Study on Low-Temperature Cracking Resistance of Carbon Fibre Geogrid Reinforced Asphalt Mixtures Based on Statistical Methods

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Geosynthetics

2.1.2. Asphalt

2.1.3. Surface Combined Body (SCB)

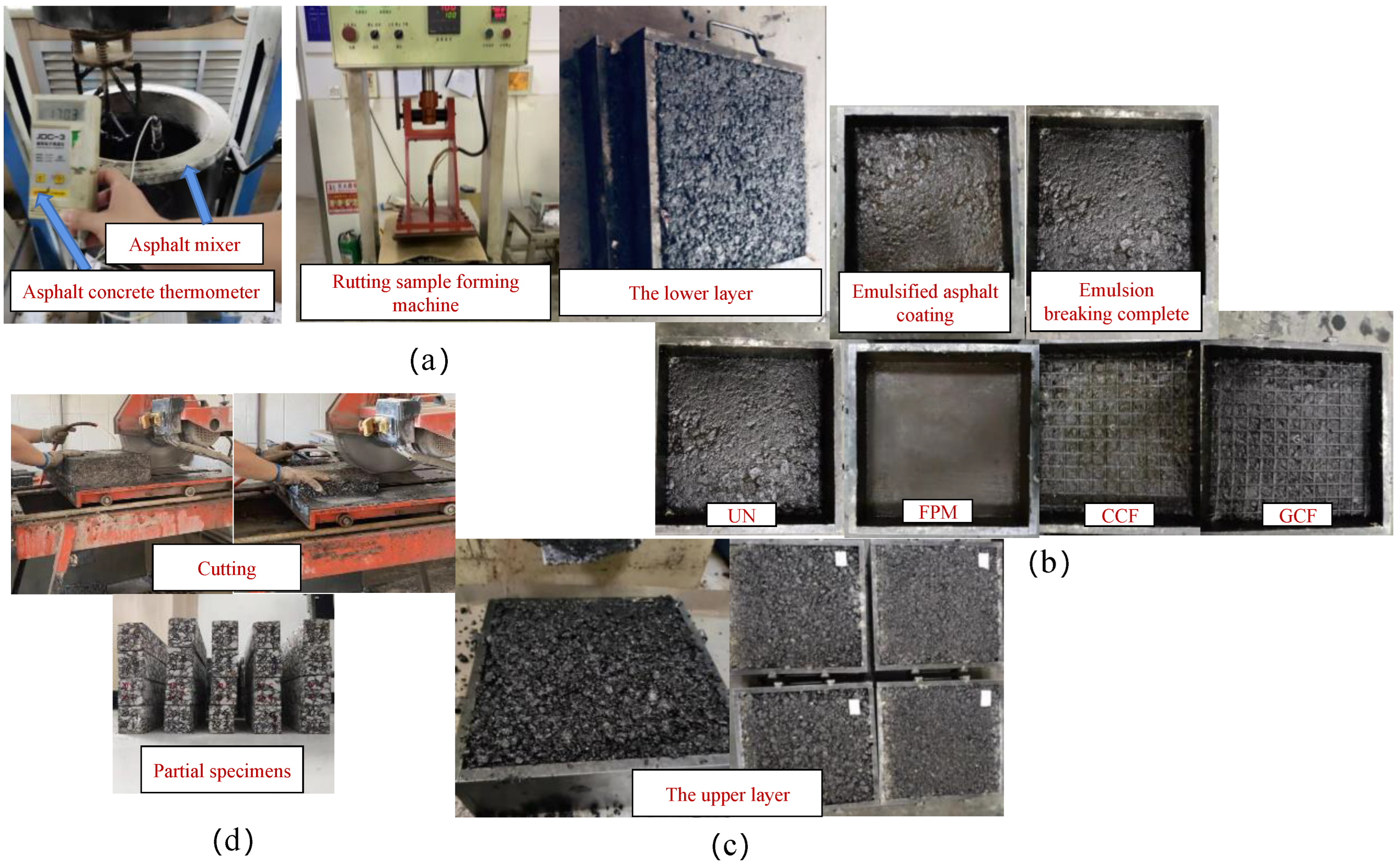

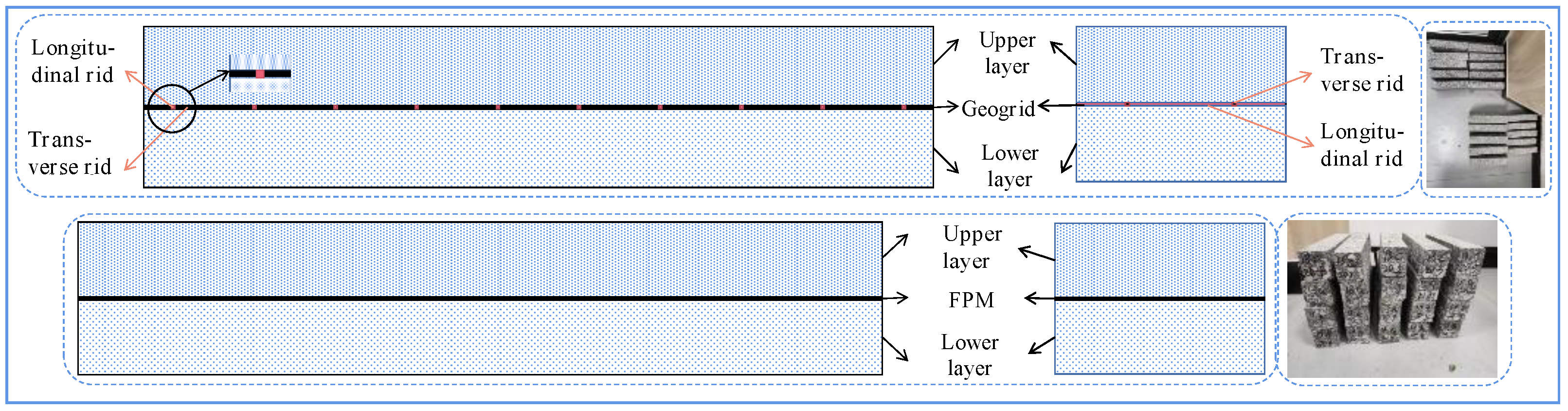

2.2. Specimen Preparation

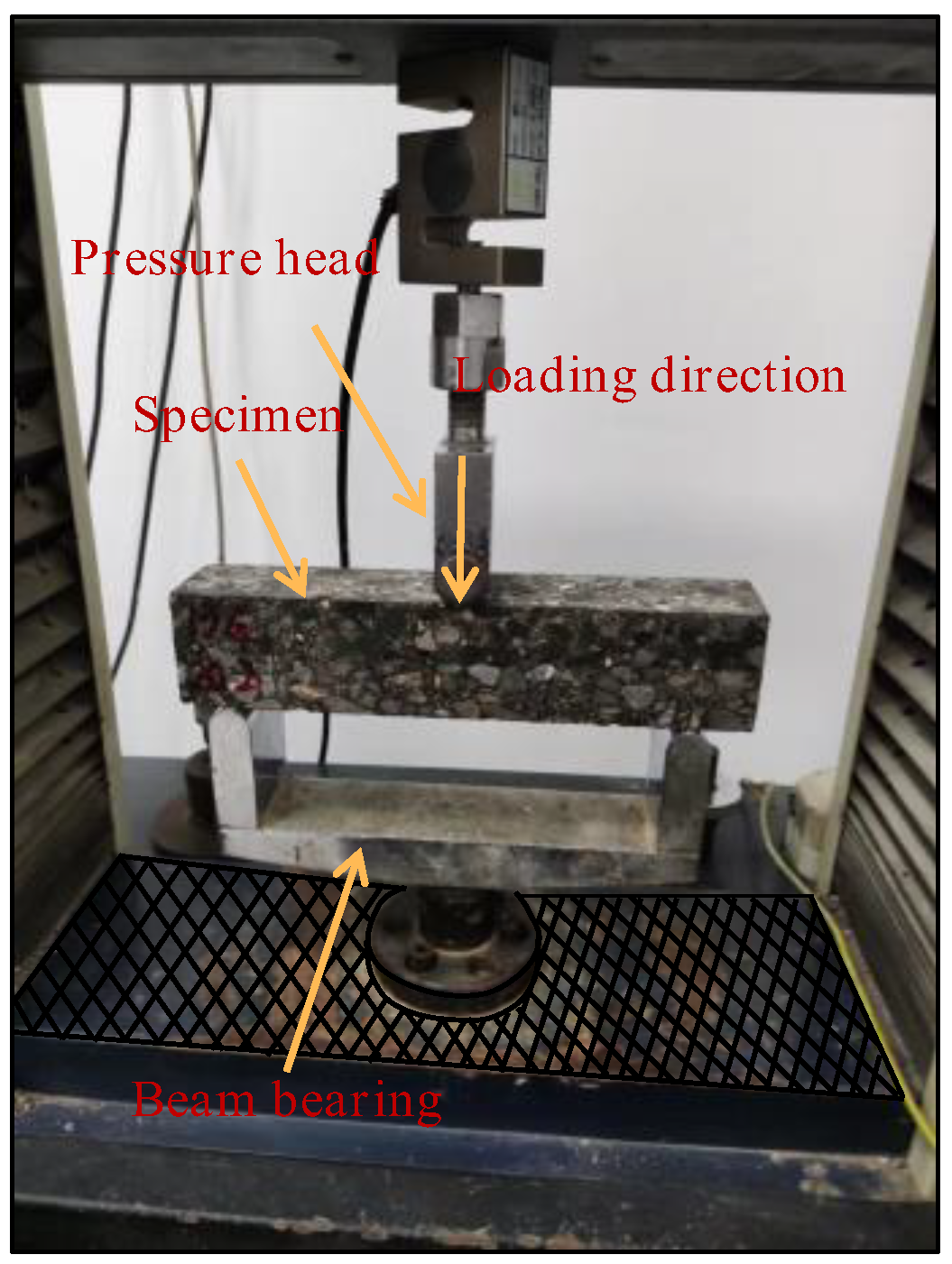

2.3. Low-Temperature Bending Damage Test

3. Results

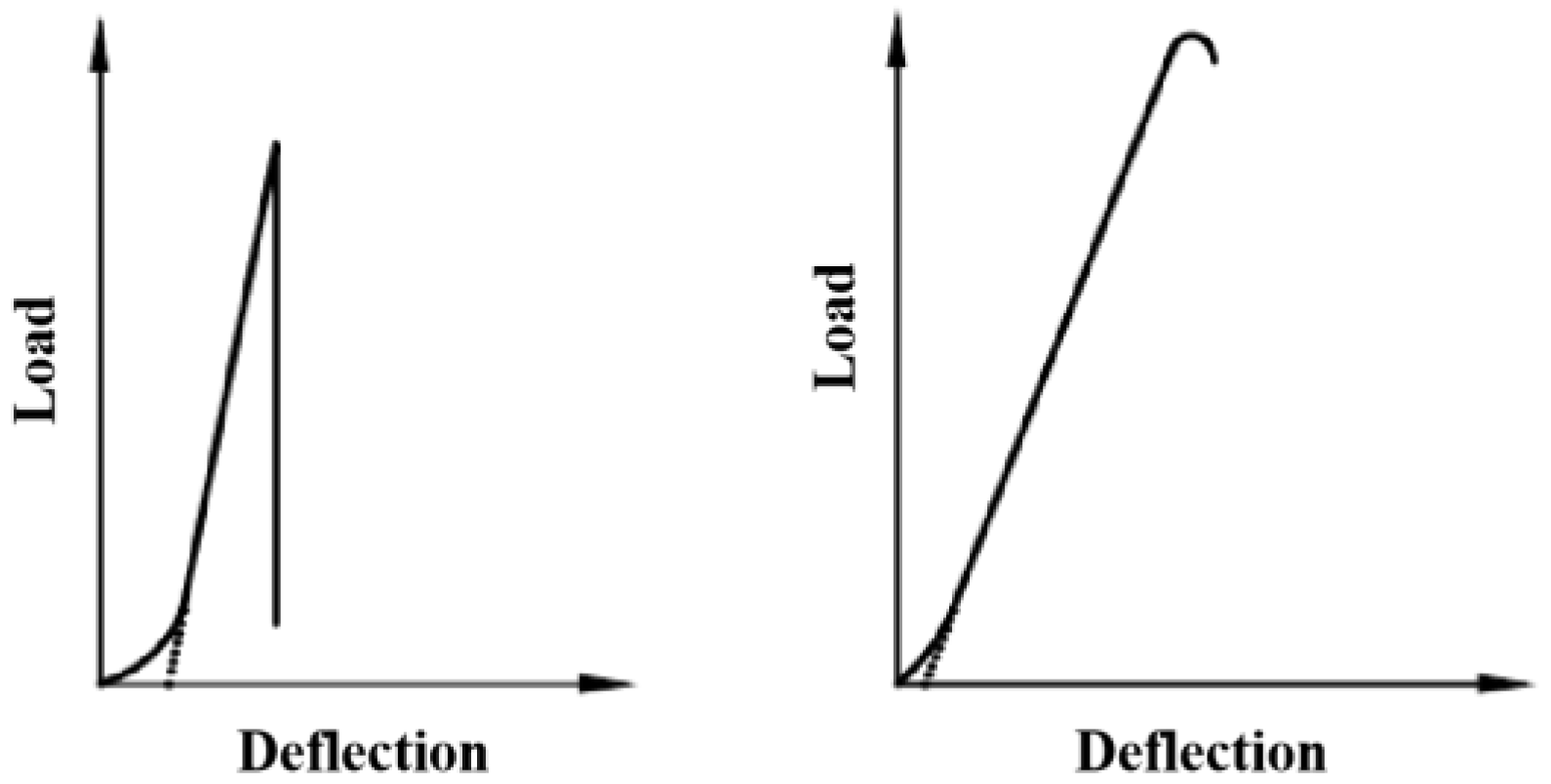

3.1. Determination of the Mid-Span Deflection

- (1)

- Take points on an approximate straight line, with the peak point as the first point, followed by the second point, the third point, etc. The GCF1 group performed linear fitting on three points, four points, five points, six points, seven points, eight points, nine points, and ten points, respectively. The GCF2 performed linear fitting on three points, four points, five points, six points, seven points, eight points, nine points, and ten points, respectively. The GCF3 group performed linear fitting on three points, four points, five points, six points, seven points, eight points, nine points, and ten points, respectively. The respective linear segment equations were obtained, as shown in Table 5.

- (2)

- The predicted value of peak load was obtained by substituting the horizontal coordinates of the peak point into the obtained linear segment equation. Differences were made with the peak load value to obtain the difference and percentage. The results are shown in Table 6.

- (3)

- The line equation corresponding to the minimum difference or percentage obtained through comparison was the obtained line equation. The linear equation of the GCF1 group was y = −25,534.553 + 5529.313 × x. The linear equation of the GCF2 group was y = −40,522.642 + 6114.495 × x. The linear equation of the GCF3 group was y = −19,932.007 + 4389.399 × x.

- (4)

- The starting point of the curve was obtained from the linear equation obtained. The difference between the horizontal coordinates of the starting point and the peak point of the curve was the mid-span deflection. The results are shown in Table 7.

3.2. Test Results and Analysis

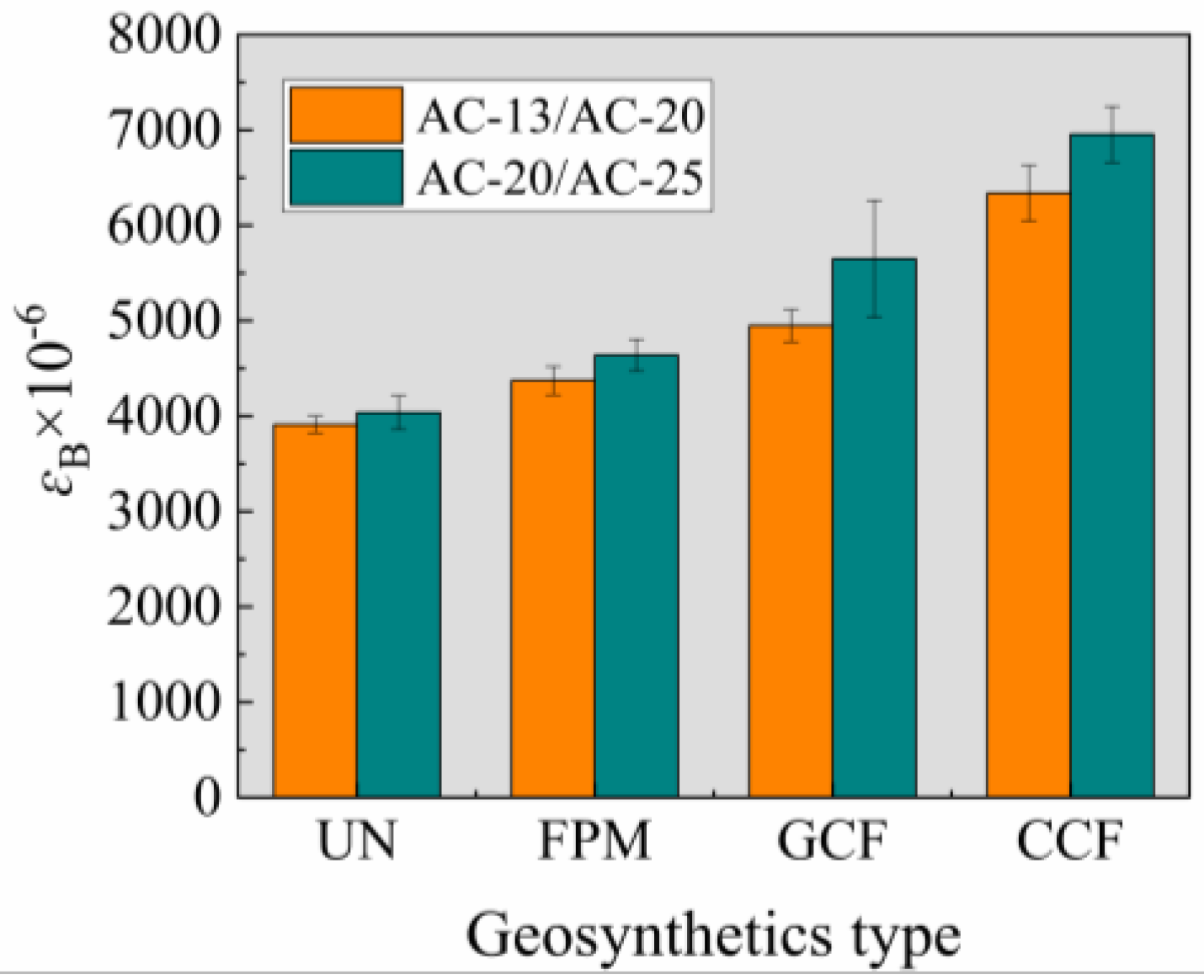

3.2.1. Effect of Geosynthetic Types on ɛB

3.2.2. Effect of SCB Type on ɛB

3.3. Two-Way Analysis of Variance

4. Discussion

5. Conclusions

- (1)

- This study proposes a new method for determining the mid-span deflection, namely the linear fitting difference method.

- (2)

- Under the same SCB type conditions, from the perspective of the ɛB index, the interlayer laying of geosynthetics can improve the low-temperature cracking resistance of asphalt pavement SCBs, with the ranked order from highest to lowest being CCF > GCF > FPM > UN.

- (3)

- In the case of reinforcement, the low-temperature cracking resistance of AC-20/AC-25 is superior to that of AC-13/AC-20 in terms of the ɛB index, especially in the case of geogrid reinforcement.

- (4)

- The two-way ANOVA with interactions shows that the geosynthetic type has a significant impact on the ɛB of asphalt pavement SCBs and that there is a strong relationship between the two. The SCB type has a significant impact on the ɛB of asphalt pavement SCBs, and there is no strong relationship between the two. In addition, the order of influence of the two factors on the ɛB ranks as geosynthetic type > SCB type.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SCB | Surface combined body |

| ANOVA | Analysis of variance |

| CCF | Carbon fibre geogrid |

| GCF | Glass/carbon fibre composite-qualified geogrid |

| FPM | Fibreglass–polyester paving mat |

| AC | Dense-graded asphalt concrete mixture |

| SBS | Styrene–butadiene–styrene block copolymer |

References

- Li, H.; Gao, Y.; Yu, W. Compaction characteristics of hot mixed asphalt and number of roller passes. J. Southeast Univ. Nat. Sci. Ed. 2011, 41, 186–189. (In Chinese) [Google Scholar]

- Li, T. Design and research on bituminous mixture composition. J. Railw. Eng. Soc. 2013, 30, 80–84+94. (In Chinese) [Google Scholar]

- Wang, Z. Experimental Study on High and Low Temperature Performance of Carbon Fiber Geogrid Reinforced Asphalt Mixture. Master’s Thesis, Shijiazhuang Railway University, Shijiazhuang, China, 2022. (In Chinese). [Google Scholar]

- Yee, P.; Aida, B.; Hesp, S.A.; Marks, P.; Tam, K.K. Analysis of Premature Low-Temperature Cracking in Three Ontario, Canada, Pavements. Transp. Res. Rec. 2006, 1962, 44–51. [Google Scholar] [CrossRef]

- Martins, Z.; Arturs, V. Comparison of two low-temperature cracking tests for use in performance-based asphalt mixture design. Int. J. Pavement Eng. 2020, 21, 1461–1469. [Google Scholar]

- Wang, Z.; Yang, G.; Wang, X.; Liang, X.; Liu, M.; Zhang, H. Study on Low Temperature Cracking Resistance of Carbon Fiber Geogrid Reinforced Asphalt Pavement Surface Combined Body. Polymers 2024, 16, 2168. [Google Scholar] [CrossRef]

- Judycki, J.; Jaczewski, M.; Ryś, D.; Pszczoła, M.; Jaskuła, P.; Glinicki, A. Field investigation of low-temperature cracking and stiffness moduli on selected roads with conventional and high modulus asphalt concrete. IOP Conf. Ser. Matr. Sci. Eng. 2017, 236, 012002. [Google Scholar] [CrossRef]

- Hui, G.; Bo, X. Research on Climatic Influencing Factors of Low Temperature Cracking Index of Asphalt Pavement in Cold Area. IOP Conf. Ser. Earth Environ. Sci. 2021, 651, 042032. [Google Scholar]

- Gnanendran, C.T. Strain measurement and interpretation of stabilizing force in geogrid reinforcement. Geotext. Geomembr. 2001, 19, 177–194. [Google Scholar] [CrossRef]

- Szwed, A.; Kamińska, I. Mitigation of Low-temperature Cracking in Asphalt Pavement by Selection of Material Stiffness. Procedia Eng. 2015, 111, 748–755. [Google Scholar] [CrossRef]

- Cao, W.Z.; Zheng, J.J.; Zhang, J.; Zhang, R.J. Field test of a geogrid-reinforced and floating pile-supported embankment. Geosynth. Int. 2016, 23, 348–361. [Google Scholar] [CrossRef]

- Neto, J.A. Application of the two-layer system theory to calculate the settlements and vertical stress propagation in soil reinforcement with geocell. Geotext. Geomembr. 2019, 47, 32–41. [Google Scholar] [CrossRef]

- Yang, G.; Zuo, Z.; Liu, Y.; Wang, Z.; Wang, H.; Yu, F. Experimental study on tensile mechanical properties of geocell strips. J. Geotech. Eng. 2021, 43, 760–767. (In Chinese) [Google Scholar]

- Khodaii, A.; Fallah, S.; Nejad, F.M. Effects of geosynthetics on reduction of reflection cracking in asphalt overlays. Geotext. Geomembr. 2008, 27, 1–8. [Google Scholar] [CrossRef]

- Wang, X.; Liu, K.; Li, S. Study on the anti-reflective crack performance of asphalt overlay interlayer materials. J. Build. Mater. 2010, 13, 247–252+271. (In Chinese) [Google Scholar]

- Nejad, F.M.; Noory, A.; Toolabi, S.; Fallah, S. Effect of using geosynthetics on reflective crack prevention. Int. J. Pavement Eng. 2015, 16, 477–487. [Google Scholar] [CrossRef]

- Gonzalez-Torre, I.; Calzada-Perez, M.A.; Vega-Zamanillo, A.; Castro-Fresno, D. Evaluation of reflective cracking in pavements using a new procedure that combine loads with different frequencies. Constr. Build. Mater. 2015, 75, 368–374. [Google Scholar] [CrossRef]

- Nejad, F.M.; Asadi, S.; Fallah, S.; Vadood, M. Statistical-experimental study of geosynthetics performance on reflection cracking phenomenon. Geotext. Geomembr. 2016, 44, 178–187. [Google Scholar] [CrossRef]

- Saride, S.; Kumar, V. Influence of geosynthetic-interlayers on the performance of asphalt overlays on pre-cracked pavements. Geotext. Geomembr. 2017, 45, 184–196. [Google Scholar] [CrossRef]

- Lee, J.-H.; Baek, S.-B.; Lee, K.-H.; Kim, J.-S.; Jeong, J.-H. Long-term performance of fiber-grid-reinforced asphalt overlay pavements: A case study of Korean national highways. J. Traffic Transp. Eng. Engl. Ed. 2019, 6, 366–382. [Google Scholar] [CrossRef]

- Ling, J.; Wei, F.; Gao, J.; Zhang, J.; Tian, Y.; Li, Y. New Test Method for Measuring Reflective Cracking in Hot-Mix Asphalt Overlay Pavements. Transp. Res. Rec. 2019, 2673, 327–336. [Google Scholar] [CrossRef]

- Solatiyan, E.; Bueche, N.; Vaillancourt, M.; Carter, A. Permeability and mechanical property measurements of reinforced asphalt overlay with paving fabrics using novel approaches. Mater. Struct. 2020, 53, 104–113. [Google Scholar] [CrossRef]

- Zofka, A.; Maliszewski, M.; Maliszewska, D. Glass and carbon geogrid reinforcement of asphalt mixtures. Road Mater. Pavement Des. 2017, 18 (Suppl. S1), 717–744. [Google Scholar] [CrossRef]

- Zofka, A.; Maliszewski, M.; Zofka, E.; Paliukaite, M.; Žalimienė, L. Geogrid Reinforcement of Asphalt Pavements. Balt. J. Road Bridge Eng. 2017, 12, 181–186. [Google Scholar] [CrossRef]

- Canestrari, F.; Belogi, L.; Ferrotti, G.; Graziani, A. Shear and flexural characterization of grid-reinforced asphalt pavements and relation with field distress evolution. Mater. Struct. 2015, 48, 959–975. [Google Scholar] [CrossRef]

- Sun, X.; Han, J.; Fei, J.; Guo, J.; Zhang, W. Geosynthetic-stabilized flexible pavements: Solution derivation and mechanistic-empirical analysis. Geotext. Geomembr. 2020, 48, 468–478. [Google Scholar] [CrossRef]

- Behnood, A. Application of rejuvenators to improve the rheological and mechanical properties of asphalt binders and mixtures: A review. J. Clean. Prod. 2019, 231, 171–182. [Google Scholar] [CrossRef]

- Teltayev, B.B.; Rossi, C.O.; Izmailova, G.G.; Amirbayev, E.D.; Elshibayev, A.O. Evaluating the effect of asphalt binder modification on the low-temperature cracking resistance of hot mix asphalt. Case Stud. Constr. Mater. 2019, 11, e00238. [Google Scholar] [CrossRef]

- Liu, C.; Du, J.; Wu, C.; Liu, K.; Jiang, K. Low-Temperature Crack Resistance of Wood Tar-Based Rejuvenated Asphalt Based on Viscoelastic Rheological Method. Int. J. Pavement Res. Technol. 2021, 15, 1340–1353. [Google Scholar] [CrossRef]

- Wang, J.; Lv, S.; Liu, J.; Peng, X.; Lu, W.; Wang, Z.; Xie, N. Performance evaluation of aged asphalt rejuvenated with various bio-oils based on rheological property index. J. Clean. Prod. 2023, 385, 135593. [Google Scholar] [CrossRef]

- Bartosz, B.; Maria, R.; Stanisław, M.; Artur, W. Influence of bitumen grade and air voids on low-temperature cracking of asphalt. Case Stud. Constr. Mater. 2023, 19, e02255. [Google Scholar]

- Lin, P.; Liu, X.; Ren, S.; Li, Y.; Xu, J.; Li, M. Unraveling the influence of fibers on aging susceptibility and performance of high content polymer modified asphalt mixtures. Case Stud. Constr. Mater. 2023, 18, e02211. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Sandra, E. Towards critical low-temperature relaxation indicators for effective rejuvenation efficiency evaluation of rejuvenator-aged bitumen blends. J. Clean. Prod. 2023, 426, 139092. [Google Scholar] [CrossRef]

- Choi, D.; Kil, H.-S.; Lee, S. Fabrication of low-cost carbon fibers using economical precursors and advanced processing technologies. Carbon 2018, 142, 610–649. [Google Scholar] [CrossRef]

- Jin, X.; Feng, C.; Creighton, C.; Hameed, N.; Parameswaranpillai, J.; Salim, N.V. On the structural evolution of textile grade poly-acrylonitrile fibers during stabilization and carbonization: Towards the manufacture of low-cost carbon fiber. Polym. Degrad. Stab. 2021, 186, 109536. [Google Scholar] [CrossRef]

- Giorgio, I.; Ciallella, A.; Scerrato, D.A. Study about the impact of the topological arrangement of fibers on fiber-reinforced composites: Some guidelines aiming at the development of new ultra-stiff and ultra-soft metamaterials. Int. J. Solids Struct. 2020, 203, 73–83. [Google Scholar] [CrossRef]

- dell’Isola, F.; Steigmann, D.; Della Corte, A. Synthesis of fibrous complex structures: Designing microstructure to deliver targeted macroscale response. Appl. Mech. Rev. 2015, 67, 060804. [Google Scholar] [CrossRef]

- Jo, A.Y.; Yoo, S.H.; Chung, Y.S.; Lee, S. Effects of ultraviolet irradiation on stabilization of textile-grade polyacrylonitrile fibers without photo-initiator for preparing carbon fibers. Carbon 2018, 144, 440–448. [Google Scholar] [CrossRef]

- Yoo, S.H.; Park, S.; Park, Y.; Lee, D.; Joh, H.I.; Shin, I.; Lee, S. Facile method to fabricate carbon fibers from textile-grade polyacrylonitrile fibers based on electron-beam irradiation and its effect on the subsequent thermal stabilization process. Carbon 2017, 118, 106–113. [Google Scholar] [CrossRef]

- Spalding, M.A. Scale-up of Novel Low-Cost Carbon Fibers Leading to High-Volume Commercial Launch; The Dow Chemical Company: Midland, MI, USA, 2014. [Google Scholar]

- JTG E20-2011; Code of China, Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Highway Research Institute Ministry of Transport: Beijing, China, 2011.

- JTG F40-2004; Code of China, Technical Specifications for Construction of Highway Asphalt Pavements. China Communications Press: Beijing, China, 2004.

- He, J. Study on the Attenuation Law of Long-Term Skid Resistance of Asphalt Pavement with Limestone and Basalt Mixed Aggregates; Chongqing Jiaotong University: Chongqing, China, 2023. [Google Scholar]

- Wang, D. Asphalt Pavement Skid Resistance of the Surface Mixed Limestone and Basalt Aggregate; Chongqing Jiaotong University: Chongqing, China, 2015. [Google Scholar]

- Ding, Z. The Research on Durability of Limestone Used for Asphalt Pavement Surface Layer; Changsha University of Science & Technology: Changsha, China, 2013. [Google Scholar]

- Wang, Z.; Yang, G.; Li, Q.; Li, T.; Xu, P.; Liang, X. Comparative assessment of the interlayer shear strength of asphalt concrete with carbon fiber geogrid as reinforcement. Constr. Build. Mater. 2024, 450, 138593. [Google Scholar] [CrossRef]

- Lee, J.; Kim, Y.R.; Lee, J. Rutting performance evaluation of asphalt mix with different types of geosynthetics using MMLS3. Int. J. Pavement Eng. 2015, 16, 894–905. [Google Scholar] [CrossRef]

- He, H.; Ai, C.; Rahman, A. Characterization of interface morphology and its impact on interlayer bonding strength in double-layered asphalt systems. J. Mater. Civ. Eng. 2024, 35, 04023121. [Google Scholar] [CrossRef]

- Brown, S.F.; Kwan, J.; Thom, N.H. Identifying the key parameters that influence geogrid reinforcement of railway ballast. Geotext. Geomembr. 2007, 25, 326–335. [Google Scholar] [CrossRef]

- Palmeira, E.M.; Gongora, I.A.G. Assessing the influence of some soil–reinforcement interaction parameters on the performance of a low fill on compressible subgrade. Part I: Fill performance and relevance of interaction parameters. Int. J. Geosynth. Ground Eng. 2016, 2, 1–17. [Google Scholar] [CrossRef]

- Sweta, K.; Hussaini, S.K.K. Effect of shearing rate on the behavior of geogridreinforced rail road ballast under direct shear conditions. Geotext. Geomembr. 2018, 46, 251–256. [Google Scholar] [CrossRef]

- Zuo, J.; Chen, Y.; Song, H. Study progress of failure behaviors and nonlinear model of deep coal-rock combined body. J. Cent. S. Univ. Sci. Technol. 2021, 52, 2510–2521. [Google Scholar]

- Jia, J.; He, X.; Jin, Y. Statistics, 7th ed.; China Renmin University Press: Beijing, China, 2018. [Google Scholar]

- Hu, G. Research on low temperature cracking resistance of carbon fibre geogrid reinforced asphalt mixtures. North. Commun. 2024, 9, 35–38. [Google Scholar]

| Index | FPM | |

|---|---|---|

| Ultimate tensile strength (kN/m) | Longitudinal | 8 |

| Transverse | 8 | |

| Ultimate elongation (%) | Longitudinal | ≤4 |

| Transverse | ≤4 | |

| Mass per unit area (g/m2) | 25 × 25 | |

| Thickness (mm) | 1.2 | |

| Index | GCF | CCF | |

|---|---|---|---|

| Ultimate tensile strength (kN/m) | Longitudinal | 50 | 80 |

| Transverse | 80 | 80 | |

| Thickness (mm) | 0.6 | 0.6 | |

| Ultimate elongation (%) | Longitudinal | ≤3 | ≤2 |

| Transverse | ≤2 | ≤2 | |

| Aperture size (mm × mm) | 25 × 25 | 25 × 25 | |

| Items | Measured Value | Standardized Requirement |

|---|---|---|

| Softening point (°C) | 64.4 | ≥60 |

| Ductility, 5 cm/min,10 °C (cm) | 25.1 | ≥20 |

| Penetration, 25 °C, 5 s, 100 g (0.1 mm) | 57.8 | 30~60 |

| Type | Cationic Rapid-Setting Emulsified Asphalt |

|---|---|

| Content of residual binder (%) | 50.1 |

| Sieve test (%) | 0.09 |

| Viscosity (Pas) | 25 |

| Identification of cationic property | Positive |

| No. of Groups | Number of Points | Equations | Determination Coefficients | Probability > |t|/ Intercept Distance | Probability > |t|/Slope | Significance |

|---|---|---|---|---|---|---|

| GCF1 | 3 | y = −23,757.865 + 5202.387 × x | 0.999 71 | 0.012,77 | 0.010,93 | Yes |

| 4 | y = −24,574.913 + 5354.764 × x | 0.999 35 | 4.33 × 10−4 | 3.25 × 10−4 | Yes | |

| 5 | y = −25,630.259 + 5552.579 × x | 0.998 36 | 4.15 × 10−5 | 2.82 × 10−5 | Yes | |

| 6 | y = −26,822.272 + 5777.036 × x | 0.996 75 | 6.30 × 10−6 | 3.97 × 10−6 | Yes | |

| 7 | y = −27,144.158 + 5837.989 × x | 0.997 79 | 1.33 × 10−7 | 7.78 × 10−8 | Yes | |

| 8 | y = −26,924.466 + 5796.164 × x | 0.998 41 | 2.31 × 10−9 | 1.26 × 10−9 | Yes | |

| 9 | y = −26,392.190 + 5694.304 × x | 0.998 12 | 1.64 × 10−10 | 8.45 × 10−11 | Yes | |

| 10 | y = −25,534.553 + 5529.313 × x | 0.996 26 | 1.11 × 10−10 | 5.37 × 10−11 | Yes | |

| GCF2 | 3 | y = −38,860.375 + 5888.887 × x | 0.999 51 | 0.015,51 | 0.014,11 | Yes |

| 4 | y = −40,013.847 + 6047.389 × x | 0.999 34 | 3.90 × 10−4 | 3.29 × 10−4 | Yes | |

| 5 | y = −41,044.743 + 6189.585 × x | 0.999 14 | 1.35 × 10−5 | 1.07 × 10−5 | Yes | |

| 6 | y = −41,964.464 + 6316.914 × x | 0.998 94 | 5.55 × 10−7 | 4.19 × 10−7 | Yes | |

| 7 | y = −42,693.542 + 6418.189 × x | 0.998 86 | 2.06 × 10−8 | 1.50 × 10−8 | Yes | |

| 8 | y = −42,170.353+ 6345.220 × x | 0.998 93 | 5.52 × 10−10 | 3.87 × 10−10 | Yes | |

| 9 | y = −40,522.642 + 6114.495 × x | 0.995 88 | 1.94 × 10−9 | 1.31 × 10−9 | Yes | |

| 10 | y = −37,857.247 + 5739.828 × x | 0.985 65 | 1.81 × 10−8 | 1.16 × 10−8 | Yes | |

| GCF3 | 3 | y = −20,211.300+ 4444.125 × x | 0.989 32 | 0.077,14 | 0.065,91 | Yes |

| 4 | y = −20,636.599 + 4523.500 × x | 0.995 52 | 0.003,01 | 0.002,24 | Yes | |

| 5 | y = −20,850.990 + 4563.715 × x | 0.997 67 | 7.22 × 10−5 | 4.76 × 10−5 | Yes | |

| 6 | y = −20,866.564 + 4566.651 × x | 0.998 67 | 1.13 × 10−6 | 6.67 × 10−7 | Yes | |

| 7 | y = −19,932.007 + 4389.399 × x | 0.996 77 | 3.85 × 10−7 | 2.02 × 10−7 | Yes | |

| 8 | y = −19,532.960 + 4313.399 × x | 0.997 1 | 1.60 × 10−8 | 7.60 × 10−9 | Yes | |

| 9 | y = −18,795.426 + 4172.176 × x | 0.995 14 | 5.48 × 10−9 | 2.34 × 10−9 | Yes | |

| 10 | y = −17,809.800+ 3982.429 × x | 0.990 16 | 6.72 × 10−9 | 2.57 × 10−9 | Yes |

| No. of Groups | Number of Points | Predicted Value | Difference | Percentage |

|---|---|---|---|---|

| GCF1 | 3 | 4428.667 | 4.333 | 0.10% |

| 4 | 4437.200 | 12.866 | 0.29% | |

| 5 | 4453.614 | 29.280 | 0.66% | |

| 6 | 4477.709 | 53.375 | 1.21% | |

| 7 | 4486.069 | 61.735 | 1.40% | |

| 8 | 4479.152 | 54.818 | 1.24% | |

| 9 | 4459.550 | 35.216 | 0.80% | |

| 10 | 4423.265 | 1.069 | 0.02% | |

| GCF2 | 3 | 4322.833 | 6.333 | 0.15% |

| 4 | 4331.656 | 15.156 | 0.35% | |

| 5 | 4343.485 | 26.985 | 0.63% | |

| 6 | 4357.465 | 40.965 | 0.95% | |

| 7 | 4371.040 | 54.540 | 1.26% | |

| 8 | 4359.147 | 42.647 | 0.99% | |

| 9 | 4314.953 | 1.547 | 0.04% | |

| 10 | 4232.911 | 83.589 | 1.94% | |

| GCF3 | 3 | 3862.528 | 17.861 | 0.46% |

| 4 | 3867.199 | 22.532 | 0.59% | |

| 5 | 3870.653 | 25.986 | 0.68% | |

| 6 | 3870.986 | 26.319 | 0.68% | |

| 7 | 3845.366 | 0.699 | 0.02% | |

| 8 | 3832.723 | 11.944 | 0.31% | |

| 9 | 3805.253 | 39.414 | 1.03% | |

| 10 | 3763.018 | 81.649 | 2.12% |

| No. of Groups | Equations | Starting Point | Peak Point | Deflection/mm |

|---|---|---|---|---|

| GCF1 | y = −25,534.553+ 5529.313 × x | 4.618 | 5.418 | 0.800 |

| GCF2 | y = −40,522.642+ 6114.495 × x | 6.627 | 7.333 | 0.706 |

| GCF3 | y = −19,932.007 + 4389.399 × x | 4.541 | 5.417 | 0.876 |

| No. of Groups | Geosynthetic Type | |||

|---|---|---|---|---|

| UN | FPM | GCF | CCF | |

| 1 | 0.508 | 0.592 | 0.692 | 0.897 |

| 2 | 0.531 | 0.563 | 0.659 | 0.853 |

| 3 | 0.532 | 0.561 | 0.633 | 0.853 |

| 4 | 0.526 | 0.594 | 0.668 | 0.791 |

| 5 | 0.510 | 0.605 | 0.646 | 0.830 |

| No. of Groups | Geosynthetic Type | |||

|---|---|---|---|---|

| UN | FPM | GCF | CCF | |

| 1 | 0.518 | 0.621 | 0.800 | 0.971 |

| 2 | 0.530 | 0.610 | 0.706 | 0.926 |

| 3 | 0.573 | 0.652 | 0.876 | 0.878 |

| 4 | 0.551 | 0.590 | 0.697 | 0.961 |

| 5 | 0.519 | 0.620 | 0.687 | 0.900 |

| SCB Type | Geosynthetic Type | |||

|---|---|---|---|---|

| UN | FPM | GCF | CCF | |

| AC-13/AC-20 | 3810 | 4440 | 5190 | 6727.5 |

| 3982.5 | 4222.5 | 4942.5 | 6397.5 | |

| 3990 | 4207.5 | 4747.5 | 6397.5 | |

| 3945 | 4455 | 5010 | 5932.5 | |

| 3825 | 4537.5 | 4845 | 6225 | |

| AC-20/AC-25 | 3885 | 4657.5 | 5152.5 | 7282.5 |

| 3975 | 4575 | 6000 | 6945 | |

| 4297.5 | 4890 | 5295 | 6585 | |

| 4132.5 | 4425 | 5227.5 | 7207.5 | |

| 3892.5 | 4650 | 6570 | 6750 | |

| Sources of Error | Degrees of Freedom/df | Square Sum/SS | Mean Square/MS | F-Value | p-Value | Fcritical-Value |

|---|---|---|---|---|---|---|

| Geosynthetic type (C) | 3 | 4.05 × 107 | 1.35 × 107 | 161.31 | 0 | 2.845 |

| SCB type (R) | 1 | 1.83 × 106 | 1.83 × 106 | 21.92 | 4.99 × 10−5 | 4.091 |

| Interaction (RC) | 3 | 5.71 × 105 | 1.90 × 105 | 2.27 | 0.10 | 2.845 |

| Error (E) | 32 | 2.68 × 106 | 83,648.67 | -- | -- | -- |

| Summation (T) | 39 | 4.56 × 107 | -- | -- | -- | -- |

| R2 Type | R2C | R2R | R2RC | R2R+C |

|---|---|---|---|---|

| Calculated value (%) | 88.82 | 4.01 | 1.25 | 94.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Wang, Z.; Yang, G. Study on Low-Temperature Cracking Resistance of Carbon Fibre Geogrid Reinforced Asphalt Mixtures Based on Statistical Methods. Polymers 2025, 17, 461. https://doi.org/10.3390/polym17040461

Huang Y, Wang Z, Yang G. Study on Low-Temperature Cracking Resistance of Carbon Fibre Geogrid Reinforced Asphalt Mixtures Based on Statistical Methods. Polymers. 2025; 17(4):461. https://doi.org/10.3390/polym17040461

Chicago/Turabian StyleHuang, Yifan, Zhiqiang Wang, and Guangqing Yang. 2025. "Study on Low-Temperature Cracking Resistance of Carbon Fibre Geogrid Reinforced Asphalt Mixtures Based on Statistical Methods" Polymers 17, no. 4: 461. https://doi.org/10.3390/polym17040461

APA StyleHuang, Y., Wang, Z., & Yang, G. (2025). Study on Low-Temperature Cracking Resistance of Carbon Fibre Geogrid Reinforced Asphalt Mixtures Based on Statistical Methods. Polymers, 17(4), 461. https://doi.org/10.3390/polym17040461