Process Monitoring for Vacuum-Assisted Resin Infusion by Using Carbon Nanotube-Based Sensors

Abstract

1. Introduction

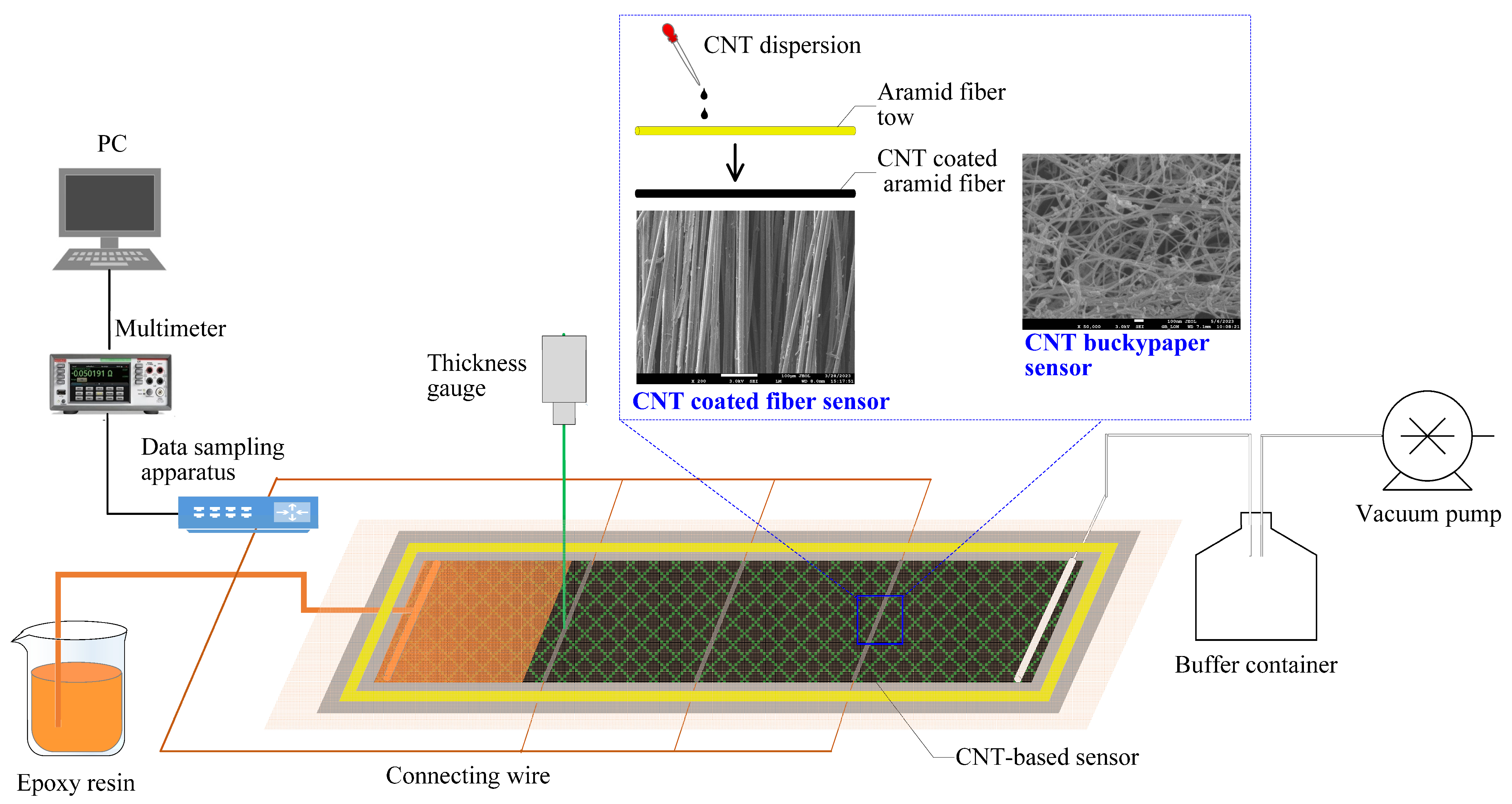

2. Materials and Methods

2.1. Materials

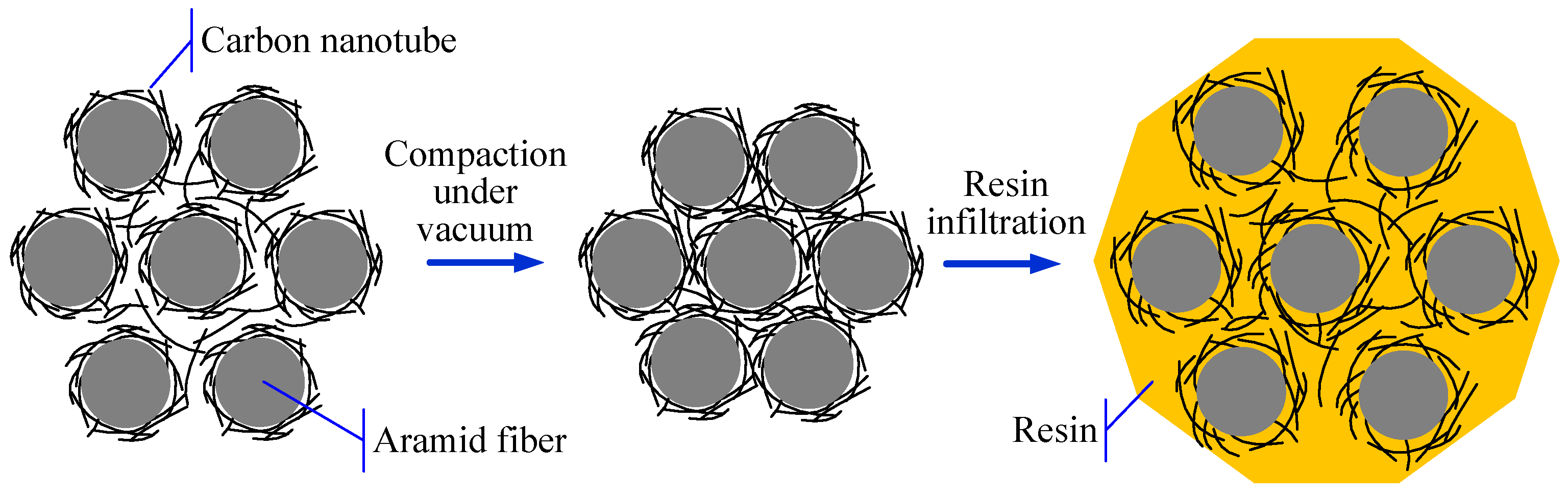

2.2. Preparation of CNT-Based Sensors and the Sensor Arrangement in VARI Process

3. Results and Discussion

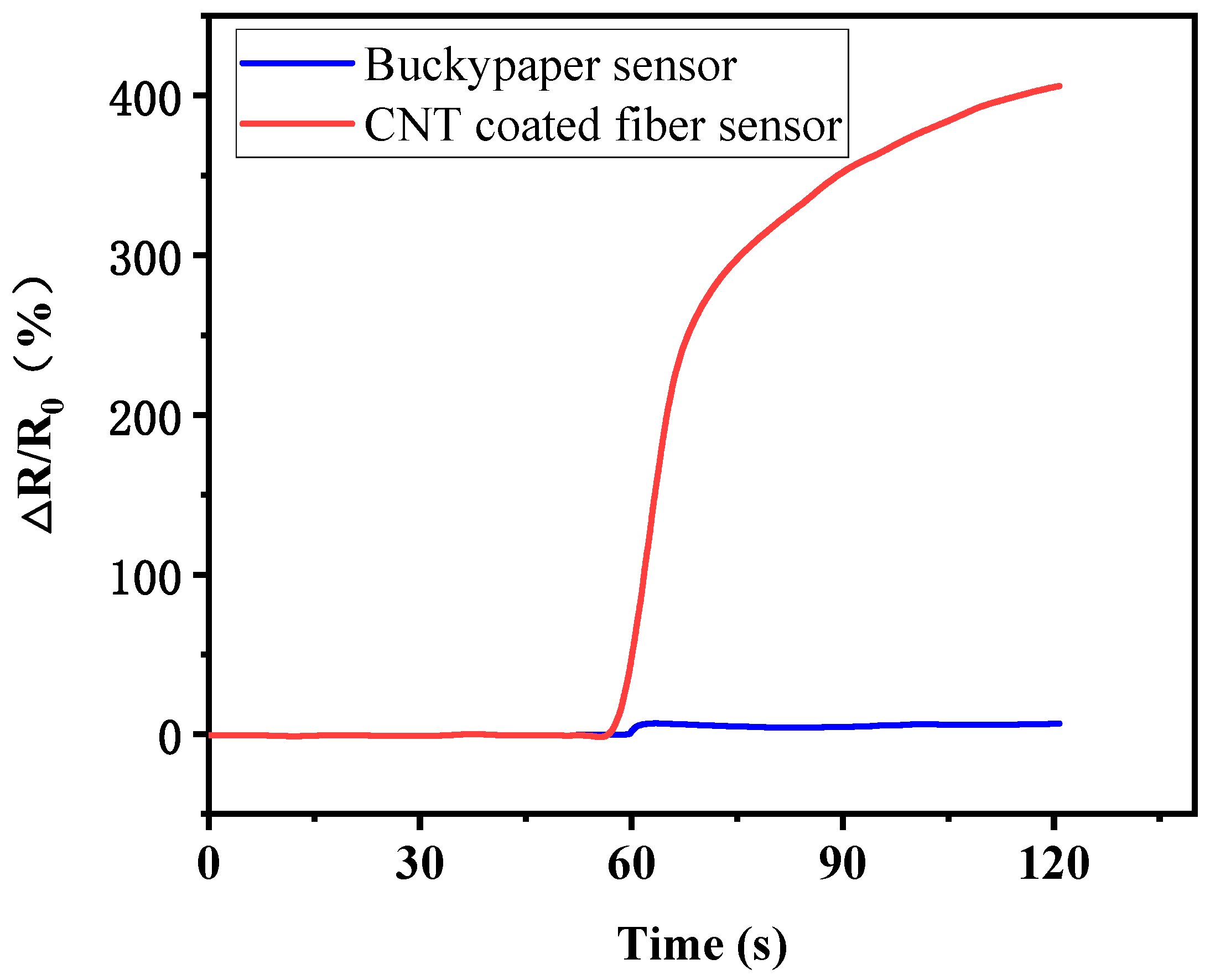

3.1. Electrical Resistance Variation of CNT-Based Materials After Resin Imbibition Freestandingly and in Closed Mold

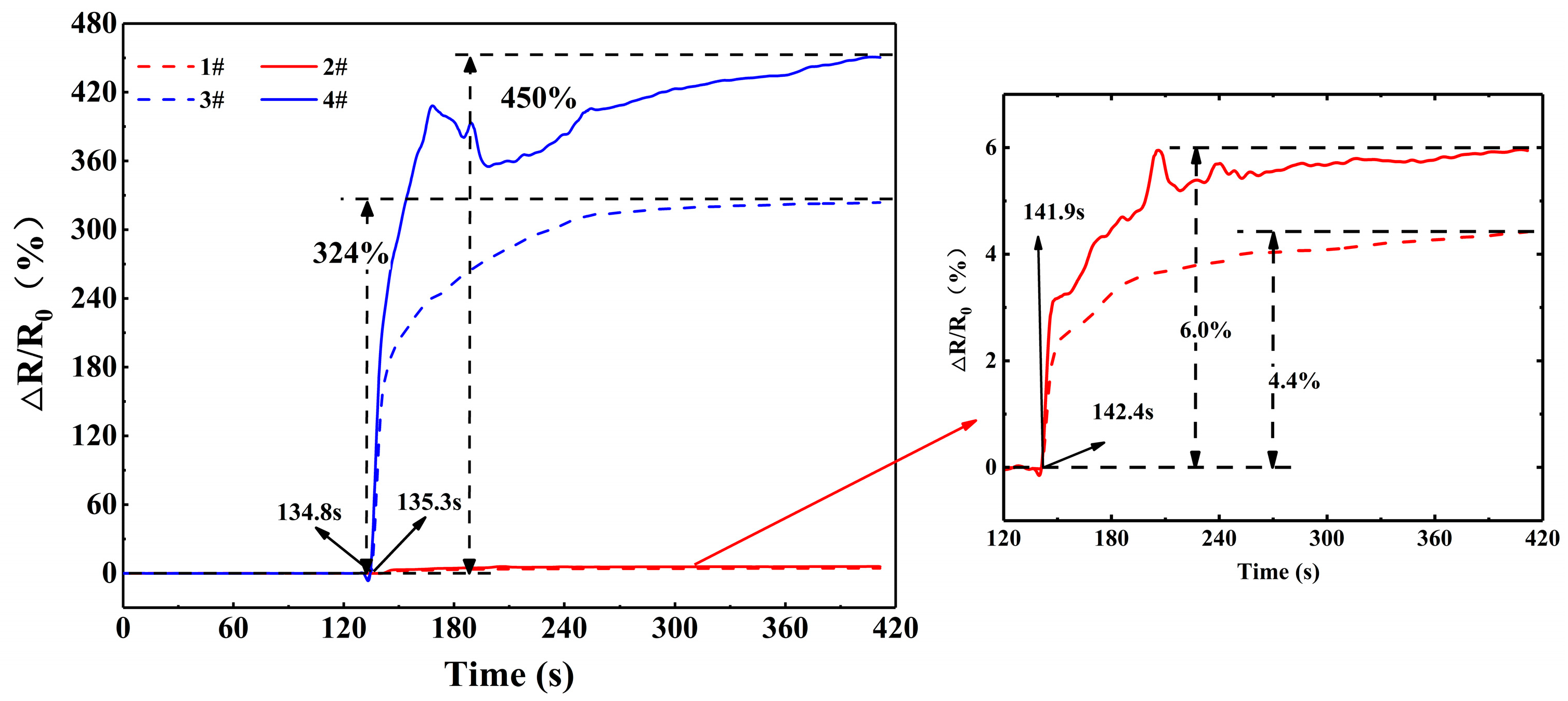

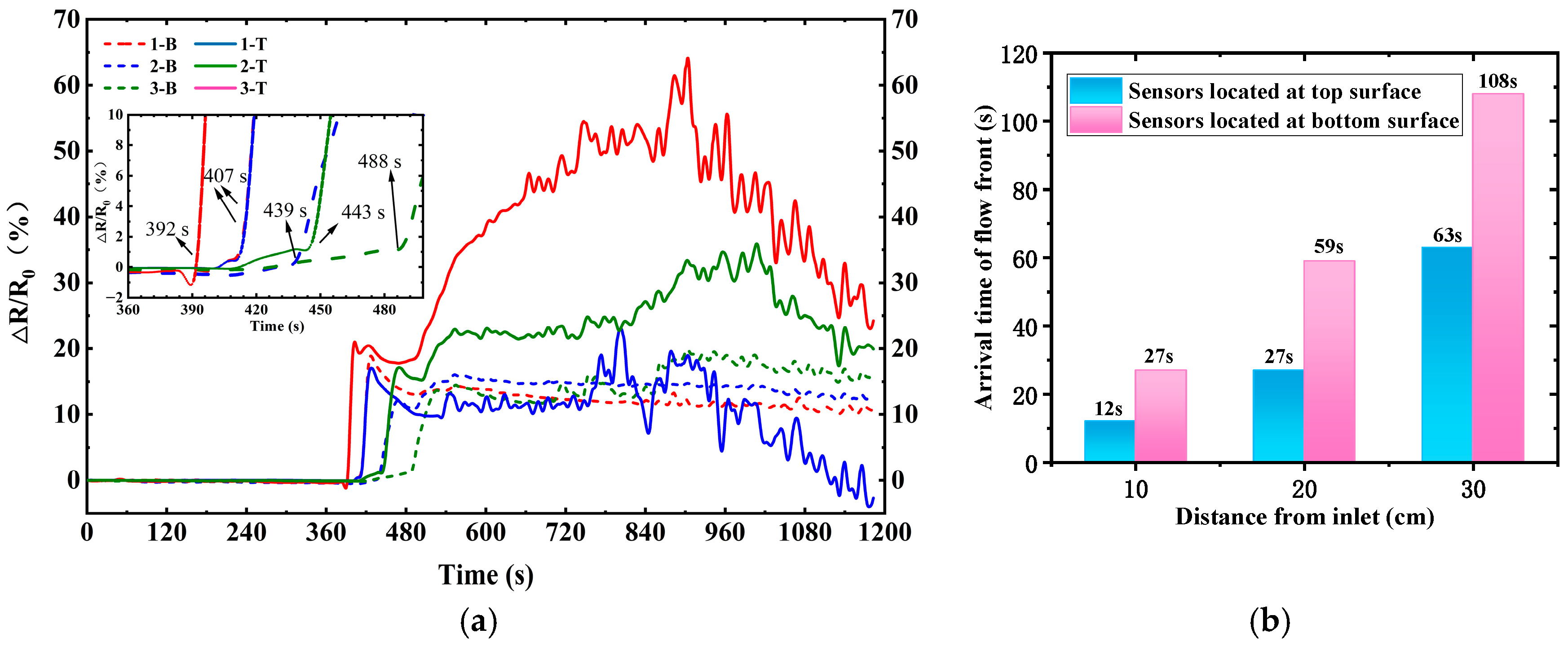

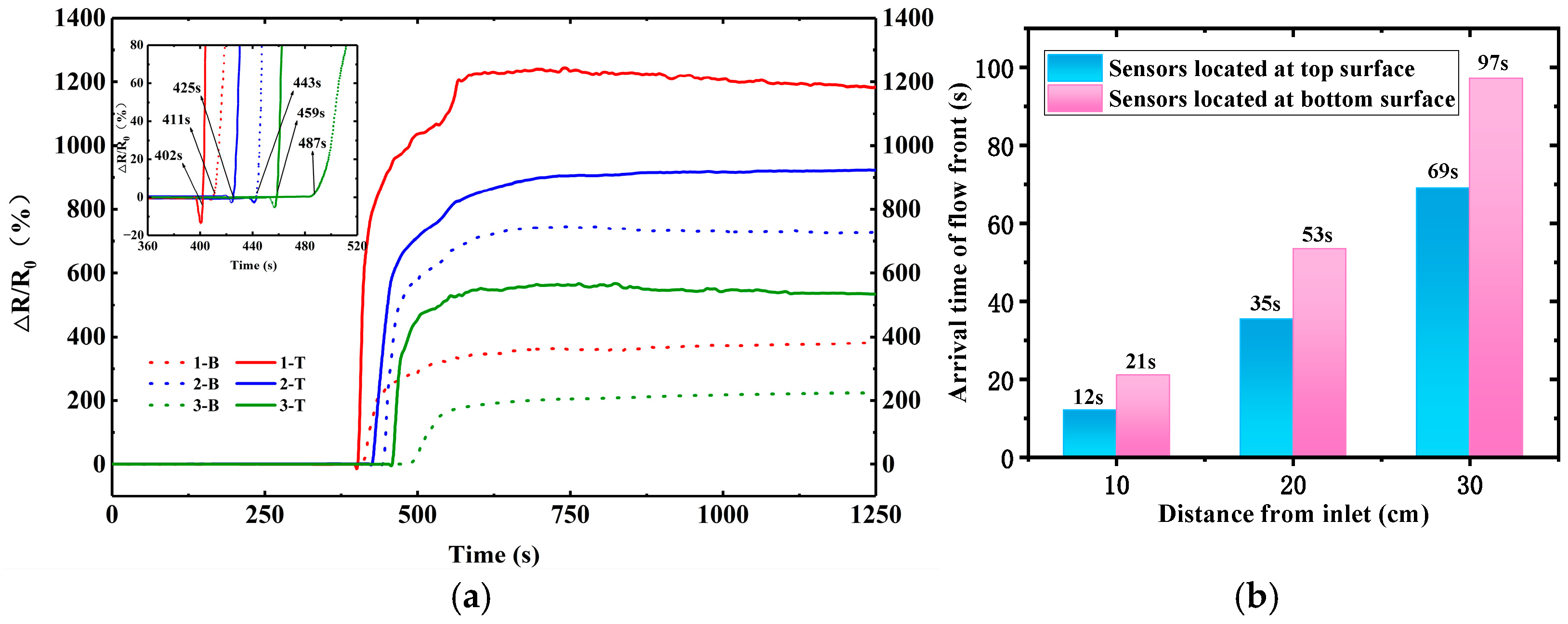

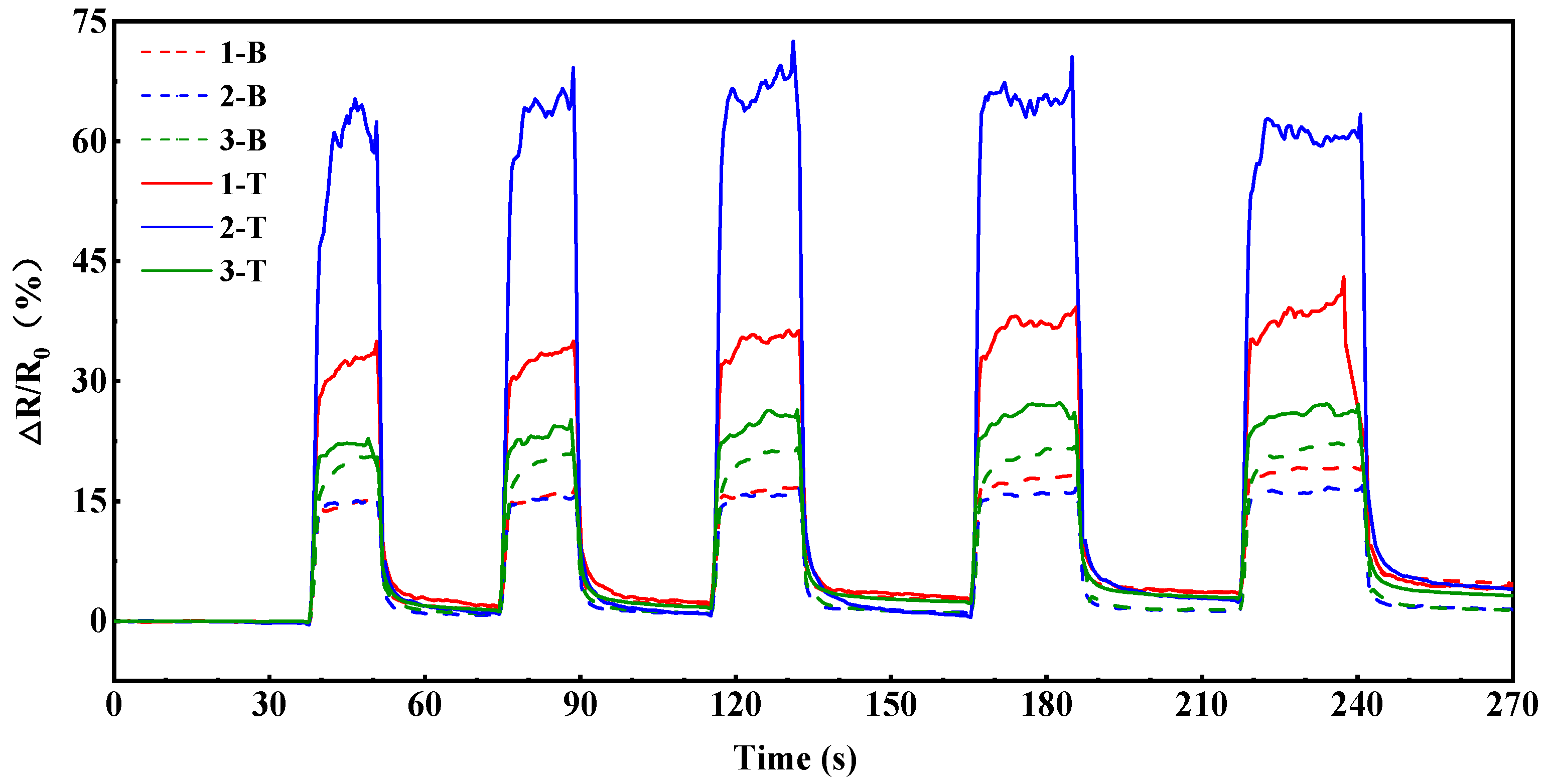

3.2. Electrical Resistance Variation of CNT-Based Sensors During Resin Infusion in VARI Process

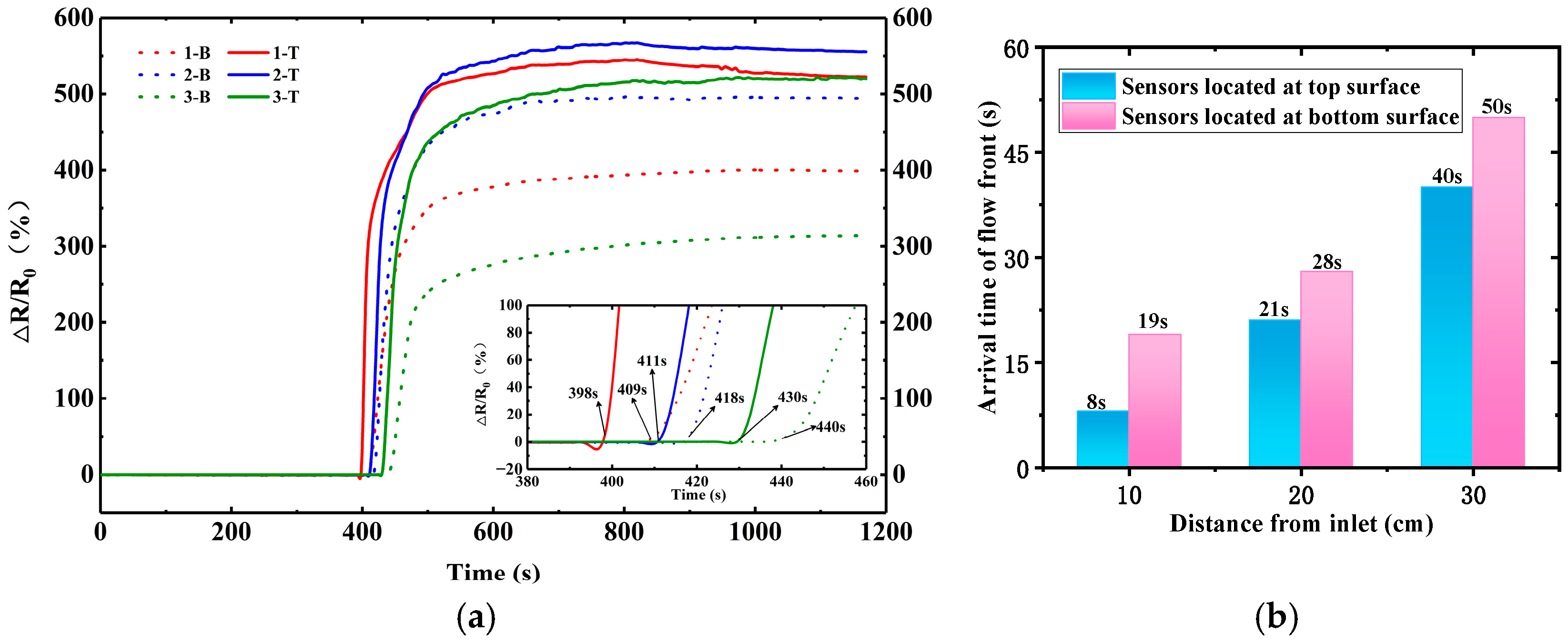

3.3. Effect of Preform Thickness on the Sensitivity of CNT-Coated Fiber Sensor

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Szarski, M.; Chauhan, S. Instant flow distribution network optimization in liquid composite molding using deep reinforcement learning. J. Intell. Manuf. 2023, 34, 197–218. [Google Scholar] [CrossRef]

- Ouezgan, A.; Mallil, E.H.; Echaabi, J. Manufacturing routes of vacuum assisted resin infusion: Numerical investigation. J. Compos. Mater. 2022, 56, 3221–3236. [Google Scholar] [CrossRef]

- Sas, H.S.; Šimáček, P.; Advani, S.G. A methodology to reduce variability during vacuum infusion with optimized design of distribution media. Compos. Part A-Appl. Sci. 2015, 78, 223–233. [Google Scholar] [CrossRef]

- Konstantopoulos, S.; Grössing, H.; Hergan, P.; Weninger, M.; Schledjewski, R. Determination of the unsaturated through-thickness permeability of fibrous preforms based on flow front detection by ultrasound. Polym. Compos. 2018, 39, 360–367. [Google Scholar] [CrossRef]

- Tuloup, C.; Harizi, W.; Aboura, Z.; Meyer, Y.; Ade, B.; Khellil, K. Detection of the key steps during liquid resin infusion manufacturing of a polymer-matrix composite using an in-situ piezoelectric sensor. Mater. Today Commun. 2020, 24, 101077. [Google Scholar] [CrossRef]

- Wan, Y.; Hu, W.; Yang, L.; Wang, Z.; Tan, J.; Liu, Y.; Wang, F.; Yang, B. In-situ monitoring of glass fiber/epoxy composites by the embedded multi-walled carbon nanotube coated glass fiber sensor: From fabrication to application. Polym. Compos. 2022, 43, 4210–4222. [Google Scholar] [CrossRef]

- Uribe-Riestra, G.; Ayuso-Faber, P.; Rivero-Ayala, M.; Cauich-Cupul, J.; Gamboa, F.; Avilés, F. Structural health monitoring of carbon nanotube-modified glass fiber-reinforced polymer composites by electrical resistance measurements and digital image correlation. Struct. Health Monit. 2024, 23, 555–567. [Google Scholar] [CrossRef]

- Koutsotolis, L.; Karalis, G.; Voudouris Itskaras, A.; Tsirka, K.; Paipetis, A.S. A carbon nanotube-based thermoelectric generator integrated into a smart composite for structural health monitoring. Mater. Res. Express 2024, 11, 045705. [Google Scholar] [CrossRef]

- Lopes, C.; Araújo, A.; Silva, F.; Pappas, P.N.; Termine, S.; Trompeta, A.F.A.; Charitidis, C.A.; Martins, C.; Mould, S.T.; Santos, R.M. Smart carbon fiber-reinforced polymer composites for damage sensing and on-line structural health monitoring applications. Polymers 2024, 16, 2698. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Lu, Y.; Lu, S.; Wang, X.; Ma, C.; Ma, K. In situ monitoring of sandwich structure in liquid composite molding process using multifunctional MXene/carbon nanotube sensors. Polym. Compos. 2022, 43, 2252–2263. [Google Scholar] [CrossRef]

- Lu, S.; Yang, X.; Zhang, L.; Ma, J.; Wang, S.; Tang, H.; Ma, K.; Wang, X. Real-time monitoring of resin infiltration process in vacuum assisted molding(VARI) of composites with carbon nanotube buckypaper sensor. Mater. Res. Express 2019, 6, 115628. [Google Scholar] [CrossRef]

- del Río, J.S.; Ridruejo, Á.; Martínez, V.; Jiménez, J.L.; Ramos, C.; Vilatela, J.J.; González, C.D. CNTs monitoring sensors for resin infusion optimization. Sens. Actuat.-Phys. 2023, 364, 114852. [Google Scholar] [CrossRef]

- Gnidakouong, J.R.N.; Roh, H.D.; Kim, J.H.; Park, Y.B. In situ process monitoring of hierarchical micro-/nano-composites using percolated carbon nanotube networks. Compos. Part A-Appl. Sci. 2016, 84, 281–291. [Google Scholar] [CrossRef]

- Wang, G.; Wang, Y.; Luo, Y.; Luo, S. Carbon nanomaterials based smart fabrics with selectable characteristics for in-line monitoring of high-performance composites. Materials 2018, 11, 1677. [Google Scholar] [CrossRef] [PubMed]

- Jeong, W.N.; Um, M.K.; Kim, W.D.; Roh, H.D. Electrical resistance-based monitoring of CFRP thickness during vacuum assisted resin infusion. Funct. Compos. Struct. 2023, 5, 035005. [Google Scholar] [CrossRef]

- Arda, E.; Mergen, Ö.B.; Pekcan, Ö. Electrical and optical percolations in PMMA/GNP composite films. Phase Transit. 2018, 91, 546–557. [Google Scholar] [CrossRef]

- Pekcan, Ö.; Evingür, G.A. Conductivity percolation of carbon nanotubes in polyacrylamide gels. In Carbon Nanotubes—Polymer Nanocomposites, 1st ed.; Yellampalli, S., Ed.; IntechOpen Limited: London, UK, 2011; pp. 197–214. [Google Scholar]

- Wang, Y.; Wang, S.; Li, M.; Gu, Y.; Zhang, Z. Piezoresistive response of carbon nanotube composite film under laterally compressive strain. Sens. Actuators A 2018, 273, 140–146. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, W.; Wang, S.; Xing, F.; Gu, Y.; Wang, Y.; Li, M. Infiltration monitoring using carbon nanotube buckypaper for the characterization of out-of-plane unsaturated permeability. Polym. Compos. 2023, 44, 3020–3028. [Google Scholar] [CrossRef]

- Li, Y.; Tanaka, T. Kinetics of swelling and shrinking of gels. J. Chem. Phys. 1990, 92, 1365–1371. [Google Scholar] [CrossRef]

- Crank, J. The Mathematics of Diffusion, 2nd ed.; Oxford University Press: Bristol, UK, 1975; pp. 286–325. [Google Scholar]

| Type of Sensor | Maximum ΔR/R0 | References |

|---|---|---|

| MXene/CNT sensor | ~11.5 | [10] |

| Filtered buckypaper sensor | ~2.5 | [11] |

| MWCNT yarn | ~0.08 | [12] |

| MWCNT-spray-coated fiber textile | ~1.8 | [13] |

| Carbon fiber fabric | <0.6 | [15] |

| CNT-coated aramid fiber sensor | 12.4 | This study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Y.; Wang, B.; Du, K.; Liu, Y.; Kang, R.; Wang, S.; Zhang, J.; Gu, Y.; Li, M. Process Monitoring for Vacuum-Assisted Resin Infusion by Using Carbon Nanotube-Based Sensors. Polymers 2025, 17, 459. https://doi.org/10.3390/polym17040459

Shi Y, Wang B, Du K, Liu Y, Kang R, Wang S, Zhang J, Gu Y, Li M. Process Monitoring for Vacuum-Assisted Resin Infusion by Using Carbon Nanotube-Based Sensors. Polymers. 2025; 17(4):459. https://doi.org/10.3390/polym17040459

Chicago/Turabian StyleShi, Yi, Beibei Wang, Kui Du, Yanan Liu, Ruiqi Kang, Shaokai Wang, Jiayu Zhang, Yizhuo Gu, and Min Li. 2025. "Process Monitoring for Vacuum-Assisted Resin Infusion by Using Carbon Nanotube-Based Sensors" Polymers 17, no. 4: 459. https://doi.org/10.3390/polym17040459

APA StyleShi, Y., Wang, B., Du, K., Liu, Y., Kang, R., Wang, S., Zhang, J., Gu, Y., & Li, M. (2025). Process Monitoring for Vacuum-Assisted Resin Infusion by Using Carbon Nanotube-Based Sensors. Polymers, 17(4), 459. https://doi.org/10.3390/polym17040459