Enhanced Photothermal Based-Heat Retention in Regenerated Cellulose Fibers via Ceramic Particles and Polyelectrolyte Binders-Based Surface Functionalization

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Surface Coating of RCFs

3. Characterization Methods

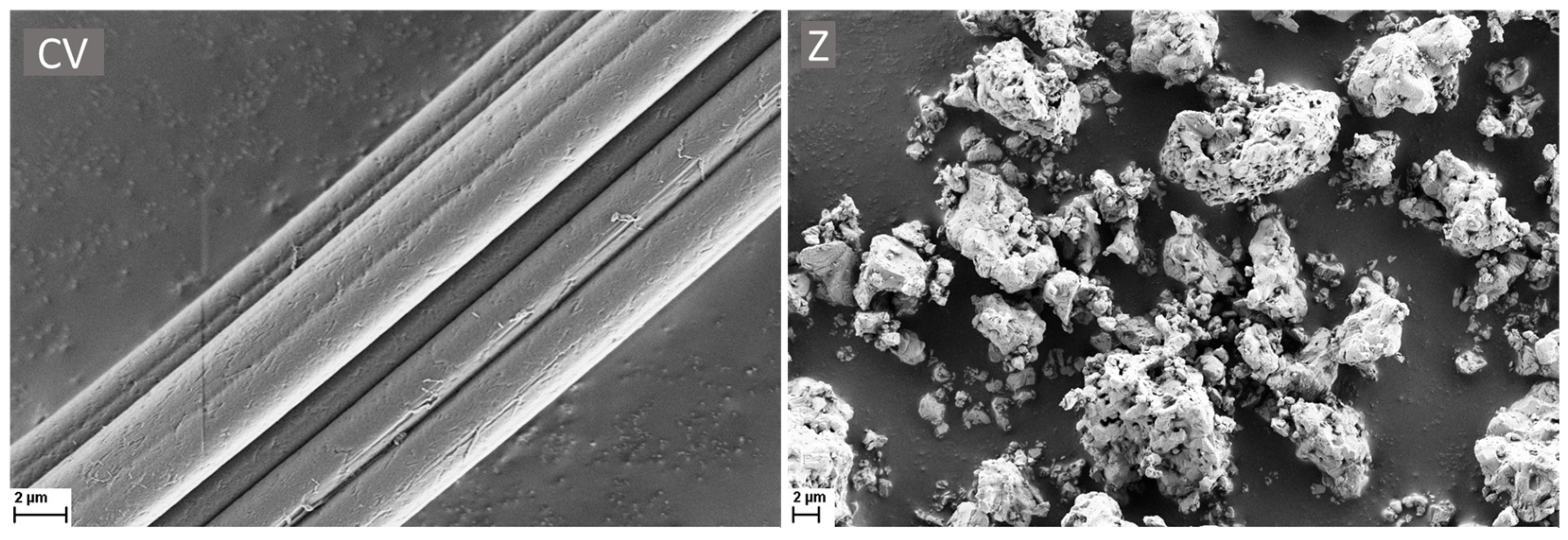

3.1. Field-Emission Scanning Electron Microscopy

3.2. Tensile Properties of RCFs

3.3. Photothermal Property Measurements of RCFs

3.4. X-Ray Photoelectron Spectroscopy (XPS) Analysis

4. Results and Discussions

4.1. Surface and Morphological Characterization of RCFs

4.2. Tensile Strength of RCFs

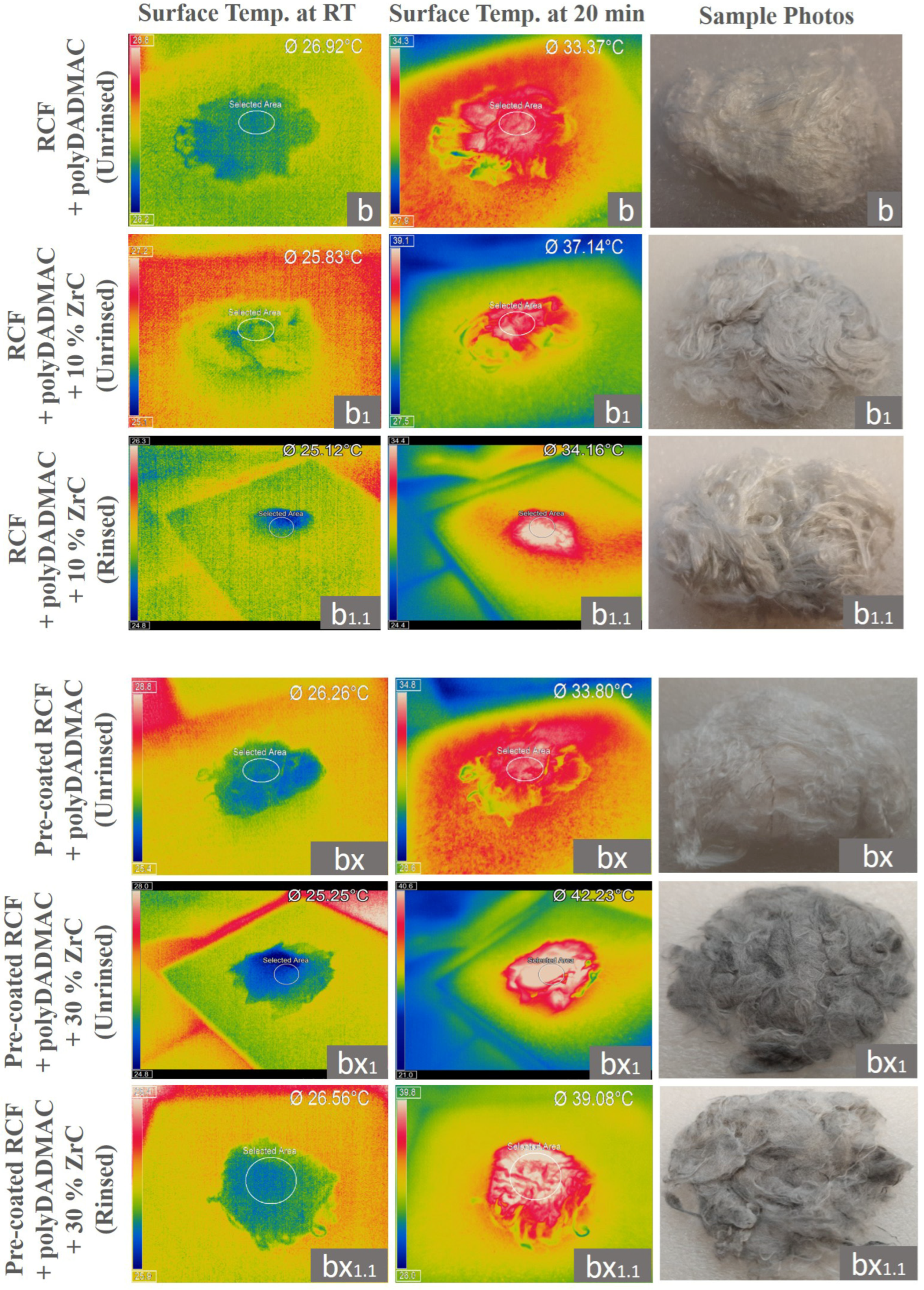

4.3. Heat Retention and Release Properties of the RCFs

5. Conclusions

- SEM micrographs confirmed the successful coating of ZrC particles on RCFs;

- The coatings exhibited notable thermal properties:

- ○

- The surface temperatures of 30% (w/v) ZrC-embedded fibers coated with PEI binders were 37.1 °C and 39.8 °C, significantly higher than the reference RCFs (32.2 °C);

- ○

- The addition of CMC and CaCl2 improved the coating efficiency of polyDADMAC binders;

- ○

- The highest temperature increase was observed in infrared (IR) heat emission diagrams for polyDADMAC-coated fibers with a CaCl2 + CMC mixture and ZrC coating, both rinsed and unrinsed (bx1: 42.23 °C; bx1.1: 39.08 °C);

- ○

- These findings highlight the suitability of the developed clothing textiles for sustainable applications in non-extreme thermal conditions, ensuring thermo-physiological comfort by maintaining body temperature within a tolerable thermal range (36.5–37.5 °C).

- A moderate decrease in tensile strength (tenacity and elongation at break) was observed compared to reference RCFs. However, the following was noted:

- ○

- This reduction did not affect fiber flexibility, making them suitable for further yarn spinning and fabric production.

- XPS spectra provided qualitative confirmation of PEI attachment onto RCFs, with and without ZrC particle coating. These findings aligned with the SEM micrograph observations;

- The ZrC-coated RCF samples in this study stabilized at an optimal temperature range of 37–39 °C, ensuring thermo-physical comfort by aligning with natural body temperature. If the heat emission exceeded 39–40 °C under IR exposure, it could compromise wearer comfort, making it unsuitable for our intended application. These findings confirm that our coating approach effectively enhances heat retention while maintaining comfort, supporting the study’s aim of developing RCF-based materials for functional clothing textiles.

Future Perspectives of This Study

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, H.; Du, Z. Preparation of a Highly Sensitive and Stretchable Strain Sensor of MXene/Silver Nanocomposite-Based Yarn and Wearable Applications. ACS Appl. Mater. Interfaces 2019, 11, 45930–45938. [Google Scholar] [CrossRef] [PubMed]

- Park, J. Functional Fibers, Composites and Textiles Utilizing Photothermal and Joule Heating. Polymers 2020, 12, 189. [Google Scholar] [CrossRef] [PubMed]

- Heo, J.S.; Eom, J.; Kim, Y.; Park, S.K. Recent Progress of Textile-Based Wearable Electronics: A Comprehensive Review of Materials, Devices, and Applications. Small 2017, 14, 1703034. [Google Scholar] [CrossRef]

- Pan, N.; Sun, G. Functional Textiles for Improved Performance, Protection and Health; Woodhead publishing series in textiles; Woodhead Publishing: Oxford, UK, 2011. [Google Scholar]

- Xu, J.; Jiang, S.; Wang, Y.; Shang, S.; Miao, D.; Guo, R. Photo-thermal conversion and thermal insulation properties of ZrC coated polyester fabric. Fibers Polym. 2017, 18, 1938–1944. [Google Scholar] [CrossRef]

- Sun, H.; Zhou, Q.; Zhao, Q.; Shi, L.; Wang, D.; Mei, T. Fabrication of ZrC/PVA-co-PE NF composite membranes with photo-thermal conversion for solar desalination. Compos. Commun. 2019, 13, 151–155. [Google Scholar] [CrossRef]

- Li, C.; Li, L.; Li, J.; Wu, X.; Qi, L.; Li, W. Fabrication and characterisation of viscose fibre with photoinduced heat-generating properties. Cellulose 2019, 26, 1631–1640. [Google Scholar] [CrossRef]

- Chang, J.; Shi, L.; Zhang, M.; Li, R.; Shi, Y.; Yu, X.; Pang, K.; Qu, L.; Wang, P.; Yuan, J. Tailor-Made White Photothermal Fabrics: A Bridge between Pragmatism and Aesthetic. Adv. Mater. 2023, 35, e2209215. [Google Scholar] [CrossRef]

- Peng, Y.; Cui, Y. Advanced Textiles for Personal Thermal Management and Energy. Joule 2020, 4, 724–742. [Google Scholar] [CrossRef]

- Farooq, A.S.; Zhang, P. Fundamentals, materials and strategies for personal thermal management by next-generation textiles. Compos. Part A Appl. Sci. Manuf. 2021, 142, 106249. [Google Scholar] [CrossRef]

- Bisoyi, H.K.; Urbas, A.M.; Li, Q. Soft Materials Driven by Photothermal Effect and Their Applications. Adv. Opt. Mater. 2018, 6, 1800458. [Google Scholar] [CrossRef]

- Sankauskaitė, A.; Rubežienė, V.; Kubilienė, D.; Abraitienė, A.; Baltušnikaitė-Guzaitienė, J.; Dubinskaitė, K. Investigation of Thermal Behavior of 3D PET Knits with Different Bioceramic Additives. Polymers 2020, 12, 1319. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, C.; Jiang, P.; Li, W. Preparation and characterization of viscose composites fiber and its enhancing effect in photothermal conversion property. Polym. Compos. 2020, 41, 4084–4092. [Google Scholar] [CrossRef]

- Kim, H.A. Wear Comfort of Heat Storage/Release Fabrics Containing Al2O3/Graphite Yarns. Fibers Polym. 2021, 23, 554–564. [Google Scholar] [CrossRef]

- Kim, H. Heat release and wear comfort characteristics of the ceramic imbedded fabrics for cold weather protective clothing. J. Ind. Text. 2022, 52, 15280837221109638. [Google Scholar] [CrossRef]

- Ke, G.; Jin, X.; Li, W. Fabrication and characterization of polyester composite yarn with PVB/ZrC/Al2O3 coating. Text. Res. J. 2022, 92, 4098–4108. [Google Scholar] [CrossRef]

- Cheng, D.; Liu, Y.; Zhang, Y.; Ran, J.; Bi, S.; Deng, Z.; Cai, G.; Tang, X.; Zhou, Y.; Wang, X. Polydopamine-assisted deposition of CuS nanoparticles on cotton fabrics for photocatalytic and photothermal conversion performance. Cellulose 2020, 27, 8443–8455. [Google Scholar] [CrossRef]

- Kim, H.-A. Ultra-Violet Protection and Anti-Static Characteristics with Heat Release/Shielding of Al2O3/ATO/TiO2-Imbedded Multi-Functional Fabrics. Materials 2022, 15, 3652. [Google Scholar] [CrossRef]

- Yan, M.; Li, Y.; Hao, Q.; Cai, S.; Xu, X.; Wang, S.; Lian, C. Photothermal Silk-based Textiles. Fibers Polym. 2022, 23, 644–650. [Google Scholar] [CrossRef]

- The National Institute of Standards and Technology (NIST). NIST Chemistry WebBook, SRD 69; U.S. Department of Commerce: Washington, DC, USA, 2023. Available online: https://webbook.nist.gov/cgi/cbook.cgi?ID=C12070143&Mask=FFFF&Units=SI (accessed on 31 March 2025).

- Peterson, G.R.; Carr, R.E.; Marinero, E.E. Zirconium Carbide for Hypersonic Applications, Opportunities and Challenges. Materials 2023, 16, 6158. [Google Scholar] [CrossRef]

- Chen, H.; Wang, F.; Wang, K.; Wu, Y.; Guo, C. Metallic zirconium carbide mediated near-infrared driven photocatalysis and photothermal sterilization for multidirectional water purification. J. Colloid Interface Sci. 2022, 624, 296–306. [Google Scholar] [CrossRef]

- Chen, C.; Feng, J.; Li, J.; Guo, Y.; Shi, X.; Peng, H. Functional Fiber Materials to Smart Fiber Devices. Chem. Rev. 2023, 123, 613–662. [Google Scholar] [CrossRef] [PubMed]

- Long, Y.; Javed, A.; Chen, J.; Chen, Z.-K.; Xiong, X. Phase composition, microstructure and mechanical properties of ZrC coatings produced by chemical vapor deposition. Ceram. Int. 2014, 40, 707–713. [Google Scholar] [CrossRef]

- Craciun, V.; McCumiskey, E.; Hanna, M.; Taylor, C. Very hard ZrC thin films grown by pulsed laser deposition. J. Eur. Ceram. Soc. 2013, 33, 2223–2226. [Google Scholar] [CrossRef]

- Zhang, A.; Deng, W.; Li, Q.; Song, Z.; Ke, G. Fabrication and properties of photothermal conversion and thermochromic cotton yarn. Pigment. Resin Technol. 2024. [CrossRef]

- Wang, Y.; Ke, G.; Chen, S.; Jin, X. Fabrication and characterization of polyurethane and zirconium carbide coated cotton yarn. Cellulose 2022, 29, 647–655. [Google Scholar] [CrossRef]

- Furuta, T.; Shimizu, Y.; Kondo, Y. Evaluating the Temperature and Humidity Characteristics of a Solar Energy Absorbing and Retaining Fabric. Text. Res. J. 1996, 66, 123–130. [Google Scholar] [CrossRef]

- Kim, H.A.; Kim, S.J. Heat Storage and Release Characteristics of Ceramic-Imbedded Woven Fabric for Emotional Clothing. Autex Res. J. 2019, 19, 165–172. [Google Scholar] [CrossRef]

- Heat Generation Performance Test, Daiwobo Rayon Co., Ltd. Kaken Test Center, General Incorporated Foundation, Osaka, Japan, Heat Generating Viscose Rayon–Converting Light into Heat (Earth Wave TM). July 2021. Available online: https://daiwaborayon.co.jp/english/wp-content/uploads/2021/05/catalog20210507102742.pdf (accessed on 2 July 2024).

- Kim, S.J.; Song, M.K.; Seo, K.O.; Kim, H.A. Physical properties of ZrC/Al2O3 imbedded heat storage woven fabrics. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 254, p. 072014. [Google Scholar] [CrossRef]

- Qi, H.; Liu, J.; Deng, Y.; Gao, S.; Mäder, E. Cellulose fibres with carbon nanotube networks for water sensing. J. Mater. Chem. A 2014, 2, 5541–5547. [Google Scholar] [CrossRef]

- ISO 139:2005; Textiles—Standard Atmospheres for Conditioning and Testing. ISO: Geneva, Switzerland, 2005.

- ISO 1973:2021; Textile Fibres—Determination of Linear Density—Gravimetric Method and Vibroscope Method. ISO: Geneva, Switzerland, 2021.

- ISO 5079:2020; Textile Fibres—Determination of Breaking Force and Elongation at Break of Individual Fibres. ISO: Geneva, Switzerland, 2020.

- Kim, H.A.; Kim, S.J. Wear comfort properties of ZrC/Al2O3/graphite-embedded, heat-storage woven fabrics for garments. Text. Res. J. 2019, 89, 1394–1407. [Google Scholar] [CrossRef]

- Havenith, G. Clothing and Thermoregulation. In Current Problems in Dermatology; Elsner, P., Hatch, K., Wigger-Alberti, W., Eds.; Karger Publishers: Basel, Switzerland, 2003; Volume 31, pp. 35–49. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, Q.; Ji, X.; Peng, J.; Nawaz, H.; Xia, G.; Ji, X.; Zhang, J.; Zhang, J. Fabrication and Characterization of Transparent and Uniform Cellulose/Polyethylene Composite Films from Used Disposable Paper Cups by the “One-Pot Method”. Polymers 2022, 14, 1070. [Google Scholar] [CrossRef]

- Shen, A.; Liao, X.; Li, Y. Polyamine functionalized cotton fibers selectively capture negatively charged dye pollutants. Colloids Surfaces A Physicochem. Eng. Asp. 2021, 623, 126666. [Google Scholar] [CrossRef]

- Di Gaudio, F.; Barreca, S.; Orecchio, S. Diallyldimethylammonium Chloride (DADMAC) in Water Treated with Poly-Diallyldimethylammonium Chloride (PDADMAC) by Reversed-Phase Ion-Pair Chromatography—Electrospray Ionization Mass Spectrometry. Separations 2023, 10, 311. [Google Scholar] [CrossRef]

- Gustavsson, C.; Snekkenes, V.; Olsson, K. Method for the Modification of Cellulose fibres. EP 1 490 5 48 B1. 2002. Available online: https://data.epo.org/publication-server/rest/v1.2/publication-dates/20100929/patents/EP1490548NWB1/document.pdf (accessed on 31 January 2025).

| Type of Textiles Used/Fabricated with Incorporated ZrC Particles | Experimental Conditions for the IR Light Heat Emission Setup | Data for Photothermal Conversion-Based Heat Retention (Δ = Heat Increase Between Reference and Max temp., °C) (Rate = +%) | Ref. | |

|---|---|---|---|---|

| IR Lamp | IR Camera/Sensor | |||

| Surface-coated RCF with PEI | IR lamp (Philips, 100 W 230 V R95) | IR camera (Optris PI400) | Reference RC fiber: 32.21 °C ZrC-coated RC fiber: 37.07 °C (Δ = Heat increase, 4.86 °C) (Rate = +15.09%) | This study |

| Distance: 50 cm (from the sample) | Distance: 20 cm (from the sample) | |||

| IR light test: Light-on (20 min) Light-off (20 min) | Specimens tested at 20 ± 2 °C and RH of 50 ± 2%. | |||

| Surface-coated RCF with polyDADMAC (pre-coated with CaCl2 + CMC) | IR lamp (Philips, 100 W 230 V R95) | IR camera (Optris PI400) | Reference RC fiber: 32.21 °C ZrC-coated RC fiber: 39.08 °C (Δ = Heat increase: 6.87 °C) (Rate = +21.34%) | This study |

| Distance: 50 cm (from the sample) | Distance: 20 cm (from the sample) | |||

| IR light test: Light-on (20 min) Light-off (20 min) | Specimens tested at 20 ± 2 °C and RH of 50 ± 2%. | |||

| Spunlace nonwoven with mélange fibers containing Heat WaveTM (*) | Reflector lamp (500 W) | N/A: Camera/Sensor | Reference RC fiber: ≈33 °C ZrC-coated RC fiber: ≈38 °C (Δ = Heat increase: ≈5 °C) (Rate = +15.15%) | [30] |

| Distance: 50 cm (from the sample) | Nonwovens tested at 20 ± 2 °C and RH: N/A | |||

| IR light test: Light-on (20 min) Light-off (15 min) | Closest material, and test setup to our study. | |||

| Knitted PES fabric with PES-textured filament Solar α™ (**) | REF lamp (PRF-500 W), central luminosity: 6000 cd) | Thermosensor on an insulator. | Reference PES knit fabric: ~23 °C ZrC-PES fabric: 26 °C (Δ = Heat increase, 3 °C) (Rate = +13.04%) | [28] |

| Distance: 80 cm (from the sample) | N/A: Specimen size N/A: Test conditions | |||

| Woven PET fabric with core-spun bicomponent PET yarn | Heat emission bulb (220 V/500 W/3200 K) | Thermometer N/A: Heat-insulator | Reference PET woven fabric: 34.8 °C ZrC-embedded PET fabric: 38 °C (Δ = Heat increase, 3.2 °C) (Rate = +9.20%) | [29] |

| Distance: 50 cm (from the sample) | Specimens prepared a 20 ± 2 °C and RH of 64 ± 4%. | |||

| IR light test: Light-on (10 min) Light-off (20 min) | ||||

| Sample Abbreviations | Sample Descriptions |

|---|---|

| RCF, (CV) | Reference RCF without any (pre-)coating |

| (a) | Coated RCFs with 1% (w/v) PEI (unrinsed) |

| (a1) | Coated RCFs with 1% (w/v) PEI with 10% (w/v) ZrC (unrinsed) |

| (a1.1) | Coated RCFs with 1% (w/v) PEI with 10% (w/v) ZrC (rinsed) |

| (a2) | Coated RCFs with 1% (w/v) PEI with 30% (w/v) ZrC (unrinsed) |

| (a2.1) | Coated RCFs with 1% (w/v) PEI with 30% (w/v) ZrC (rinsed) |

| (b) | Coated RCFs with 1% (w/v) polyDADMAC (unrinsed) |

| (b1) | Coated RCFs with 1% (w/v) polyDADMAC with 10% (w/v) ZrC (unrinsed) |

| (b1.1) | Coated RCFs with 1% (w/v) polyDADMAC with 10% (w/v) ZrC (rinsed) |

| (bx) | Pre-coated RCFs with (0.5 M CaCl2 + 5% w/v CMC) mixture and coated with 1% (w/v) polyDADMAC (unrinsed) |

| (bx1) | Pre-coated RCFs with (0.5 M CaCl2 + 5% w/v CMC) mixture and coated with 1% (w/v) polyDADMAC with 30% (w/v) ZrC particles (unrinsed) |

| (bx1.1) | Pre-coated RCFs with (0.5 M CaCl2 + 5% w/v CMC) mixture and coated with 1% (w/v) polyDADMAC (unrinsed) with 30% (w/v) ZrC particles (rinsed) |

| RCF Samples | Surface Compositions (at.%) | |||

|---|---|---|---|---|

| Oxygen (O) | Carbon (C) | O/C Ratio | Nitrogen (N) | |

| (CV) Reference RCF | 34.9 | 63.1 | 0.55 | - |

| (a) Coated RCFs with 1% (w/v) PEI | 15.6 | 68.5 | 0.23 | 15.6 |

| (a2) Coated RCFs with 1% (w/v) PEI + 30% (w/v) ZrC | 37.4 | 60.7 | 0.62 | 0.8 |

| Specifications of the Tested Samples | Titer (dtex) | Tenacity (cN/tex) | Elongation (%) |

|---|---|---|---|

| Regenerated cellulose fiber (RCF) (CV) | 1.41 ± 0.2 | 23.7 ± 2.3 | 20.4 ± 2.6 |

| Coated RCF with 1% (w/v) PEI (unrinsed) (a) | 1.44 ± 0.2 | 21.9 ± 1.7 | 19.2 ± 2.1 |

| Coated RCF with 1% (w/v) PEI + 10% (w/v) ZrC (unrinsed) (a1) | 1.45 ± 0.3 | 21.3 ± 3.1 | 19.1 ± 1.3 |

| Coated RCF with 1% (w/v) PEI + 10% (w/v) ZrC (rinsed) (a1.1) | 1.43 ± 0.4 | 23.4 ± 0.9 | 15.4 ± 3.3 |

| Coated RCF with 1% (w/v) PEI + 30% (w/v) ZrC (unrinsed) (a2) | 1.47 ± 0.6 | 20.0 + 5.2 | 12.9 ± 3.3 |

| Coated RCF with 1% (w/v) PEI + 30% (w/v) ZrC (rinsed) (a2.1) | 1.44 ± 0.3 | 22.3 + 3.4 | 14.1 ± 2.4 |

| Coated RCF with 1% (w/v) polyDADMAC (unrinsed) (b) | 1.35 ± 0.1 | 20.3 ± 1.8 | 15.1 ± 2.3 |

| Coated RCF with 1% (w/v) polyDADMAC + 10% (w/v) ZrC (rinsed) (b1) | 1.50 ± 0.4 | 21.6 ± 1.4 | 15.8 ± 2.5 |

| Coated RCF with 1% (w/v) polyDADMAC + 10% (w/v) ZrC (rinsed) (b1.1) | 1.52 ± 0.3 | 19.9 ± 2.3 | 17.9 ± 2.3 |

| Pre-coated RCFs with CMC + CaCl2 mixture, then coated with 1% (w/v) polyDADMAC (unrinsed) (bx) | 1.51 ± 0.4 | 19.7 ± 1.5 | 16.7 ± 1.7 |

| Pre-coated RCFs with CMC + CaCl2 mixture, then coated with 1% (w/v) polyDADMAC and 30% (w/v) ZrC (unrinsed) (bx1) | 1.45 ± 0.1 | 17.8 ± 6.8 | 15.8 ± 6.0 |

| Pre-coated RCFs with CMC + CaCl2 mixture, then coated with 1% (w/v) polyDADMAC and 30% (w/v) ZrC (rinsed) (bx1.1) | 1.50 ± 0.1 | 19.1 ± 2.3 | 14.9 ± 2.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yapar, Ö.; Hadela, A.; Ojstršek, A.; Lobnik, A. Enhanced Photothermal Based-Heat Retention in Regenerated Cellulose Fibers via Ceramic Particles and Polyelectrolyte Binders-Based Surface Functionalization. Polymers 2025, 17, 961. https://doi.org/10.3390/polym17070961

Yapar Ö, Hadela A, Ojstršek A, Lobnik A. Enhanced Photothermal Based-Heat Retention in Regenerated Cellulose Fibers via Ceramic Particles and Polyelectrolyte Binders-Based Surface Functionalization. Polymers. 2025; 17(7):961. https://doi.org/10.3390/polym17070961

Chicago/Turabian StyleYapar, Özkan, Ajra Hadela, Alenka Ojstršek, and Aleksandra Lobnik. 2025. "Enhanced Photothermal Based-Heat Retention in Regenerated Cellulose Fibers via Ceramic Particles and Polyelectrolyte Binders-Based Surface Functionalization" Polymers 17, no. 7: 961. https://doi.org/10.3390/polym17070961

APA StyleYapar, Ö., Hadela, A., Ojstršek, A., & Lobnik, A. (2025). Enhanced Photothermal Based-Heat Retention in Regenerated Cellulose Fibers via Ceramic Particles and Polyelectrolyte Binders-Based Surface Functionalization. Polymers, 17(7), 961. https://doi.org/10.3390/polym17070961