.0173 | BODout | 0.3900 | |

| Model | NH3out = 0.8NH3in + 0.1TSSin − 5.2 TSSout | TNout = 0.8TNin − 0.3CODin + 0.6 CODout | NH3out = 1.1NH3in + CODin − 0.1CODout | ONout = 0.6ONin − 0.3BODin + 0.5BODout | ||||

| R2 | 0.9989 | 0.9972 | 0.9999 | 0.9999 | ||||

| p-values | NH3in | 0.0018 | TNin | 0.0045 | NH3in | 0.0005 | ONin | 0.00657 |

| TSSin | 0.1723 | CODin | 0.1218 | CODin | 0.7403 | BODin | 0.01863 | |

| TSSout | 0.0520 | CODout | 0.0822 | CODout | 0.0404 | BODout | 0.00594 | |

| Model | ONout = 2.1ONin + 6.1pHin − 50pHout * | NH3out = 0.8NH3in + 0.2CODin + 0.4CODout | ||||||

| R2 | 0.9932 | 0.9960 | ||||||

| p-values | ONin | 0.0540 | NH3in | 0.0098 | ||||

| pHin | 0.3634 | CODin | 0.1405 | |||||

| pHout | 0.0573 | CODout | 0.0914 | |||||

| ST | UAF | HFCW | |||||

|---|---|---|---|---|---|---|---|

| Parameter | Mean | Std. Dev. | Mean | Std. Dev. | Mean | Std. Dev. | |

| BOD5 | Yx/s | 0.6705 | 0.0003 | 0.6693 | 0.0082 | 0.6514 | 0.0008 |

| Ks | 57.6254 | 0.0081 | 58.7322 | 2.5482 | 64.4711 | 0.0884 | |

| µmax | 0.1249 | 0.0090 | 0.0554 | 0.0027 | 0.0154 | 0.0031 | |

| COD | Yx/s | 0.5526 | 0.0004 | 0.5585 | 0.0003 | 0.5613 | 0.0002 |

| Ks | 3.4685 | 0.0004 | 3.4575 | 0.0004 | 3.4559 | 0.0002 | |

| µmax | 0.1515 | 0.0080 | 0.0536 | 0.0043 | 0.0134 | 0.0037 | |

| NH3 | Yx/s | 0.3214 | 0.0001 | 0.3210 | 0.0001 | 0.3208 | 0.0001 |

| Ks | 4.6072 | 0.0008 | 4.6072 | 0.0002 | 4.6077 | 0.0003 | |

| µmax | −0.0009 | 0.0001 | 0.0009 | 0.0004 | 0.0020 | 0.0006 | |

| TKN | Yx/s | 0.5613 | 0.0001 | 0.5614 | 0.0002 | 0.5612 | 0.0001 |

| Ks | 5.7596 | 0.0003 | 5.7595 | 0.0003 | 5.7598 | 0.0003 | |

| µmax | 0.0061 | 0.0010 | 0.0054 | 0.0010 | 0.0070 | 0.0014 | |

| ON | Yx/s | 0.5617 | 0.0000 | 0.5618 | 0.0000 | 0.5619 | 0.0000 |

| Ks | 3.4556 | 0.0001 | 3.4553 | 0.0000 | 3.4554 | 0.0001 | |

| µmax | 0.0078 | 0.0007 | 0.0039 | 0.0004 | 0.0036 | 0.0004 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández del Castillo, A.; Verduzco Garibay, M.; Senés-Guerrero, C.; Yebra-Montes, C.; de Anda, J.; Gradilla-Hernández, M.S. Mathematical Modeling of a Domestic Wastewater Treatment System Combining a Septic Tank, an Up Flow Anaerobic Filter, and a Constructed Wetland. Water 2020, 12, 3019. https://doi.org/10.3390/w12113019

Fernández del Castillo A, Verduzco Garibay M, Senés-Guerrero C, Yebra-Montes C, de Anda J, Gradilla-Hernández MS. Mathematical Modeling of a Domestic Wastewater Treatment System Combining a Septic Tank, an Up Flow Anaerobic Filter, and a Constructed Wetland. Water. 2020; 12(11):3019. https://doi.org/10.3390/w12113019

Chicago/Turabian StyleFernández del Castillo, Alberto, Marycarmen Verduzco Garibay, Carolina Senés-Guerrero, Carlos Yebra-Montes, José de Anda, and Misael Sebastián Gradilla-Hernández. 2020. "Mathematical Modeling of a Domestic Wastewater Treatment System Combining a Septic Tank, an Up Flow Anaerobic Filter, and a Constructed Wetland" Water 12, no. 11: 3019. https://doi.org/10.3390/w12113019

APA StyleFernández del Castillo, A., Verduzco Garibay, M., Senés-Guerrero, C., Yebra-Montes, C., de Anda, J., & Gradilla-Hernández, M. S. (2020). Mathematical Modeling of a Domestic Wastewater Treatment System Combining a Septic Tank, an Up Flow Anaerobic Filter, and a Constructed Wetland. Water, 12(11), 3019. https://doi.org/10.3390/w12113019