Groundwater Abstraction through Siphon Wells—Hydraulic Design and Energy Savings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Hydraulic Calculation of Siphon Wells

2.2. Site Descriptions

2.2.1. Fictional Lake Bank Filtration Site

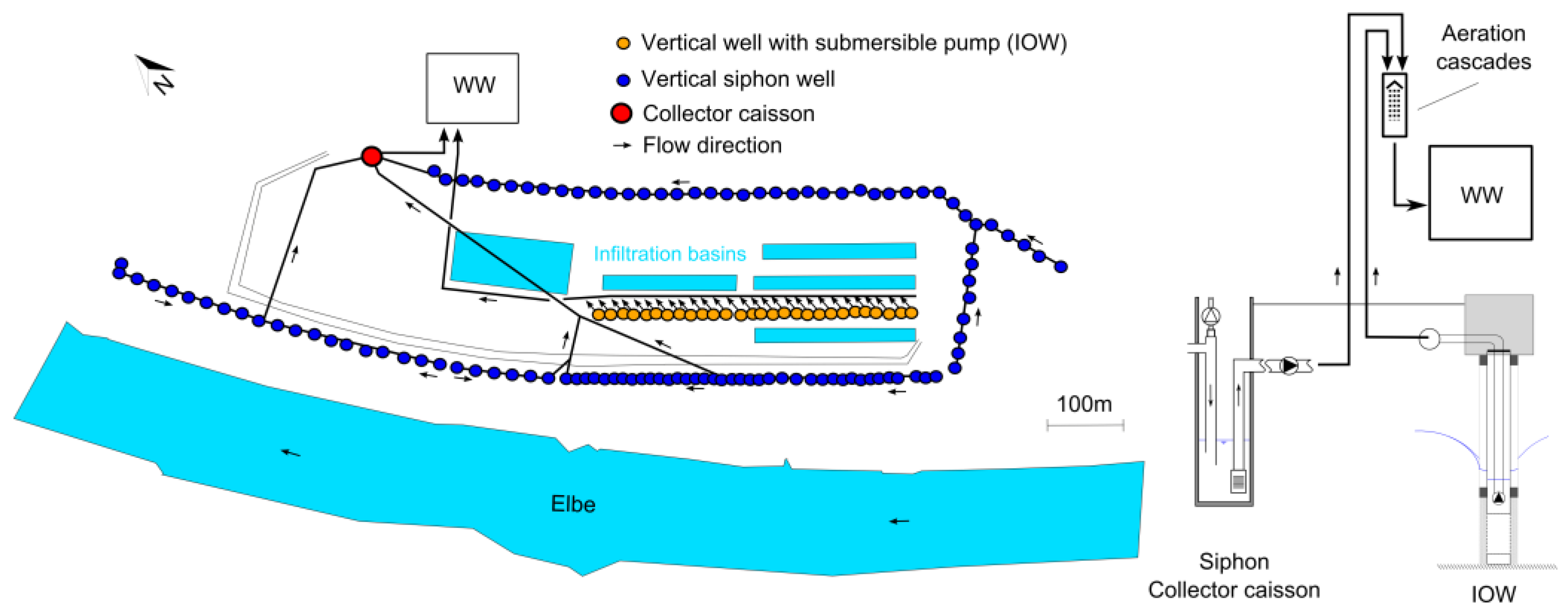

2.2.2. Waterworks Dresden-Hosterwitz, Germany

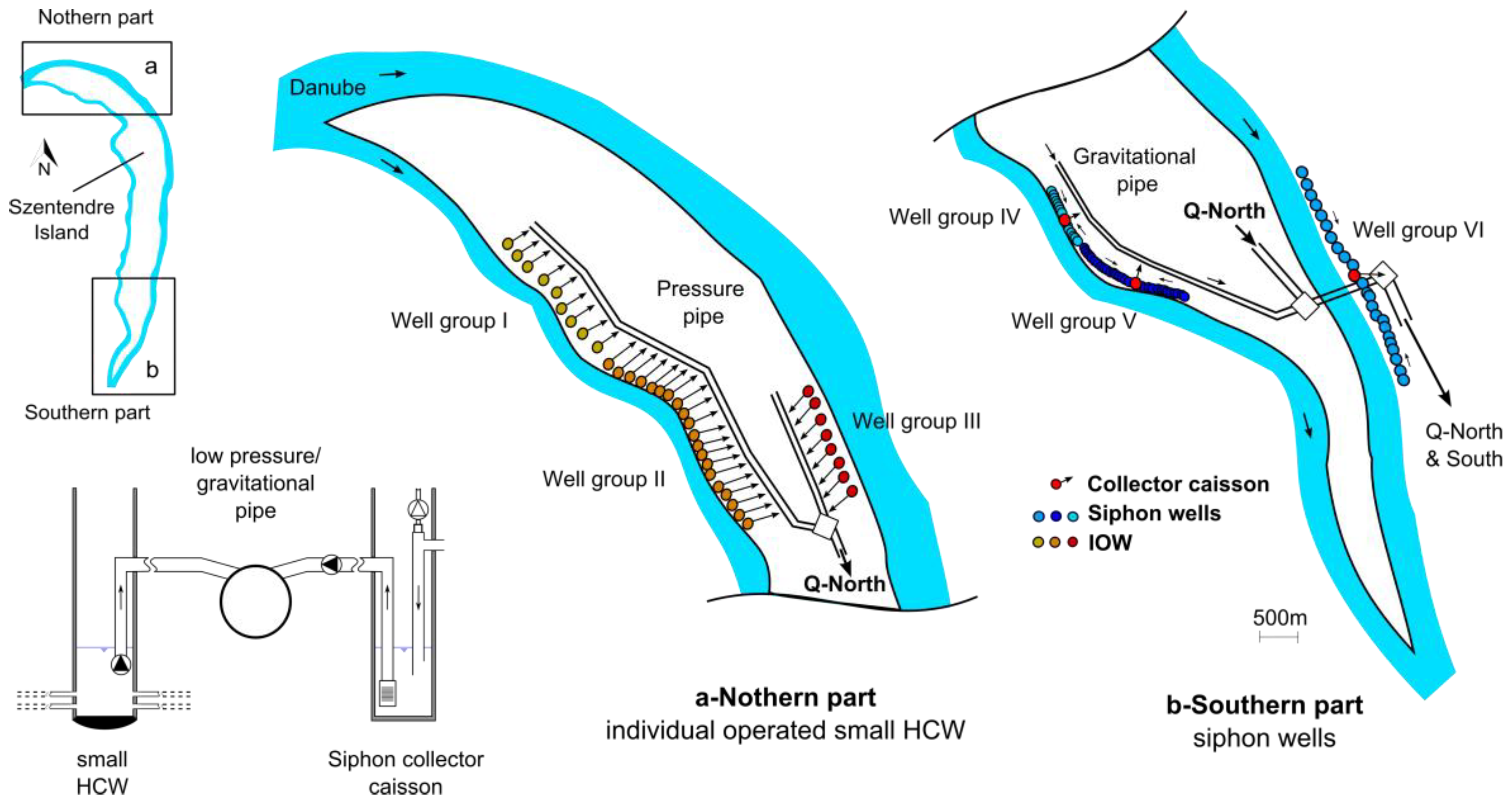

2.2.3. Szentendre Island, Budapest Waterworks, Hungary

2.3. Energy Assessment

3. Results and Discussion

3.1. Hydraulic Calculation of Siphon Wells

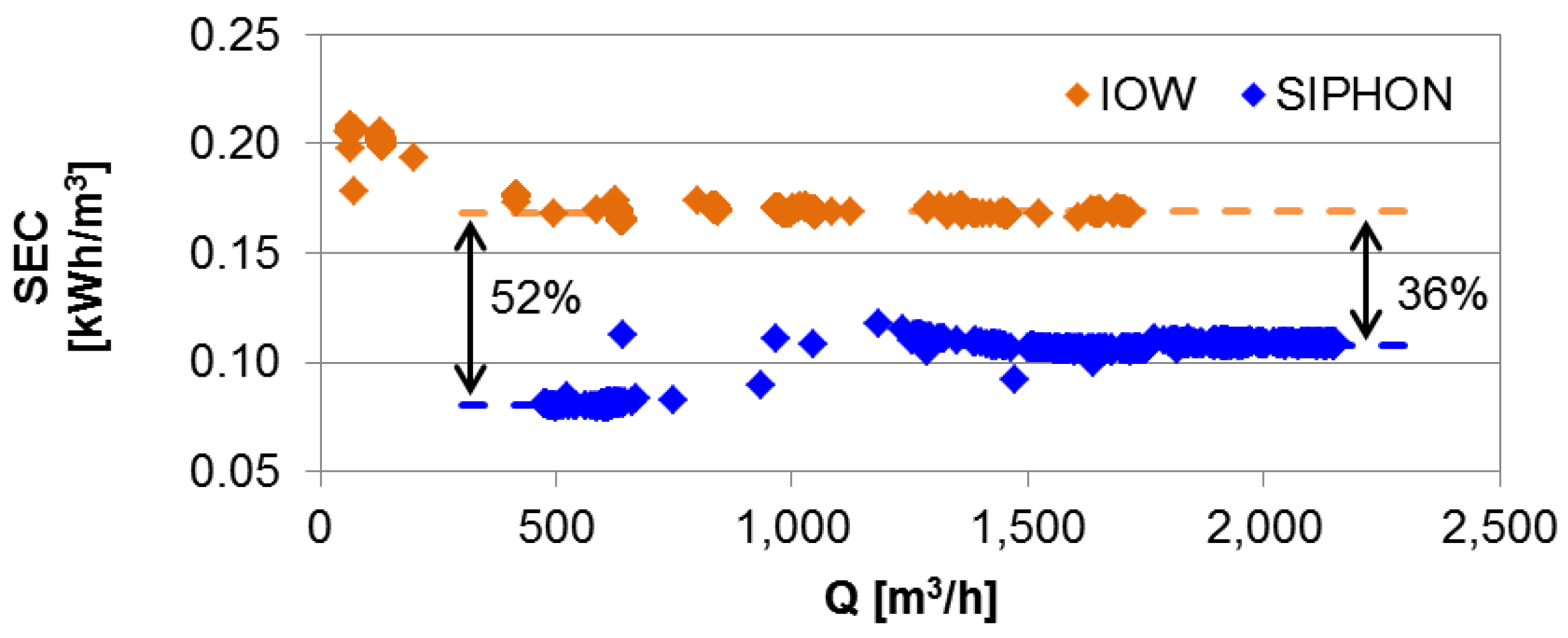

3.2. Energetic Comparison of Siphon and Individually Operated Wells with Submersible Pumps

3.2.1. Fictional Lake Bank Filtration Site

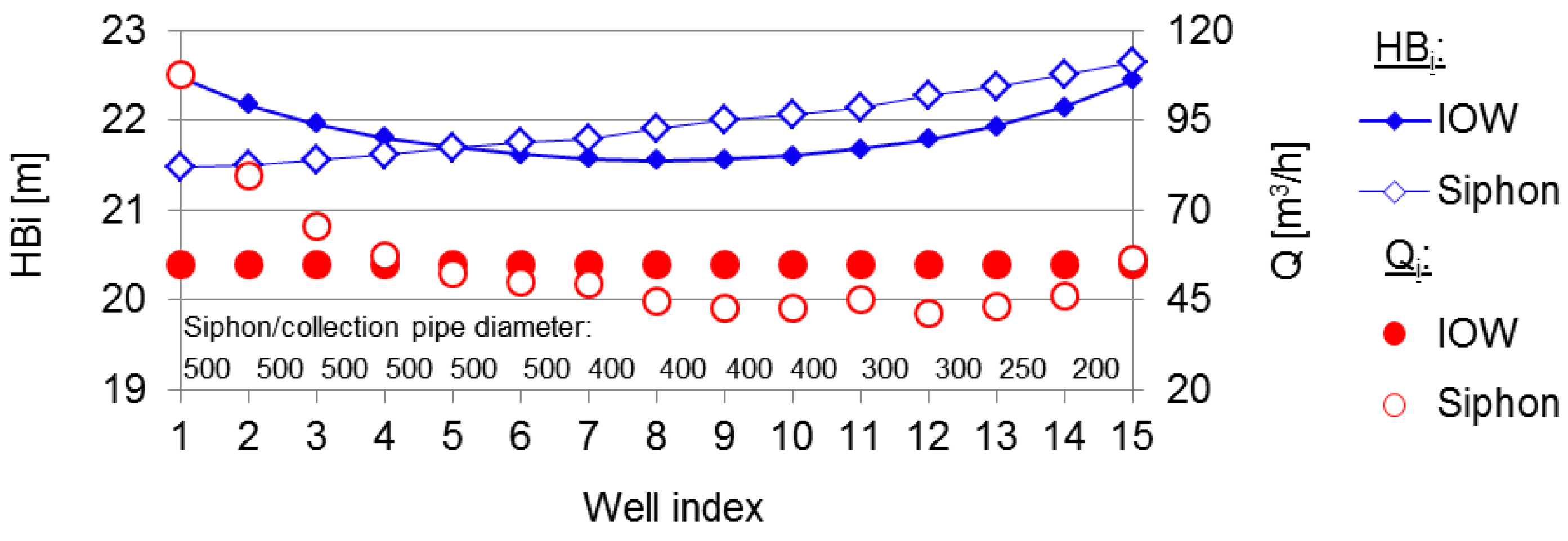

3.2.2. WW Dresden-Hosterwitz

3.2.3. Szentendre Island

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Luckner, L.; Eichhorn, D.; Bornitz, U. Calculation of well groups with siphon pipes. Wasserwirtsch. Wassertech. 1971, 21, 354–361. (In German) [Google Scholar]

- Bartak, R.; Grischek, T. Hydraulic calculation of siphon wells. bbr 2018, 69, 64–69. (In German) [Google Scholar]

- Kroening, H. Renewal of the waterworks Curslack. Wasserwirtsch. Wassertech. 2006, 5, 8–15. (In German) [Google Scholar]

- Mauder, S. Rehabilitation of well groups-focus on well chamber design. In Proceedings of the Berlin-Brandenburger Brunnentage, Potsdam, Germany, 12–13 May 2014. (In German). [Google Scholar]

- Scheck, R. Rehabilitation of well group 1 of the state water supply after 100 years of operation. LW-Schriftenreihe 2015, 30, 20–29. (In German) [Google Scholar]

- Huebner, M. Modern system engineering for energy efficient water supply. bbr 2011, 12, 72–78. (In German) [Google Scholar]

- Plath, M.; Wichmann, K. German Technical and Scientific Association for Gas and Water—Information water No. 77 on energy efficiency. Energ. Wasser Prax. 2011, 1, 58–60. (In German) [Google Scholar]

- Sperlich, A.; Gnirß, R.; Schimmelpfennig, S. Subproject 6: Microbial Clogging in Drinking Water Wells, at Its Pumps and in the Raw Water Networks—Developments and Evaluation of Operational Measures; BMBF Project 02WT1189; Berlin Water Works: Berlin, Germany, 2014. (In German) [Google Scholar]

- Paavel, V. Calculation of Well Groups with Siphon Pipes. Ph.D. Thesis, TH Braunschweig, Braunschweig, Germany, 1947. (In German). [Google Scholar]

- Eichhorn, D. Calculation of Well Groups with Siphon Pipes. Ph.D. Thesis, TU Dresden, Dresden, Germany, 1968. (In German). [Google Scholar]

- Luckner, L.; Ziems, J.; Peukert, D.; Tiemer, K.; Eichhorn, D.; Wissel, D. Wells for Groundwater Abstraction-Study on Design Fundamentals; Project Report IG 131/151/70; VEB Projektierung Wasserwirtschaft (WAPRO): Halle/Saale, Germany, 1970; p. 9. (In German) [Google Scholar]

- Busch, K.-F.; Luckner, L. Geohydraulics, 2nd ed.; Dt. Verlag für Grundstoffindustrie: Leipzig, Germany, 1973; pp. 259–263. (In German) [Google Scholar]

- Eckert, P.; Lamberts, R.; Irmscher, R. Impact of river Rhine low flow conditions on the operation of a siphon well group. Energ. Wasser Prax. 2006, 12, 20–23. (In German) [Google Scholar]

| Parameter | Siphon Wells | IOW |

|---|---|---|

| No. of wells | 111 | 28 |

| Year of construction | 1908, 1928/29 | 1980s |

| Well design | VW | VW |

| Filter screen material | Copper & stoneware, slotted & some stainless steel wire | Steel, bridge slotted |

| Filter screen length | 3–5 m | 3 m |

| Screen diameter | 250–300 mm | 350 mm |

| No. of pumps | 3 (in collector caisson) | 46 |

| Type of pump | DM | SP |

| VFD | Yes | No |

| Parameter | Well Group | |||||

|---|---|---|---|---|---|---|

| I | II | III | IV | V | VI | |

| No. of wells | 9 | 20 | 8 | 56 | 70 | 22 |

| Well design | sHCW | sHCW | sHCW | VW | VW | sHCW |

| Operation | IOW | IOW | IOW | Siphon | Siphon | Siphon |

| Filter screen material | Steel, slotted | Steel, slotted | Steel, slotted | Stainless, bridge slotted | Stainless, slotted | |

| Total screen length | 1465 m | 3540 m | 1733 m | n.a. | n.a. | 3154 m |

| Screen diameter | 219 mm | 219 mm | 200 mm | 300 mm | 300 mm | 200 mm |

| No. of lateral levels | 1–2 | 2 | 1–2 | n.a. | n.a. | 1 |

| No. of pumps | 9 | 20 | 8 | 2 | 3 | 4 |

| Type of pump | SP | SP | SP | SP | DM | SP |

| VFD | Yes | Yes | Yes | Yes | Yes | Yes |

| Parameter | Unit | Siphon Wells | IOW | % Difference |

|---|---|---|---|---|

| No. of pumps | [/] | 1 | 15 | - |

| Model | [/] | NK250-350/342 | SP46-4, 15A21904 | - |

| Motor power draw | [kW] | 75 | 7.5 | - |

| Pump head | [m] | 25.2 | 24.1–26.2 | - |

| Pump discharge | [m3/h] | 825 | 55 | |

| Total efficiency 1 | [%] | 83.8 | 51.9–54.1 | 29.7–31.9 |

| Energy consumption | [kWh/a] | 5.91 × 105 | 9.50 × 105 | 37.8 |

| SEC | [kWh/m3] | 0.082 | 0.132 | 37.9 |

| Parameter | Unit | I (IOW) | II (IOW) | III IOW | IV | V | VI |

|---|---|---|---|---|---|---|---|

| Pump head | [m] | 1.3–6.3 | 0.8–6.2 | 1.3–5.4 | 4.3–5.9 | 3.5–5.9 | 2.3–4.5 |

| Energy consumption | [kWh/a] | 4.27 × 105 | 7.48 × 105 | 9.90 × 104 | 7.77 × 104 | 1.02 × 105 | 8.62 × 104 |

| Pressure-normalized SEC | [kWh/(m3·m)] | 0.028 (0.017–0.042) | 0.018 (0.011–0.030) | 0.022 (0.014–0.039) | 0.006 | 0.011 | 0.004 |

| SEC | [kWh/m3] | 0.075 (0.055–0.114) | 0.061 (0.052–0.120) | 0.053 (0.050–0.058) | 0.026 | 0.033 | 0.030 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartak, R.; Grischek, T. Groundwater Abstraction through Siphon Wells—Hydraulic Design and Energy Savings. Water 2018, 10, 570. https://doi.org/10.3390/w10050570

Bartak R, Grischek T. Groundwater Abstraction through Siphon Wells—Hydraulic Design and Energy Savings. Water. 2018; 10(5):570. https://doi.org/10.3390/w10050570

Chicago/Turabian StyleBartak, Rico, and Thomas Grischek. 2018. "Groundwater Abstraction through Siphon Wells—Hydraulic Design and Energy Savings" Water 10, no. 5: 570. https://doi.org/10.3390/w10050570

APA StyleBartak, R., & Grischek, T. (2018). Groundwater Abstraction through Siphon Wells—Hydraulic Design and Energy Savings. Water, 10(5), 570. https://doi.org/10.3390/w10050570