Effect of Laser Power on Formation and Joining Strength of DP980-CFRP Joint Fabricated by Laser Circle Welding

Abstract

1. Introduction

2. Experiment Details

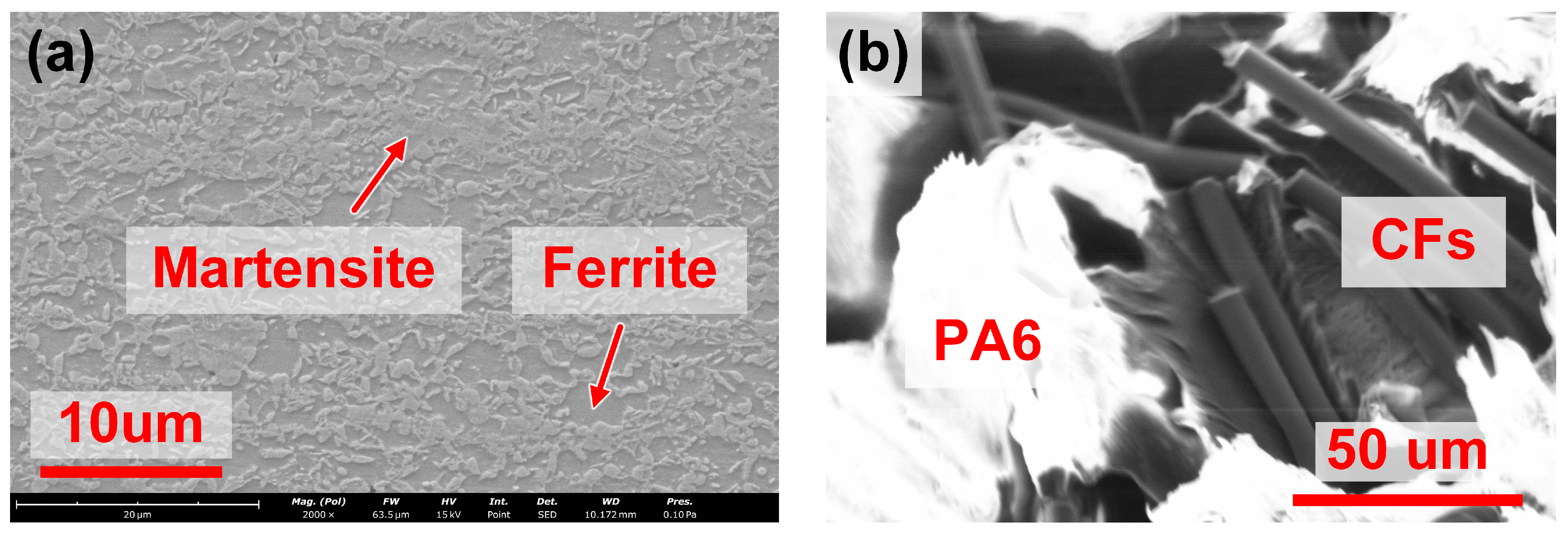

2.1. Materials

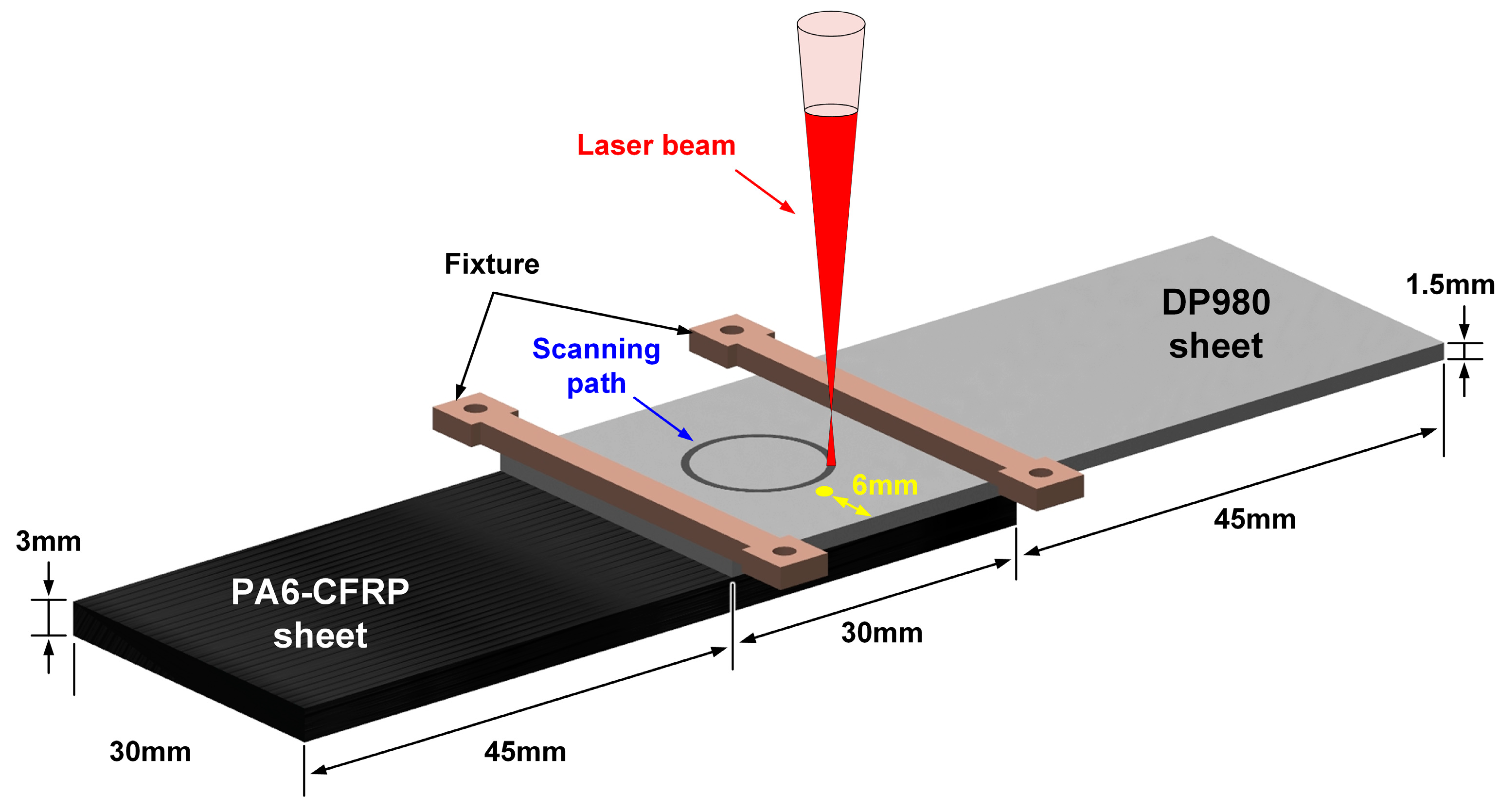

2.2. Laser Circle Welding

2.3. Characterization Experiments

3. Numerical Analysis

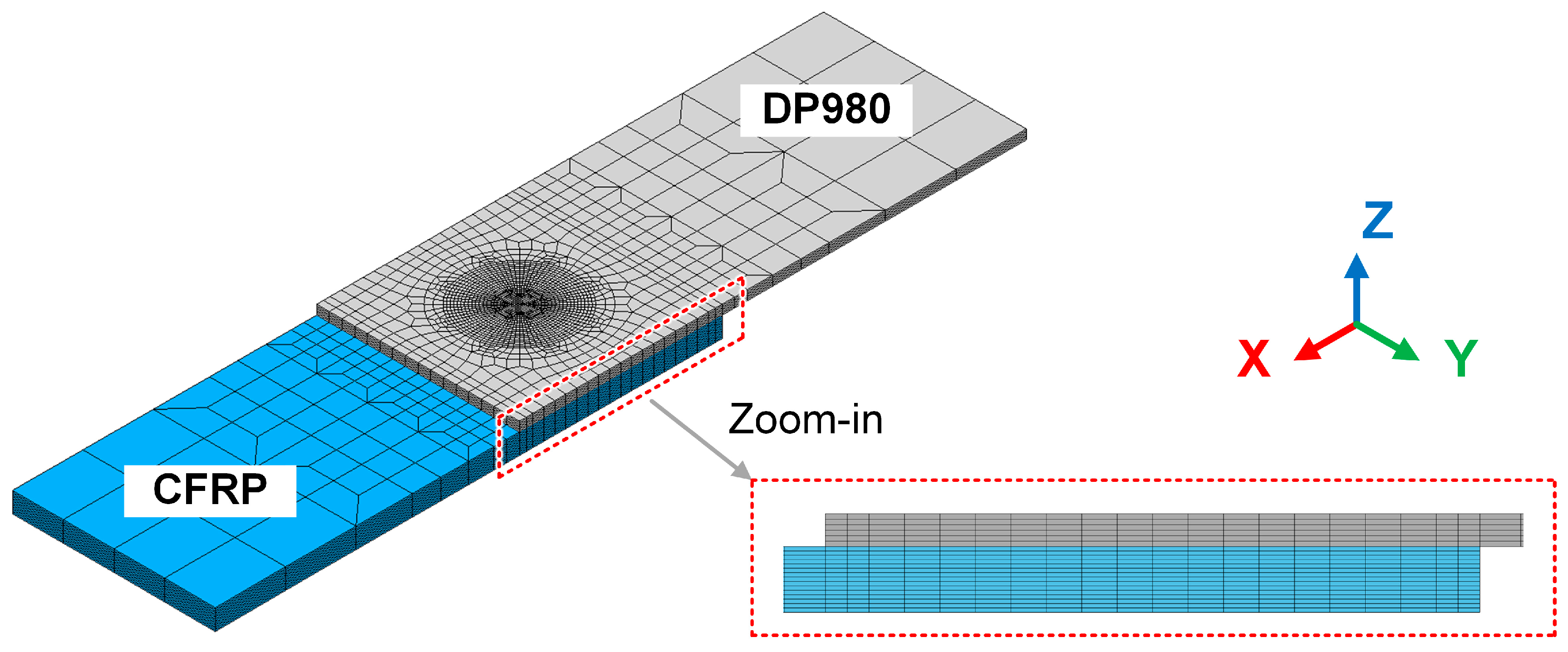

3.1. Finite Element Modeling

3.2. Material Properties

4. Results and Discussion

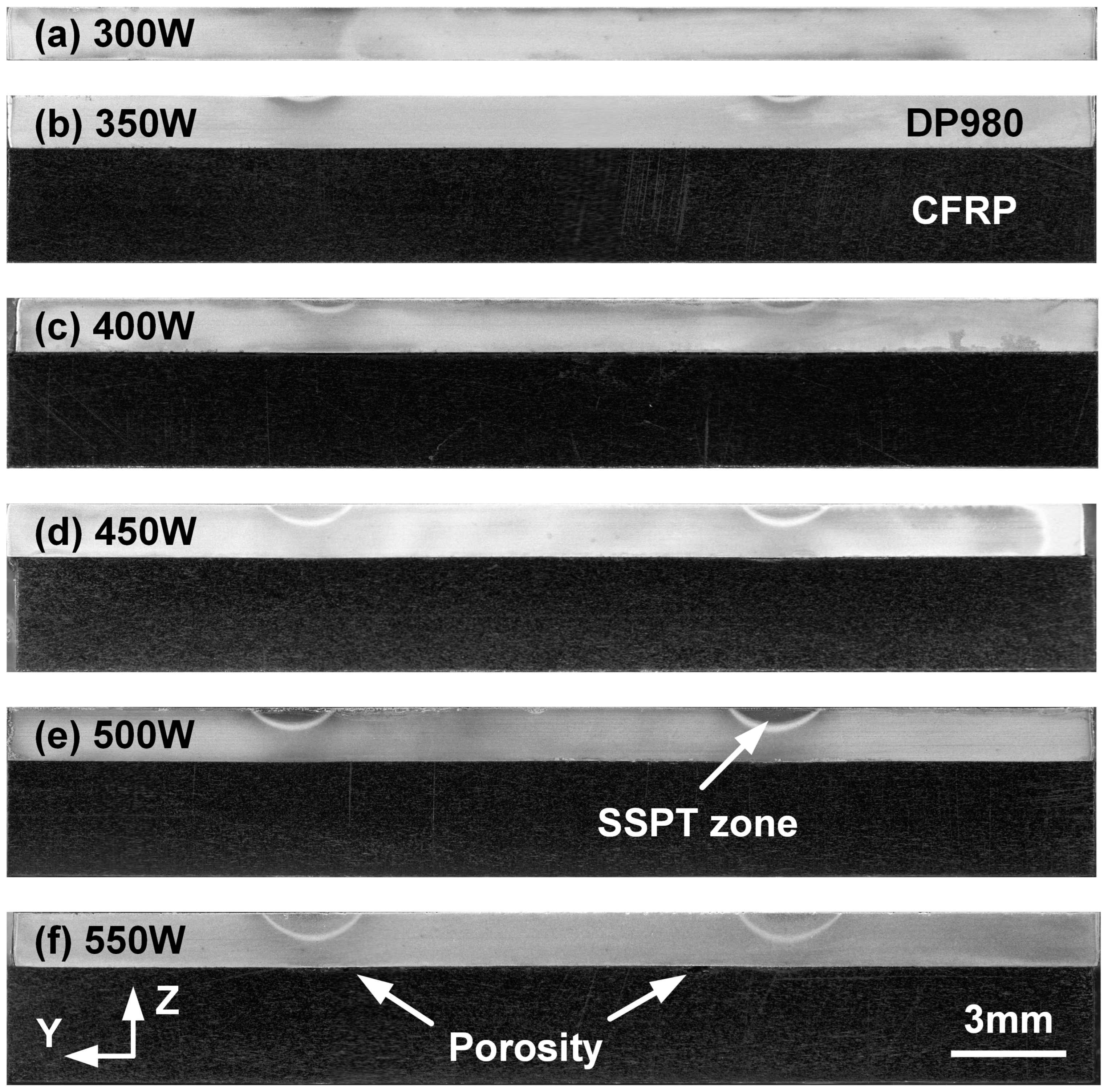

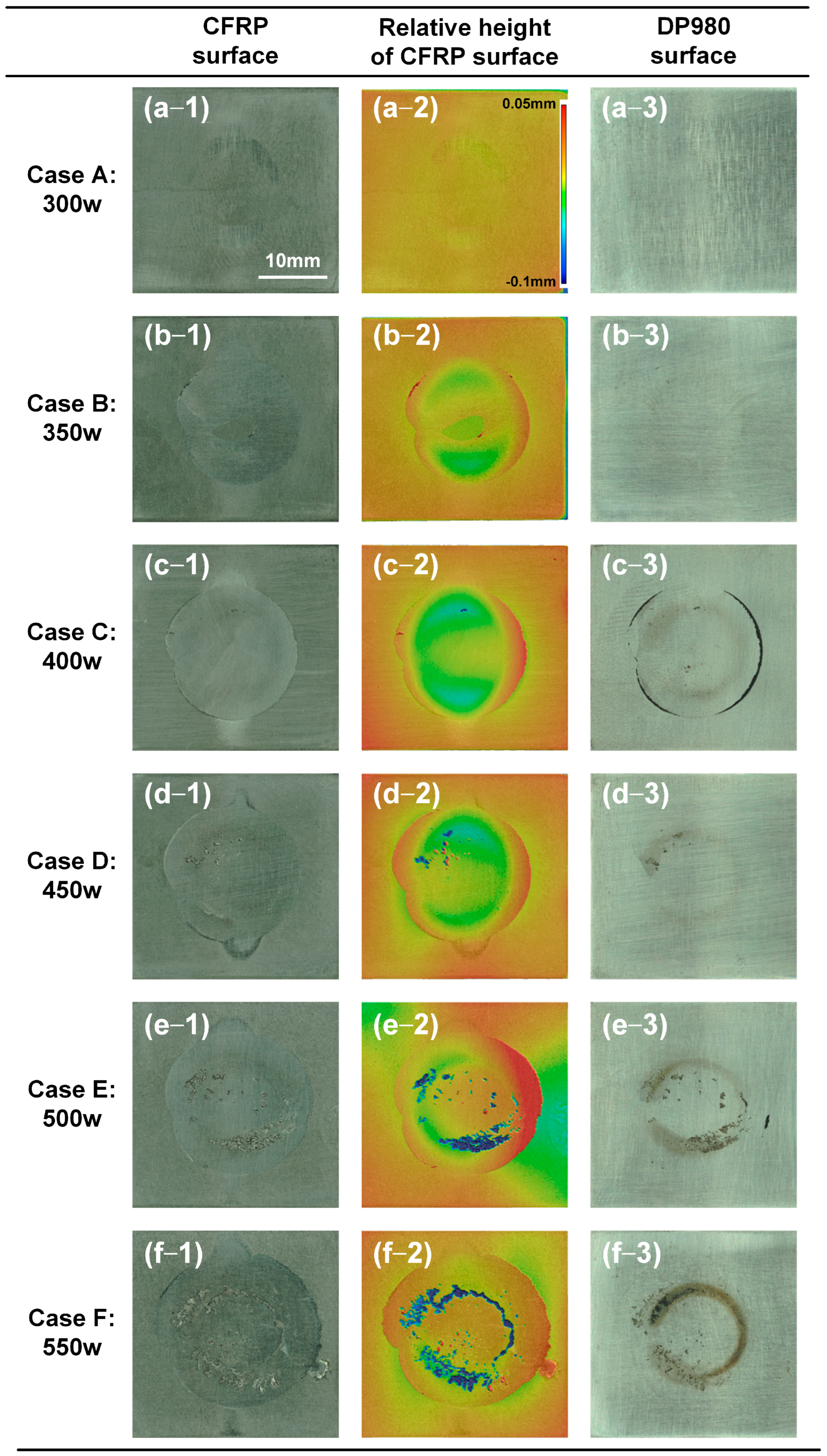

4.1. Welding Appearance

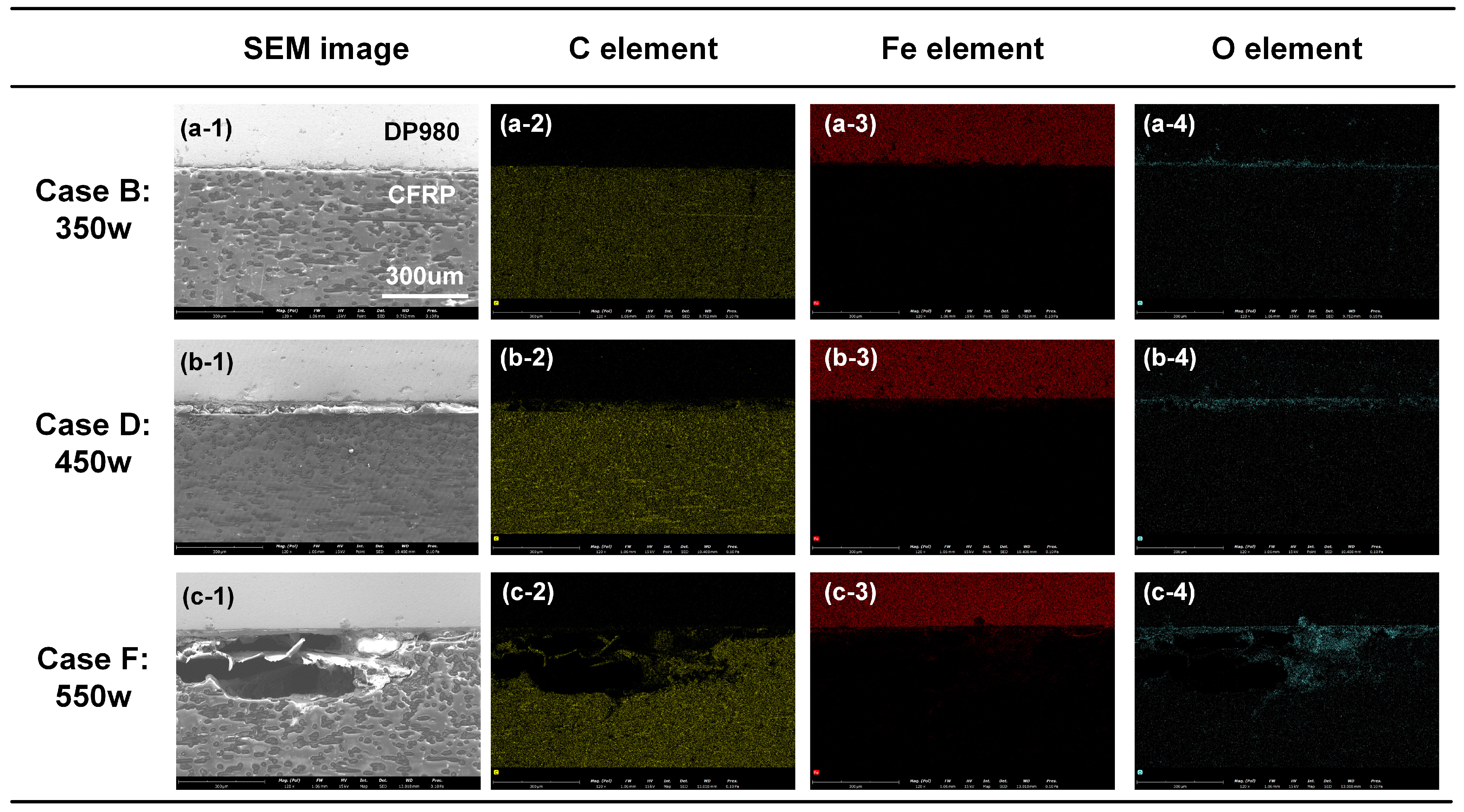

4.2. Analysis of Cross-Section

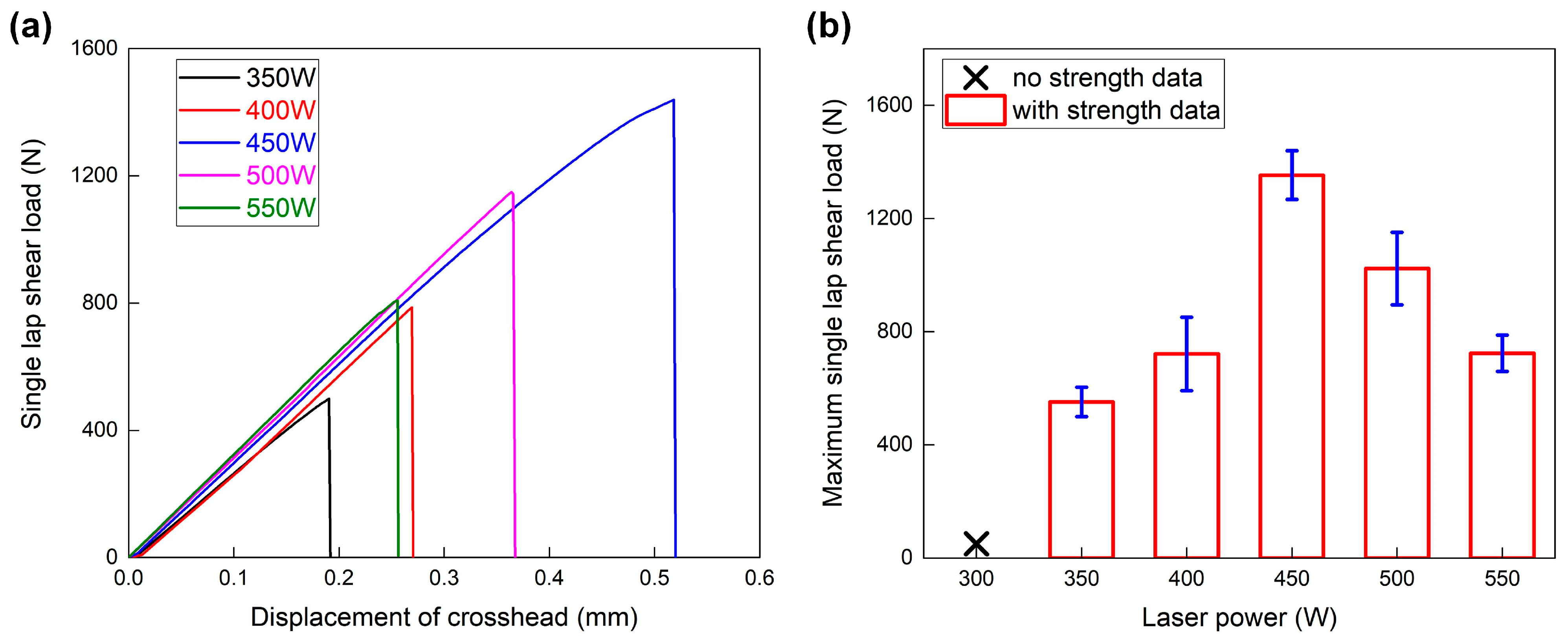

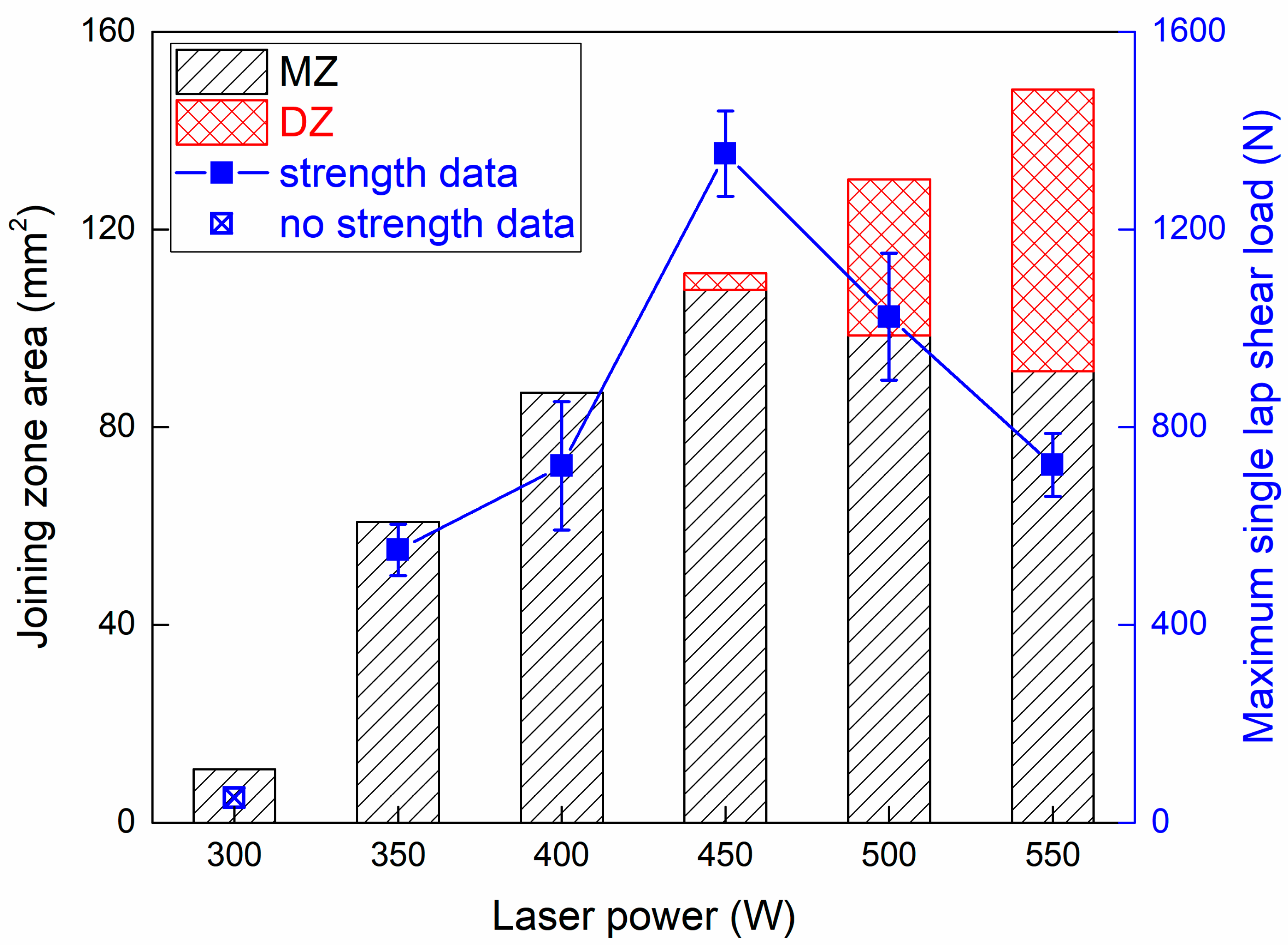

4.3. Analysis of Mechanical Performance

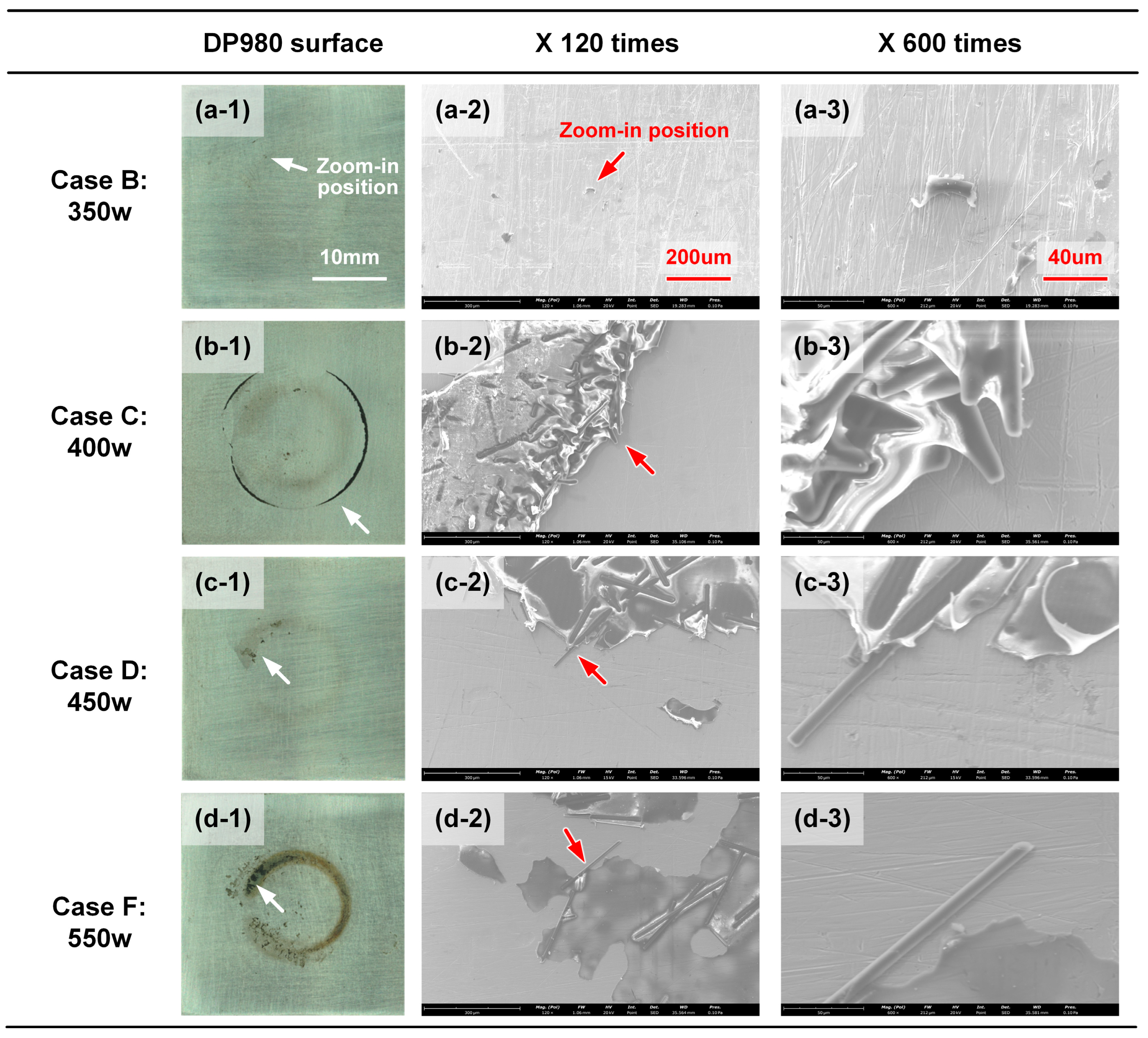

4.4. Analysis of Fracture Surface

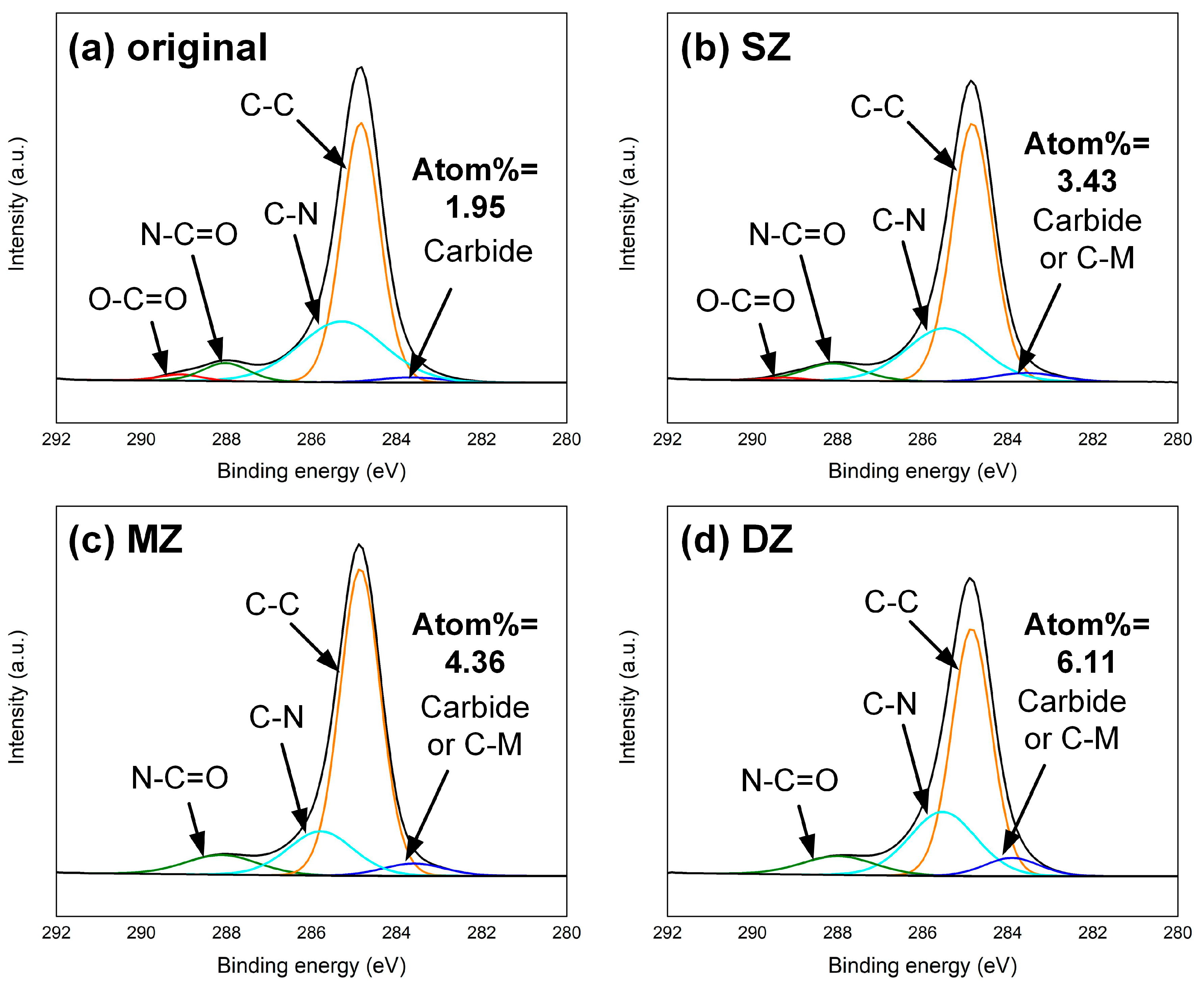

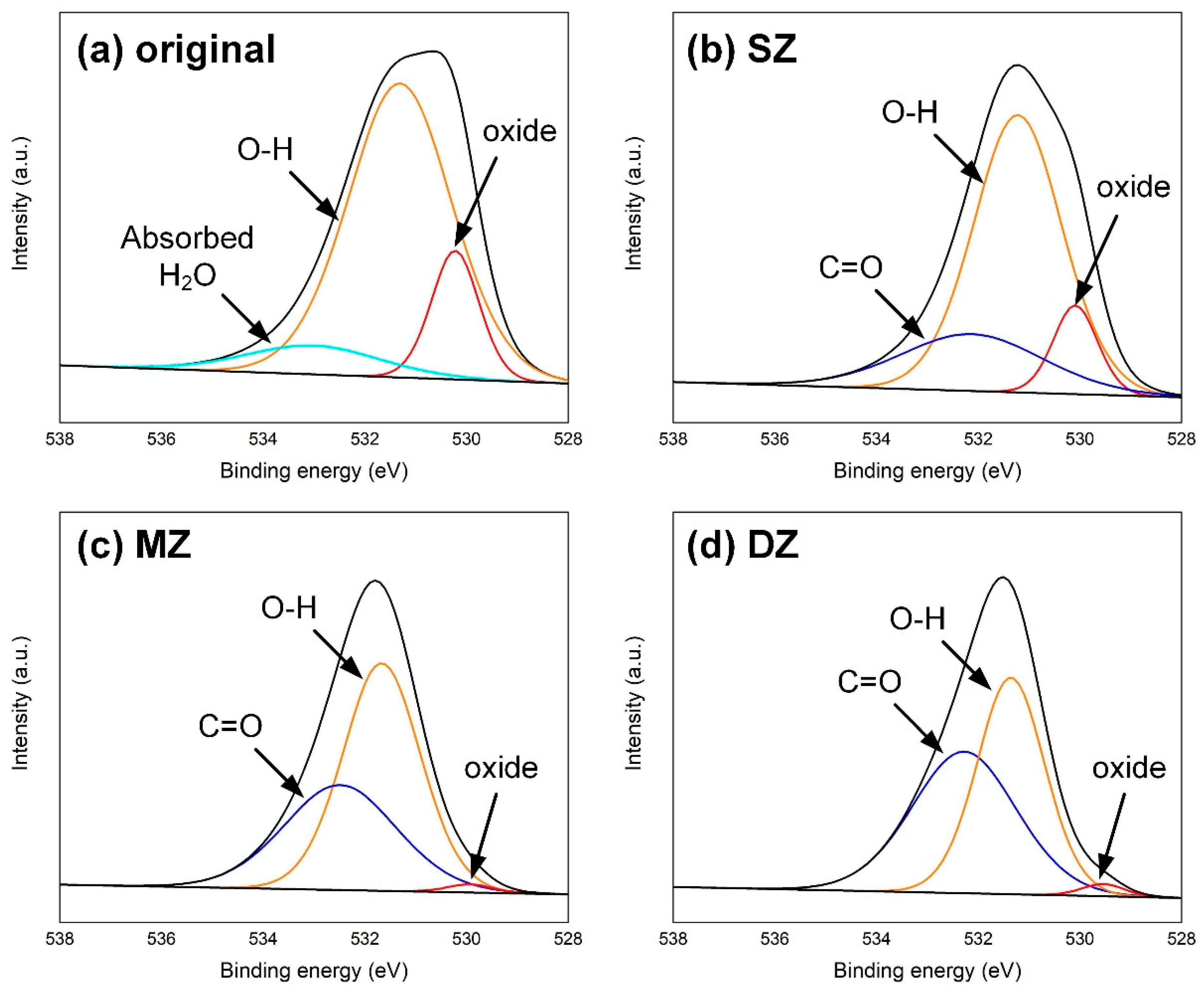

4.5. Analysis of Interfacial Chemical Bonding

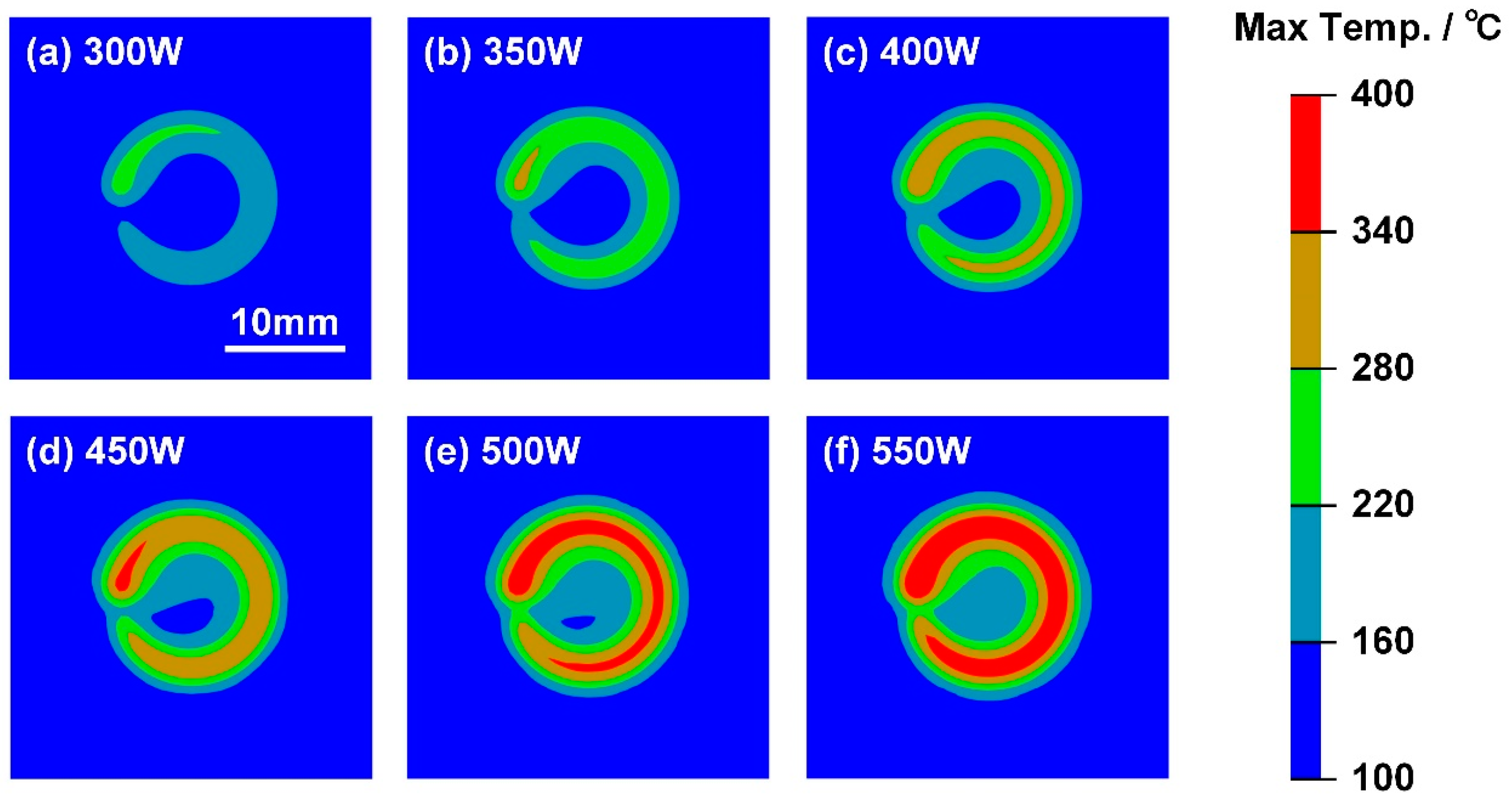

4.6. Analysis of Interface Temperature Distribution

5. Conclusions

- Laser circle welding can join DP980 and PA6-CFRP successfully when the laser power was larger than 300 W with 12 mm/s scanning speed and 12 mm scanning diameter.

- The LCW joints always presented a brittle fracture. The maximum joining strength reached about 1353.2 N (12.2 MPa), which was about 43% of the CFRP strength.

- The joining zone of LCW joints can be subdivided into three parts according to the morphology of CFRP, which were defined as the squeezed zone (SZ), molten zone (MZ) and decomposition zone (DZ).

- The chemical reaction between the O-C=O bond on the CFRP surface and the -OH bond on the DP980 sheet provided the joining force between dissimilar materials.

- The influence of laser power on joining strength was dual character. The joining strength variation reflected the competitive result between joining zone expansion and local bonding quality change.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khan, F.; Hossain, N.; Mim, J.J.; Rahman, S.M.; Iqbal, J.; Billah, M.; Chowdhury, M.A. Advances of composite materials in automobile applications—A review. J. Eng. Res. 2024, in press. [Google Scholar]

- Pervaiz, M.; Panthapulakkal, S.; Sain, M.; Tjong, J. Emerging Trends in Automotive Lightweighting through Novel Composite Materials. Mater. Sci. Appl. 2016, 7, 13. [Google Scholar]

- Matheis, R.; Eckstein, L. Aluminium-carbon fibre-reinforced polymer hybrid crash management system incorporating braided tubes. Int. J. Automot. Compos. 2016, 2, 330–355. [Google Scholar]

- Ravichandran, B.; Balasubramanian, M. Joining methods for Fiber Reinforced Polymer (FRP) composites—A critical review. Compos. Part A Appl. Sci. Manuf. 2024, 186, 108394. [Google Scholar] [CrossRef]

- Hu, S.; Li, F. Laser joining of CFRTP to metal: A review on welding parameters, joint enhancement, and numerical simulation. Polym. Compos. 2024, 45, 1931–1955. [Google Scholar]

- Jamunkar, S.; Dhole, L.; Chavhan, G.; Burande, S. Recent advances in ultrasonic welding of dissimilar materials: A review. AIP Conf. Proc. 2024, 3108, 030004. [Google Scholar]

- Sheikh-Ahmad, J.; Zitoune, R.; Morel, C.; Ferrero, J.F.; Vieille, B. Joining of AA5052 to CF/PEEK by friction lap welding. Int. J. Adv. Manuf. Technol. 2024, 132, 1137–1150. [Google Scholar] [CrossRef]

- Ren, S.; Chen, H.; Ma, N.; Li, W.; Saeki, S.; Iwamoto, Y.; Yang, J. Coaxial one-side resistance spot welding for cross-lap joints of Al5052 and CFRP: Thermal process and strength evaluation. J. Mater. Res. Technol. 2024, 28, 1032–1043. [Google Scholar] [CrossRef]

- He, Z.; Zhou, D.; Zhou, S.; Du, X.; Liu, A.; Wang, X.; Liu, J. Effect of linear heat input on the interface and mechanical properties of steel/CFRP laser welding joint. Compos. Struct. 2024, 327, 117652. [Google Scholar]

- Xia, H.; Ma, Y.; Chen, C.; Su, J.; Zhang, C.; Tan, C.; Li, L.; Geng, P.; Ma, N. Influence of laser welding power on steel/CFRP lap joint fracture behaviors. Compos. Struct. 2022, 285, 115247. [Google Scholar] [CrossRef]

- Lee, S.-J.; Kim, J.-D.; Suh, J. Basic Study of Laser Direct Joining for CFRTP and Metals using High Power Diode Laser. J. Weld. Join. 2019, 37, 572–578. [Google Scholar]

- Zou, P.; Yang, F.; Liu, J.; Zhang, H. Effect of micro-arc oxidation treatment on laser joint microstructures of Ti-6Al-4V alloy/CFRP. Surf. Interface Anal. 2023, 55, 127–137. [Google Scholar] [CrossRef]

- Li, L.; Chuan, J.; Xu, S.; Huang, C.; Luo, Y.; Deng, B.; Bai, W.; Kong, H.J.; Chen, R. Effect of heat input on characteristics of TC4-CFRTP laser welding joints with PA6/epoxy resin interlayer. Opt. Laser Technol. 2024, 174, 110560. [Google Scholar]

- Ashong, A.N.; Arkhurst, B.M.; Lee, Y.S.; Lee, M.-Y.; Kim, J.H. Effect of hydrogen fluoride and magnesium oxide on AZ31 Mg alloy/carbon fiber-reinforced plastic composite by thermal laser joining technique. J. Magnes. Alloys 2024, 12, 2874–2889. [Google Scholar]

- Tan, C.; Liu, Y.; Liu, F.; Su, J.; Zhang, Z.; Zhang, X.; Song, K.; Chen, B.; Song, X. Effect of laser power on laser joining of carbon fiber reinforced plastic to AZ31B Mg alloy. Opt. Laser Technol. 2022, 145, 107449. [Google Scholar]

- Wang, L.; Rong, Y.; Wu, C.; Xu, J.; Hu, J.; Huang, Y.; Zhang, G. Improving the joint strength of laser-welded CFRTP/TC4 joints via appropriate groove design. Appl. Surf. Sci. 2024, 644, 158752. [Google Scholar] [CrossRef]

- Schricker, K.; Alhomsi, M.; Bergmann, J.P. Thermal Efficiency in Laser-Assisted Joining of Polymer–Metal Composites. Materials 2020, 13, 4875. [Google Scholar] [CrossRef]

- Huang, S.; Lu, R.; Lou, M.; Lv, T.; Yao, J.; Li, Y. Effect of oscillation parameters on adjustable-ring mode (ARM) laser beam welding of aluminum alloys. J. Manuf. Process. 2024, 113, 307–318. [Google Scholar]

- Kuzu, A.T.; Karaguzel, U.; Erbay, B.; Bakkal, M. Effect of scanning strategies and laser parameters on metal-composite joining. Mater. Manuf. Process. 2021, 36, 1199–1207. [Google Scholar]

- Ren, S.; Shen, Y.; Chen, H.; Zheng, W.; Ma, Y.; Feng, D.; Yang, J. Investigation on the joining process and strength of laser circle welding between Al5052 and CFRP dissimilar materials. J. Manuf. Process. 2024, 120, 426–434. [Google Scholar]

- Ren, S.; Ma, Y.; Saeki, S.; Iwamoto, Y.; Ma, N. Numerical analysis on coaxial one-side resistance spot welding of Al5052 and CFRP dissimilar materials. Mater. Des. 2020, 188, 108442. [Google Scholar]

- Nishimura, R.; Ma, N.; Liu, Y.; Li, W.; Yasuki, T. Measurement and analysis of welding deformation and residual stress in CMT welded lap joints of 1180 MPa steel sheets. J. Manuf. Process. 2021, 72, 515–528. [Google Scholar]

- Ma, N. An accelerated explicit method with GPU parallel computing for thermal stress and welding deformation of large structure models. Int. J. Adv. Manuf. Technol. 2016, 87, 2195–2211. [Google Scholar]

- Ren, S.; Li, S.; Wang, Y.; Deng, D.; Ma, N. Predicting welding residual stress of a multi-pass P92 steel butt-welded joint with consideration of phase transformation and tempering effect. J. Mater. Eng. Perform. 2019, 28, 7452–7463. [Google Scholar]

- Károly, Z.; Kalácska, G.; Zsidai, L.; Mohai, M.; Klébert, S. Improvement of Adhesion Properties of Polyamide 6 and Polyoxymethylene-Copolymer by Atmospheric Cold Plasma Treatment. Polymers 2018, 10, 1380. [Google Scholar] [CrossRef]

- Chen, H.; Cai, Q.; Wu, J.; Xia, X.; Liu, H.; Luo, Z. Interfacial enhancement of carbon fiber/nylon 12 composites by grafting nylon 6 to the surface of carbon fiber. Appl. Surf. Sci. 2018, 441, 538–545. [Google Scholar]

- Ren, J.; Du, X.; Zhang, W.; Xu, M. From wheat bran derived carbonaceous materials to a highly stretchable and durable strain sensor. RSC Adv. 2017, 7, 22619–22626. [Google Scholar]

- Nagatsuka, K.; Kitagawa, D.; Yamaoka, H.; Nakata, K. Friction lap joining of thermoplastic materials to carbon steel. ISIJ Int. 2016, 56, 1226–1231. [Google Scholar] [CrossRef]

- Fantauzzi, M.; Secci, F.; Angotzi, M.S.; Passiu, C.; Cannas, C.; Rossi, A. Nanostructured spinel cobalt ferrites: Fe and Co chemical state, cation distribution and size effects by X-ray photoelectron spectroscopy. RSC Adv. 2019, 9, 19171–19179. [Google Scholar]

- Tan, X.; Shan, J.; Ren, J. Effects of Cr plating layer on shear strength and interface bonding characteristics of mild steel/CFRP joint by laser heating. Acta Metall. Sin. 2013, 49, 751–756. [Google Scholar]

| C | Si | Mn | P | S | Cr | Ni | Mo | Al | Ti | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.09 | 0.56 | 2.63 | 0.013 | 0.009 | 0.17 | 0.014 | 0.023 | 0.025 | 0.02 | Bal. |

| Case | Laser Power (W) | Scanning Speed (mm/s) | Scanning Diameter (mm) | Specimen Number (n) |

|---|---|---|---|---|

| A | 300 | 12 | 12 | 4 |

| B | 350 | 12 | 12 | 4 |

| C | 400 | 12 | 12 | 4 |

| D | 450 | 12 | 12 | 4 |

| E | 500 | 12 | 12 | 4 |

| F | 550 | 12 | 12 | 4 |

| Temperature (°C) | Specific Heat (J/(g⋅°C)) | Thermal Conductivity (J/(mm⋅°C⋅s)) | Density (g/cm3) |

|---|---|---|---|

| 20.0 | 1.344 | 0.000427 | 1.1225 |

| 60.0 | 1.759 | 0.000435 | - |

| 160.0 | 2.231 | 0.000437 | - |

| 200.0 | 2.843 | 0.0004375 | 1.1225 |

| Temperature (°C) | Specific Heat (J/(g⋅°C)) | Thermal Conductivity (J/(mm⋅°C⋅s)) | Density (g/cm3) |

|---|---|---|---|

| 25.0 | 0.482 | 0.0325 | 7.66 |

| 200.0 | 0.556 | 0.0351 | - |

| 400.0 | 0.635 | 0.0342 | - |

| 600.0 | 0.785 | 0.0316 | - |

| 800.0 | 0.789 | 0.0297 | 7.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, S.; Shen, Y.; Wang, T.; Chen, H.; Ma, N.; Yang, J. Effect of Laser Power on Formation and Joining Strength of DP980-CFRP Joint Fabricated by Laser Circle Welding. Polymers 2025, 17, 997. https://doi.org/10.3390/polym17070997

Ren S, Shen Y, Wang T, Chen H, Ma N, Yang J. Effect of Laser Power on Formation and Joining Strength of DP980-CFRP Joint Fabricated by Laser Circle Welding. Polymers. 2025; 17(7):997. https://doi.org/10.3390/polym17070997

Chicago/Turabian StyleRen, Sendong, Yihao Shen, Taowei Wang, Hao Chen, Ninshu Ma, and Jianguo Yang. 2025. "Effect of Laser Power on Formation and Joining Strength of DP980-CFRP Joint Fabricated by Laser Circle Welding" Polymers 17, no. 7: 997. https://doi.org/10.3390/polym17070997

APA StyleRen, S., Shen, Y., Wang, T., Chen, H., Ma, N., & Yang, J. (2025). Effect of Laser Power on Formation and Joining Strength of DP980-CFRP Joint Fabricated by Laser Circle Welding. Polymers, 17(7), 997. https://doi.org/10.3390/polym17070997