Design Analysis of Adhesively Bonded Structures

Abstract

:1. Introduction

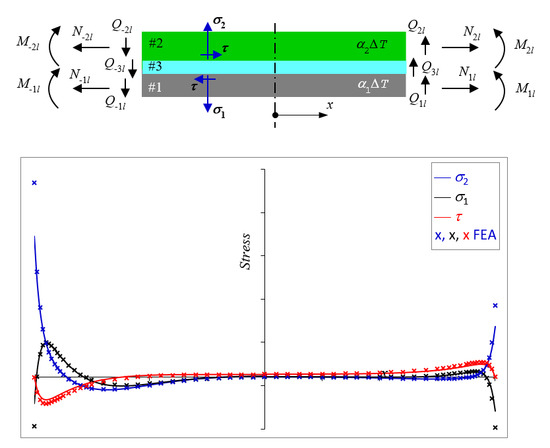

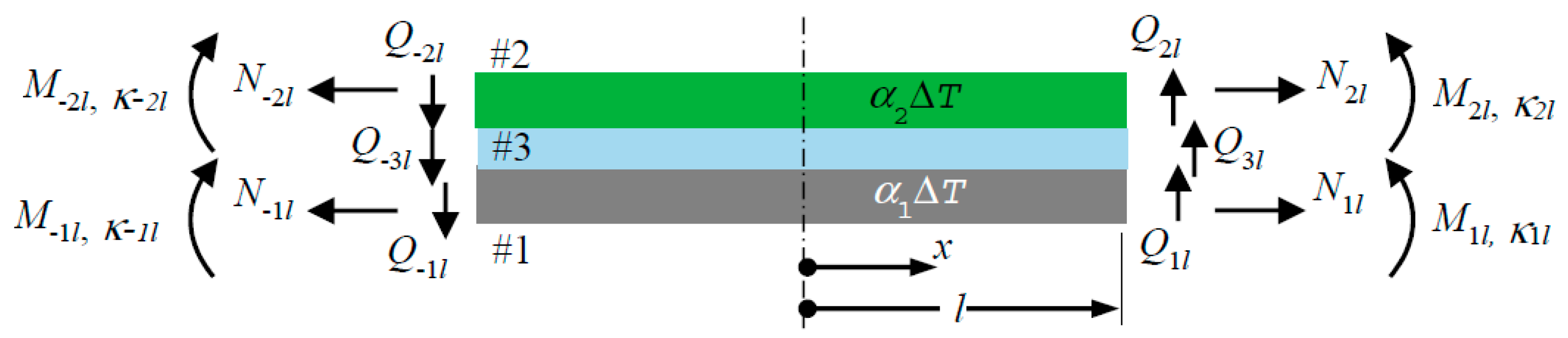

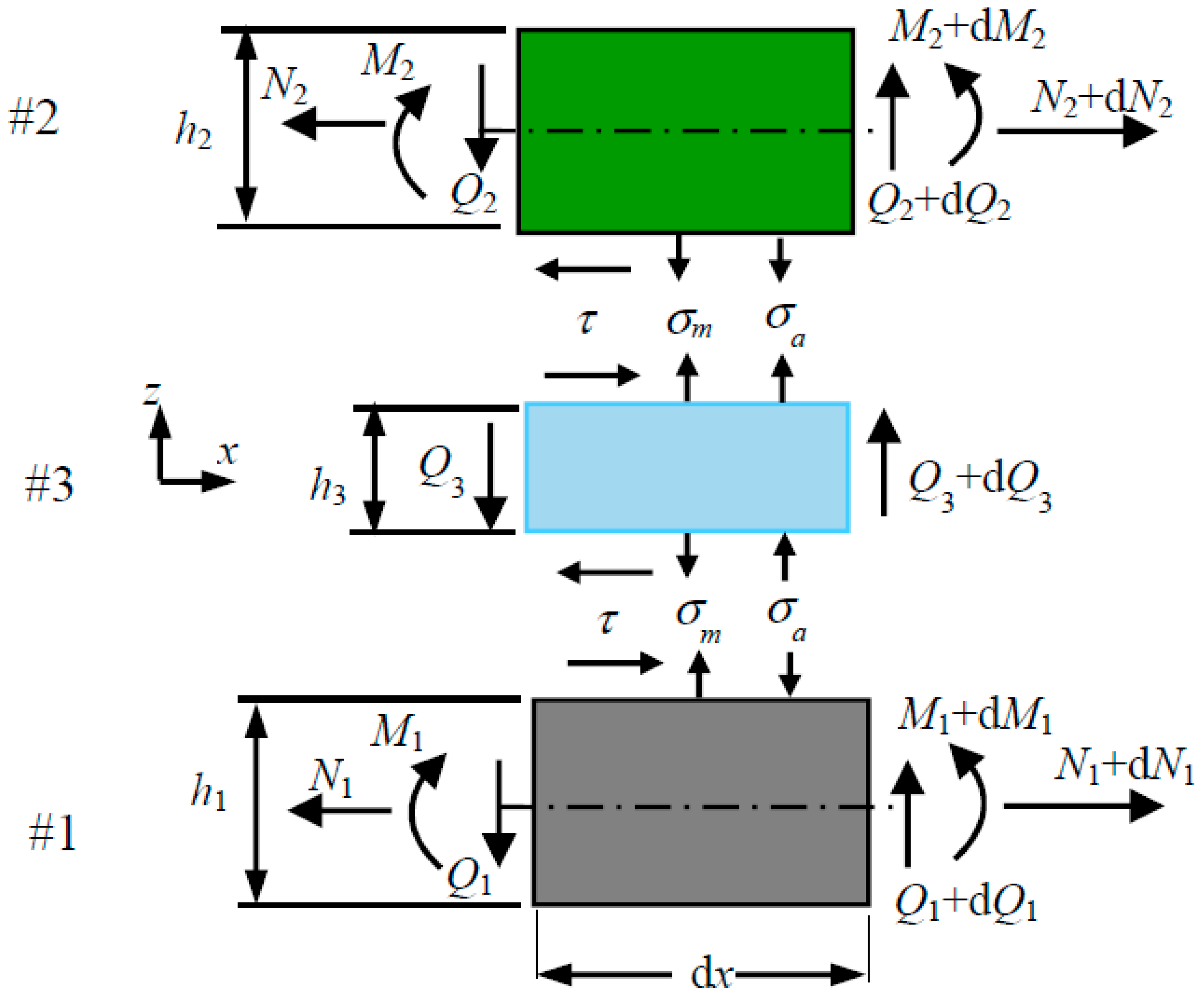

2. Analytical Equations

2.1. Balanced Structures

2.2. Unbalanced Structures

2.2.1. Non-Free Edge Solutions

2.2.2. Free Edge Solutions

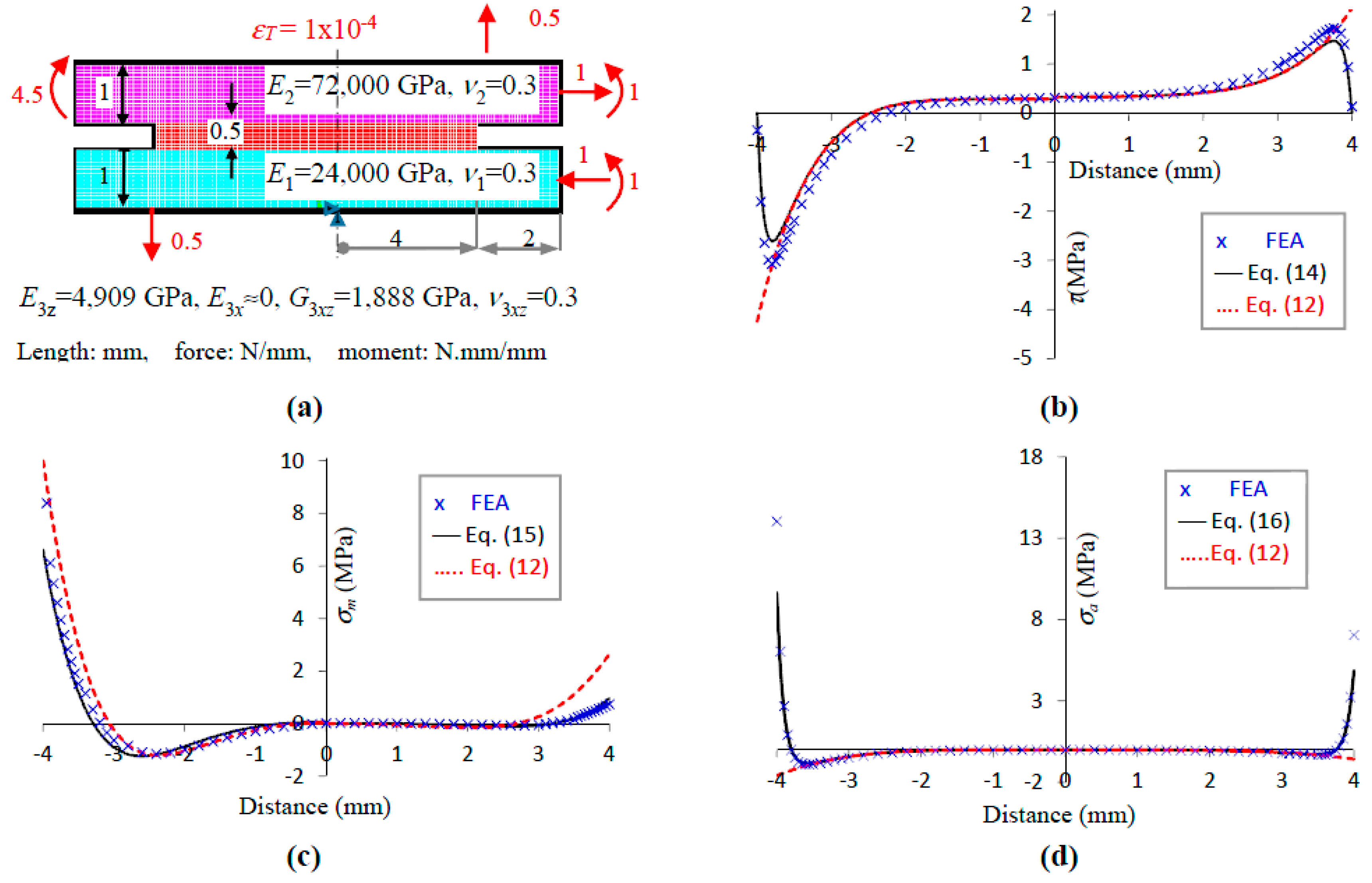

3. Numerical Validations

4. Design Analysis

4.1. Balanced Structures

4.2. Unbalanced Structures

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclatures

| Subscript #i | Subscript #1 and #2 are adherends and #3 is adhesive. |

| Di, Ei, Gi, hi | Flexural rigidity, elastic modulus, shear modulus, thickness of member #i. |

| Flexural compliance of the bonded structure. | |

| M±il, N±il, Q±il | Moment, sectional stretching force, sectional shear force applied on adherend #i at x = ±l. |

| l | Half-length of the bonded structure. |

| α, β | Characteristic parameters of a bonded structure in peeling, shearing. |

| αi | Coefficient of thermal expansion of adherend #i. |

| εT, ε±Nl, ε±Ml | Differential strain between adherends #2 and #1 at x = ±l due to temperature and edge stretching; effective bending strain due to edge bending at x = ±l. |

| κ±il | Edge curvature of adherend #i at x = ±l. |

| κsi, κs | Shear compliance of member #i, of the bonded structure between the centroid planes of adherends #1 and #2. |

| λxi, λx | x-compliance of adherend #i, of the bonded structure. |

| λxθ | Additional x-compliance of the bonded structure attributed to its flexural deformation. |

| λzi, λz | z-compliance of member #i, of the bonded structure between the centroid planes of adherends #1 and #2. |

| θi | Rotation of the centroid axis of adherend #i (due to bending). |

| σm(x), σa(x) | Mean, amplitude of variation, of transverse stress along the thickness of the adhesive (or between the bonded interfaces). |

| σp(x) | Peeling stress along the bonded interfaces. |

| τ(x) | Shear stress within the adhesive (and along the interfaces). |

| ΔT | Temperature change. |

| Basic formulas | |

| ; . | |

| (plane stress); . | |

Appendix A. Fundamental Equations

Appendix B. Imposing Free-Edge Condition

References

- Volkersen, Q. Die NietKraftverteilung in zugbeanspruchten Nietverbindungen mit Konstanten Laschenquerschnitten. Luftfahrtforschung 1938, 15, 41–47. [Google Scholar]

- Goland, M.; Reissner, E. Stresses in cemented joints. ASME J. Appl. Mech. 1944, 11, A17–A27. [Google Scholar]

- Tsai, M.Y.; Oplinger, D.W.; Morton, J. Improved theoretical solutions for adhesive lap joints. Int. J. Solids Struct. 1998, 35, 1163–1185. [Google Scholar] [CrossRef]

- Suhir, E. Stresses in bi-metal thermostats. ASME J. Appl. Mech. 1986, 53, 657–660. [Google Scholar] [CrossRef]

- Suhir, E. Interfacial stresses in bimetal thermostats. ASME J. Appl. Mech. 1989, 56, 595–600. [Google Scholar] [CrossRef]

- Timoshenko, S.P.; Goodier, J.N. Theory of Electricity, 3rd ed.; McGraw-Hill: New York, NY, USA, 1970. [Google Scholar]

- Chen, W.T.; Nelson, C.W. Thermal Stress in Bonded Joint. IBM J. Res. Dev. 1979, 23, 179–188. [Google Scholar] [CrossRef]

- Delale, F.; Erdogan, F.; Aydinoglu, M.N. Stresses in adhesively bonded joints: A closed-form solution. J. Compos. Mater. 1981, 15, 249–271. [Google Scholar] [CrossRef]

- Bigwood, D.A.; Crocombe, A.D. Elastic analysis and engineering design formulae for bonded joints. Int. J. Adhes. Adhes. 1989, 9, 229–242. [Google Scholar] [CrossRef]

- Zou, G.P.; Shahin, K.; Taheri, F. An analytical solution for the analysis of symmetric composite adhesively bonded joints. Compos. Struct. 2004, 65, 499–510. [Google Scholar] [CrossRef]

- Liu, Z.; Huang, Y.; Yin, Z.; Bennati, S.; Valvo, P.S. A general solution for the two-dimensional stress analysis of balanced and unbalanced adhesively bonded joints. Int. J. Adhes. Adhes. 2014, 54, 112–123. [Google Scholar] [CrossRef]

- Cabello, M.; Zurbitu, J.; Renart, J.; Turon, A.; Martínez, F. A general analytical model based on elastic foundation beam theory for adhesively bonded DCB joints either with flexible or rigid adhesives. Int. J. Solids Struct. 2016, 94, 21–34. [Google Scholar] [CrossRef]

- Ojalvo, I.U.; Eidinoff, H.L. Bond thickness effects upon stresses in single-lap adhesive joints. AIAA J. 1978, 16, 204–211. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, C. Three-parameters, elastic foundation model for analysis of adhesively bonded joints. Int. J. Solids Struct. 2009, 29, 495–502. [Google Scholar] [CrossRef]

- Wong, E.H. The mechanics of bondline thickness in balanced sandwich structures. Int. J. Adhes. Adhes. 2017, 78, 4–12. [Google Scholar] [CrossRef]

- Zhao, B.; Lu, Z.-H.; Lu, Y.-N. Closed-form solutions for elastic stress–strain analysis in unbalanced adhesive single-lap joints considering adherend deformations and bond thickness. Int. J. Solids Struct. 2011, 31, 434–445. [Google Scholar] [CrossRef]

- Zhang, Z.-W.; Li, Y.-S.; Liu, R. An analytical model of stresses in adhesive bonded interface between steel and bamboo plywood. Int. J. Solids Struct. 2015, 52, 103–113. [Google Scholar] [CrossRef]

- Allman, D. A theory for elastic stresses adhesive bonded lap joints. Q. J. Mech. Appl. Math. 1977, 30, 10–15. [Google Scholar] [CrossRef]

- Chen, D.; Cheng, S. An analysis of adhesive-bonded single-lap joints. ASME J. Appl. Mech. 1983, 50, 109–115. [Google Scholar] [CrossRef]

- Yin, W.-L. Thermal stresses and free-edge effects in laminated beams: A variational approach using stress fFunctions. ASME J. Electron. Packag. 1991, 113, 68–75. [Google Scholar] [CrossRef]

- Adams, R.D.; Mallick, V. A method for the stress analysis of lap joints. J. Adhes. 1992, 38, 199–217. [Google Scholar] [CrossRef]

- Wu, X.F.; Zhao, Y. Stress-function variational method for interfacial stress analysis of adhesively bonded joints. Int. J. Solids Struct. 2013, 50, 4305–4319. [Google Scholar] [CrossRef]

- Wong, E.H. Design analysis of sandwiched structures experiencing differential thermal expansion and differential free-edge stretching. Int. J. Adhes. Adhes. 2016, 65, 19–27. [Google Scholar] [CrossRef]

| Compliances | Characteristic parameters (mm−1) | Free edge parameters | |||||

|---|---|---|---|---|---|---|---|

| κs | 2.83 × 10−4 | α | 1.08 | ϕ | 0.45 | ||

| λx | 4.31 × 10−4 | β | 1.23 | n | 7.4 | ||

| λz | 1.21 × 10−4 | Coupling parameters (N−1) | |||||

| µσ | 1.67 × 10−4 | µτ | 2.50 × 10−4 | ||||

| Stress coefficients (N. mm−2) | |||||||

| Domain | As | A4 | Ap1 | Ap2 | B1n | B2n | Bp |

| −l ≤ x ≤ 0 | 3.23 | 0.31 | 1.33 | 0.83 | 4.94 | 7.23 | 1.67 |

| 0 ≤ x ≤ l | 1.53 | 0.3 | 0.1 | 0.35 | 0.98 | 0.61 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wong, E.-H.; Liu, J. Design Analysis of Adhesively Bonded Structures. Polymers 2017, 9, 664. https://doi.org/10.3390/polym9120664

Wong E-H, Liu J. Design Analysis of Adhesively Bonded Structures. Polymers. 2017; 9(12):664. https://doi.org/10.3390/polym9120664

Chicago/Turabian StyleWong, Ee-Hua, and Johan Liu. 2017. "Design Analysis of Adhesively Bonded Structures" Polymers 9, no. 12: 664. https://doi.org/10.3390/polym9120664

APA StyleWong, E.-H., & Liu, J. (2017). Design Analysis of Adhesively Bonded Structures. Polymers, 9(12), 664. https://doi.org/10.3390/polym9120664