Volatile Organic Compounds Arising from Wood Polymers on Thermal Loading of Spruce Wood

Abstract

1. Introduction

2. Materials and Methods

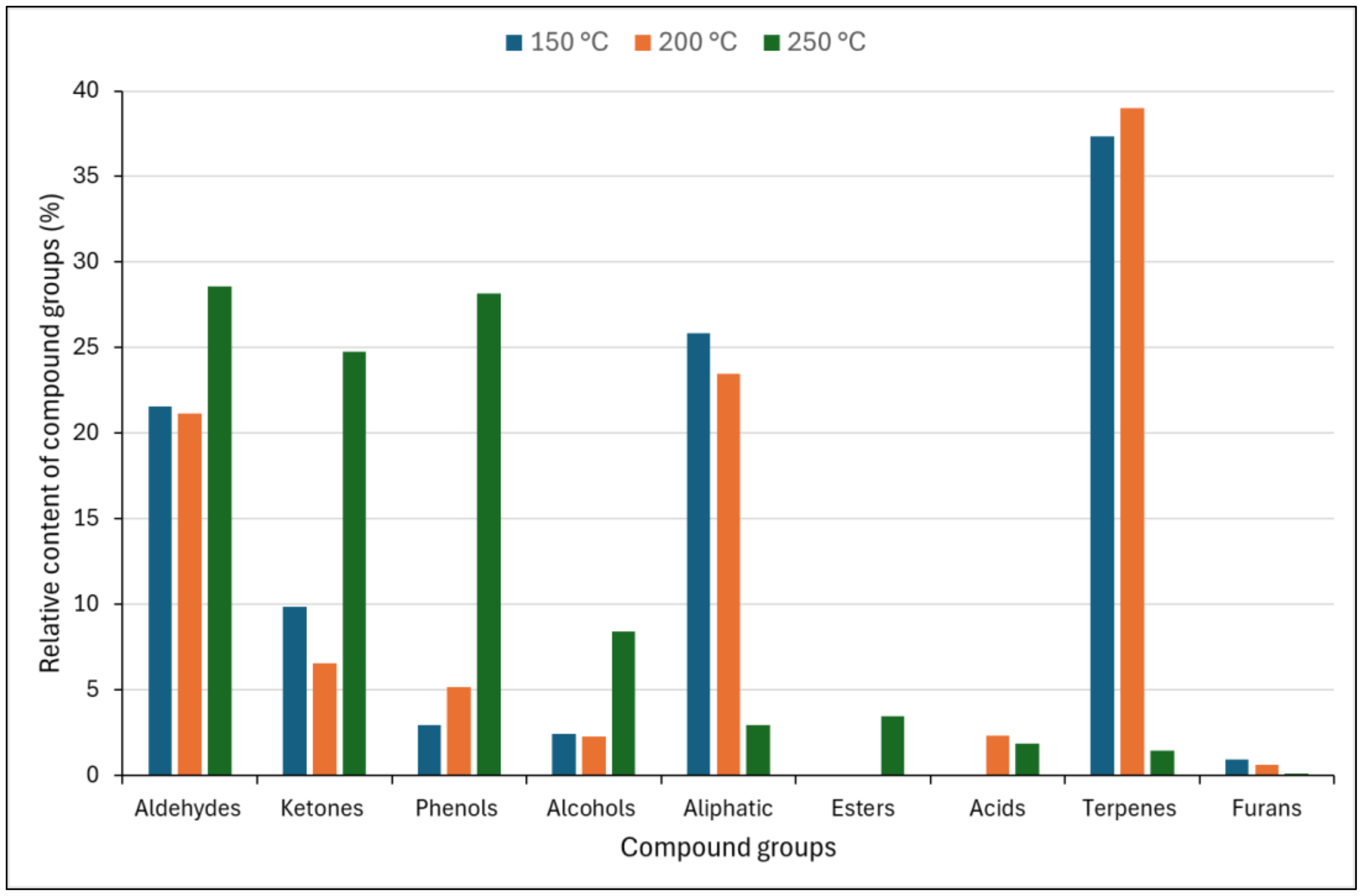

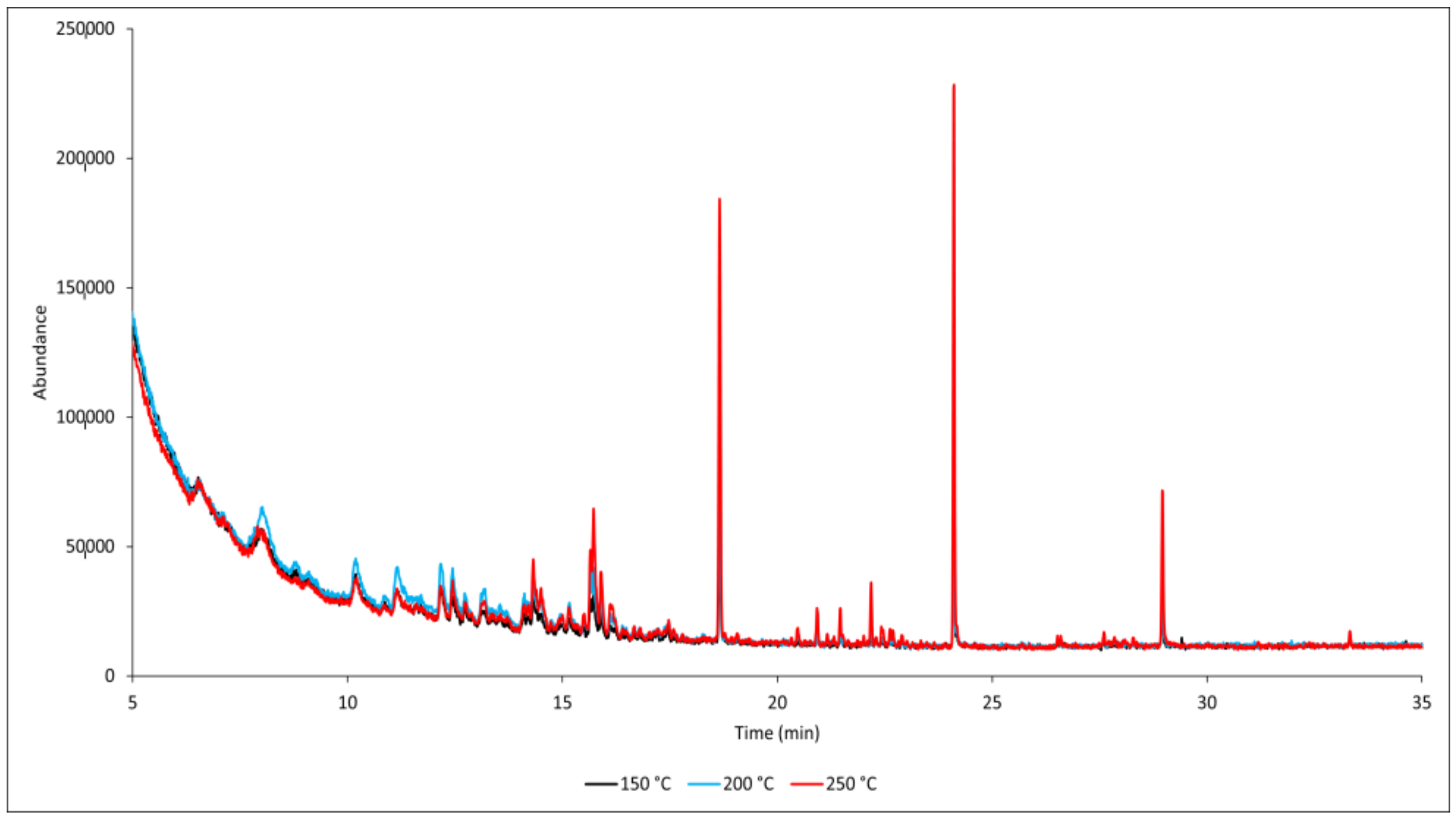

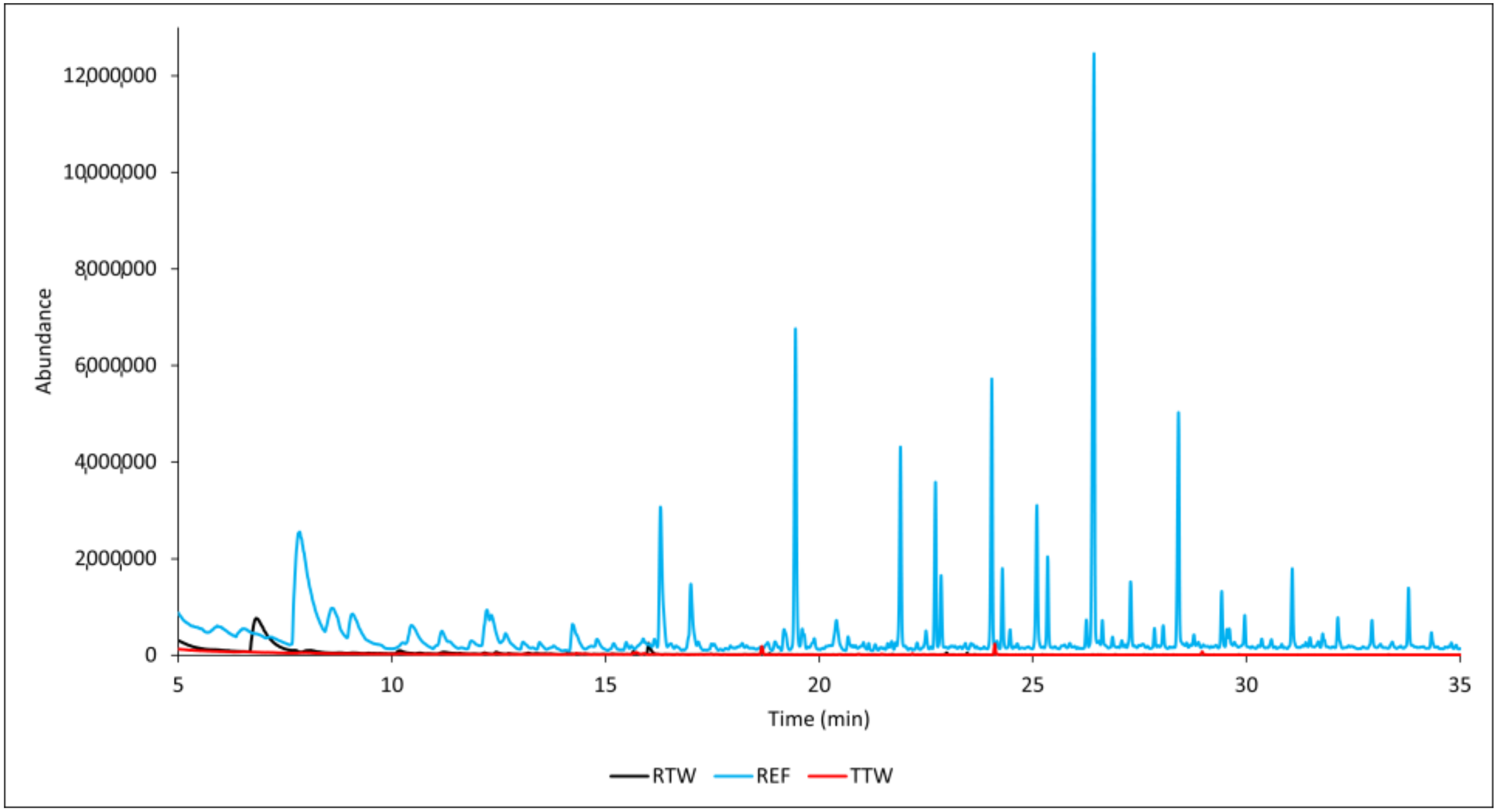

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lowden, L.A.; Hull, T.R. Flammability Behaviour of Wood and a Review of the Methods for Its Reduction. Fire Sci. Rev. 2013, 2, 4. [Google Scholar] [CrossRef]

- Mai, C.; Zhang, K. Wood Chemistry. In Springer Handbook of Wood Science and Technology; Niemz, P., Teischinger, A., Sandberg, D., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 179–279. ISBN 978-3-030-81315-4. [Google Scholar]

- Mensah, R.A.; Jiang, L.; Renner, J.S.; Xu, Q. Characterisation of the Fire Behaviour of Wood: From Pyrolysis to Fire Retardant Mechanisms. J. Therm. Anal. Calorim. 2023, 148, 1407–1422. [Google Scholar] [CrossRef]

- Lee, Y.X.; Wang, W.; Lei, Y.; Xu, L.; Agarwal, V.; Wang, C.; Yeoh, G.H. Flame-Retardant Coatings for Wooden Structures. Prog. Org. Coat. 2025, 198, 108903. [Google Scholar] [CrossRef]

- Reinprecht, L. Wood Deterioration, Protection and Maintenance; Wiley & Sons: Hoboken, NJ, USA, 2016; ISBN 978-1-119-10650-0. [Google Scholar]

- Júda, M.; Sydor, M.; Rogoziński, T.; Kučerka, M.; Pędzik, M.; Kminiak, R. Effect of Low-Thermal Treatment on the Particle Size Distribution in Wood Dust after Milling. Polymers 2023, 15, 1059. [Google Scholar] [CrossRef]

- Gaff, M.; Kačík, F.; Gašparík, M.; Todaro, L.; Jones, D.; Corleto, R.; Makovická Osvaldová, L.; Čekovská, H. The Effect of Synthetic and Natural Fire-Retardants on Burning and Chemical Characteristics of Thermally Modified Teak (Tectona Grandis L. f.) Wood. Constr. Build. Mater. 2019, 200, 551–558. [Google Scholar] [CrossRef]

- Li, T.; Wu, Q.; Lu, W.; Zhang, J.; Yue, Z.; Jie, Y.; Zhang, J.; Cheng, Z.; Ji, W.; Wu, J. Effects of Different Accelerated Aging Modes on the Mechanical Properties, Color and Microstructure of Wood. J. Build. Eng. 2024, 98, 111026. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Karlsson, O.; Jones, D. Wood Modification Technologies: Principles, Sustainability, and the Need for Innovation, 1st ed.; CRC Press: Boca Raton, FL, USA, 2021; ISBN 978-1-351-02822-6. [Google Scholar]

- Candelier, K.; Chaouch, M.; Dumarçay, S.; Pétrissans, A.; Pétrissans, M.; Gérardin, P. Utilization of Thermodesorption Coupled to GC–MS to Study Stability of Different Wood Species to Thermodegradation. J. Anal. Appl. Pyrol. 2011, 92, 376–383. [Google Scholar] [CrossRef]

- Candelier, K.; Dumarçay, S.; Pétrissans, A.; Pétrissans, M.; Kamdem, P.; Gérardin, P. Thermodesorption Coupled to GC–MS to Characterize Volatiles Formation Kinetic during Wood Thermodegradation. J. Anal. Appl. Pyrol. 2013, 101, 96–102. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, Y.; Shen, Y.; Li, C.; Wang, Y.; Ma, Z.; Sun, W. New Perspective on Wood Thermal Modification: Relevance between the Evolution of Chemical Structure and Physical-Mechanical Properties, and Online Analysis of Release of VOCs. Polymers 2019, 11, 1145. [Google Scholar] [CrossRef]

- Poletto, M.; Zattera, A.J.; Santana, R.M.C. Thermal Decomposition of Wood: Kinetics and Degradation Mechanisms. Bioresour. Technol. 2012, 126, 7–12. [Google Scholar] [CrossRef]

- Vargun, E.; Baysal, E.; Turkoglu, T.; Yuksel, M.; Toker, H. Thermal Degradation of Oriental Beech Wood Impregnated with Different Inorganic Salts. Maderas Cienc. Tecnol. 2019, 21, 163–170. [Google Scholar] [CrossRef]

- Dietenberger, M.; Hasburgh, L. Wood Products Thermal Degradation and Fire. Ref. Modul. Mater. Sci. Mater. Eng. 2016, 1, 9712–9716. [Google Scholar] [CrossRef]

- Gaff, M.; Kačík, F.; Sandberg, D.; Babiak, M.; Turčani, M.; Niemz, P.; Hanzlík, P. The Effect of Chemical Changes during Thermal Modification of European Oak and Norway Spruce on Elasticity Properties. Compos. Struct. 2019, 220, 529–538. [Google Scholar] [CrossRef]

- Ornaghi, H.L.; Ornaghi, F.G.; Motta Neves, R.; Magalhães De Oliveira, D.; Poletto, M. Thermal Decomposition of Wood Fibres: Thermal Simulation Using the F-Test Statistical Tool. Cellul. Chem. Technol. 2021, 55, 231–241. [Google Scholar] [CrossRef]

- Albert, C.M.; Liew, K.C. Recent Development and Challenges in Enhancing Fire Performance on Wood and Wood-Based Composites: A 10-Year Review from 2012 to 2021. J. Bioresour. Bioprod. 2024, 9, 27–42. [Google Scholar] [CrossRef]

- De Angelis, M.; Humar, M.; Kržišnik, D.; Tamantini, S.; Romagnoli, M. Influence of Thermal Modification and Impregnation with Biocides on Physical Properties of Italian Stone Pine Wood (Pinus Pinea L.). Appl. Sci. 2022, 12, 3801. [Google Scholar] [CrossRef]

- Popescu, C.-M.; Pfriem, A. Treatments and Modification to Improve the Reaction to Fire of Wood and Wood Based Products—An Overview. Fire Mater. 2020, 44, 100–111. [Google Scholar] [CrossRef]

- Lazar, S.T.; Kolibaba, T.J.; Grunlan, J.C. Flame-Retardant Surface Treatments. Nat. Rev. Mater. 2020, 5, 259–275. [Google Scholar] [CrossRef]

- Lai, Y.; Liu, X.; Davies, M.; Fisk, C.; Holliday, M.; King, D.; Zhang, Y.; Willmott, J. Characterisation of Wood Combustion and Emission under Varying Moisture Contents Using Multiple Imaging Techniques. Fuel 2024, 373, 132397. [Google Scholar] [CrossRef]

- Pohleven, J.; Burnard, M.D.; Kutnar, A. Volatile Organic Compounds Emitted from Untreated and Thermally Modified Wood—A Review. Wood Fiber Sci. 2019, 51, 231–254. [Google Scholar] [CrossRef]

- Sokamte Tegang, A.; Mbougueng, P.D.; Sachindra, N.M.; Douanla Nodem, N.F.; Tatsadjieu Ngoune, L. Characterization of Volatile Compounds of Liquid Smoke Flavourings from Some Tropical Hardwoods. Sci. Afr. 2020, 8, e00443. [Google Scholar] [CrossRef]

- Adamová, T.; Hradecký, J.; Pánek, M. Volatile Organic Compounds (VOCs) from Wood and Wood-Based Panels: Methods for Evaluation, Potential Health Risks, and Mitigation. Polymers 2020, 12, 2289. [Google Scholar] [CrossRef] [PubMed]

- Tuppurainen, V.; Fleitmann, L.; Kangas, J.; Leonhard, K.; Tanskanen, J. Conceptual Design of Furfural Extraction, Oxidative Upgrading and Product Recovery: COSMO-RS-Based Process-Level Solvent Screening. Comput. Chem. Eng. 2024, 191, 108835. [Google Scholar] [CrossRef]

- Palai, Y.N.; Fukuoka, A.; Shrotri, A. Unlocking the Potential of 5-Hydroxy-2(5H)-Furanone as a Platform for Bio-Based Four Carbon Chemicals. ACS Catal. 2024, 14, 2545–2551. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, M.; Yuan, D.; Li, C.; Ma, Y.; Wang, S.; Wang, S. Fire Hazards of PMMA-Based Composites Combined with Expandable Graphite and Multi-Walled Carbon Nanotubes: A Comprehensive Study. Fire Saf. J. 2023, 135, 103727. [Google Scholar] [CrossRef]

- Mizera, K.; Borucka, M.; Przybysz, J.; Gajek, A. Identification of Substances Emitted During Combustion and Thermal Decomposition of Wood-Based Materials. Chem. Eng. Trans. 2024, 111, 283–288. [Google Scholar] [CrossRef]

- Manninen, A.-M.; Pasanen, P.; Holopainen, J.K. Comparing the VOC Emissions between Air-Dried and Heat-Treated Scots Pine Wood. Atmos. Environ. 2002, 36, 1763–1768. [Google Scholar] [CrossRef]

- Kačík, F.; Veľková, V.; Šmíra, P.; Nasswettrová, A.; Kačíková, D.; Reinprecht, L. Release of Terpenes from Fir Wood during Its Long-Term Use and in Thermal Treatment. Molecules 2012, 17, 9990–9999. [Google Scholar] [CrossRef]

- Atiku, F.A.; Lea-Langton, A.R.; Bartle, K.D.; Jones, J.M.; Williams, A.; Burns, I.; Humphries, G. Some Aspects of the Mechanism of Formation of Smoke from the Combustion of Wood. Energy Fuels 2017, 31, 1935–1944. [Google Scholar] [CrossRef]

- Adamová, T.; Hradecký, J.; Prajer, M. VOC Emissions from Spruce Strands and Hemp Shive: In Search for a Low Emission Raw Material for Bio-Based Construction Materials. Materials 2019, 12, 2026. [Google Scholar] [CrossRef]

- Shen, D.K.; Gu, S.; Bridgwater, A.V. Study on the Pyrolytic Behaviour of Xylan-Based Hemicellulose Using TG–FTIR and Py–GC–FTIR. J. Anal. Appl. Pyrol. 2010, 87, 199–206. [Google Scholar] [CrossRef]

- Peters, J.; Fischer, K.; Fischer, S. Characterization of Emissions from Thermally Modified Wood and Their Reduction by Chemical Treatment. BioResources 2008, 3, 491–502. [Google Scholar] [CrossRef]

- Hyttinen, M.; Masalin-Weijo, M.; Kalliokoski, P.; Pasanen, P. Comparison of VOC Emissions between Air-Dried and Heat-Treated Norway Spruce (Picea Abies), Scots Pine (Pinus Sylvesteris) and European Aspen (Populus Tremula) Wood. Atmos. Environ. 2010, 44, 5028–5033. [Google Scholar] [CrossRef]

- Liang, Y.; Jian, H.; Deng, C.; Xu, J.; Liu, Y.; Park, H.; Wen, M.; Sun, Y. Research and Application of Biomass-Based Wood Flame Retardants: A Review. Polymers 2023, 15, 950. [Google Scholar] [CrossRef] [PubMed]

- McDonald, J.D.; Zielinska, B.; Fujita, E.M.; Sagebiel, J.C.; Chow, J.C.; Watson, J.G. Fine Particle and Gaseous Emission Rates from Residential Wood Combustion. Environ. Sci. Technol. 2000, 34, 2080–2091. [Google Scholar] [CrossRef]

- Sivrikaya, H.; Tesařová, D.; Jeřábková, E.; Can, A. Color Change and Emission of Volatile Organic Compounds from Scots Pine Exposed to Heat and Vacuum-Heat Treatment. J. Build. Eng. 2019, 26, 100918. [Google Scholar] [CrossRef]

| Group | Compound | RT (min) | Temperature (°C) | ||

|---|---|---|---|---|---|

| 150 | 200 | 250 | |||

| Aldehydes | Vanillin | 24.097 | 10.1 | 13.2 | 52.7 |

| Furfural | 6.841 | 0.0 | 0.0 | 306.7 | |

| 2-Furancarboxaldehyde, 5-methyl- | 11.230 | 0.0 | 0.0 | 53.1 | |

| 5-Hydroxymethylfurfural | 19.406 | 0.3 | 0.3 | 20.7 | |

| 5-Acetoxymethyl- 2-furaldehyde | 21.724 | 0.0 | 0.0 | 44.3 | |

| 4-Hydroxy- 2-methoxycinnamaldehyde | 31.938 | 0.3 | 0.0 | 18.7 | |

| 5-Norbornane- 2-carboxaldehyde | 12.783 | 0.0 | 0.0 | 11.4 | |

| 1,2-Dimethoxy- 4-n-propylbenzene | 26.847 | 0.0 | 0.0 | 10.5 | |

| Ketones | 2(5H)-Furanone | 9.472 | 0.0 | 0.0 | 79.9 |

| 4-Methyl-5H-furan-2-one | 11.662 | 0.0 | 0.0 | 31.4 | |

| 2-Furanone, 2,5-dihydro-3,5-dimethyl | 12.460 | 1.5 | 1.1 | 5.1 | |

| 4-Methyl-5H-furan-2-one | 13.797 | 0.0 | 0.0 | 18.6 | |

| 2(3H)-Furanone, 5-acetyldihydro- | 16.483 | 0.6 | 0.4 | 2.7 | |

| 4-Methoxycarbonyl- 4-butanolide | 19.675 | 0.0 | 0.0 | 6.1 | |

| 1-(acetyloxy)-2-Propanone (Acetoxyacetone) | 8.081 | 0.0 | 0.0 | 150.5 | |

| 2-Butanone, 4-(acetyloxy)- | 12.083 | 0.0 | 0.0 | 12.2 | |

| 1,2-Cyclopentanedione, 3-methyl- | 13.236 | 1.4 | 1.4 | 28.9 | |

| Levoglucosenone | 15.997 | 1.0 | 0.9 | 37.7 | |

| 2-Propanone, 1-(4-hydroxy- 3-methoxyphenyl)- | 27.408 | 0.0 | 0.0 | 73.8 | |

| Phenols | Phenol, 2-methyl- | 14.196 | 0.0 | 5.3 | |

| Phenol, 2-methoxy- | 15.286 | 0.0 | 1.3 | 74.8 | |

| Creosol | 18.446 | 0.0 | 0.0 | 108.5 | |

| Phenol, 4-ethyl-2-methoxy- | 20.905 | 0.7 | 0.6 | 60.3 | |

| 2-Methoxy-4-vinylphenol | 21.854 | 0.0 | 0.0 | 42.3 | |

| Eugenol | 23.040 | 0.4 | 0.4 | 73.5 | |

| Phenol, 2-methoxy-4-propyl- | 23.288 | 0.0 | 0.0 | 21.2 | |

| trans-Isoeugenol | 24.345 | 0.0 | 0.3 | 25.2 | |

| Phenol, 2-methoxy-4-propyl- | 25.629 | 0.0 | 0.0 | 21.2 | |

| (Z)-4-(But-1-en-1-yl)guaiacol | 26.082 | 0.0 | 0.0 | 4.2 | |

| Apocynin | 26.286 | 0.0 | 0.0 | 38.3 | |

| (E)-4-(But-1-en-1-yl)guaiacol | 27.764 | 0.3 | 0.7 | 4.3 | |

| 4-(1-Hydroxyallyl)- 2-methoxyphenol | 28.422 | 0.0 | 0.0 | 31.7 | |

| Phenol, 2-methoxy- 4-(1-propenyl)-, Acetate | 29.360 | 0.0 | 0.0 | 5.4 | |

| Alcohols | 3-Pyridinol | 14.488 | 1.2 | 0.8 | 7.1 |

| Orcinol | 14.887 | 0.0 | 0.3 | 11.2 | |

| Benzenepropanol, 4-hydroxy-3-methoxy- | 30.072 | 0.0 | 0.3 | 1.6 | |

| 2-furanmethanol (Furfuryl alcohol) | 7.617 | 0.0 | 0.0 | 132.9 | |

| Aliphatic | Undecane | 15.652 | 5.2 | 3.6 | 4.9 |

| Heptane, 4-ethyl- | 18.607 | 0.0 | 0.3 | 19.4 | |

| Tridecane | 21.465 | 1.4 | 1.4 | 0.0 | |

| Hexadecane | 28.961 | 5.0 | 7.8 | 15.6 | |

| Heptadecane | 33.329 | 0.8 | 1.5 | 7.4 | |

| Oktadecane | 37.126 | 0.4 | 0.4 | 6.4 | |

| Esters | Benzoic acid, 4-hydroxy- 3-methoxy-, methyl ester | 27.052 | 0.0 | 0.0 | 15.4 |

| Benzeneacetic acid, 4-hydroxy-3-methoxy-, methyl ester | 28.594 | 0.0 | 0.0 | 5.5 | |

| Ethyl-.beta.-(4-hydroxy-3-methoxy-phenyl)propionate | 32.790 | 0.0 | 0.0 | 18.0 | |

| 7-Oxodehydroabietic acid, methyl ester | 42.475 | 0.0 | 0.0 | 15.7 | |

| 1-Phenanthrenecarboxylic acid,1,2,3,4,4a,10a-hexahydro-1,4a-dimethyl-7-(1-methyl ethyl)-,methyl ester, [1R-(1.alpha.,4a.beta.,10a.alpha.)]- | 40.534 | 0.0 | 0.0 | 8.1 | |

| Terpenes | α-Pinene | 10.173 | 13.0 | 18.8 | 26.6 |

| β-Pinene | 11.597 | 2.5 | 6.0 | 0.0 | |

| Δ3-carene | 12.729 | 3.1 | 0.0 | 0.0 | |

| Acids | Phenylacetylformic acid, 4-hydroxy-3-methoxy- | 31.140 | 0.0 | 0.0 | 10.6 |

| Methyl dehydroabietate | 40.577 | 0.0 | 1.5 | 23.0 | |

| Furans | Furane, 2,5-dihydro-2,5-dimethoxy- | 20.312 | 0.5 | 0.4 | 2.7 |

| Group | Compound | RT (min) | Temperature (°C) | ||

|---|---|---|---|---|---|

| 150 | 200 | 250 | |||

| Aldehydes | Furfural | 6.827 | 0.00 | 31.04 | 391.10 |

| Ketones | Levoglucosenone | 16.016 | 0.37 | 0.99 | 5.86 |

| 4-Hexen-3-one | 23.504 | 0.00 | 0.26 | 6.86 | |

| Terpenes | α-pinene | 10.184 | 0.00 | 5.27 | 9.68 |

| Aliphatic | Undecane | 15.649 | 0.43 | 2.41 | 3.81 |

| Dodecane | 18.658 | 1.52 | 3.67 | 3.99 | |

| 4-Methyl-2-hexene, c&t | 22.986 | 0.00 | 0.42 | 7.05 | |

| Tetradecane | 24.105 | 1.96 | 13.95 | 6.35 | |

| Hexadecane | 28.958 | 0.89 | 12.13 | 2.07 | |

| Group | Compound | RT (min) | Temperature (°C) | ||

|---|---|---|---|---|---|

| 150 | 200 | 250 | |||

| Aliphatic | Dodecane | 18.658 | 1.6 | 1.7 | 3.8 |

| Tetradecane | 24.105 | 1.8 | 1.6 | 5.3 | |

| Hexadecane | 28.958 | 0.6 | 0.6 | 1.4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trojanová, K.; Veľková, V.; Kačík, F. Volatile Organic Compounds Arising from Wood Polymers on Thermal Loading of Spruce Wood. Polymers 2025, 17, 875. https://doi.org/10.3390/polym17070875

Trojanová K, Veľková V, Kačík F. Volatile Organic Compounds Arising from Wood Polymers on Thermal Loading of Spruce Wood. Polymers. 2025; 17(7):875. https://doi.org/10.3390/polym17070875

Chicago/Turabian StyleTrojanová, Katarína, Veronika Veľková, and František Kačík. 2025. "Volatile Organic Compounds Arising from Wood Polymers on Thermal Loading of Spruce Wood" Polymers 17, no. 7: 875. https://doi.org/10.3390/polym17070875

APA StyleTrojanová, K., Veľková, V., & Kačík, F. (2025). Volatile Organic Compounds Arising from Wood Polymers on Thermal Loading of Spruce Wood. Polymers, 17(7), 875. https://doi.org/10.3390/polym17070875