The Influence of Cellulose Nanocrystals on the Hydration and Flexural Strength of Portland Cement Pastes

Abstract

:1. Introduction

- Will CNCs from different raw material sources and from different processing procedures perform differently?

- Will CNCs perform equally well in cements of different types and chemical compositions?

- What are the most appropriate screening tests to evaluate the performance of CNC-cement composites?

- What are the factors that influence the performance of CNC-cement composites?

2. Experimental Methods

2.1. Materials

2.2. CNC-Cement Composite Preparation

2.3. Isothermal Calorimetry and Thermogravimetric Analysis

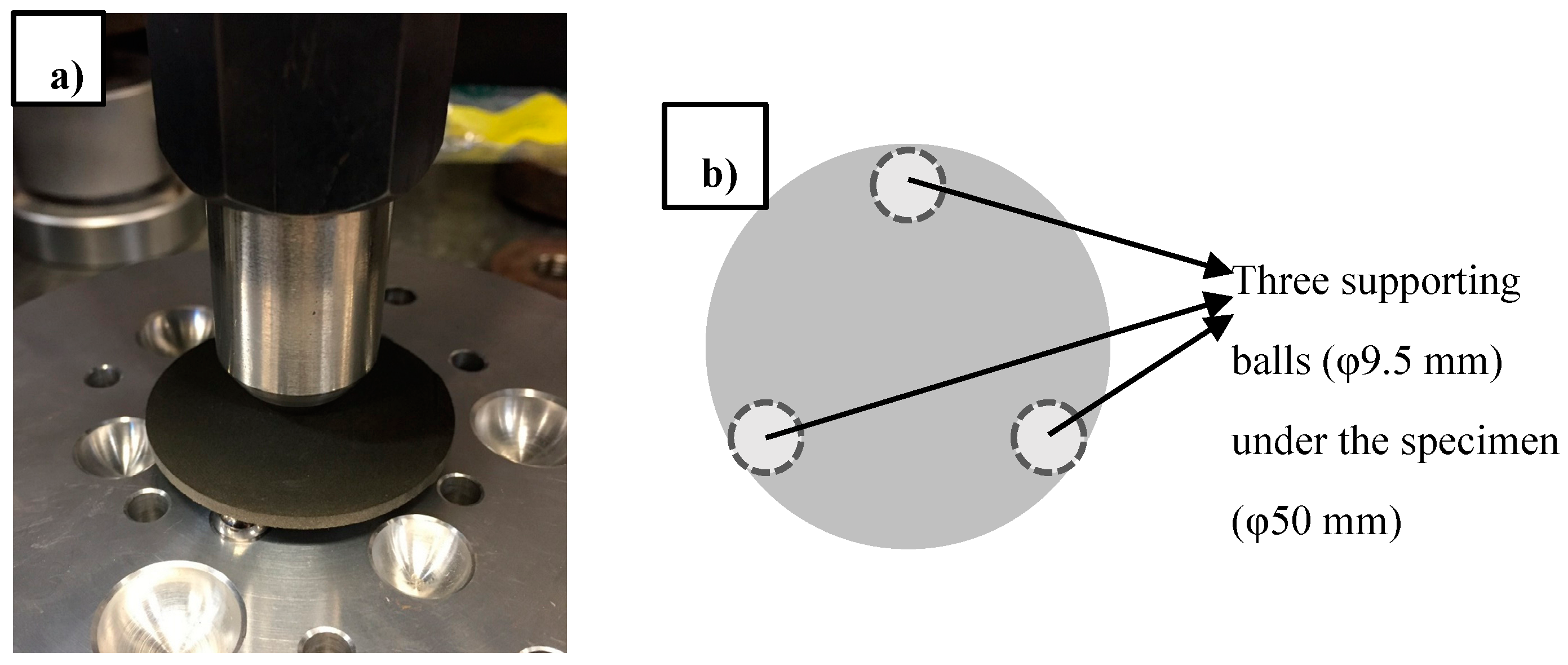

2.4. Ball-On-Three-Ball Test

3. Results and Discussion

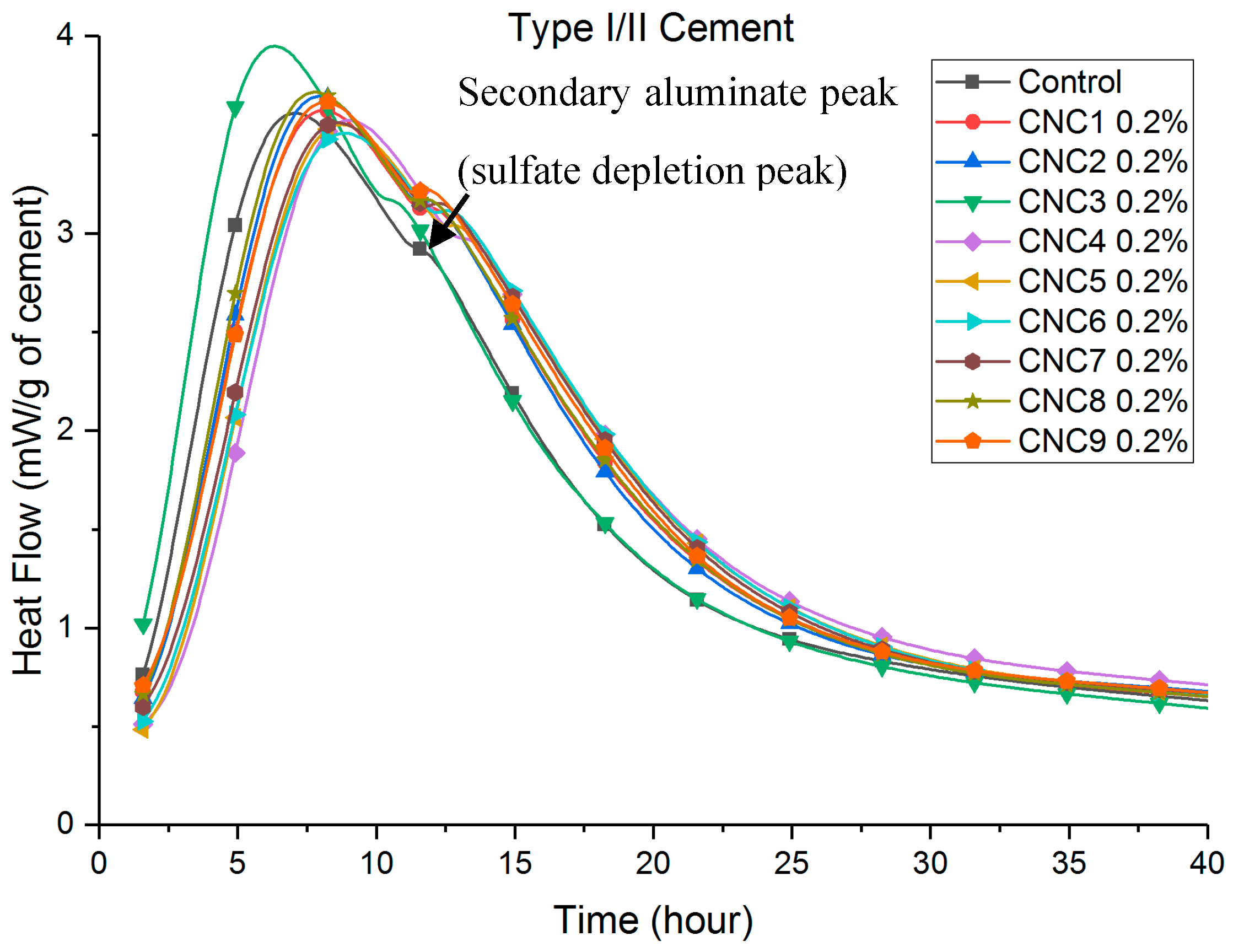

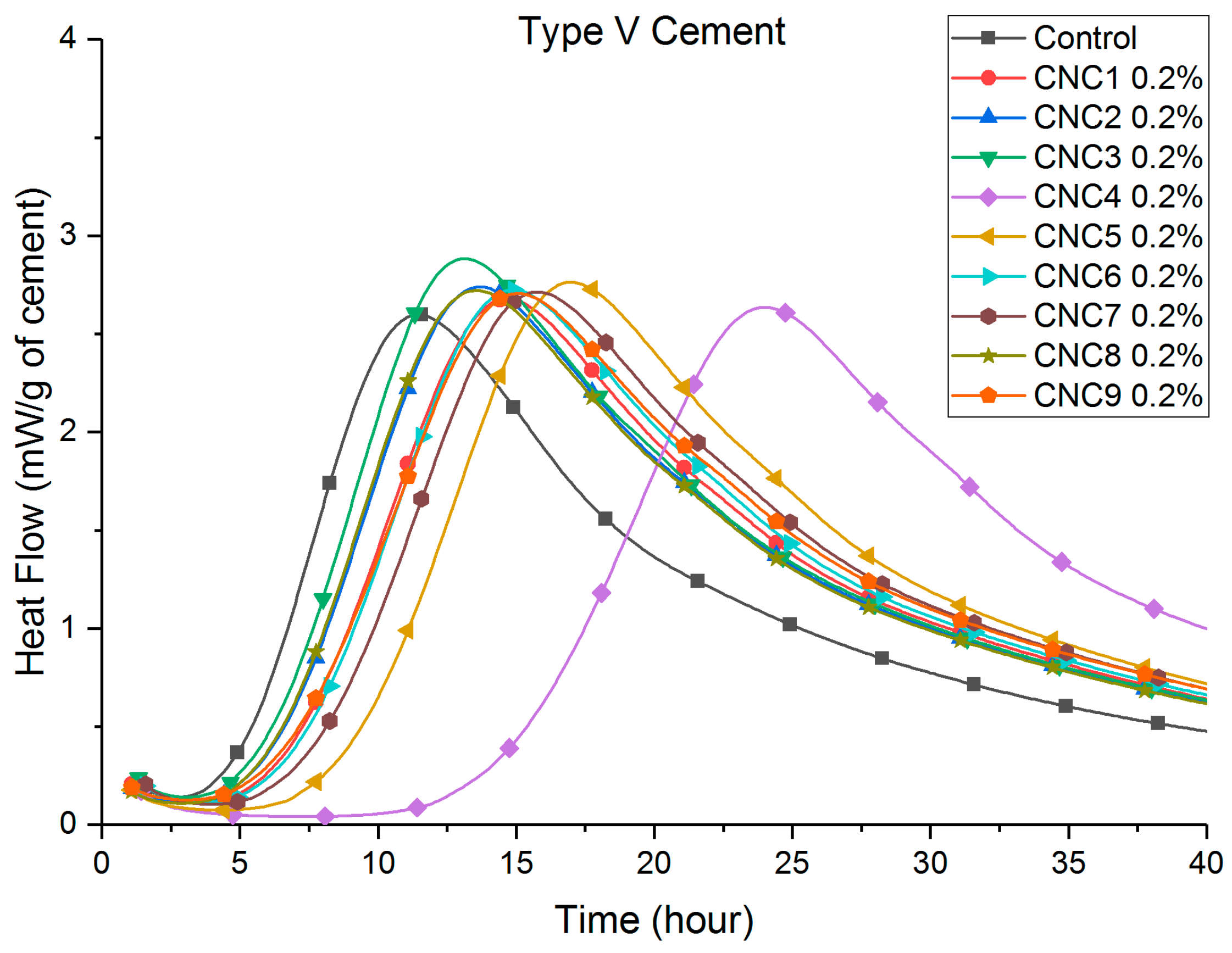

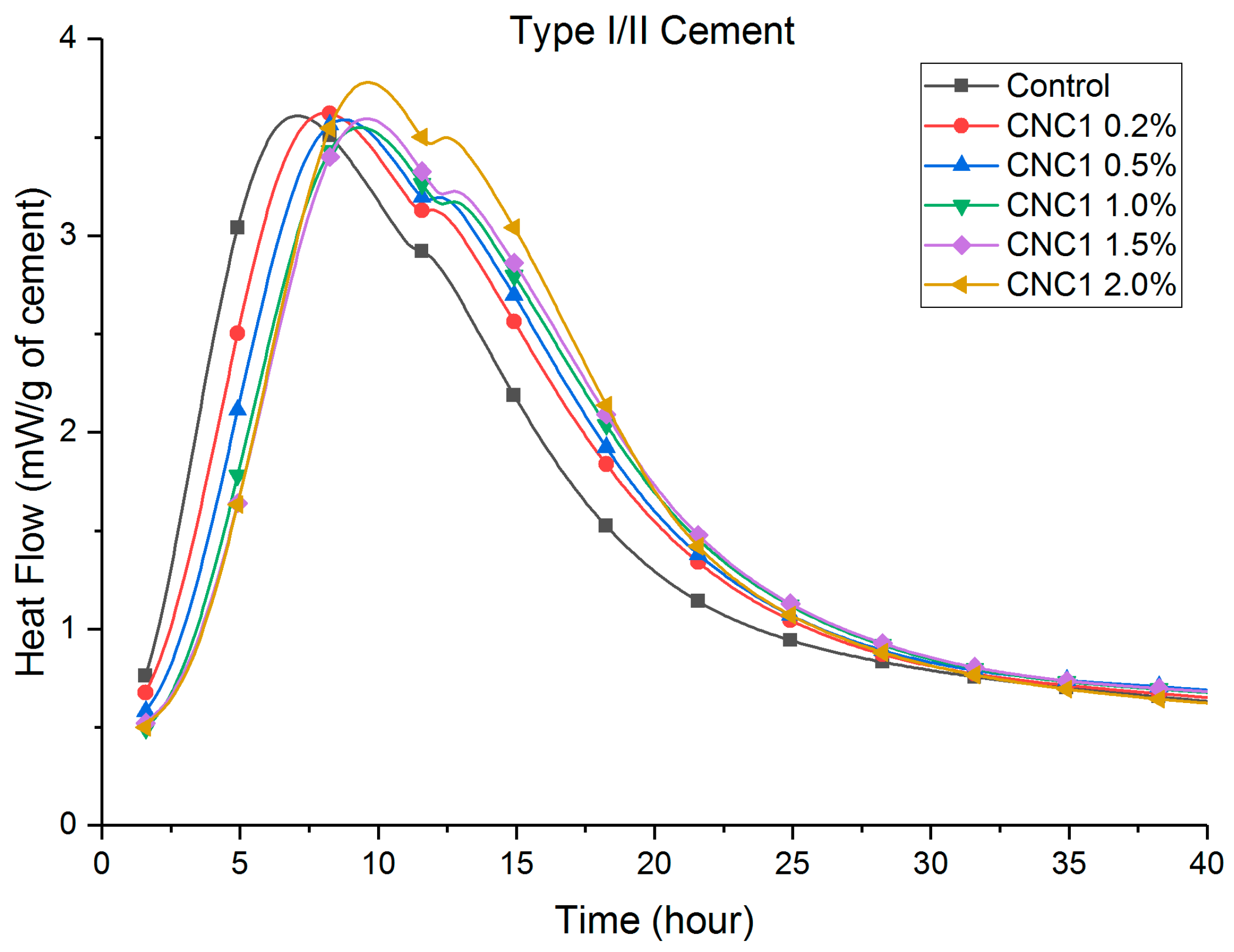

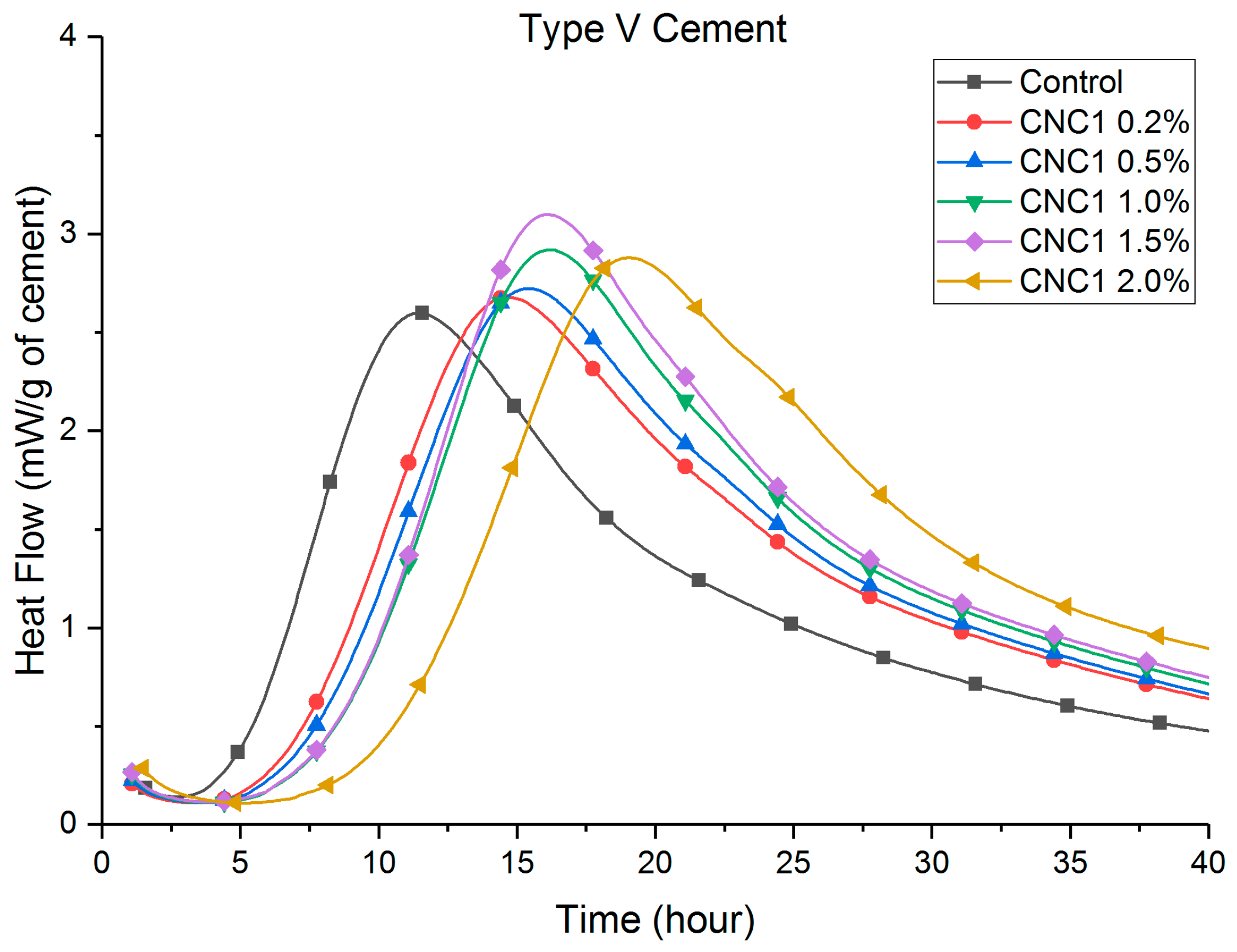

3.1. Isothermal Calorimetry

3.2. Thermogravimetric Analysis

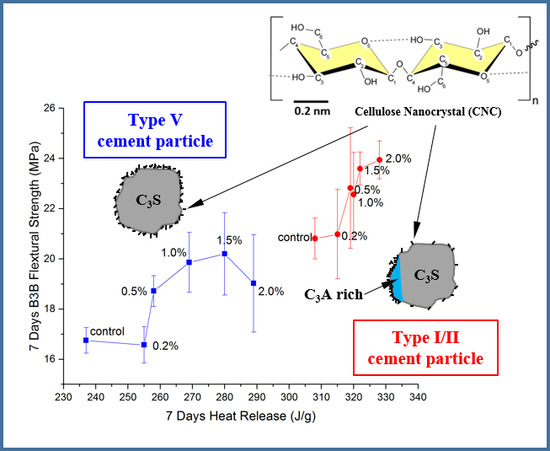

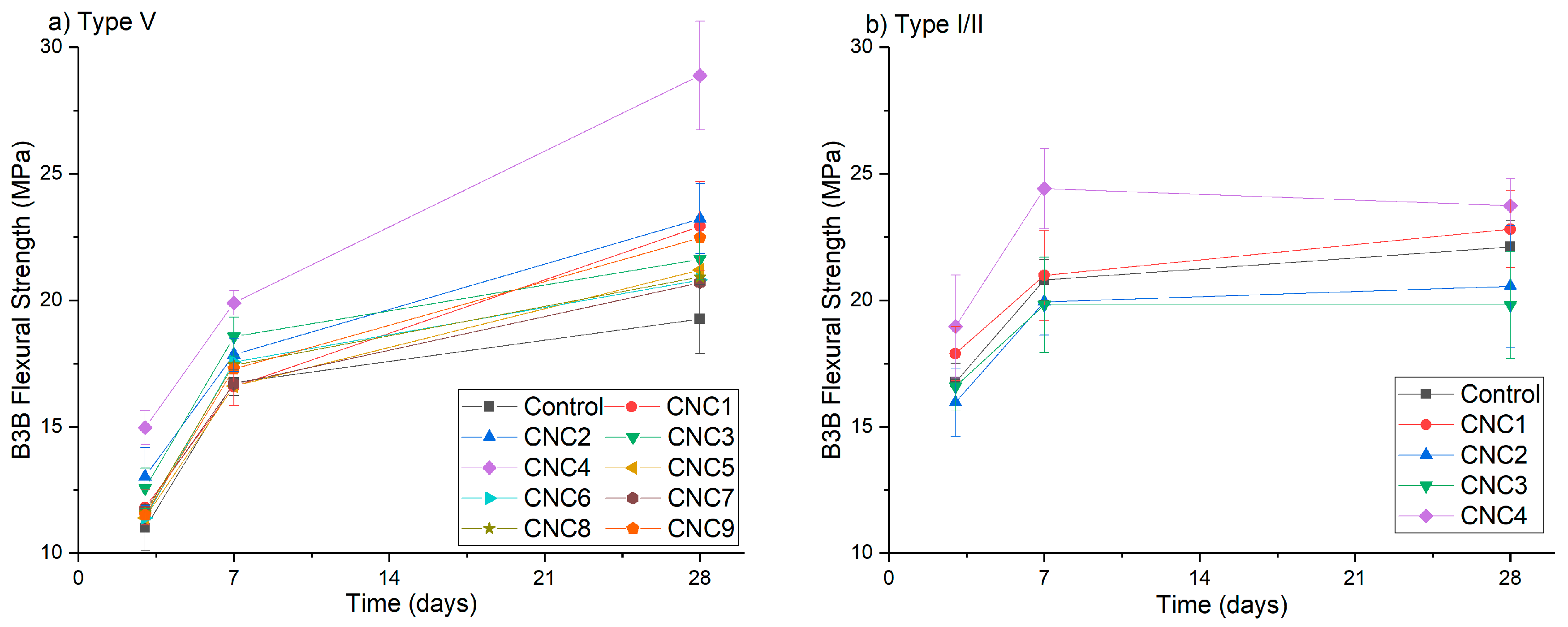

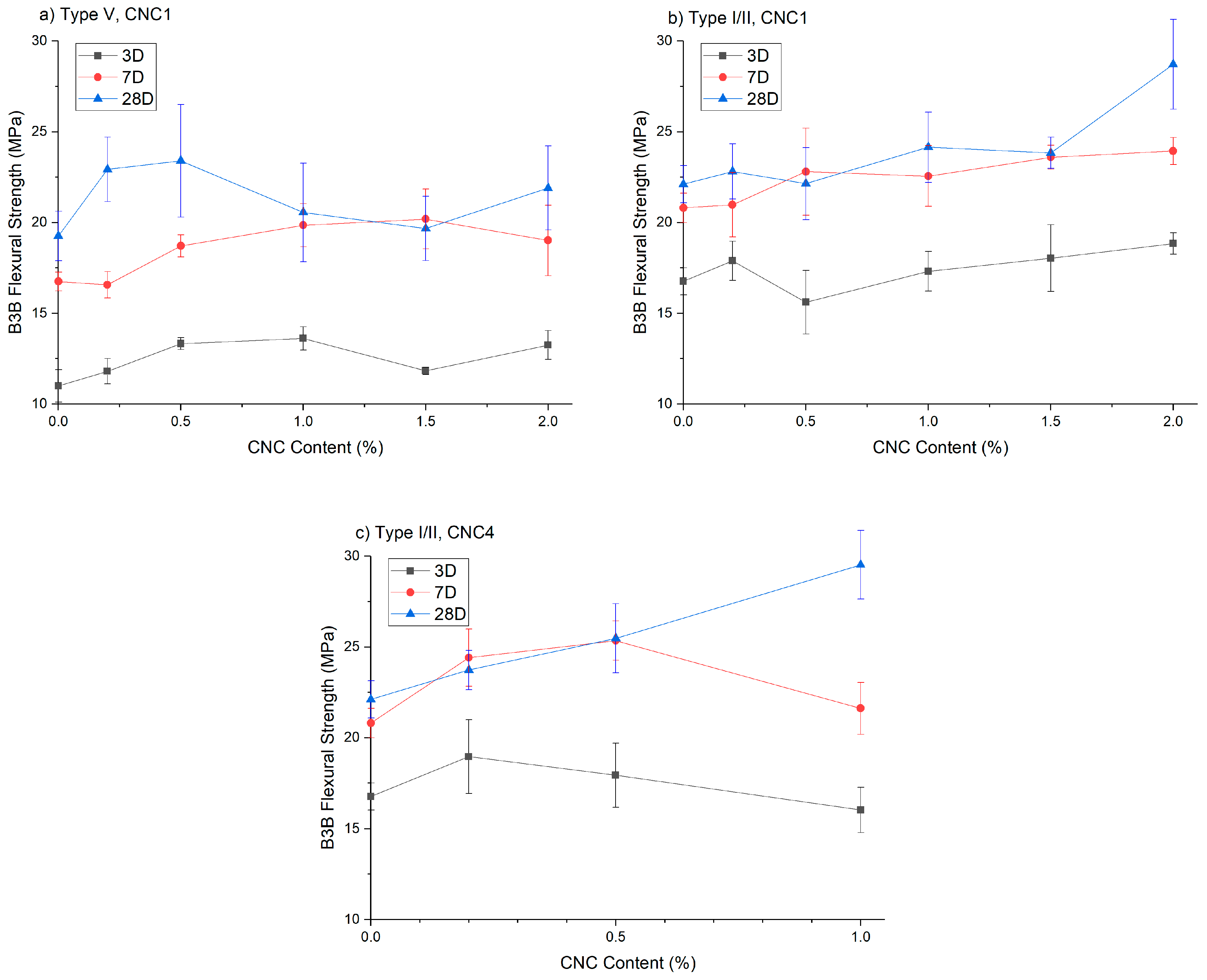

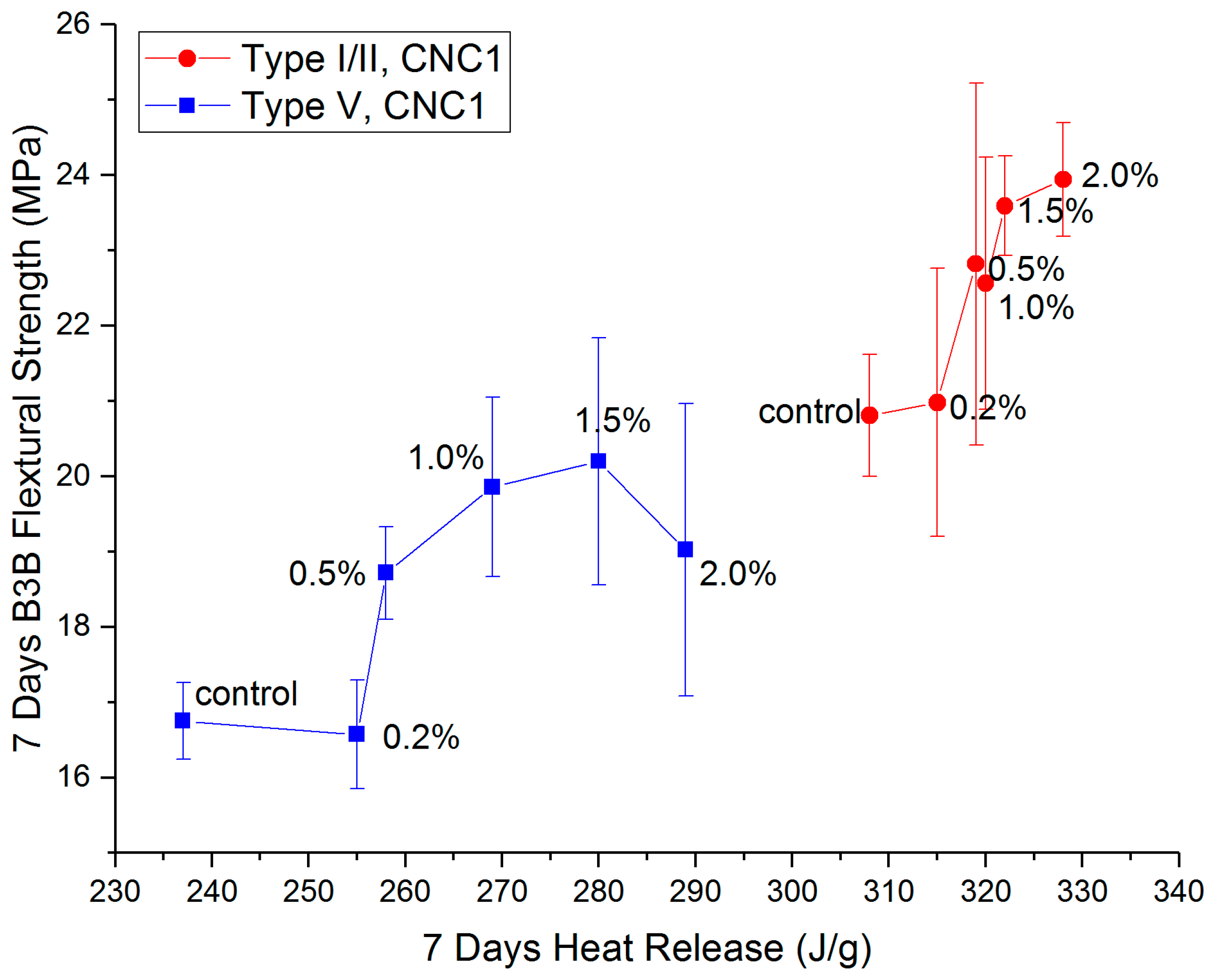

3.3. B3B Flexural Strength

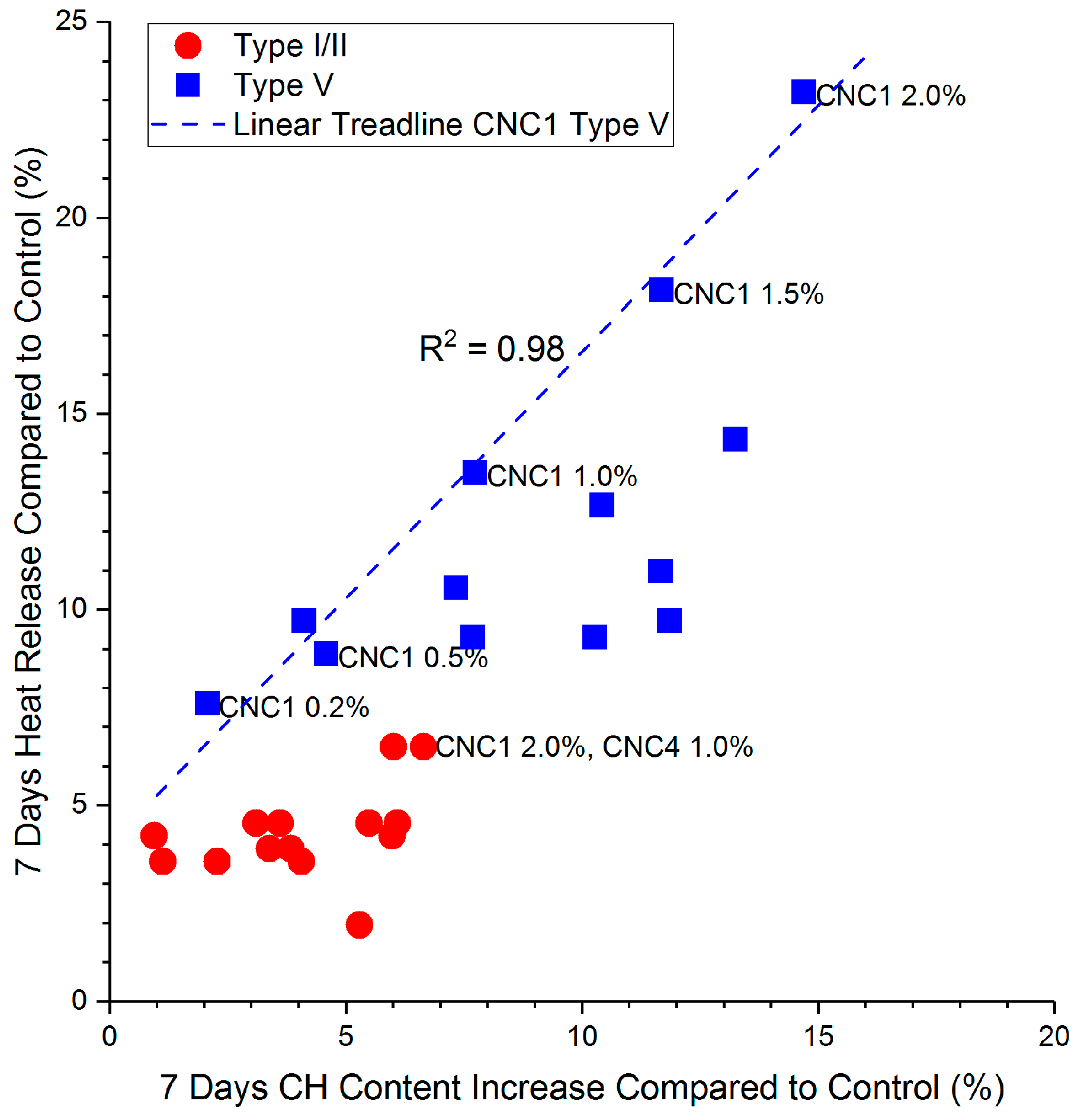

3.4. Effect of Aluminate Content

3.5. Comments on CNCs Source and Treatment

4. Conclusions

- The degree of hydration increased for all CNC mixtures for both Type I/II (~5%) and Type V (10–20%) cement systems, as determined via heat release and CH content measurements;

- All CNCs (except for CNC3 in Type V cement) showed a mild retardation effect at early ages. At higher dosages (>0.5%), CNC4 can cause significant retardation, which might raise concerns depending on the desired application for use of this particular CNC;

- All CNCs showed a greater increase in the heat release when Type V cement was used in comparison to Type I/II cement. The aluminate content in Type I/II cement is believed to decrease the SCD effect between silicate phases and CNC (especially at low dosage), resulting in less benefit seen in the Type V system;

- CNC1 and CNC4 tested in the study showed promising results for increasing the B3B flexural strength (by approximately 20% in both the Type I/II and Type V systems). In addition, optimum CNC dosages seem to exist for Type I/II and Type V cement systems;

- CNC4 was particular effective at increasing hydration heat release and B3B flexural strength in both Type I/II and Type V cement systems. This was believed to relate to its treatment (transition metal catalyzed oxidation), which is different from the treatment of other CNCs (acid hydrolysis);

- The hydration and strength of CNC-cement composites do not appear to be sensitive to CNC particle length or surface charge (zeta potential).

- IC testing and B3B flexural strength testing can be used as practical screening tools for evaluating the performance of CNC-cement composites.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete—A review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Kawashima, S.; Hou, P.; Corr, D.J.; Shah, S.P. Modification of cement-based materials with nanoparticles. Cem. Concr. Compos. 2013, 36, 8–15. [Google Scholar] [CrossRef]

- Moon, R.J.; Schueneman, G.T.; Simonsen, J. Overview of cellulose nanomaterials, Their capabilities and applications. JOM 2016, 68, 2383–2394. [Google Scholar] [CrossRef]

- Zubik, K.; Singhsa, P.; Wang, Y.; Manuspiya, H.; Narain, R. Thermo-responsive poly(N-isopropylacrylamide)-cellulose nanocrystals hybrid hydrogels for wound dressing. Polymers 2017, 9, 119. [Google Scholar] [CrossRef]

- Fu, T.; Moon, R.; Youngblood, J.; Zavattieri, P.; Weiss, J. 20-nanocellulose as additive for cement composites. In Cellulose-Reinforced Nanofiber Composites: Production, Properties and Applications; Woodhead Publishing: Cambridge, UK, 2017; pp. 445–482. [Google Scholar]

- Siqueira, G.; Bras, J.; Dufresne, A. Cellulosic bionanocomposites: A review of preparation, properties and applications. Polymers 2010, 2, 728. [Google Scholar] [CrossRef]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Zavattieri, P.; Youngblood, J.; Moon, R.; Weiss, J. The relationship between cellulose nanocrystal dispersion and strength. Constr. Build. Mater. 2016, 119, 71–79. [Google Scholar] [CrossRef]

- Cao, Y.; Zavaterri, P.; Youngblood, J.; Moon, R.; Weiss, J. The influence of cellulose nanocrystal additions on the performance of cement paste. Cem. Concr. Compos. 2015, 56, 73–83. [Google Scholar] [CrossRef]

- Cao, Y.; Tian, N.; Bahr, D.; Zavattieri, P.D.; Youngblood, J.; Moon, R.J.; Weiss, J. The influence of cellulose nanocrystals on the microstructure of cement paste. Cem. Concr. Compos. 2016, 74, 164–173. [Google Scholar] [CrossRef]

- Flores, J.; Kamali, M.; Ghahremaninezhad, A. An investigation into the properties and microstructure of cement mixtures modified with cellulose nanocrystal. Materials 2017, 10, 498. [Google Scholar] [CrossRef] [PubMed]

- ACI Committee 544. State-of-the-Art Report on Fiber Reinforced Concrete; American Concrete Institute: Farmingon Hills, MI, USA, 1996; reapproved 2009. [Google Scholar]

- Dubey, A. (Ed.) SP-224: Thin Reinforced Cement-Based Products and Construction Systems; American Concrete Institute: Farmington Hills, MI, USA, 2004. [Google Scholar]

- Reiner, R.; Rudie, A. Process scaleup of cellulose nanocrystal production to 25 kg per batch at the forest products laboratory. In Production and Applications of Cellulose; Tappi Press: Peachtree Corners, GA, USA, 2013; pp. 21–24. [Google Scholar]

- Nelson, K.; Retsina, T. Innovative nanocellulose process breaks the cost barrier. TAPPI J. 2014, 13, 19–23. [Google Scholar]

- Reid, M.S.; Villalobos, M.; Cranston, E.D. Benchmarking cellulose nanocrystals: From the laboratory to industrial production. Langmuir 2017, 33, 1583–1598. [Google Scholar] [CrossRef] [PubMed]

- Pane, I.; Hansen, W. Investigation of blended bement hydration by isothermal calorimetry and thermal analysis. Cem. Concr. Res. 2005, 35, 1155–1164. [Google Scholar] [CrossRef]

- Kim, T.; Olek, J. Effects of sample preparation and interpretation of thermogravimetric curves on calcium hydroxide in hydrated pastes and mortars. Transp. Res. Rec. J. Transp. Res. Board 2012, 2290, 10–18. [Google Scholar] [CrossRef]

- Cao, Y. Nano-Modification for High Performance Cement Composites with Cellulose Nanocrystals and Carbon Nanotubes. Ph.D. Dissertation, Purdue University, West Lafayette, IN, USA, 2014. [Google Scholar]

- Börger, A.; Supancic, P.; Danzer, R. The ball on three balls yest for strength yesting of brittle discs: Stress distribution in the disc. J. Eur. Ceram. Soc. 2002, 22, 1425–1436. [Google Scholar] [CrossRef]

- Montgomery, J.K.; Faber, K.T. Processing and surface flaw tolerance of alumina bilayers. J. Am. Ceram. Soc. 2005, 88, 287–292. [Google Scholar] [CrossRef]

- Cao, Y.; Weiss, J.; Youngblood, J.; Moon, R.; Zavaterri, P. Performance-enhanced cementitious matrerials by cellulose nanocrystal additions. In Production and Applications of Cellulose Nanomaterials; TAPPI Press: Peachtree Corners, GA, USA, 2013; pp. 135–146. [Google Scholar]

- Kim, J.; Yi, C.; Zi, G. Biaxial flexural strength of concrete by two different methods. Mag. Concr. Res. 2012, 64, 1057–1065. [Google Scholar] [CrossRef]

- ASTM Standard C1550, Standard test Method for Flexural Toughness of Fiber Reinforced Concrete (Using Centrally Loaded Round Panel); ASTM International: West Conshohocken, PA, USA, 2012.

- Börger, A.; Supancic, P.; Danzer, R. The ball on three balls test for strength testing of brittle discs: Part II: Analysis of possible errors in the strength determination. J. Eur. Ceram. Soc. 2004, 24, 2917–2928. [Google Scholar] [CrossRef]

- Winnefeld, F.; Zingg, A.; Holzer, L.; Figi, R.; Pakusch, J.; Becker, S. Interaction of polycarboxylate-based superplasticizers and cements: Influence of polymer structure and C3A-content of cement. In 12th International Congress on Teh Chemistry of Cement; ICCC: Montréal, Quebec, QC, Canada, 2007. [Google Scholar]

- Nawa, T. Effect of chemical structure on steric stabilization of polycarboxylate-based superplasticizer. J. Adv. Concr. Technol. 2006, 4, 225–232. [Google Scholar] [CrossRef]

- Plank, J.; Hirsch, C. Impact of zeta potential of early cement hydration phases on superplasticizer adsorption. Cem. Concr. Res. 2007, 37, 537–542. [Google Scholar] [CrossRef]

- Gelardi, G.; Flatt, R.J. 11-Working mechanisms of water reducers and superplasticizers. In Science and Technology of Concrete Admixtures; Woodhead Publishing: Cambridge, UK, 2016; pp. 257–278. [Google Scholar]

- Suraneni, P.; Flatt, R.J. Use of micro-reactors to obtain new insights into the factors influencing tricalcium silicate dissolution. Cem. Concr. Res. 2015, 78, 208–215. [Google Scholar] [CrossRef]

- Cheung, J.; Jeknavorian, A.; Roberts, L.; Silva, D. Impact of admixtures on the hydration kinetics of portland cement. Cem. Concr. Res. 2011, 41, 1289–1309. [Google Scholar] [CrossRef]

- Blue Goose Biorefineries Inc. Certificate of Analysis-Lot Number AUU06–002; Blue Goose Biorefineries Inc.: Saskatchewan, SK, Canada, 2016. [Google Scholar]

- Pearson, R. Chemical Hardness—Applications from Molecules to Solids; Wiley-VCH: Weinheim, Germany, 1997; p. 198. [Google Scholar]

- Vollpracht, A.; Lothenbach, B.; Snellings, R.; Haufe, J. The pore solution of blended cements: A review. Mater. Struct. 2016, 49, 3341–3367. [Google Scholar] [CrossRef]

| Components | Mass (%) | |

|---|---|---|

| Type I/II | Type V | |

| Silicon dioxide (SiO2) | 20.1 | 21.9 |

| Aluminum oxide (Al2O3) | 4.7 | 2.8 |

| Ferric oxide (Fe2O3) | 3.5 | 4.5 |

| Calcium oxide (CaO) | 63.7 | 64.3 |

| Magnesium oxide (MgO) | 0.7 | 2.4 |

| Sulfur trioxide (SO3) | 3.1 | 2.9 |

| Loss on ignition | 2.6 | 0.85 |

| Limestone | 4.0 | 0.51 |

| Insoluble residue | 0.3 | 0.15 |

| Equivalent alkali as Na2O | 0.51 | 0.19 |

| C3S * | 53 | 64 |

| C2S * | 18 | 13 |

| C3A * | 7 | 0 |

| C4AF * | 11 | 13 |

| Blaine fineness (m2/kg) | 364 | 305 |

| CNC type | Availability | Source | Form | Treatment | Zeta potential (mV) at pH 13 | Average particle length (nm) | Aspect ratio |

|---|---|---|---|---|---|---|---|

| CNC1 | Lab-made | Wood pulp | Aqueous suspension | Sulfuric acid hydrolysis | −44 | 93 | 13 |

| CNC2 | Lab-made | Cotton fiber | Aqueous suspension | Sulfuric acid hydrolysis | −47 | 127 | 14 |

| CNC3 | Lab-made | Algae (Cladophora) | Aqueous suspension | Sulfuric acid hydrolysis | −42 | 966 | 46 |

| CNC4 | Commercial | Acetate-grade dissolving pulp | Aqueous suspension | Transition metal catalyzed oxidation | −39 | 125 | 11 |

| CNC5 | Commercial | Acetate-grade dissolving pulp | Aqueous suspension | Natural oxidation | −34 | 83 | 12 |

| CNC6 | Commercial | Wood pulp | Dry powder | Sulfuric acid hydrolysis | −49 | 90 | 12 |

| CNC7 | Commercial | Wood pulp | Dry powder | Sulfuric acid hydrolysis | −55 | 85 | 11 |

| CNC8 | Commercial | Rayon-grade dissolving pulp | Aqueous suspension | Sulfuric acid hydrolysis | −21 | 184 | 15 |

| CNC9 | Commercial | Pulp sludge from paper industry | Aqueous suspension | Controlled acid hydrolysis | −53 | 156 | 17 |

| Mix | Difference in time to reach peak heat flow: (h) | Heat (J/g) at 7 days (difference comparing to control) | ||

|---|---|---|---|---|

| Type I/II | Type V | Type I/II | Type V | |

| Control | - * | - * | 308 (-) | 237 (-) |

| CNC1 0.2% | 1.0 | 3.3 | 319 (3.6%) | 255 (7.6%) |

| CNC1 0.5% | 1.5 | 4.0 | 319 (3.6%) | 258 (8.9%) |

| CNC1 1.0% | 2.1 | 4.8 | 320 (4.0%) | 269 (13.5%) |

| CNC1 1.5% | 2.3 | 4.7 | 322 (4.7%) | 280 (18.1%) |

| CNC1 2.0% | 2.3 | 7.7 | 319 (3.6%) | 292 (23.2%) |

| CNC2 0.2% | 0.9 | 2.3 | 320 (3.9%) | 260 (9.7%) |

| CNC3 0.2% | −0.8 | 1.8 | 314 (1.9%) | 271 (14.3%) |

| CNC4 0.2% | 1.9 | 12.6 | 321 (4.2%) | 259 (9.3%) |

| CNC4 0.5% | 4.6 | 98.8 | 328 (6.5%) | 251 (5.9%) |

| CNC4 1.0% | 11.5 | >168 ** | 334 (8.6%) | 4.1 ** (−98.1%) |

| CNC5 0.2% | 1.7 | 5.6 | 322 (4.5%) | 263 (11.0%) |

| CNC6 0.2% | 1.7 | 3.4 | 319 (3.6%) | 260 (9.7%) |

| CNC7 0.2% | 1.5 | 4.4 | 321 (4.2%) | 262 (10.5%) |

| CNC8 0.2% | 0.7 | 2.4 | 322 (4.5%) | 259 (9.3%) |

| CNC9 0.2% | 1.1 | 3.7 | 322 (4.5%) | 267 (12.7%) |

| Mix ID | Type I/II | Type V | ||

|---|---|---|---|---|

| CH content, % | CH content, % | |||

| 7 days | 28 days | 7 days | 28 days | |

| Control | 11.0 | 11.5 | 11.7 | 12.5 |

| CNC1 0.2% | 11.1 | 11.8 | 11.9 | 11.8 |

| CNC1 0.5% | 11.4 | 11.6 | 12.2 | 11.9 |

| CNC1 1.0% | 11.5 | 12.3 | 12.6 | 12.6 |

| CNC1 1.5% | 11.4 | 11.4 | 13.0 | 13.3 |

| CNC1 2.0% | 11.7 | 11.8 | 13.4 | 13.8 |

| CNC2 0.2% | 11.4 | 11.6 | 13.1 | 12.5 |

| CNC3 0.2% | 11.6 | 12.4 | 13.2 | 13.5 |

| CNC4 0.2% | 11.7 | 12.6 | 12.6 | 12.7 |

| CNC4 1.0% | 11.7 | 13.0 | - * | 13.2 |

| CNC5 0.2% | 11.4 | 11.9 | 13.4 | 12.9 |

| CNC6 0.2% | 11.3 | 11.8 | 12.2 | 12.5 |

| CNC7 0.2% | 11.1 | 12.3 | 12.5 | 13.2 |

| CNC8 0.2% | 11.6 | 11.9 | 12.9 | 13.0 |

| CNC9 0.2% | 11.7 | 11.7 | 12.9 | 12.8 |

| Average length (nm) | Mixture ID | Zeta potential (mV) pH = 13 | Increase comparing to control at 7 days | |||||

|---|---|---|---|---|---|---|---|---|

| Type I/II | Type V | |||||||

| CH | Heat | B3B | CH | Heat | B3B | |||

| 83 | CNC5 | −34 | 3.1% | 4.5% | - | 11.7% | 11.0% | −0.8% |

| 85 | CNC7 | −55 | 0.9% | 4.2% | - | 7.3% | 10.5% | −0.4% |

| 90 | CNC6 | −49 | 2.3% | 3.6% | - | 4.1% | 9.7% | 4.9% |

| 93 | CNC1 | −44 | 1.1% | 3.6% | 0.8% | 2.1% | 7.6% | −1.1% |

| 125 | CNC4 | −39 | 6.0% | 4.2% | 17.3% | 7.7% | 9.3% | 18.7% |

| 127 | CNC2 | −47 | 3.4% | 3.9% | −4.2% | 11.9% | 9.7% | 6.5% |

| 156 | CNC9 | −53 | 6.1% | 4.5% | - | 10.4% | 12.7% | 3.2% |

| 184 | CNC8 | −21 | 5.5% | 4.5% | - | 10.3% | 9.3% | 4.1% |

| 966 | CNC3 | −42 | 5.3% | 1.9% | −4.8% | 13.2% | 14.3% | 10.8% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, T.; Montes, F.; Suraneni, P.; Youngblood, J.; Weiss, J. The Influence of Cellulose Nanocrystals on the Hydration and Flexural Strength of Portland Cement Pastes. Polymers 2017, 9, 424. https://doi.org/10.3390/polym9090424

Fu T, Montes F, Suraneni P, Youngblood J, Weiss J. The Influence of Cellulose Nanocrystals on the Hydration and Flexural Strength of Portland Cement Pastes. Polymers. 2017; 9(9):424. https://doi.org/10.3390/polym9090424

Chicago/Turabian StyleFu, Tengfei, Francisco Montes, Prannoy Suraneni, Jeffrey Youngblood, and Jason Weiss. 2017. "The Influence of Cellulose Nanocrystals on the Hydration and Flexural Strength of Portland Cement Pastes" Polymers 9, no. 9: 424. https://doi.org/10.3390/polym9090424

APA StyleFu, T., Montes, F., Suraneni, P., Youngblood, J., & Weiss, J. (2017). The Influence of Cellulose Nanocrystals on the Hydration and Flexural Strength of Portland Cement Pastes. Polymers, 9(9), 424. https://doi.org/10.3390/polym9090424