1. Introduction

While responding to a wet flow event, storm water pipe systems experience complex transient flow in which both open channel and pressurized flow regimes may coexist [

1]. The resulting transient flows may induce significant positive and negative pressure surges that can be intense enough to compromise the integrity of the system. A 3D multiphase Computational Fluid Dynamic (CFD) model can theoretically replicate the transient flow but it is computationally too expensive and time consuming to be used in the context of the design of such systems that are iterative in nature. Thus, simplified models are usually employed in practice to calculate the transient response of sewer systems in practice. Since mass, momentum, and energy is mainly transferred in the longitudinal direction of the pipe, one-dimensional models have shown to be a reliable tool for capturing the main features of the transient flows in pipe systems.

One of the simplest models employed to calculate transient mixed flow in pipe systems is built upon the rigid water column theory. Wiggert [

2], Liou and Hunt [

3], and Razak and Karney [

4], among others employed the rigid column model both in simple and complex pipe systems and obtained reasonable results. Malekpour and Karney [

5] showed that as long as the water column is not locally disturbed, it tends to move along the pipeline as a rigid column. However, more complete dynamic models are required to calculate and trace the waterhammer pressures induced in the system when the flow is locally disturbed in the system.

There are two different types of dynamic models that can be used to calculate transient mixed flow in closed conduit systems [

6]. The first one is the shock fitting-based model, which has been widely used in treating transient mixed flow in sewer pipe systems [

7,

8,

9,

10,

11,

12,

13,

14]. In this method, the interface separating open channel flow from pressurized flow is tracked explicitly by both enforcing mass and momentum conservation across the interface. Having the interface flow characteristics calculated, the flow on either side of the interface is then calculated with its own theory. A variety of shock fitting models have been proposed and shown to provide promising results [

7,

8,

10,

15,

16]. Nevertheless, interface tracking is the biggest challenge of the shock fitting approach, particularly in complex systems maintaining several simultaneous interfaces. Further, replicating the interaction of the interfaces with themselves and with the boundaries of the system are another challenges of the shock fitting approach; making the implementation of this approach even more difficult.

Shock capturing is another method widely used for calculating transient mixed flows in conduit systems [

12,

15,

17,

18,

19,

20,

21,

22]. In this approach, both open channel and pressurized flow are treated using a single set of equations governing unsteady flow in open channels. One of the most popular and earliest methods is the Preissmann slot method (generally abbreviated as PSM) [

23], named after its innovator engineer Preissmann [

24]. In the PSM, a virtual narrow slot above the crowns of the pipe allows the system to remain in an open channel flow condition even when the conduit becomes completely full. The width of the slot is calculated in such a way that the celerity of the wave motion in the slot becomes identical to the pipe acoustic speed; the higher pipe acoustic speed, the narrower slot width. The main drawback of this approach is the spurious numerical oscillation onset when the flow switches from open channel to pressurized flow. Depending on the magnitude of acoustic speed of the conduit, the resulting numerical oscillations could be strong enough to halt the simulation. The second weak point of the Preissmann slot method is that it cannot maintain negative pressures. As soon as negative pressure is about to occur, the flow switches back to open channel flow.

A few novel methods have been proposed to resolve the negative pressure problem. Kerger et al. [

19] proposed a negative slot method (NSL) approach in which the mass flow released during depressurization is compensated by a negative slot extended below the crowns of the pipe. In this approach, when negative pressure is imminent, the conduit cross-section is kept full and the mass release required for depressurization of the conduit is compensated from the negative slot; negative depth in the slot measures the magnitude of the negative pressure head. Vasconcelos et al. [

25] proposed a two-component pressure approach (TPA) in which the pressure term in the momentum equation is split into two components that measure the flow depth and pressure head in the conduit. Like NSL, when negative pressure tends to occur, the flow depth component is set to the maximum depth of the conduit and the pressure head component is let to calculate the magnitude of the negative pressure. This method has been successfully used for analyzing transient flow in sewer pipe networks [

25].

Although experimental results show that both NSM and TPA can calculate both negative and positive pressures quite accurately during the course of the transient flow, they both suffer from spurious numerical oscillations induced when the flow regime changes from open channel to pressurized flow. The intensity of the numerical oscillations depends on the magnitude of acoustic wave speed of the conduit and can be high enough to corrupt the solution. Numerical experiments have shown that beyond an acoustic speed of 30–50 m/s the resulting oscillations tend to corrupt the solution and even cause the computer code to crash. Since the acoustic wave speed in pipes may be significantly higher than 100 m/s, the occurrence of numerical oscillation is a real challenge in the use of PSM and its alternative approaches (NSM and TPA), particularly when the capture of waterhammer pressures is the primary concern of modeling. That is why the cause and remediation of spurious numerical oscillation have been the focus of interest in the last four decades.

In order to suppress the numerical oscillations, researchers have proposed several methods thus far, but most of them have not been entirely satisfactory. Artificially reducing pipe acoustic speed by increasing the slot width is the most popular approach to reduce the numerical oscillation and has been employed by many [

15,

21,

26]. In this method, the numerical oscillations are suppressed through preventing drastic change in wave velocity during flow transition. This approach provides a reasonable model result as long as inertia dominates the flow and the elastic feature of the flow is not of great importance. Otherwise, the magnitude and track of the resulting waterhammer pressures are significantly distorted. Furthermore, in deep and long Combined Sewer Overflow (CSO) tunnels, increasing the width of the slot produces large virtual storage that unrealistically slows down the transient flow discharges and significantly underestimates the filling bore’s speed; this is an issue that is crucially important to the real time operation of pipe systems [

5]. An alternative approach is to connect the pipe to the slot by a smooth transition. Sjoberg [

27] proposed a transition that smoothly connects the pipe to the slot and employed an implicit finite difference method to solve the equations. The model was shown to succeed in capturing transient pressures free of numerical oscillations. Leon et al. [

28] proposed a funnel-shaped slot along with a second-order Godunov-type numerical solution and showed that the model can provide non-oscillatory solutions over a wide range of operational conditions. However, the method is exclusively presented for circular pipes, and it is not applicable for other conduits. Vasconcelos et al. [

22] contented that the numerical oscillations have the same root as in a slowly moving shock in gas dynamics (Jin and Liu [

29]; Karni and Čanić, [

30]; Arora and Roe [

31]). They proposed a first-order Roe scheme in which the numerical viscosity of the scheme increases through calculating the numerical fluxes by a so-called hybrid flux method. In the hybrid flux method, the numerical viscosity of the scheme increases by artificially increasing the wave velocities that permit the fluxes to be calculated. The results showed that the hybrid flux method can partially suppress the numerical oscillations, but data smearing becomes significant when the numerical viscosity further increases to completely remove the spurious numerical oscillations. Nonetheless, the test cases presented by Vasconcelos et al. [

22] imply that this method can be effectively used only when the pipe acoustic speed does not exceed 100 to 150 m/s. Vasconcelos et al. [

22] further proposed a digital filter by which the numerical results obtained in each time step are smoothed before the calculations proceed to the new time step. The results showed that the proposed numerical filter can suppress the numerical oscillations, although like the hybrid flux method, this method is effective only if the pipe acoustic speed is less than around 150 m/s.

Malekpour and Karney [

32] proposed a slot method-based model utilizing the Godunov finite volume numerical scheme that employs the Harten, Lax, and van Leer (HLL) Riemann solution for calculating numerical fluxes. To suppress the numerical oscillations, the authors proposed an HLL solver that can automatically add some artificial viscosity to the scheme by increasing the wave velocity in the vicinity of the locations at which the pipe pressurization is imminent. It was shown that this approach can produce oscillation-free solutions even at pipe acoustic speeds of over 1000 m/s.

The dissipative HLL solver proposed by Malekpour and Karney [

32] has been successfully employed by other researchers [

33,

34]. Nevertheless, it is not known if this solver performs well in conjunction with the TPA approach as well because all research thus far has applied the HLL solver in the context of the slot method. Resolving this uncertainty is the main objective of this paper, which will be shown decisively if this HLL solver can also suppress the numerical oscillations while used in the context of the TPA.

2. Theoretical Background: Governing Equations

This conservative form of one-dimensional continuity and momentum equations in open channels can be written as follows [

35]:

where

,

, and

are the vectors representing flow variables, fluxes, and source terms, respectively, and can be represented as follows:

where

𝐴 is the flow cross sectional area,

Q is the flow discharge,

h is the distance between the free surface and the centroid of the flow cross-sectional area,

S0 is the bottom slope of the channel,

Sf is the slope of energy grade line,

g is the gravitational acceleration,

ρ is the flow density,

R is the flow hydraulic radius, and

nm is the Manning coefficient.

As discussed before, regarding PSM, a virtual slot above the crown of the pipe allows pressurized flows to be regulated by the above equation as well. In such a case when the calculated water depth exceeds the pipe diameter, it represents the pressure head in the system, and the amount of mass in the slot replicates the mass compressed in the pipe due to the rise in the pressure head. The width of the slot required to replicate the acoustic wave speed of the pipe (a) can simply be calculated as follows:

where

is the pipe cross section, a is pipe acoustic speed, and

is the slot width.

In using TPA, it is assumed that the pipe is expanded and contracted during pipe pressurization and depressurization, respectively. In this method, the cross-sectional area of the pipe can be related to the surcharging pressure head (

) through the following equation (Sanders and Bradford, 2010 [

20]):

The above equation accounts for the pipe expansion and contraction due to the pressurization and depressurization phases. It is noteworthy to mention that by multiplying either side of Equation (2) by and performing some algebra, Equation (3) can be easily reached, confirming that both PSM and TPA have an identical underlying concept.

In order to include the effect of negative pressures on the momentum equation, we can rewrite fluxes in Equation (1) as follows:

As can be seen, the pressure term in Equation (1) is split into two terms, and , where measures distance between the free surface and the centroid of the flow cross-sectional area and represents surcharging head. In an open channel flow regime, is set to zero, and when the pipe is pressurized, represents the distance between the crowns of the pipe to the centroid of the pipe cross-sectional area. Note that during pipe depressurization, while the system has sufficient ventilation, negative pressures cannot be maintained. This causes the flow to be switched back to an open channel flow with = 0; otherwise measures negative pressure.

3. Numerical Solution

In this work, the Godunov scheme is utilized to numerically solve the governing equations. The Godunov scheme is an upwind finite volume-based numerical scheme that is widely used for solving partial differential equations [

36]. In this method, the spatial domain of the computation is broken down to a number of computational cells with a spatial distance of

, and the temporal domain is split by a constant time interval of

. The order of accuracy of the Godunov scheme depends on the data reconstruction at the computational cells; piecewise constant data reconstruction provides first-order accuracy and the piecewise linear data reconstruction results in second-order accuracy. In this research, the first-order accuracy is employed because, as will be discussed later, the significant amount of artificial viscosity required for dissipating the spurious numerical oscillations associated with mixed flow modelling prevents the numerical scheme from providing second-order accuracy, even when linear data reconstruction is utilized.

By discretizing Equation (1), unknowns at the current time level can explicitly be calculated on the basis of the data retrieved from the previous timeline using the following equation:

where subscript

is the computational cell number;

and

are upstream and downstream boundaries of the

ith computational cell, respectively;

is the previous time step; and

is the current time step.

Equation (5) can be used to calculate the discharge and flow depth, provided that the flux at the boundaries of the cells are known. In the Godunov scheme, the fluxes at the cell boundaries are calculated through solving the Riemann problem. A Riemann problem includes a system of hyperbolic equations at a flow discontinuity with initial piecewise constant data [

36]. The exact Riemann solution can be obtained for the current system of equations, but considering the iterative nature of the solution, it is quite time-consuming, which in turn compromises the efficiency of the numerical analysis. To resolve this problem, approximate Riemann solution can also be utilized to speed up the calculations [

36]. Several approximate Riemann solutions have been proposed, including Roe, HLL, and Harten, Lax, and van Leer Contact HLLC [

36], among which the HLL Riemann solution is one of the most efficient ones, and thus we utilized it in this study. The HLL Riemann solution was originally proposed by Harten, Lax, and van Leer, who developed it on the basis of the assumption that the generated waves either side of the discontinuity are both of shock wave type.

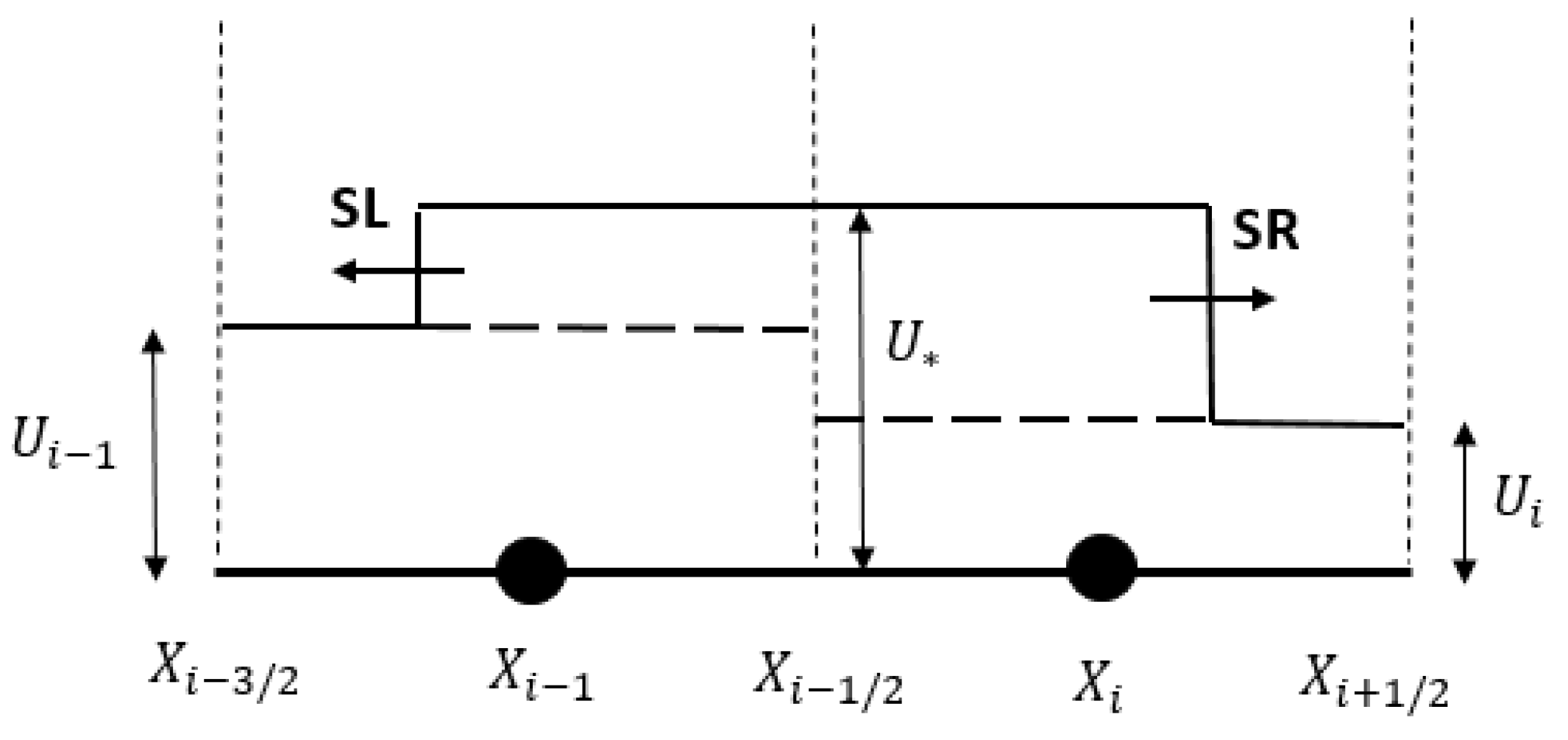

Figure 1 describes the wave structure for the (HLL) solver.

Left and right shock wave velocities can be calculated by the following formula:

In the HLL Riemann solution, if the shock waves move in opposite directions, flux (i.e.,

at the cell interface can be calculated by cancelling out

in Equations (7) and (8). Otherwise, data sampling is required for calculating the fluxes. If the left wave velocity (

) is greater than zero, the flow would be of a supercritical type and the flux at the cell interface becomes equal to

. However, if

is less than zero, the flux at the cell interface would be equal to

because the flow is supercritical but moves in the opposite direction. The following equations summarize flux at the cell interface under different flow conditions:

Although the first-order Godunov scheme with the HLL Riemann solver generally provides monotonous and oscillation-free solution, it still produces significant spurious oscillations when used in the context of transient mixed flow analysis. Drastic change in wave velocity during the pressurization has been accepted as the key reason of the numerical oscillation. However, more investigation is required to understand under what specific mechanism the change in wave velocity results in numerical oscillation.

Vasconcelos et al. [

22] concluded that the post-shock oscillations associated with the PSM have the same origin as slow-moving shocks in gas dynamics [

30,

31], proposing two different methods for dissipating the numerical oscillations. In the first method, a numerical filter was proposed to smooth the numerical results in each time step. However, this method was shown not to be efficient in higher pipe acoustic speed. In addition, it does not discriminate between spurious numerical oscillation and the numerical oscillations with physical basis. In the second method, a hybrid flux is utilized to gradually add artificial numerical viscosity to the numerical scheme through increasing the wave velocity. This method efficiently suppresses spurious numerical oscillation as long as the pipe acoustic speed does not exceed a certain value (100–150 m/s). Nevertheless, in higher pipe acoustic speed, too much artificial viscosity is required to dissipate the numerical oscillation but at the expense of significant numerical diffusion that compromises the accuracy of the results.

Malekpour and Karney [

4] studied the numerical orbits of a first order Godunov numerical scheme with a HLL Riemann solver on the phase plan and realized that artificial numerical viscosity should be admitted only when the flow pressurization is imminent in order to suppress the spurious numerical oscillations. Moreover, they found that adding artificial viscosity only at the computational cell in which flow transition occurs may even exacerbate the spurious numerical oscillations. To resolve this problem, the authors showed that the artificial viscosity should be distributed among several computational cells located around the computational cell receiving flow transition. The numerical results showed that this approach can provide oscillation-free results, even at a high pipe acoustic speed over 1000 m/s. The robustness of the proposed HLL solver by Malekpour and Karney has been confirmed by other researchers [

33,

34], and thus we adopted it in this research.

In order to show how artificial numerical viscosity can be increased in the HLL solver, consider Equation (9) representing flux at the star zone. Assuming that the absolute value of the left and right wave velocities is equal, we can rewrite flux in the star zone presented in Equation (9) as follows:

The first term on the right-hand side of Equation (10) provides a flux that is unconditionally unstable [

37]. This concludes that the second term plays an important role to stabilizing the flux through admitting artificial viscosity to the scheme. This implies that the magnitude of the numerical viscosity can be increased by increasing the wave velocity. It is important to note that adding too much numerical viscosity produces significant data smearing and numerical diffusion, which in turn compromises the accuracy of the results. To control data smearing, Malekpour and Karney [

32] proposed a method for calculating the left and right wave velocities that can automatically increase the amount of artificial numerical viscosity in the neighborhood of the pressurization interface. To calculate the wave velocities, we adopted the following formula in this research, which is the adjusted version of that of Leon et al.

where

is given by

where

is the gravity wave velocity, and the variables with sub-index

G are the function of

that need to be estimated.

Malekpour and Karney [

32] show that if

is greater than the height of the conduit, the wave velocity calculated by Equation (11) does not differ from the gravity wave velocity except in the vicinity of the conduit roof. In other words, by using Equation (11), significant artificial velocity is admitted to the numerical scheme only when the water surface in the conduit becomes very close to the conduit roof and the conduit is about to become pressurized. Extensive numerical experiments by Malekpour and Karney produced the following formula for calculating

:

where

.

By using the above equation, the maximum d is calculated within a number of cells (

NS) located on either side the

ith cell for which the wave velocity is being calculated.

is then calculated by multiplying the maximum d by the factor

. In this way, numerical viscosity is distributed within a number of cells rather than being injected just in one cell. If all

s are greater than the conduit height, the system is pressurized and a

= 1.001 would provide reasonable results. When there is a pressurization front located within the cells, the numerical viscosity is further intensified by applying

= 1.4. The number of cells (

NS) considered depend on the resolution of the computational grid and should be selected such that the numerical viscosity is adequately distributed on either side of the computational cell for which the wave velocity is being calculated. Malekpour and Karney [

32] suggested that the number of cells should cover a distance equal to at least three times as large as the conduit height but in any case it should not be less than three cells. If the

ith computational cell is found near a boundary, we should also incorporate the flow depth at the boundary point into Equation (13).

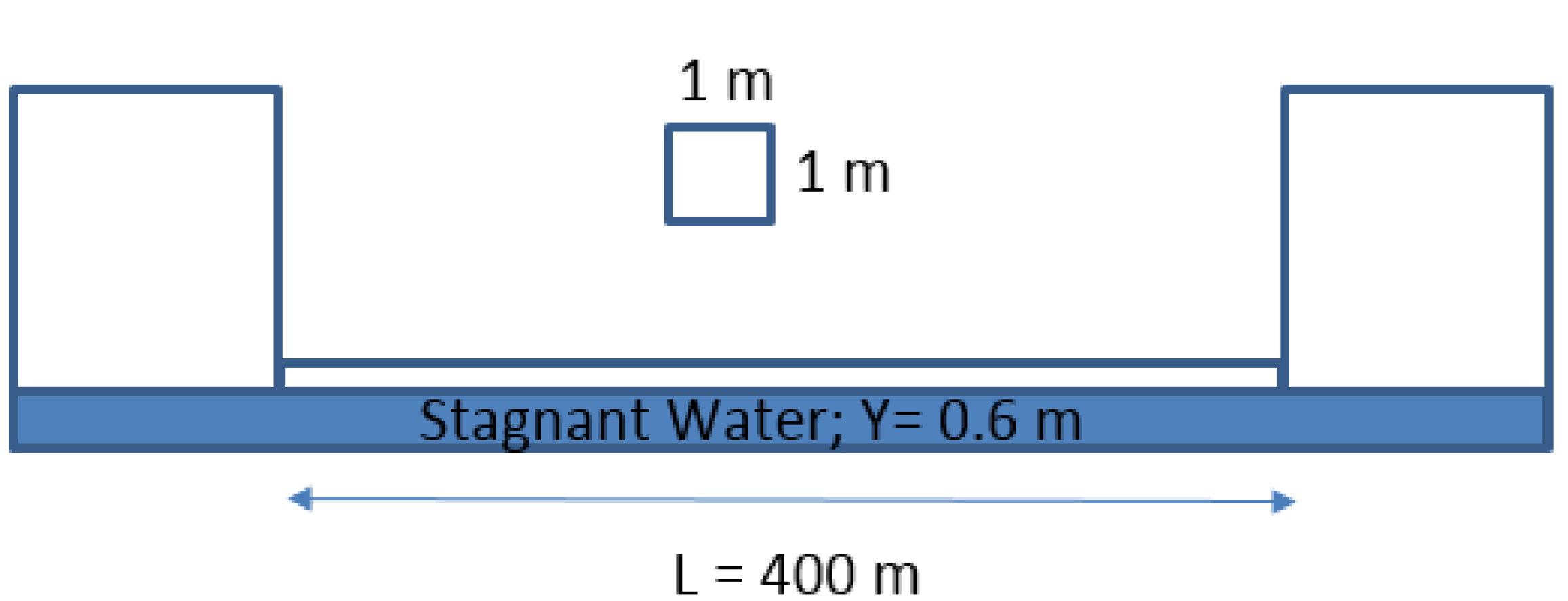

5. Discussion

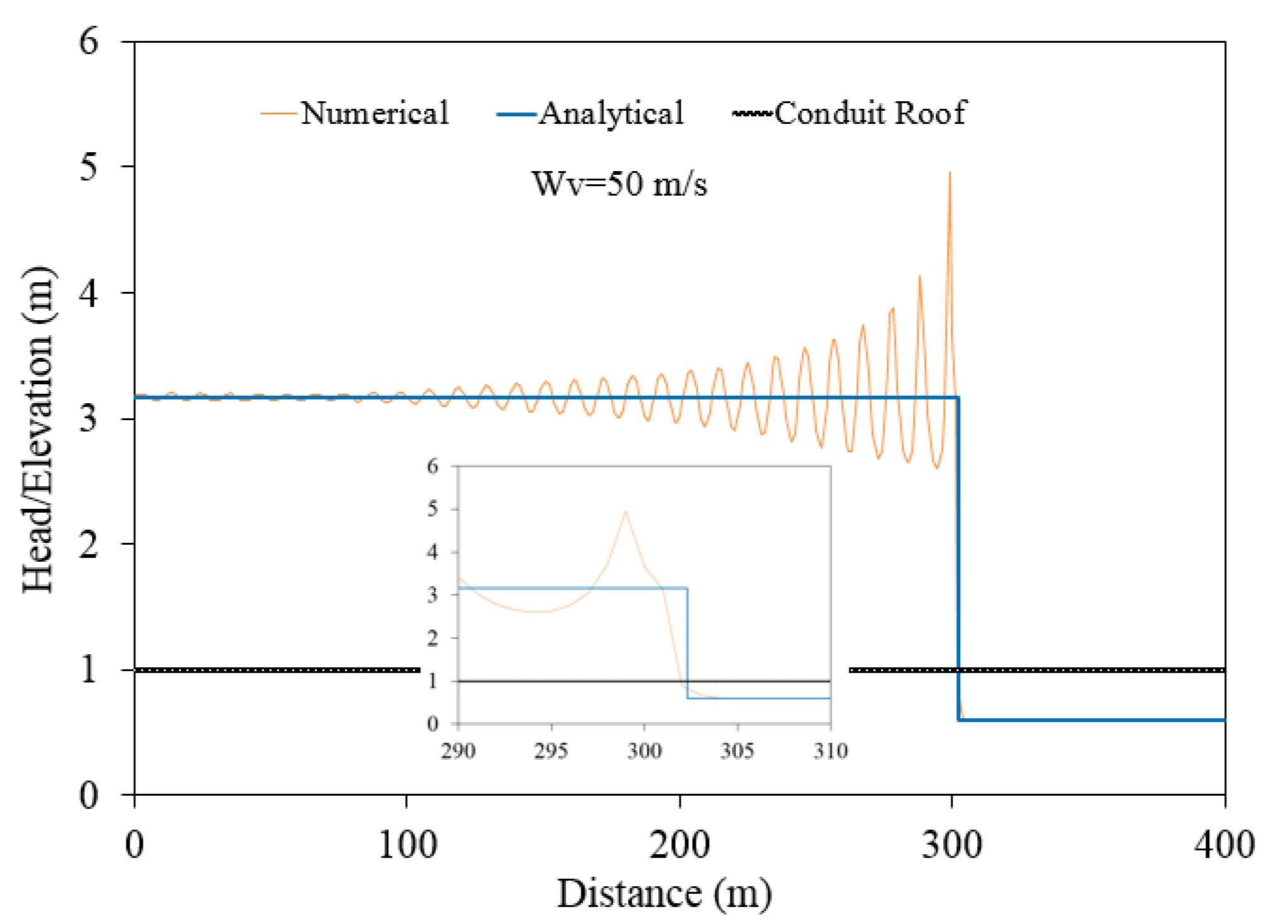

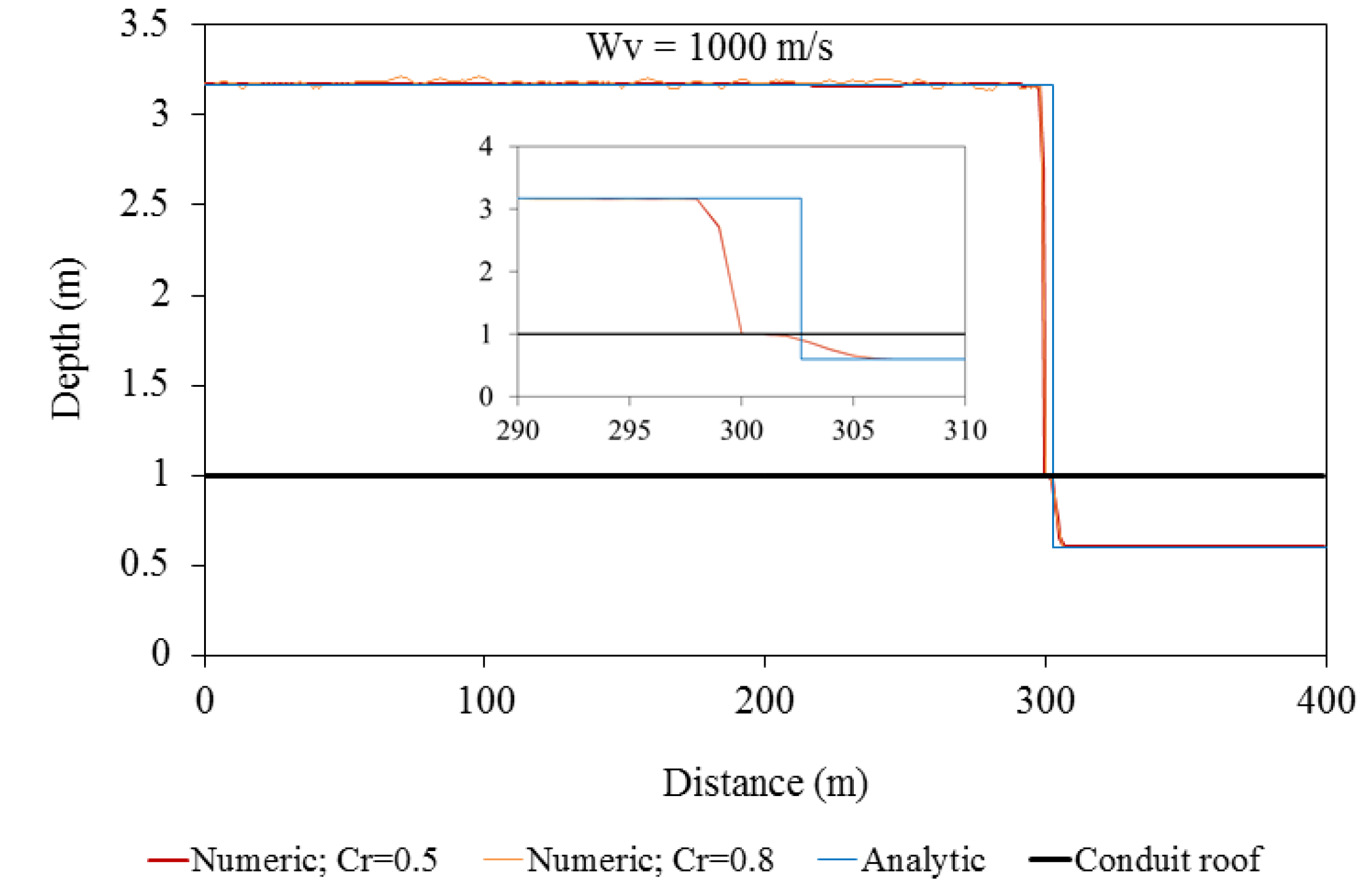

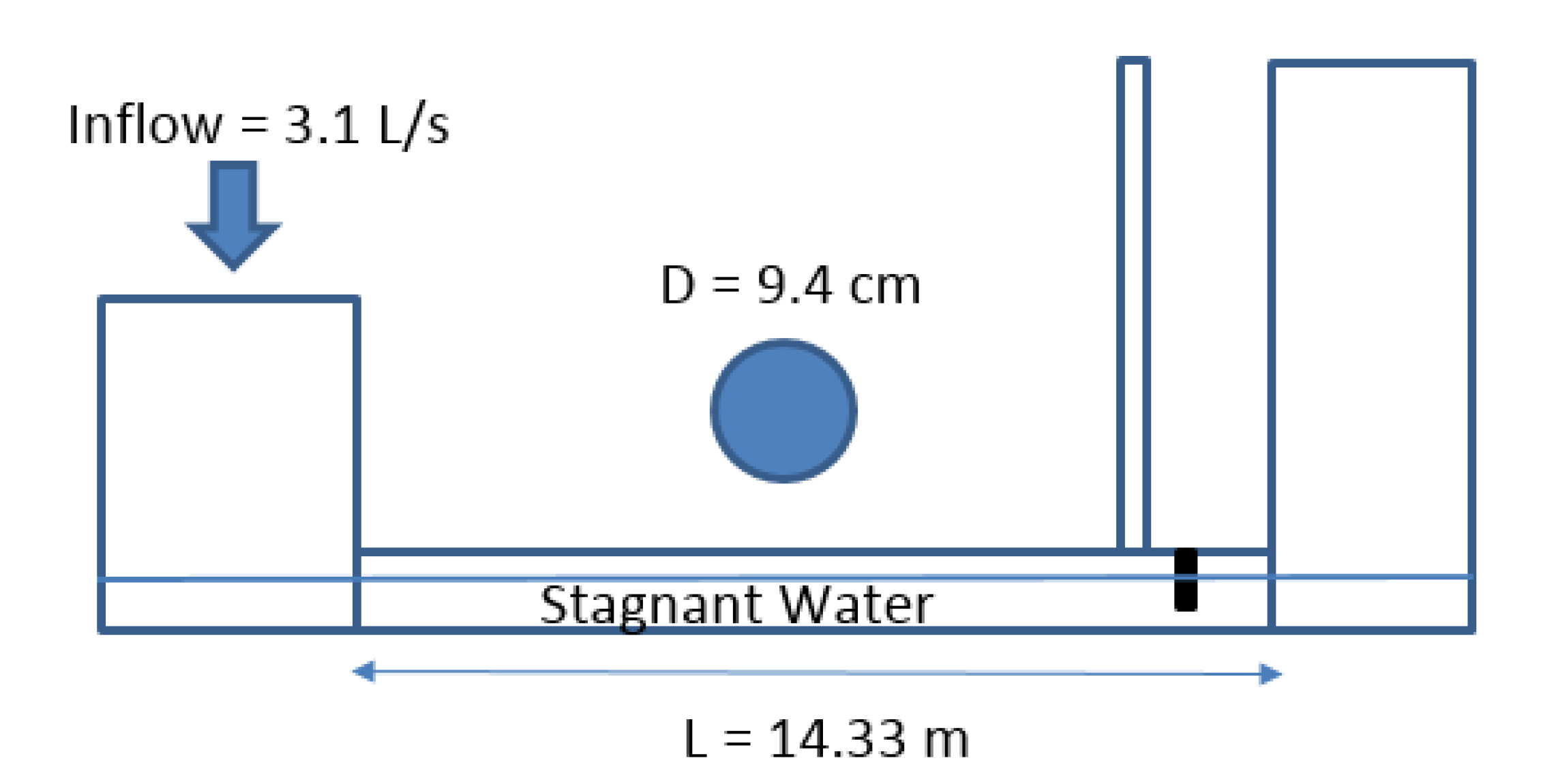

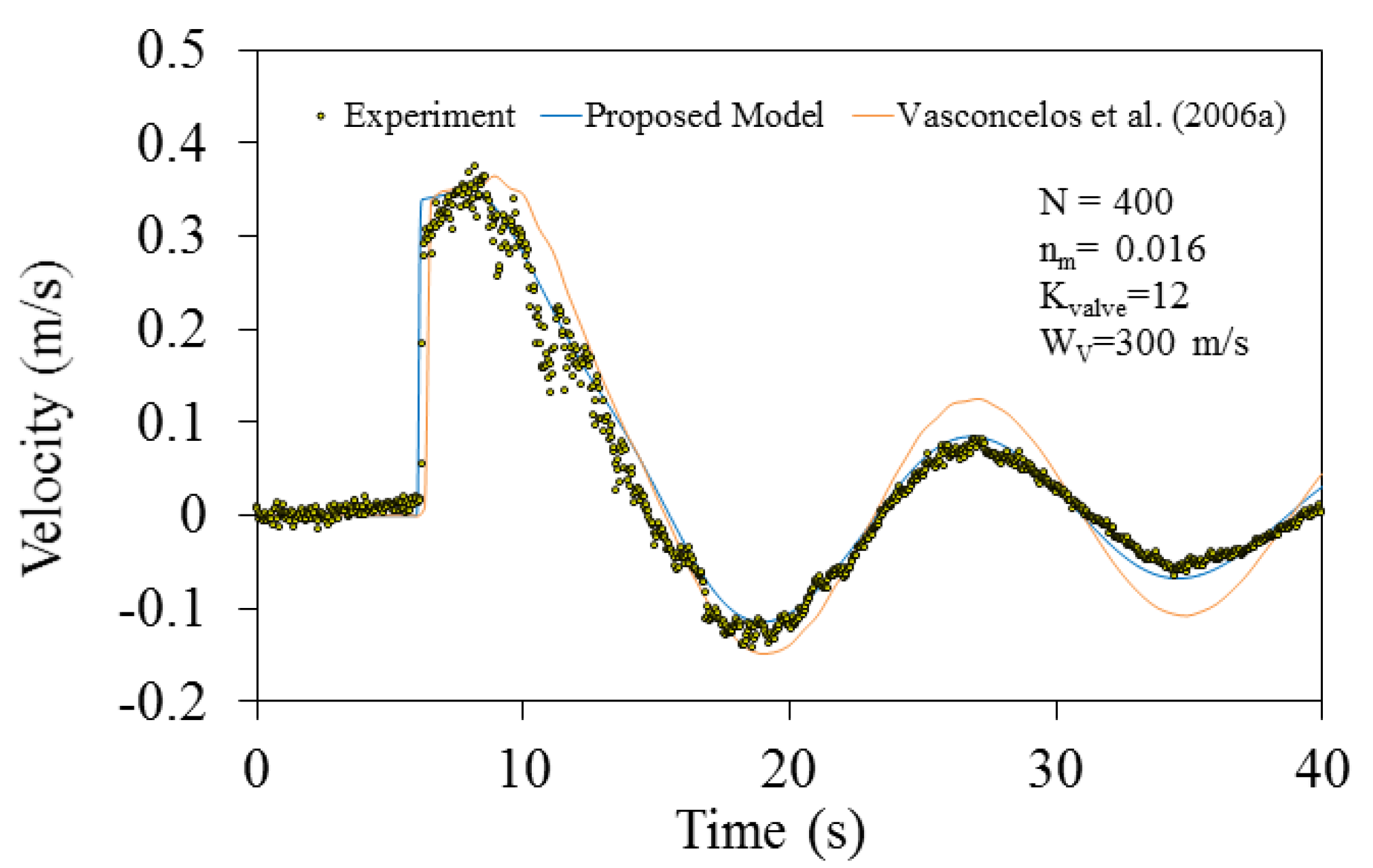

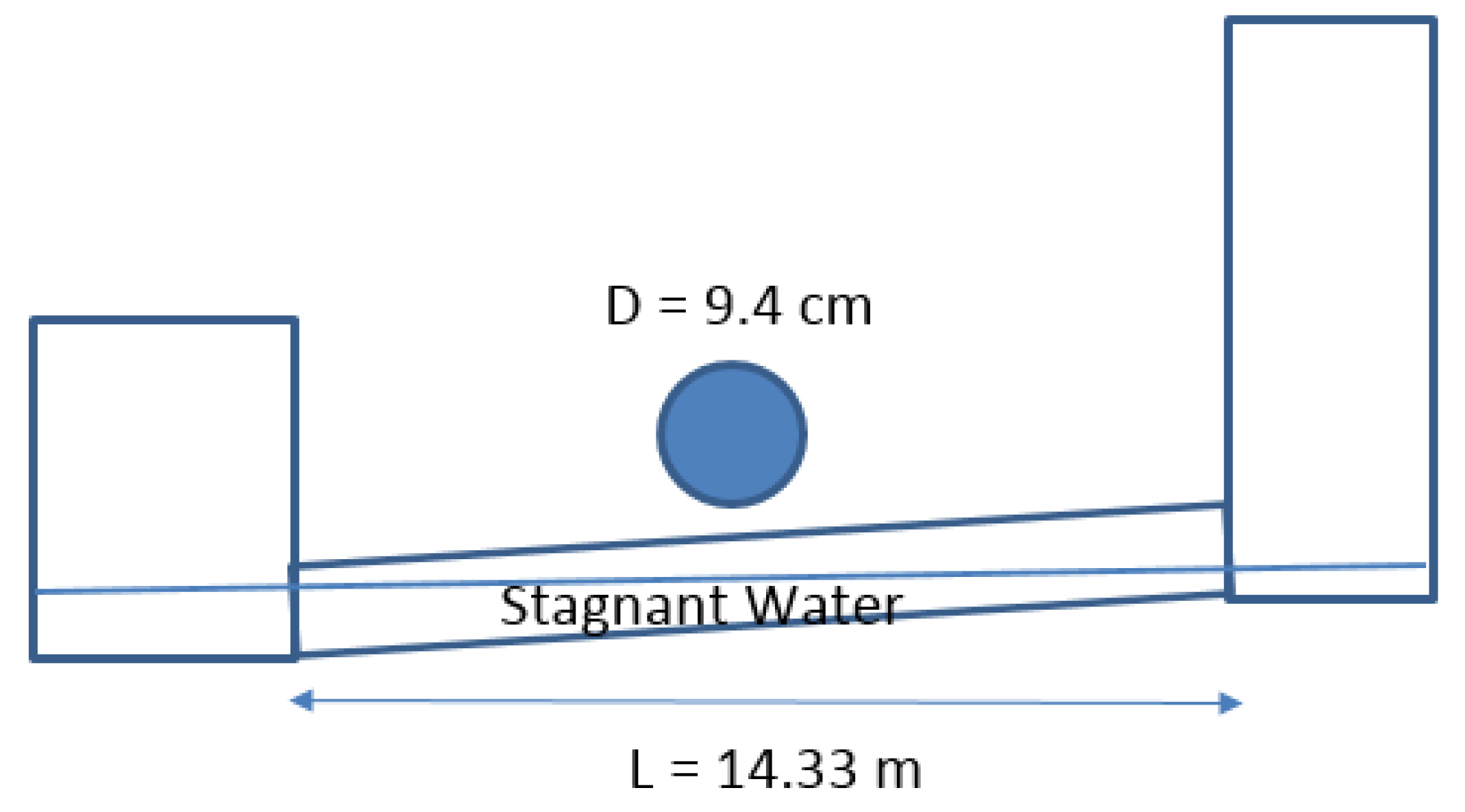

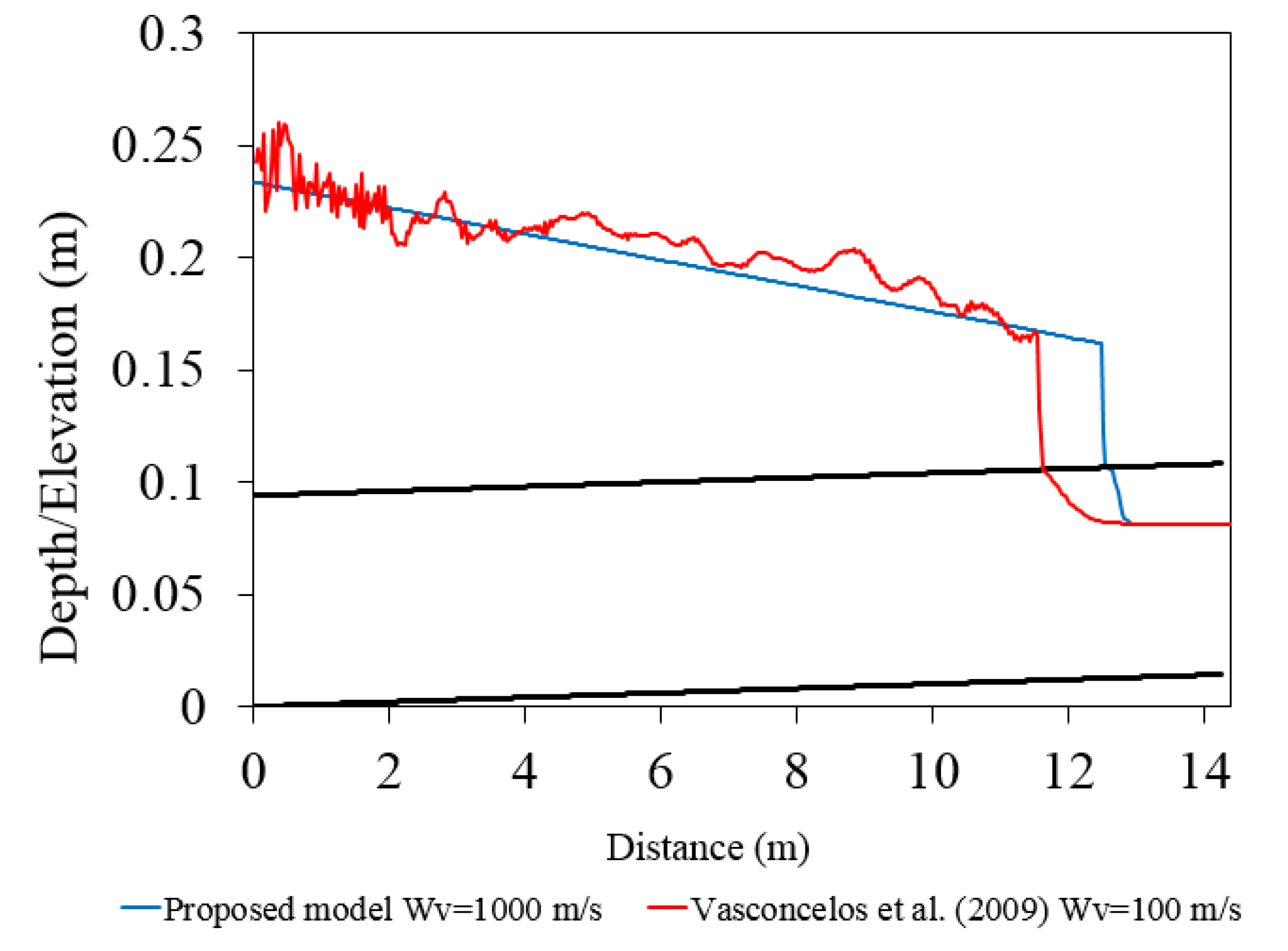

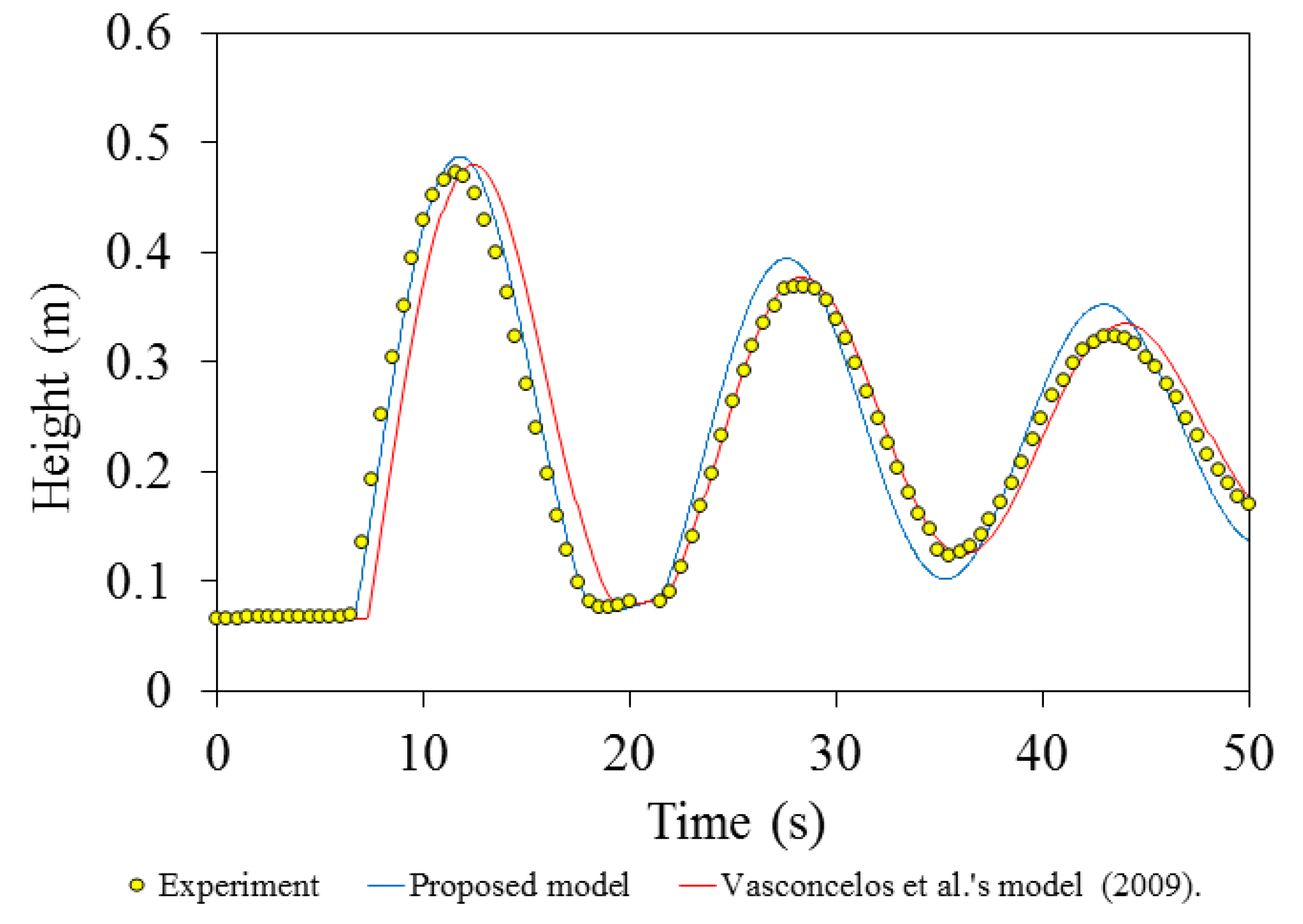

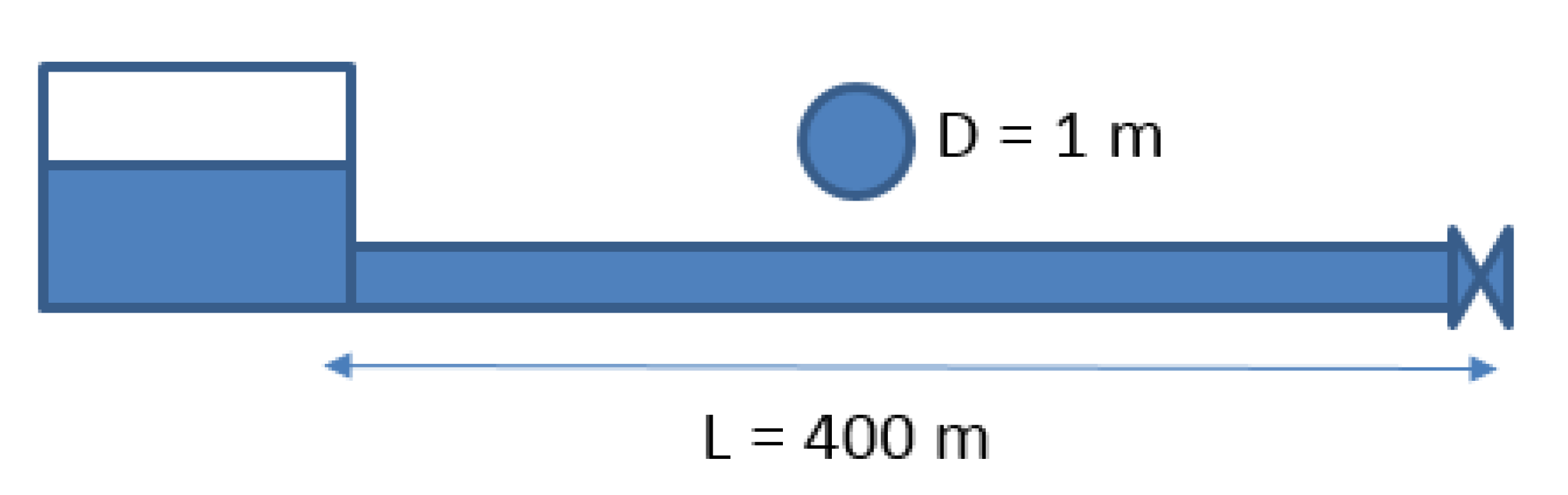

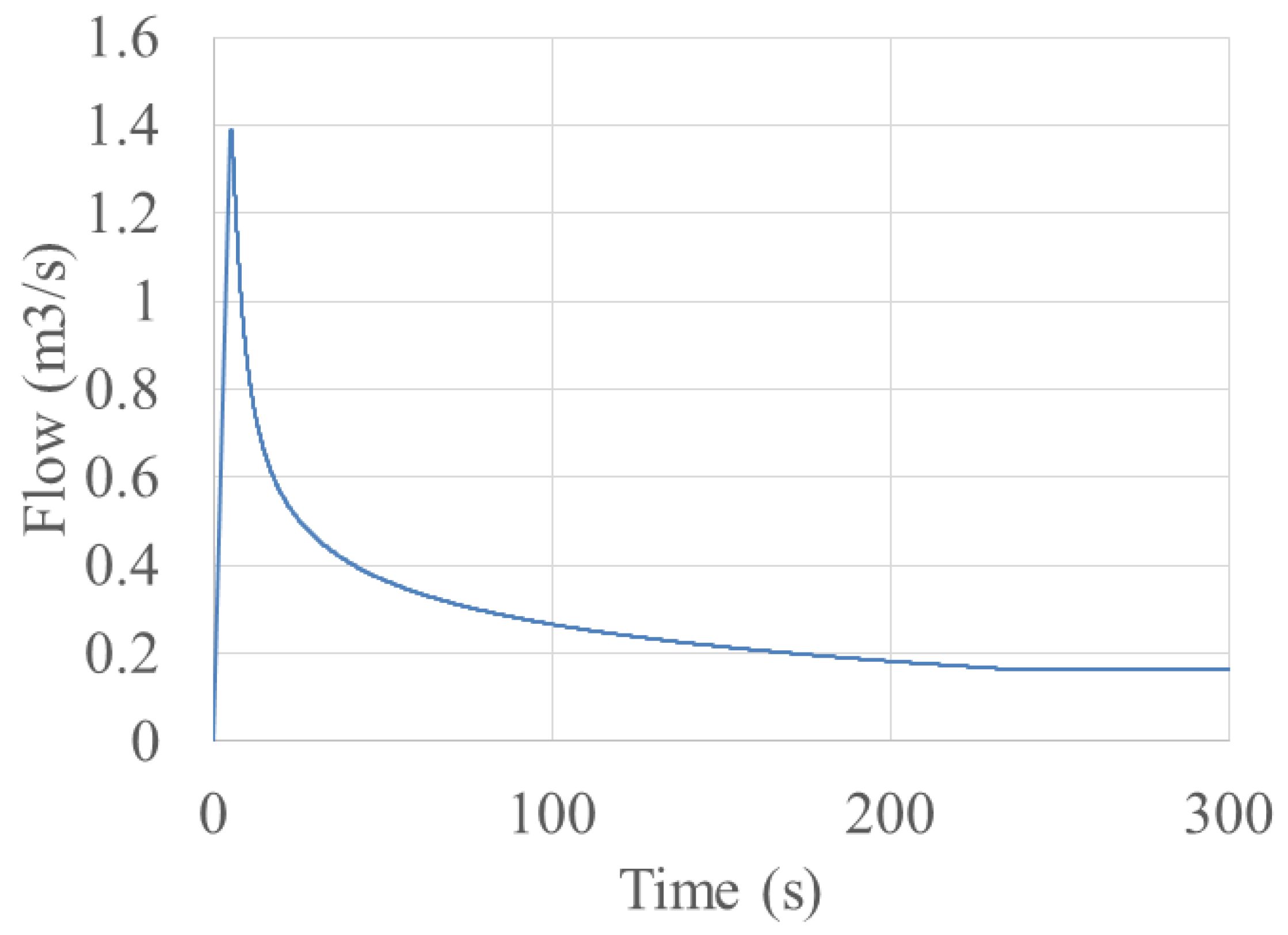

Test case 1’s results reveals that spurious numerical oscillations are induced when the flow regime wis changed from open channel to pressurized flow. The numerical oscillations ware attributed to the fact that during the pipe pressurization, the wave velocity drastically increases when the flow is switched from open channel to pressurized flow; the higher the pipe’s acoustic wave speed, the more intensified the numerical oscillations become. In such cases, the conventional Godunov finite volume scheme fails to dissipate the numerical oscillations, with extensive non-physical positive and negative pressure spikes appearing in the solution, which can eventually lead the procedure to the collapse of the computer code. Several studies tended to add artificial velocity only at the computational cell containing the pressurization front, but the results showed that this approach is unable to efficiently dissipate the numerical oscillations, particularly when the acoustic wave speed exceeds 150 m/s. This is far below the realistic pipe’s acoustic wave speed, which may exceed 1000 m/s, depending on the fluid properties, physical characteristics, and rigidity of each pipe. Rather than admitting the artificial viscosity at a local point, the modified HLL Riemann solution utilized in this research distributes artificial numerical viscosity over several computational cells around the cell containing the pressurization front. Test cases 1 and 3 justify that the proposed numerical model can dissipate the spurious numerical oscillations without producing significant data smearing.

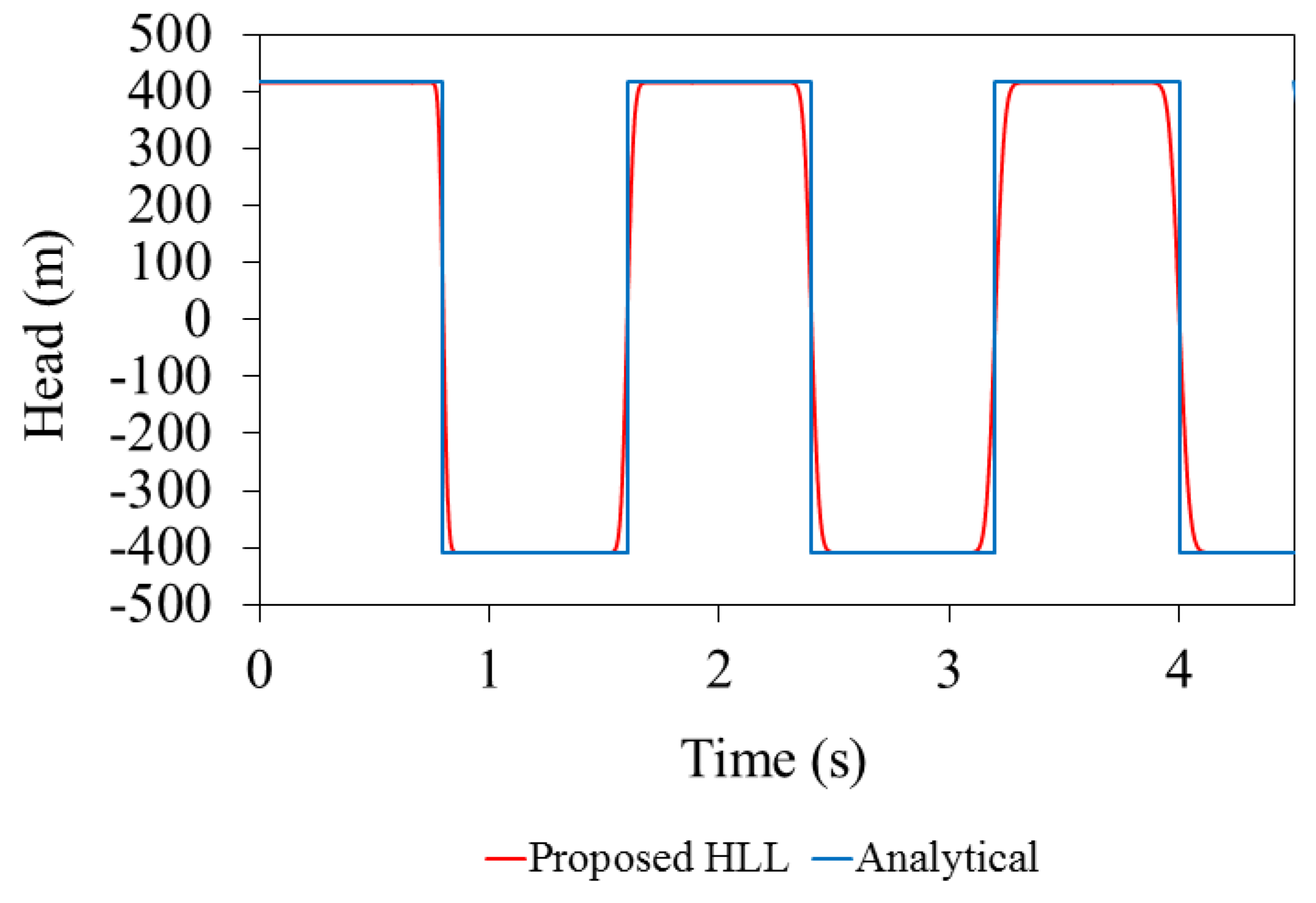

To justify that the admitted artificial numerical viscosity does not dissipate the real pressure oscillations with a physical basis, we considered test case 2, which manifested both mass oscillations and waterhammer pressures. As test case 2’s results imply, the proposed numerical scheme discriminates between physical and non-physical numerical oscillations and automatically controls the value of the artificial numerical viscosity without damping the physical pressure oscillations. It is worth mentioning that the artificial numerical viscosity can still affect physical pressure oscillations but the dissipation is too little to compromise the results. Test case 4’s results showed that the model captures severe waterhammer pressure oscillations, and the admitted artificial viscosity also rounds the corner of the waterhammer pressure signals, which is ideally supposed to have rectangular shapes.

Finally, test cases 4 and 5 are used to confirm that the model enables capturing of negative pressures while controlling spurious numerical oscillations. As the results show, negative pressures are correctly replicated by the model but the model is unable to capture water column separation. Test case 5’s results clearly show that the induced negative pressure heads drop to nearly −400 m, but in reality it is limited to the liquid vapor pressure head. As soon as the pressure falls to the vapor pressure head, cavitation forms and the water column is locally separated. Replicating column separation requires more modification to the model, which is currently being perused by the authors.