Abstract

The use of biopolymers like Xanthan Gum (XG) for soil stabilization offers an eco-friendly alternative, enhancing soil properties while reducing CO2 emissions, gaining attention in sustainable engineering. This study investigated the interaction and geotechnical improvements of clay mixed with XG and polypropylene fibers (PPF). Biopolymer was used in proportions of 1%, 3%, and 5%, while the PPF percentage was kept constant at 0.5% by weight. Additionally, the molding density was varied at 1.65 g/cm3, 1.70 g/cm3, and 1.76 g/cm3. A total of 108 specimens were prepared using two curing times (28 and 90 days), and the samples were subjected to unconfined compressive strength (UCS) tests, ultrasonic pulse velocity (UPV), and Scanning Electron Microscopy (SEM). The results demonstrate that the addition of XG and PPF in the specified proportions provides significant mechanical improvements to the stabilized soil. The curing time had a notable impact on these improvements; a curing time of 90 days resulted in strength increases of up to 37% compared to 28 days, while the maximum dry density improved this property by up to 87% compared to the minimum density. The incorporation of PPF enhanced strength by 53.93%, while stiffness increased by 63.55%. Additionally, the strength () and stiffness () results were successfully correlated using the porosity/binder index , achieving determination coefficients (R²) greater than 0.90 and 0.80, respectively.

1. Introduction

Soil stabilization is a fundamental technique to improve the mechanical properties of problematic soils, such as low-plasticity clays. These soils exhibit high compressibility, low strength, and significant susceptibility to wetting and drying cycles, posing challenges for the construction of durable and safe infrastructure [1,2]. Traditionally, materials such as Portland cement and lime have been employed due to their effectiveness. However, their use is associated with significant environmental impacts, including the emission of greenhouse gases. Several studies highlight that traditional cementitious products and some synthetic materials produce large quantities of CO2 during their production [3,4,5,6]. Specifically, each ton of cement generates approximately one ton of CO2, while lime production emits around 0.86 tons of CO2 per ton produced [7,8,9]. These emissions account for approximately 8% of global CO2 emissions, significantly contributing to climate change [10,11].

In addition to environmental impacts, the use of these stabilizers can alter groundwater pH, negatively affecting local ecosystems and posing additional environmental risks [12,13]. These limitations have driven the search for sustainable alternatives, increasing interest in unconventional stabilizers, such as polymers, resins, acids, silicates, enzymes, and waste materials, including fly ash [14,15,16,17]. Polymers, in particular, help form physicochemical bonds between soil minerals and reduce porosity within the soil matrix [18,19]. Biopolymers, on the other hand, stand out as natural, carbon-neutral, and energy-efficient alternatives, suitable for various geotechnical applications [20].

Among the biopolymers most studied for addressing geotechnical problems are Guar Gum (GG), Microcrystalline Cellulose (MCC) [20], Chitosan, Persian Gum [21], β-Glucan (BG), and γ-Polyglutamic Acid (GPA) [22], and Zein Biopolymer [23]. However, XG has gained particular attention in geotechnical engineering due to the recent reduction in its market price and its effectiveness in mitigating soil weaknesses [24]. This extracellular polysaccharide, secreted by Xanthomonas campestris [25,26], forms cohesive bonds, improves mechanical strength, and increases soil cohesion even at low concentrations ranging from 1% to 2% by weight [1,2,11,19,25,27,28,29]. Studies have demonstrated that XG can triple soil cohesion, reduce susceptibility to wetting-drying cycles, and significantly enhance durability [30,31]. Additionally, Moghal et al. [13] highlight the potential of biopolymers such as XG and GG to stabilize various soil types, including mine tailings.

The reinforcement of soils with randomly distributed fibers is another effective technique that enhances soil engineering properties. Unlike traditional geosynthetics, fibers, such as Polypropylene Fibers (PPF), are homogeneously mixed with the soil, avoiding weak planes parallel to the reinforcement [32]. These fibers increase the unconfined compressive strength (UCS) and reduce both compressibility and swelling of the soil. For instance, the addition of 1% PPF can reduce the compression index by 69% and the swelling index by 78%, while also improving soil cohesion by forming a stable structural network [33,34].

Singh et al. [2] evaluated the effect of XG on expansive soils using proportions of 0%, 0.2%, 0.5%, 0.8%, and 1.0% by weight. The results indicate that the plasticity index of the soil initially increases with the addition of XG but significantly decreases beyond 0.5%. Although compressibility shows a slight increase, swelling pressure, free swell, and hydraulic conductivity decrease notably, while compressive strength and durability improve. Similarly, Khalid et al. [33] investigated the use of PPF in proportions ranging from 0.5% to 1.5% in clayey soils, observing increases in liquid and plastic limits, as well as in UCS. Adding 1% PPF significantly reduced soil compressibility, lowering the compression index by 69% and the swelling index by 78%.

Baldovino et al. [31] analyzed the change from the porosity/Binder ratio to the porosity/Xanthan gum ratio (). This parameter relates the porosity of the compacted mixture () to the volumetric content of XG (), adjusted by an internal exponent (x), similar to the interaction between cement and clay in stabilized mixtures [34]. They found that this parameter adjusted for XG is 0.04, compared to 0.28 for Portland cement. This suggests that porosity has a more significant impact on the strength development of XG-treated soils. To counterbalance this effect, increasing the XG content in the mixtures is necessary to offset the influence of voids in the material.

Recent studies [35,36,37] highlight the effectiveness of XG in the stabilization of different soils. Missoum et al. [35] found that the biopolymer improves the shear strength and cohesion of sandy soils and also incorporated fine particles as an addition, observing an amplification of the improvements. On the other hand, Chang et al. [36] emphasized that the interaction between XG and soil is influenced by pore fluid chemistry, where XG can reduce the liquid limit through particle aggregation or increase it via hydrogel formation. Studying the addition of XG to clays, Barani and Barfar [37] concluded that XG-treated clays exhibit higher fracture energy and durability, particularly in dry states, addressing challenges associated with high water content.

The combination of XG and PPF represents a synergistic and innovative approach to soil stabilization. While XG enhances cohesion and fills soil voids, fibers mechanically reinforce the structure, creating a dense and resilient matrix. Scanning electron microscopy (SEM) analyses confirm that this combination reduces porosity and improves interconnection between particles and fibers, resulting in a more cohesive and stable material [1,30]. Samples treated with this mixture have shown greater strength and durability, remaining intact even after extended periods of water immersion, unlike untreated soils, which rapidly disintegrate [2,30].

The present study aims to analyze the mechanical behavior of a clay (CL) from the northern region of Cartagena de Indias (Colombia) [38], stabilized with XG and to evaluate the effect of adding PPF as reinforcement. The goal is to reduce the required percentage of XG to achieve specific values of strength () and stiffness , optimizing the stabilization process. The mixtures will be subjected to curing times of 28 and 90 days and evaluated through unconfined compression tests to determine strength properties and ultrasonic pulse measurements to analyze stiffness. This analysis will be complemented by scanning electron microscopy with energy-dispersive spectroscopy (SEM-EDS), along with the development of predictive equations based on the porosity/binder index (). Together, this comprehensive approach will provide insights into both the mechanical and microstructural characteristics of the stabilized mixtures, promoting a more efficient and sustainable solution for improving clay soils.

The limited research addressing the interaction of these materials (i.e., XG and PPF), particularly in clays, combined with the application of the porosity-binder index capable of generating equations and dosage curves from experimental data, represents a significant advancement in soil stabilization through sustainable alternatives.

2. Materials and Methods

This study aims to experimentally evaluate the improvement of a low-plasticity clay (CL) soil through the incorporation of Xanthan Gum (XG) and Polypropylene Fibers (PPF). Mixtures were prepared with XG dosages of 1%, 3%, and 5%, relative to the dry mass of the soil, along with PPF at 0.5% of the total sample mass. A total of 108 specimens were produced, subjected to curing periods of 28 and 90 days, with variations in dry density. The specimens were assessed through unconfined compressive strength (UCS) tests and ultrasonic pulse velocity (UPV).

2.1. Materials

A Clay, XG, and PPF are the raw materials used in this research (Figure 1). Acuña et al. [38] previously investigated the dispersivity level of this clay using the pinhole test and the crumb test. Additionally, Roman et al. [39] analyzed the mechanical behavior of this soil, including its strength and stiffness, along with its microstructure. This analysis was conducted using crushed limestone waste as an improvement material, evaluating the soil’s properties through the porosity-binder index.

Figure 1.

Materials used in the research: (a) Clay (CL), (b) Biopolymer XG, (c) PPF.

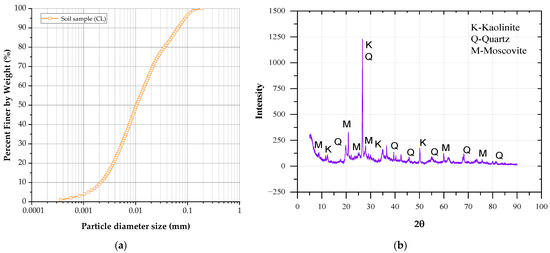

Figure 2 shows the particle size distribution of the soil and its mineralogical composition.

Figure 2.

(a) The granulometric curve of soil sample. (b) X-ray diffraction (XRD) of the soil sample.

Table 1 provides the soil’s chemical composition obtained through X-ray fluorescence. The soil was composed mainly of kaolinite clay minerals.

Table 1.

Chemical composition of soil sample (% by weight).

Table 2 presents its geotechnical characterization. The soil was classified as low-plasticity clay (CL) according to the Unified Soil Classification System (USCS) [40]. Its specific gravity was measured as 2.80 following ASTM D854 [41]. The particle size distribution revealed 10% clay, 78% silt, and 12% sand, with coefficients of curvature and uniformity of 0.96 and 7.14, respectively. The additional morphological composition of the sample and details of the soil’s geotechnical properties can be found in Roman et al. [39].

Table 2.

Geotechnical properties of the soil sample.

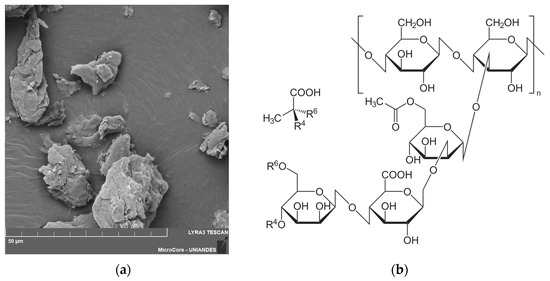

The XG used in this study is a polysaccharide produced by the bacterium Xanthomonas campestris. Its structure consists of repeating pentasaccharide units containing glucose, mannose, and glucuronic acid in a molar ratio of 2:2:1 [26,31,46]. The density of XG () was found to be 1.5 g/cm3, with a pH of 6.34 and a viscosity of 1200 MPa∙s.

XG has an elemental composition primarily consisting of carbon (54.05%), oxygen (43.47%), sodium (1.59%), and calcium (0.89%) (Figure 3). This chemical composition enhances its ability to form ionic and covalent bonds, improving cohesion and the structural integrity of the treated soil.

Figure 3.

(a) XG morphology recorded in the SEM analysis (b) Molecular structure of XG.

PPF were sourced from a local supplier. These fibers have a length of 20 mm and a density () of 0.91 g/cm3.

2.2. Methodology

2.2.1. Specimen Molding and Preparation

XG was mixed using distilled water for dissolution with soil in proportions of 1%, 3%, and 5% these percentages were selected based on the literature [29,31,46,47]. The water content was adjusted based on the maximum dry unit weight, and the mixture was manually prepared to ensure homogeneity (Figure 4).

Figure 4.

Manual mixing of XG in water. (a) Addition of XG in water (b) Partial mixing of the gum in water. (c) Final homogeneous mixture of XG.

A total of 108 specimens were fabricated, following the distribution outlined in Table 3. These samples were made in cylindrical metal molds with a diameter of 2 inches and a height of 4 inches, complying with the 1:2 ratio specified by ASTM D1632 [48].

Table 3.

Mixed proportion design for compacted blends of soil, XG, and PPF.

Each specimen was compacted in three layers, with the surface of each layer being scarified to ensure uniformity in density and overall characteristics. Additionally, the same number of specimens was prepared with the inclusion of 0.5% PPF relative to the dry weight of the soil. All specimens were compacted in triplicate to ensure consistency in the results.

Specific acceptance and rejection criteria for the specimens were applied during the process, based on recommendations from the literature [49,50]. The specimens underwent a curing process under controlled temperature and humidity conditions to prevent moisture loss, with curing periods of 28 and 90 days. Additional curing conditions and controls were implemented following the methodology described by Baldovino et al. [31].

2.2.2. Program of Ultrasonic Pulse Velocity Test and UCS Test

Upon completion of the curing process, the specimens were removed from the humid chamber and immersed in distilled water for 24 h to reduce matric suction, as suggested by previous studies [31,39,49,50,51].

To determine the stiffness of the samples, the Pundit Lab Plus equipment (Proceq, Schwerzenbach, Switzerland) was used following the ASTM C597 standard [52]. This procedure provided the necessary values to calculate the small-strain shear modulus (). Compression waves were generated using transducers at a frequency of 54 kHz, while shear waves were recorded at 250 kHz.

Subsequently, UCS tests were conducted in accordance with the ASTM D2166 standard [53]. For this purpose, the specimens were subjected to axial loading using a 50 kN multitest hydraulic press with a sensitivity of 0.1 kN and a controlled deformation rate of 1.15 mm/min.

2.2.3. Microstructural Analysis

SEM analyses were performed on strategically selected points of the samples, reaching magnifications of up to 5000×. The resolution was adjusted based on the material: up to 5 microns for Soil-XG samples and 100 microns for Soil-XG-PPF samples. These analyses were conducted using the LYRA-3 dual-beam SEM-FIB system manufactured by TESCAN (Tescan Orsay Holding, Brno-Kohoutovice, Czech Republic).

2.2.4. Application of the Porosity-Binder Index

The porosity/binder index (), introduced by Consoli et al. [54], has become a widely used tool for analyzing the UCS of artificially cemented soils [31,34,39,49,51,54,55,56]. Volumetric Binder content () is calculated using the original formula proposed by Baldovino et al. [57]. The porosity () adapted to account for the addition of XG and PPF (Equation (1)).

The Equation (1) incorporates the percentage of XG and PPF (), the material densities defined in Section 2.1, the specific gravity of the soil () presented in Table 1, the molding densities () indicated in Table 3, as well as the volume of the specimen () and the soil volume ().

The UCS ) and the initial stiffness at small strains () are related to the η/Biv index through adjustments based on two empirical exponents (x and C) and an empirical constant Aq. These properties are expressed in kPa and MPa, respectively, as defined in Equation (2).

The scalar Aq is defined by the interplay between the strength of cementation bonds and the soil matrix properties, representing a key parameter in modeling resistance [58]. This value is also influenced by factors related to the physical and chemical characteristics of the soil, enabling a more accurate representation of structural behavior under varying conditions [59].

3. Results and Discussion

The results obtained in the improvement of a clayey soil using XG as a stabilizing agent are presented and analyzed below. This study evaluated key factors such as dry unit weight, curing time, and binder content, considering their influence on the UCS () and UPV () of the resulting mixtures.

Additionally, the mechanical and microstructural behavior induced by the incorporation of PPF was examined, identifying structural changes and their impact on the properties of the treated material. Furthermore, the application of a rational predictive methodology based on the porosity/binder index, proposed by Consoli et al. [54] was validated for predicting the stiffness and strength results.

3.1. Influence of XG Content, Dry Unit Weight and Curing Time on the Strength and Stiffnes of a Stabilized Clayey Soil

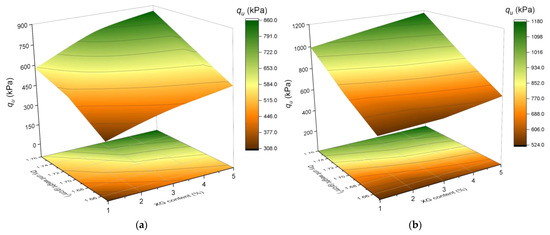

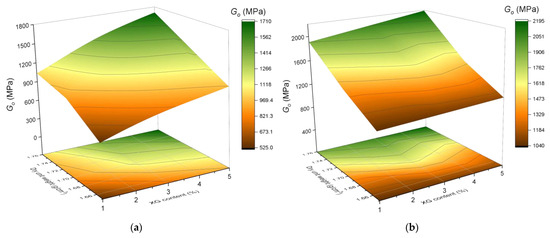

Figure 5 and Figure 6 demonstrate that curing time, XG content, and dry density are key factors that significantly affect both the UCS and stiffness of the stabilized soil. Samples cured for 90 days show notable improvements compared to those cured for 28 days, with increases of up to 37% in UCS and even greater values for stiffness. The addition of XG to the soil contributes to the retention of water content within the soil matrix pores, which can enhance soil cohesion. This, in turn, influences the expansion and contraction of the soil due to moisture changes, improving both stability and strength [31].

Figure 5.

Influence of curing time, dry unit weight (g/cm3), and XG content (%) on compressive strength. (a) Compressive strength results after 28 days of curing. (b) Compressive strength results after 90 days of curing.

Figure 6.

Influence of curing time, dry unit weight (g/cm3), and XG content (%) on stiffness. (a) Stiffness results after 28 days of curing. (b) Stiffness results after 90 days of curing.

Increasing the XG content from 1% to 5% leads to significant improvements in both properties. In terms of UCS, the increases range between 30% and 39%, depending on the initial soil conditions, while stiffness exhibits proportional increments under the same conditions. Additionally, increasing the molding density from 1.65 g/cm3 to 1.76 g/cm3 results in UCS improvements of up to 87%, while stiffness also shows significant enhancements, reaching more than double the initial values in some cases. These findings highlight the importance of adequate initial compaction to maximize the positive impact of the stabilizer on the interaction between soil particles.

Moreover, in Figure 5b and Figure 6b, noticeable changes in the trends of UCS and stiffness lines can be observed compared to Figure 5a and Figure 6a. After transitioning to a curing time of 90 days, these lines gain greater steepness relative to the dry unit weight axis, suggesting that this parameter may have a more pronounced influence as curing times increase.

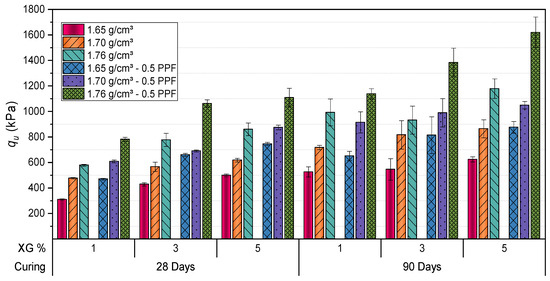

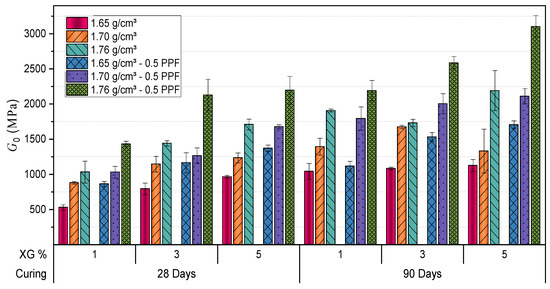

3.2. Influence of XG Content, Dry Unit Weight, Curing Time, and PPF on the Strength and Stiffnes of a Stabilized Clayey Soil

Figure 7 and Figure 8 show how the addition of PPF significantly impacts the mechanical properties of XG stabilized soil, regardless of the dry unit weight being analyzed. For instance, in mixtures with 1% XG, the data indicate that after 28 days of curing, UCS increased from 308.12 kPa without PPF to 463.86 kPa with 0.5% fibers at a dry unit weight of 1.65 g/cm3, representing a 51% increase. When the dry unit weight is increased to 1.76 g/cm3, the differences remain evident, reaching a compressive strength of 774.05 kPa with PPF compared to 576.01 kPa without fibers. This 34% increase suggests higher initial density conditions of the mixture.

Figure 7.

Influence of curing time, dry unit weight (g/cm3), XG, and PPF on strength of stabilized Clayey Soil.

Figure 8.

Influence of curing time, dry unit weight (g/cm3), XG, and PPF on stiffness of stabilized Clayey Soil.

With 3% XG, significant improvements in soil properties were observed. For samples compacted at a dry unit weight of 1.65 g/cm3, the UCS increased from 435.50 kPa (no fibers) to 670.90 kPa (with 0.5% PPF), representing a 54% enhancement. At higher dry unit weights, such as 1.76 g/cm3, the strength rose from 770.69 kPa to 1062.38 kPa, reflecting a 38% improvement. Stiffness values exhibited similar trends, increasing from 861.42 MPa to 1071.76 MPa at 1.65 g/cm3 and from 1408.44 MPa to 1900.81 MPa at 1.76 g/cm3.

These findings align with prior studies demonstrating the ability of XG to enhance interparticle bonding and improve mechanical performance in stabilized soils [27,31].

After 90 days of curing, the effects of stabilization were more pronounced. In samples with 5% XG and a dry unit weight of 1.65 g/cm3, UCS increased from 611.50 kPa (no fibers) to 898.57 kPa (with fibers), while stiffness improved from 1162.34 MPa to 1769.10 MPa, reflecting gains of 47% and 52%, respectively. For a dry unit weight of 1.76 g/cm3, UCS increased from 1215.50 kPa to 1698.50 kPa, and stiffness rose from 2520.46 MPa to 3247.25 MPa. These results emphasize the importance of compaction and curing time in optimizing the performance of stabilized materials. The progressive formation of cohesive soil-polymer matrices during curing significantly enhances strength and stiffness [60].

Overall, the results confirm the suitability of XG for geotechnical applications. By forming cohesive matrices, XG enhances both the strength and stiffness of treated soils, providing an efficient and sustainable alternative for soil stabilization [27,37]. Proper management of variables such as XG content, compaction, and curing time is crucial to achieving optimal performance in stabilized materials.

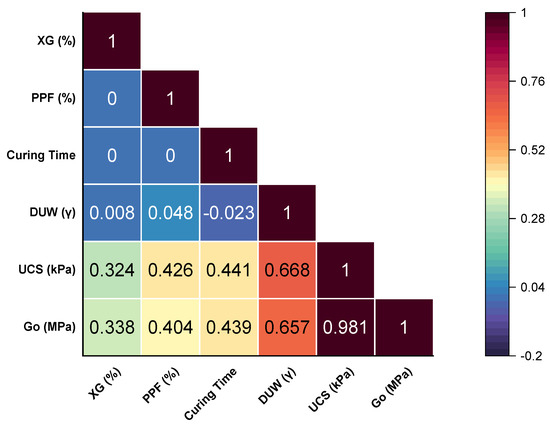

The analysis of the mechanical properties of stabilized soils reveals that dry unit weight is the most influential factor on UCS () and stiffness () (Figure 9). This is reflected in positive correlations of 0.668 and 0.657, respectively, indicating that higher density enhances particle-additive interactions, significantly improving the material’s performance.

Figure 9.

Correlation Matrix of Variables.

Curing time, with correlations of 0.441 and 0.439 for UCS and stiffness, allows chemical reactions to reach their full potential, thereby increasing the structural stability of the soil. Additionally, PPF contribute as reinforcements that distribute stresses, showing a moderate positive impact with values of 0.426 and 0.404.

XG, while exhibiting lower correlations (0.324 for and 0.338 for ), acts as a binder that enhances particle cohesion. This highlights its usefulness as a complementary additive in stabilized systems, especially when combined with other factors such as density and curing time.

The combined use of XG and PPF effectively improves the mechanical properties of treated clay soils. Increasing XG content consistently enhances the UCS, as demonstrated in various studies. Weng et al. [61] observed that an optimal XG content of 1.5% to 2% resulted in UCS improvements of up to 2.41 times compared to untreated soils. Although the inclusion levels in the present work were slightly higher, the trends confirm the positive impact of XG as a stabilizer. Similarly, Bozyigit et al. [60] reported that XG increased the dry unit weight of treated soils from 12.75 kN/m3 to 14.52 kN/m3, while also improving the Atterberg limits. The liquid limit increased by 32% with XG, highlighting its role in altering the plasticity of treated materials.

Extended curing periods further amplify the benefits of XG stabilization. After 90 days, samples prepared at optimum water content demonstrated significant gains in both strength and stiffness. Conversely, excessive water content reduced long-term strength, underscoring the importance of precise preparation conditions. These findings are consistent with previous studies emphasizing the role of curing time in fostering enhanced soil-polymer interactions [16,31].

3.3. Application of the Porosity/Binder Index to Predict the Strength and Stiffnes of Compacted Blends

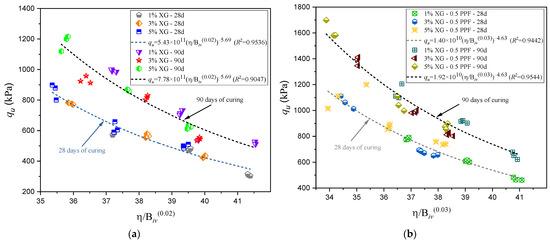

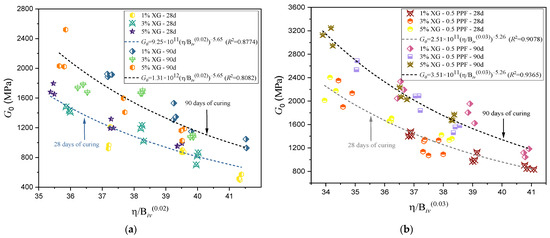

Figure 10a,b depict the Porosity/Binder index adjustments for Soil-XG conditions under two curing times, as well as for the addition of PPF. It was observed that a reduction in porosity led to an increase in the UCS () of the prepared mixture, aligning with findings from previous studies [49,50,53,54,55].

Figure 10.

Effect of the Porosity/Binder Index on Predicting UCS. (a) Specimens of soil and XG cured for 28 and 90 days. (b) Specimens of Soil–XG–PPF tested after 28 and 90 days of curing.

The equations derived for UCS () incorporate an exponent of 0.02 for the index in soil-XG mixtures. This value is consistent with the study by Baldovino et al. [31], where the exponent was adjusted to 0.04. The discrepancy may be attributed to the inclusion of two curing periods and the simultaneous adjustment for these conditions.

Conversely, for soil-XG-PPF mixtures, the exponent is adjusted to 0.03, reflecting the mechanical contribution of the fibers, particularly in stress redistribution and structural behavior modification of the stabilized soil.

An increase in the strength and stiffness of the soil following densification of the soil [62] is possible by applying the appropriate densification method and using suitable proportions of materials in the design. This principle aligns with the findings of the study, where a rational model relating porosity and binder content successfully described the initial stiffness at small deformations for the different soil mixtures evaluated. However, it is important to note that the coefficients of determination for showed lower values compared to those obtained for (see Table 4 and Table 5). In Figure 11b, the maximum stiffness value was observed for the combination of 5% XG with 0.5% PPF, after 90 days of curing and a density of 1.76 g/cm3. Similar to UCS, the stiffness demonstrated a direct relationship with curing time. Figure 11a presents results for specimens without PPF, while Figure 11b includes PPF, confirming that the addition of PPF improves soil stiffness. In cases with equivalent densities, XG percentages, and curing times, higher stiffness values were observed when PPF was incorporated.

Table 4.

UCS equation of compacted blends.

Table 5.

Stiffness Equation of compacted blends.

Figure 11.

Effect of the Porosity/Binder Index on Predicting Stiffness. (a) Specimens of soil and XG cured for 28 and 90 days. (b) Specimens of Soil–XG–PPF tested after 28 and 90 days of curing.

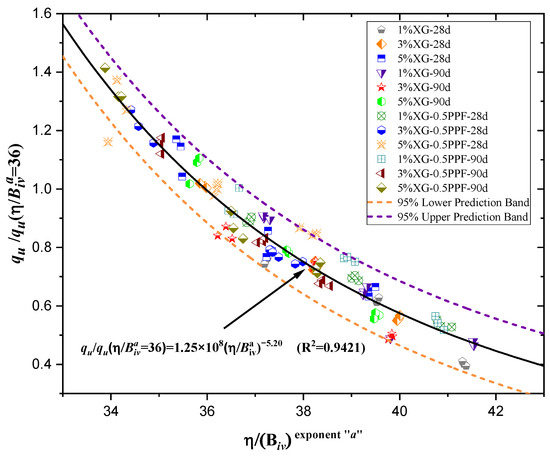

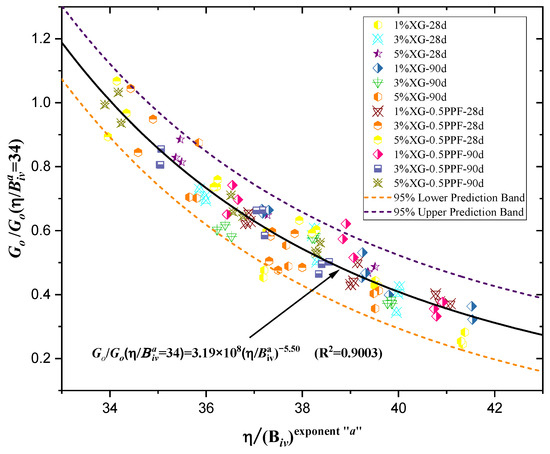

3.4. Normalization of Equations for the Strength and Stiffness of Compacted Blends

Normalization involves the development of accurate predictive models that eliminate the inherent variations in individual samples, enabling the identification of global and unique trends. In this case, the aim is to derive a suitable equation to estimate and as a function of the normalized index , with a single potential trend for the studied clay under the various parameters adjusted in the study. In recent studies, Lopez et al. [55] applied normalization to four sands, performing identical tests to evaluate the mechanical properties of the improved soil. To establish a normalized equation, the initial step was determining all normalized strengths and stiffnesses using a specific value of ) = . For the present study, the normalization range of is between 30 and 45, applicable to both the UCS () and the small-strain initial stiffness (). For , a value of = 36 was selected, and for , = 34 (see Figure 10 and Figure 11) to calculate the normalized strength qu−n and stiffness .

The normalized strengths are 767.94 kPa for XG-0PPF-28d, 1099.88 kPa for XG-0PPF-90d, 874.79 kPa for XG-0.5PPF-28d, and 1201.24 kPa for XG-0.5PPF-90d. The normalized stiffnesses are 2029.64 MPa for XG-0PPF-28d, 2882.24 MPa for XG-0PPF-90d, 2251.18 MPa for XG-0.5PPF-28d, and 3145.23 MPa for XG-0.5PPF-90d. After calculating the normalized strength and stiffness values, the UCS and the small-strain initial stiffness for each sample were divided by their corresponding normalized values for the type of sand studied (for both and ). This normalization was performed for a total of 108 results of and . The strength and stiffness values used for normalization are provided in Table 6. Figure 12 and Figure 13, and Equation (3) represent the best fit for the normalized strength values based on the chosen parameter, with a normalization coefficient of 0.9421, indicating a unique trend encompassing all experimental and normalized data points.

Table 6.

Normalization data.

Figure 12.

Normalization using the porosity/binder index for UCS data.

Figure 13.

Normalization using the porosity/binder index for stiffness () data.

Similarly, the small-strain initial stiffness data () were used to generate Figure 12 and Equation (4), which achieved a determination coefficient of 0.9003. Although this is slightly lower than the fit obtained for the UCS, in both cases, the fit exceeded 0.90. Therefore, it is critical to validate the use of Equations (3) and (4) to describe the mechanical behavior of the studied clay when mixed with varying percentages of XG and PPF.

3.5. Microstructure and Microanalysis of Soil Mixtures

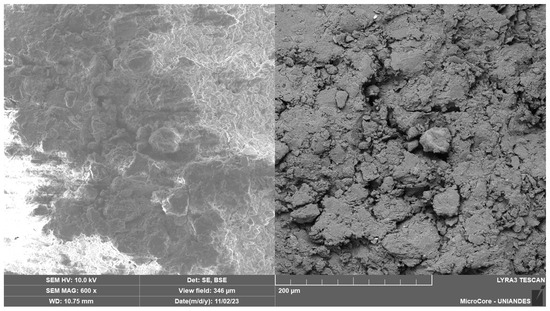

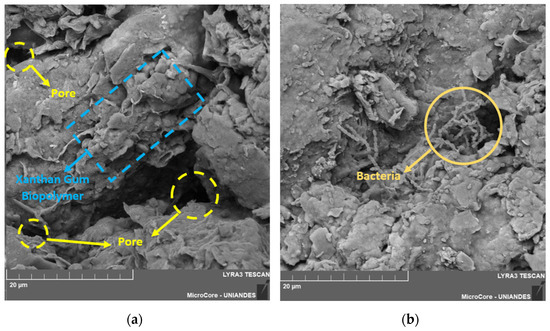

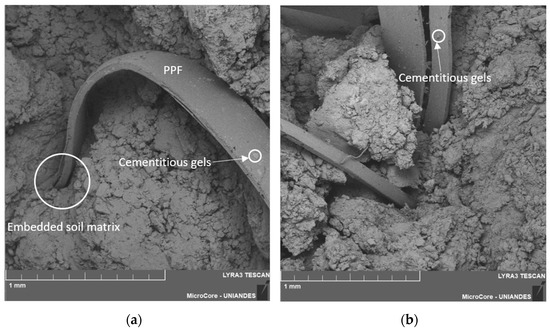

Microstructural analyses of soil mixtures with XG and PPF using SEM-EDS imaging were conducted on a single type of specimen. These specimens were molded with an XG content of 5% and a PPF content of 0.5%, a selection based on the highest mechanical performance values recorded for the soil mixture after a curing period of 90 days.

Biopolymers function as a surface layer that encapsulates soil particles, establishing connections and direct chemical interactions that bind previously separated particles. The behavior of the soil matrix treated with biopolymers is complex and influenced by several factors, including the electrical charges of the biopolymer itself, the inherent cations within the clay, and the total charge density in the system [63].

Figure 14 shows the interface between the soil and XG alone. A homogeneous matrix with reduced voids (low porosity) is observed, as evidenced by a 200 and 20 μm zoom view.

Figure 14.

SEM images of soil treated with XG biopolymer.

This confirms why the combination of 5% XG with 90 days of curing exhibited high results in UCS and small-strain initial stiffness. In Figure 15b, certain voids are visible at the soil mixture interface. The reaction between the XG biopolymer and water generates a substantial amount of biopolymer film accumulating on soil surfaces. This biopolymer film, known as hydrogel, provided a denser structure and thicker adhesive bonds between soil particles for the utilized 5% XG content. Similar results were reported in previous studies by Yang et al. [64], which investigated mechanisms for improving biopolymer-reinforced soil stabilized with XG. Lastly, Figure 15b identifies the presence of a dead bacterium, Xanthomonas campestris, which is used in the production of XG, an organic-origin biopolymer.

Figure 15.

SEM images of soil treated with XG biopolymer: (a) Voids at the interface between the soil and the XG. (b) Xanthomonas campestris bacteria present in the soil-XG matrix.

Figure 16a,b demonstrate that the combination of PPF and soil-XG led to the formation of a reinforcement matrix, further emphasizing the significance of low porosity. The lighter-colored zones indicate the presence of XG, and in some regions, the PPF adhered to the cementitious gels, enhancing the roughness of the fibers. Additionally, a more solid matrix was evident due to the interaction between the soil and XG. This microscopic analysis corroborates the superior mechanical performance observed for the soil mixture containing 0.5% PPF and 5% XG. Lang et al. [65] reported similar findings in their microanalysis of a sedimented soil matrix stabilized with cement and PPF. Their study revealed that hydration products filled microcracks and pores between fibers and soil particles, resulting in a more compact microstructure.

Figure 16.

SEM images of Soil–XG–PPF mixture. (a) the XG biopolymer content of 5% and 0.5% PPF. (a) Interaction between Soil-XG-PPF. (b) Reinforcement matrix between Soil-XG-PPF.

4. Conclusions

In this study, the effects of XG and PPF on the geotechnical improvements of clay were evaluated using UCS tests, UPV and SEM-EDS. Based on the results and analyses obtained, the following conclusions can be drawn:

- XG is effective for soil stabilization due to its ability to improve cohesion and moisture retention in treated soils. However, its limited availability and relatively high cost make its use at lower percentages a more sustainable alternative. The combination with PPF presents itself as an alternative, providing adequate strength and stiffness while optimizing resources and costs.

- The results show that extending the curing time from 28 to 90 days increases strength by up to 37%, while raising the dry density from 1.65 to 1.76 g/cm3 improves this property by up to 87%. Additionally, the impact of fiber usage is highly significant; regarding strength , the minimum and maximum percentage increases observed between samples without fibers and those with fibers were 14.70% and 53.93%, respectively. For stiffness (), the minimum and maximum percentage increases were 7.06% and 63.55%, respectively. These factors are crucial for achieving optimal mechanical performance of the soil.

- The porosity/binder index , accurately models the mechanical behavior of soils stabilized with XG, even with the addition of fibers, achieving equations with reliability coefficients R2 above 0.9 for strength and over 0.8 for stiffness .

- The normalization of two equations, one for and another for , enabled the derivation of expressions that adapt to all conditions and variations in the XG and PPF percentages used in the samples. These generated determination coefficients (R2) of 0.9421 for UCS and 0.9003 for stiffness.

- In the microstructure of the soil mixture incorporating XG and PPF, a denser matrix with reduced porosity was observed due to hydrogel formation. This facilitated a more compact interface, where the fibers acted as reinforcement material, effectively distributing internal stresses and preventing brittle failures.

The future scope of this research lies in optimizing soil-polymer mixtures for various soil types, exploring the development of new biopolymers and sustainable additives, and analyzing the environmental impact associated with their use. All of this aims to generate sufficient information to support and establish regulations, standards, and the validity of biopolymer applications in the field of engineering.

Author Contributions

Conceptualization, J.d.J.A.B., J.A.A.V. and L.C.S.L.; methodology J.d.J.A.B., J.A.A.V. and L.C.S.L.; software, J.A.A.V. and L.C.S.L.; validation, O.P.C. and Y.E.N.d.l.R.; formal analysis, J.d.J.A.B., J.A.A.V. and L.C.S.L.; investigation, J.A.A.V. and L.C.S.L.; resources, J.d.J.A.B., Y.E.N.d.l.R. and O.P.C.; data curation, J.A.A.V. and L.C.S.L.; writing—original draft preparation, J.d.J.A.B., J.A.A.V. and L.C.S.L.; writing—review and editing, J.d.J.A.B., J.A.A.V. and L.C.S.L.; visualization, O.P.C.; and Y.E.N.d.l.R.; supervision, J.d.J.A.B.; project administration, J.d.J.A.B. and Y.E.N.d.l.R.; funding acquisition, Y.E.N.d.l.R. All authors have read and agreed to the published version of the manuscript.

Funding

The Fundación Universitaria Los Libertadores—Colombia (FULL) (Project N° ING-39-24) funded the APC.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors thank the Universidad de Cartagena (Cartagena, Colombia) and Fundación Universitaria Los Libertadores (Bogotá, Colombia).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bagheri, P.; Gratchev, I.; Rybachuk, M. Effects of Xanthan Gum Biopolymer on Soil Mechanical Properties. Appl. Sci. 2023, 13, 887. [Google Scholar] [CrossRef]

- Singh, S.P.; Das, R. Geo-engineering properties of expansive soil treated with xanthan gum biopolymer. Geomech. Geoengin. 2020, 15, 107–122. [Google Scholar] [CrossRef]

- Chang, I.; Lee, M.; Cho, G.-C. Global CO2 Emission-Related Geotechnical Engineering Hazards and the Mission for Sustainable Geotechnical Engineering. Energies 2019, 12, 2567. [Google Scholar] [CrossRef]

- Etim, R.; Eberemu, A.; Osinubi, K. Stabilization of black cotton soil with lime and iron ore tailings admixture. Transp. Geotech. 2017, 10, 85–95. [Google Scholar] [CrossRef]

- Rahgozar, M.A.; Saberian, M.; Li, J. Soil stabilization with non-conventional eco-friendly agricultural waste materials: An experimental study. Transp. Geotech. 2018, 14, 52–60. [Google Scholar] [CrossRef]

- Afshar, A.; Jahandari, S.; Rasekh, H.; Shariati, M.; Afshar, A.; Shokrgozar, A. Corrosion resistance evaluation of rebars with various primers and coatings in concrete modified with different additives. Constr. Build. Mater. 2020, 262, 120034. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO 2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef]

- Khayat, N.; Nasiri, H. Study of Strength Characteristics and Micro-structure Analysis of Soil Stabilized with Wastewater and Polymer. Int. J. Pavement Res. Technol. 2024, 17, 1213–1224. [Google Scholar] [CrossRef]

- Acharya, R.; Pedarla, A.; Bheemasetti, T.V.; Puppala, A.J. Assessment of Guar Gum Biopolymer Treatment toward Mitigation of Desiccation Cracking on Slopes Built with Expansive Soils. Transp. Res. Rec. 2017, 2657, 78–88. [Google Scholar] [CrossRef]

- Uwasu, M.; Hara, K.; Yabar, H. World Cement Production and Environmental Implications. Environ. Dev. 2015, 10, 36–47. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Cho, G.-C. Introduction of Microbial Biopolymers in Soil Treatment for Future Environmentally-Friendly and Sustainable Geotechnical Engineering. Sustainability 2016, 8, 251. [Google Scholar] [CrossRef]

- Reddy, N.G.; Rao, B.H.; Reddy, K.R. Biopolymer amendment for mitigating dispersive characteristics of red mud waste. Géotech. Lett. 2018, 8, 201–207. [Google Scholar] [CrossRef]

- Moghal, A.A.B.; Vydehi, K.V. State-of-the-art review on efficacy of xanthan gum and guar gum inclusion on the engineering behavior of soils. Innov. Infrastruct. Solut. 2021, 6, 108. [Google Scholar] [CrossRef]

- Liu, J.; Shi, B.; Jiang, H.; Huang, H.; Wang, G.; Kamai, T. Research on the stabilization treatment of clay slope topsoil by organic polymer soil stabilizer. Ing. Geol. 2011, 117, 114–120. [Google Scholar] [CrossRef]

- Rajabi, A.M.; Hosseini, A. Effect of Liquid Polyvinyl Acetate and Micronized Calcium Carbonate on Strength Parameters of Silty Sand Soil. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 46, 385–395. [Google Scholar] [CrossRef]

- Li, J.-D.; Wang, X.; Zhang, Y.-J.; Jiang, D.-J.; Liu, D.-R.; Wang, J.-L. Study on strength characteristics and mechanism of loess stabilized by F1 ionic soil stabilizer. Arab. J. Geosci. 2021, 14, 1162. [Google Scholar] [CrossRef]

- Wattez, T.; Patapy, C.; Frouin, L.; Waligora, J.; Cyr, M. Interactions between alkali-activated ground granulated blastfurnace slag and organic matter in soil stabilization/solidification. Transp. Geotech. 2021, 26, 100412. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; Soltani, A.; Khayat, N. Stabilization of soft clay using short fibers and poly vinyl alcohol. Geotext. Geomembr. 2018, 46, 646–655. [Google Scholar] [CrossRef]

- Murphy, E.; Ginn, T. Modeling microbial processes in porous media. Hydrogeol. J. 2000, 8, 142–158. [Google Scholar] [CrossRef]

- Arun, L.; Sujatha, E.R.; Baldovino, J.A.; Nuñez de la Rosa, Y.E. Microcrystalline Cellulose—A Green Alternative to Conventional Soil Stabilizers. Polymers 2024, 16, 2043. [Google Scholar] [CrossRef]

- Ghasemzadeh, H.; Farzaneh, M. Application of novel Persian gum hydrocolloid in soil stabilization. Carbohydr. Polym. 2020, 246, 116639. [Google Scholar] [CrossRef] [PubMed]

- Vishweshwaran, M.; Sujatha, E.R.; Baldovino, J.A. Freeze-Dried β-Glucan and Poly-γ-glutamic Acid: An Efficient Stabilizer to Strengthen Subgrades of Low Compressible Fine-Grained Soils with Varying Curing Periods. Polymers 2024, 16, 1586. [Google Scholar] [CrossRef]

- Babatunde, Q.O.; Byun, Y.-H. Soil Stabilization Using Zein Biopolymer. Sustainability 2023, 15, 2075. [Google Scholar] [CrossRef]

- Mendonça, A.; Morais, P.V.; Pires, A.C.; Chung, A.P.; Oliveira, P.V. A Review on the Importance of Microbial Biopolymers Such as Xanthan Gum to Improve Soil Properties. Appl. Sci. 2021, 11, 170. [Google Scholar] [CrossRef]

- Lee, S.; Chang, I.; Chung, M.-K.; Kim, Y.; Kee, J. Geotechnical shear behavior of Xanthan Gum biopolymer treated sand from direct shear testing. Geomech. Eng. 2017, 12, 831–847. [Google Scholar] [CrossRef]

- Lee, S.; Chung, M.; Park, H.M.; Song, K.I.; Chang, I. Xanthan gum biopolymer as soil-stabilization binder for road construction using local soil in Sri Lanka. J. Mater. Civ. Eng. 2019, 31, 06019012. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.C. Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Y.; Wei, X.; Liang, X.; Zhang, J.; Li, X. Unconfined Compressive Strength of Cement-Stabilized Qiantang River Silty Clay. Materials 2024, 17, 1082. [Google Scholar] [CrossRef]

- Sulaiman, H.; Taha, M.R.; Abd Rahman, N.; Mohd Taib, A. Performance of Soil Stabilized with Biopolymer Materials—Xanthan Gum and Guar Gum. Phys. Chem. Earth Parts A/B/C 2022, 128, 103276. [Google Scholar] [CrossRef]

- Chen, C.; Wu, L.; Perdjon, M.; Huang, X.; Peng, Y. The drying effect on xanthan gum biopolymer treated sandy soil shear strength. Constr. Build. Mater. 2019, 197, 271–279. [Google Scholar] [CrossRef]

- Baldovino, J.d.J.A.; Palma Calabokis, O.; Saba, M. From Bibliometric Analysis to Experimental Validation: Bibliometric and Literature Review of Four Cementing Agents in Soil Stabilization with Experimental Focus on Xanthan Gum. Sustainability 2024, 16, 5363. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Gao, W.; Chen, F.; Cai, Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- Khalid, K.W.A.A.K.; Abd Al-Kaream, W.; Fattah, M.Y.; Hameedi, M.K.H.M.K. Compressibility and strength development of soft soil by polypropylene fiber. Geomate J. 2022, 22, 91–97. [Google Scholar]

- Consoli, N.C.; da Silva Lopes, L., Jr.; Heineck, K.S. Key Parameters for the Strength Control of Lime Stabilized Soils. J. Mater. Civ. Eng. 2009, 21, 210–216. [Google Scholar] [CrossRef]

- Missoum Benziane, M.; Della, N.; Bedr, S.; Flitti, A.; Kaddour Djebbar, M.; Baizid, M. Mechanical behavior of bio-cemented silty sand. Arab. J. Geosci. 2022, 15, 577. [Google Scholar] [CrossRef]

- Chang, I.; Kwon, Y.M.; Im, J.; Cho, G.C. Soil consistency and interparticle characteristics of xanthan gum biopolymer–containing soils with pore-fluid variation. Can. Geotech. J. 2019, 56, 1206–1213. [Google Scholar] [CrossRef]

- Barani, O.R.; Barfar, P. Effect of xanthan gum biopolymer on fracture properties of clay. J. Mater. Civ. Eng. 2021, 33, 04020426. [Google Scholar] [CrossRef]

- Acuña, C.; Betancur, J.; Baldovino, J.A.; Barboza, G.; Saba, M. Analysis of Dispersivity in Marine Clays of Cartagena de Indias, Colombia. Geosciences 2023, 13, 162. [Google Scholar] [CrossRef]

- Román Martínez, C.; Nuñez de la Rosa, Y.E.; Estrada Luna, D.; Baldovino, J.A.; Jordi Bruschi, G. Strength, Stiffness, and Microstructure of Stabilized Marine Clay-Crushed Limestone Waste Blends: Insight on Characterization through Porosity-to-Cement Index. Materials 2023, 16, 4983. [Google Scholar] [CrossRef]

- ASTM D2487-11; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM Stand. Guide. ASTM International: West Conshohocken, PA, USA, 2017; p. 11.

- ASTM D854; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM 4318; Standard Test Methods for Liquid Limit, Plastic Limit and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2011; pp. 1–16.

- Skempton, A.W. The Colloidal “Activity” of Clays. In Proceedings of the 3rd International Conference on Soil Mechanics, Zurich, Switzerland, 16–27 August 1953; Volume 1, pp. 57–61. [Google Scholar]

- ASTM D1557-12; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3 or 2,700 kN-m/m3). ASTM International: West Conshohocken, PA, USA, 2012.

- Ni, J.; Li, S.S.; Ma, L.; Geng, X.Y. Performance of soils enhanced with eco-friendly biopolymers in unconfined compression strength tests and fatigue loading tests. Constr. Build. Mater. 2020, 263, 120039. [Google Scholar] [CrossRef]

- Fateh, S.; Mansourkiaei, Y.; Shalchian, M.M.; Arabani, M.; Payan, M.; Ranjbar, P.Z. A Comparison of Temperature and Freeze-Thaw Effects on High-swelling and Low-swelling Soils Stabilized with Xanthan Gum. Results Eng. 2024, 25, 103719. [Google Scholar] [CrossRef]

- ASTM D1631; Standard Practice for Making and Curing Soil-Cement Compression and Flexure Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2007.

- Baldovino, J.A.; Moreira, E.B.; Teixeira, W.; Izzo, R.L.; Rose, J.L. Effects of lime addition on geotechnical properties of sedimentary soil in Curitiba, Brazil. J. Rock Mech. Geotech. Eng. 2018, 10, 188–194. [Google Scholar] [CrossRef]

- Vergara, J.A.A.; López, L.C.S.; de la Rosa, Y.E.N.; Calabokis, O.P.; Baldovino, J.d.J.A. Analysis of Porosity–Water/Binder Index for Prediction of Strength and Stiffness of Cemented Sands: A Comparative Study. Materials 2025, 18, 268. [Google Scholar] [CrossRef]

- Baldovino, J.A.; Nuñez de la Rosa, Y.E.; Namdar, A. Sustainable Cement Stabilization of Plastic Clay Using Ground Municipal Solid Waste: Enhancing Soil Properties for Geotechnical Applications. Sustainability 2024, 16, 5195. [Google Scholar] [CrossRef]

- ASTM C597-22; Standard Test Method for Ultrasonic Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 2022; pp. 1–4.

- ASTM D 2166-03; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil 1. ASTM International: West Conshohocken, PA, USA, 2003; p. 4.

- Consoli, N.C.; Foppa, D.; Festugato, L.; Heineck, K.S. Key Parameters for Strength Control of Artificially Cemented Soils. J. Geotech. Geoenviron. Eng. 2007, 133, 197–205. [Google Scholar] [CrossRef]

- López, L.C.S.; Vergara, J.A.A.; de la Rosa, Y.E.N.; Arrieta, A.; Baldovino, J.d.J.A. Effect of Grain Size and Porosity/Binder Index on the Unconfined Compressive Strength, Stiffness and Microstructure of Cemented Colombian Sands. Materials 2024, 17, 5193. [Google Scholar] [CrossRef]

- Muñoz, Y.O.; Villota-Mora, A.J.E.; Brandão, D.L.; Orioli, M.A.; Britto, T.S.S.; Baldovino, J.A.; Izzo, R.L.d.S. Enhancing Soil–Cement Properties Using Glass Polishing Waste: Impact of Porosity and Binder Indices. Geotech. Geol. Eng. 2025, 43, 100. [Google Scholar] [CrossRef]

- Baldovino, J.J.; Izzo, R.L.; Rose, J.L.; Domingos, M.D. Strength, durability, and microstructure of geopolymers based on recycled-glass powder waste and dolomitic lime for soil stabilization. Constr. Build. Mater. 2021, 271, 121874. [Google Scholar] [CrossRef]

- Diambra, A.; Festugato, L.; Ibraim, E.; da Silva, A.P.; Consoli, N.C. Modelling tensile/compressive strength ratio of artificially cemented clean sand. Soils Found. 2018, 58, 199–211. [Google Scholar] [CrossRef]

- Scheuermann Filho, H.C.; Dias Miguel, G.; Cesar Consoli, N. Porosity/cement index over a wide range of porosities and cement contents. J. Mater. Civ. Eng. 2022, 34, 06021011. [Google Scholar] [CrossRef]

- Bozyigit, I.; Javadi, A.; Altun, S. Strength properties of xanthan gum and guar gum treated kaolin at different water contents. J. Rock Mech. Geotech. Eng. 2021, 13, 1160–1172. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, L.; Liu, Q.; Pan, X.; Xu, Y.; Li, J. Improving the unconfined compressive strength of red clay by combining biopolymers with fibers. J. Renew. Mater. 2021, 9, 1503–1517. [Google Scholar] [CrossRef]

- Elseifi, M.; Dhakal, N. Lime Utilization in the Laboratory, Field, and Design of Pavement Layers (No. FHWA/LA. 16/575); Louisiana State University. Department of Civil and Environmental Engineering: Baton Rouge, LA, USA, 2017. [Google Scholar]

- Pydi, R.; Yadu, L.; Chouksey, S.K. Evaluation of Xanthan and Guar Gum for Stabilising Soil in Terms of Strength Parameters-A Review. Indian Geotech. J. 2024, 54, 1621–1643. [Google Scholar] [CrossRef]

- Yang, L.; An, L.; Yan, K.; Du, G. Cumulative Strain and Improvement Mechanisms of Soil Reinforced by Xanthan Gum Biopolymer Under Traffic Loading. Polymers 2024, 16, 3500. [Google Scholar] [CrossRef] [PubMed]

- Lang, L.; Li, J.; Chen, X.; Han, L.; Wang, P. Tensile strength behavior of cement-stabilized dredged sediment reinforced by polypropylene fiber. Front. Struct. Civ. Eng. 2024, 18, 380–392. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).