Enhancing Mechanical and Impact Properties of Flax/Glass and Jute/Glass Hybrid Composites Through KOH Alkaline Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Alkaline Treatment of Natural Fabrics/Reinforcements

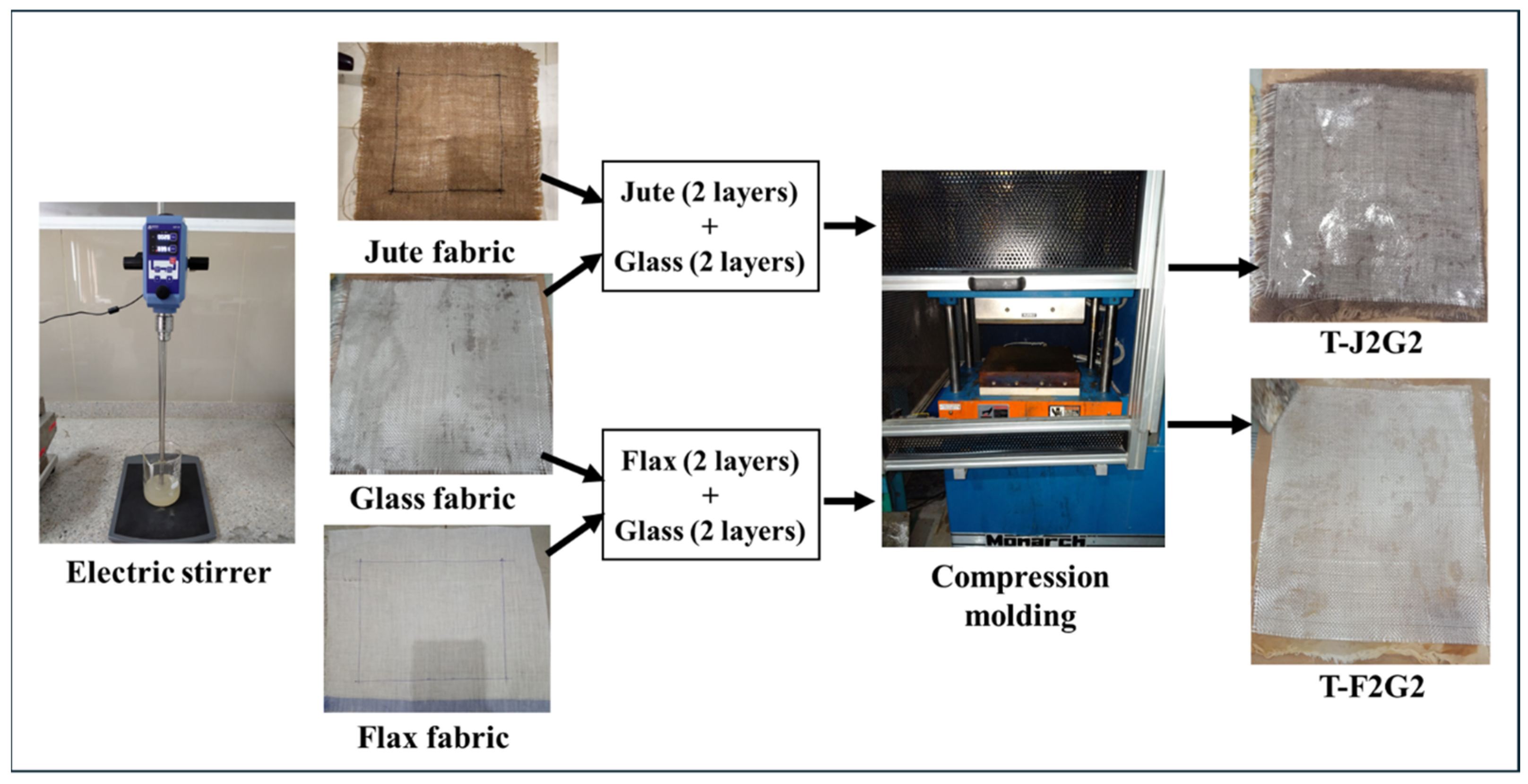

2.3. Fabrication of Hybrid Composites

2.4. Characterisation of Fabrics/Reinforcements

2.4.1. Fourier Transform Infrared Spectroscopy (FTIR)

2.4.2. Mechanical Testing and Characterisation

2.5. Evaluation and Testing of Composites

2.5.1. Tensile Testing

2.5.2. Flexural Testing

2.5.3. Impact Testing

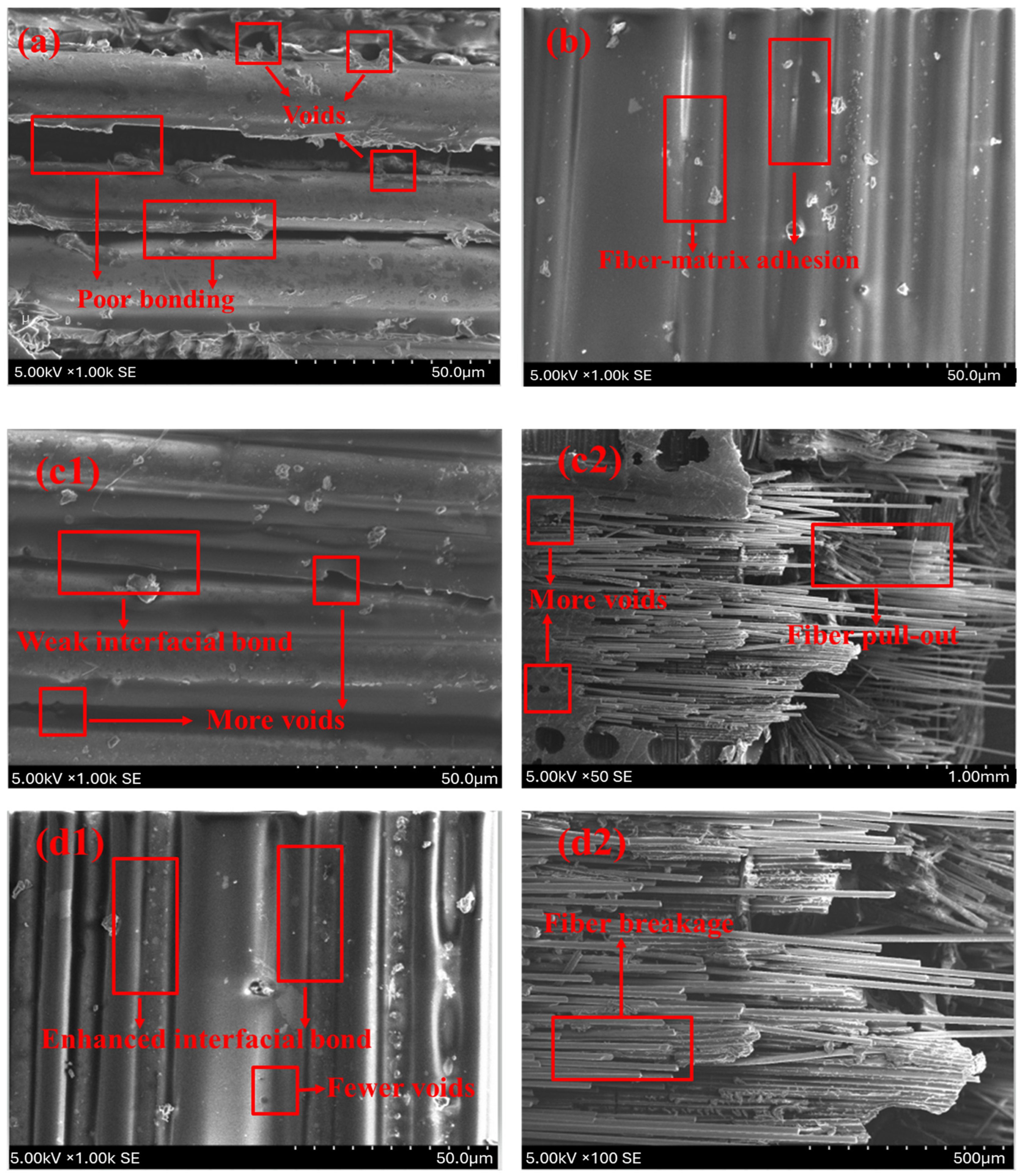

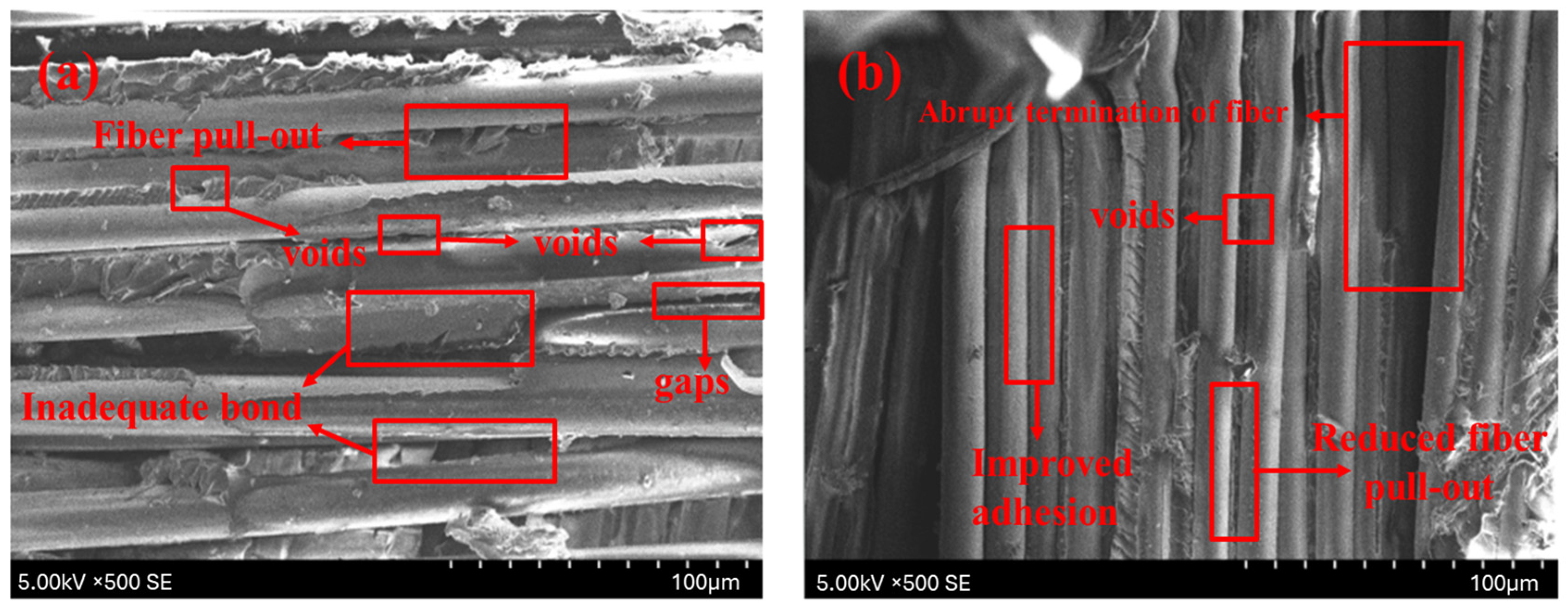

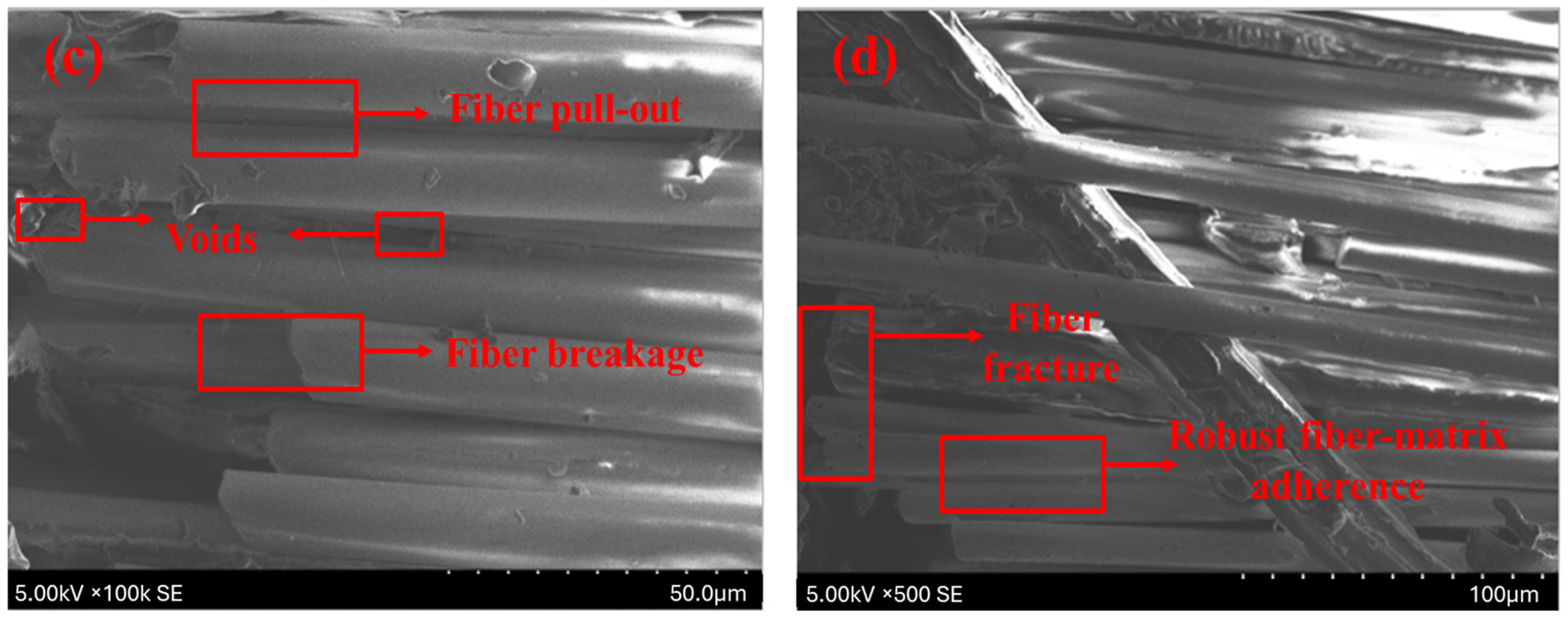

2.5.4. Scanning Electron Microscopy (SEM)

3. Results and Discussions

3.1. Characterisation of Composite Preform

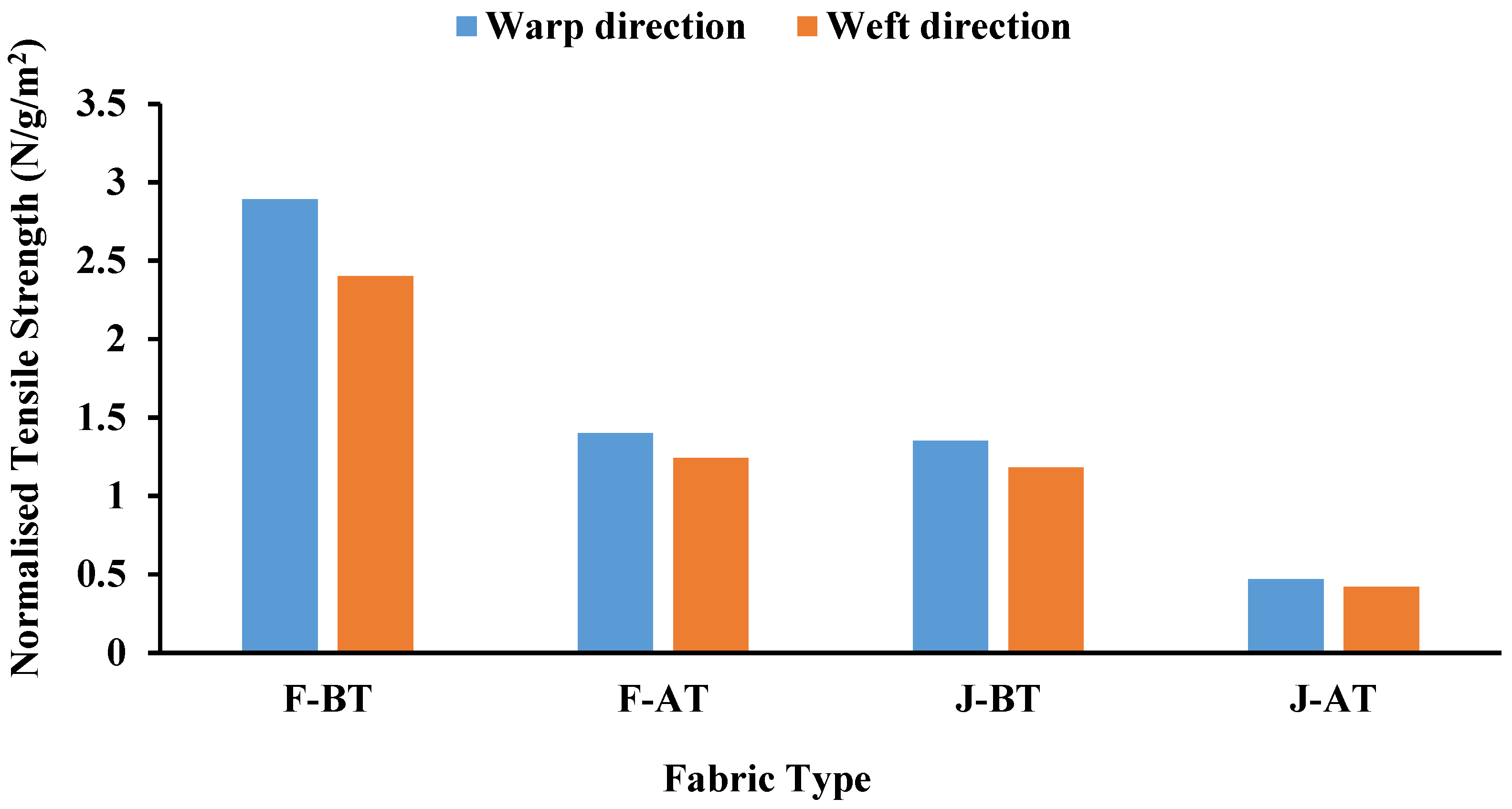

3.1.1. Physical and Tensile Properties of Flax and Jute Fabrics

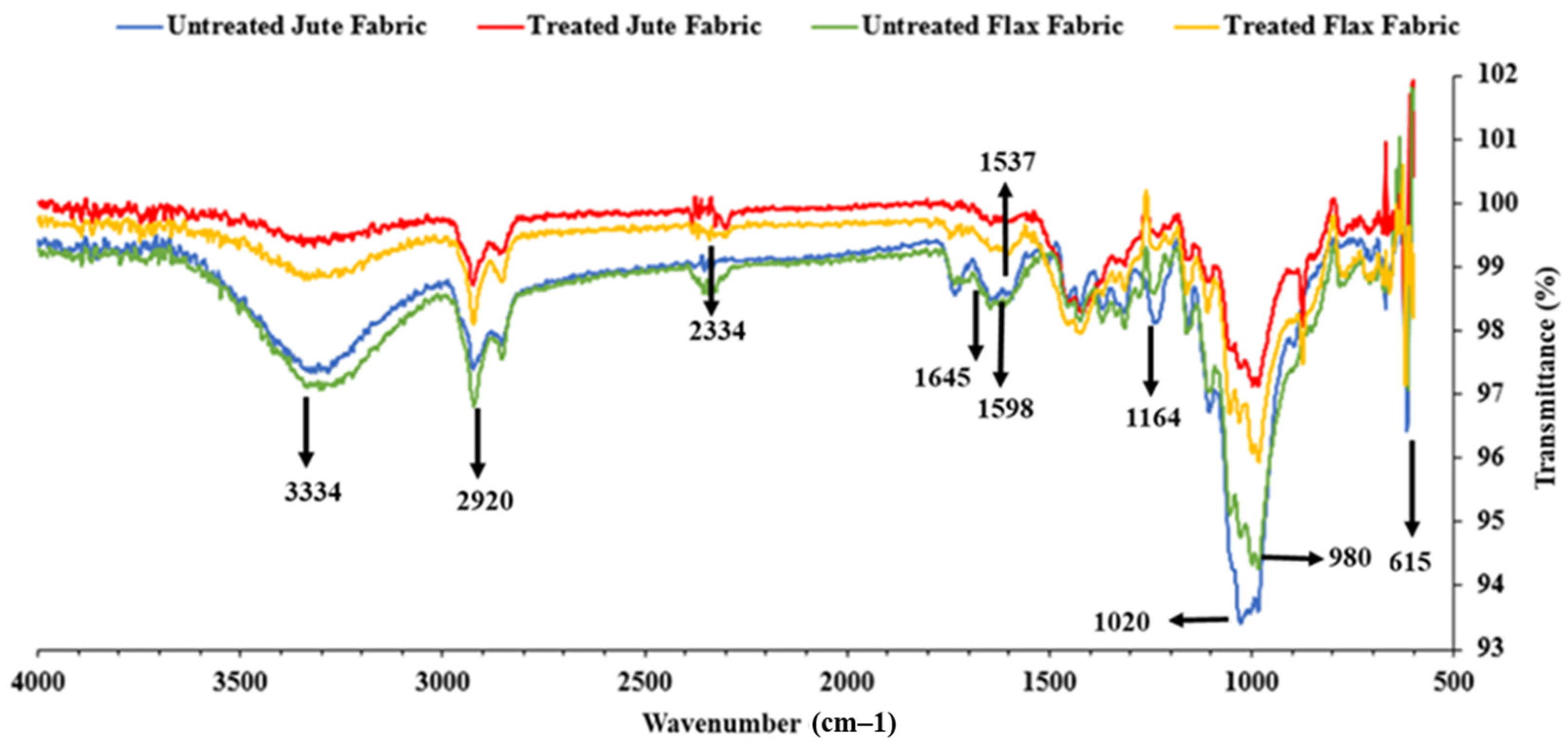

3.1.2. FTIR Analysis

3.2. Characterisation of Composites

3.2.1. Tensile Properties

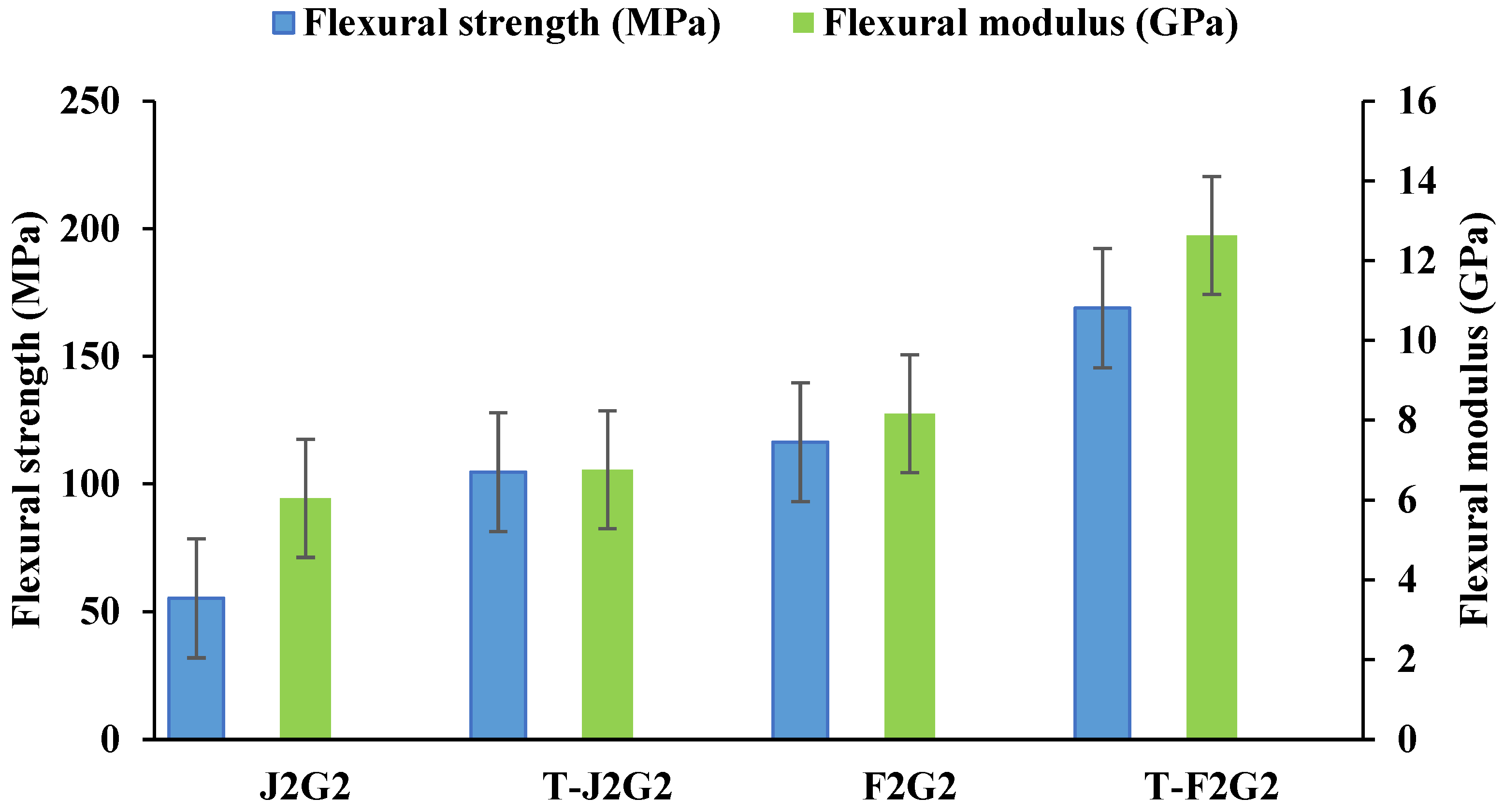

3.2.2. Flexural Properties

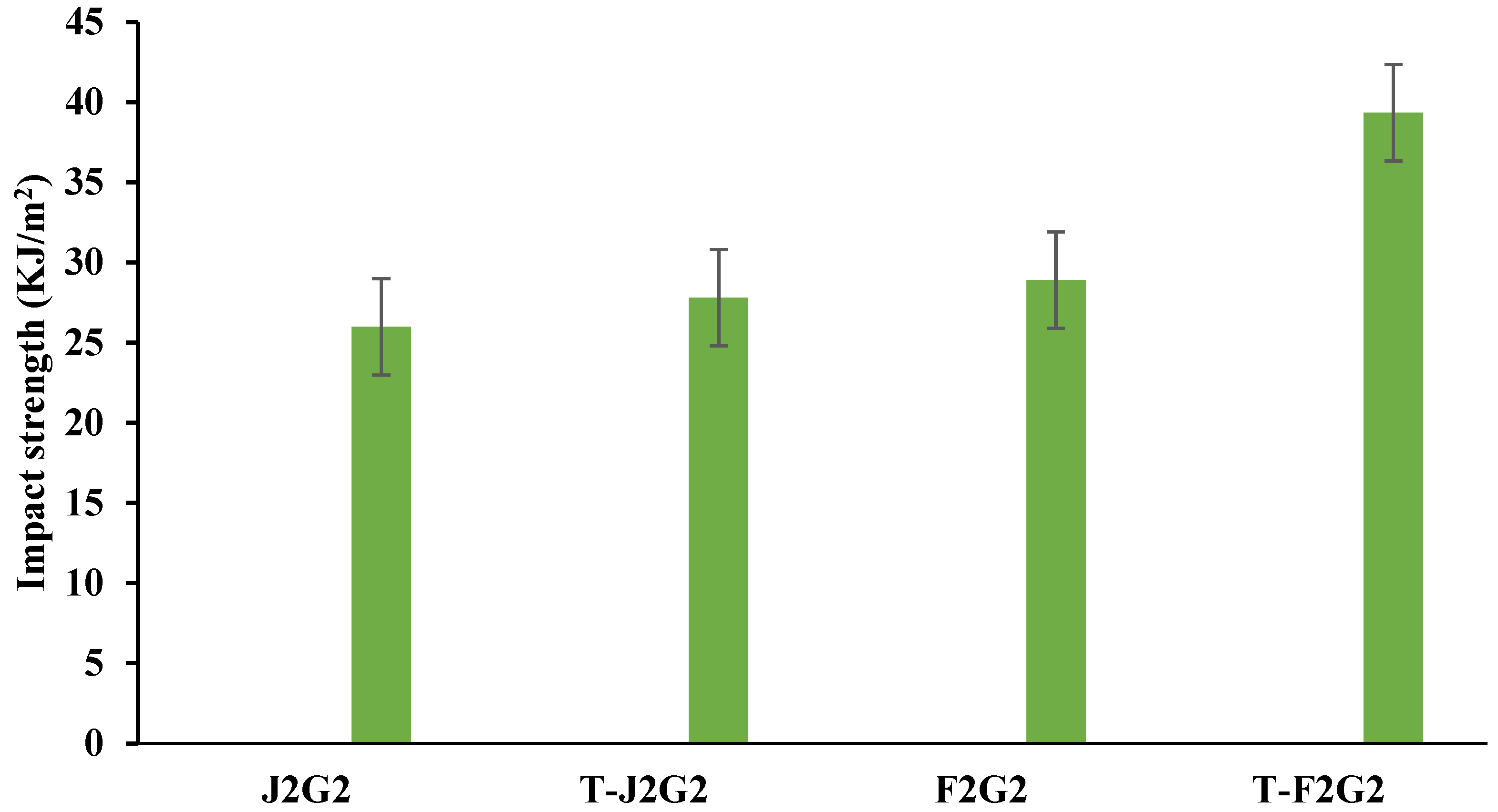

3.2.3. Impact Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gholampour, A.; Ozbakkaloglu, T. A Review of Natural Fiber Composites: Properties, Modification and Processing Techniques, Characterization, Applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Basri, M.S.M.; Rayung, M.; Abu, F.; Ahmad, S.; Norizan, M.N.; Osman, S.; Sarifuddin, N.; Desa, M.S.Z.M.; Abdullah, U.H.; et al. A Review on Natural Fiber Reinforced Polymer Composites (NFRPC) for Sustainable Industrial Applications. Polymers 2022, 14, 3698. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Duan, Y.; An, H.; Wang, X.; Liang, S.; Li, N. Research Progress and Application of Natural Fiber Composites. J. Nat. Fibers 2023, 20, 2206591. [Google Scholar] [CrossRef]

- Ono, H.; Tanaka, S.; Tamura, M.; Yoshida, M.; Inagaki, S. Synthesis of Poly[(R)3HB], Poly[(S)3HB], and Poly[(R)3HB-co-(S)3HB] by Phosphazene Base-Catalyzed Ring-Opening Polymerization of β-Butyrolactone Enantiomers Derived from (R)-Methyl 3-Hydroxybutyrate. J. Polym. Environ. 2024, 33, 1–11. [Google Scholar] [CrossRef]

- Nagaraja, S.; Anand, P.B.; Mohan Kumar, K.; Ammarullah, M.I. Synergistic Advances in Natural Fibre Composites: A Comprehensive Review of the Eco-Friendly Bio-Composite Development, Its Characterization and Diverse Applications. RSC Adv. 2024, 14, 17594–17611. [Google Scholar] [CrossRef]

- Adekunle, K.F. Surface Treatments of Natural Fibres—A Review: Part 1. Open J. Polym. Chem. 2015, 05, 41–46. [Google Scholar] [CrossRef]

- Seisa, K.; Chinnasamy, V.; Ude, A.U. Surface Treatments of Natural Fibres in Fibre Reinforced Composites: A Review. Fibres Text. East. Eur. 2022, 30, 82–89. [Google Scholar] [CrossRef]

- Verma, D.; Goh, K.L. Effect of Mercerization/Alkali Surface Treatment of Natural Fibres and Their Utilization in Polymer Composites: Mechanical and Morphological Studies. J. Compos. Sci. 2021, 5, 175. [Google Scholar] [CrossRef]

- Amiandamhen, S.O.; Meincken, M.; Tyhoda, L. Natural Fibre Modification and Its Influence on Fibre-Matrix Interfacial Properties in Biocomposite Materials. Fibers Polym. 2020, 21, 677–689. [Google Scholar] [CrossRef]

- Neto, J.; Queiroz, H.; Aguiar, R.; Lima, R.; Cavalcanti, D.; Banea, M.D. A Review of Recent Advances in Hybrid Natural Fiber Reinforced Polymer Composites. J. Renew. Mater. 2022, 10, 561–589. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Reddy, B.M.; Reddy, B.C.M.; Kumar, A.K.; Kumar, G.S.; Reddy, R.M.; Sankaraiah, G. Mechanical and Water Absorption Characterization of Jute/Flax/Polyester Hybrid Composite for Indoor and Outdoor Applications. J. Polym. Res. 2024, 31, 351. [Google Scholar] [CrossRef]

- Jawalkar, C.S.; Kant, S. Critical Review on Chemical Treatment of Natural Fibers to Enhance Mechanical Properties of Bio Composites. Silicon 2021, 14, 5103–5124. [Google Scholar] [CrossRef]

- Amin, M.N.; Ahmad, W.; Khan, K.; Ahmad, A. A Comprehensive Review of Types, Properties, Treatment Methods and Application of Plant Fibers in Construction and Building Materials. Materials 2022, 15, 4362. [Google Scholar] [CrossRef]

- Monaco, C.; Arena, A.; Scotti, R.; Krejci, I. Fracture Strength of Endodontically Treated Teeth Restored with Composite Overlays with and without Glass-fiber Reinforcement. J. Adhes. Dent. 2016, 18, 143–149. [Google Scholar] [CrossRef]

- Wu, Y.; Xia, C.; Cai, L.; Garcia, A.C.; Shi, S.Q. Development of Natural Fiber-Reinforced Composite with Comparable Mechanical Properties and Reduced Energy Consumption and Environmental Impacts for Replacing Automotive Glass-Fiber Sheet Molding Compound. J. Clean. Prod. 2018, 184, 92–100. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S. Cellulose synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Sreekumar, P.; Thomas, S.P.; Saiter, J.M.; Joseph, K.; Unnikrishnan, G.; Thomas, S. Effect of fiber surface modification on the mechanical and water absorption characteristics of sisal/polyester composites fabricated by resin transfer molding. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1777–1784. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C. Combined effects of sustained bending loading, water immersion and fiber hybrid mode on the mechanical properties of carbon/glass fiber reinforced polymer composite. Compos. Struct. 2022, 281, 115060. [Google Scholar] [CrossRef]

- Gupta, M.K.; Ramesh, M.; Thomas, S. Effect of hybridization on properties of natural and synthetic fiber-reinforced polymer composites (2001–2020): A review. Polym. Compos. 2021, 42, 4981–5010. [Google Scholar] [CrossRef]

- Barjasteh, E.; Nutt, S. Moisture absorption of unidirectional hybrid composites. Compos. Part A Appl. Sci. Manuf. 2011, 43, 158–164. [Google Scholar] [CrossRef]

- Mohapatra, D.K.; Ranjan Deo, C.; Mishra, P. Investigation of glass fiber influence on me-chanical characteristics of natural fiber reinforced polyester composites: An ex-perimental and numerical approach. Compos. Theory Pract. 2022, 22, 123–129. [Google Scholar]

- Sahu, P.; Gupta, M. A Review on the Properties of Natural Fibres and Its Bio-Composites: Effect of Alkali Treatment. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 234, 198–217. [Google Scholar] [CrossRef]

- Santhosh, N.; Praveena, B.A.; Gowda, A.C.; Duhduh, A.A.; Rajhi, A.A.; Alamri, S.; Berwal, P.; Khan, M.A.; Wodajo, A.W. Innovative Eco-Friendly Bio-Composites: A Comprehensive Review of the Fabrication, Characterization, and Applications. Rev. Adv. Mater. Sci. 2024, 63, 20240057. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Jawaid, M. A Review on the Characterisation of Natural Fibres and Their Composites after Alkali Treatment and Water Absorption. Plast. Rubber Compos. 2017, 46, 119–136. [Google Scholar] [CrossRef]

- Genc, G.; Ozdemir, Y. Improvement of the Mechanical Properties of Plant Fiber-Reinforced Composites through Hybridization. J. Nat. Fibers 2022, 19, 2805–2812. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Yogesha, B. Studies on natural/glass fiber reinforced polymer hybrid composites: An Evolution. Mater. Today Proc. 2017, 4, 2739–2747. [Google Scholar] [CrossRef]

- Umashankaran, M.; Gopalakrishnan, S. Effect of Sodium Hydroxide Treatment on Physico-chemical, Thermal and Tensile, and Surface Morphological Properties of Pongamia pinnata L. Bark Fiber. J. Nat. Fibers 2021, 18, 2063–2076. [Google Scholar] [CrossRef]

- Bekele, A.E.; Lemu, H.G.; Jiru, M.G. Study of the Effects of Alkali Treatment and Fiber Orientation on Mechanical Properties of Enset/Sisal Polymer Hybrid Composite. J. Compos. Sci. 2023, 7, 37. [Google Scholar] [CrossRef]

- Gassan, J.; Bledzki, A.K. Possibilities of improving the mechanical properties of jute/epoxy composites by alkali treatment of fibers. Compos. Sci. Technol. 1999, 59, 1303–1309. [Google Scholar] [CrossRef]

- Ahmad, J.; González-Lezcano, R.A.; Majdi, A.; Ben Kahla, N.; Deifalla, A.F.; El-Shorbagy, M.A. Glass Fibers Reinforced Concrete: Overview on Mechanical, Durability and Microstructure Analysis. Materials 2022, 15, 5111. [Google Scholar] [CrossRef] [PubMed]

- Mukhopadhyay, S.; Fangueiro, R. Physical Modification of Natural Fibers and Thermoplastic Films for Composites—A Review. J. Thermoplast. Compos. Mater. 2009, 22, 135–162. [Google Scholar] [CrossRef]

- Kumar Acharya, S.; Mishra, P.; Kumar Mehar, S. Composites with Bagasse. BioResources 2011, 6, 3155–3165. [Google Scholar]

- Swain, P.T.R.; Biswas, S. A Comparative Analysis of Physico-Mechanical, Water Absorption, and Morphological Behaviour of Surface Modified Woven Jute Fiber Composites. Polym. Compos. 2018, 39, 2952–2960. [Google Scholar] [CrossRef]

- Basak, R.; Gohil, P.; Dey, S. Analyzing and Improvising KOH-Treated Jute Fibre Composites for the Medical Equipment. Fibers Polym. 2023, 24, 2867–2876. [Google Scholar] [CrossRef]

- Wantahe, E.; Kindole, C.F.; Bigambo, P. Effect of Chemical Treatment on the Physicochemical and Mechanical Properties of Sansevieria ehrenbergii (SE) Leaf Fibers and Their Utilization in Textiles. J. Nat. Fibers 2024, 21, 2407896. [Google Scholar] [CrossRef]

- Wang, H.; Memon, H.; Hassan, E.A.M.; Miah, S.; Ali, A. Effect of Jute Fiber Modification on Mechanical Properties of Jute Fiber Composite. Materials 2019, 12, 1226. [Google Scholar] [CrossRef]

- Chen, J.-H.; Xu, J.-K.; Huang, P.-L.; Sun, R.-C. Effect of Alkaline Pretreatment on the Preparation of Regenerated Lignocellulose Fibers from Bamboo Stem. Cellulose 2016, 23, 2727–2739. [Google Scholar] [CrossRef]

- Xia, X.; Liu, W.; Zhou, L.; Hua, Z.; Liu, H.; He, S. Modification of Flax Fiber Surface and Its Compatibilization in Polylactic Acid/Flax Composites. Iran. Polym. J. 2015, 25, 25–35. [Google Scholar] [CrossRef]

- Khusairy Bin Bakri, M.; Jayamani, E.; Hamdan, S.; Rahman, R.; Soon, K.; Kakar, A. Fundamental study on the effect of alkaline treatment on natural fibers structures and behaviors. J. Eng. Appl. Sci. Engl. Ed. 2016, 11, 8759–8763. [Google Scholar]

- Shadhin, M.; Jayaraman, R.; Rahman, M.; Mann, D. Effect of Fiber Surface Treatment on Mechanical, Interfacial, and Moisture Absorption Properties of Cattail Fiber-Reinforced Composites. J. Appl. Polym. Sci. 2024, 141, e54765. [Google Scholar] [CrossRef]

- Gomes, A.; Matsuo, T.; Goda, K.; Ohgi, J. Development and Effect of Alkali Treatment on Tensile Properties of Curaua Fiber Green Composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1811–1820. [Google Scholar] [CrossRef]

- Kumar, S.; Dang, R.; Manna, A.; Dhiman, N.K.; Sharma, S.; Dwivedi, S.P.; Kumar, A.; Li, C.; Tag-Eldin, E.M.; Abbas, M. Optimization of Chemical Treatment Process Parameters for Enhancement of Mechanical Properties of Kenaf Fiber-Reinforced Polylactic Acid Composites: A Comparative Study of Mechanical, Morphological and Microstructural Analysis. J. Mater. Res. Technol. 2023, 26, 8366–8387. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Saba, N.; Chandrasekar, M.; Jawaid, M.; Rajini, N.; Siengchin, S.; Ayrilmis, N.; Mohammad, F.; Al-Lohedan, H.A. Compressive, Dynamic and Thermo-Mechanical Properties of Cellulosic Pineapple Leaf Fibre/Polyester Composites: Influence of Alkali Treatment on Adhesion. Int. J. Adhes. Adhes. 2021, 106, 102823. [Google Scholar] [CrossRef]

- Zhang, Q.; Ma, Y.; Qi, Z.; Song, W.; Li, L.; Chen, Z. Effect of Alkali Modification on the Powder Flowability of Rapeseed Straw Cellulose Fibers. J. Nat. Fibers 2023, 20, 2151546. [Google Scholar] [CrossRef]

- Gapsari, F.; Wijatmiko, I.; Andoko, A.; Diharjo, K.; Rangappa, S.M.; Siengchin, S. Modification on Fiber from Alkali Treatment and AESO Coating to Enhance UV-Light and Water Absorption Resistance in Kapok Fiber Reinforced Polyester Composites. J. Nat. Fibers 2024, 21, 2383970. [Google Scholar] [CrossRef]

- Scheibe, M.; Urbaniak, M.; Kukulka, W.; Bledzki, A. Application of Natural (Plant) Fibers Particularly Hemp Fiber as Reinforcement in Hybrid Polymer Composites—Part III. Investigations of Physical and Mechanical Properties of Composites Reinforced with Hemp Fibers. J. Nat. Fibers 2024, 21, 2414194. [Google Scholar] [CrossRef]

- Kim, J.T.; Netravali, A.N. Fabrication of Advanced “Green” Composites Using Potassium Hydroxide (KOH) Treated Liquid Crystalline (LC) Cellulose Fibers. J. Mater. Sci. 2013, 48, 3950–3957. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. The Effect of Alkaline Treatment on Mechanical Properties of Kenaf Fibers and Their Epoxy Composites. Compos. Part B Eng. 2015, 68, 14–21. [Google Scholar] [CrossRef]

- Haris, N.I.N.; Hassan, M.Z.; Ilyas, R.; Suhot, M.A.; Sapuan, S.; Dolah, R.; Mohammad, R.; Asyraf, M. Dynamic Mechanical Properties of Natural Fiber Reinforced Hybrid Polymer Composites: A Review. J. Mater. Res. Technol. 2022, 19, 167–182. [Google Scholar] [CrossRef]

- Narayana, V.L.; Rao, L.B. A Brief Review on the Effect of Alkali Treatment on Mechanical Properties of Various Natural Fiber Reinforced Polymer Composites. Mater. Today Proc. 2021, 44, 1988–1994. [Google Scholar] [CrossRef]

- Pokhriyal, M.; Rakesh, P.K.; Rangappa, S.M.; Siengchin, S. Effect of Alkali Treatment on Novel Natural Fiber Extracted from Himalayacalamus Falconeri Culms for Polymer Composite Applications. Biomass-Convers. Biorefinery 2023, 14, 18481–18497. [Google Scholar] [CrossRef]

- Bhagat, M.S.; Jadhav, V.D.; Kulkarni, S.K.; Satishkumar, P.; Saminathan, R. Comparative Analysis of Alkali-Treated Natural Fibres for Improved Interfacial Adhesion in Composite Materials. Interactions 2024, 245, 206. [Google Scholar] [CrossRef]

| Properties/Features | Value |

|---|---|

| Fiber density | 1.45 ± 0.02 g/cm3 |

| Areal density | 204 g/m2 |

| Elongation at break | 1.3% |

| Water content 1 | 5–7% |

| Apparent modulus | 58 ± 2 GPa |

| Properties/Features | Value |

|---|---|

| Fiber density | 1.45 ± 0.03 g/cm3 |

| Areal density | 233 g/m2 |

| Elongation at break | 1.5–2.0% |

| Water content 1 | 8–10% |

| Apparent modulus | 30 ± 2 GPa |

| Properties/Features | Value |

|---|---|

| Fiber density | 2.54 ± 0.02 g/cm3 |

| Areal density | 200 g/m2 |

| Elongation at break | 2.5% |

| Water content | 0% |

| Apparent modulus | 70 ± 2 GPa |

| Properties/Features | Value |

|---|---|

| Density | 1.2 g/cm3 |

| Tensile strength | 85–90 MPa |

| Tensile modulus | 2.8–3.2 GPa |

| Tensile elongation at break | 4.5–5.5 |

| Flexural strength | 120–130 MPa |

| Flexural modulus | 2.9–3.5 |

| Glass transition temperature | 120–130 °C |

| Sample Code | Reinforcement | Reinforcement Treatment |

|---|---|---|

| J2G2 | 2 layers of jute, 2 layers of glass (J/G/J/G [0/90/90/0]) | No treatment |

| F2G2 | 2 layers of flax, 2 layers of glass (F/G/F/G [0/90/90/0]) | No treatment |

| T-J2G2 | 2 layers of jute, 2 layers of glass (J/G/J/G [0/90/90/0]) | Alkaline with KOH |

| T-F2G2 | 2 layers of flax, 2 layers of glass (F/G/F/G [0/90/90/0]) | Alkaline with KOH |

| Sample Code | Yarn Count (Warp) | Yarn Count (Weft) | Ends/Inch | Picks/Inch | Areal Density (g/m2) | Tensile Strength (Warp) (N) | Tensile Strength (Weft) (N) | Shrinkage (Warp) (%) | Shrinkage (Weft) (%) |

|---|---|---|---|---|---|---|---|---|---|

| F-BT | 12.15 | 18.41 | 52.5 | 51.5 | 204 | 588.6 | 490.5 | 4.43 | 3.04 |

| F-AT | ___ | ___ | 62 | 58 | 210 | 294.3 | 259.97 | 0.55 | 0.45 |

| J-BT | 1.91 | 1.81 | 9 | 9 | 233 | 313.92 | 274.68 | 5.00 | 2.14 |

| J-AT | ___ | ___ | 12 | 10 | 315 | 147.15 | 132.44 | 0.35 | 0.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ullah, S.; Palevicius, A.; Janusas, G.; Ul-Hasan, Z. Enhancing Mechanical and Impact Properties of Flax/Glass and Jute/Glass Hybrid Composites Through KOH Alkaline Treatment. Polymers 2025, 17, 804. https://doi.org/10.3390/polym17060804

Ullah S, Palevicius A, Janusas G, Ul-Hasan Z. Enhancing Mechanical and Impact Properties of Flax/Glass and Jute/Glass Hybrid Composites Through KOH Alkaline Treatment. Polymers. 2025; 17(6):804. https://doi.org/10.3390/polym17060804

Chicago/Turabian StyleUllah, Sultan, Arvydas Palevicius, Giedrius Janusas, and Zeeshan Ul-Hasan. 2025. "Enhancing Mechanical and Impact Properties of Flax/Glass and Jute/Glass Hybrid Composites Through KOH Alkaline Treatment" Polymers 17, no. 6: 804. https://doi.org/10.3390/polym17060804

APA StyleUllah, S., Palevicius, A., Janusas, G., & Ul-Hasan, Z. (2025). Enhancing Mechanical and Impact Properties of Flax/Glass and Jute/Glass Hybrid Composites Through KOH Alkaline Treatment. Polymers, 17(6), 804. https://doi.org/10.3390/polym17060804